Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Improve liquid crystal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

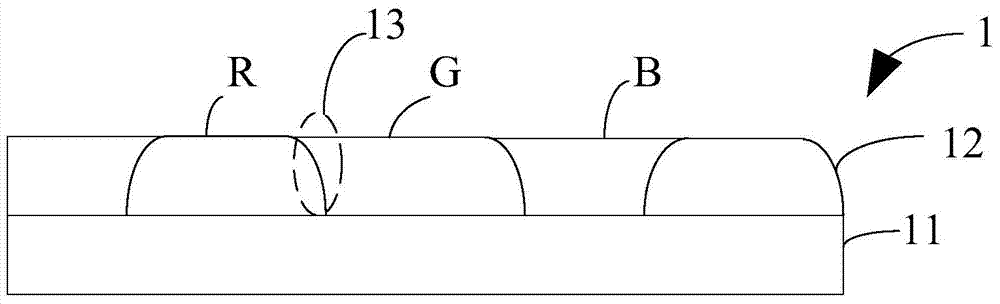

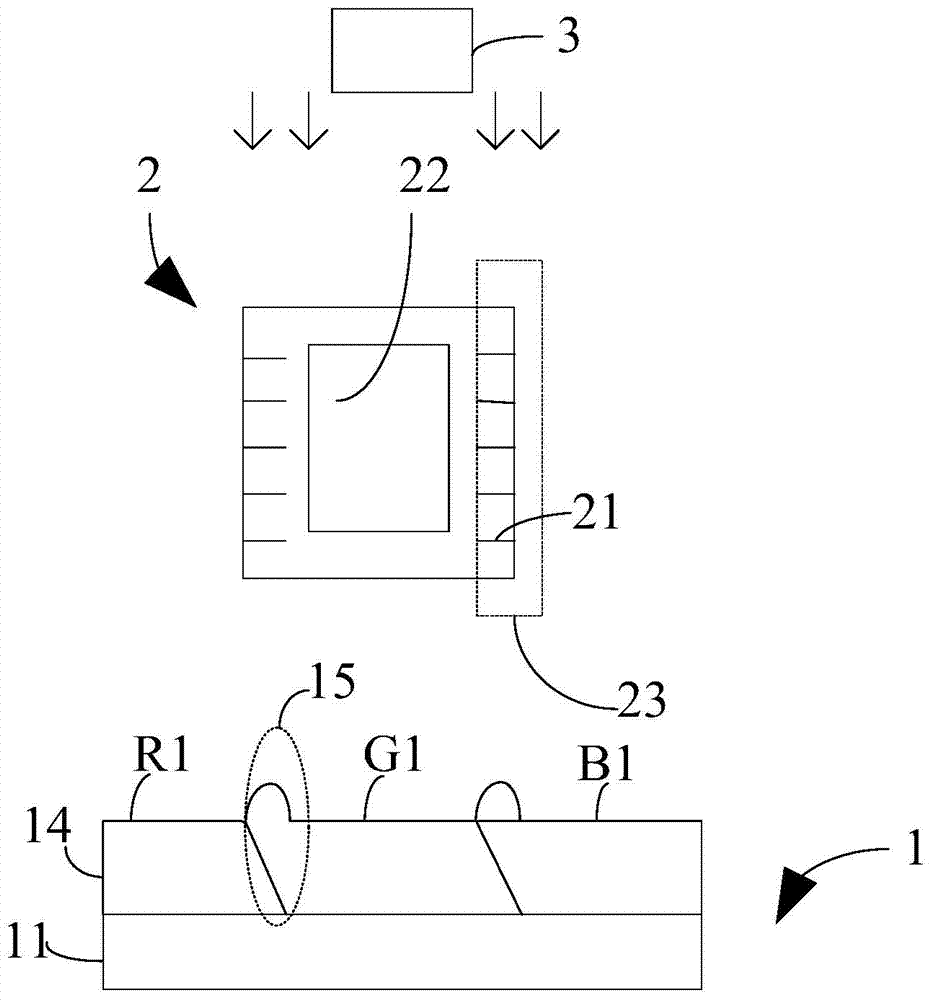

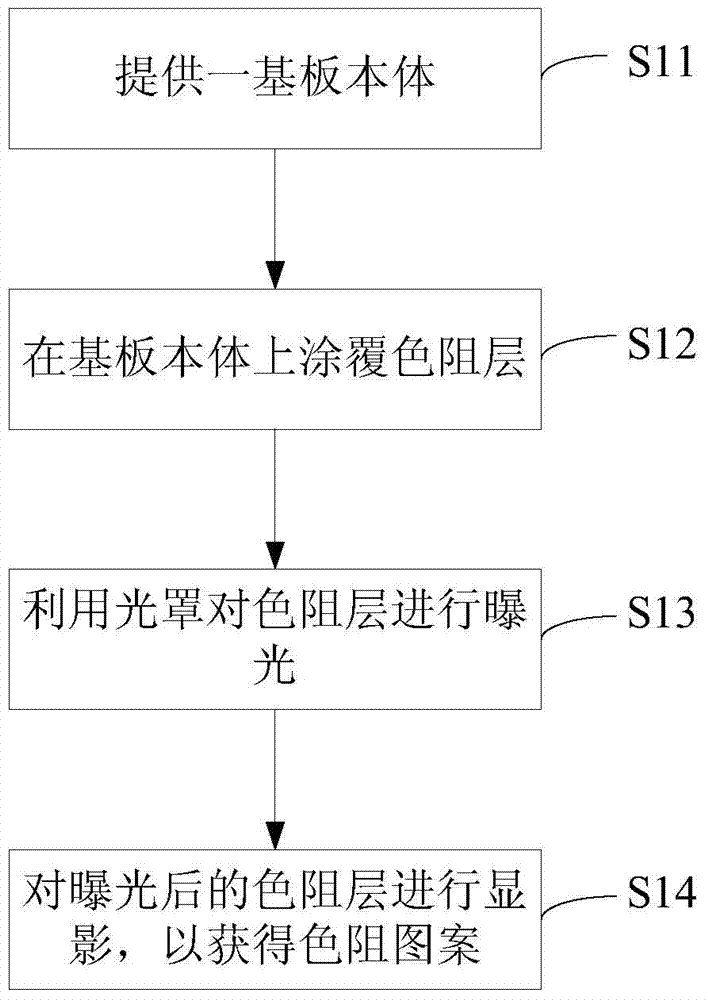

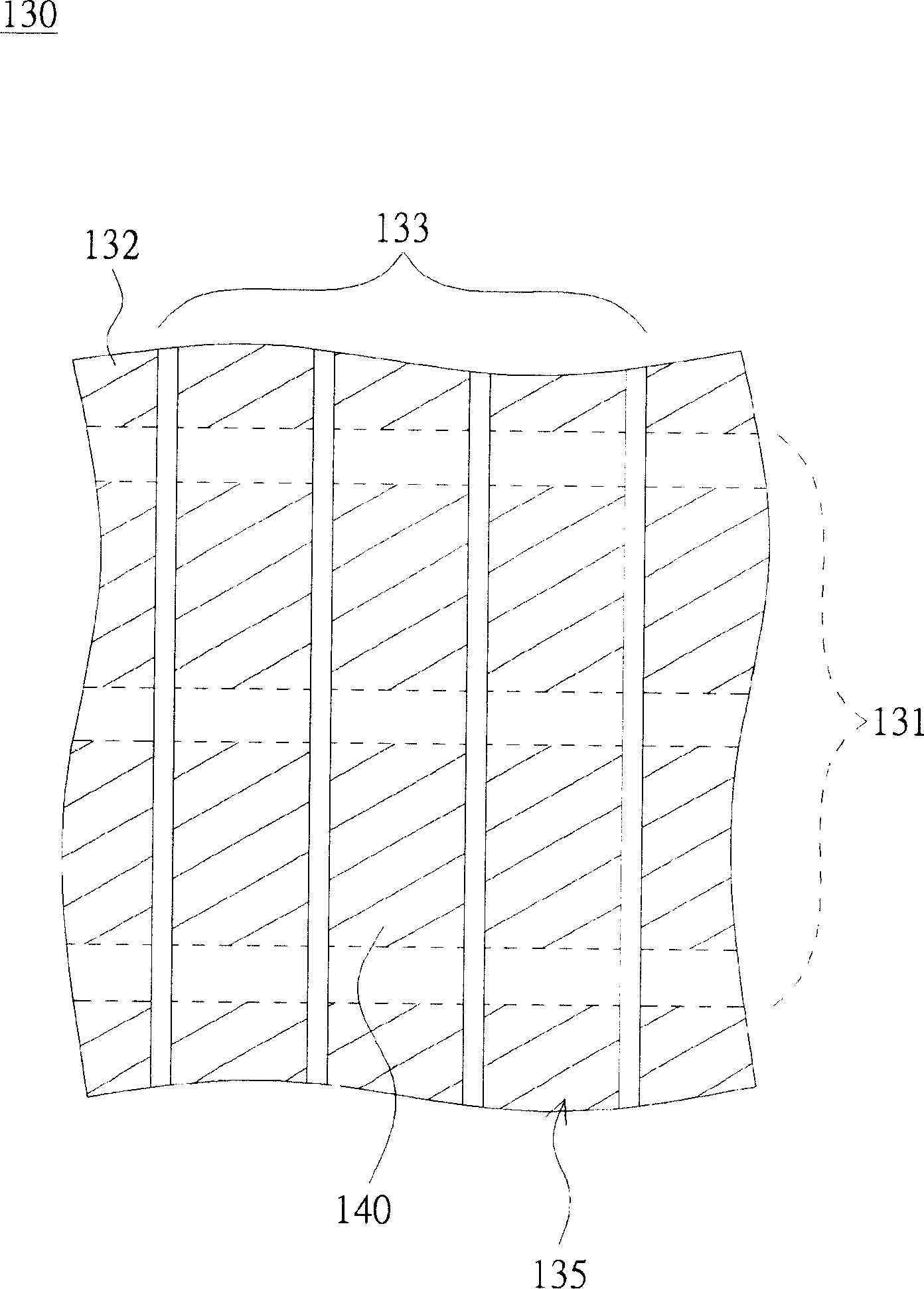

Color film substrate for display, method for manufacturing color film substrate and light mask thereof

ActiveCN104503128AFlat surfaceReduce production processPhotomechanical exposure apparatusPhotosensitive material processingLiquid-crystal displayDisplay device

The invention discloses a color film substrate for a display, a method for manufacturing the color film substrate and a light mask thereof. The color film substrate comprises a substrate body and a plurality of color resistance patterns. The color resistance patterns are arranged on the substrate body, the adjacent color resistance patterns are partially overlapped on one another, and the thicknesses of the lower color resistance patterns in overlapped regions are gradually reduced in the directions of the edges of the lower color resistance patterns. Owing to the mode, the color film substrate, the method and the light mask have the advantages that horn segment difference of the overlapped regions of the adjacent RGB (red, green and blue) color resistance patterns of the color film substrate can be reduced, and accordingly the liquid crystal efficiency can be improved; extra OC (over-coat) flat layers on RGB color resistance layers of the color film substrate can be omitted, accordingly, the production cost of liquid crystal display panels can be reduced, and the production efficiency can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

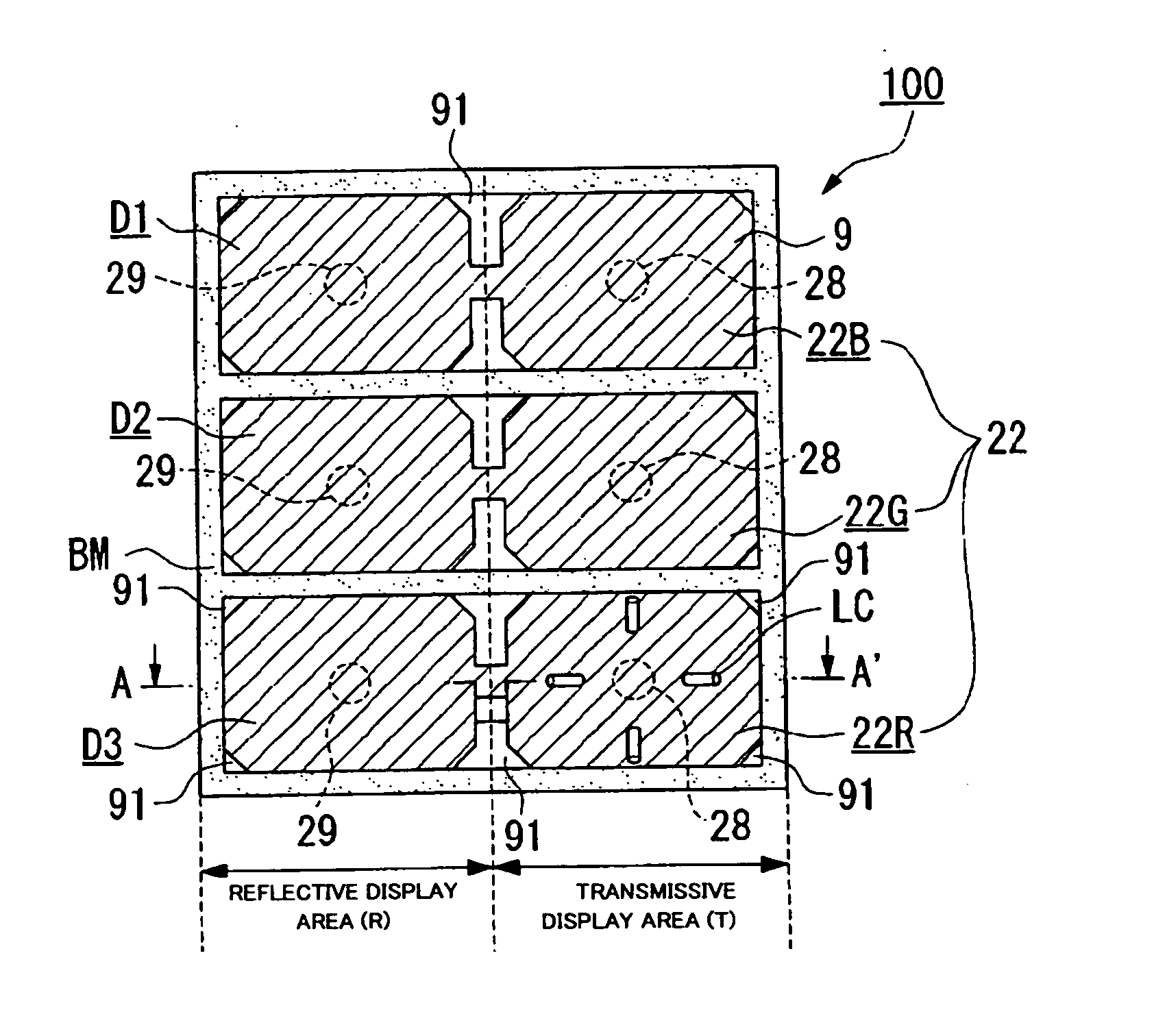

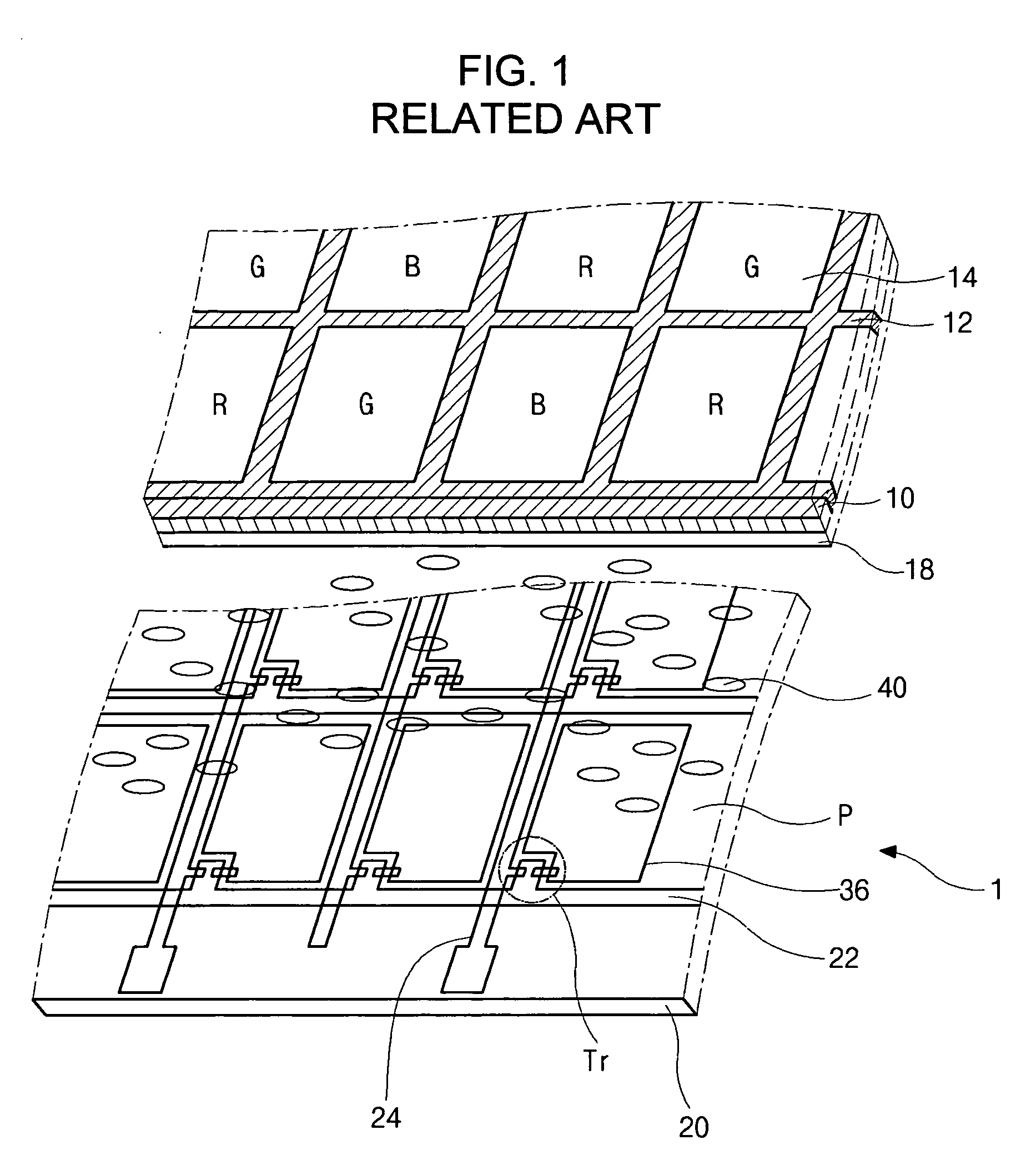

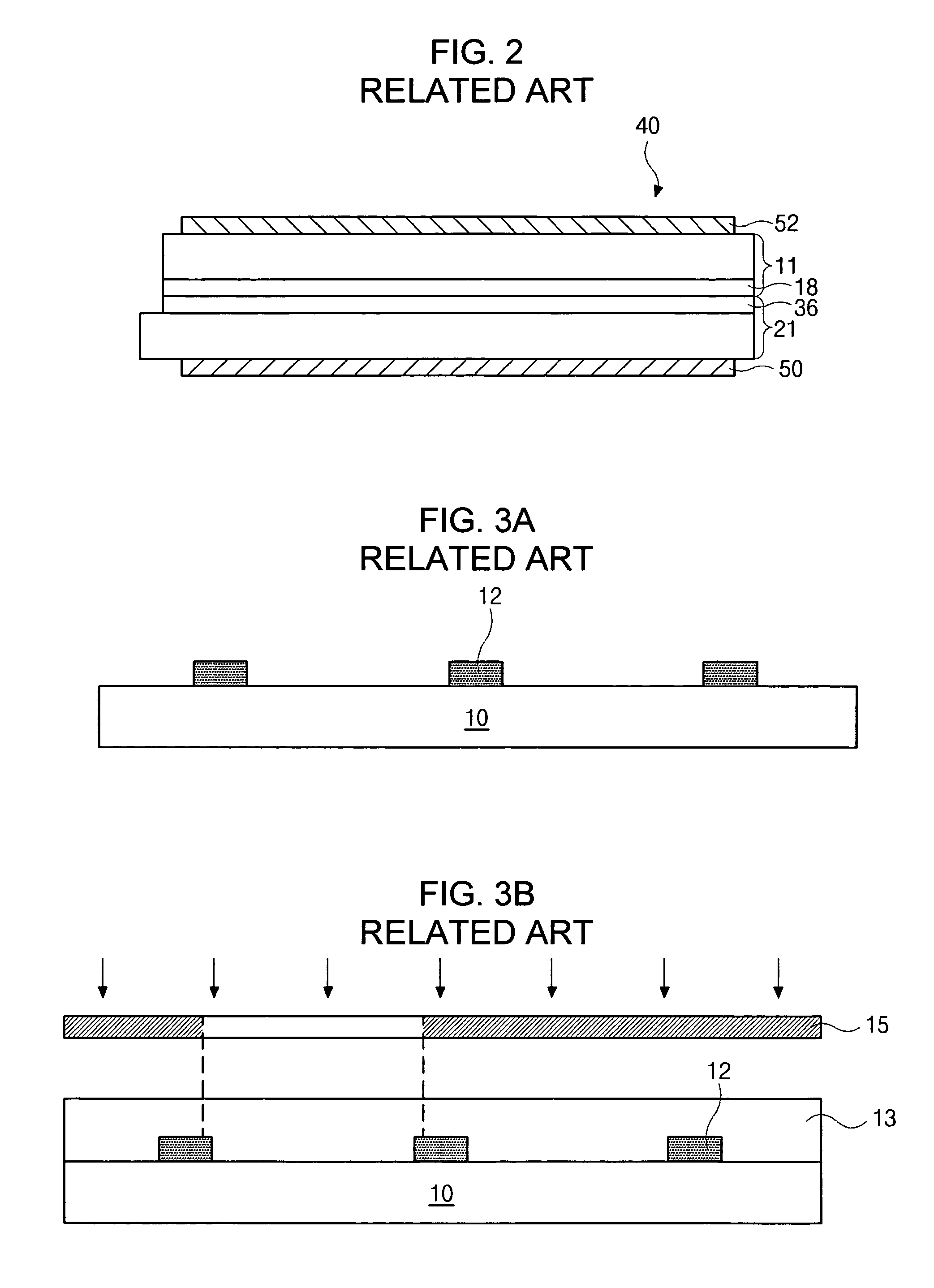

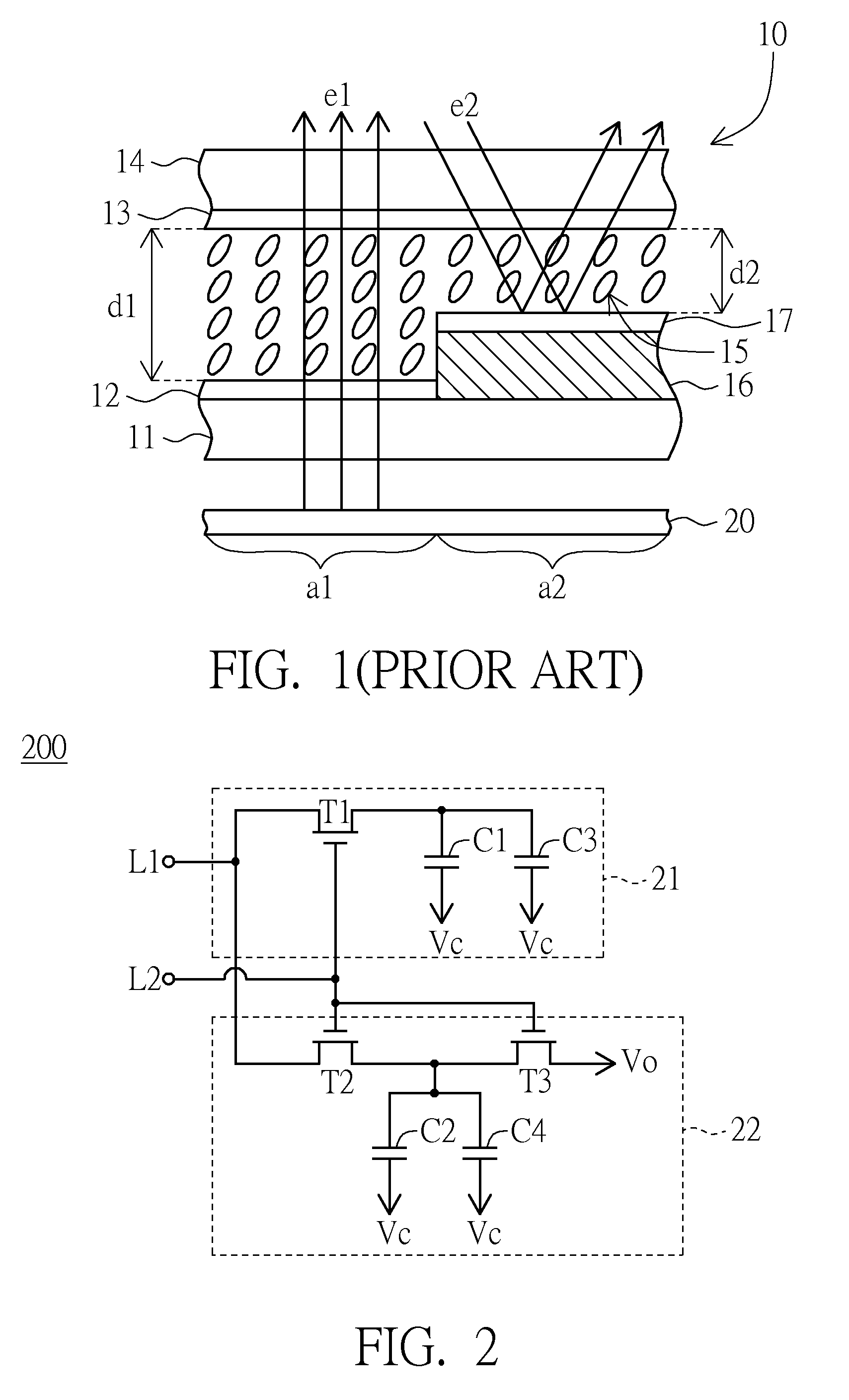

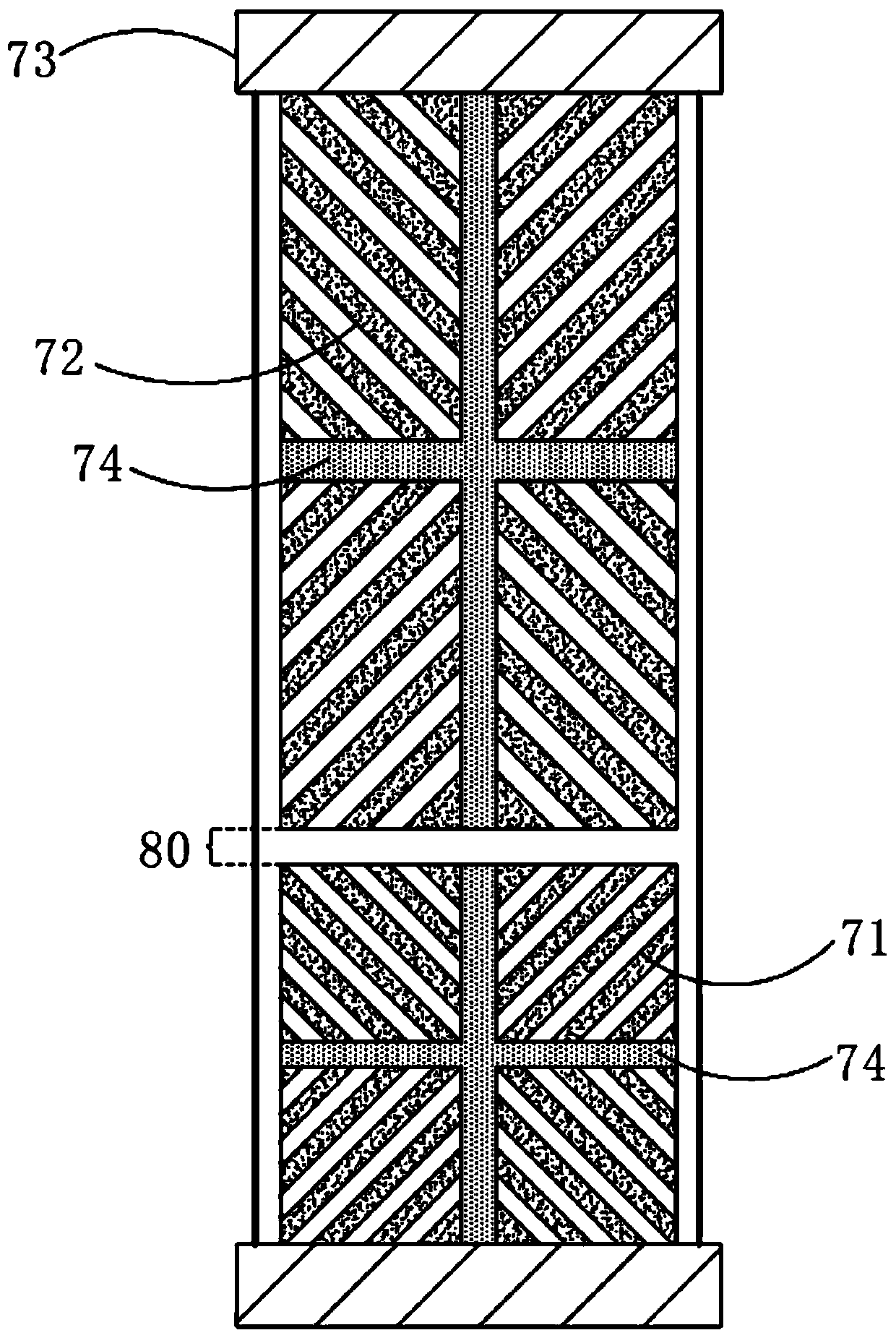

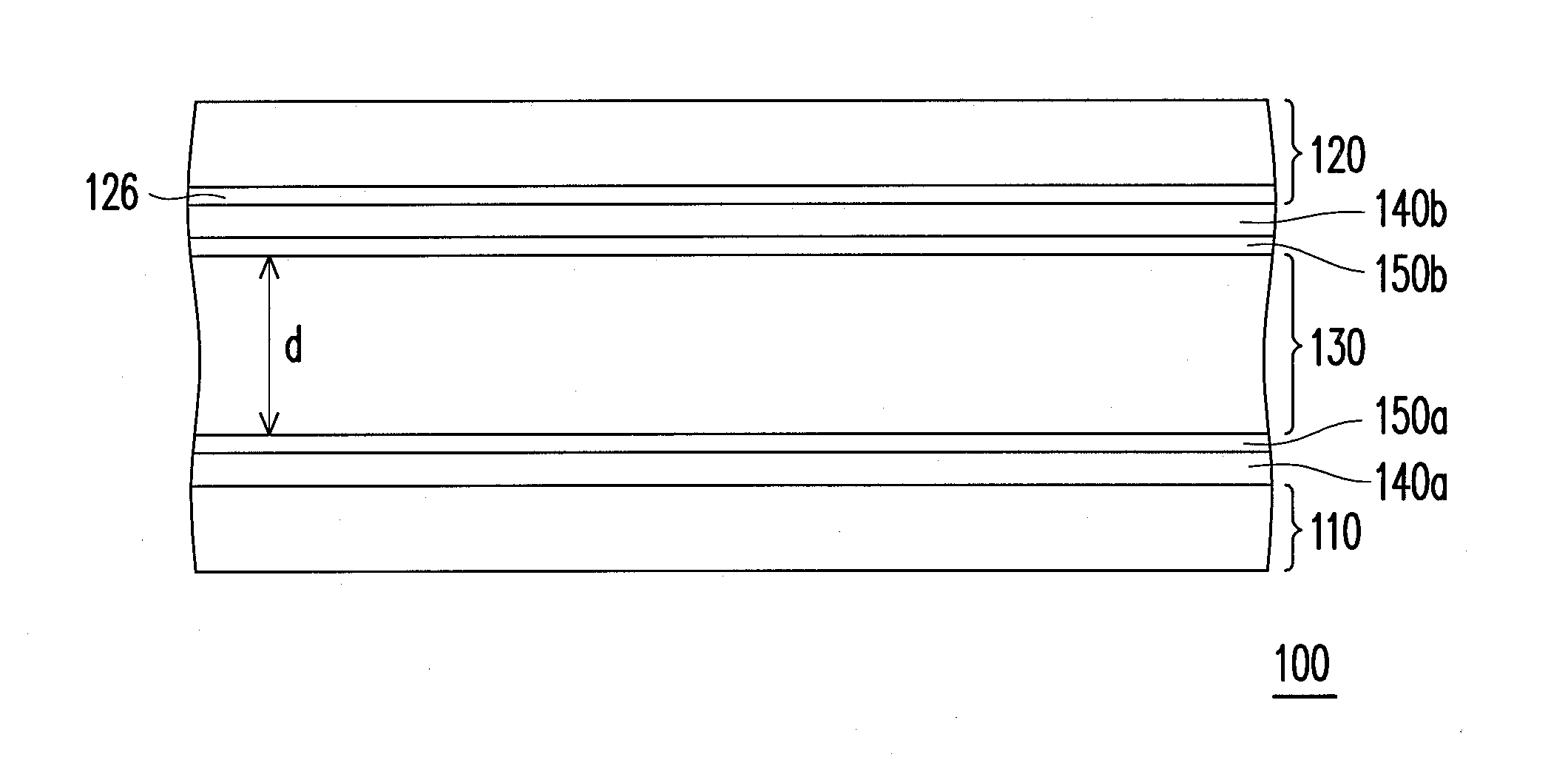

Liquid crystal display device and electronic apparatus

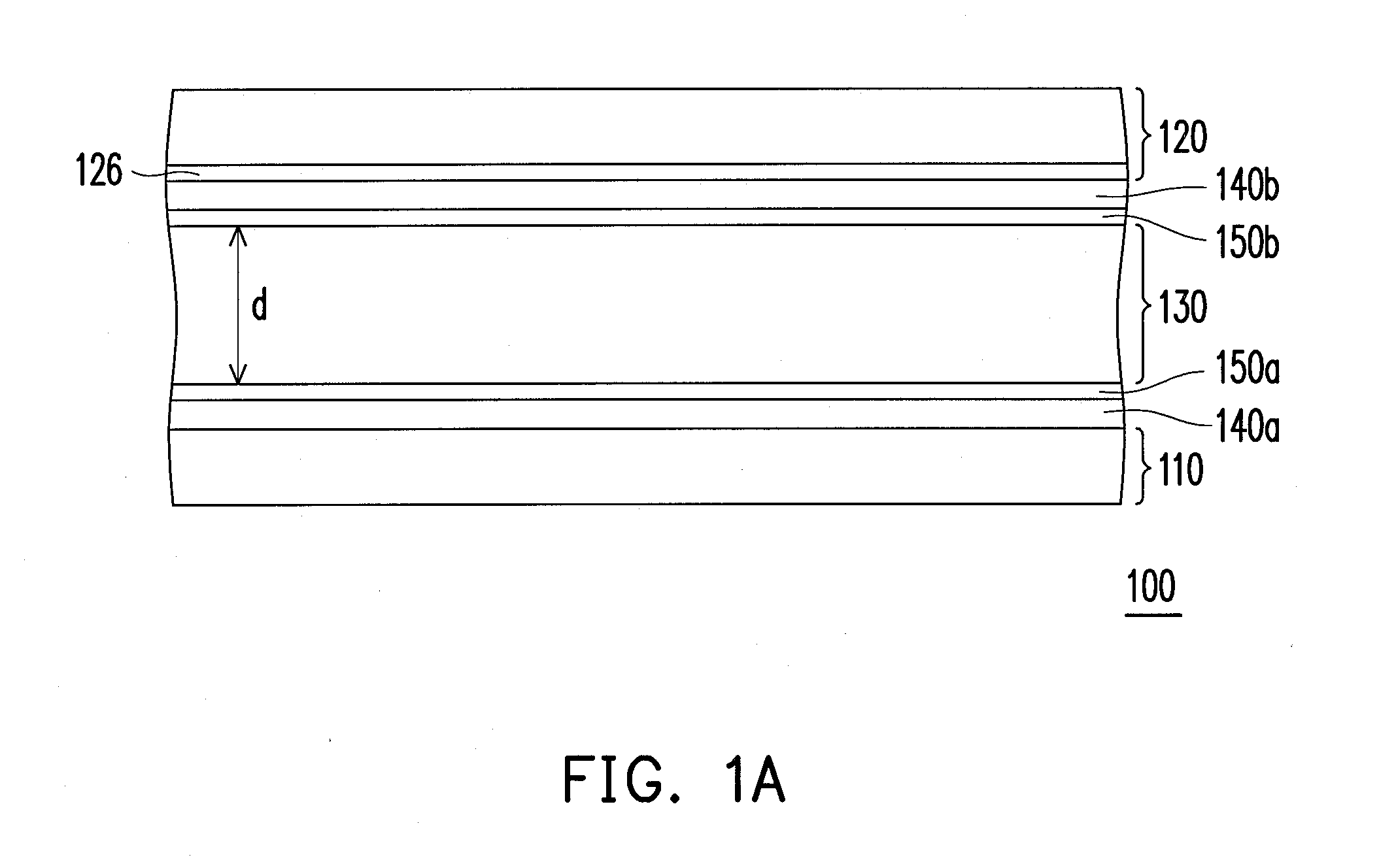

ActiveUS20050030453A1Effective balanceEasy to controlNon-linear opticsLiquid-crystal displayLayer thickness

