Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve enhancement efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

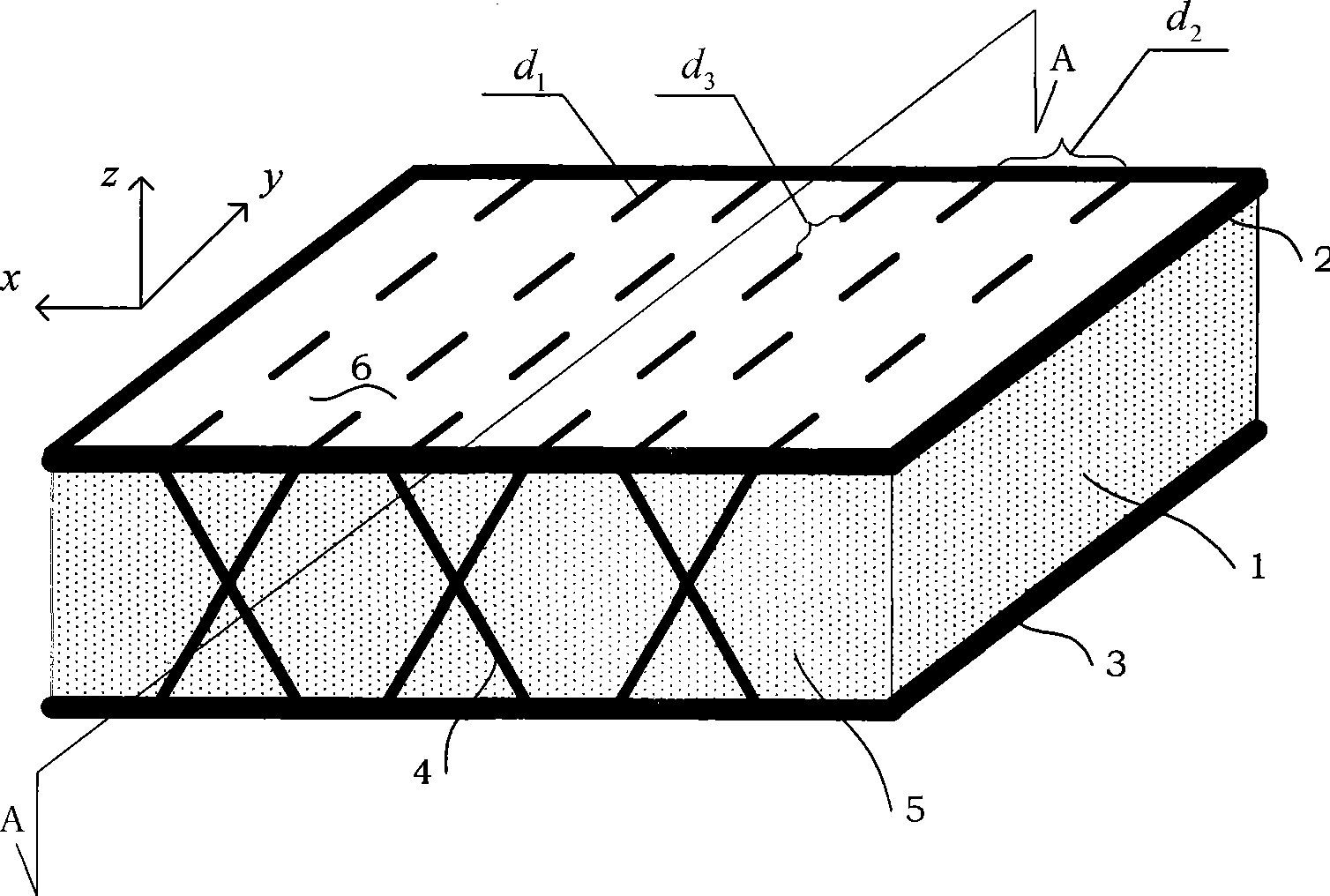

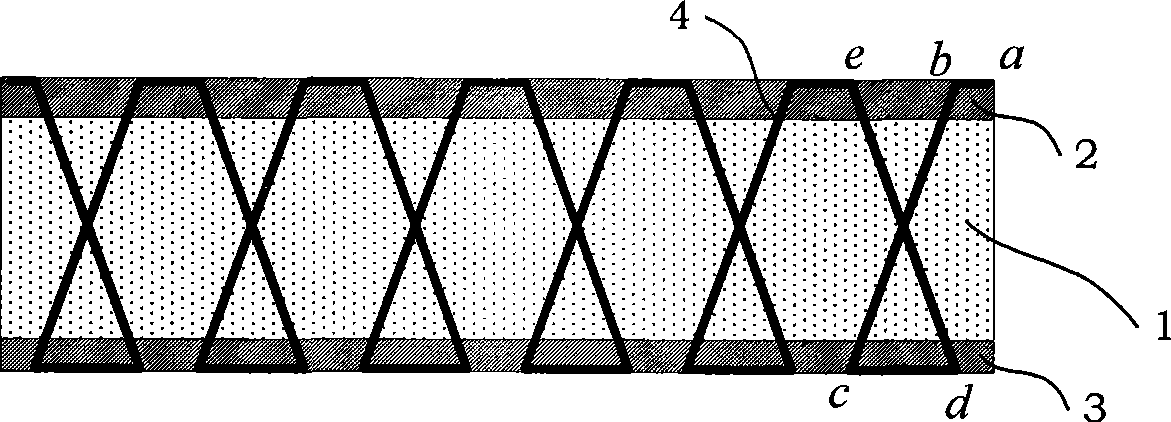

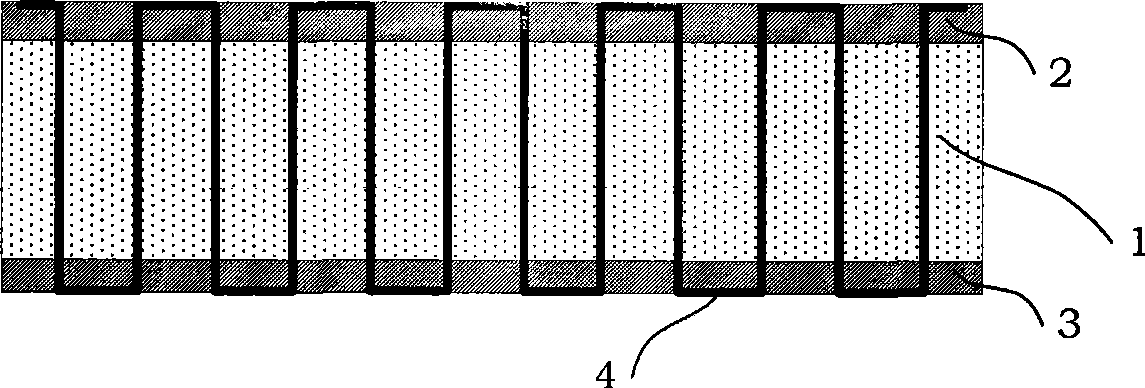

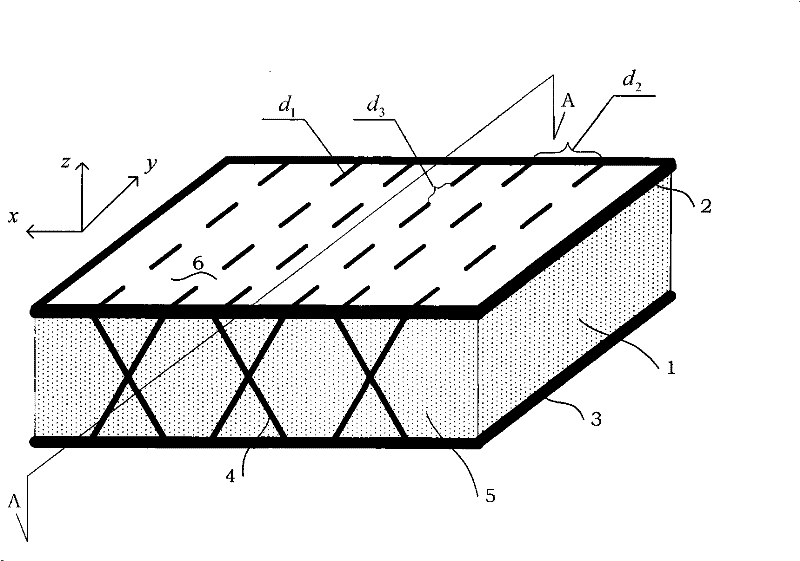

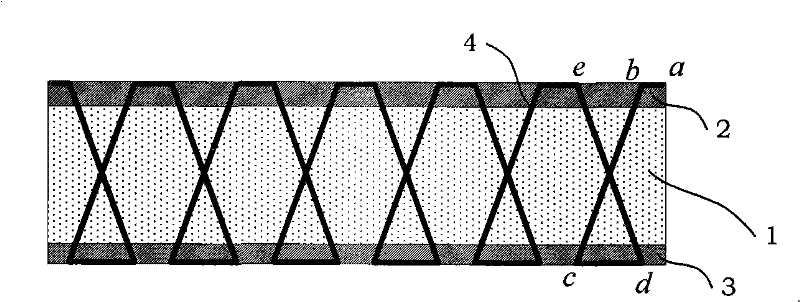

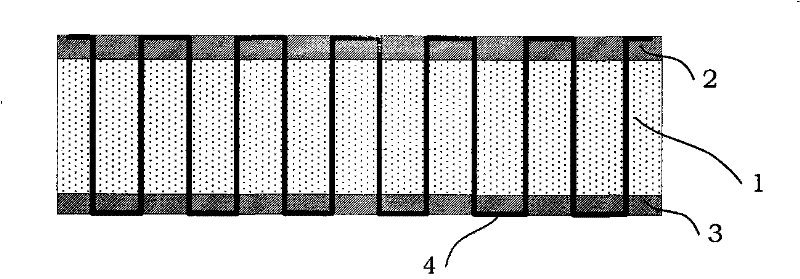

Foam reinforced sandwich structure with fiber bundle and preparation method using sewing-thermal expansion curing molding

InactiveCN101508190ANot bentImprove enhancement efficiencyLaminationLamination apparatusFiber bundleThermal expansion

The invention discloses a reinforced foam interlayer structure with fiber bundles and a preparation method by adopting sewing-thermal expansion curing molding. according to certain pin length d1, pin pitch d3 and row pitch d2, the fiber bundles are connected up and down and sewed on a preforming body in the depth direction of the preforming body so as to realize that an upper panel, a compressed core material and a lower panel are sewed together; subsequently, at temperature of between 60 and 220 DEG C, foam core expands to produce expansion pressure of between 0.05 and 0.7 MPa; after the foam core is cured for 30 and 300 minutes at expansion pressure, the foam core is cooled and demoulded and the reinforced foam interlayer structure with fiber bundles is obtained.

Owner:BEIHANG UNIV

Thermoplastic resin composition, thermoplastic resin composition production method, cellulose-reinforced resin molded product, and cellulose-reinforced resin molded product manufacturing method

