Lifting lug for automobile exhaust system and vehicle with lifting lugs

An exhaust system and lifting lug technology, which is applied to vehicle components, power plant gas intake, power plant, etc., can solve the problems of short service life of lifting lugs and high production costs, and achieve reduced production costs and reduced exhaust Tube vibration, reducing the effect of the possibility of lug failure or even tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0040] The present invention will be described in detail below with reference to the accompanying drawings and examples.

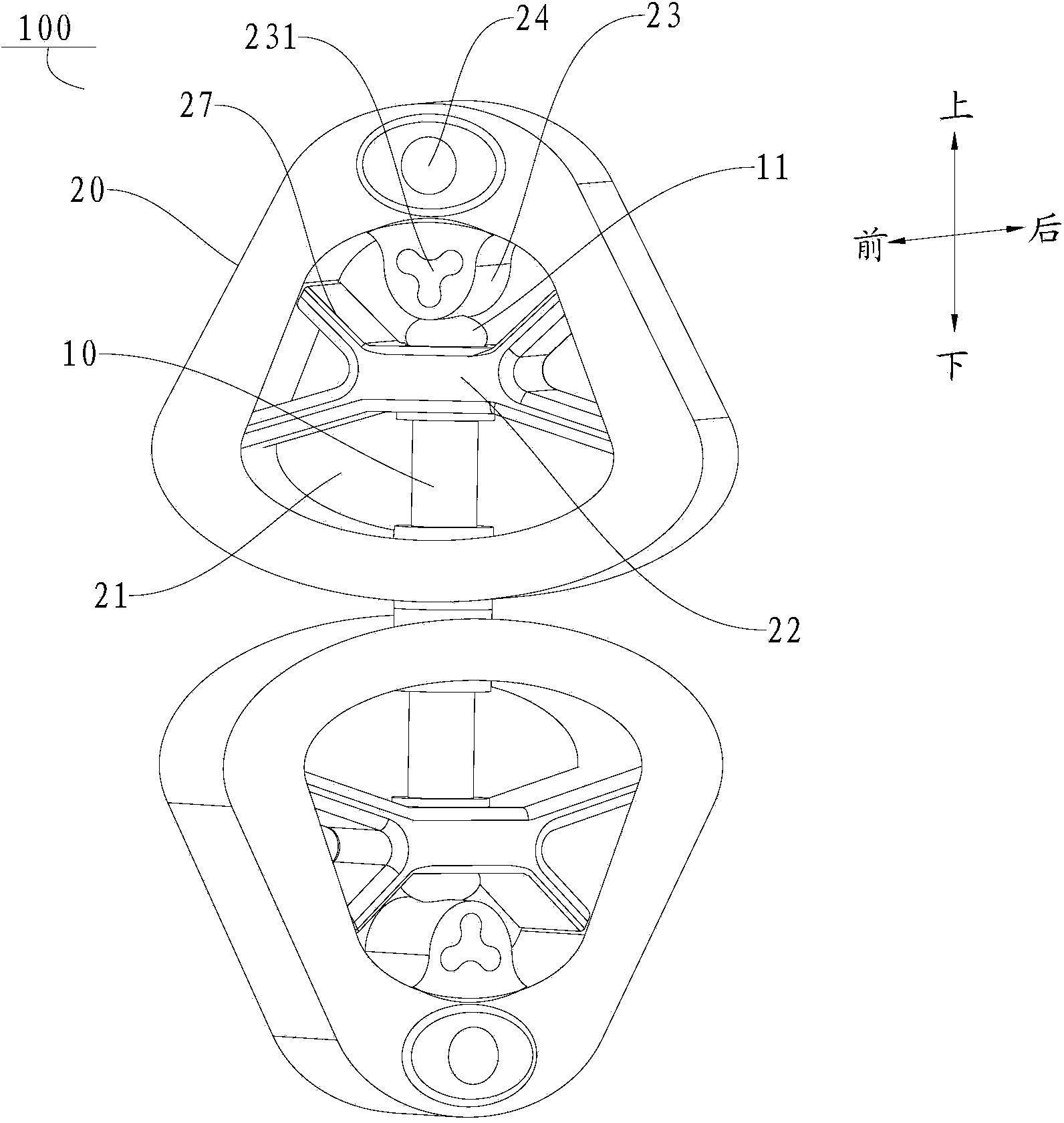

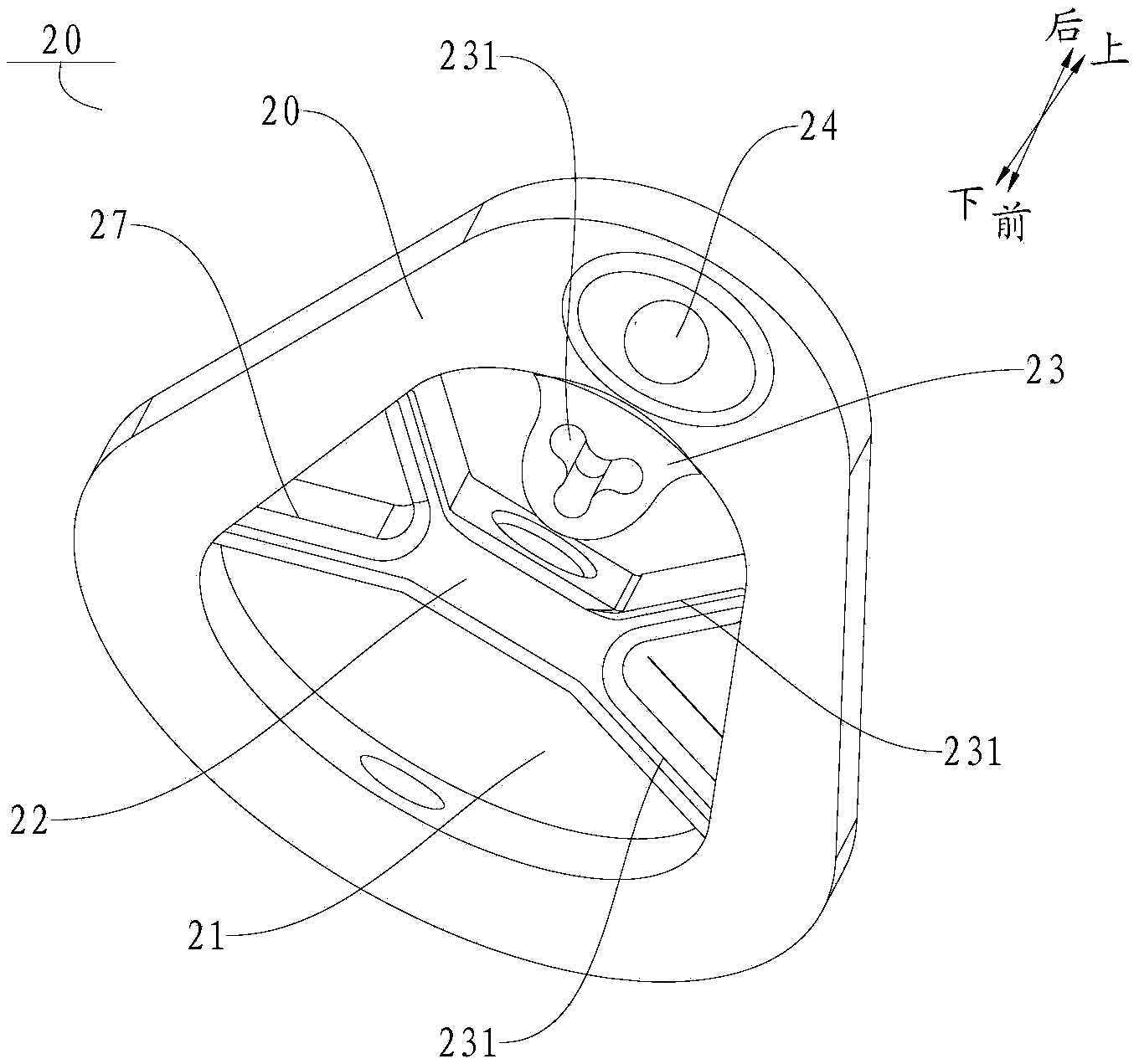

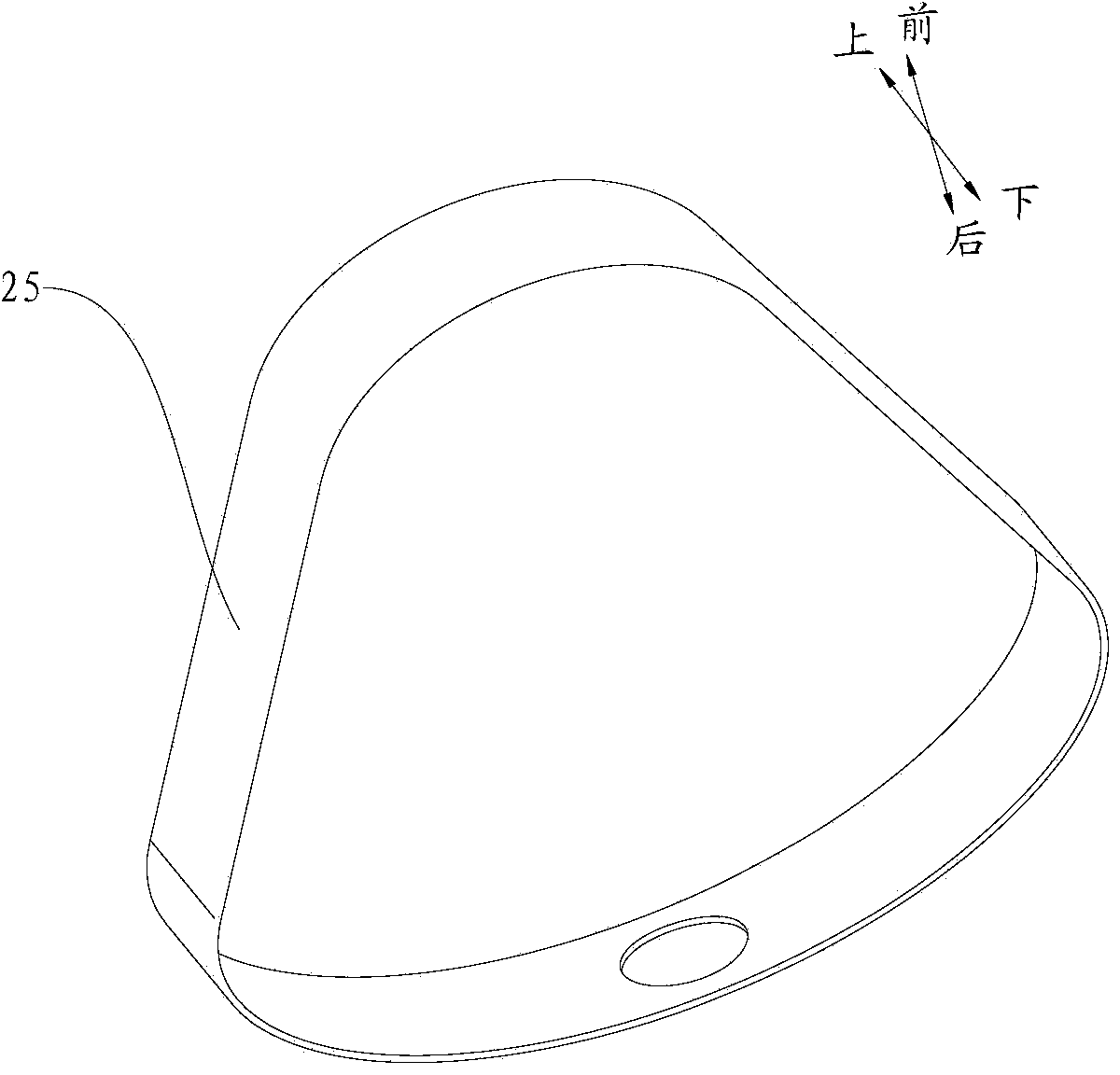

[0041] like Figure 1-Figure 6 As shown, the lifting lug 100 for the exhaust system of a vehicle (not shown in the figure) according to the embodiment of the present invention includes: a connecting rod 10 and a body 20 . It should be noted that the exhaust system of the vehicle includes an exhaust pipe 220 , and the lifting lug 100 is connected between the exhaust pipe 220 and the floor 210 of the vehicle.

[0042] Specifically, the lifting ear 100 has two symmetrically arranged bodies 20 , and an opening 21 is formed in each body 20 through its thickness. Both ends of the connecting rod 10 respectively pass through the side walls of the corresponding opening 21 and protrude into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com