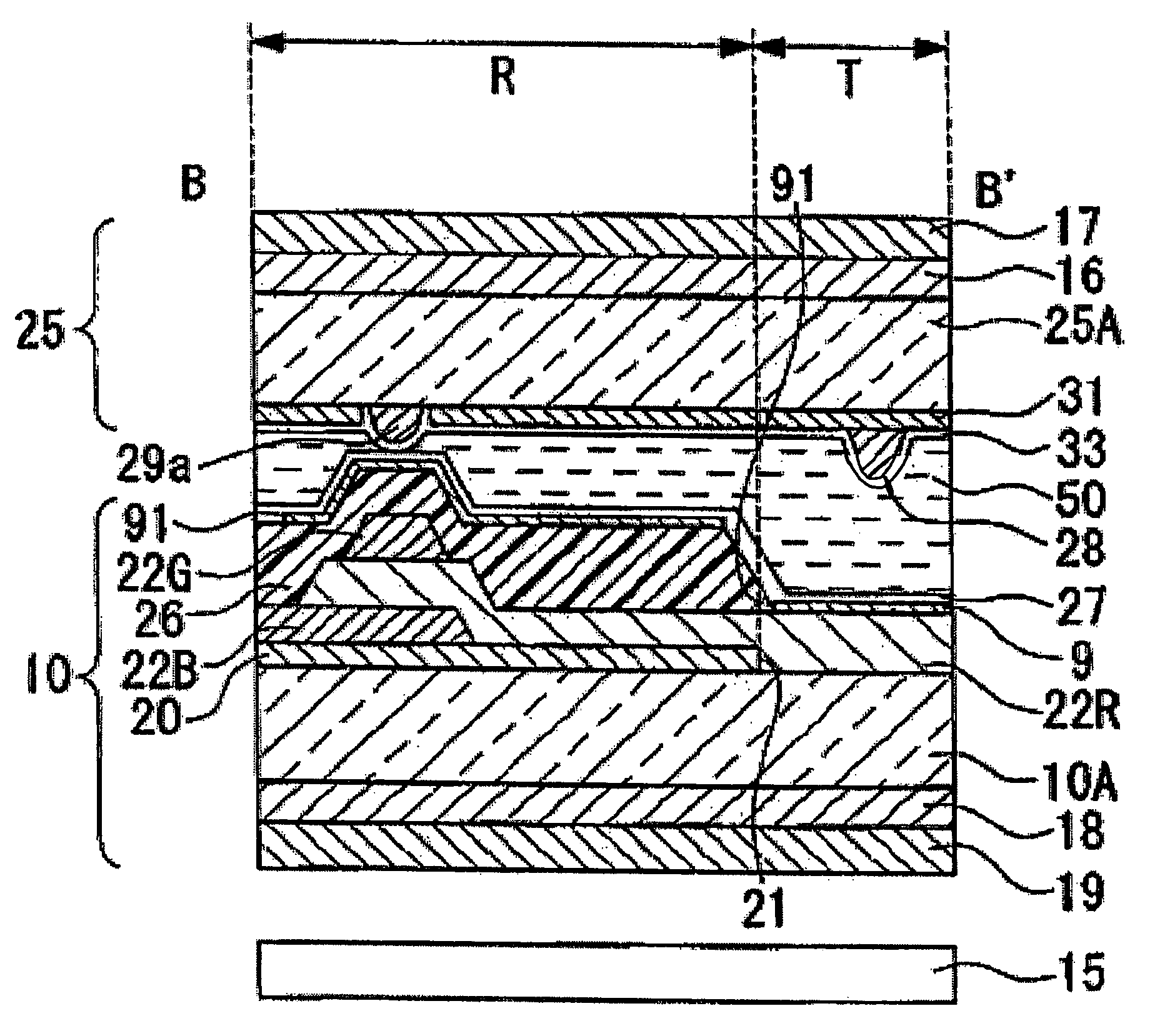

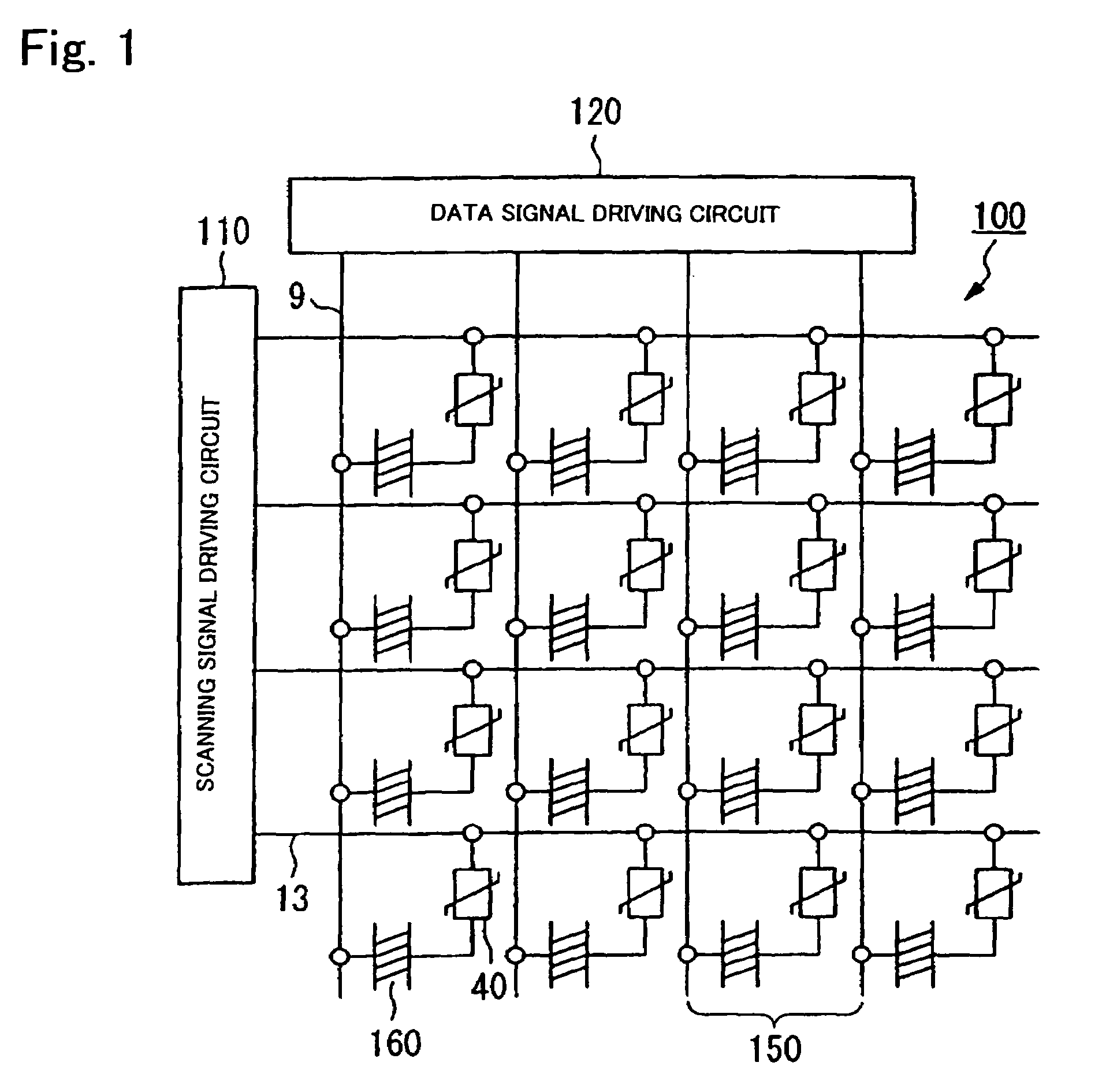

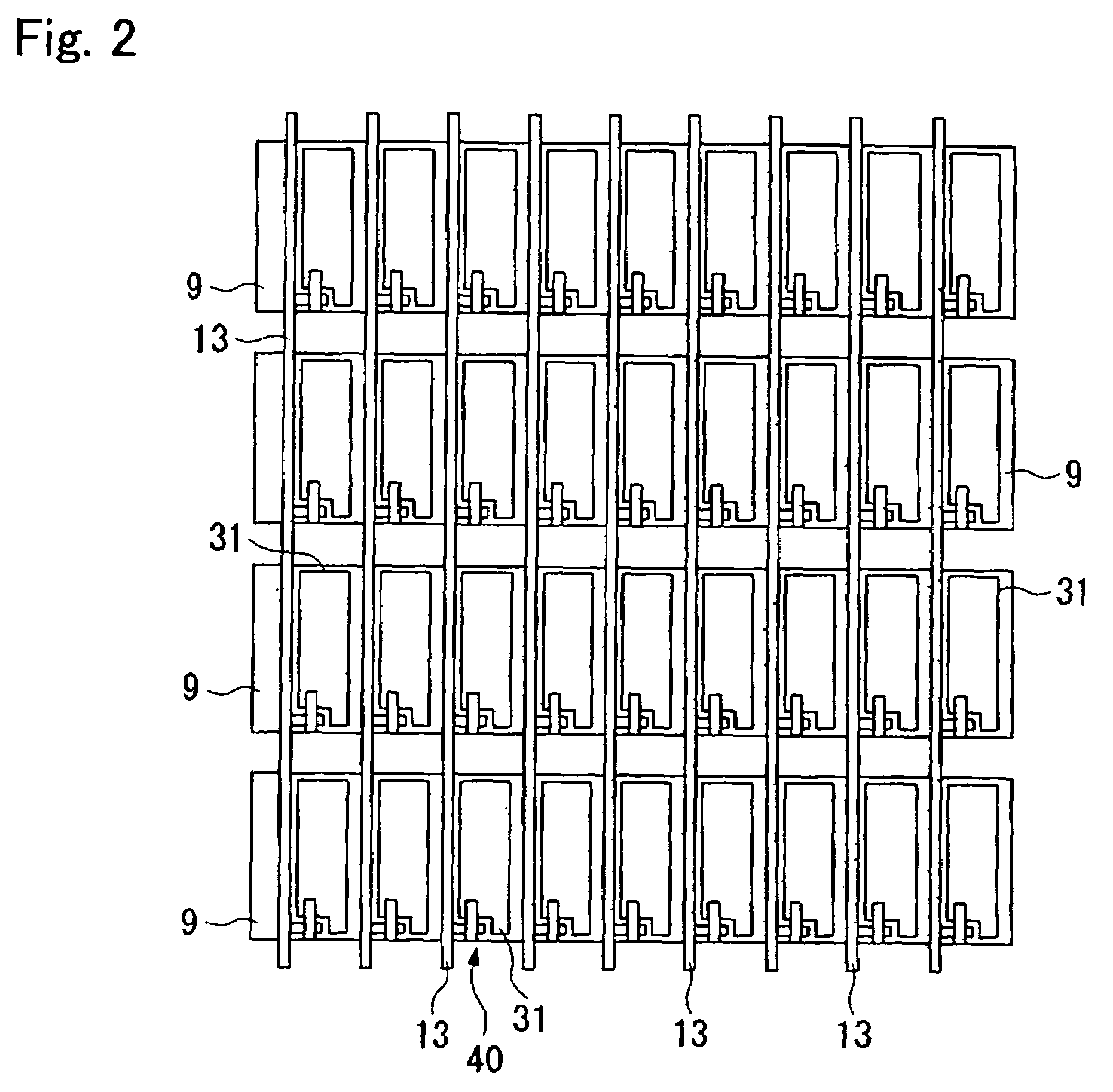

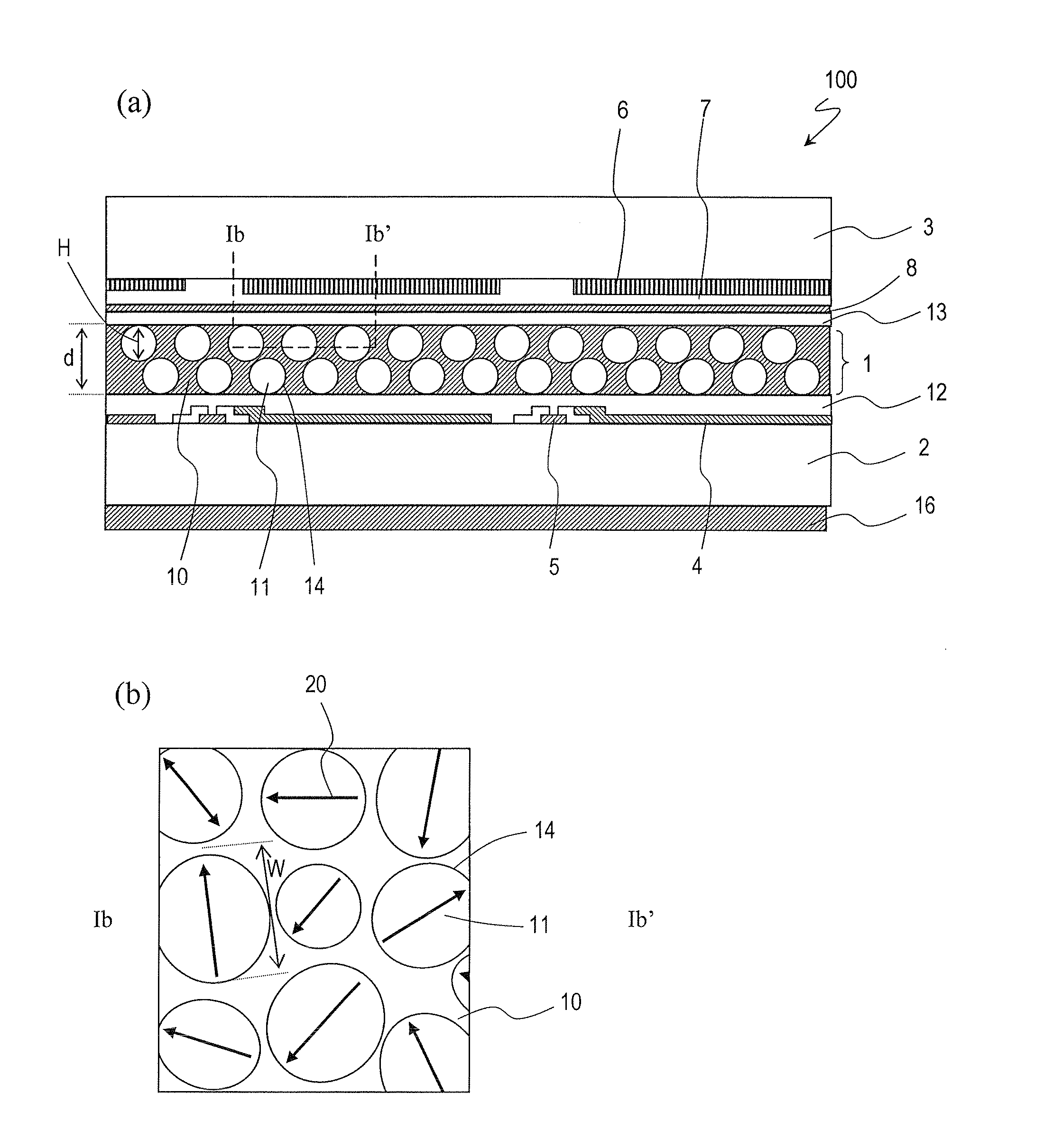

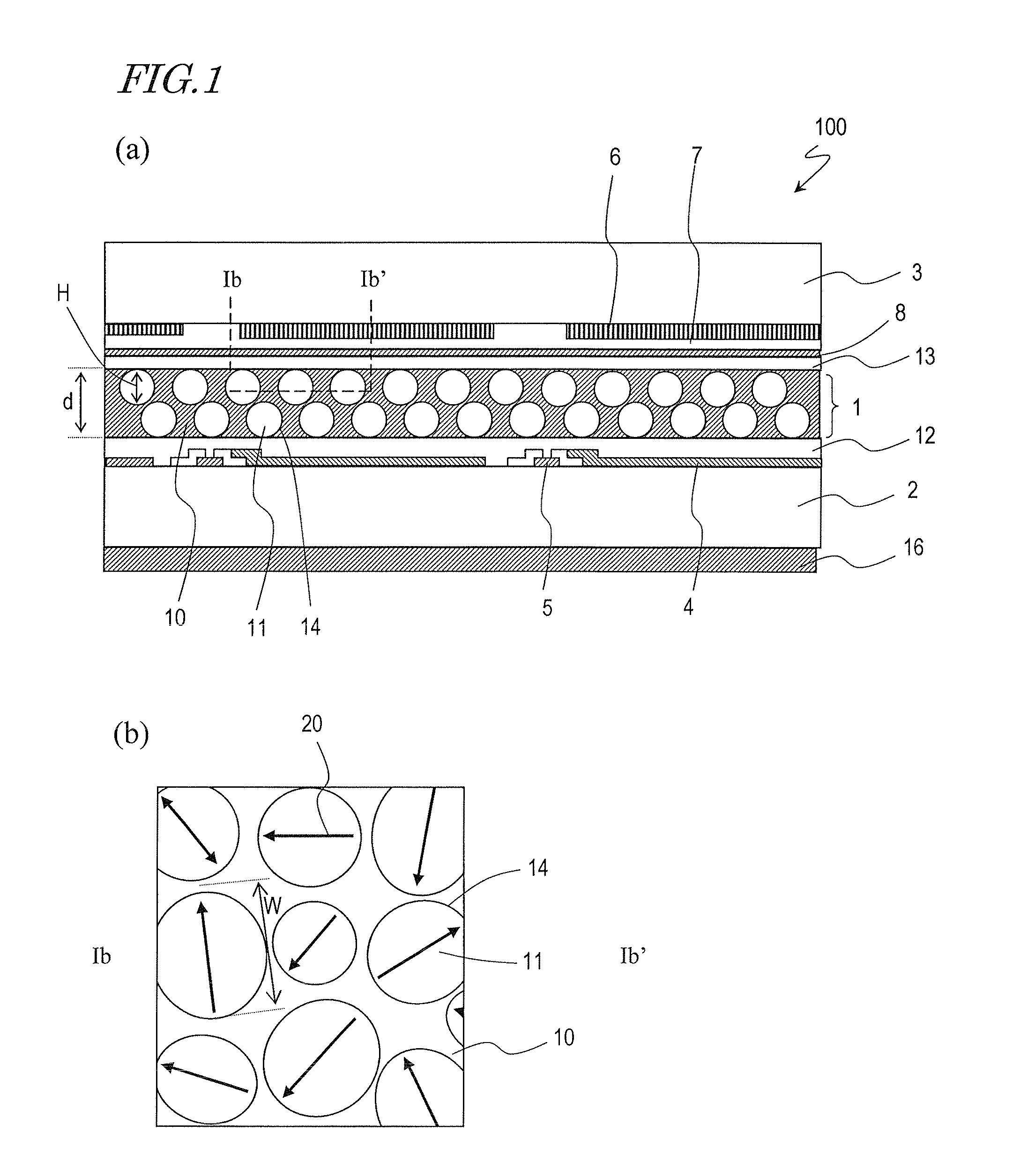

The invention provides a liquid crystal display device having a wide viewing angle for transmissive display and reflective display. The liquid crystal display device according to the invention can include a homeotropic liquid crystal layer interposed between a pair of substrates. The liquid crystal display device has a transmissive display area and a reflective display area in each dot area. A liquid crystal layer thickness-adjustment layer can be interposed between at least the substrate of the pair of substrates and the liquid crystal layer. The liquid crystal layer thickness-adjustment layer reduces the liquid crystal layer thickness of the reflective display area in comparison with the liquid crystal layer thickness of the transmissive display area. On the substrate opposing the substrate with the liquid crystal layer thickness-adjustment layer, protrusions protruding from the inner surface of the substrate to the liquid crystal layer are formed.