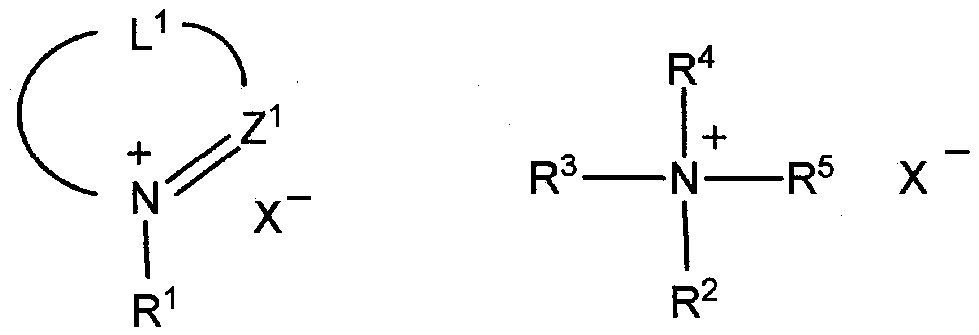

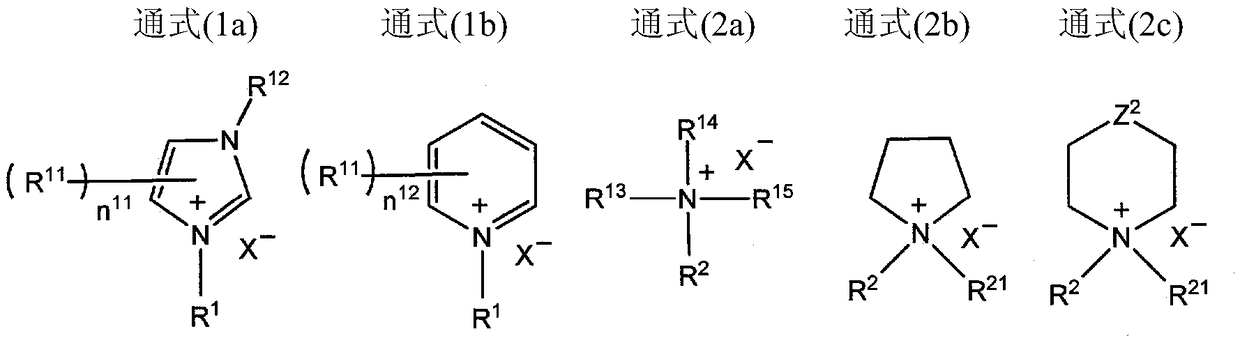

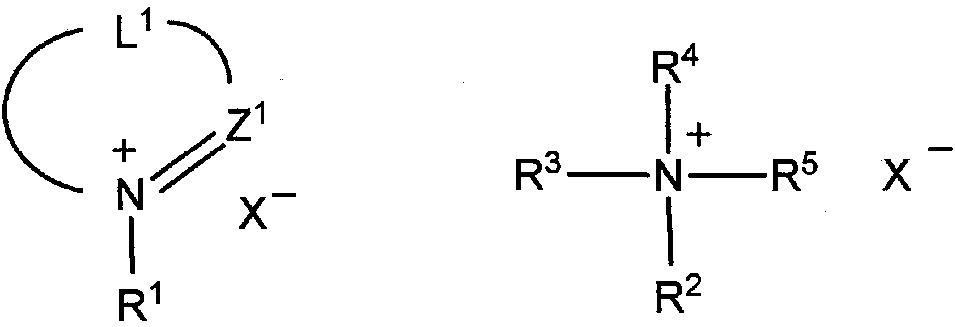

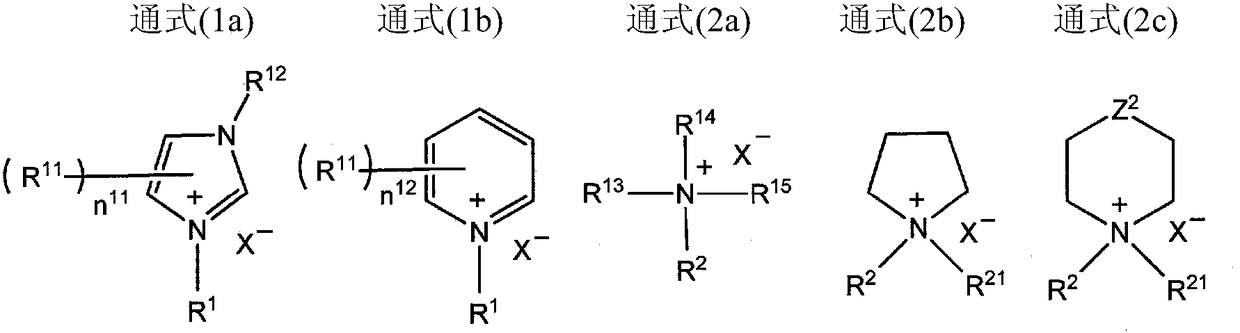

This thermoplastic resin composition contains a thermoplastic synthetic resin, cellulose and an ion compound, wherein, the cellulose content is 1-100 parts by mass per 100 parts by mass of the thermoplastic resin 100, and the content of the ion compound is at least 0.001 times and less than 1.000 times the cellulose. Also provided are: a thermoplastic resin composition production method, a cellulose-reinforced resin molded product, and a cellulose-reinforced resin molded product manufacturing method.

Owner:FURUKAWA ELECTRIC CO LTD

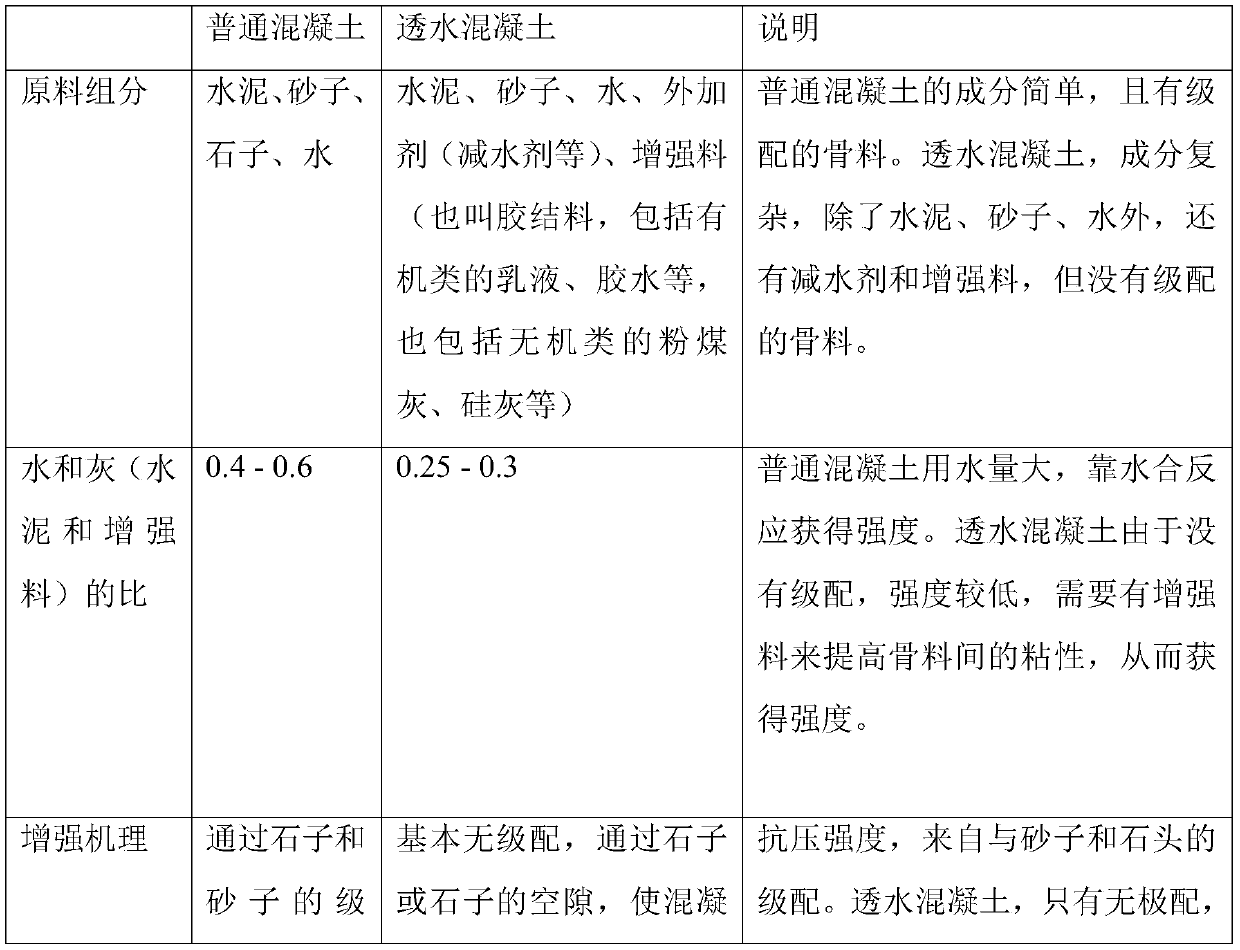

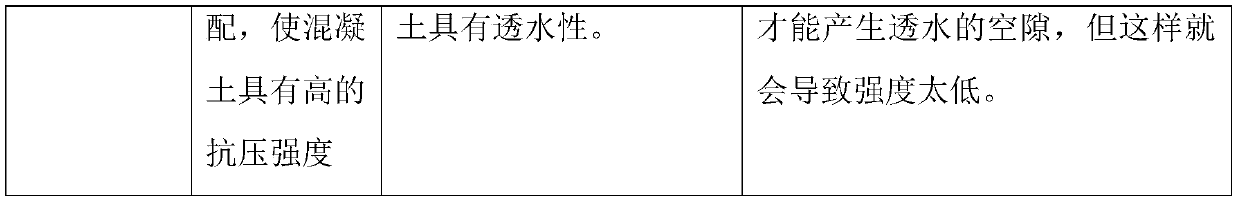

High-strength modified synthetic fiber reinforced pervious concrete and preparation method thereof

PendingCN111268956AImprove enhancement efficiencyHigh tensile strengthConjugated synthetic polymer artificial filamentsMonocomponent polyolefin artificial filamentSynthetic fiberPervious concrete

