Oil pan assembly including laminate and clinch nut

A technology of rivet nut and oil pan, applied in oil pan, lubricating parts, engine components, etc., can solve the problems of unsuitable aluminum layer laminate, aluminum layer failure, complexity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

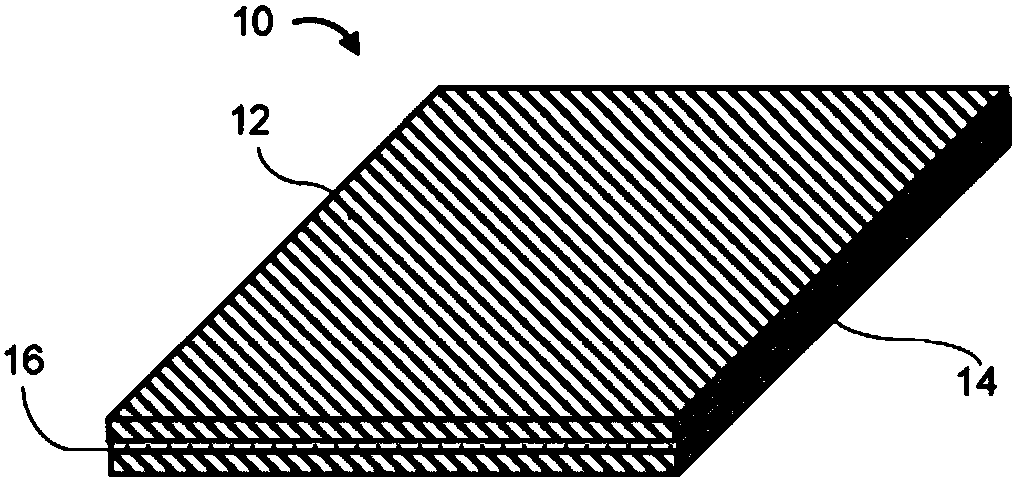

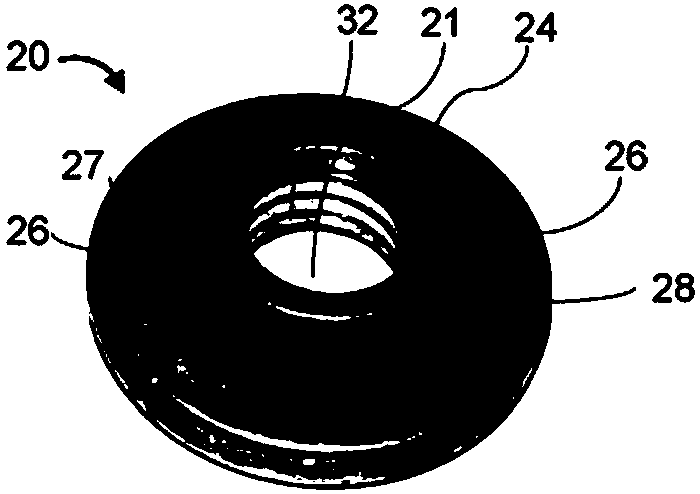

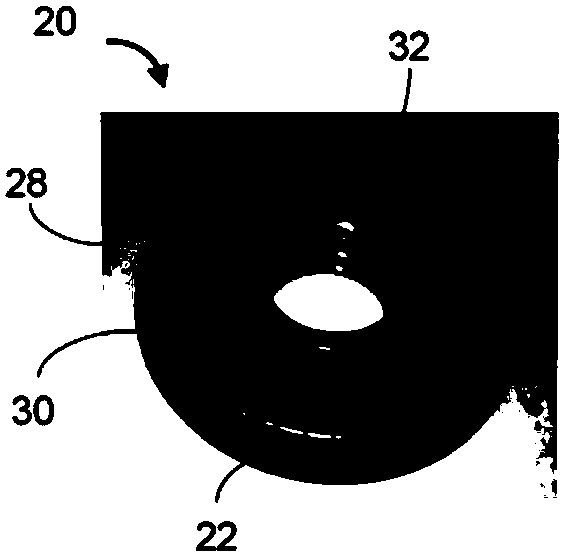

[0042] The oil sump assembly includes a container having a cavity for containing fluid and a drain attached to the container to remove oil from the cavity. The container preferably comprises a composite material having a polymer layer to improve one or more NVH properties. The drain member preferably comprises or consists essentially of a rivet nut. The discharge member may be sealed by one or more seals, preferably using primary and secondary seals. The discharge of the fluid is preferably through the opening of the rivet nut. The oil pan assembly may also include a sealing member (eg, a drain plug) for reversibly sealing the drain member.

[0043] container:

[0044] The oil pan assembly includes a container (eg, an oil pan) having a cavity for holding a quantity of oil. The container may have one or more openings for circulating oil to the mechanical components to control the temperature of the mechanical components. It may be necessary to periodically drain the oil fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com