Owner:BOE TECH GRP CO LTD

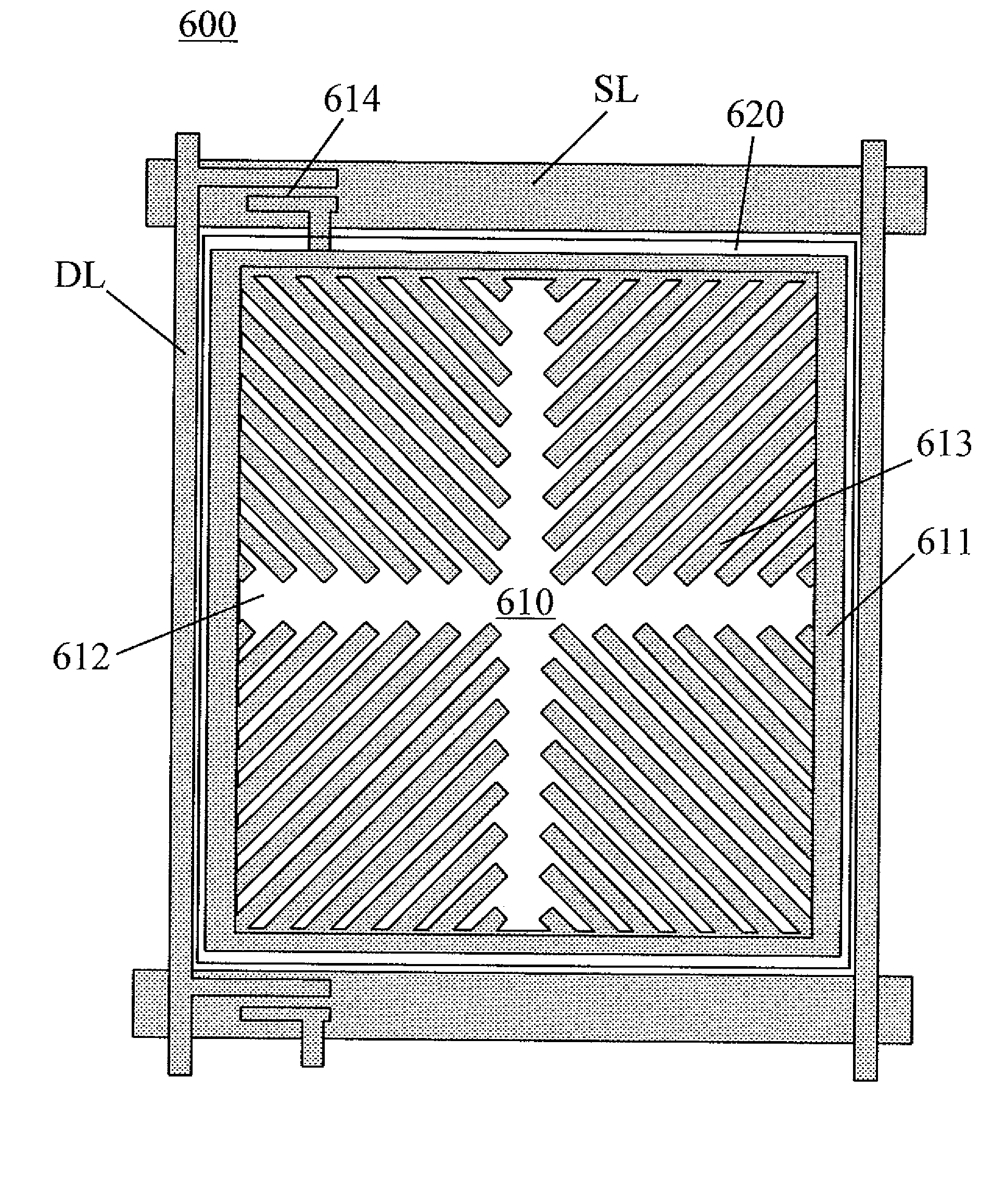

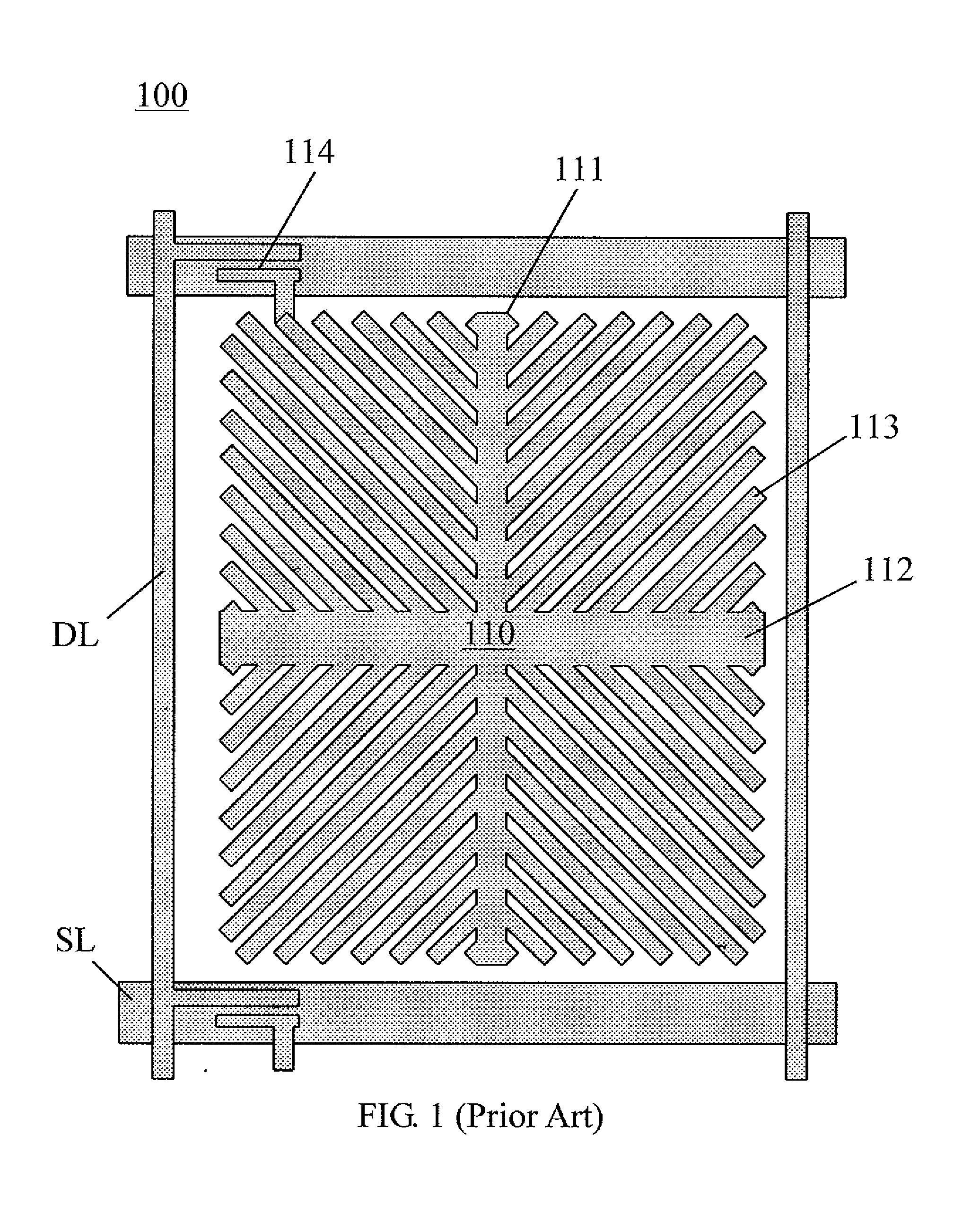

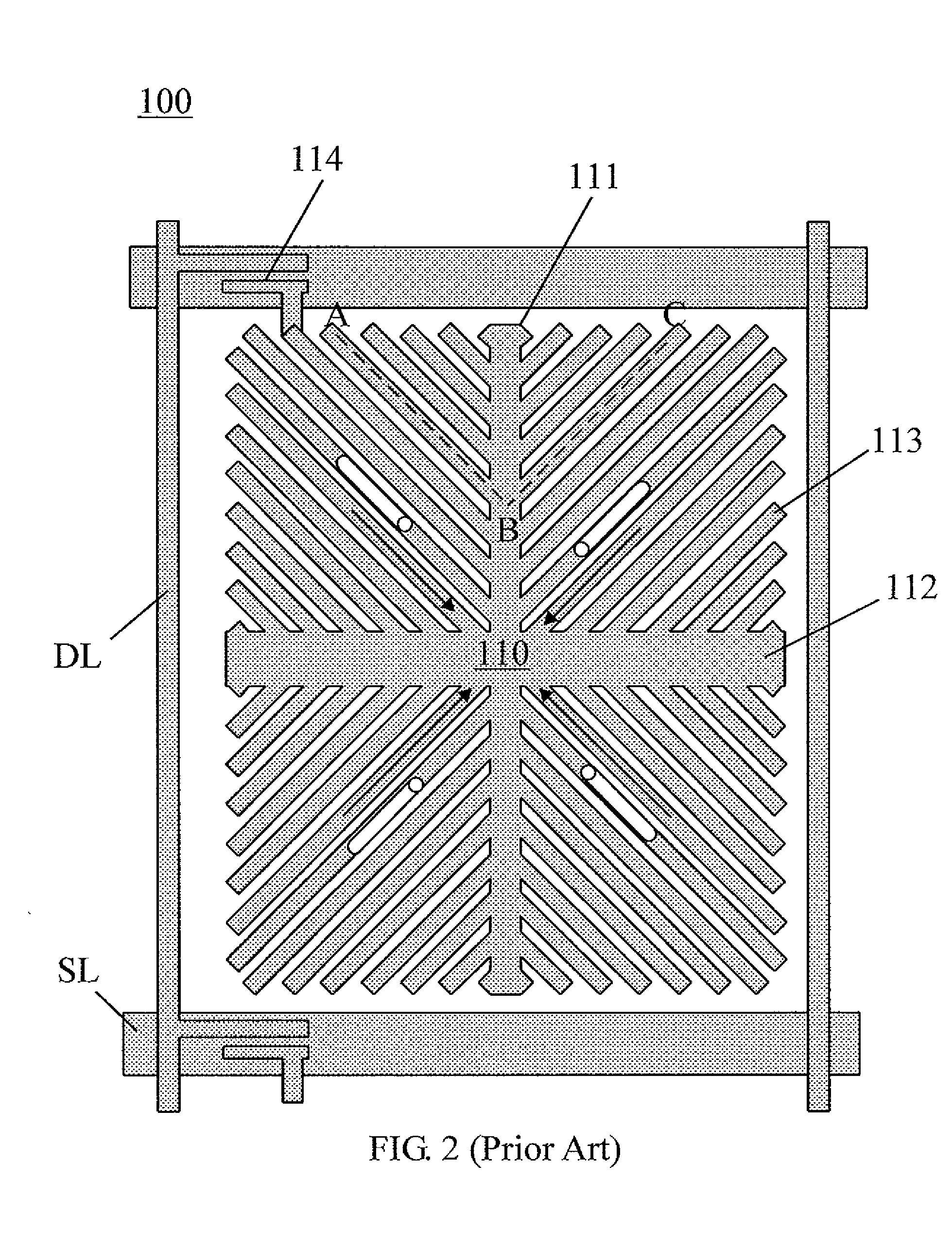

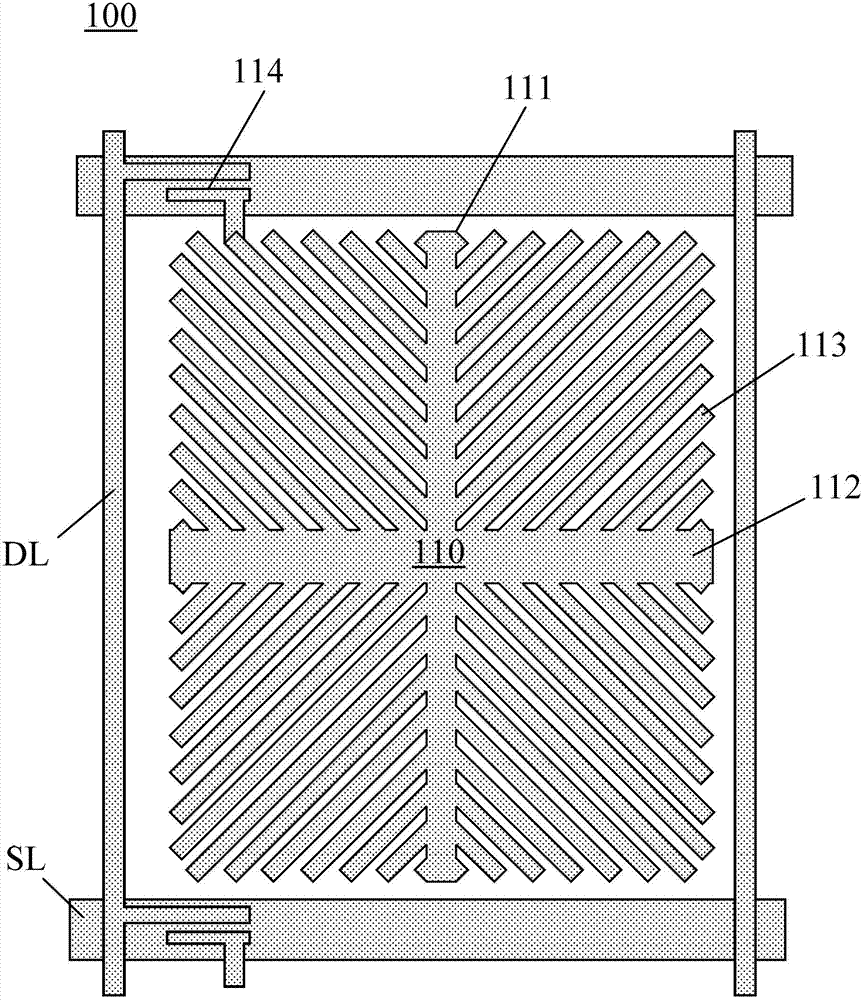

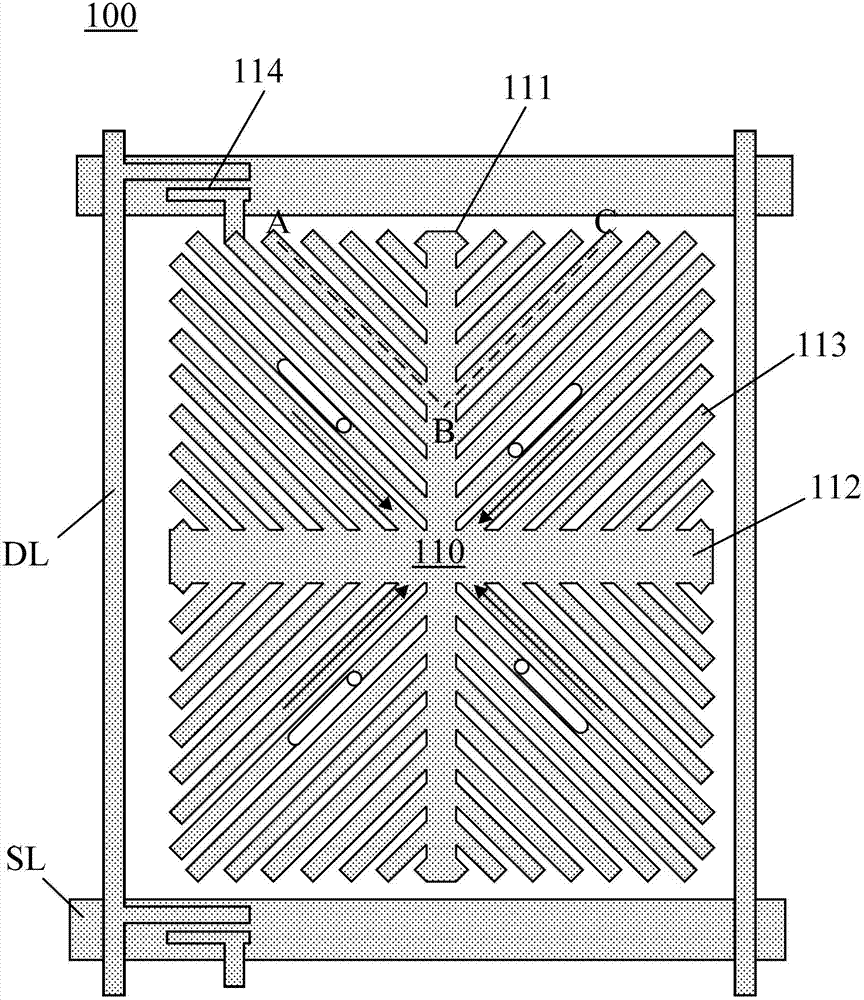

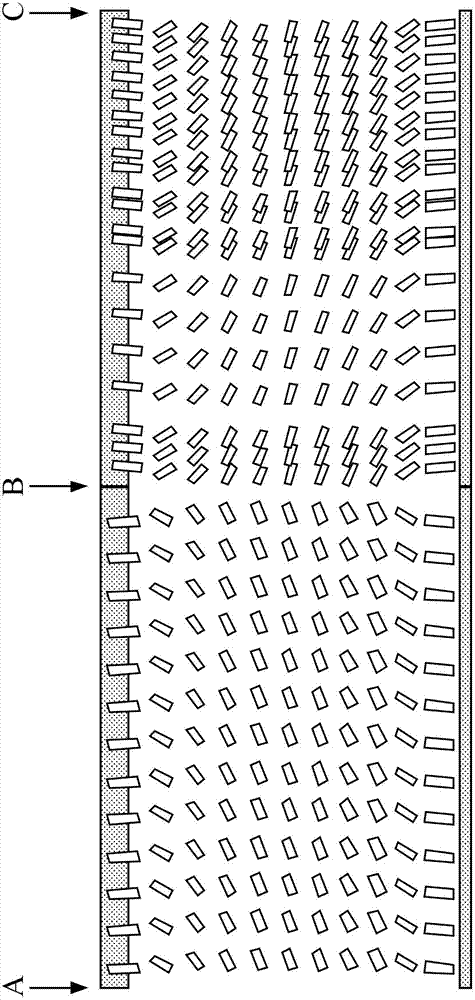

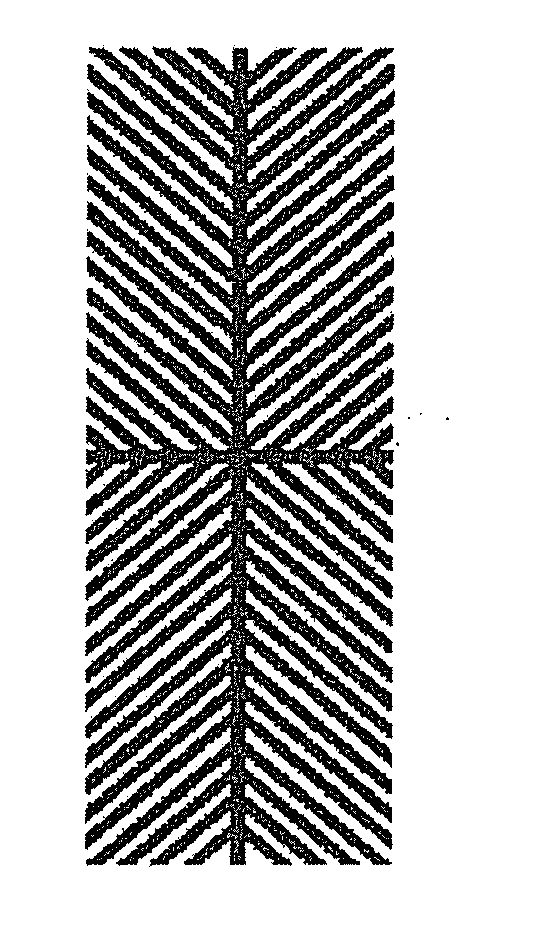

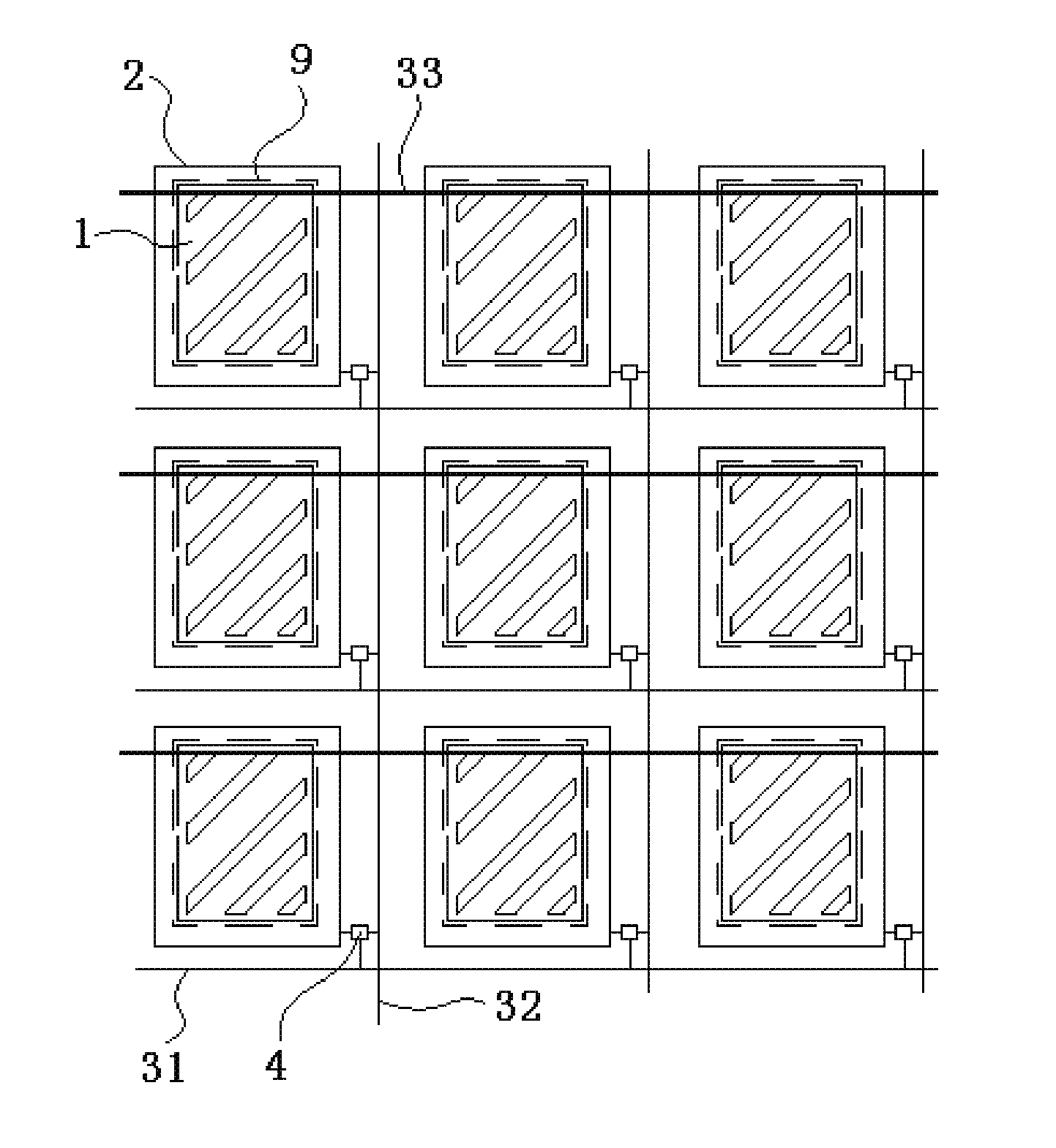

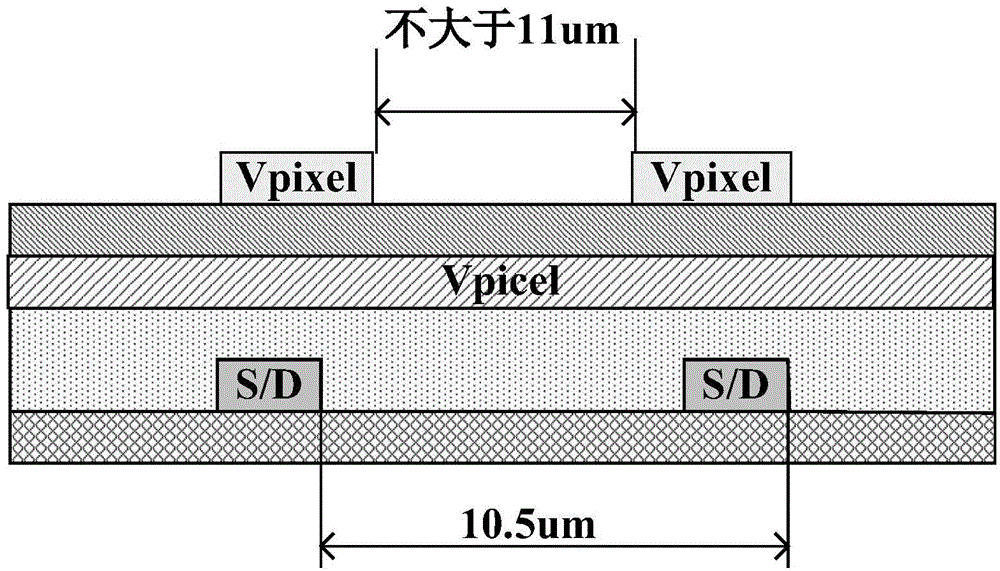

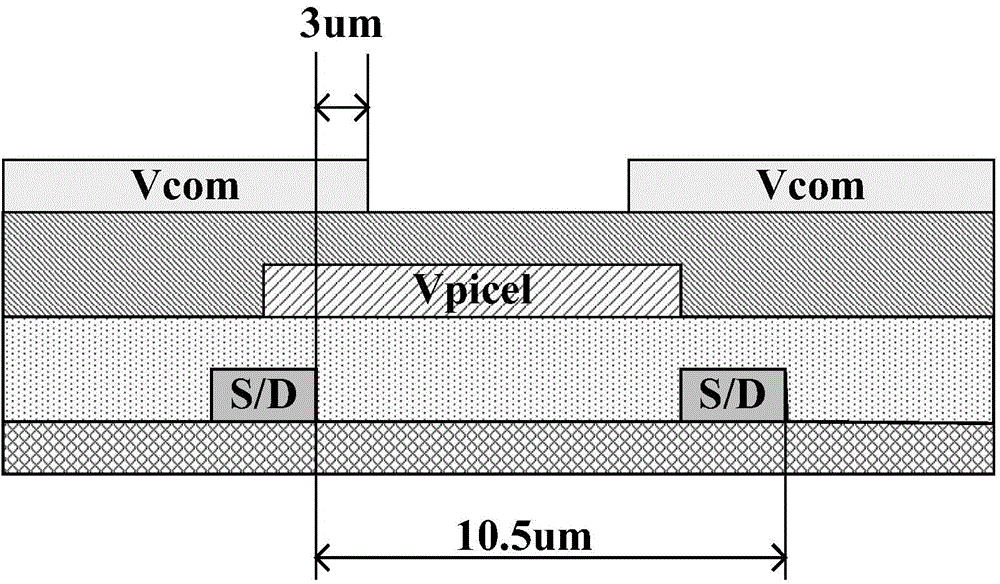

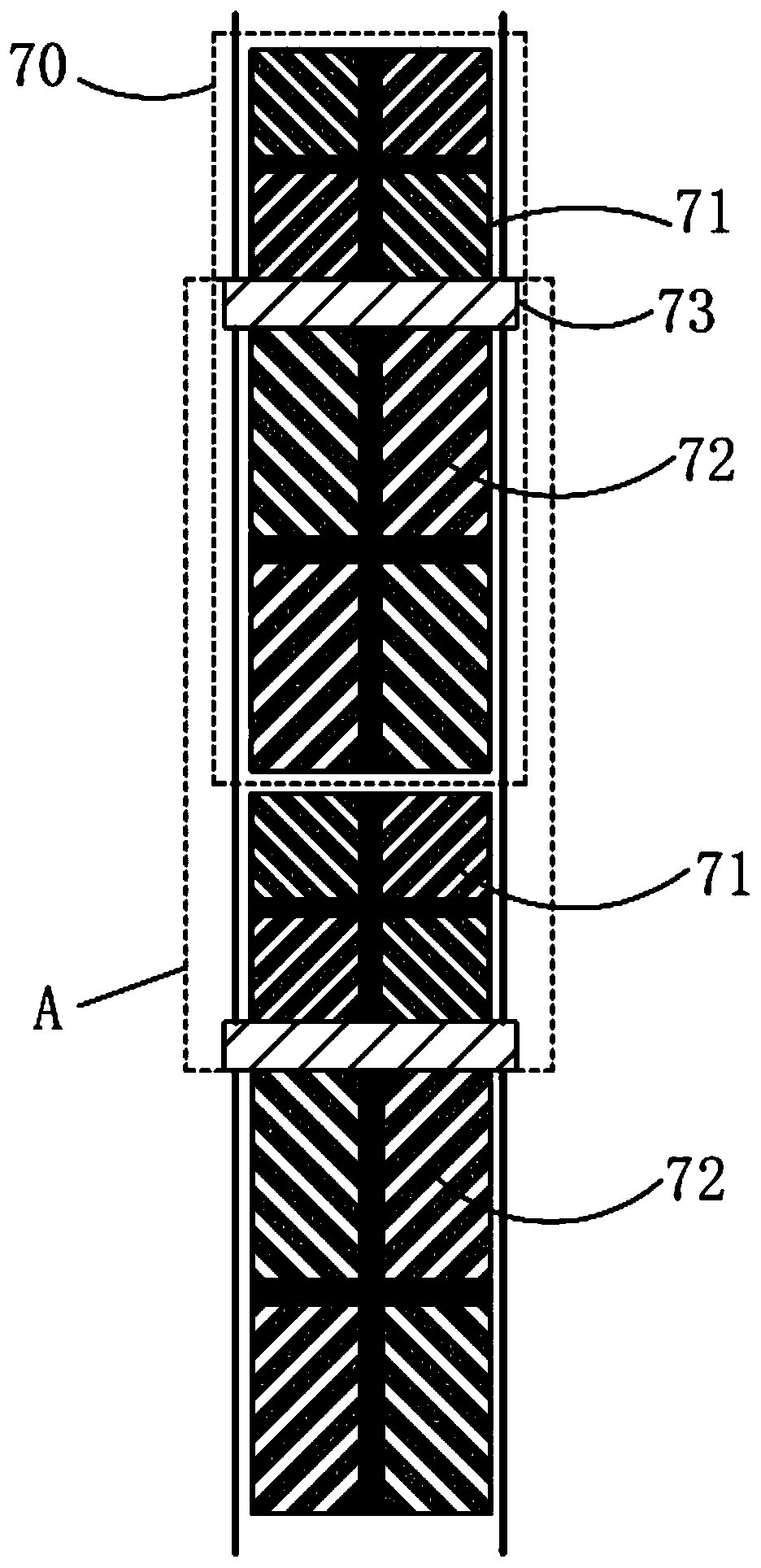

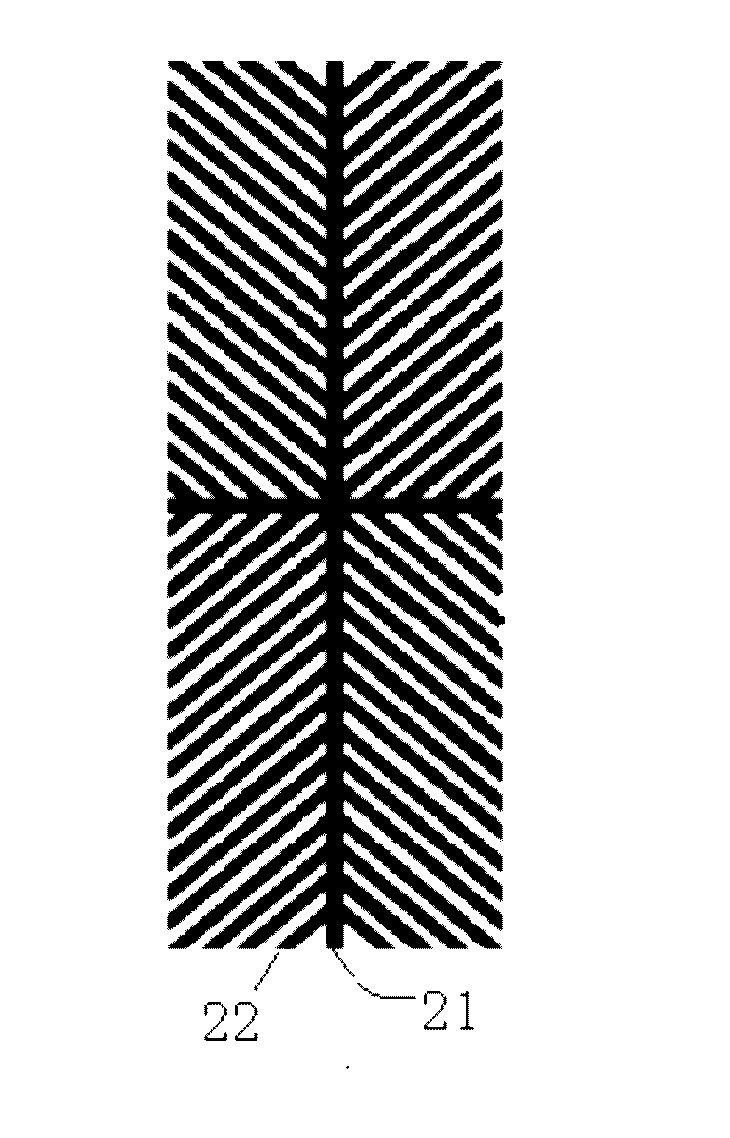

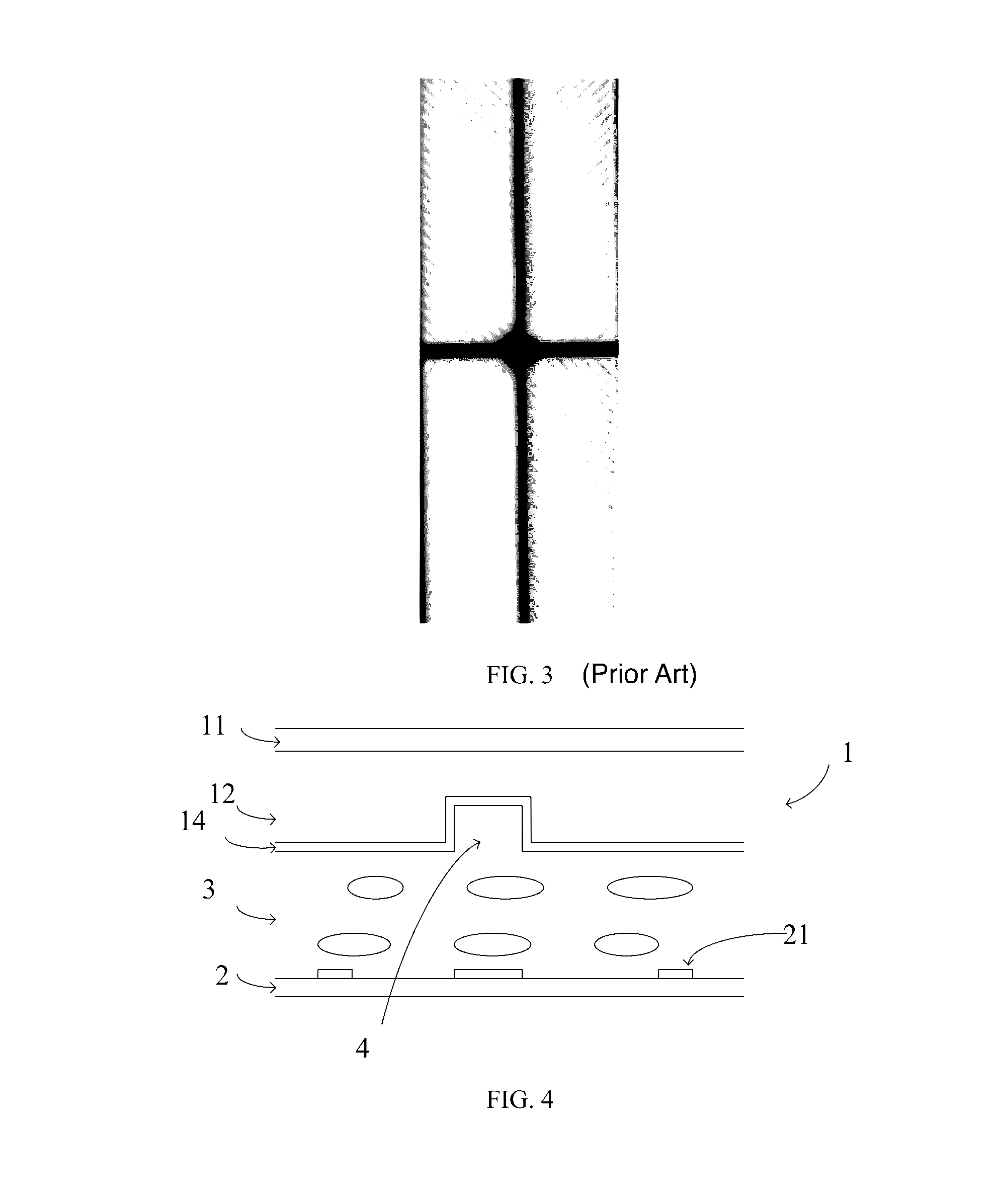

Liquid crystal display panel

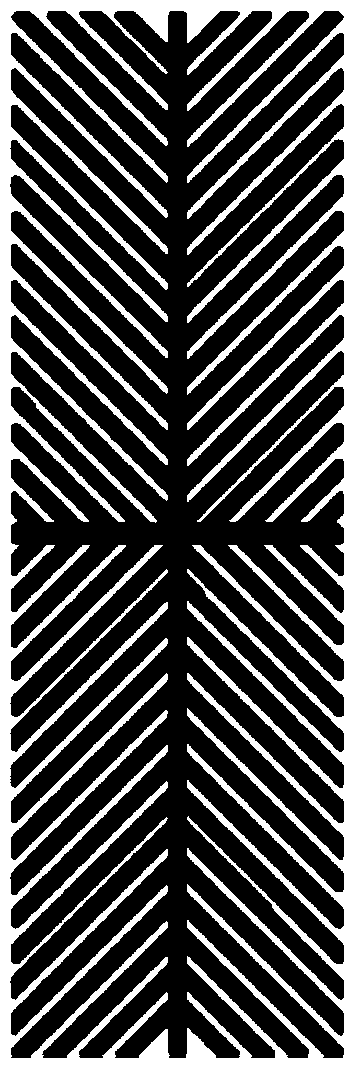

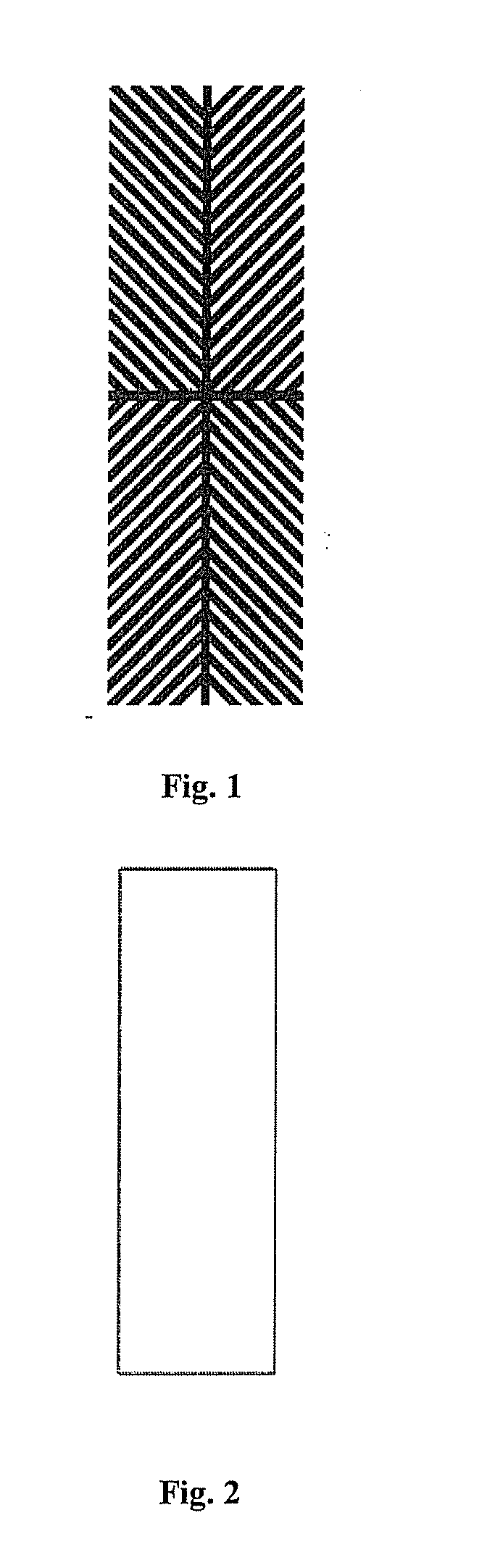

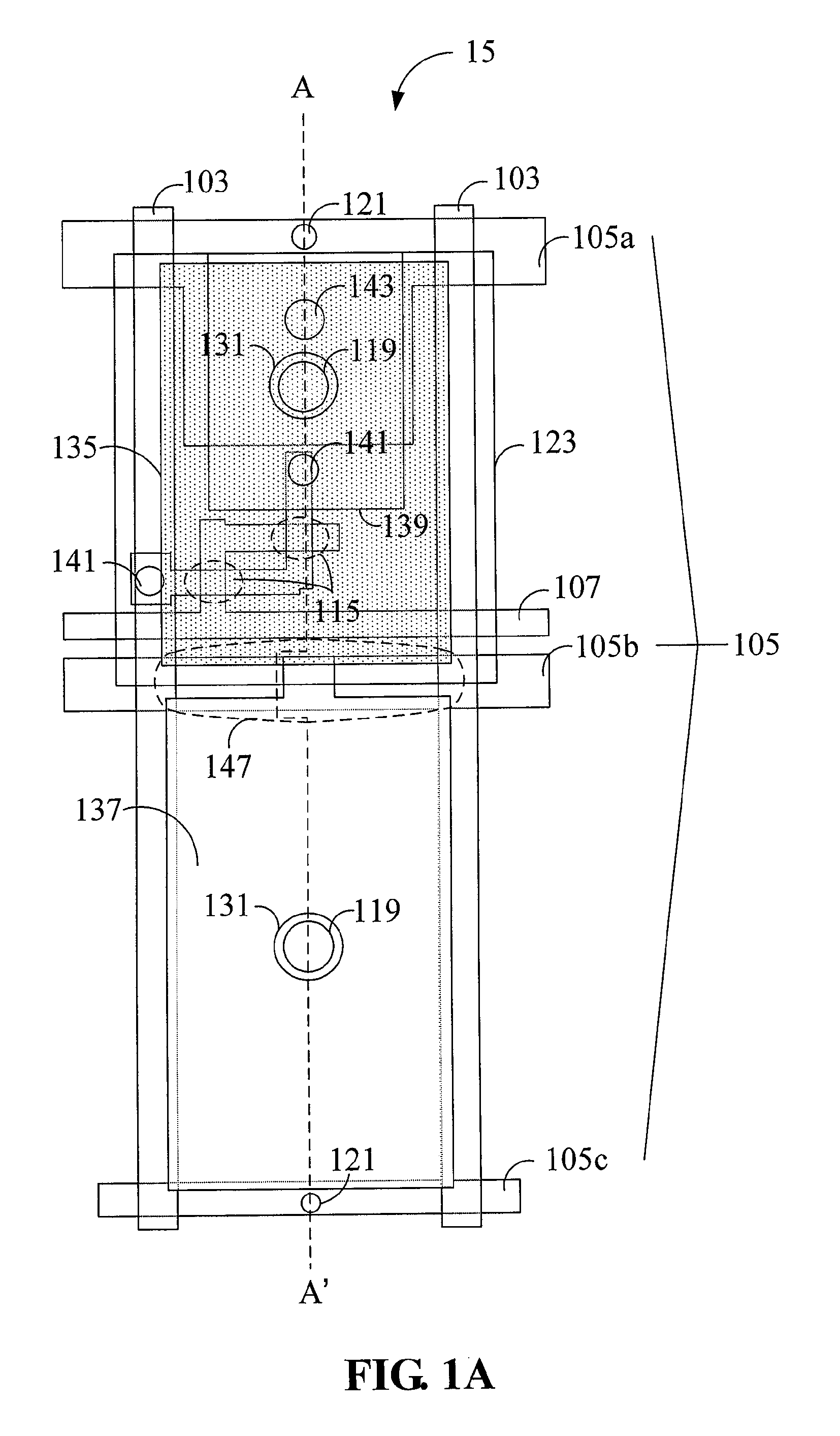

ActiveCN103454816AImprove liquid crystal efficiencyReduce widthNon-linear opticsMulti fieldVertical alignment

The invention relates to the technical field of liquid crystal display, in particular to a liquid crystal display panel. The efficiency of liquid crystals of the liquid crystal display panel can be improved. The liquid crystal display panel comprises an array substrate and a color film substrate. A liquid crystal layer is sandwiched between the array substrate and the color film substrate, a pixel electrode of the array substrate is of a multi-field structure, the multi-field structure comprises trunk portions and branch portions, and slits are formed in a common electrode of the color film substrate. Dark lines in the prior art can be narrowed by the slits. The liquid crystal display panel has the advantages that the common electrode for the color film substrate of the liquid crystal display panel is improved and is divided by gaps, so that the widths of the dark lines in the prior art can be greatly reduced, the efficiency of the liquid crystals of pixels in a vertical alignment mode is improved, and application of the vertical alignment mode to high-resolution liquid panels is broadened.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

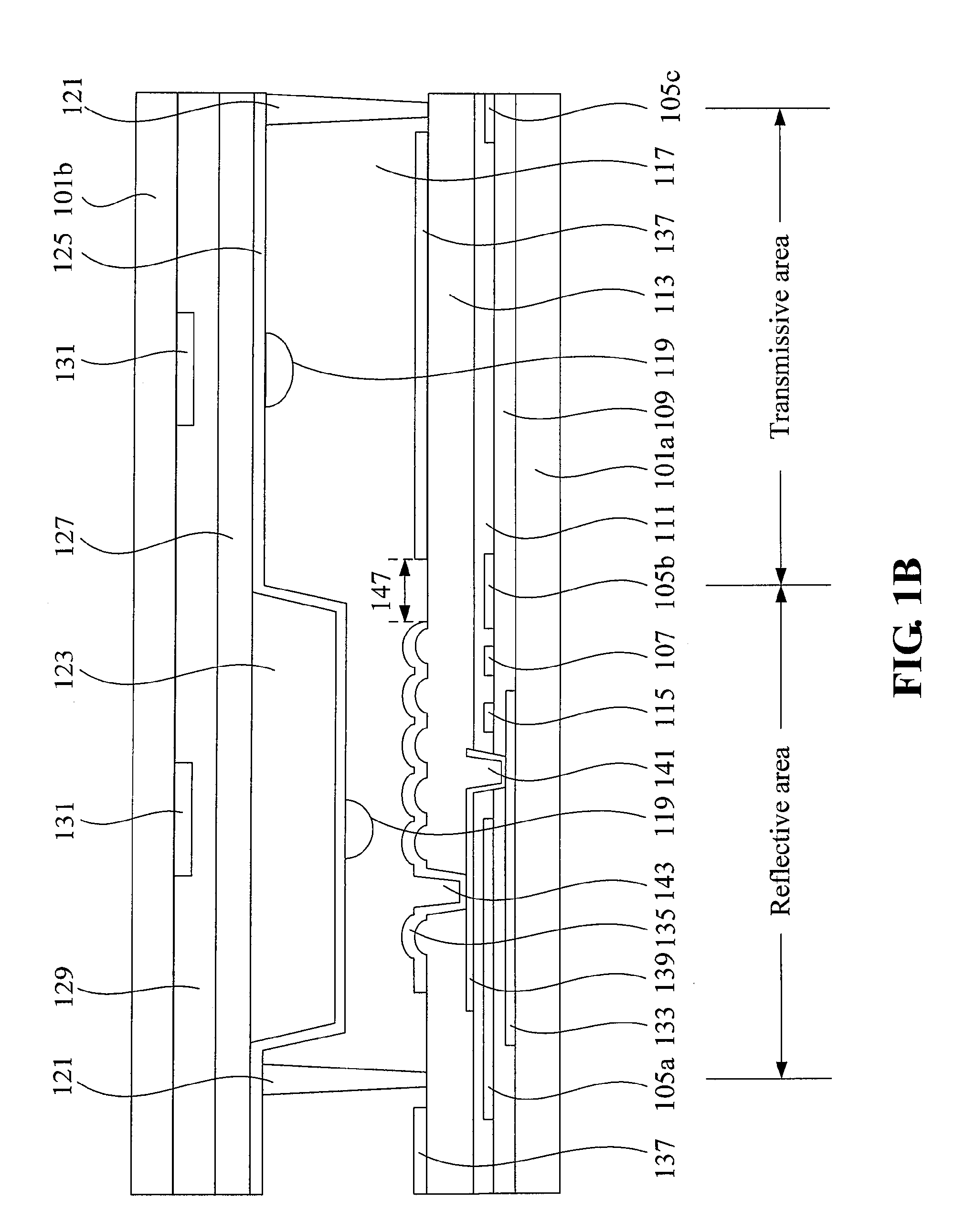

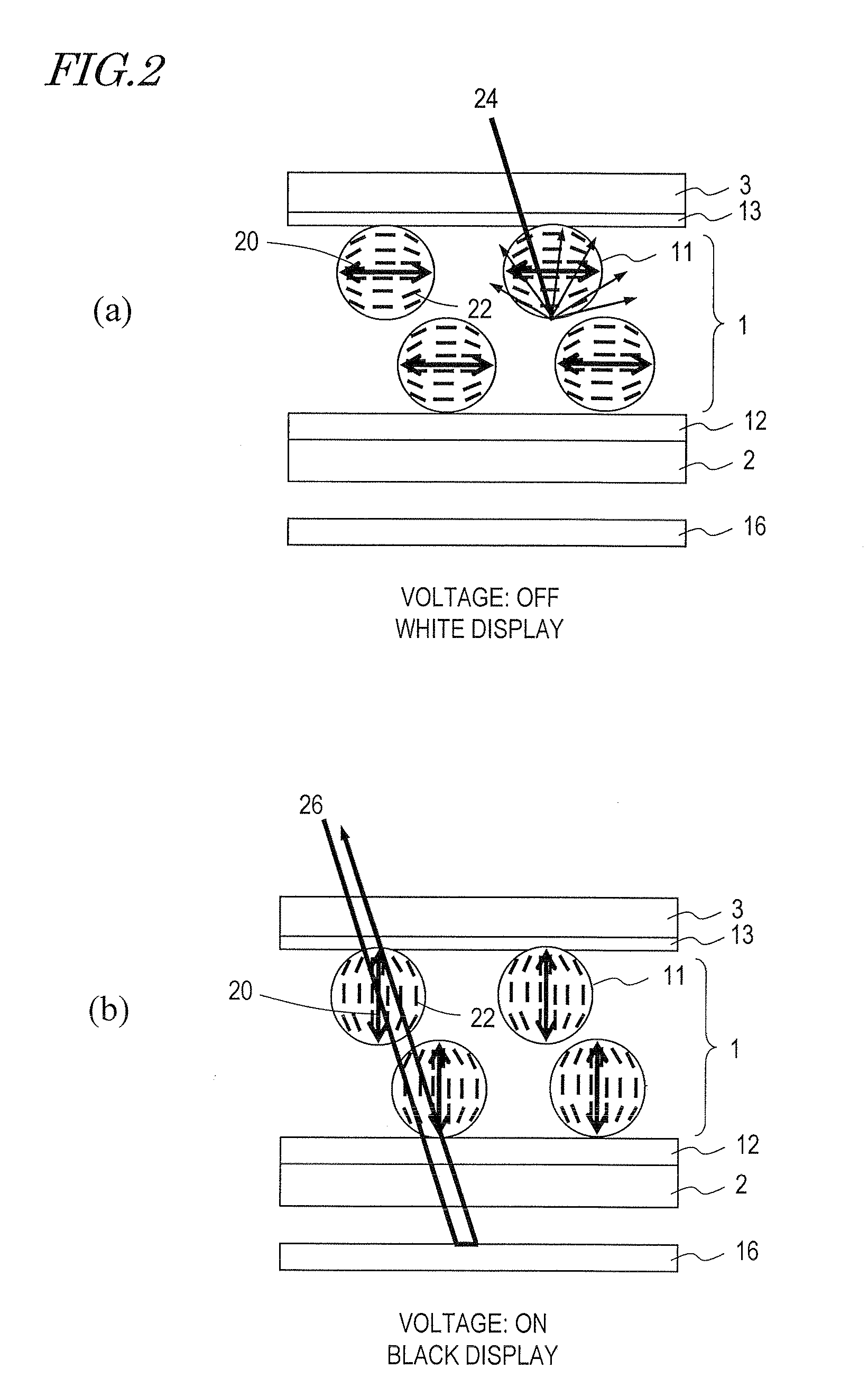

Vertical alignment mode LCD with larger dielectric protrusions in transmissive region than in reflection region

ActiveUS7277146B2Easy to controlImprove liquid crystal efficiencyNon-linear opticsVertical alignmentLayer thickness

The invention provides a liquid crystal display device having a wide viewing angle for transmissive display and reflective display. The liquid crystal display device according to the invention can include a homeotropic liquid crystal layer interposed between a pair of substrates. The liquid crystal display device has a transmissive display area and a reflective display area in each dot area. A liquid crystal layer thickness-adjustment layer can be interposed between at least the substrate of the pair of substrates and the liquid crystal layer. The liquid crystal layer thickness-adjustment layer reduces the liquid crystal layer thickness of the reflective display area in comparison with the liquid crystal layer thickness of the transmissive display area. On the substrate opposing the substrate with the liquid crystal layer thickness-adjustment layer, protrusions protruding from the inner surface of the substrate to the liquid crystal layer are formed.

