Thermal management system and electric vehicle

A technology of thermal management system and heat dissipation channel, applied in the field of thermal management system and electric vehicles, can solve problems such as huge demand for cooling capacity, high-voltage alarm shutdown, and insufficient cooling capacity to meet requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

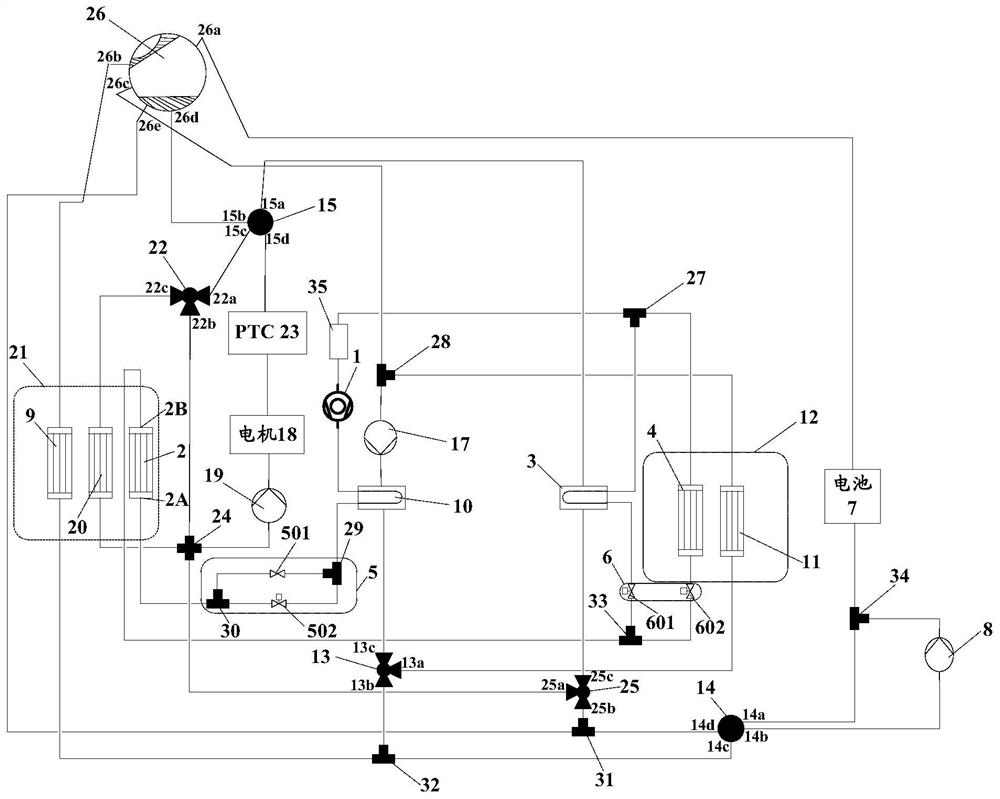

[0056] In order to make the purpose, technical solution and advantages of the application clearer, the application will be further described in detail below in conjunction with the accompanying drawings.

[0057] Reference to "one embodiment" or "some embodiments" or the like in this specification means that a particular feature, structure, or characteristic described in connection with the embodiment is included in one or more embodiments of the present application. Thus, appearances of the phrases "in one embodiment," "in some embodiments," "in other embodiments," "in other embodiments," etc. in various places in this specification are not necessarily All refer to the same embodiment, but mean "one or more but not all embodiments" unless specifically stated otherwise. The terms "including", "comprising", "having" and variations thereof mean "including but not limited to", unless specifically stated otherwise. In addition, in the present application, unless otherwise specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com