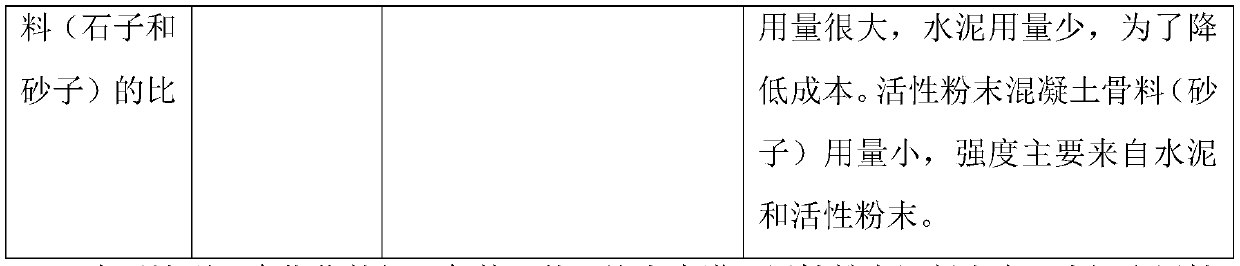

The invention discloses high-strength modified synthetic fiber reinforced pervious concrete. High-strength modified synthetic fibers are doped into the pervious concrete; the content of the high-strength modified synthetic fibers in the pervious concrete is 2kg / m < 3 >-120kg / m < 3 >, the high-strength modified synthetic fiber is obtained by modifying synthetic resin or synthetic fiber with a modifier, and the pervious concrete is concrete with a continuous void structure, which is formed by mutually bonding low-grade or stepless aggregate and a cement-based cementing material coated on the surface of the low-grade or stepless aggregate, and hydrating and hardening the low-grade or stepless aggregate. Polar groups such as Si, Si-O,-OH and-COOH are grafted to the surface of the synthetic fiber through the modifier, the groups act and react with a reinforcing material, a cementing material and an additive in the pervious concrete, and the strength and the dispersity of the fiber and the binding power of the fiber and the concrete are greatly improved.