Owner:BOE TECH GRP CO LTD

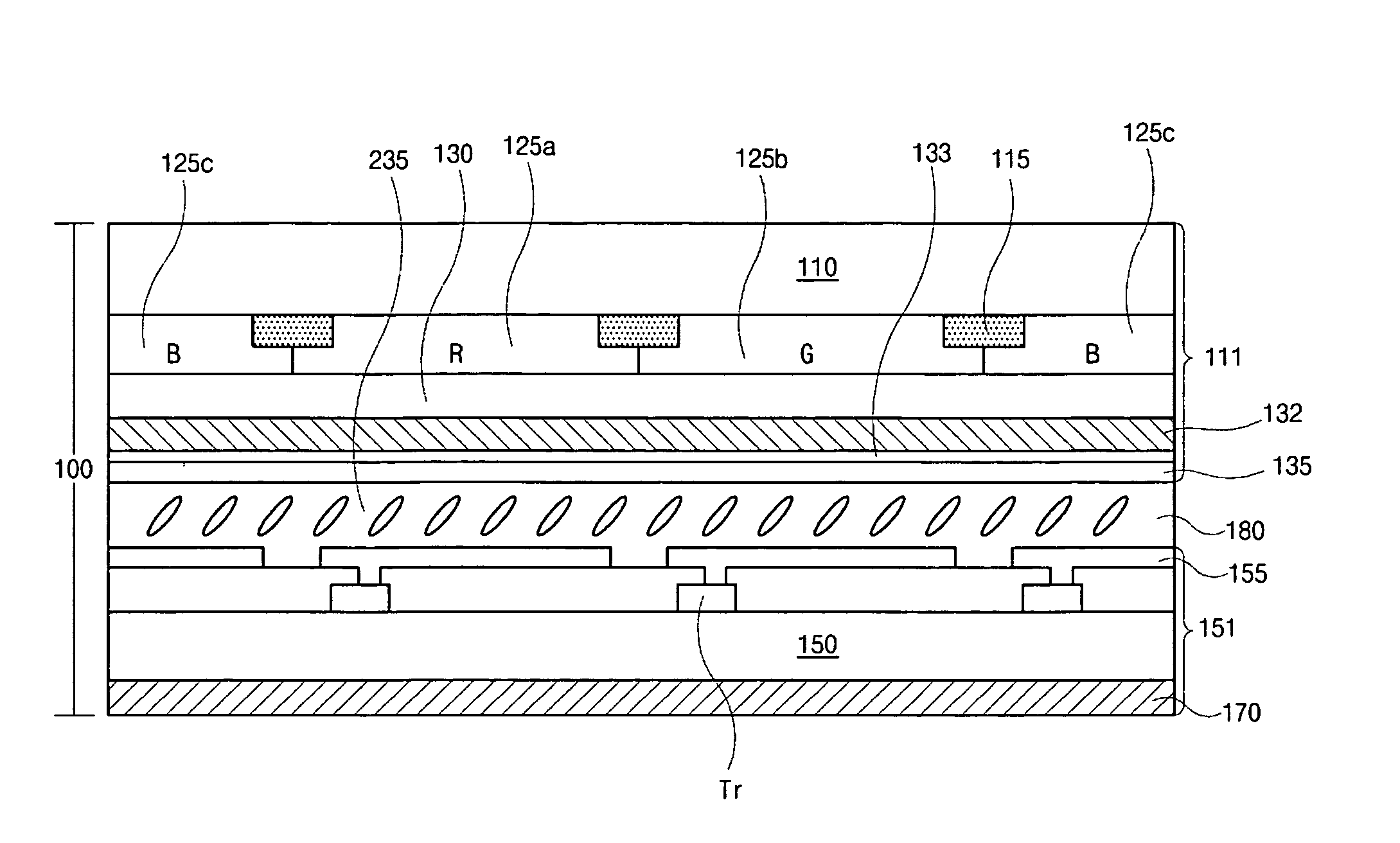

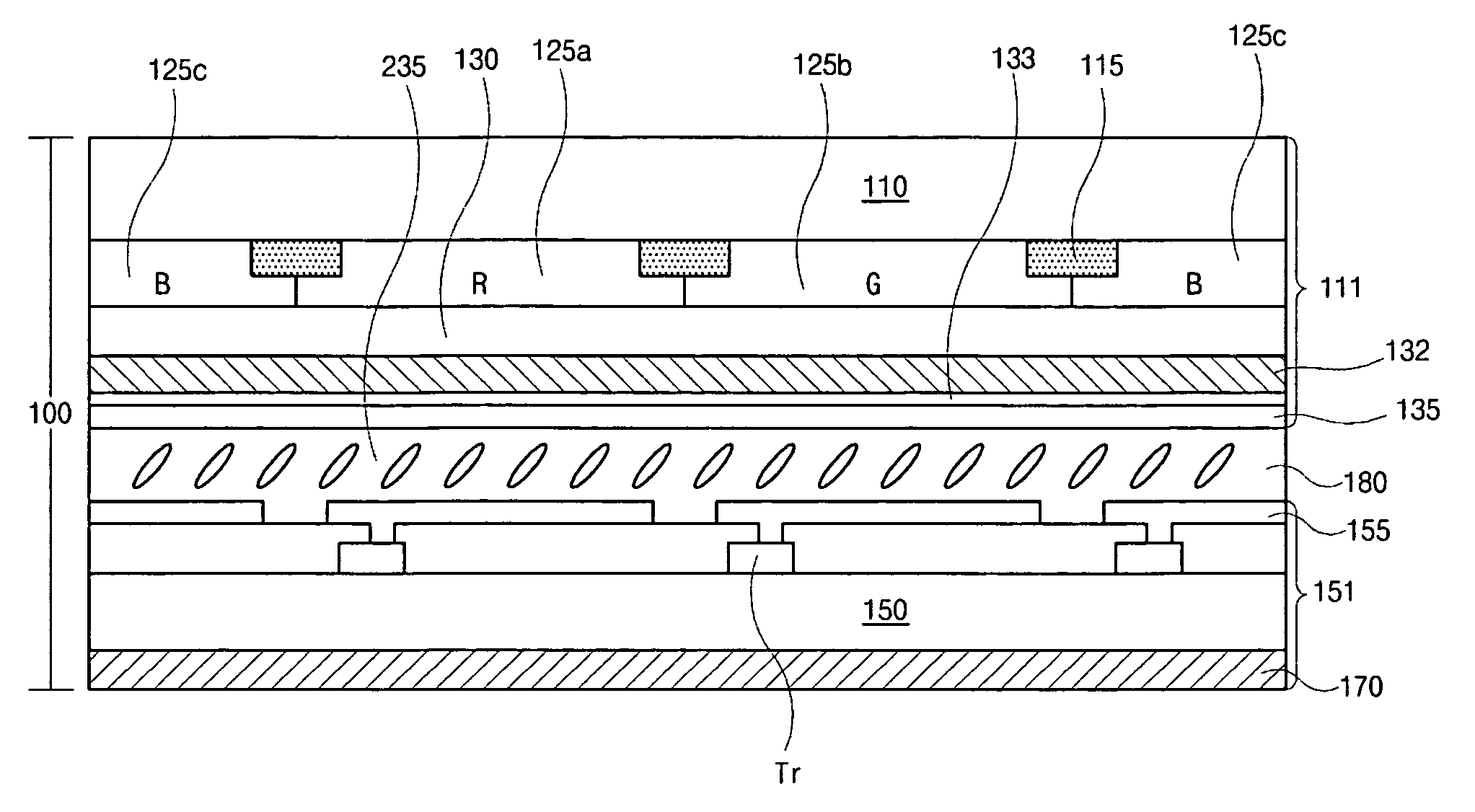

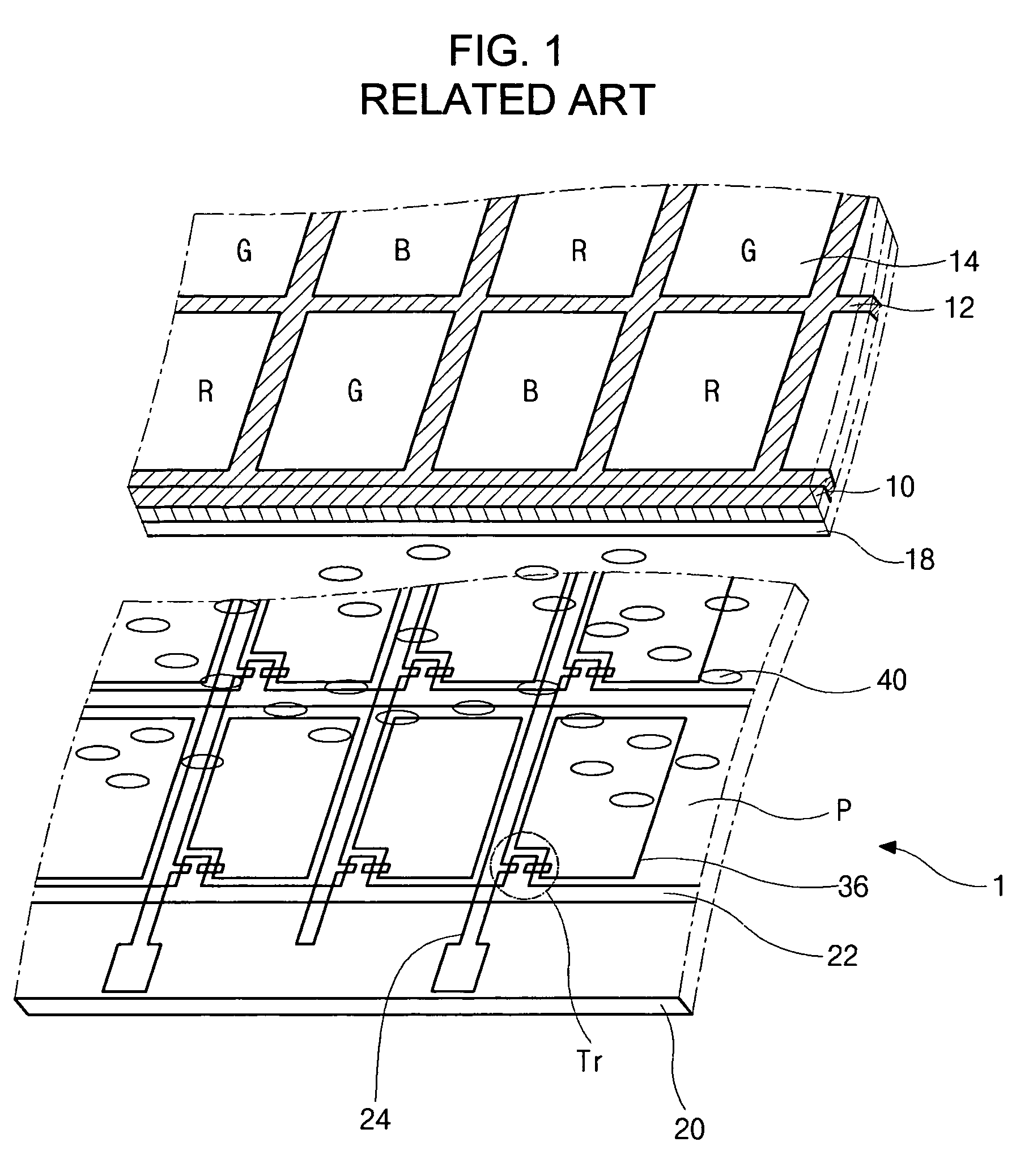

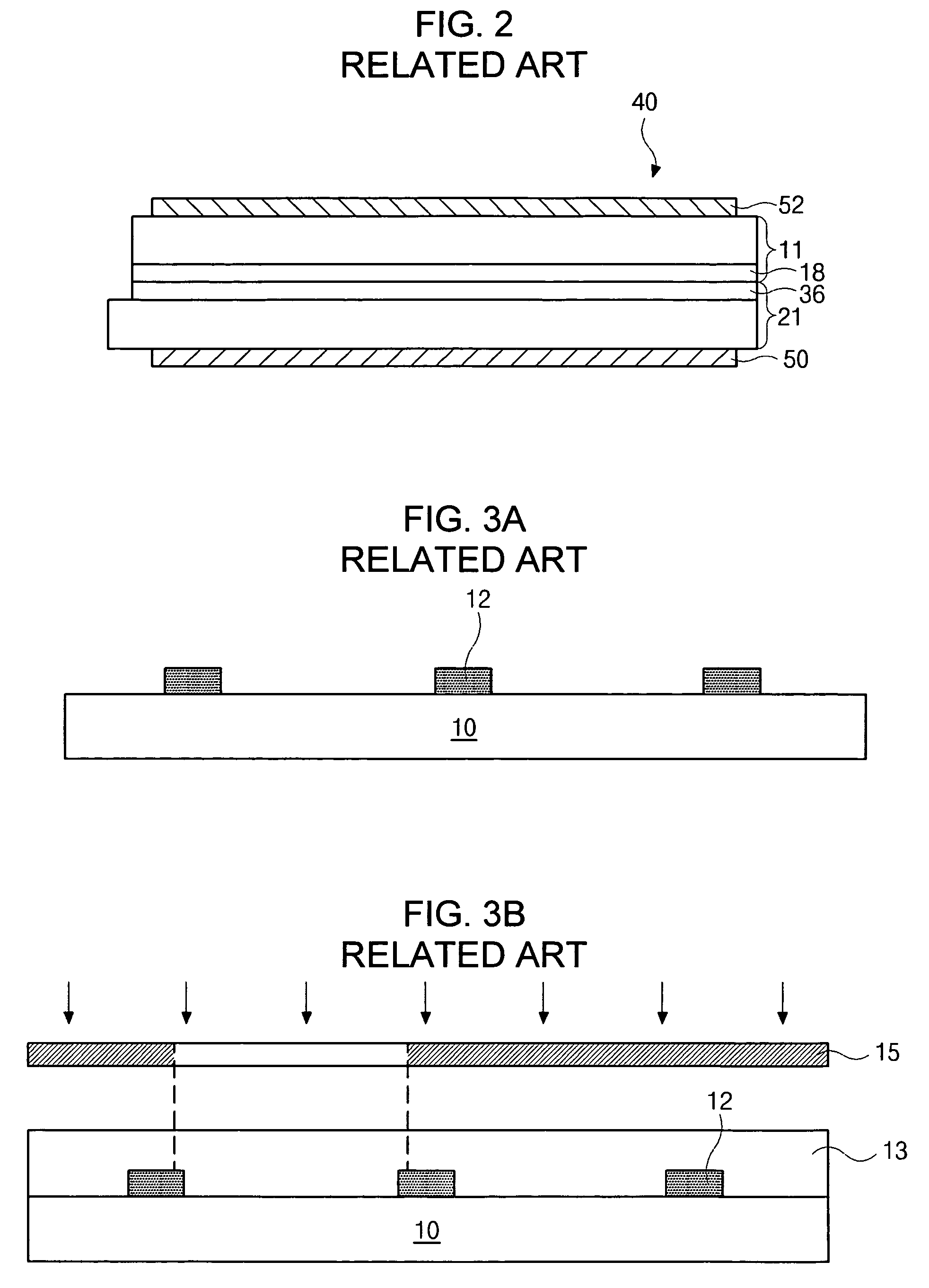

Liquid crystal display device and fabricating method thereof

InactiveUS20050140894A1Improve liquid crystal efficiencyIncrease flexibilityNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display (LCD) device includes: first and second substrates, inner surfaces of the first and second substrates facing each other; gate and data lines crossing each other to define a pixel region on the inner surface of the first substrate; a thin film transistor at the crossing of the gate and data lines; a pixel electrode connected with the thin film transistor; a color filter pattern on the inner surface of the second substrate; a first polarizing layer between the first and second substrates and adjacent to the color filter pattern; and a liquid crystal material between the first and second substrates.

Owner:LG DISPLAY CO LTD

Liquid crystal display device and fabricating method for forming polarizer by depositing, drying and curing lyotropic liquid crystal on color filter pattern

InactiveUS7423707B2Improve liquid crystal efficiencyIncrease flexibilityNon-linear opticsLiquid-crystal displayPolarizer

A liquid crystal display (LCD) device includes: first and second substrates, inner surfaces of the first and second substrates facing each other; gate and data lines crossing each other to define a pixel region on the inner surface of the first substrate; a thin film transistor at the crossing of the gate and data lines; a pixel electrode connected with the thin film transistor; a color filter pattern on the inner surface of the second substrate; a first polarizing layer between the first and second substrates and adjacent to the color filter pattern; and a liquid crystal material between the first and second substrates.

Owner:LG DISPLAY CO LTD

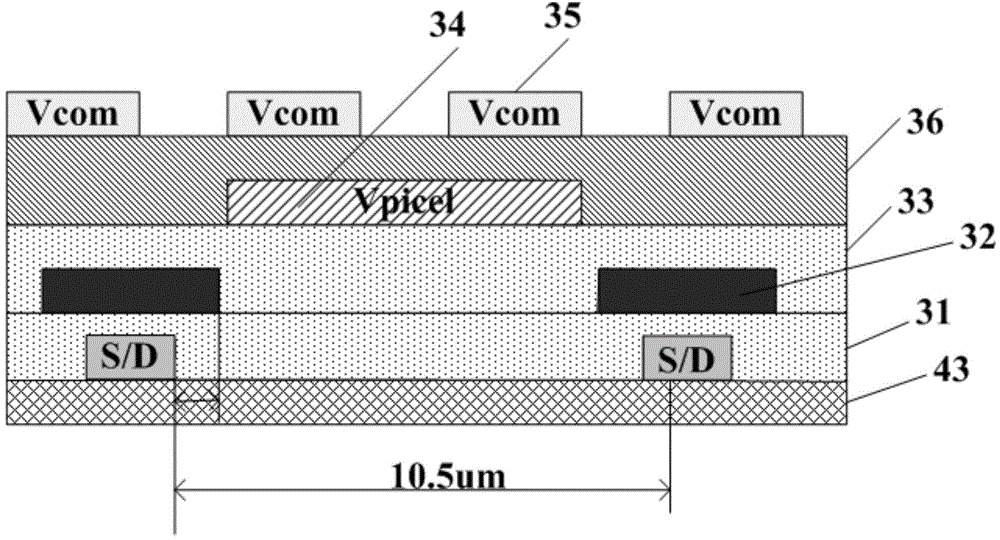

Thin film transistor base plate

ActiveCN1909236AIncrease opening ratioImprove liquid crystal efficiencySemiconductor/solid-state device detailsSolid-state devicesPellicle membraneTransistor

The invention relates to a film transistor base board, which comprises: substrate; several scanning wires; several data wires and pixel units, wherein the scanning wires are above the substrate; the data wires are above the scanning wires, while they are vertical to define several pixel areas; the pixel units are above the substrate and inside the pixel area; the pixel unit comprises film transistor and pixel electrode; the film transistor comprises source and drain; the pixel electrode is connected to the drain; the pixel electrode comprises the first bus electrode, the second bus electrode and several branched electrode; the first bus electrode is vertical to the second bus electrode; the branched electrode is connected to the first bus electrode and / or the second bus electrode; the first bus electrode uniformly divides the pixel area; and the film transistor is relative to one end of first bus electrode.

Owner:AU OPTRONICS CORP

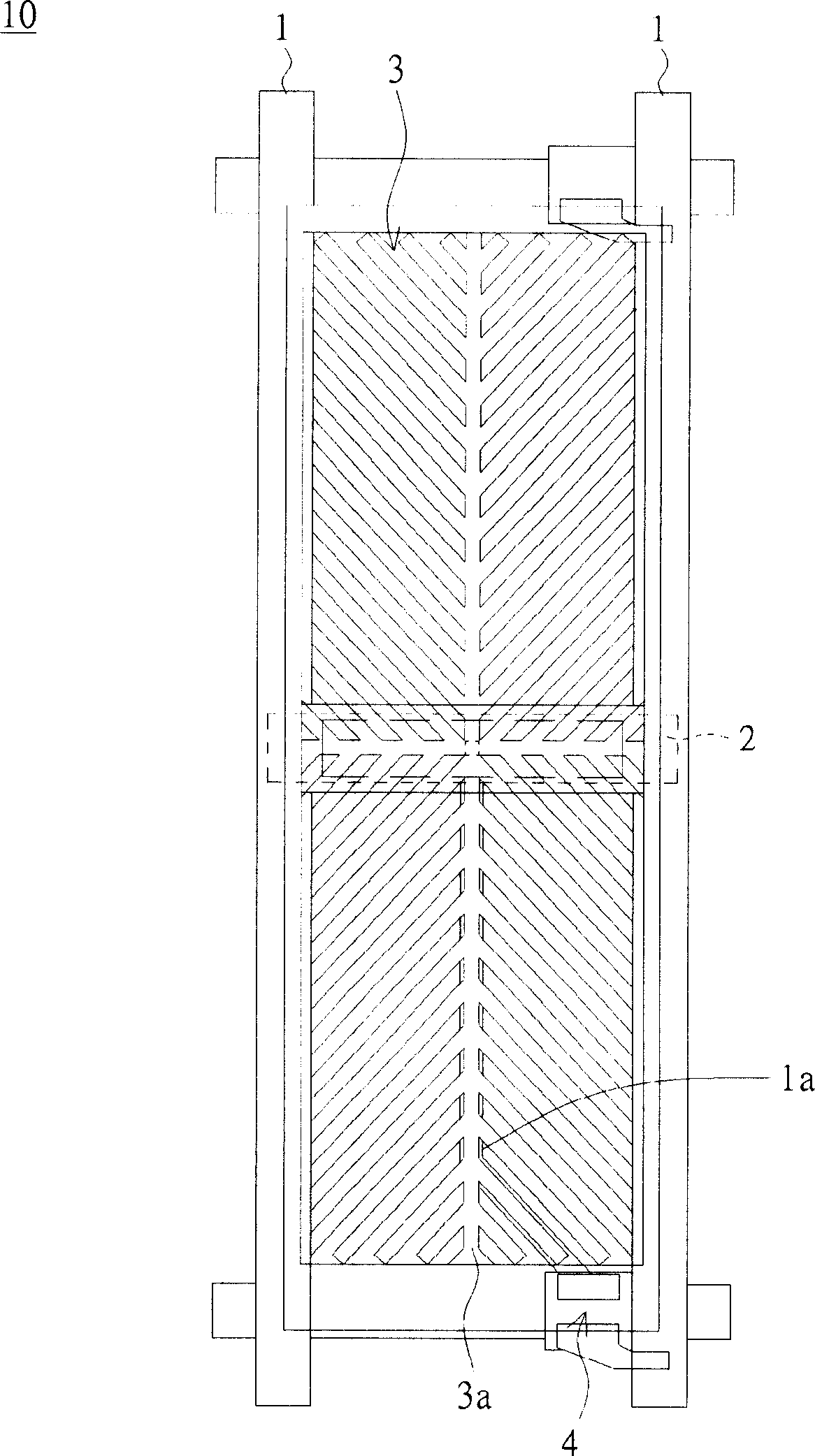

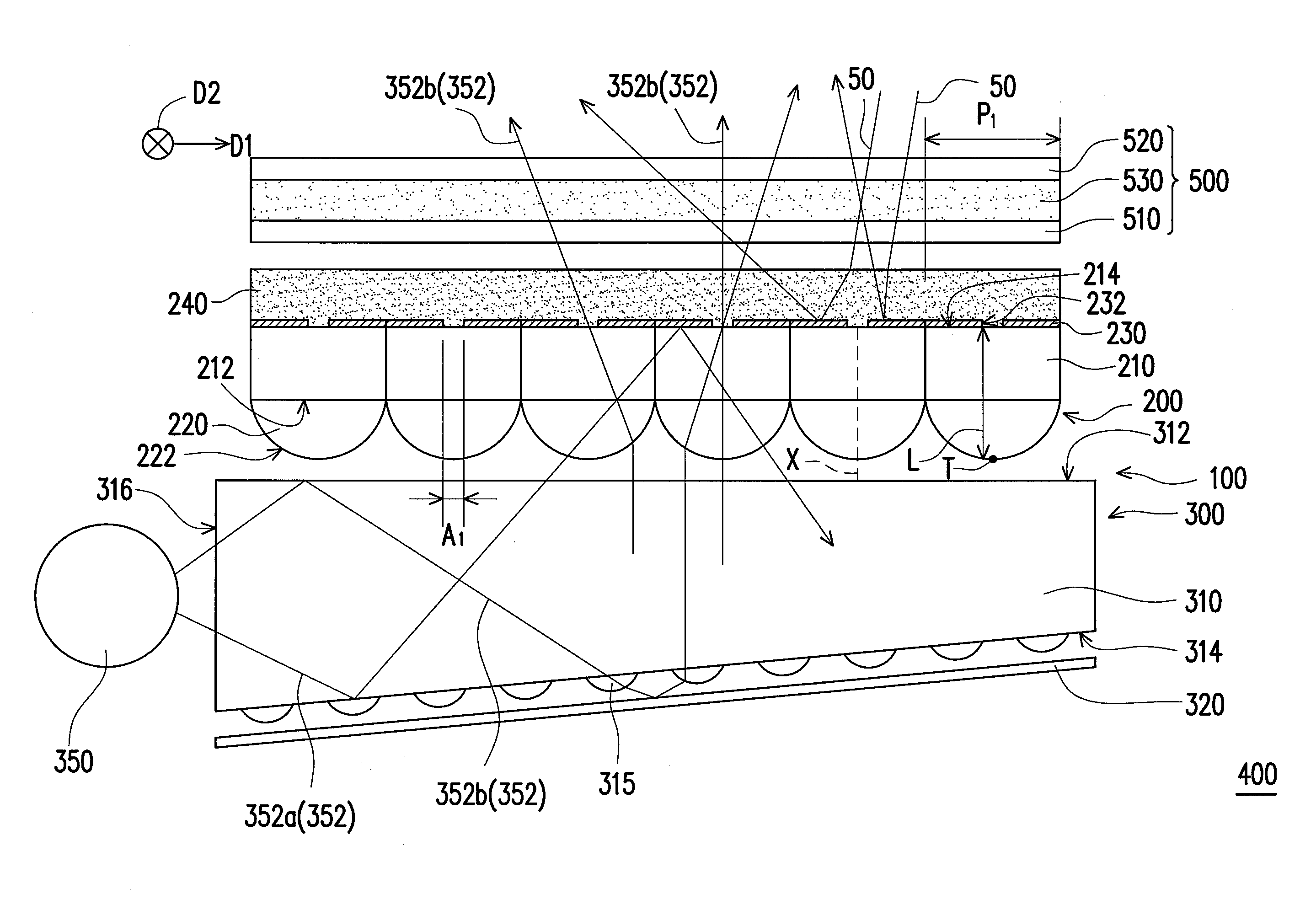

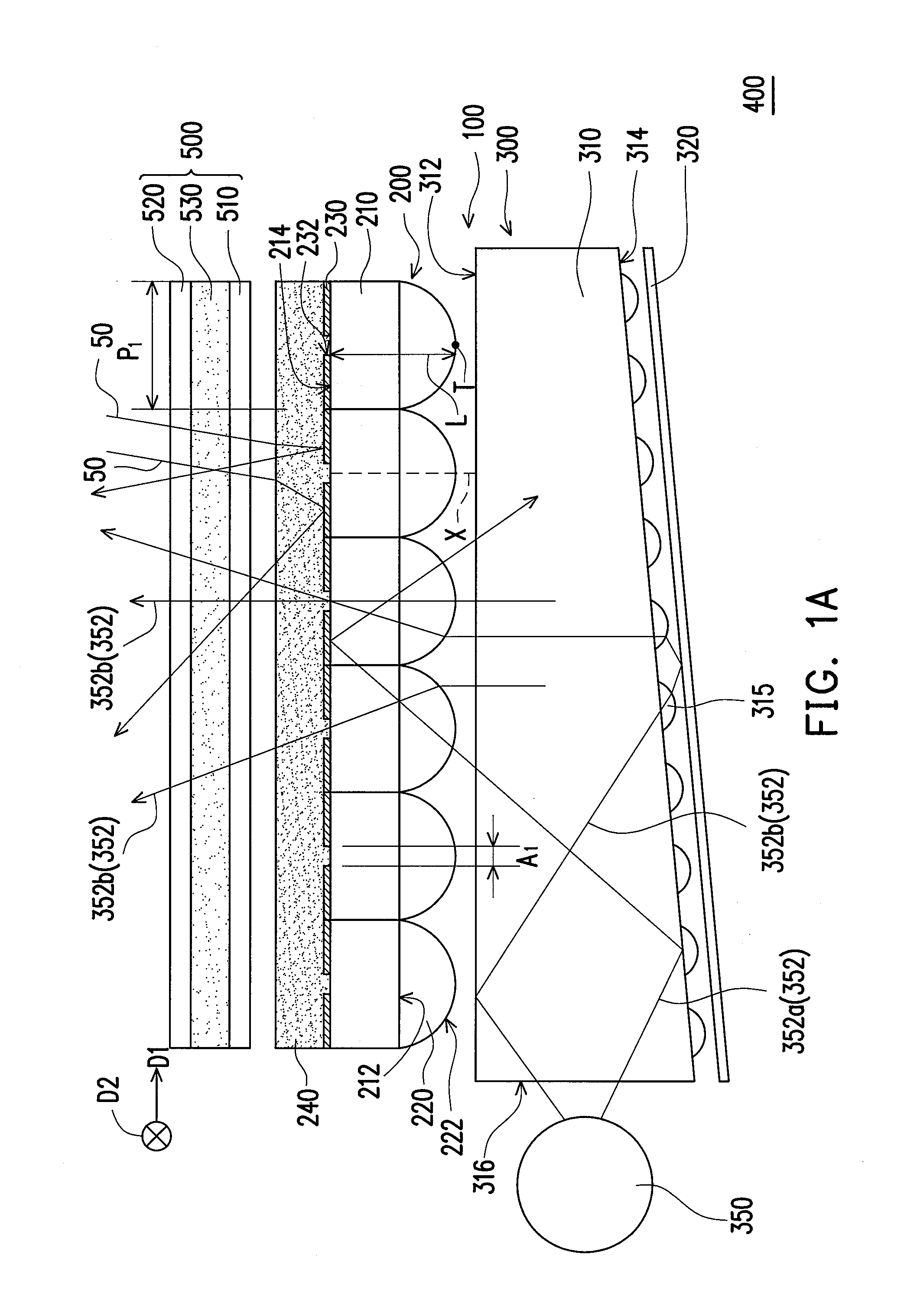

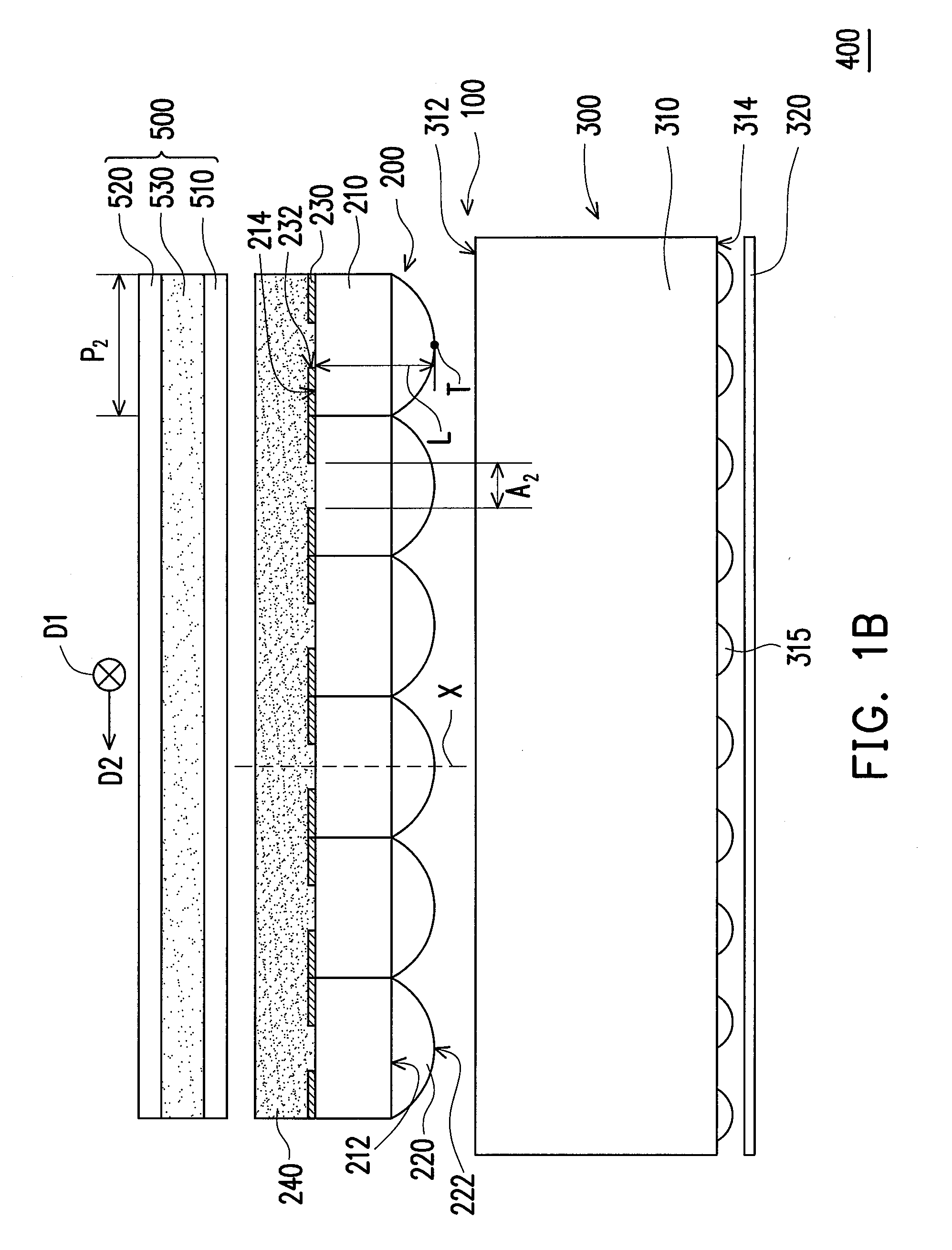

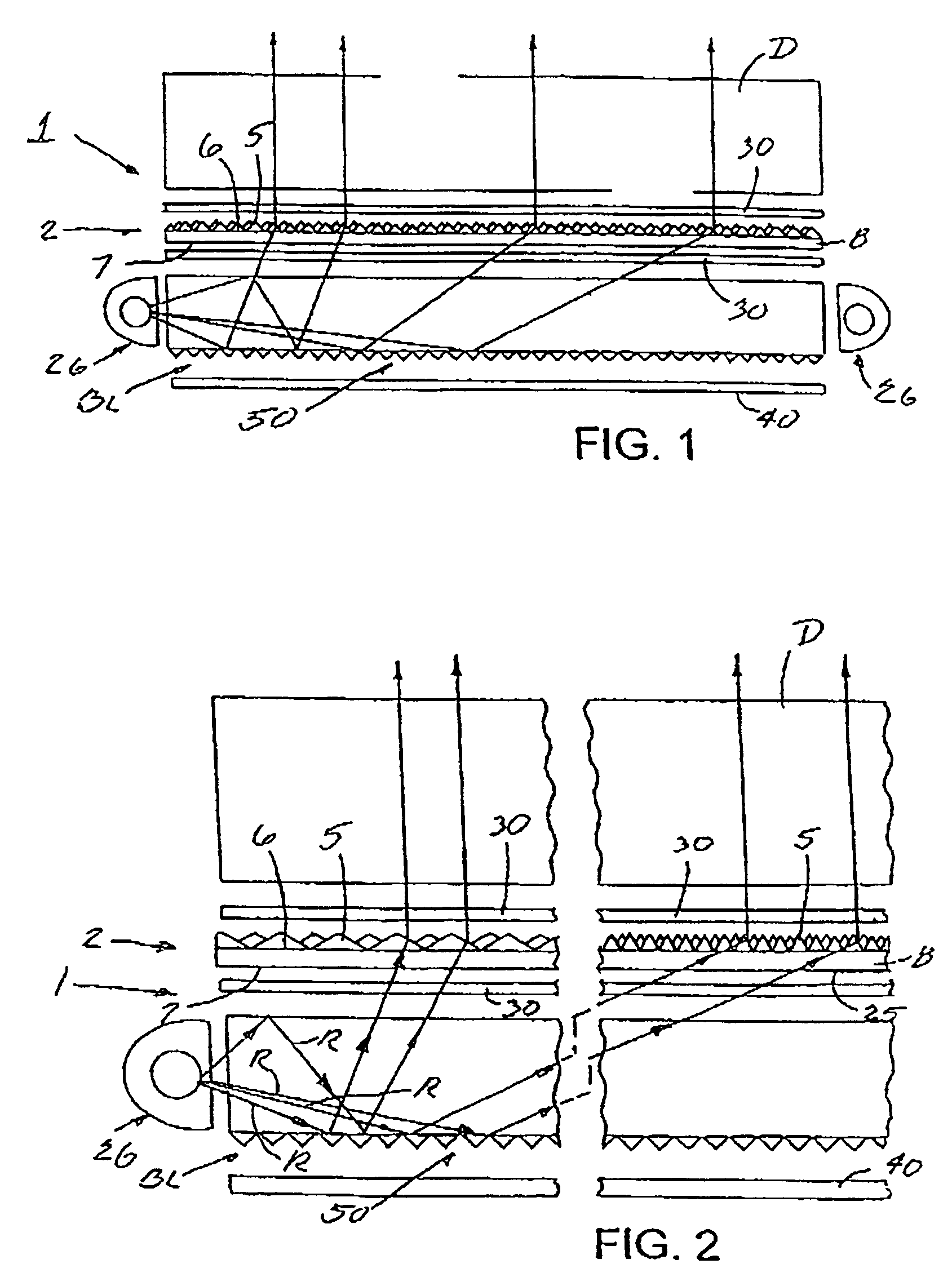

Backlight module and liquid crystal display apparatus

InactiveUS20110069249A1Easy to assembleLow costDiffusing elementsOptical light guidesLiquid-crystal displayOptical axis

A backlight module includes a lighting unit and a brightness enhancement sheet. The brightness enhancement sheet is disposed beside the lighting unit. The brightness enhancement sheet includes a light-transmissive substrate, a plurality of lenses, a reflective layer, and a diffusion layer. The light-transmissive substrate has a first surface and a second surface opposite to the first surface. The first surface is located between the second surface and the lighting unit. The lenses are disposed on the first surface. The reflective layer is disposed on the second surface. The reflective layer has a plurality of light-transmissive openings respectively located on the optical axes of the lenses. The diffusion layer is disposed on the reflective layer and covers the light-transmissive openings. The reflective layer is disposed between the diffusion layer and the second surface. A liquid crystal display apparatus is also provided.

