Motor and speed reducer integrated case and casting and welding method thereof

A reducer and integrated technology, applied in the field of new energy vehicle motors, can solve the problems of increasing the complexity of the low-pressure casting process, increasing the axial length of the whole machine, unfavorable vehicle layout, etc., so as to improve the NVH characteristics and reduce the end cover. , the effect of eliminating the process hole structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

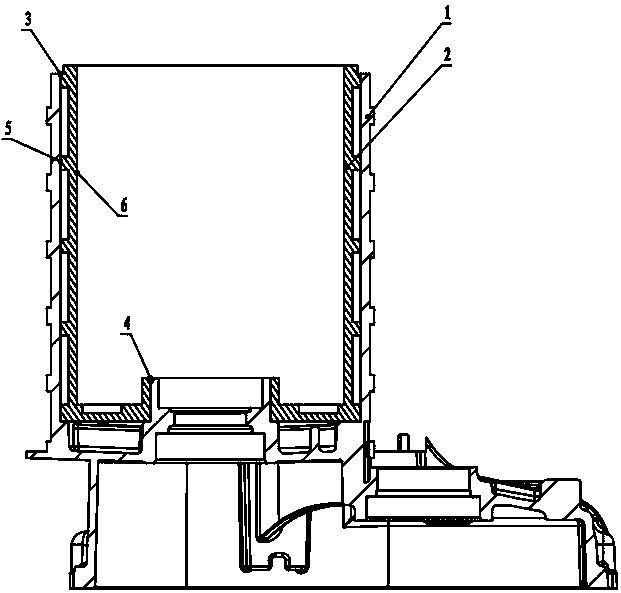

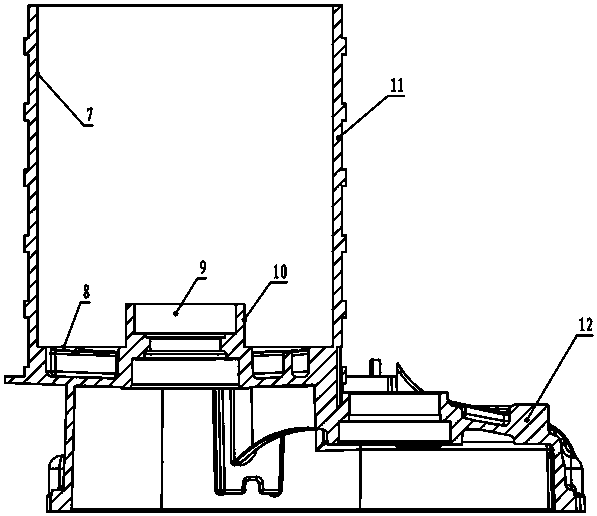

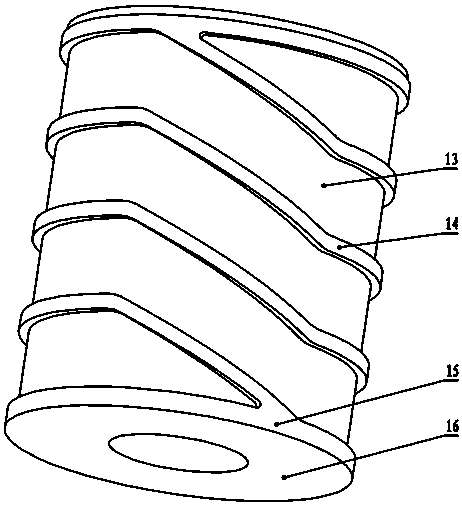

[0031] Such as Figure 1~3 As shown, the integrated housing of the motor and reducer of the present invention includes an outer housing 1 and an inner housing 2. The outer housing 2 includes a motor outer housing 11 and a reducer outer housing 12 integrally formed by high pressure casting. The outer surface of the inner casing 2 is provided with spiral water channel ribs 14, and the space between adjacent spiral water channel ribs cooperates with the outer wall of the inner casing 2 and the inner wall of the motor outer casing 11 to form a spiral water channel 13. The inner shell 2 is sleeved inside the motor outer shell 11 with a clearance fit between the two.

[0032] Such as Figure 2~3 As shown, the inner wall of the motor housing 11 is the first processing surface 7 of the housing, the bottom of the motor housing 11 is the second processing surface 8 of the housing, and the center of the bottom of the motor housing 11 is provided with a bearing chamber 9 protruding upwards. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com