Owner:殷石

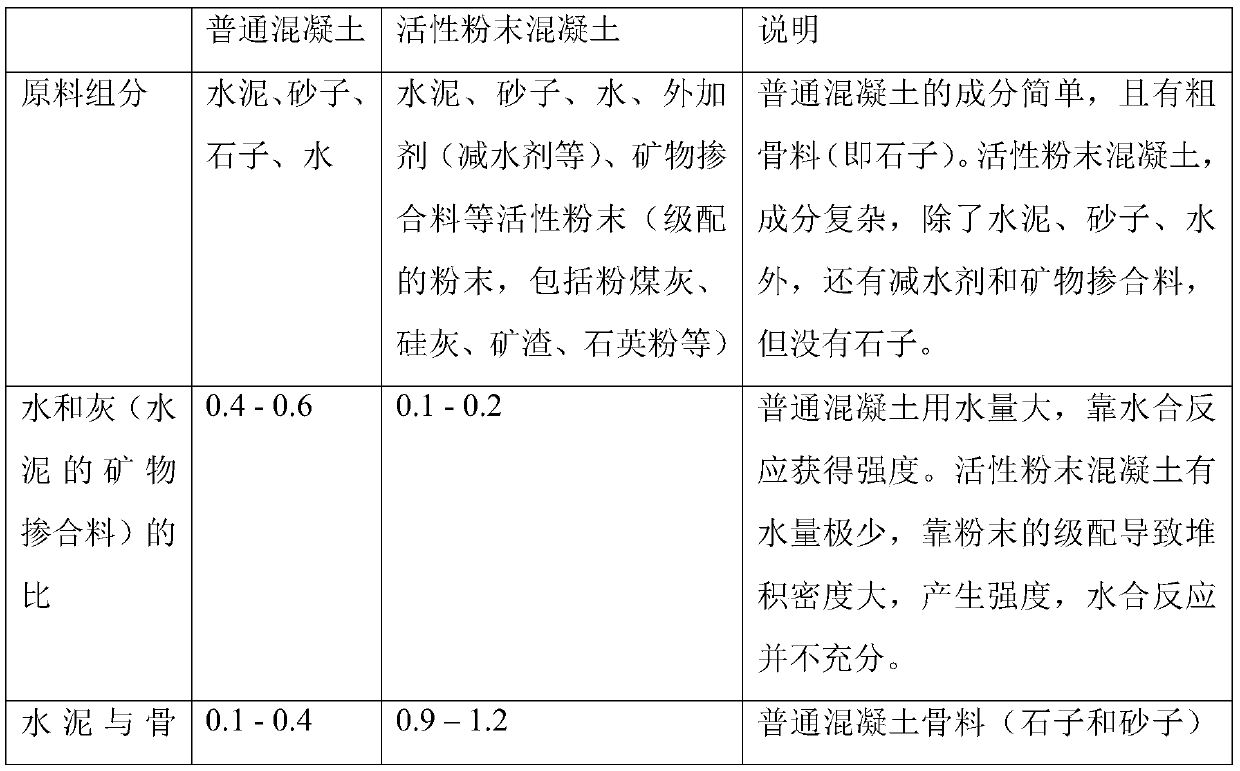

High-strength modified synthetic fiber reinforced reactive powder concrete

PendingCN111233383AHigh tensile strengthIncrease elasticityMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentSynthetic resinSynthetic fiber

The invention discloses high-strength modified synthetic fiber reinforced reactive powder concrete. High-strength modified synthetic fibers are doped into the reactive powder concrete, wherein the content of the high-strength modified synthetic fibers in the reactive powder concrete is 0.1-100 kg / m3; the high-strength modified synthetic fiber is obtained by modifying synthetic resin or synthetic fiber with a modifier, wherein the active powder concrete is produced by taking cement, mineral admixtures and other active powder materials, fine aggregate, additives and water as raw materials. Due to the fact that polar groups such as Si, Si-O, -OH and -COOH are grafted to the surface of the synthetic fiber through the modifier, so that the groups react with active powder minerals in the activepowder concrete, and the strength, dispersion and binding power with the concrete of the fiber are greatly improved.

Owner:殷石

Method for enhancing optical image

ActiveCN102063702AImpact enhancementSuitable for realizationImage enhancementMarine navigationOptical image