Owner:CORETRONIC

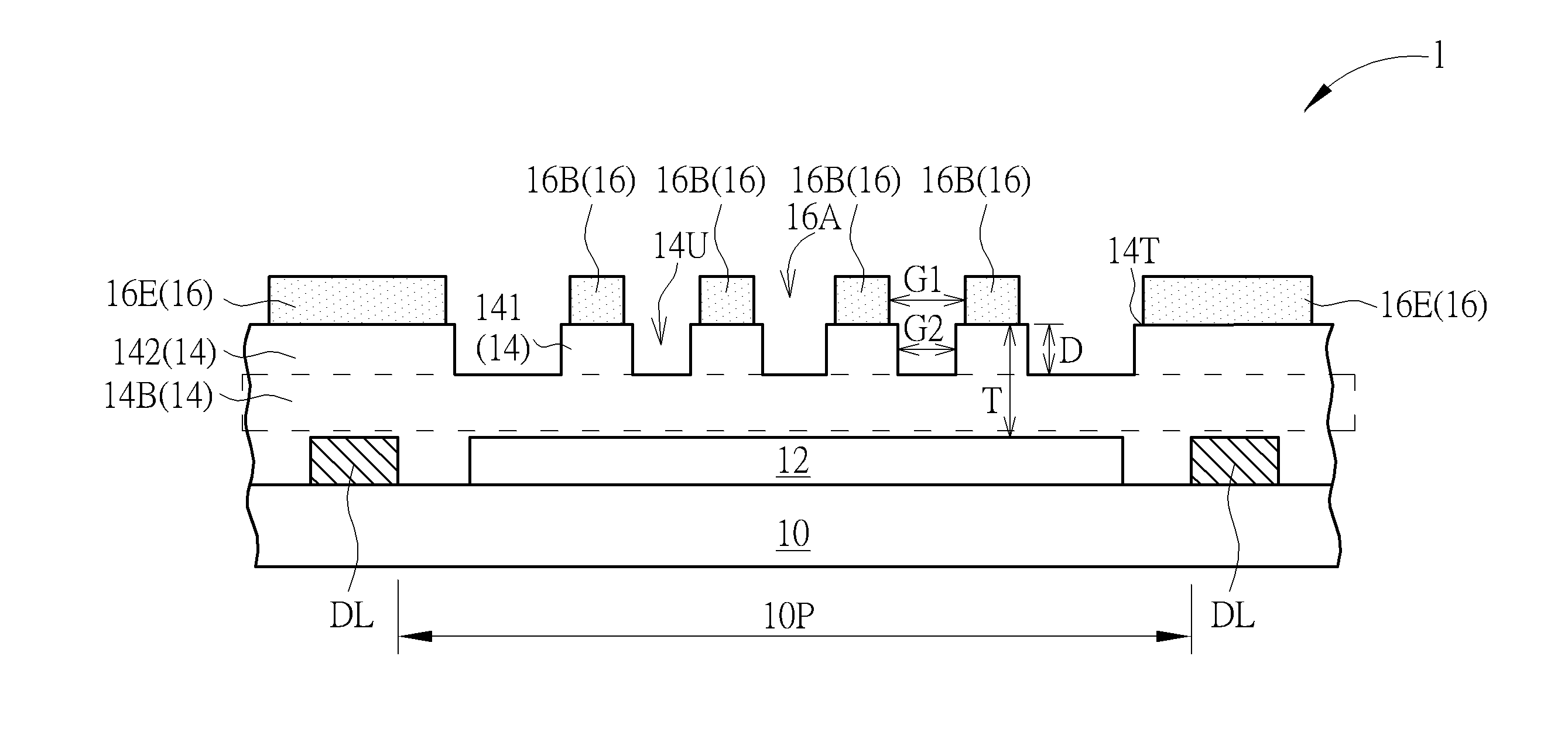

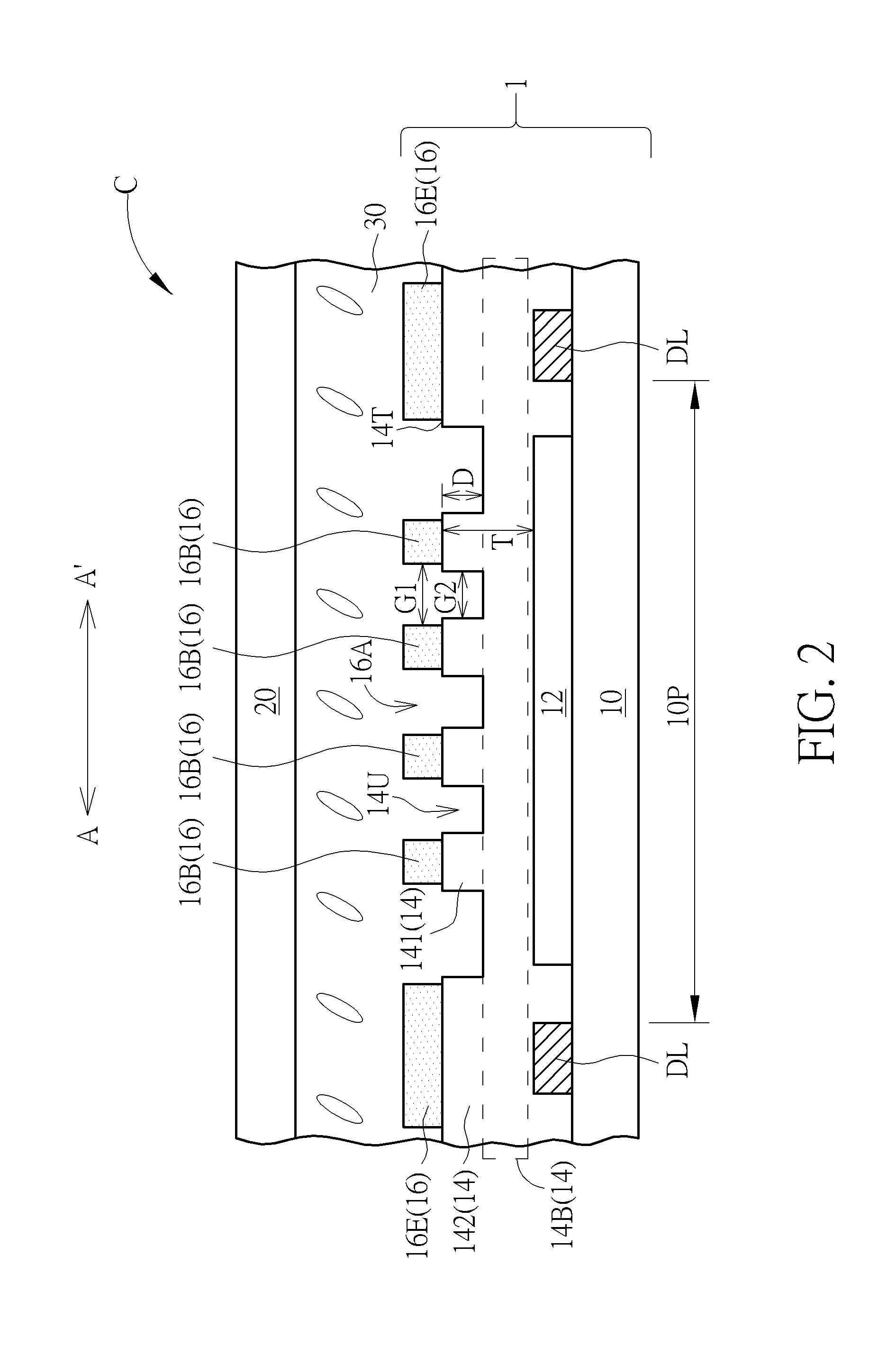

Pixel structure and liquid crystal panel

ActiveUS20150212380A1Increased capacity with capacitive loadsImprove efficiencySolid-state devicesNon-linear opticsLiquid-crystal displayDielectric layer

A pixel structure includes a substrate, a plurality of gate lines and data lines, and at least one first pixel. The gate lines and the data lines are disposed on the substrate. The first pixel is disposed on the substrate and electrically connected to corresponding gate line and data line. The first pixel includes a first electrode, a first dielectric layer and a second electrode. The first electrode is disposed on the substrate. The first dielectric layer is disposed on the first electrode, and the first dielectric layer has at least one first island structure. The second electrode is disposed on a top surface of the first island structure, and the second electrode partially exposes the top surface of the first island structure.

Owner:AU OPTRONICS CORP

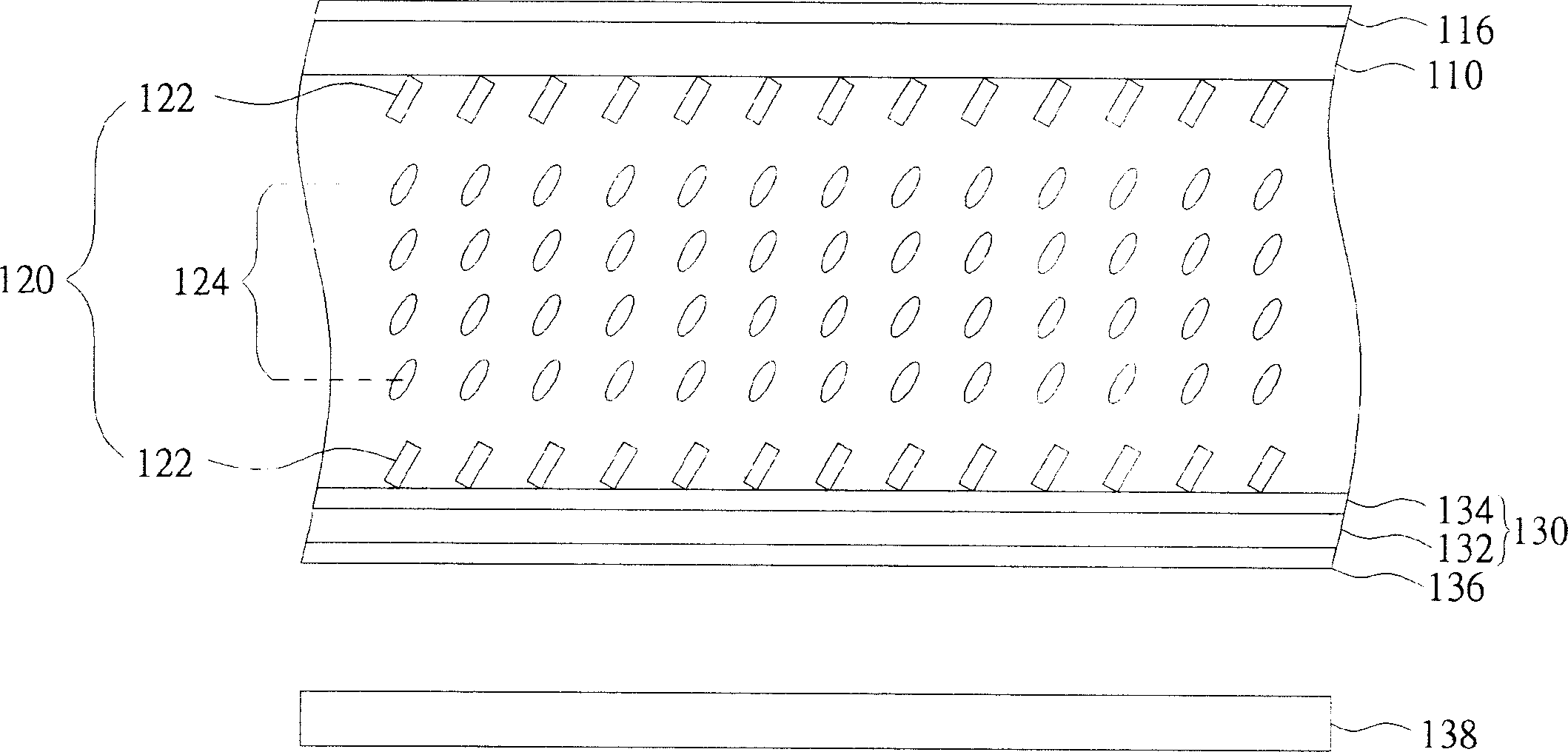

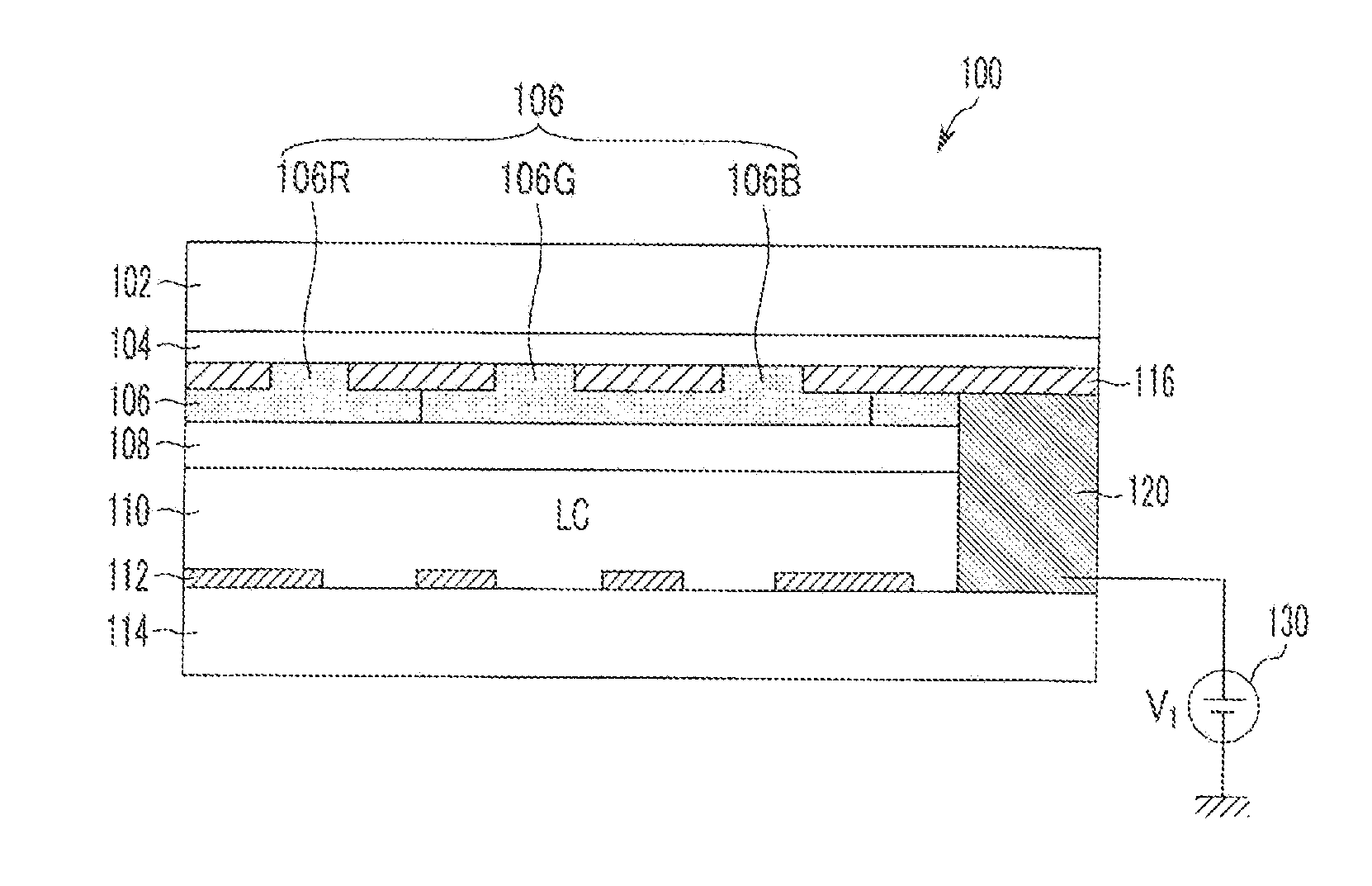

Liquid crystal display panel and manufacturing method thereof

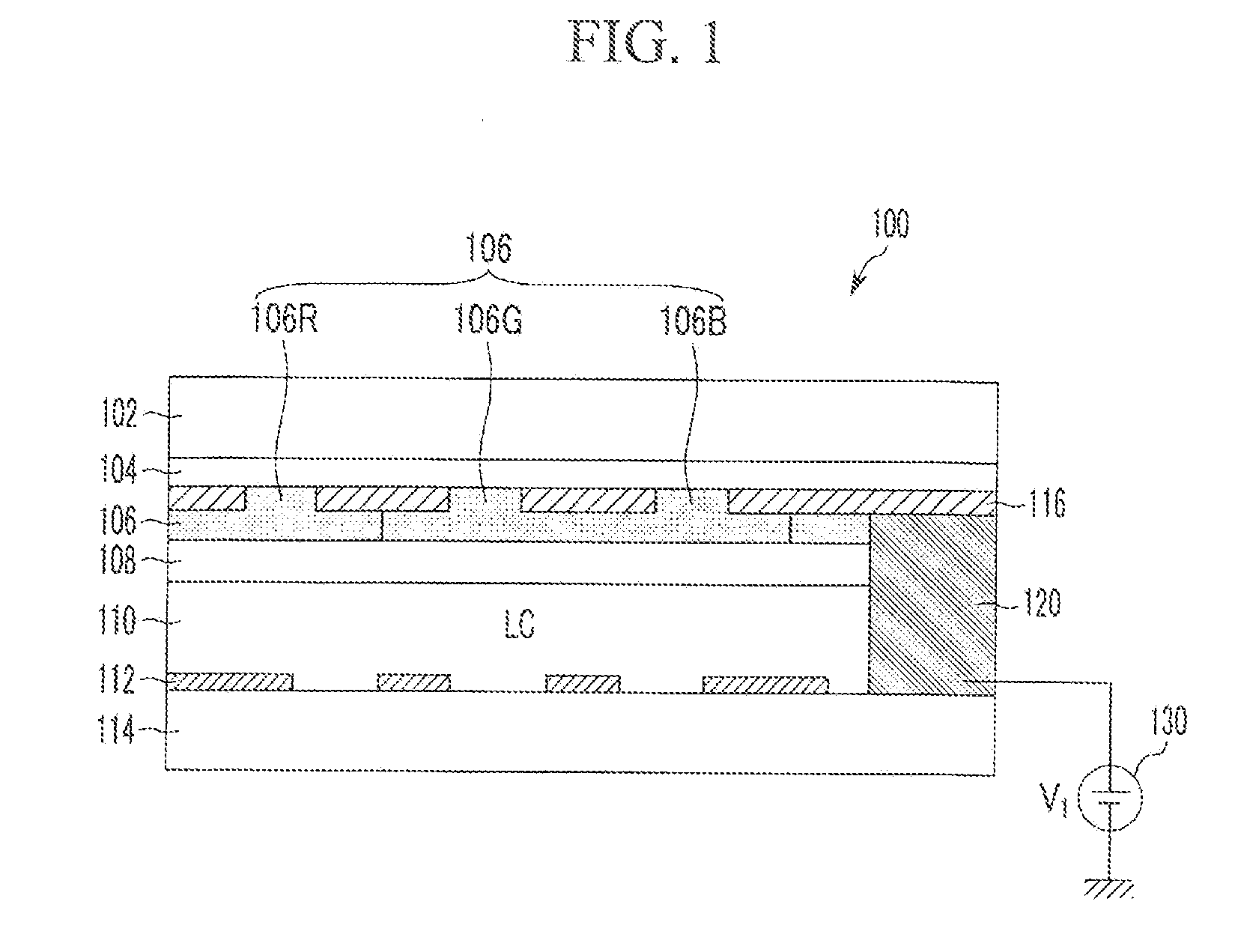

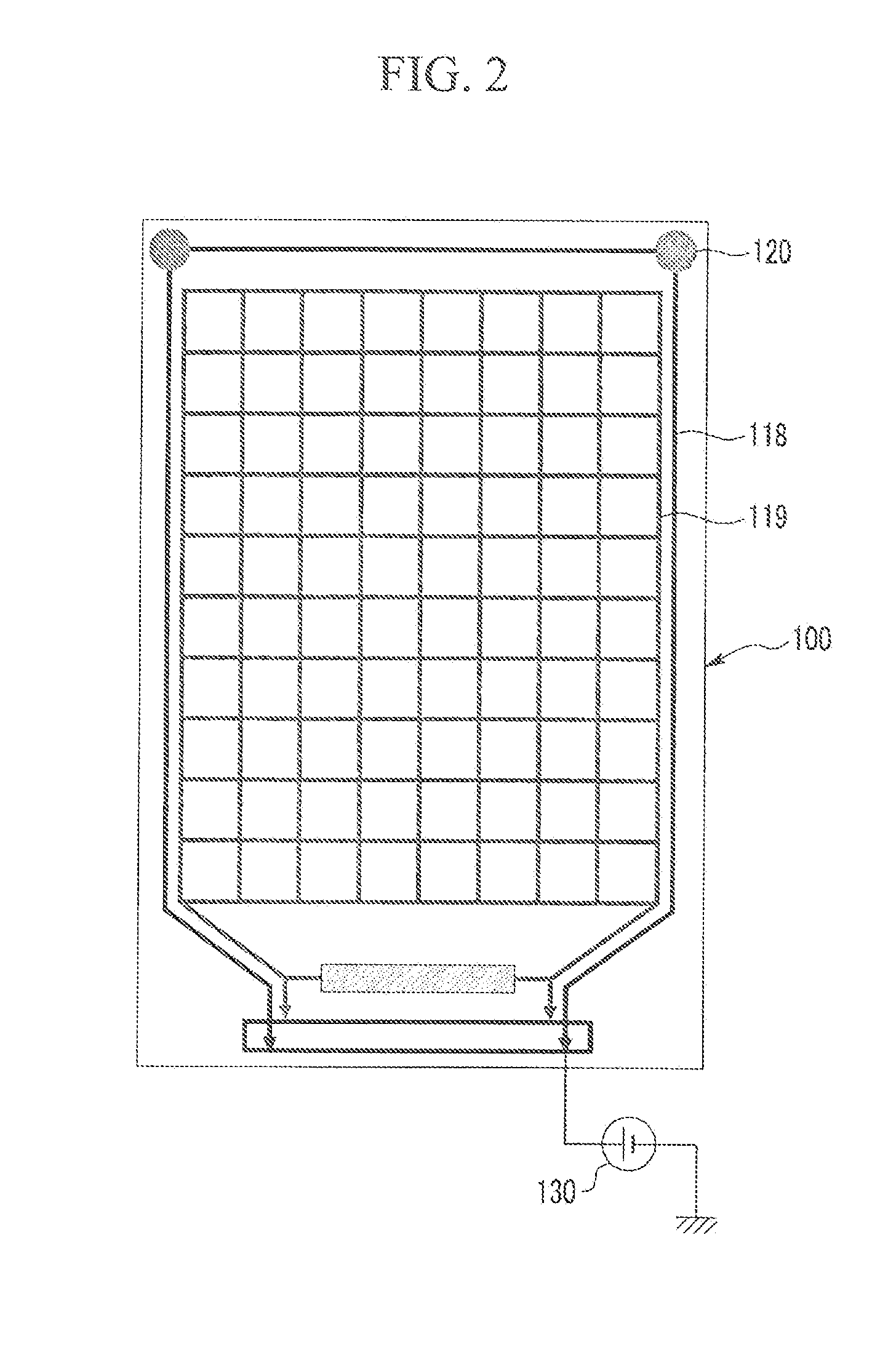

ActiveUS20110170043A1Simple structurePrevent static electricityStatic indicating devicesNon-linear opticsPixel arrayVoltage

A liquid crystal display panel is disclosed. The liquid crystal display panel includes: a first substrate with a conductive layer formed on one surface thereof; a color filter layer including a plurality of color filters formed on the conductive layer; a conductive light shielding layer formed between the plurality of color filters; a second substrate with a pixel array formed on one surface thereof; and a liquid crystal layer filled between the conductive light shielding layer and the pixel array, wherein the conductive layer is electrically short-circuited with the pixel array. Since a voltage is applied to the conductive layer formed on the front surface of the first substrate, liquid crystal molecules of the liquid crystal layer between the conductive layer and the pixel array can be prevented from being vertically aligned, thus improving liquid crystal efficiency.

Owner:SAMSUNG DISPLAY CO LTD

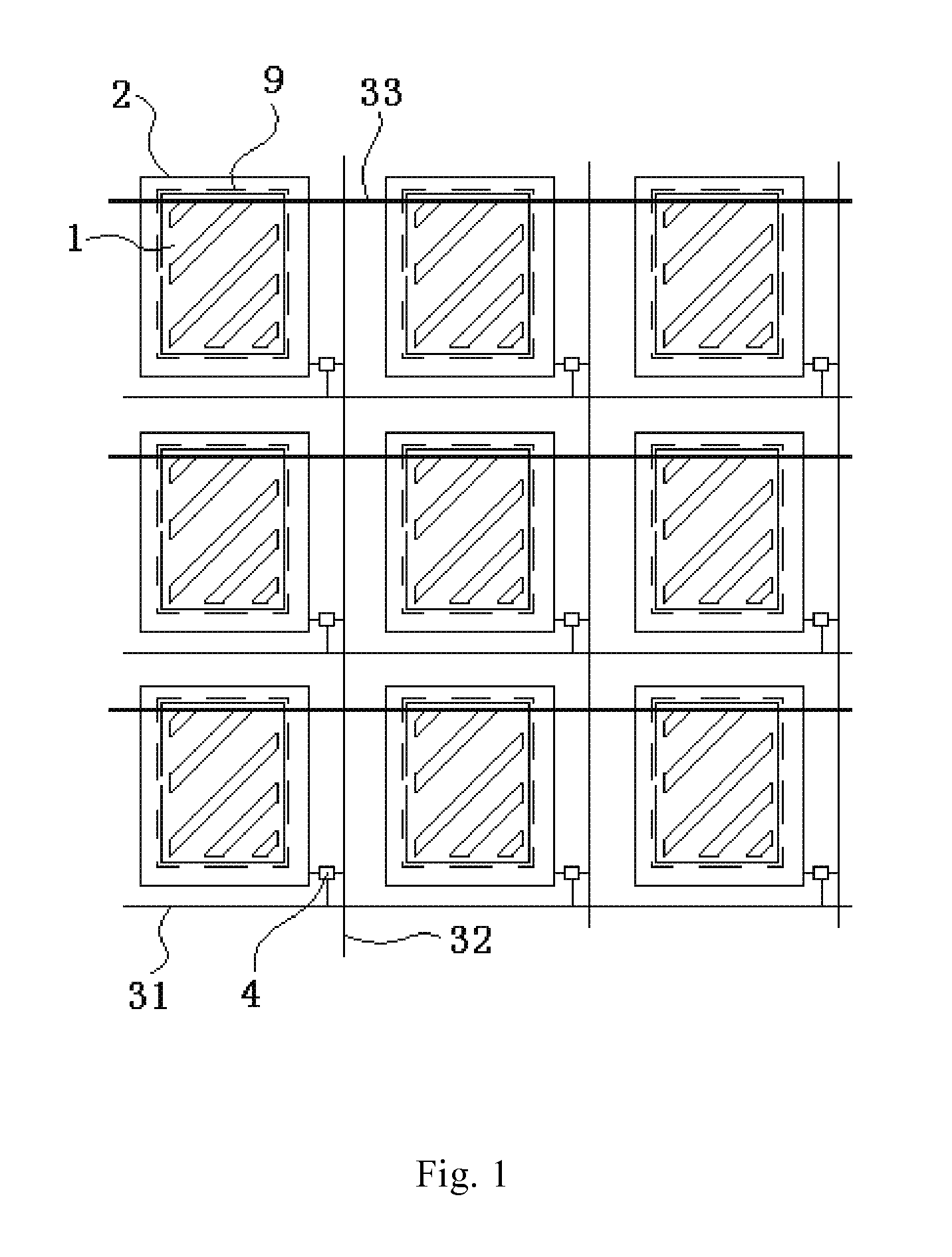

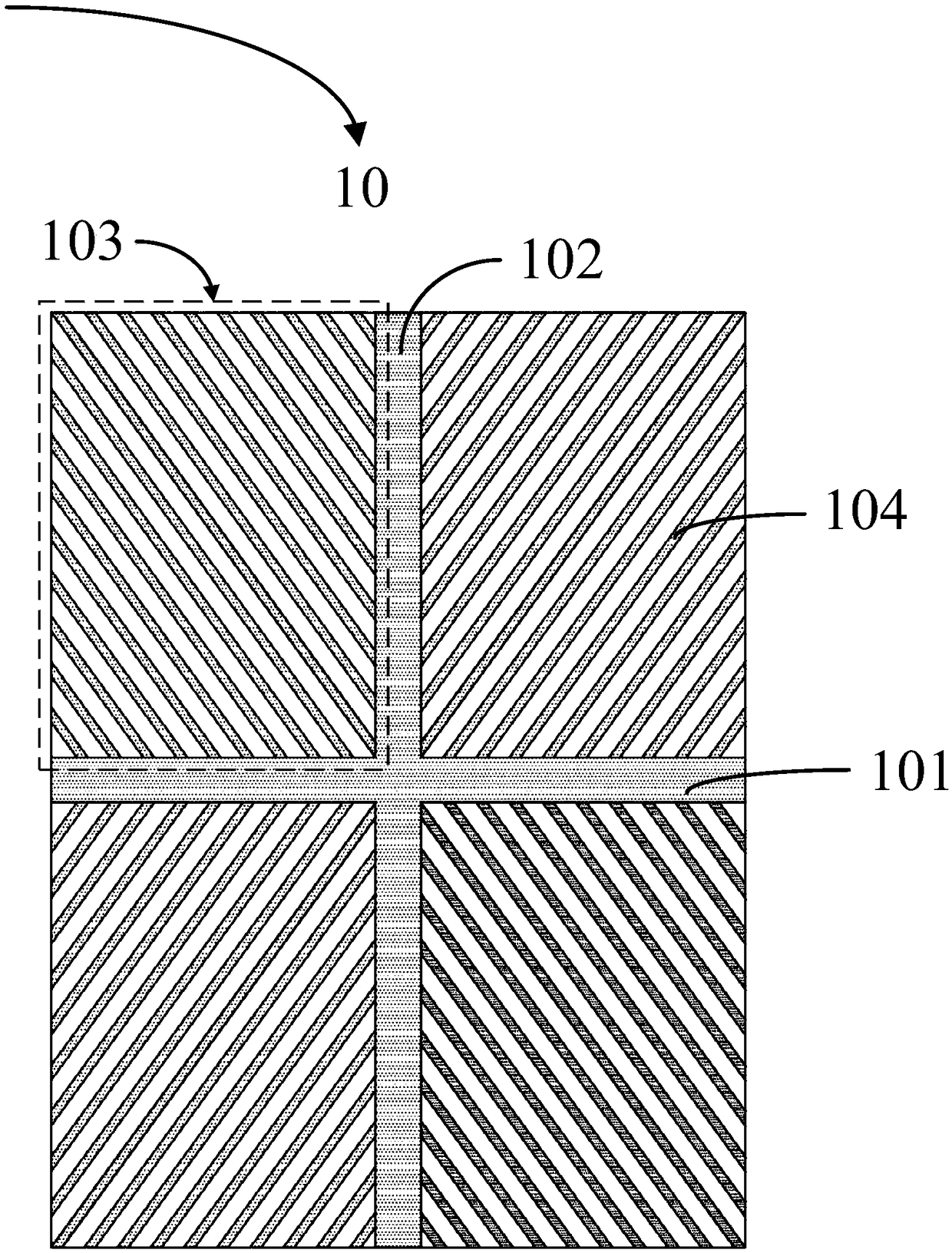

Liquid crystal display panel

InactiveCN104199224AGood orientationImprove liquid crystal efficiencyNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal display panel comprising a first substrate, a second substrate and a liquid crystal layer between the first substrate and the second substrate. The first substrate comprises a plurality of pixels; each pixel comprises a corresponded pixel electrode including a main electrode and branch electrodes extending from the main electrode; the second substrate comprises a liner substrate and a public electrode layer formed on the liner substrate; the public electrode layer is provided with concave portions towards the liner substrate, and each concave portion right faces to the main electrode of one corresponded pixel electrode. Thus, the liquid crystal efficiency of the pixels can be improved, and the applicant range of a perpendicular aligning mode to a small high-resolution panel can be expanded.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display panel

The present invention discloses a liquid crystal display panel, which has a scan line, a data line, a switch unit, liquid crystal molecules, and a pixel domain. The scan line and the data line are electrically connected to the switch unit. The liquid crystal display panel comprises: a pixel electrode disposed in the pixel domain, the pixel electrode being electrically connected to the switch unit; and a conductive electrode layer disposed below a peripheral region of the pixel electrode, the conductive electrode layer and the pixel electrode being separated by an insulating layer, wherein the conductive electrode layer is used to supply a voltage for forming pre-tilt angles of the liquid crystal molecules. The liquid crystal panel can solve the problem of non-uniform brightness of the display panel or dark lines occurred on said panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display panel

InactiveCN102854673AImprove the display effectImprove fringe fieldNon-linear opticsComputer scienceVoltage

The invention discloses a liquid crystal display panel which comprises a scanning line, a data line, a switch unit, a liquid crystal molecule and a pixel area, wherein the scanning line and the data line are electrically connected to the switch unit. The liquid crystal display panel is characterized in that the liquid crystal display panel comprises a pixel electrode and a conductive electrode layer; the pixel electrode is arranged in the pixel area and electrically connected with the switch unit; the conductive electrode layer is arranged below the periphery of the pixel electrode; the conductive electrode layer and the pixel electrode are separated by an insulating layer, and the conductive electrode layer is used for providing voltage when a preset inclination angle of the liquid crystal molecule is formed. The liquid crystal display panel disclosed by the invention can improve the situations of occurence of a dark ray or uneven brightness of the display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display panel

InactiveUS20150153618A1Reduce widthImprove liquid crystal efficiencyNon-linear opticsDark lineEngineering

The present disclosure relates to the technical field of liquid crystal display, and particularly relates to a liquid crystal display panel that can improve liquid crystal efficiency. The liquid crystal display panel includes an array substrate and a color filter substrate, a liquid crystal layer being sandwiched between the array substrate and the color filter substrate, wherein a pixel electrode of the array substrate has a multi-domain structure including a trunk portion and a branch portion, and a common electrode of the color filter substrate is provided with slits. The slits can enable the dark lines existing in the prior art to be narrowed. The common electrode of the color filter substrate can be improved through being divided by gaps, so that the widths of the dark lines existing in the prior art can be greatly reduced, and the liquid crystal efficiency of the pixels of the vertical alignment display pattern can be improved. Therefore, the vertical alignment display pattern can be better applied in the high-resolution liquid crystal panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

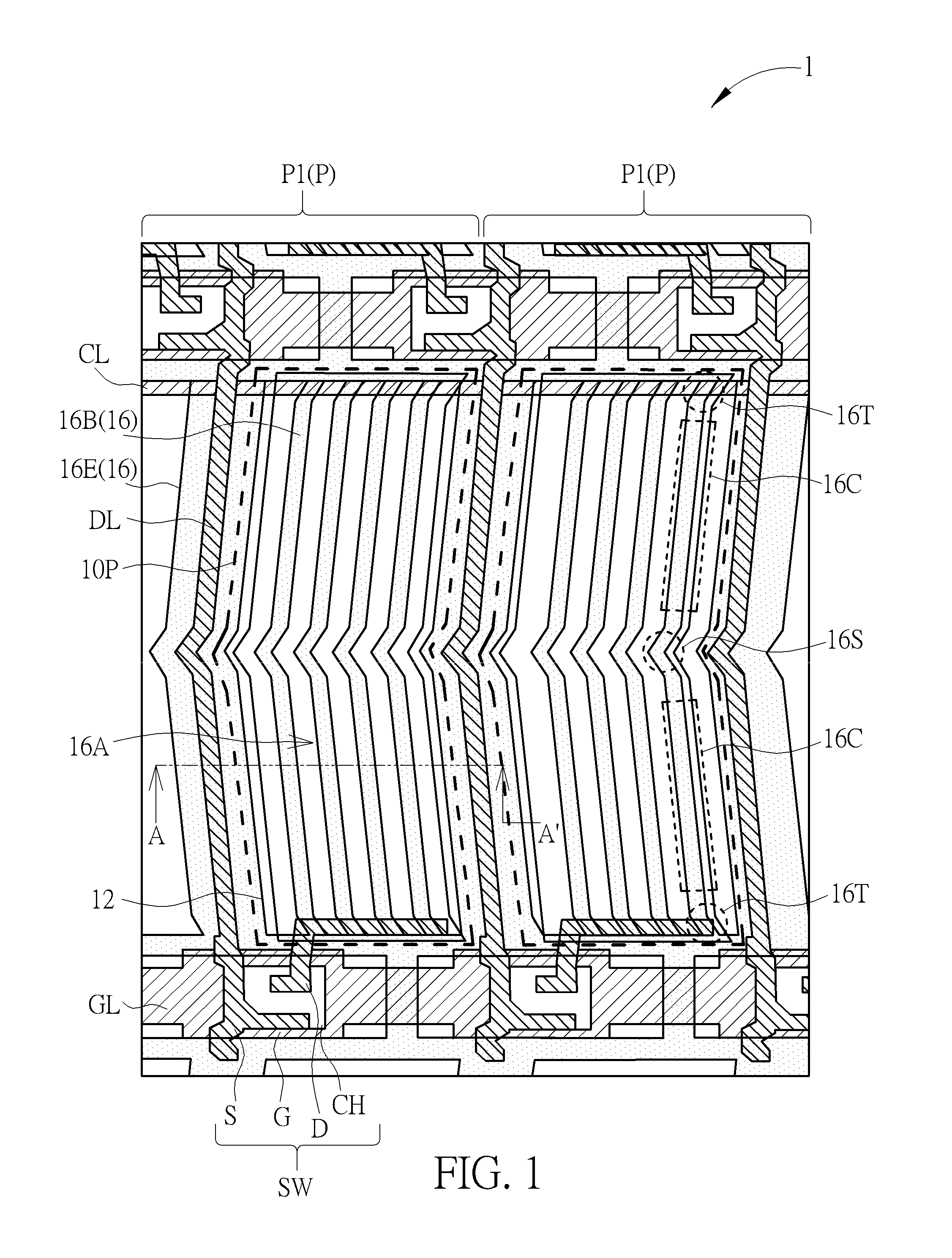

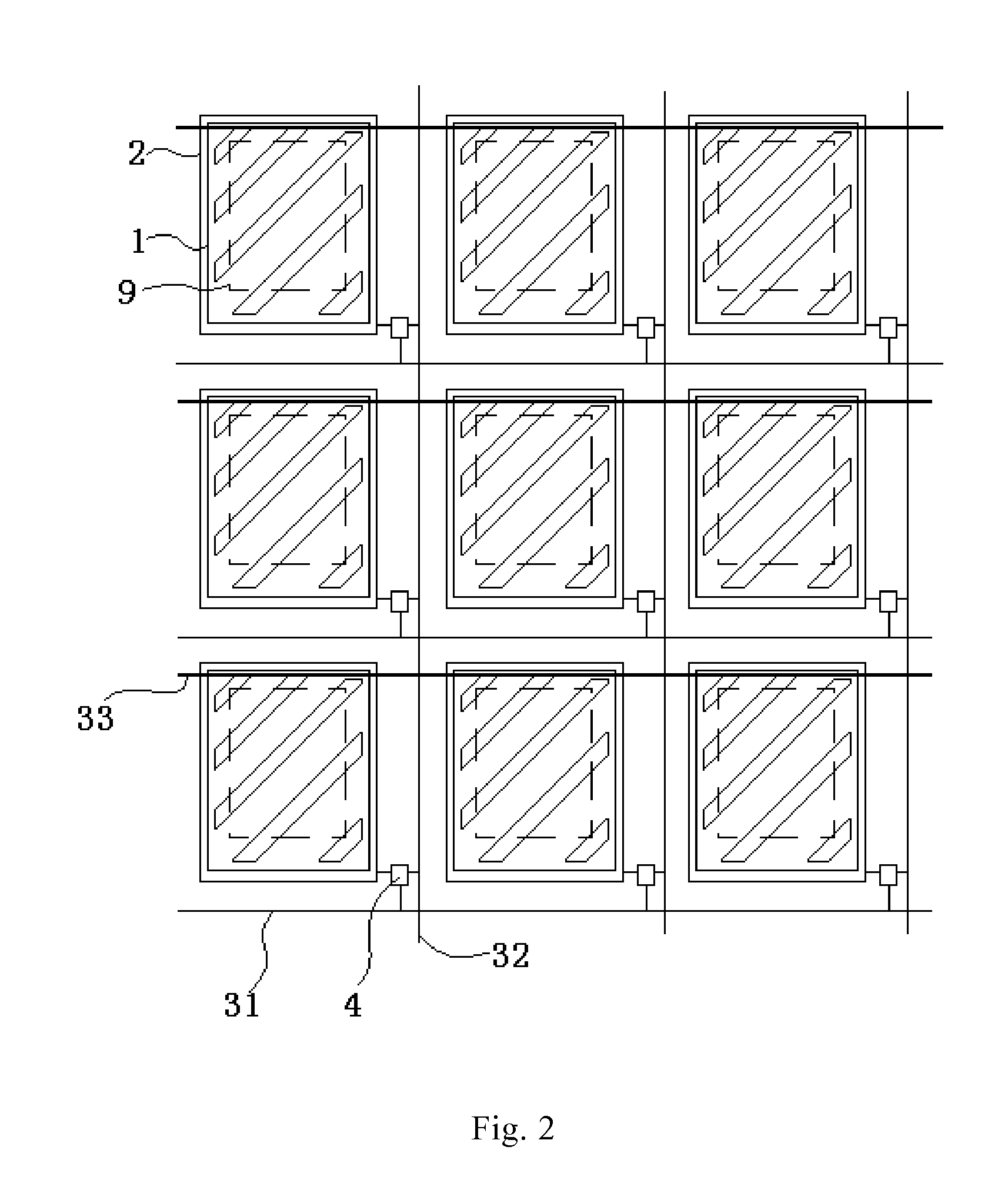

Display Panel, Electro-Optical Device, and Methods for Fabricating the Same

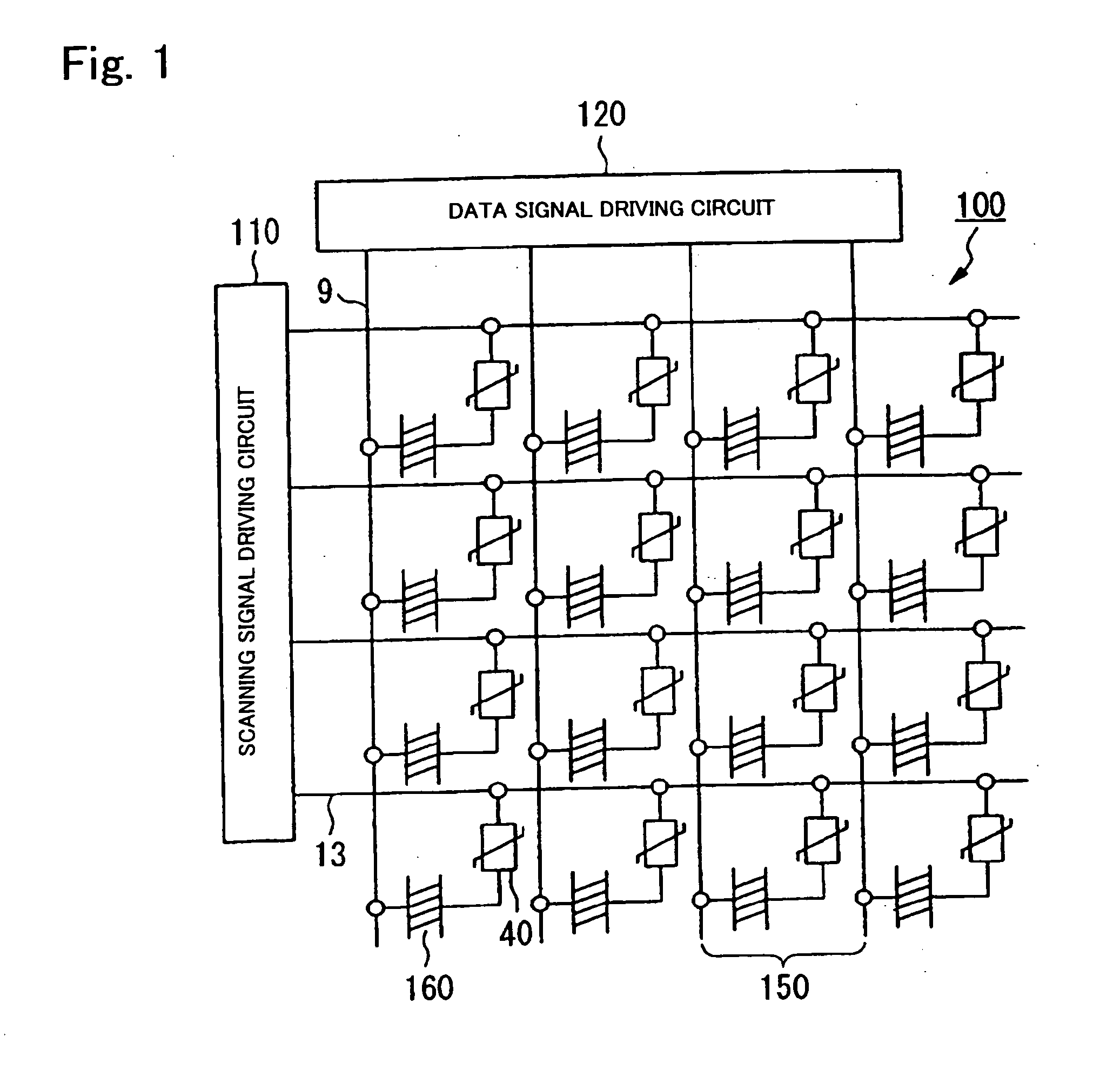

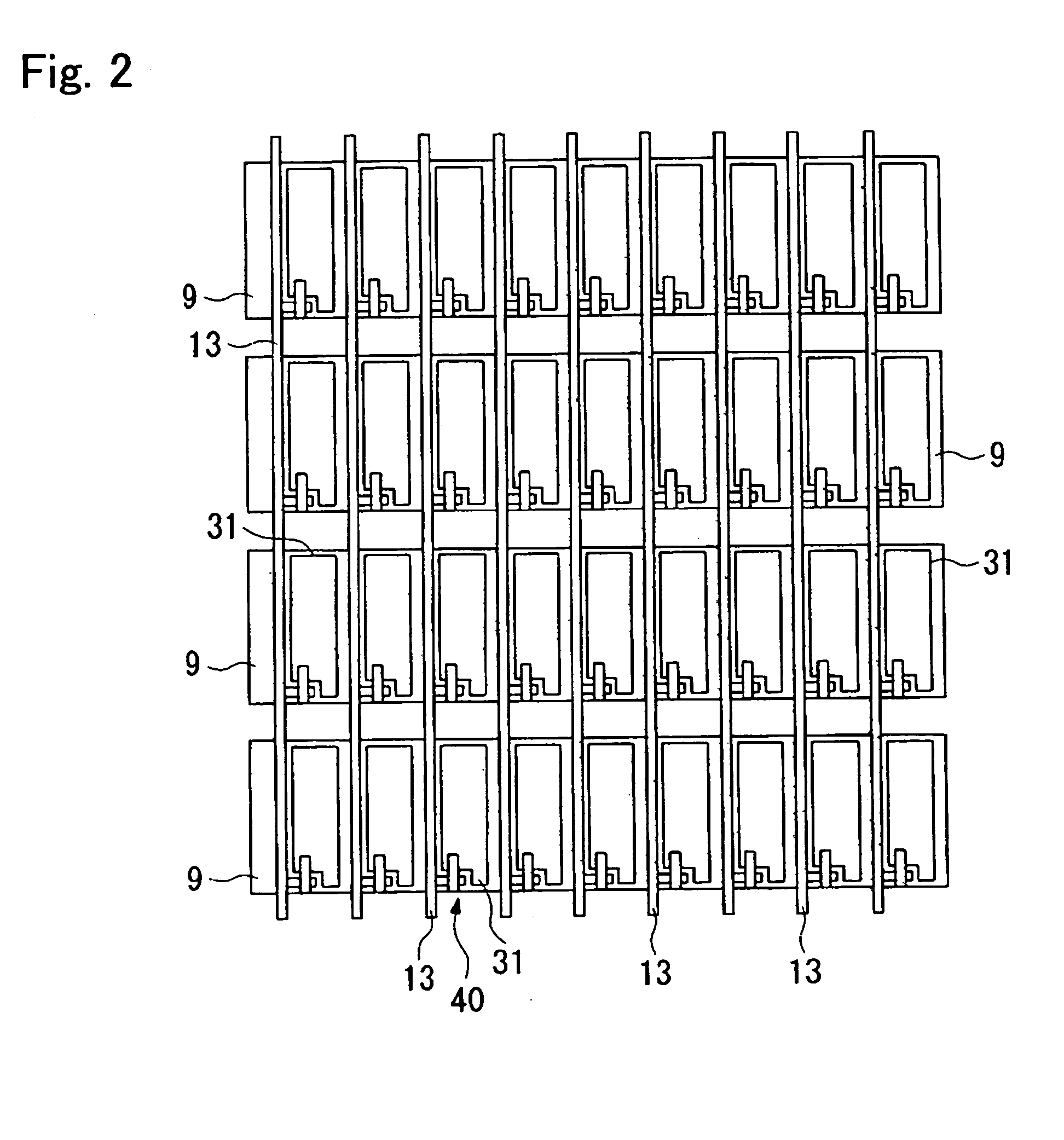

ActiveUS20080316402A1Improve liquid crystal efficiencyImprove dark state light leakageStatic indicating devicesNon-linear opticsScan lineCommon line

A display panel and an electro-optical device thereof are provided. The display panel comprises a pair of substrates, at least one data line, at least three common lines, at least one scan line, at least one switch element, a common electrode, and a display media layer. The pair of substrates comprises a first substrate and a second substrate. The data line and the three common lines are formed on the first substrate. The data line and the common lines interlace to form a plurality of areas. Each of the areas comprises an electrode. The electrodes are connected to each other to form a pixel electrode. The scan line is formed on the first substrate and under an electrode of one of the areas. The switch element is formed under an electrode of one of the areas, and comprises a source connected to the pixel electrode, a drain connected to the data line, and a gate \ connected to the scan line. The common electrode is formed on the second substrate, with a display media layer disposed between the two substrates.

Owner:AU OPTRONICS CORP

Array Substrate and Liquid Crystal Display Device

ActiveUS20150236042A1Reduce transmittanceImprove transmittanceSolid-state devicesNon-linear opticsInsulation layerLiquid-crystal display

The present invention relates to the field of liquid crystal display technology and provides an array substrate and a liquid crystal display device which can solve the problem of low transmissivity of existing liquid crystal display devices. The array substrate of the present invention comprises a plurality of pixel units, each pixel unit is provided with a plate electrode and a slit electrode arranged above the plate electrode, an insulation layer is provided between the plate electrode and the slit electrode, and the plate electrode extends to the periphery region of the pixel unit, the slit electrode extends to the periphery region of the pixel unit; the slit electrode and the plate electrode are both provided in at least part of the peripheral region of the pixel unit. the present invention is applicable to liquid crystal display devices, especially the liquid crystal display devices taking a “dual gate lines” design.

Owner:BOE TECH GRP CO LTD

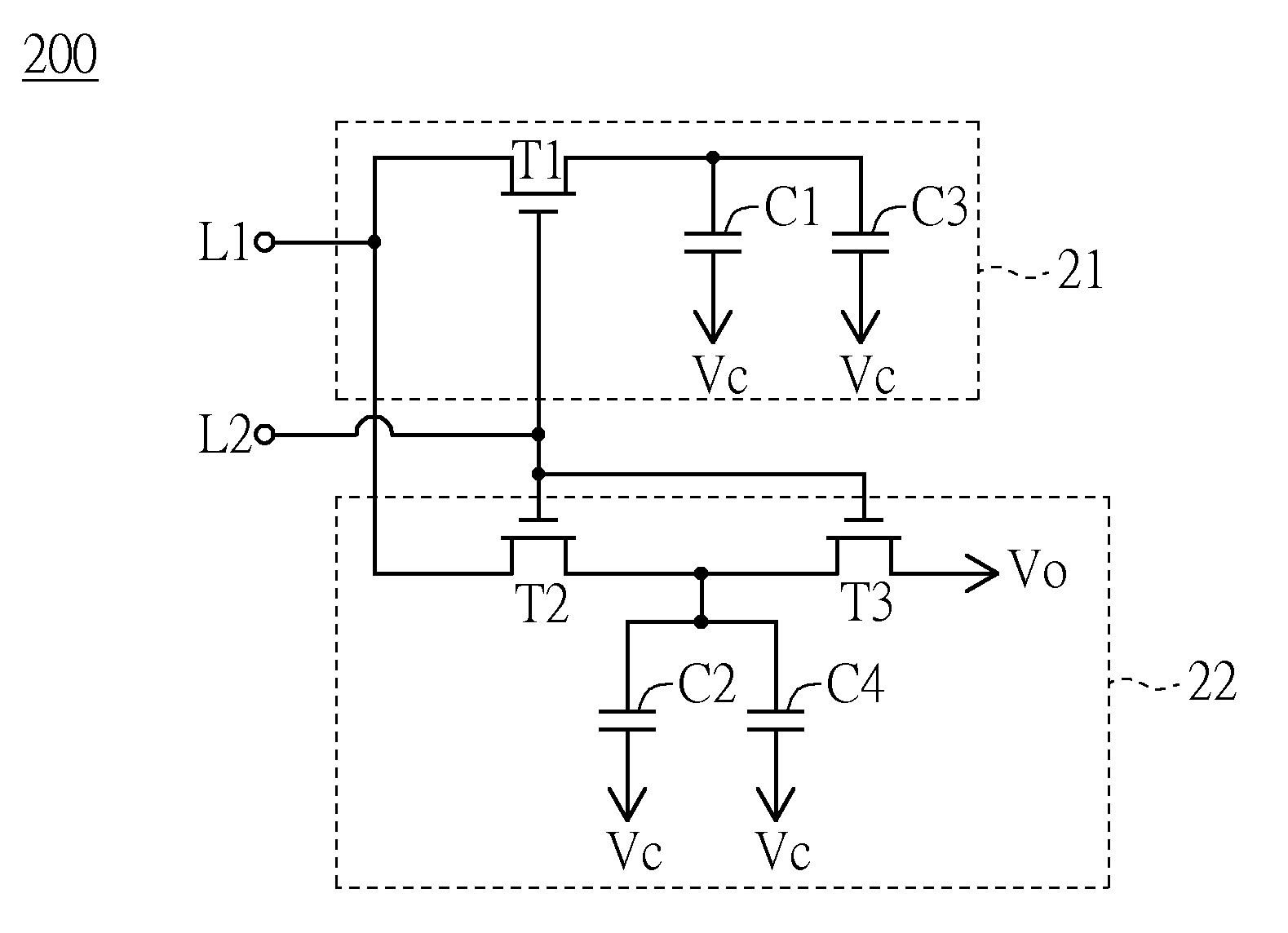

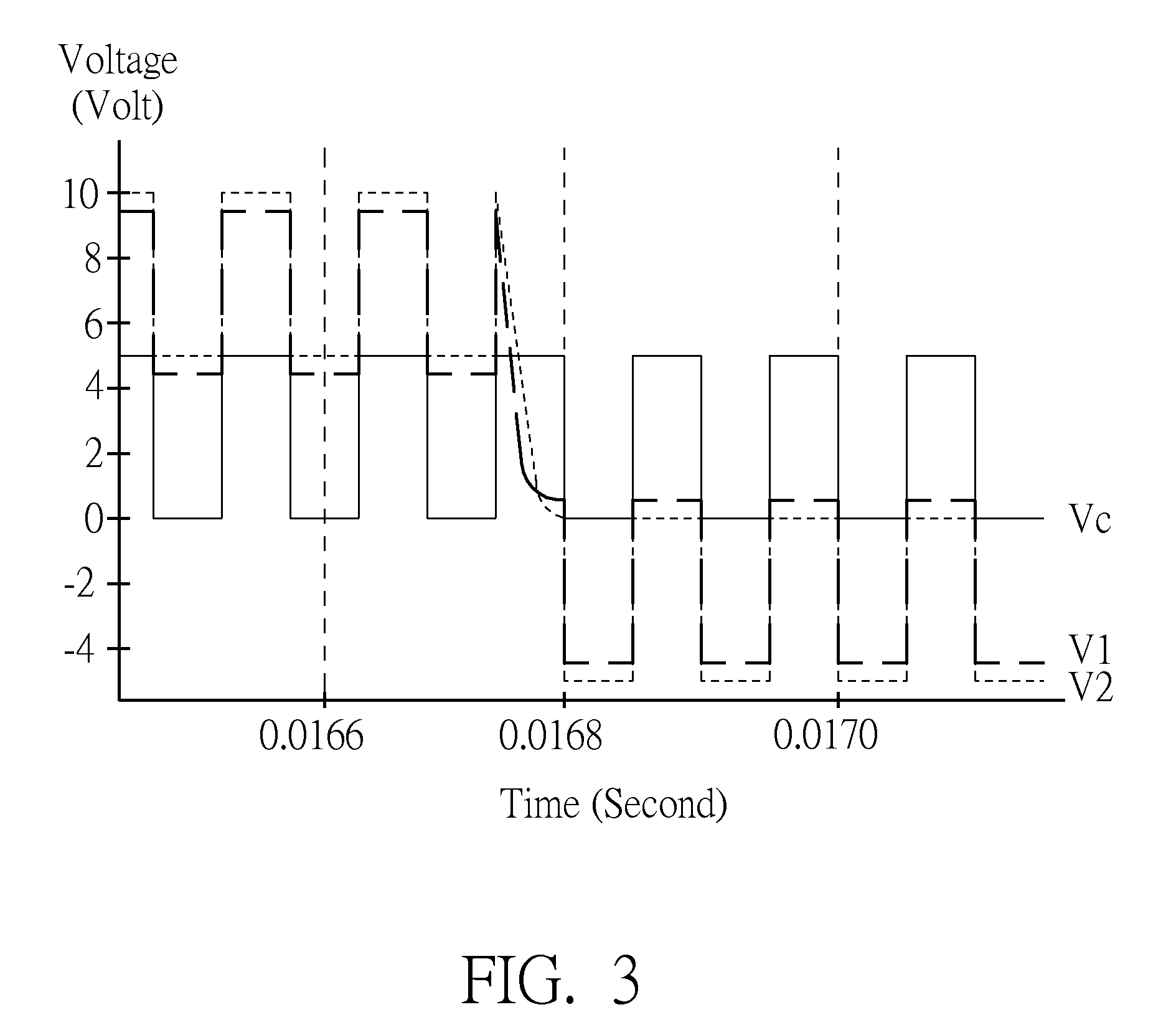

Pixel circuit structure

InactiveUS20090091670A1Improve liquid crystal efficiencyImprove display qualityStatic indicating devicesNon-linear opticsPotential differenceVoltage source

A pixel circuit structure applied in an LCD panel, which has a common voltage and includes at least one data line, is provided. The pixel circuit structure includes a first and a second circuit. The first circuit includes a first switch and a first capacitor. The second circuit includes a second switch, a third switch and a second capacitor. One end of the first capacitor receives the common voltage. Two ends of the first switch are respectively coupled to the data line and the other end of the first capacitor. The second and the third switch are coupled serially between the data line and a voltage source. One end of the second capacitor receives the common voltage, and the other end is coupled between the second and the third switch. The potential difference between the two ends of the first capacitor is different from that of the second capacitor.