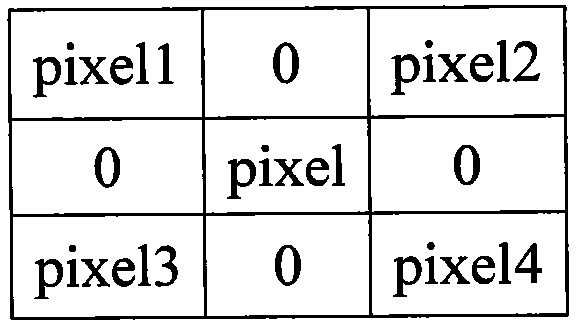

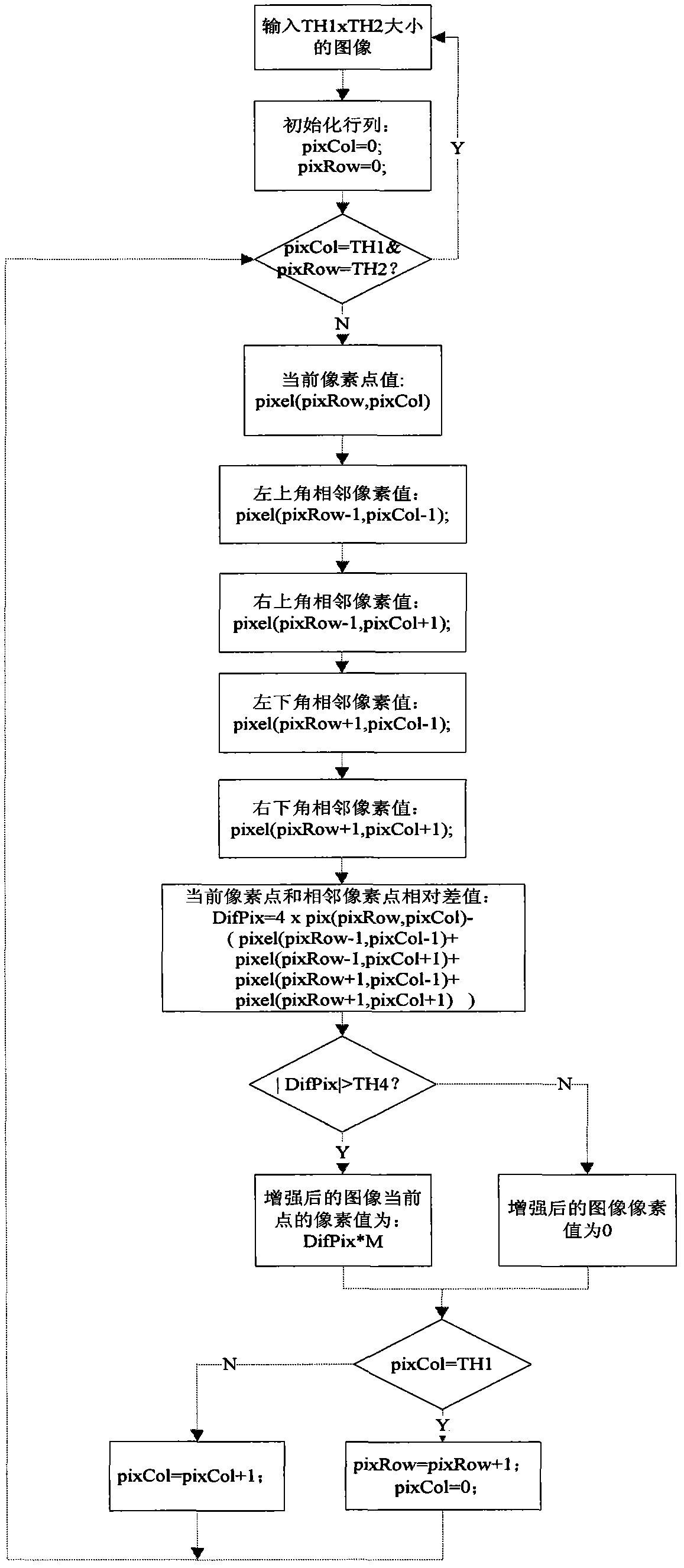

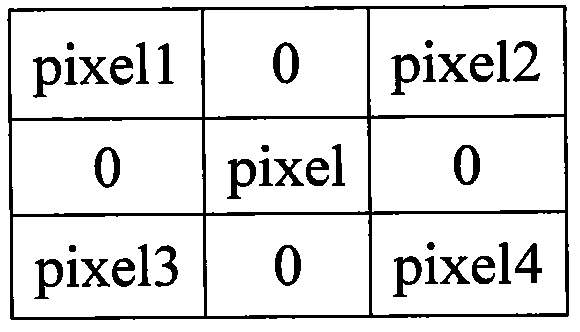

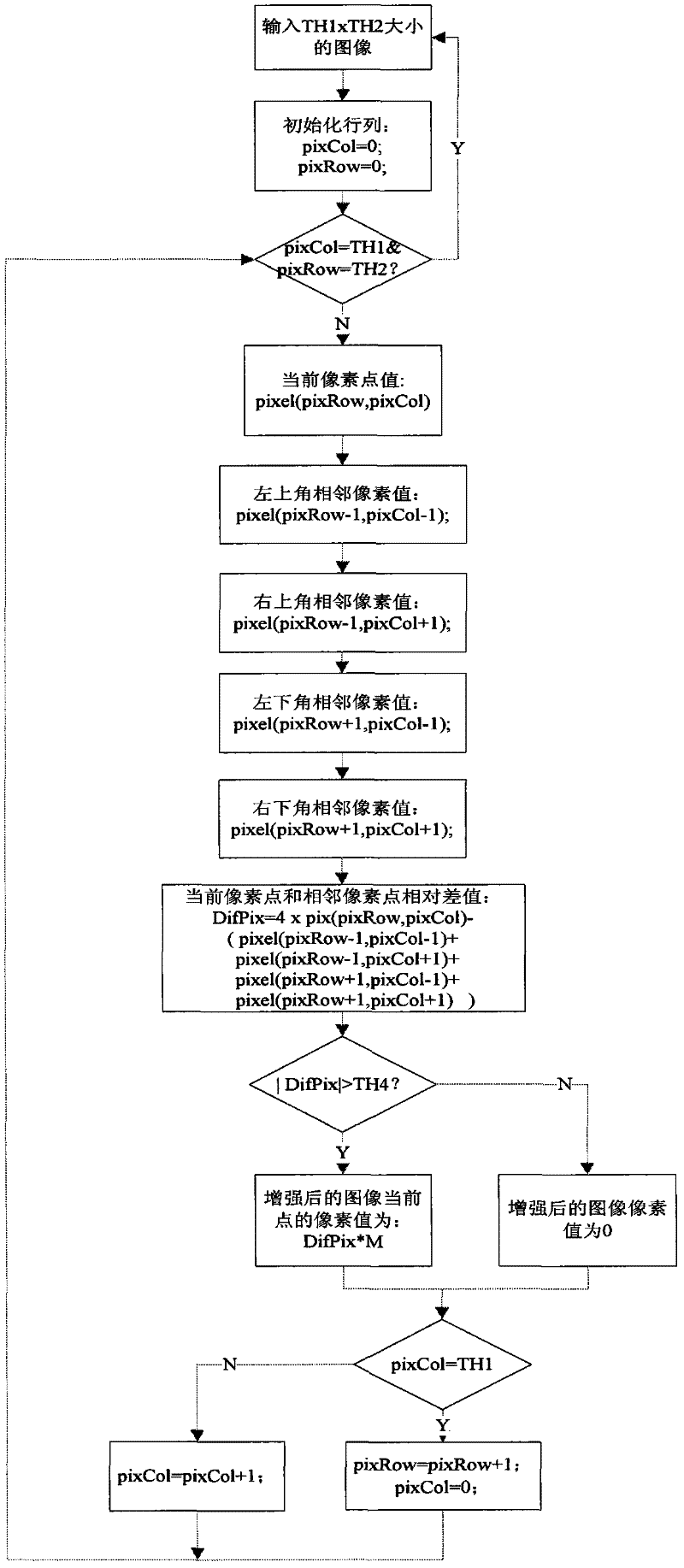

The invention relates to a method for enhancing an optical image. The method comprises the following steps of: 1, inputting an image acquired in photoelectric navigation; 2, performing point-by-point scanning on the image, and acquiring a pixel value, namely pixel (a, b) of the current pixel point; 3, acquiring pixel values of adjacent pixel points at the top left corner, the bottom left corner, the top right corner and the bottom right corner of the current pixel point respectively; 4, solving relative difference values, namely difpix of the current pixel point and (2<n> + 2<m>) adjacent pixel points obtained in the step 3; 5, solving an absolute value of the relative difference value, namely the absolute value of difpix, comparing the absolute value with a set threshold, namely TH4, setting the pixel value of the current pixel point with a coordinate value of a (a, b) point to be the absolute value of difpix multiplying by M when the absolute value is larger than the threshold, namely the TH4, and setting the pixel value of the current pixel point with the coordinate value of the (a, b) point to be 0 when the absolute value is smaller than the threshold, namely the TH4; and 6, after performing the point-by-point scanning on the image, acquiring an enhanced contrast image. The method is easy to operate, good in enhancement effect and suitable for circuit realization, and enhancement efficiency is improved.

Owner:江苏钜芯集成电路技术股份有限公司

Thermoplastic resin composition, thermoplastic resin composition production method, cellulose-reinforced resin molded product, and cellulose-reinforced resin molded product manufacturing method

The invention discloses a method is for producing a thermoplastic resin composition, a cellulose-reinforced resin molded product and a cellulose-reinforced resin molded product manufacturing method. The thermoplastic resin composition contains a thermoplastic synthetic resin and cellulose, wherein at least one type of the thermoplastic resin is a resin having a group that includes a partial structure of acid anhydride in the polymer molecule.