Owner:WINTEK CORP

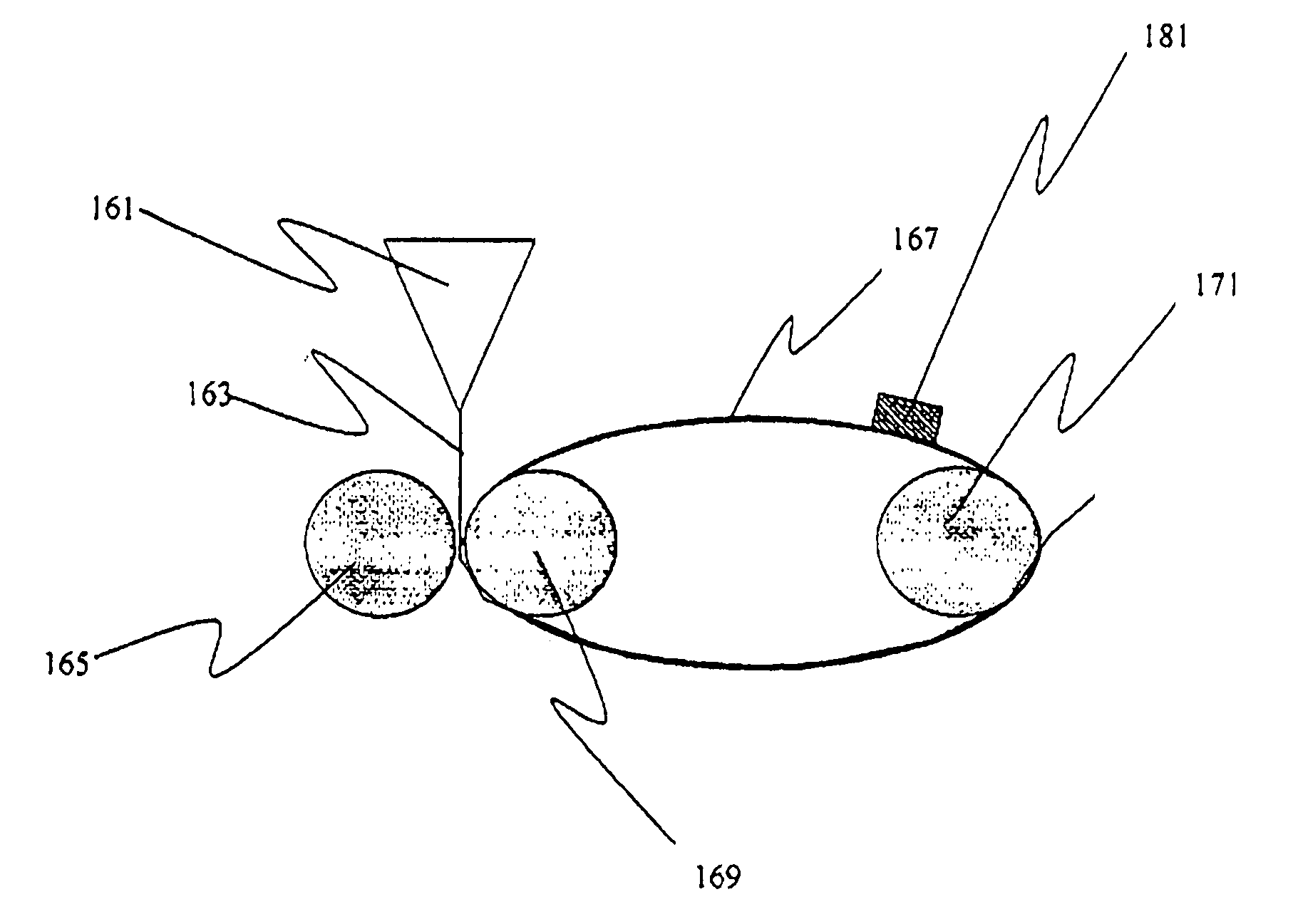

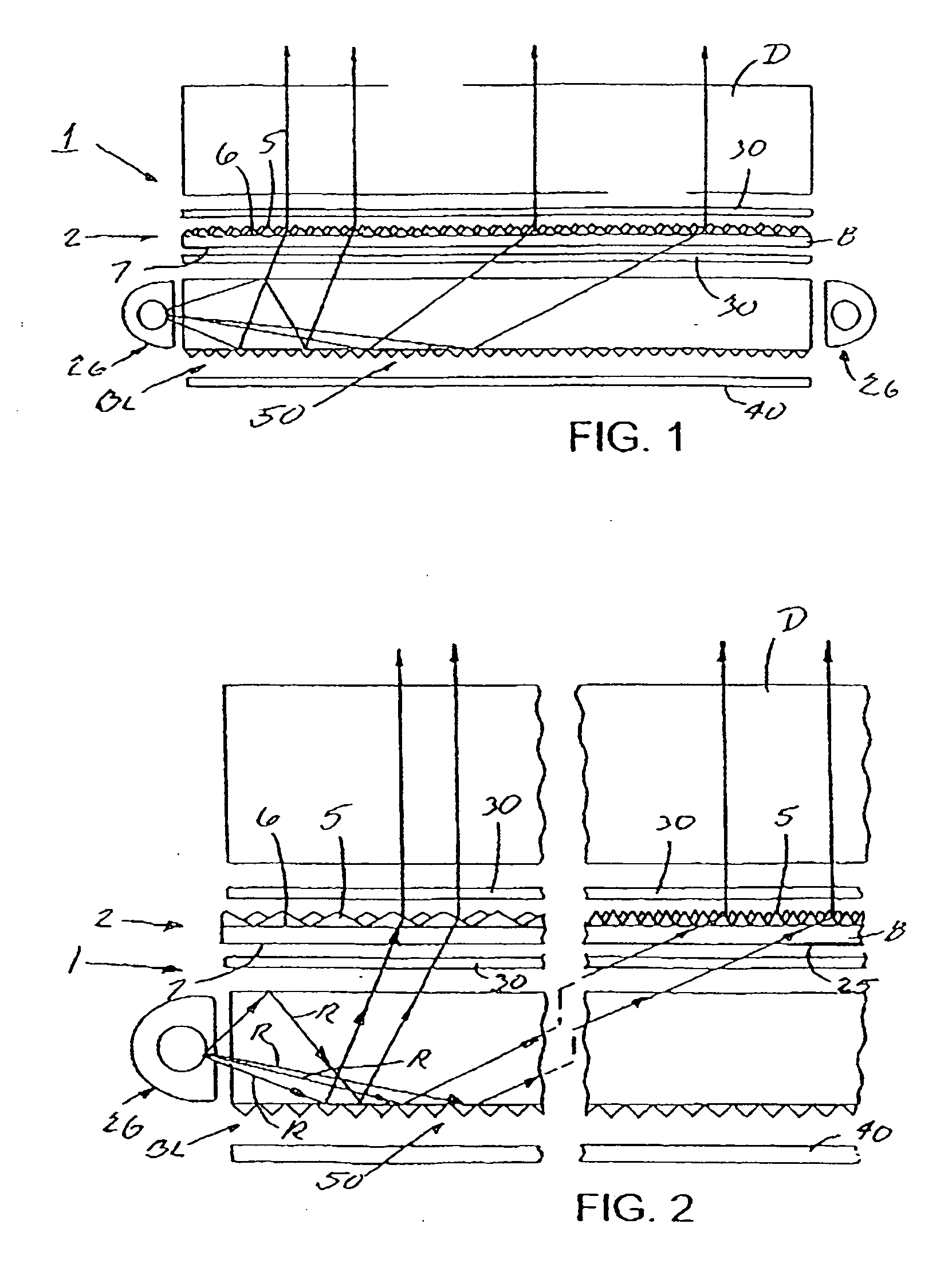

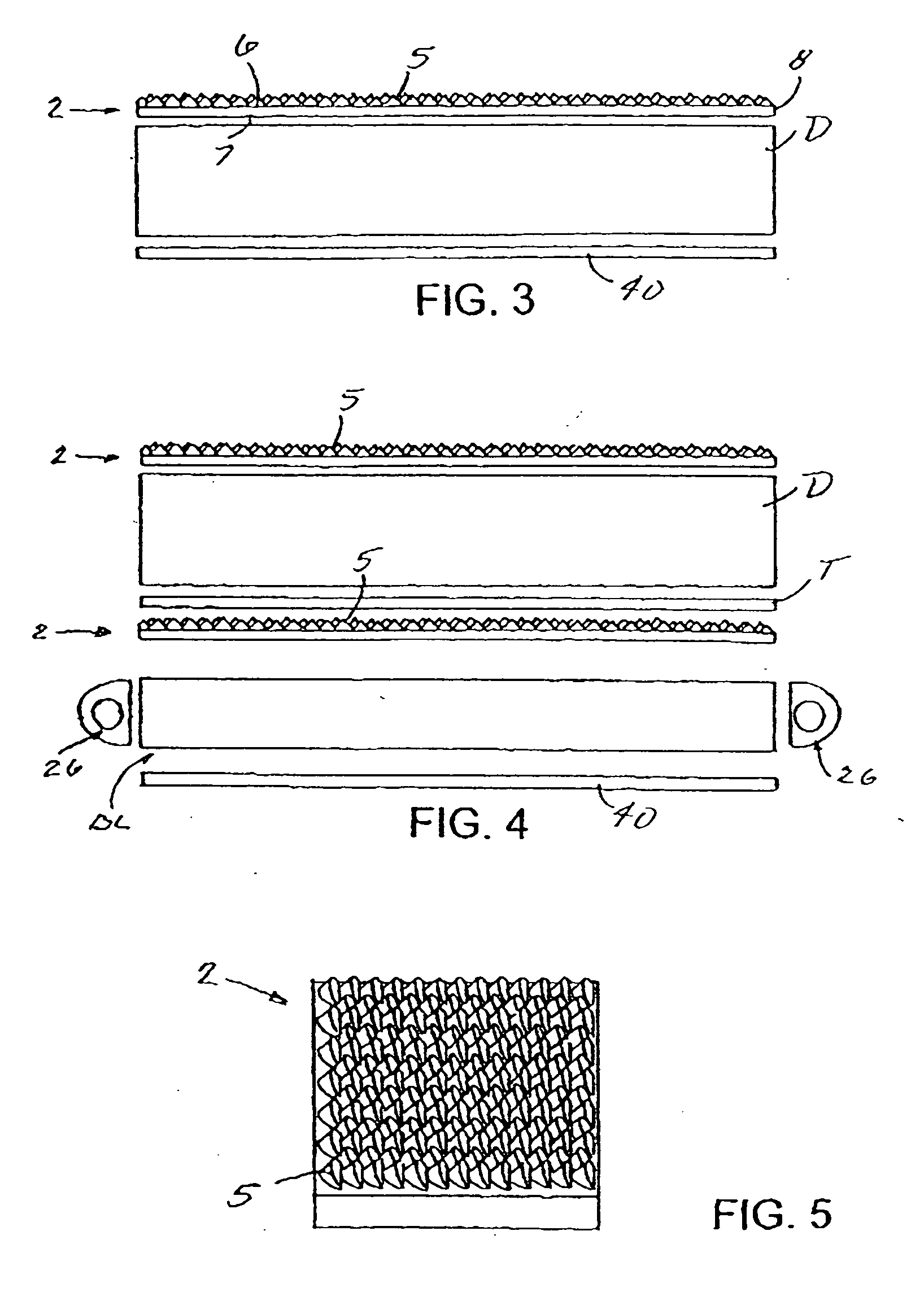

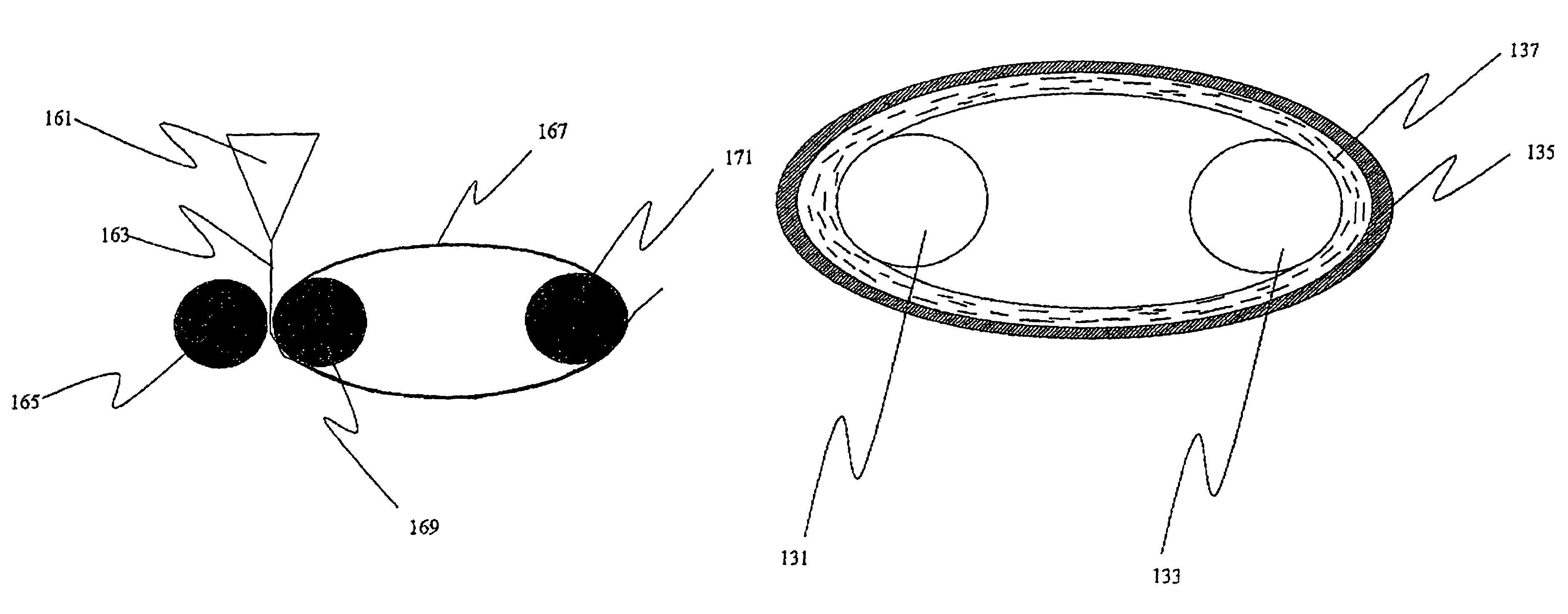

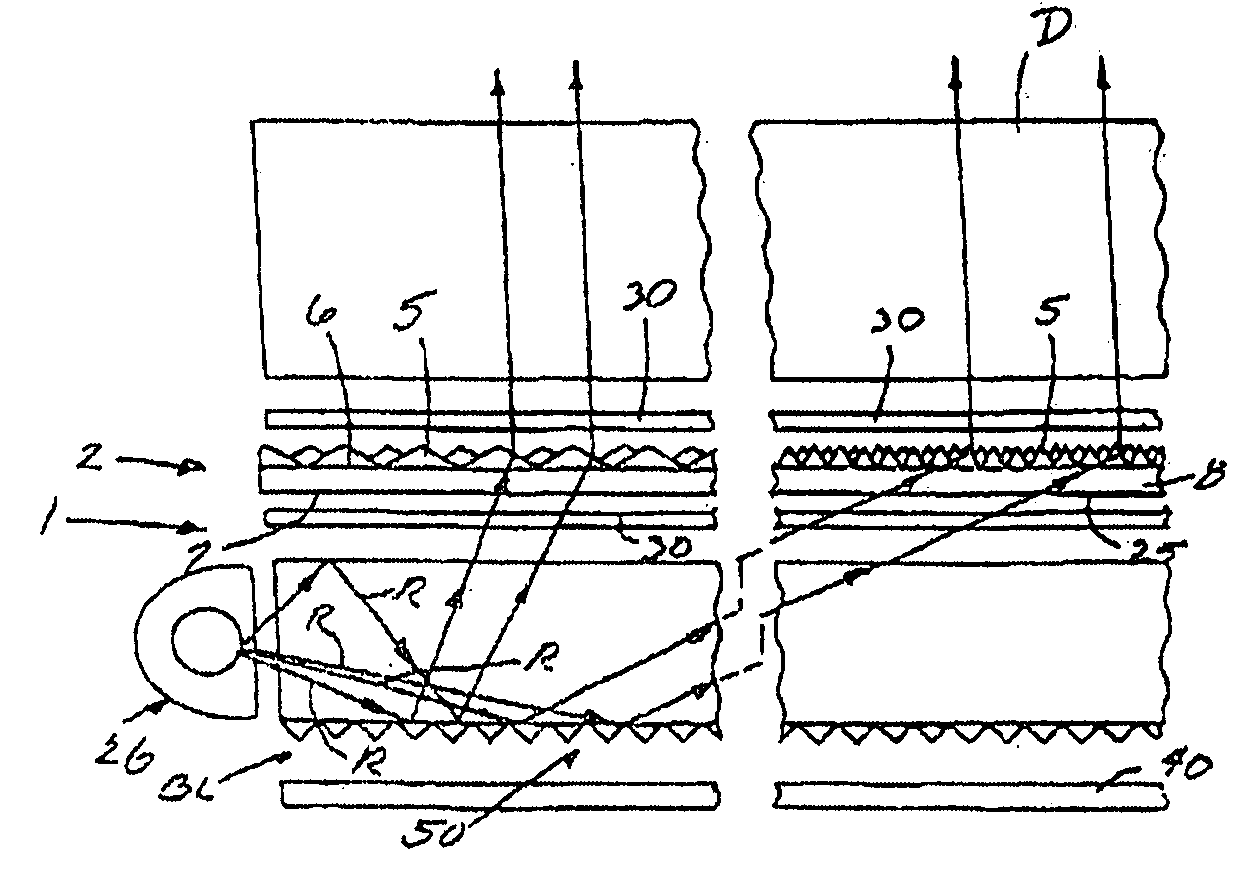

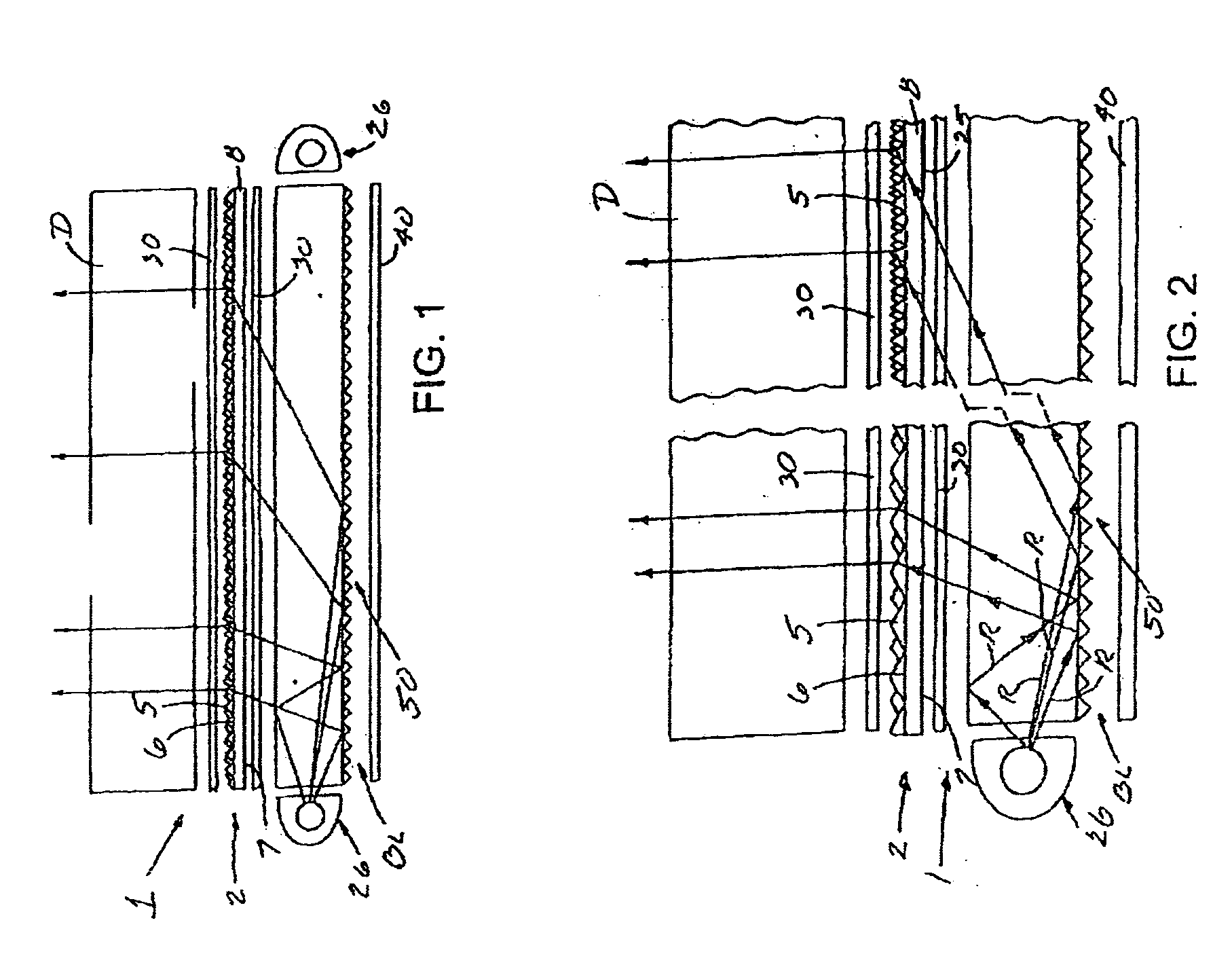

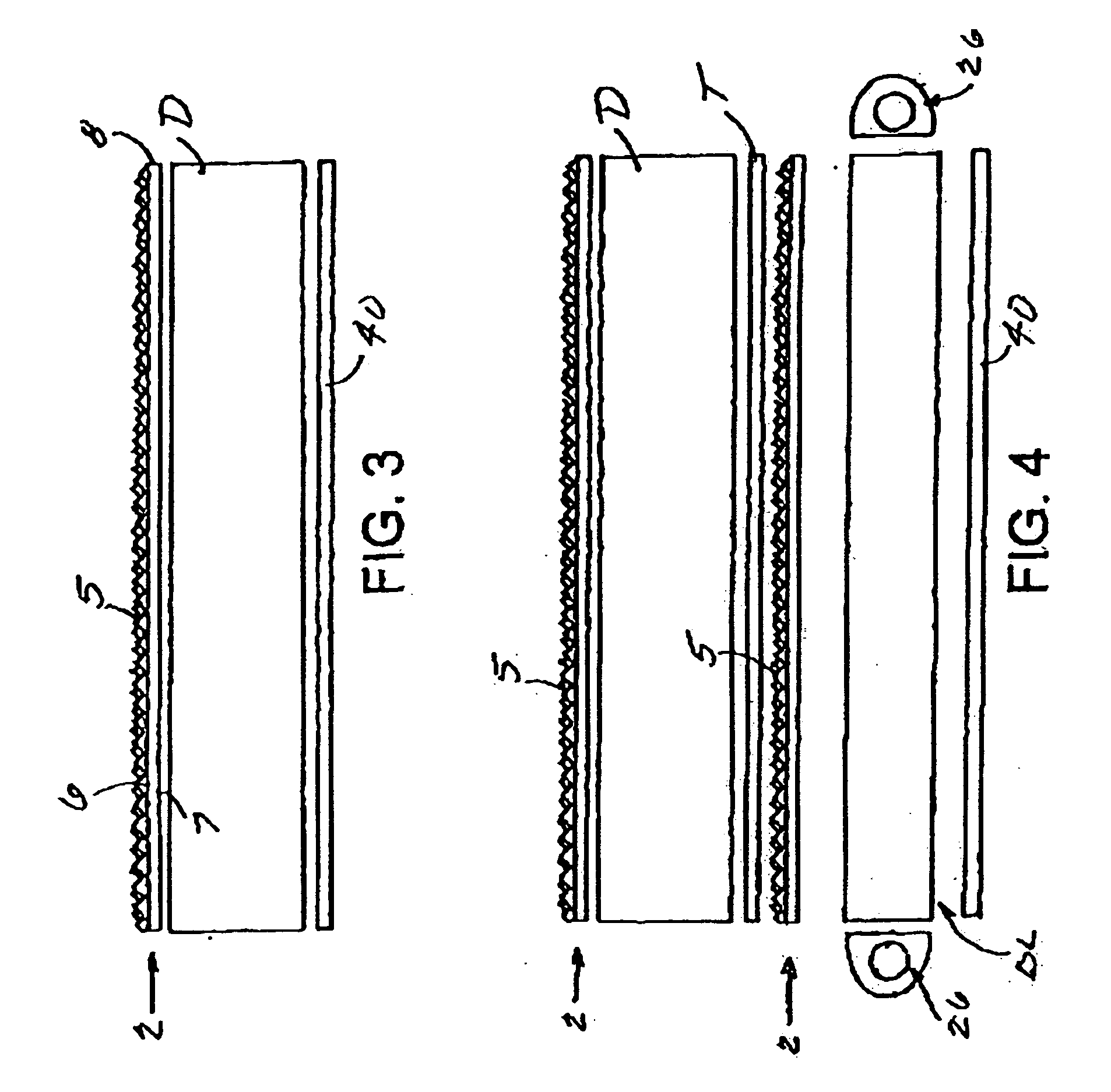

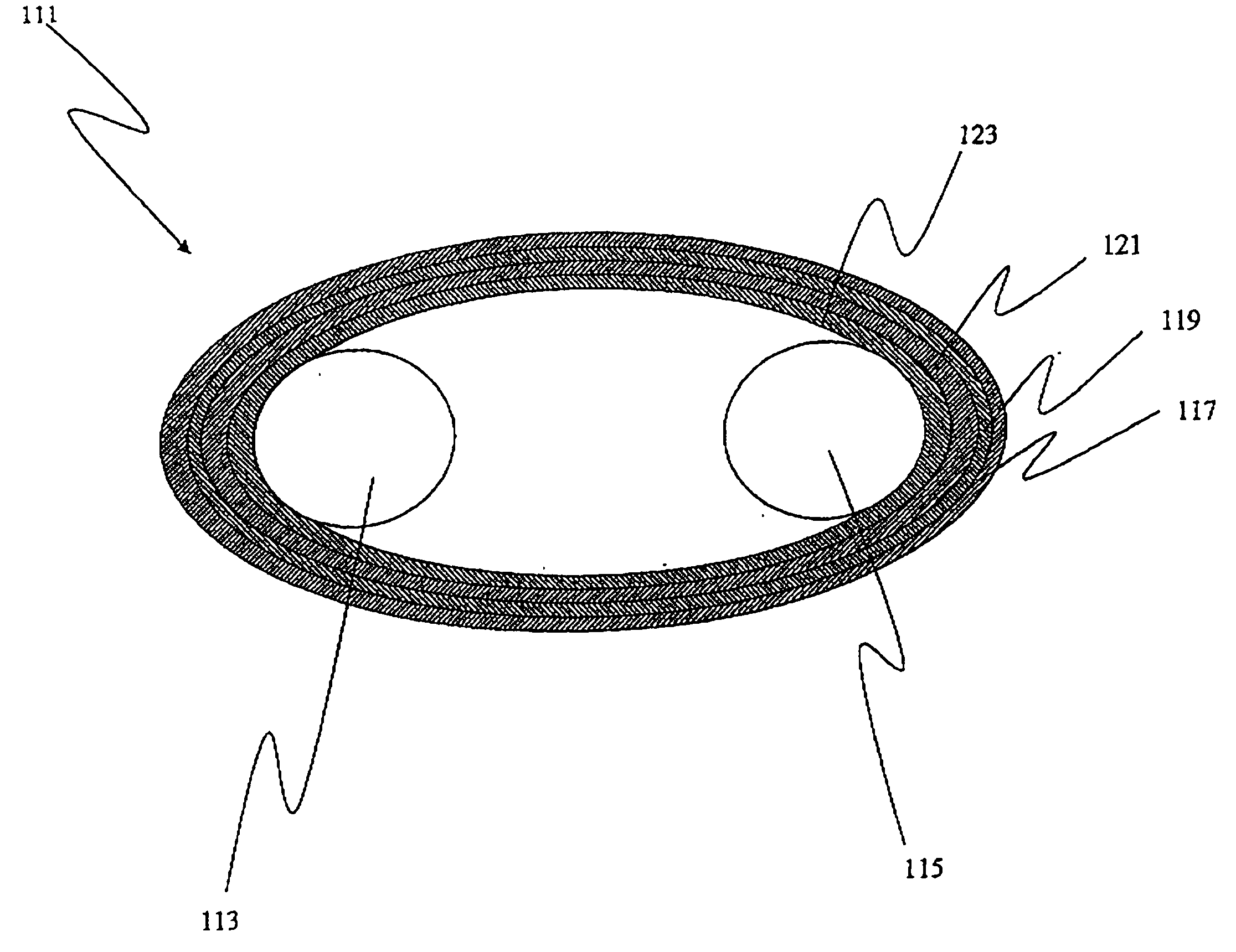

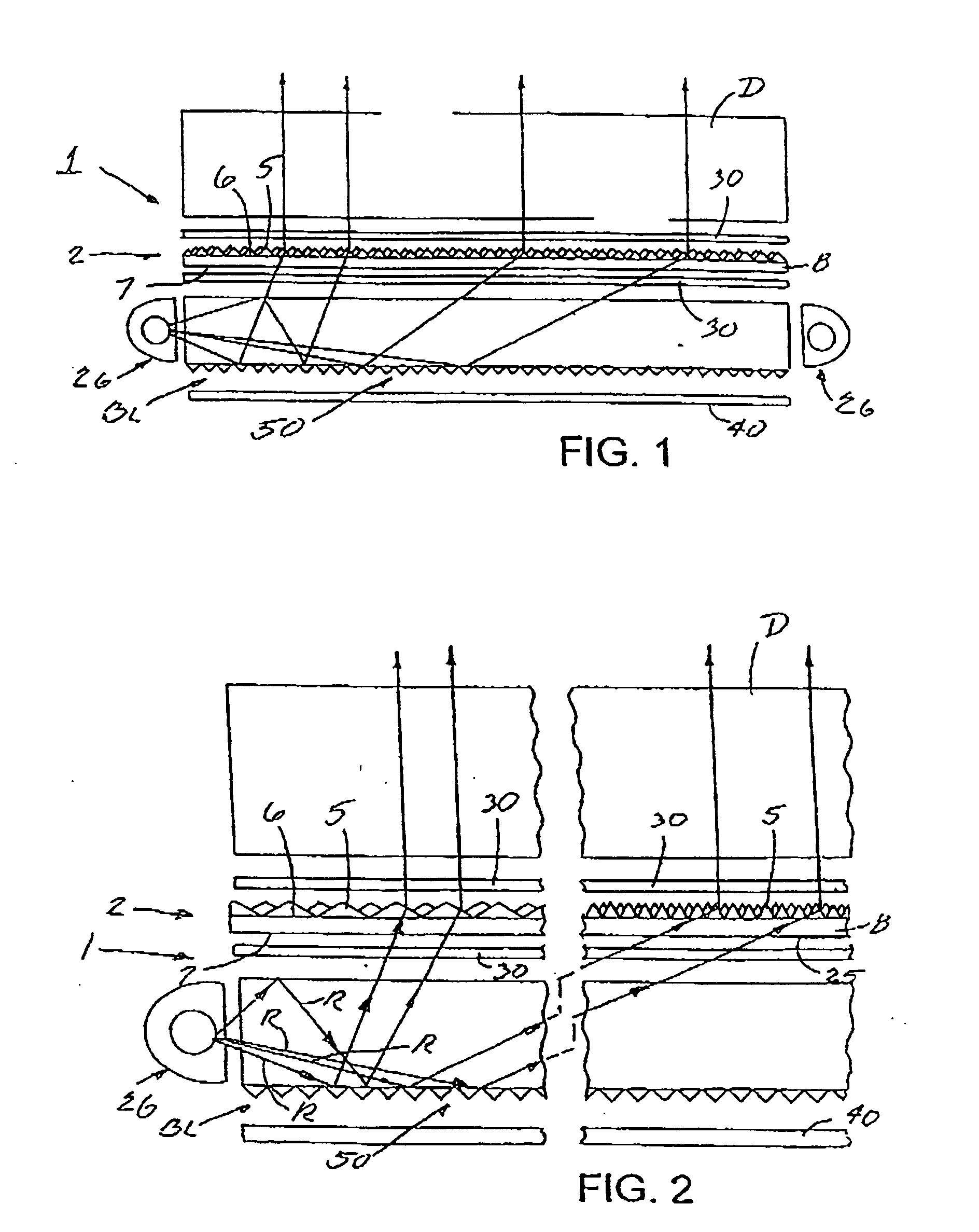

Belt over compliant roller used with molding roller

InactiveUS20050275132A1Exact copyImprove liquid crystal efficiencyOptical articlesEngineeringSolid film

The invention relates to an apparatus and method of making a solid film. Viscous material (163) is input into a nip between a patterned roller (165) and a belt (167). The nip between the patterned roller (165) and belt (167) is facilitated by a compliant roller (169). Accordingly, a film may be produced that has discrete optical elements and a smooth backside.

Owner:ROHM & HAAS DENMARK FINANCE

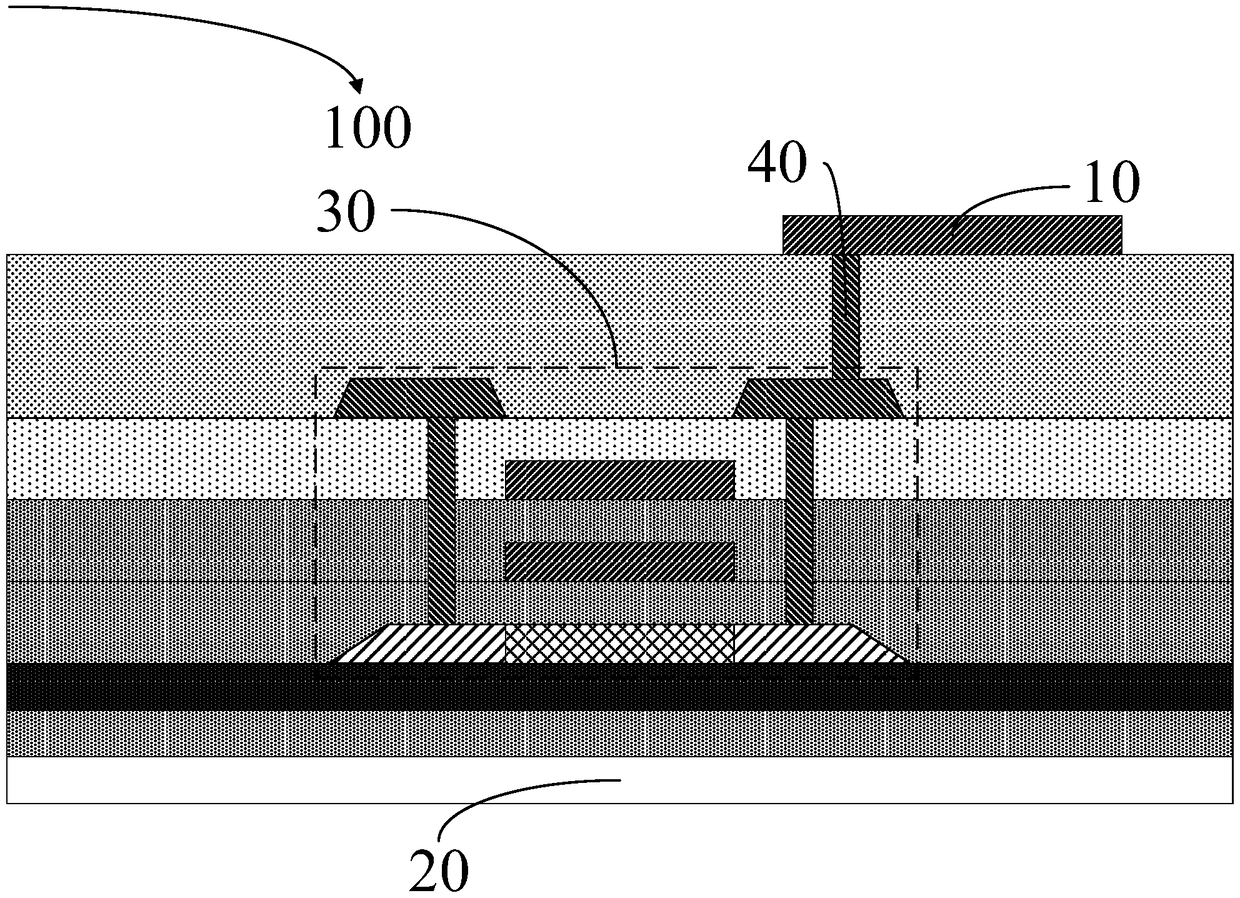

Array substrate, preparation method thereof, display panel and display device

InactiveCN104834139AImprove liquid crystal efficiencyReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDisplay device

The invention discloses an array substrate, a preparation method thereof, a display panel and a display device. At least two public electrode slots are formed. The problem that adjacent pixels are affected to cause color mixing is avoided, and meanwhile the liquid crystal efficiency is improved. The array substrate comprises a plurality of grid lines and a plurality of data lines which are crossed. A plurality of pixel areas are defined by the crossed grid lines and data lines. Each pixel area comprises a thin film transistor and further comprises a first insulation layer, a metal layer, a second insulation layer, a pixel electrode and a public electrode, wherein the first insulation layer is arranged above the thin film transistor and the corresponding data line, the metal layer is arranged above the first insulation layer, the second insulation layer is arranged above the metal layer, the pixel electrode and the public electrode are arranged above the second insulation layer, and a third insulation layer is arranged between the pixel electrode and the public electrode. The public electrode in each pixel area at least comprises two slots. The metal layers cover the data lines.

Owner:BOE TECH GRP CO LTD

Smooth compliant belt for use with molding roller

InactiveUS7465163B2Exact copyImprove liquid crystal efficiencyDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringSolid film

The invention relates to an apparatus and method of making a solid film. Viscous material (163) is input into a nip between a patterned roller (165) and a belt (167). The nip between the patterned roller (165) and belt (167) is facilitated by a compliant roller (169). Accordingly, a film may be produced that has discrete optical elements and a smooth backside.

Owner:SKC HAAS DISPLAY FILMS CO LTD

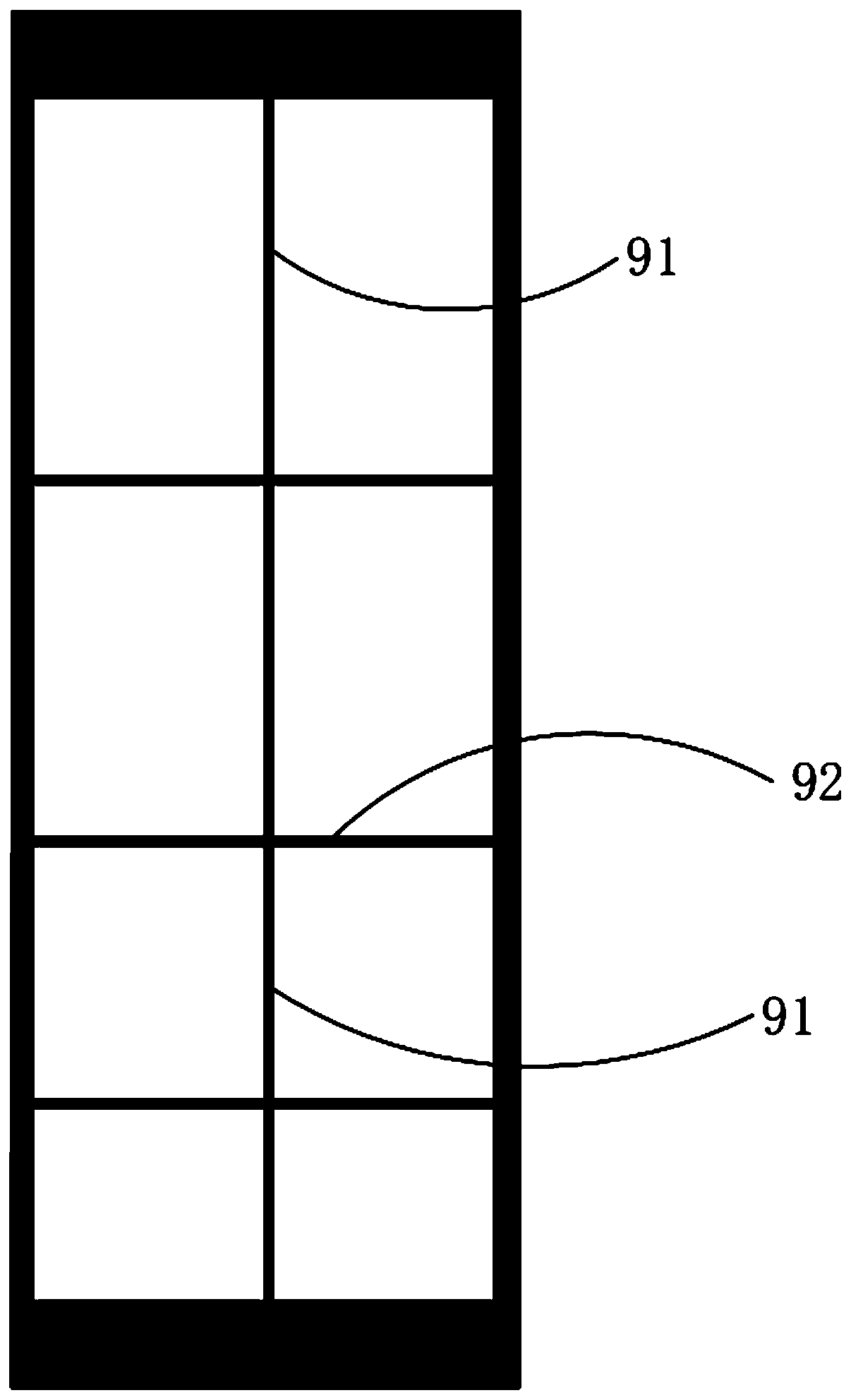

Pixel structure, array substrate and display panel

ActiveCN111221189AEliminate voltage differencePrevent dumpingSolid-state devicesNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a pixel structure, an array substrate and a display panel. The pixel structure comprises a plurality of pixel areas distributed in an array mode and pixel electrodes corresponding to the pixel areas in a one-to-one mode. Each pixel electrode comprises a first pixel electrode and a second pixel electrode which are spaced, and a wiring area is arranged between every two adjacent rows of pixel areas. A large distance is provided by utilizing the wiring area; the liquid crystal display panel and the display device have the advantages that voltage difference between upper and lower rows of pixel electrodes can be eliminated, liquid crystal toppling at junctions of two adjacent rows of pixel regions due to influence of the voltage difference can be prevented, dark fringesat junctions of the two adjacent rows of pixel regions can be prevented, extra spacer regions do not need to be arranged between the two adjacent rows of pixel regions, and accordingly the pixel aperture ratio can be increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

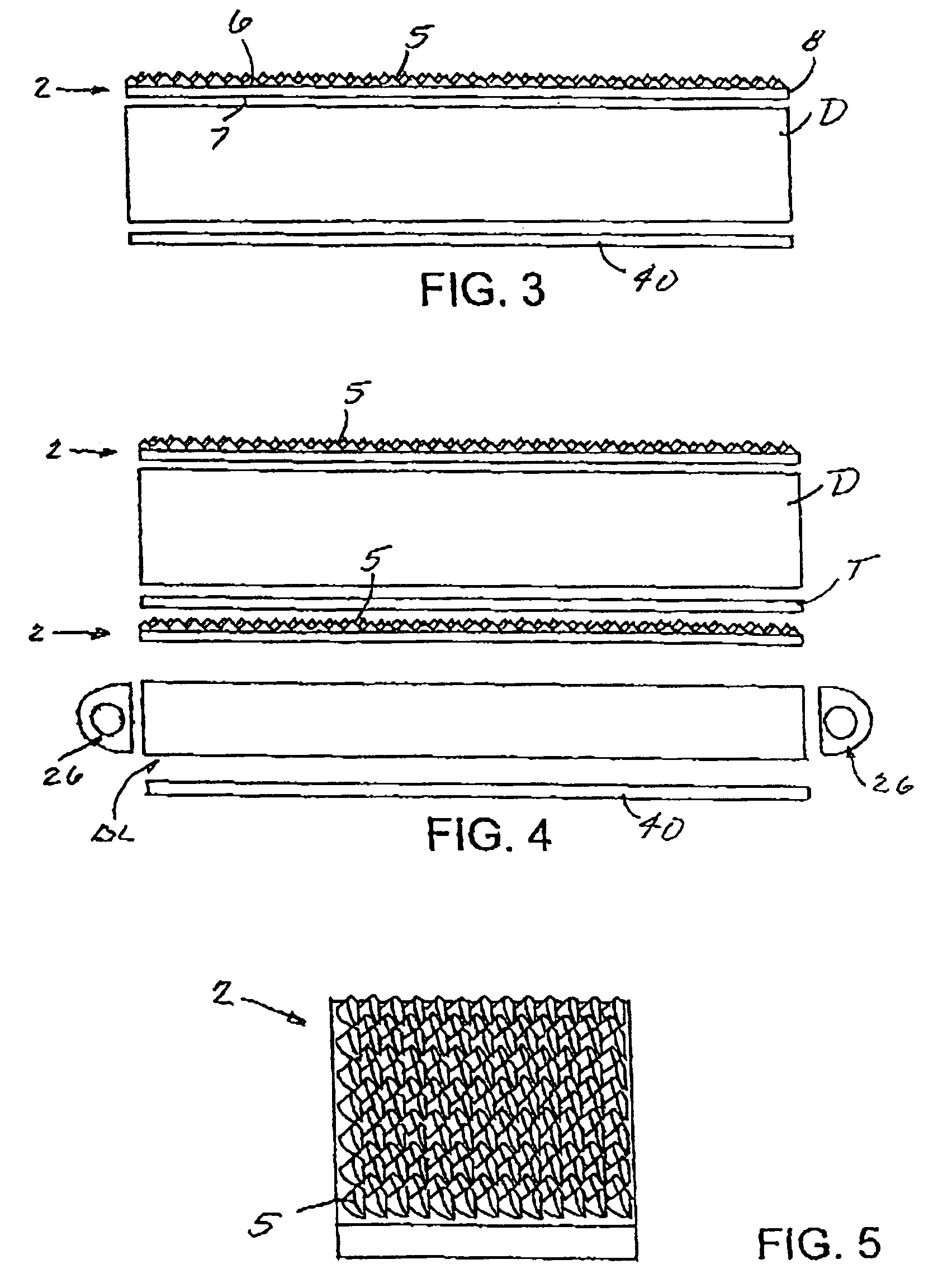

Method for making tools for micro replication

InactiveUS20050269742A1Exact copyImprove liquid crystal efficiencyButtonsMechanical apparatusShell moldingEngineering

A method includes electromechanical engraving a three-dimensional molding pattern (N) in a rigid surface. The rigid surface is configured to micro replicate according to the molding pattern (N). The rigid surface may be a pattern roller. The molding pattern may be for micro replication of optical elements (5) of a light redirecting film (2).

Owner:ROHM & HAAS DENMARK FINANCE

Smooth compliant belt for use with molding roller

InactiveUS20050275122A1Exact copyImprove liquid crystal efficiencyDough-sheeters/rolling-machines/rolling-pinsConfectionerySolid filmViscous material

The invention relates to an apparatus and method of making a solid film. Viscous material (163) is input into a nip between a patterned roller (165) and a belt (167). The nip between the patterned roller (165) and belt (167) is facilitated by a compliant roller (169). Accordingly, a film may be produced that has discrete optical elements and a smooth backside.

Owner:SKC HAAS DISPLAY FILMS CO LTD

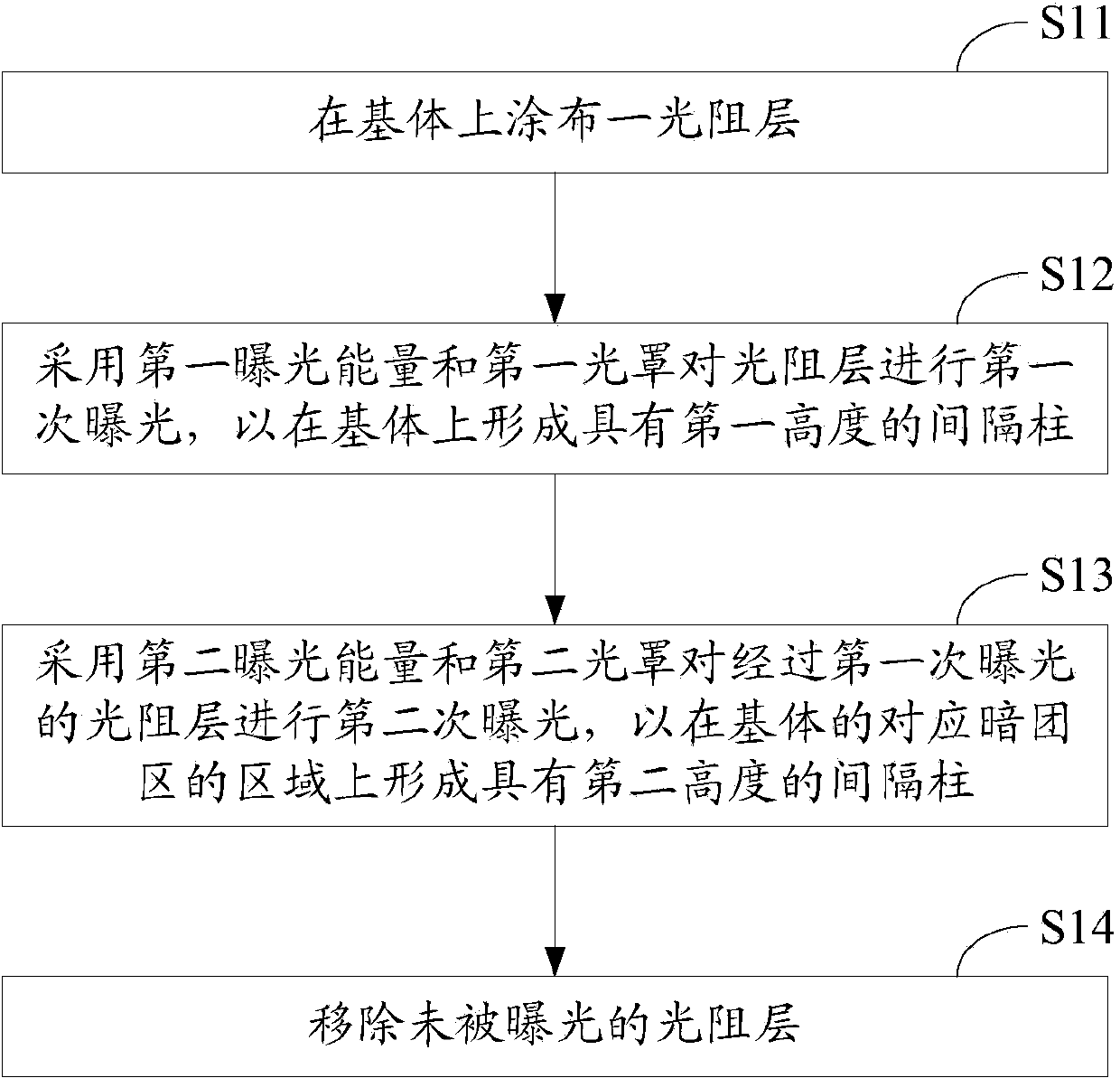

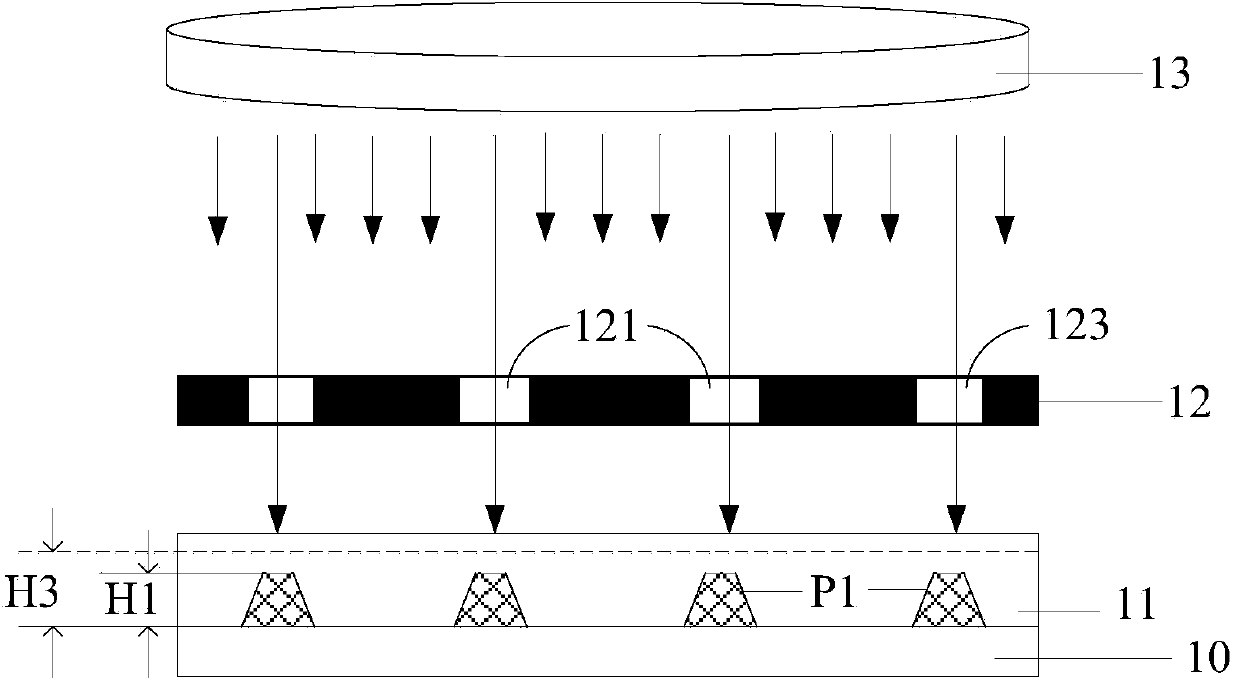

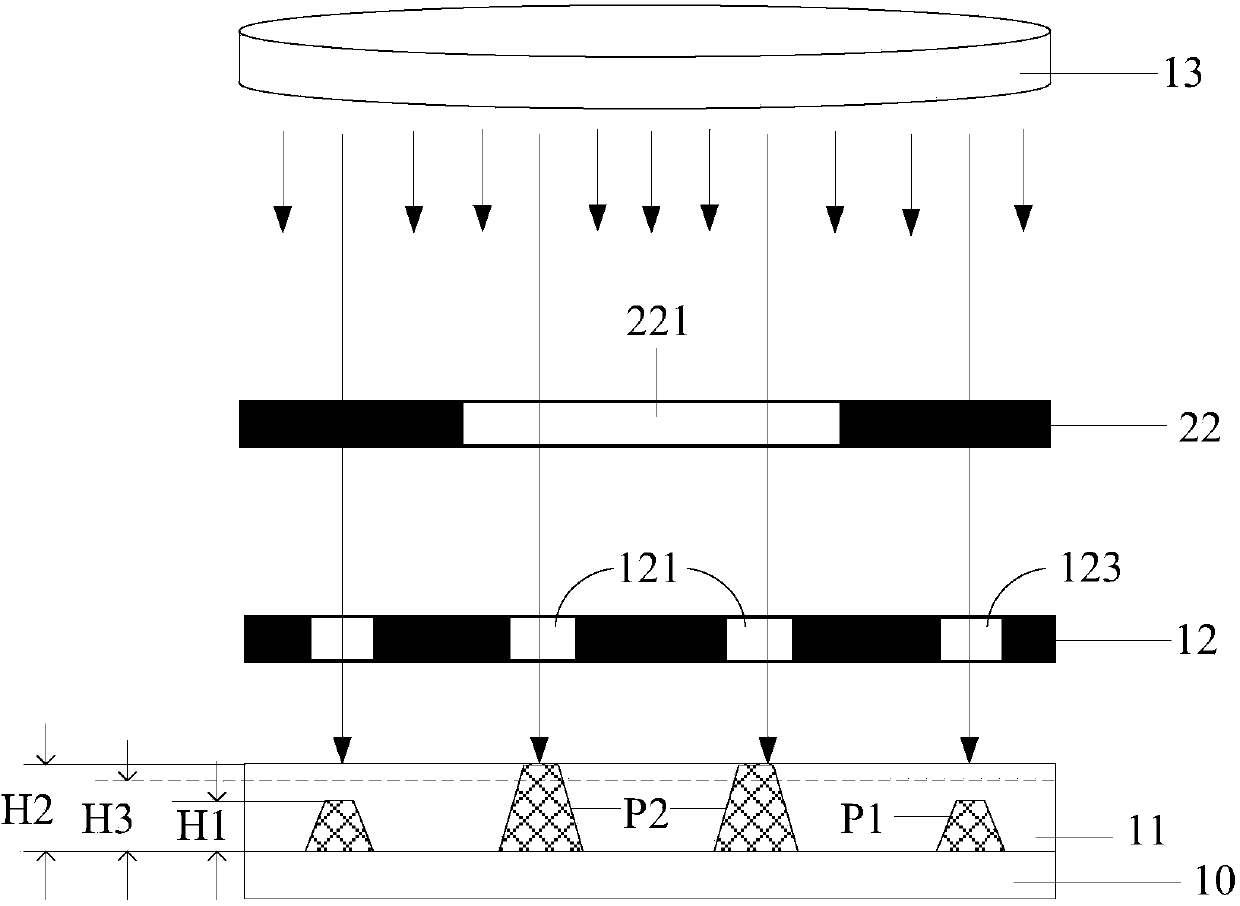

Liquid crystal display panel and method for manufacturing same

ActiveCN104199203AImprove liquid crystal efficiencyEnsure Pixel PenetrationNon-linear opticsLiquid-crystal displayTransmittance

The invention provides a liquid crystal display panel and a method for manufacturing the same. The method for manufacturing the liquid crystal display panel includes coating a photoresistance layer on a matrix; primarily exposing the photoresistance layer by the aid of first exposure energy and a first photomask to form spacing columns with first heights; secondarily exposing the photoresistance layer by the aid of second exposure energy and a second photomask to form spacing columns with second heights; removing unexposed portions of the photoresistance layer. The first photomask is provided with first transmittance zones corresponding to dark cluster zones. The second photomask is provided with second transmittance zones corresponding to dark cluster zones, and the second heights are larger than the first heights. Owing to the mode, the liquid crystal display panel and the method have the advantages that the efficiency of liquid crystal in the dark cluster zones can be enhanced, the penetration rates of pixels in the dark cluster zones can be guaranteed, and accordingly the dark cluster zones of the liquid crystal display panel can be reduced or eliminated.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

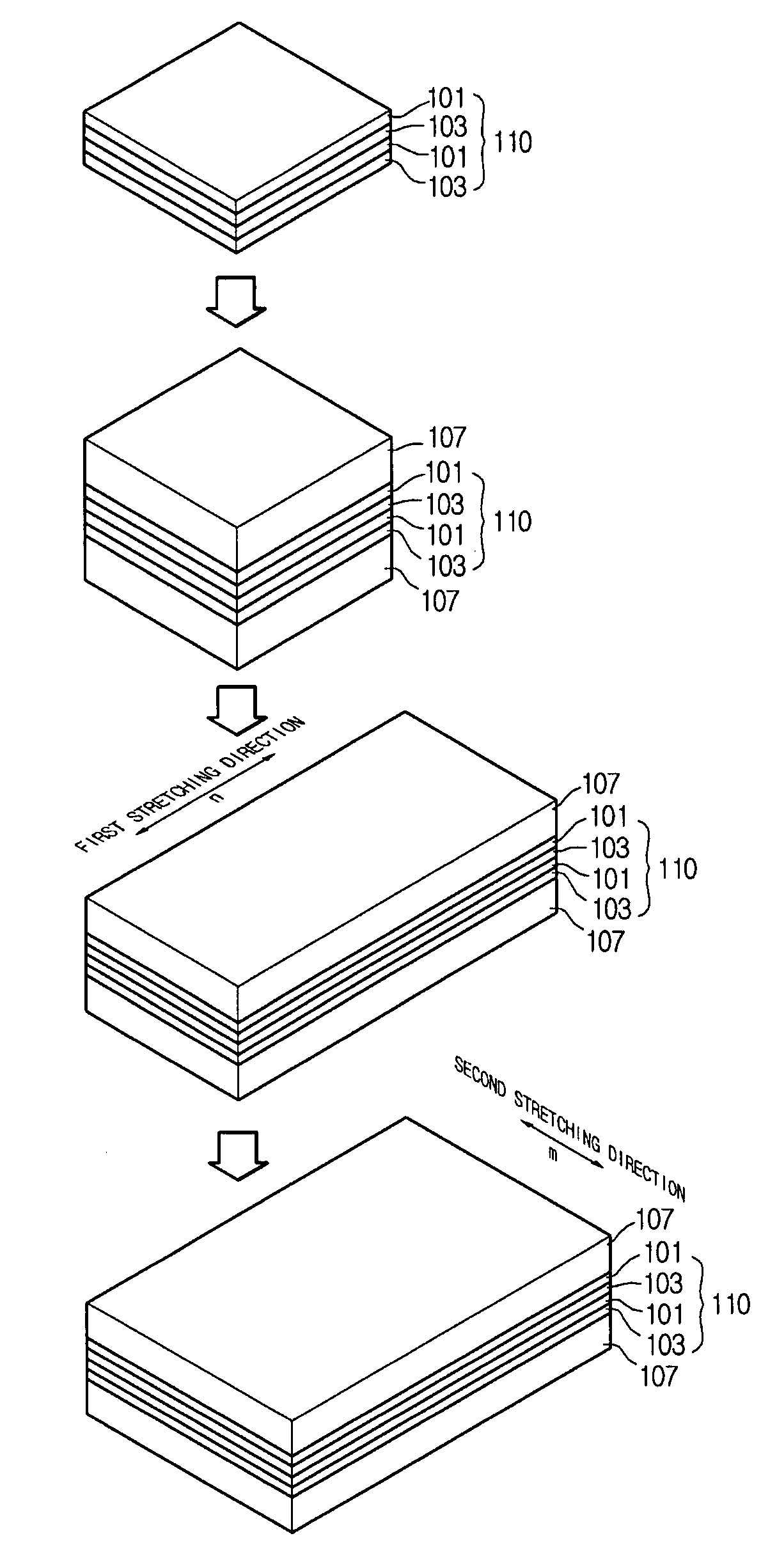

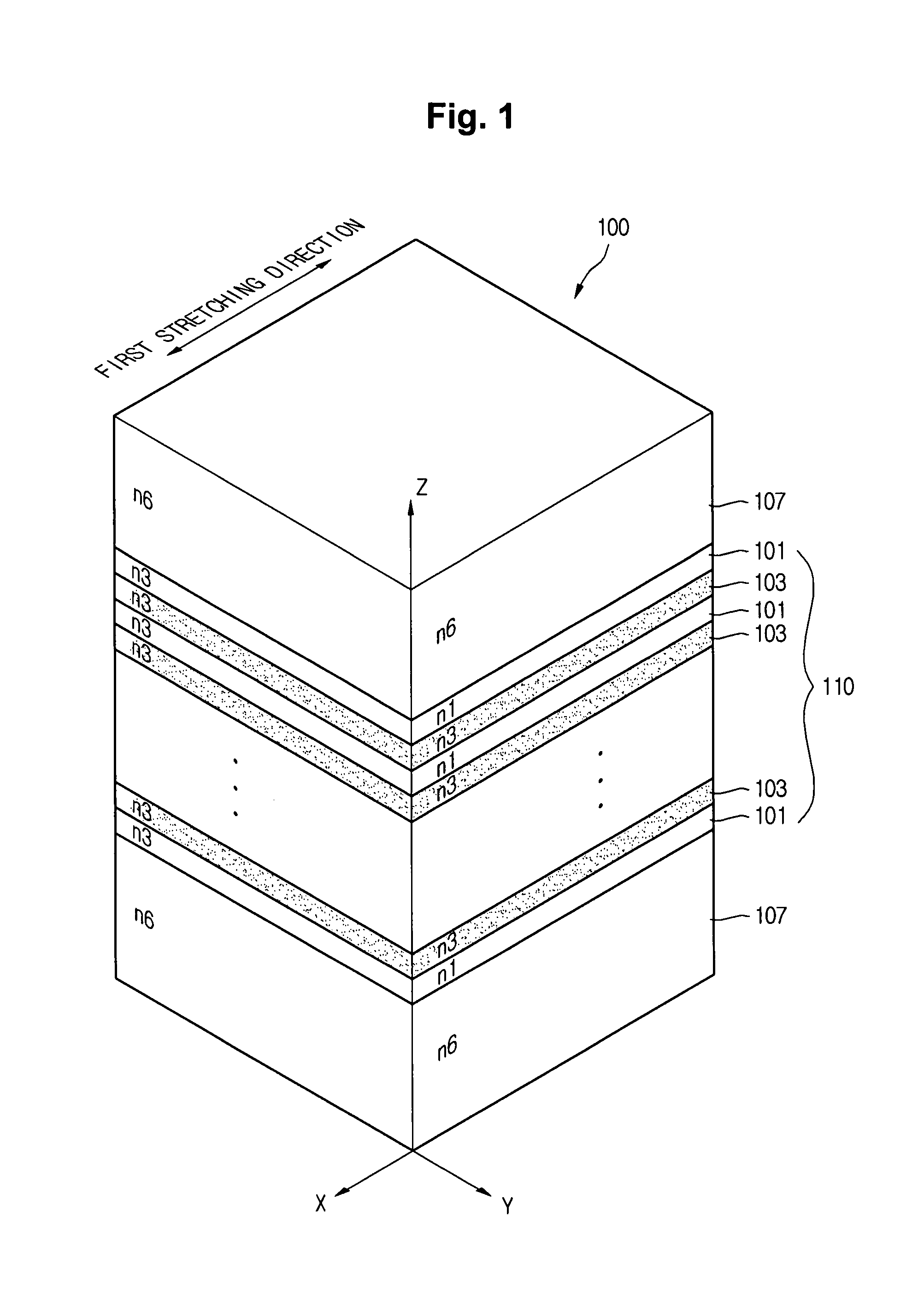

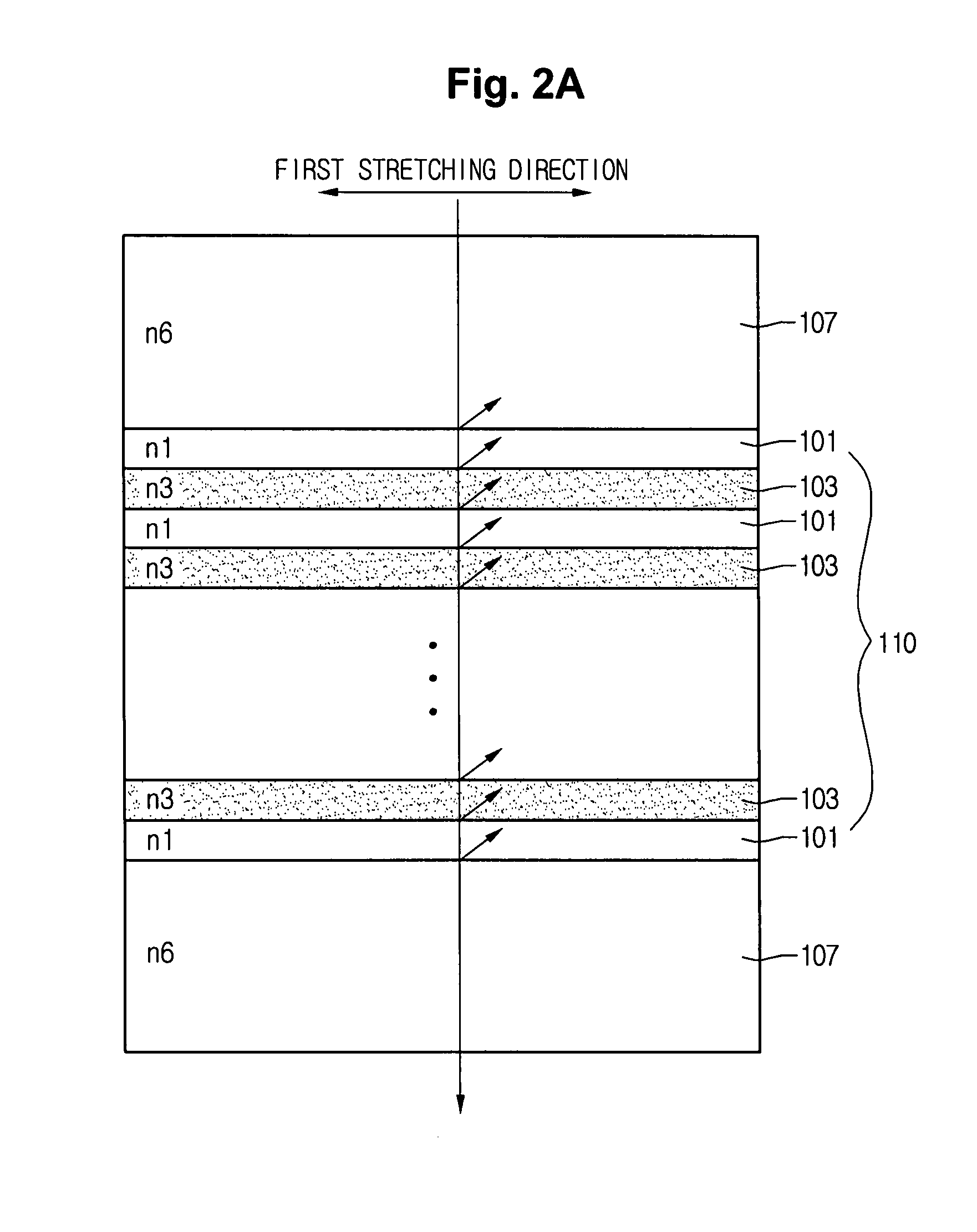

Optical film, method of manufacturing optical film and liquid crystal display device having the same

InactiveUS20080113122A1Improve liquid crystal efficiencyIncrease brightnessLiquid crystal compositionsSynthetic resin layered productsPolyethylene terephthalateLiquid-crystal display

An optical film includes a multi-layer sheet having a plurality of polyethylene terephthalate polymer layers, the polymer layers having a first refraction index in a first direction parallel to a plane of the polymer layers and a second refraction index in a second direction parallel to the plane of the polymer layers, and a plurality of polyethylene terephthalate copolymer layers, the copolymer layers having a third refraction index in both the first and second directions, and a protection sheet directly on at least one side of the multi-layer sheet.

Owner:LG DISPLAY CO LTD

Reflection type liquid crystal display device with controlled directors

ActiveUS8482702B2Improve liquid crystal efficiencyIncreasing azimuth dependenceNon-linear opticsLiquid-crystal displayLiquid crystal

Owner:SHARP KK

Liquid crystal panels

A liquid crystal panel is disclosed. The liquid crystal panel includes a first substrate, a second substrate, and a liquid crystal layer between the first substrate and the second substrate. The first substrate includes a plurality of pixels respectively corresponding to one pixel electrode. The pixel electrode includes a plurality of primary electrodes and a plurality of branch electrodes extending from the primary electrodes. The second substrate includes a base substrate and a common electrode layer formed on the base substrate. The common electrode layer includes a plurality of recessed portions facing toward the base substrate, and each of the recessed portions faces toward one corresponding primary electrode of the pixel electrode. In this way, the liquid crystal efficiency of pixels is enhanced and an applicable range of ultra-high-resolution, small-sized panels of VA mode may be extended.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

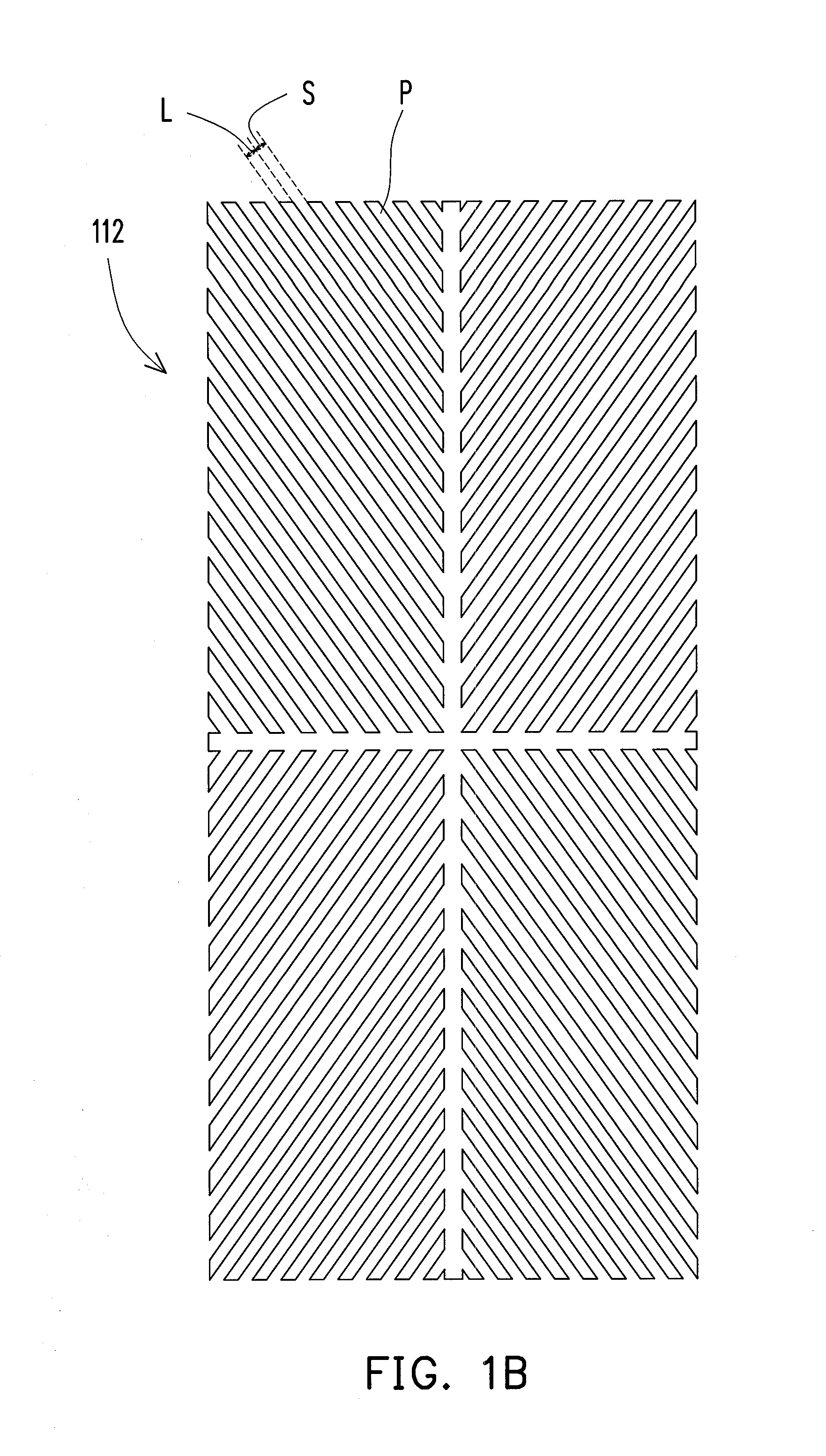

Liquid crystal display panel

InactiveUS20120002148A1Improve liquid crystal efficiencyNon-linear opticsDielectric anisotropyEngineering

A liquid crystal display panel including an active device array substrate, an opposite substrate, and a liquid crystal layer is provided. The active device array substrate includes a plurality of pixel electrodes and each of the pixel electrodes includes a plurality of sets of stripe patterns extending along different directions. Each of the stripe patterns has a width of L and a space between two neighboring stripe patterns is S. The opposite substrate is disposed over the active device array substrate. The liquid crystal layer is disposed between the active device array substrate and the opposite substrate. A cell gap between the active device array substrate and the opposite substrate is d, birefringence of the liquid crystal layer is Δn, and dielectric anisotropy of the liquid crystal layer is Δ∈, wherein S, d, Δn, and Δ∈ comply with the inequality: S / |Δ∈|≦2.8×Δn×d.

Owner:AU OPTRONICS CORP

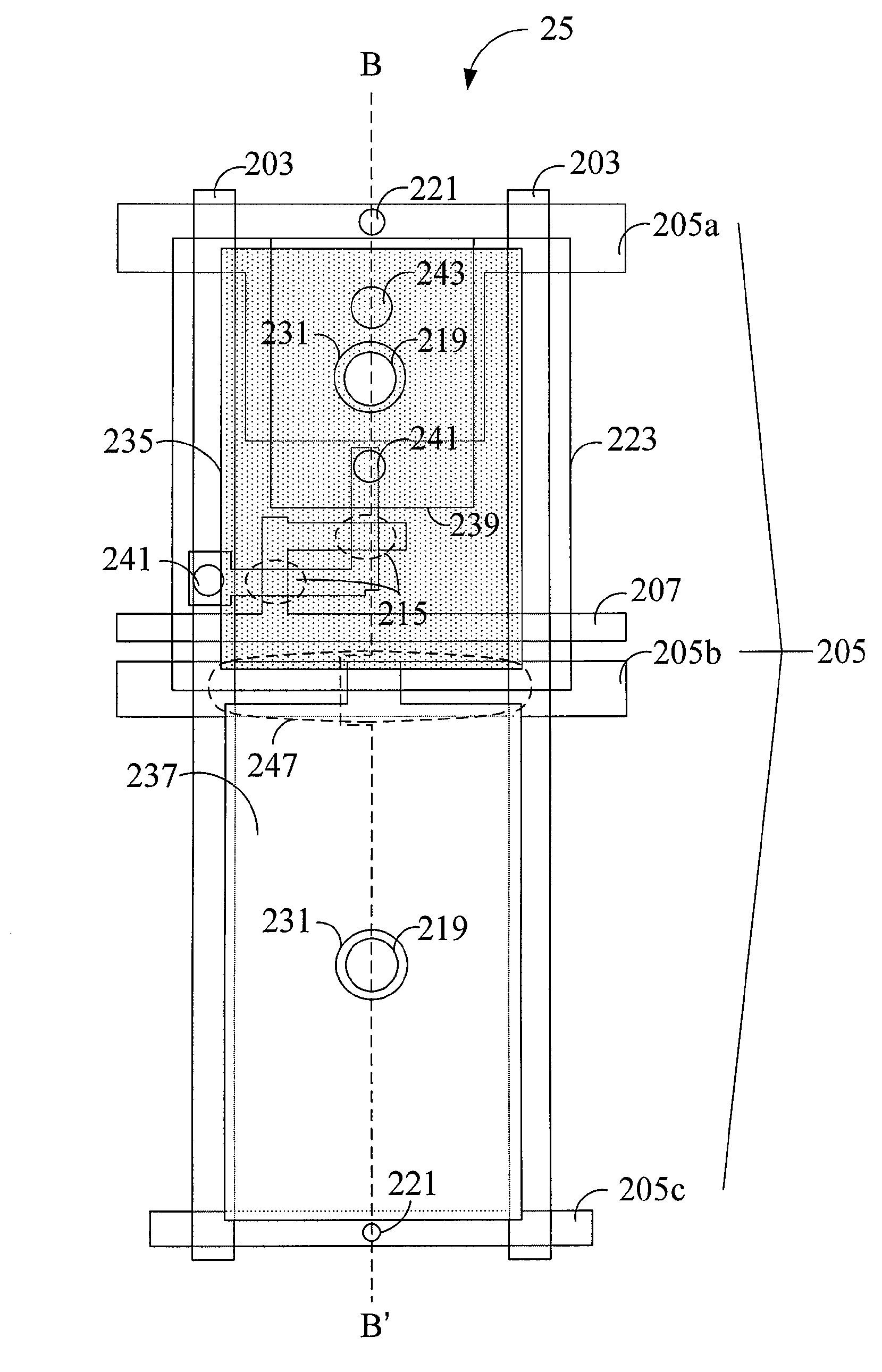

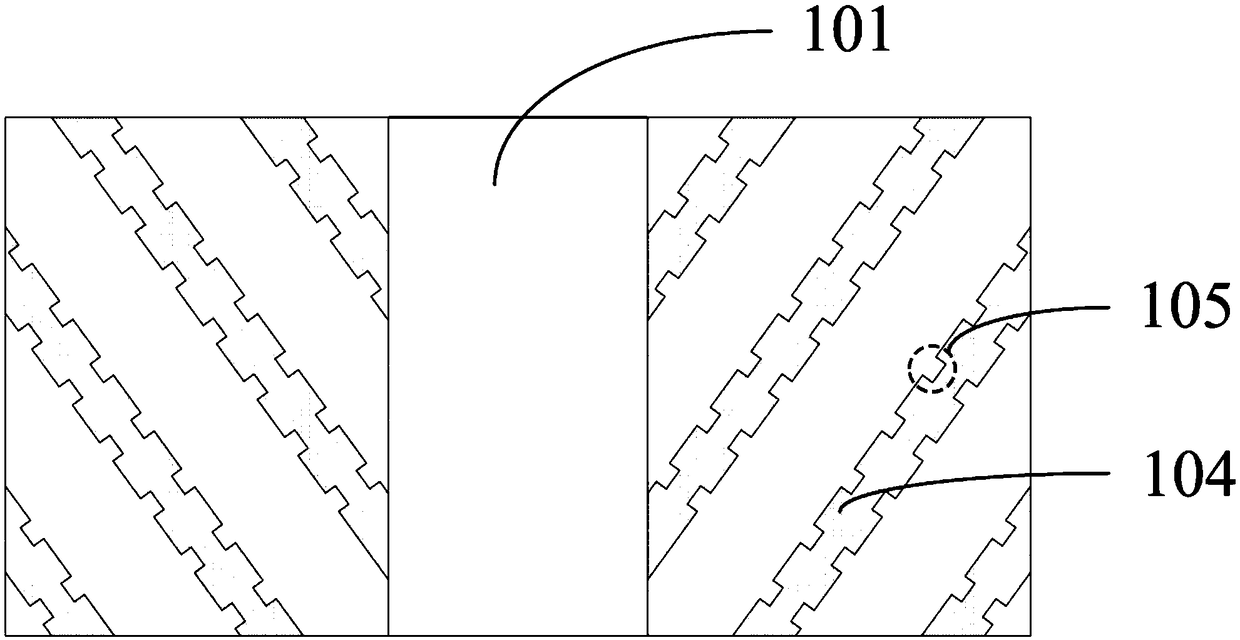

Pixel electrode and array substrate

InactiveCN109375434AReduce line widthExpand line spacingNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a pixel electrode and an array substrate. The pixel electrode comprises a first main electrode and a second main electrode which is vertically intersected with the first main electrode; the first main electrode and the second main electrode divide the pixel electrode into a plurality of liquid crystal alignment areas, a plurality of branch electrodes are arranged in each liquid crystal alignment area, and a preset included angle is formed between each branch electrode and the first main electrode or the second main electrode, wherein each branch electrode is provided with a hollowed-out part. According to the pixel electrode, the hollowed-out parts are arranged on the branch electrodes of the pixel electrode, so that the wire width of the branch electrodes is reduced, and the wire distance between every two adjacent branch electrodes is increased in order to improve the liquid crystal efficiency in a liquid crystal displayer and lower the energy consumption of the displayer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Pixel structure and liquid crystal display including the same

ActiveUS20160291423A1Reducing disclination linePreferable qualityNon-linear opticsLiquid-crystal displayMechanical engineering

A pixel structure is provided and disposed in a pixel region divided up by a dummy line. The pixel structure includes a pixel electrode. The pixel electrode includes first branches and second branches located at opposite sides and disposed symmetrically with respect to the dummy line. One first branch has an extending portion and an end portion. A direction is directing from a front end toward a terminal end of the extension portion, and the terminal end of the extension portion is connected to a front end of the end portion. A bending direction is directing from the front end to a terminal end of the end portion. The direction is toward the dummy line and the bending direction is parallel to or away from the dummy line, or the direction is away from the dummy line and the bending direction is parallel to or toward the dummy line.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com