Owner:FURUKAWA ELECTRIC CO LTD

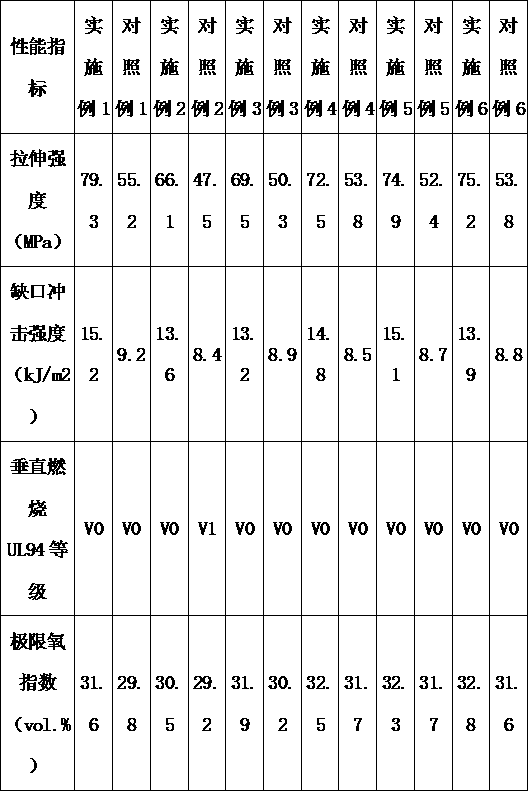

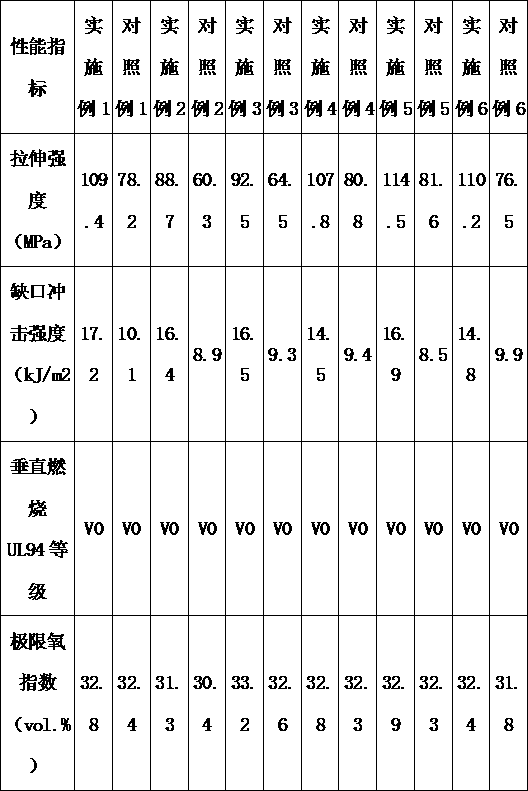

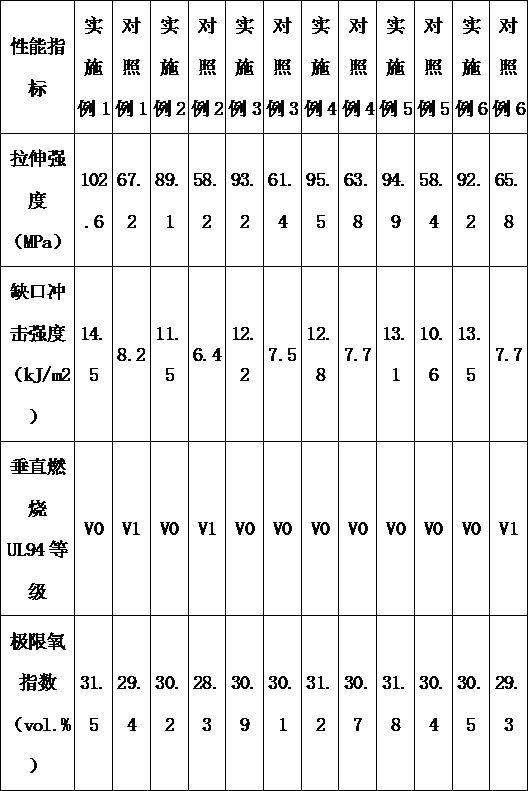

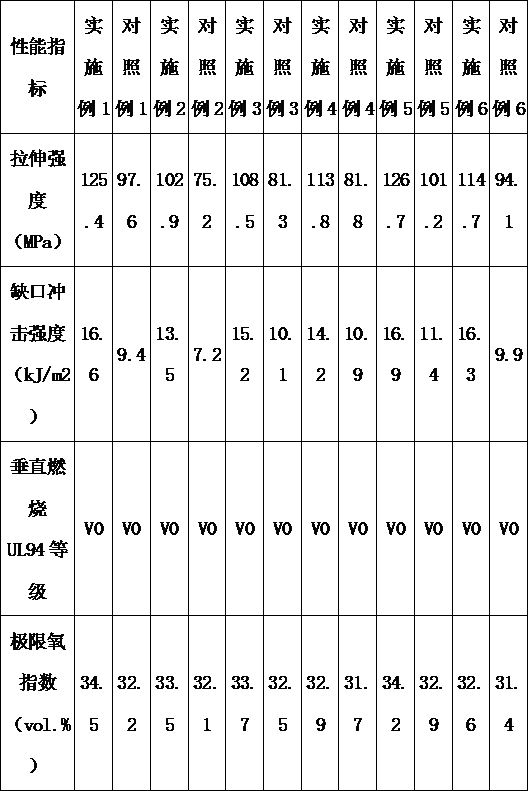

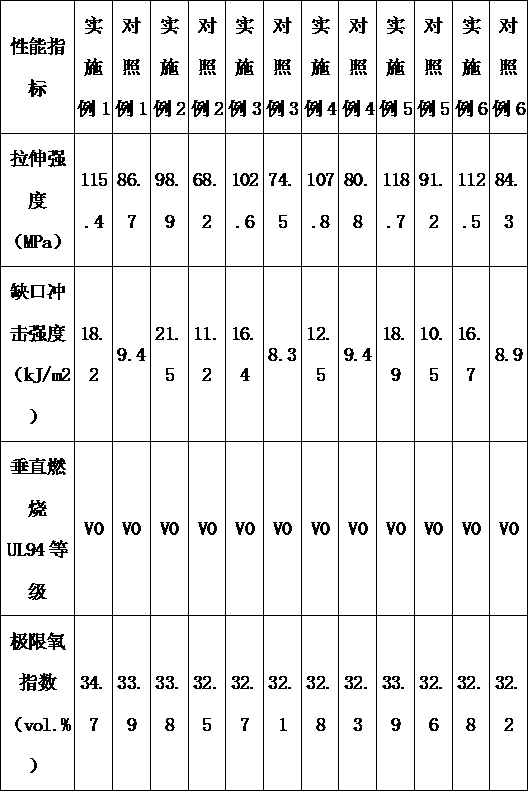

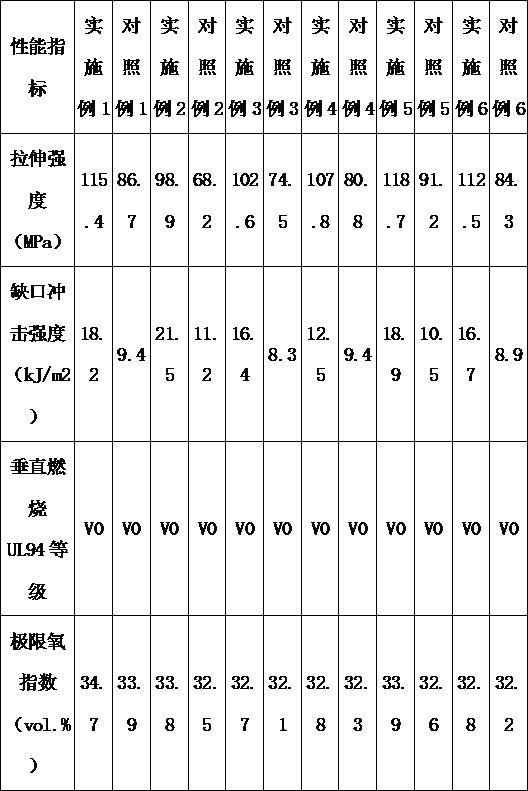

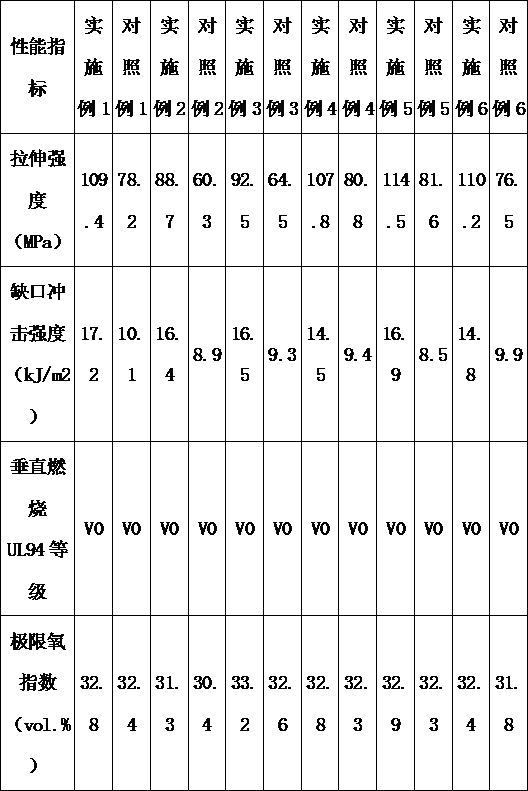

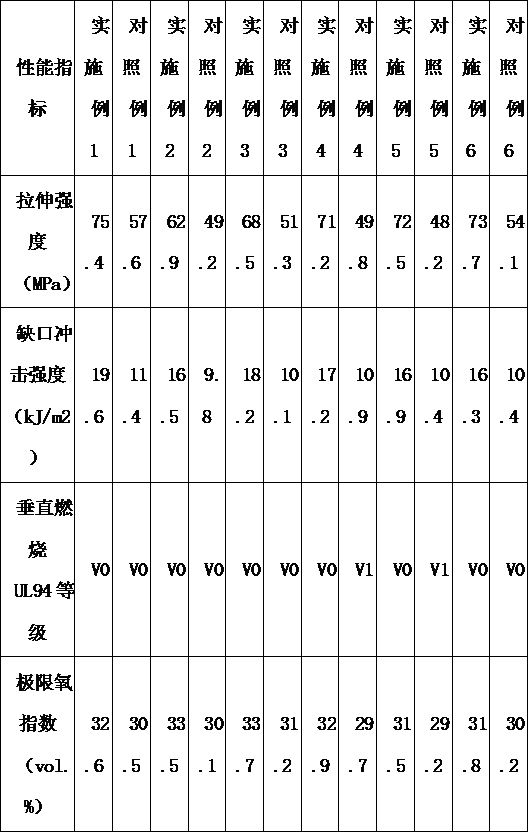

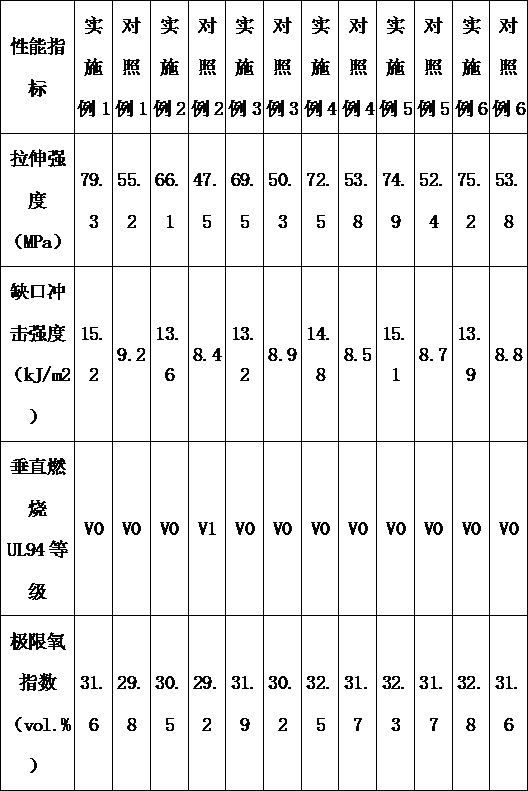

High-efficiency enhanced halogen-free flame-retardant functional master batch for polypropylene direct injection molding and preparation method of functional master batch

ActiveCN109486013ASolve the technical problem of mismatching processing temperatureAvoid damageIonomerGlass fiber

The invention belongs to the technical field of plastic modification and processing and in particular relates to a high-efficiency enhanced halogen-free flame-retardant functional master batch capableof being directly applied to injection molding of polypropylene products and a preparation method of the functional master batch. The functional master batch is prepared by combining a master batch Aand a master batch B, wherein the master batch A comprises the following components in percentage by mass: 50.0-70.0% of glass fibers, 15.0-35.0% of high-fluidity polypropylene, 5.0-10.0% of an elastic ionomer, 3.0-6.0% of atactic polypropylene, 1.0-3.0% of maleic anhydride grafted polypropylene, 1.0-3.0% of polytetrafluoroethylene powder and 0.1-0.3% of an antioxidant. Compared with the traditional plastic functional master batch, the functional master batch prepared by the invention has the advantages that the condition that the modification effectiveness is low because the glass fibers andthe flame retardant perform mutual shearing friction to produce heat in the processing procedures of an enhanced halogen-free flame-retardant polypropylene modified system is avoided, the problem that mutual modification effectiveness damage is caused by mismatching of processing temperatures of the two modified systems is solved, and the modification effectiveness of the two is obviously enhanced.

Owner:江苏万纳普新材料科技有限公司

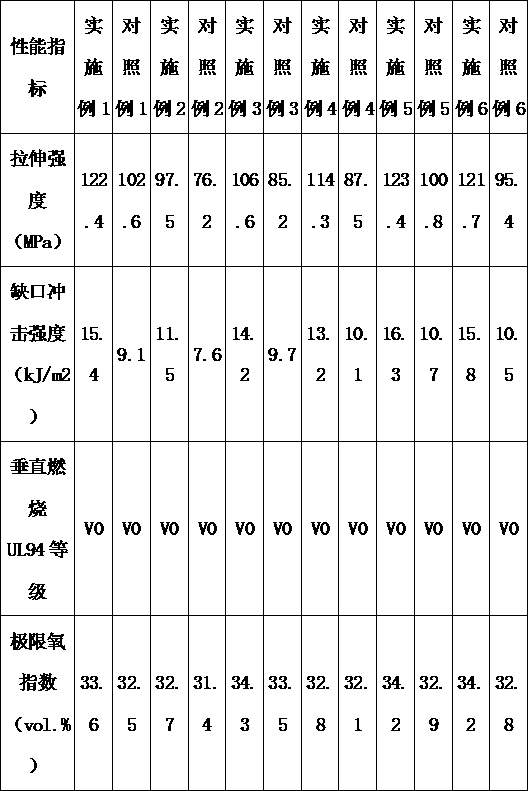

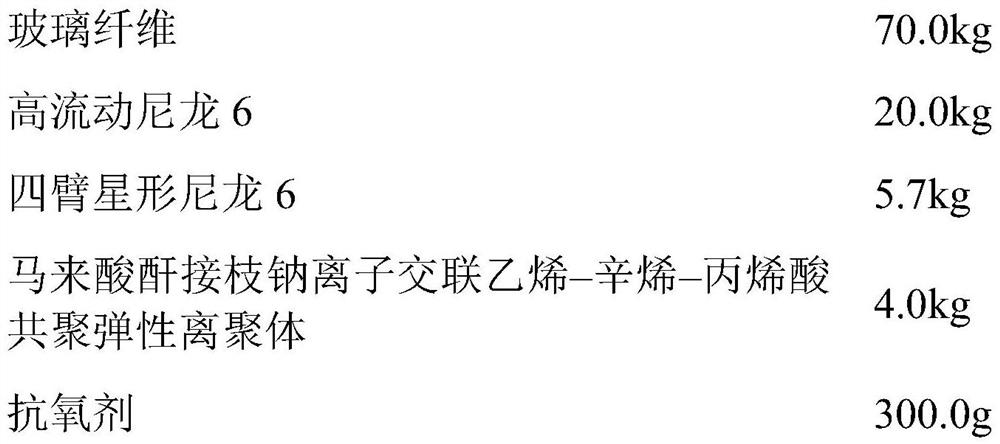

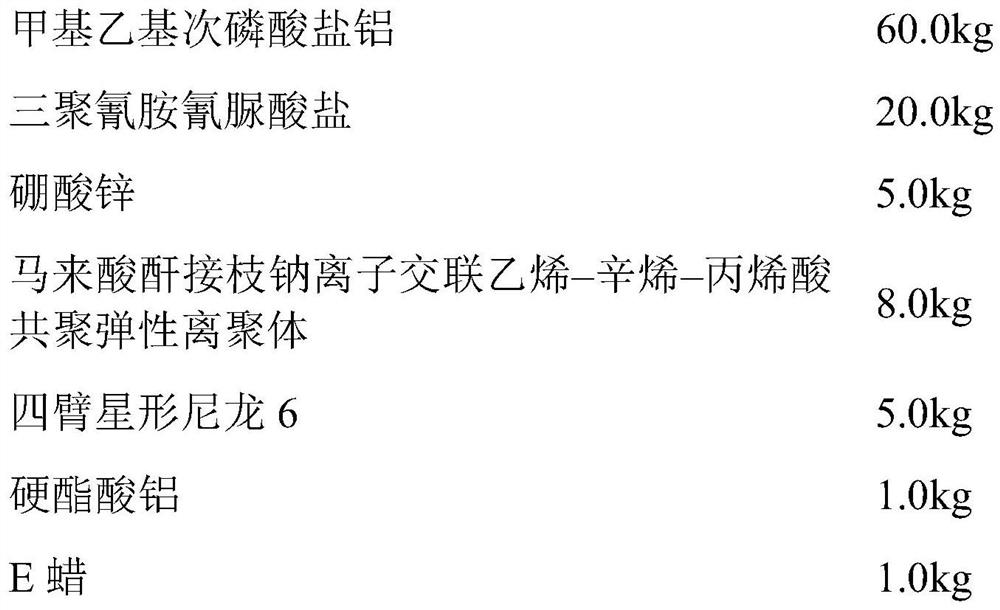

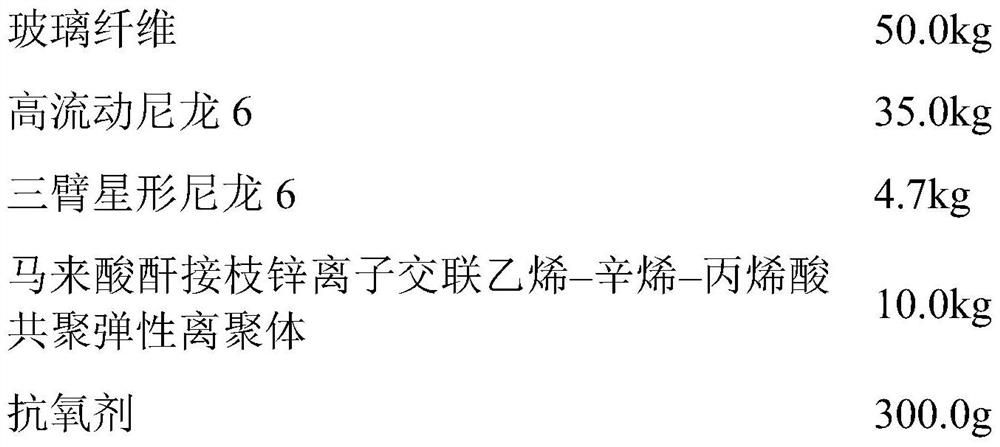

Efficient enhanced type halogen-free flame-retardant functional master batch for direct injection molding of nylon 6 and preparation method of efficient enhanced type halogen-free flame-retardant master batch

ActiveCN109370210ASolve the technical problem of mismatching processing temperatureAvoid damageGlass fiberAntioxidant

The invention belongs to the technical field of plastic modification and processing, and particularly relates to an efficient enhanced type halogen-free flame-retardant functional master batch for direct injection molding of nylon 6 products and a preparation method of the efficient enhanced type halogen-free flame-retardant functional master batch. The functional master batch is formed by combining a mater batch A and a master batch B, the master batch A is prepared from the following materialss in percentage by weight: 50.0-70.0% of glass fibers, 20.0-35.0% of high-flow nylon 6 resin, 3.0-10.0% of maleic anhydride grafted elastic ionomer, 3.0-6.0% of star-shaped nylon 6 resin, and 0.1-0.3% of an antioxidant. Compared with traditional plastic functional master batches, the functional master batch prepared through the method avoids mutual modification efficiency loss caused by mutual shear abrasion of glass fibers and a flame retardant in the processing course of enhanced type halogen-free flame retardant nylon 6 modification systems, and meanwhile solves the problem of mismatched processing temperatures of the two modification systems is solved and remarkably enhances the modification efficiency of the two modification systems is remarkably enhanced; the mater batch has a feature of easy dispersion processing and can be directly and simply mixed with nylon 6 resin according tothe proportion and then subjected to injection molding, and an excellent modification effect can be achieved.

Owner:江苏万纳普新材料科技有限公司

High-efficiency enhanced flame-retardant functional masterbatch for direct injection molding of nylon 6 and preparation method thereof

ActiveCN109535701AGood modification effectSolve the technical problem of mismatching processing temperatureMasterbatchPolyoxymethylene

The invention belongs to the technical field of plastic modification and processing, and especially relates to a high-efficiency enhanced flame-retardant functional masterbatch for direct injection molding of a nylon 6 product and a preparation method thereof. The functional masterbatch is composed of two kinds of masterbatch A and B. The masterbatch A comprises the following components by mass percentage: 50.0-70.0 wt.% of glass fiber, 15.0-35.0 wt.% of high flow nylon 6 resin, 3.0-10.0 wt.% of a maleic anhydride grafted ionomer, 3.0-6.0 wt.% of star nylon 6 resin, and 0.1-0.3 wt.% of an antioxidant. Compared with the traditional plastic functional masterbatch, the functional masterbatch prepared by the invention avoids the problems that during processing of polyoxymethylene in an enhanced halogen-free flame-retardant nylon 6 modification system, mutual modification of the modification efficiency caused by mutual shearing and friction between the glass fiber and a flame retardant canbe solved, and mismatch problem of the processing temperatures of the above two modified systems is solved, and the modification efficiency of the two modified systems is remarkably enhanced. The masterbatch has the characteristics of easy dispersibility and easy processing, and can be directly injected and molded with nylon 6 resin in a simple ratio.

Owner:江苏万纳普新材料科技有限公司

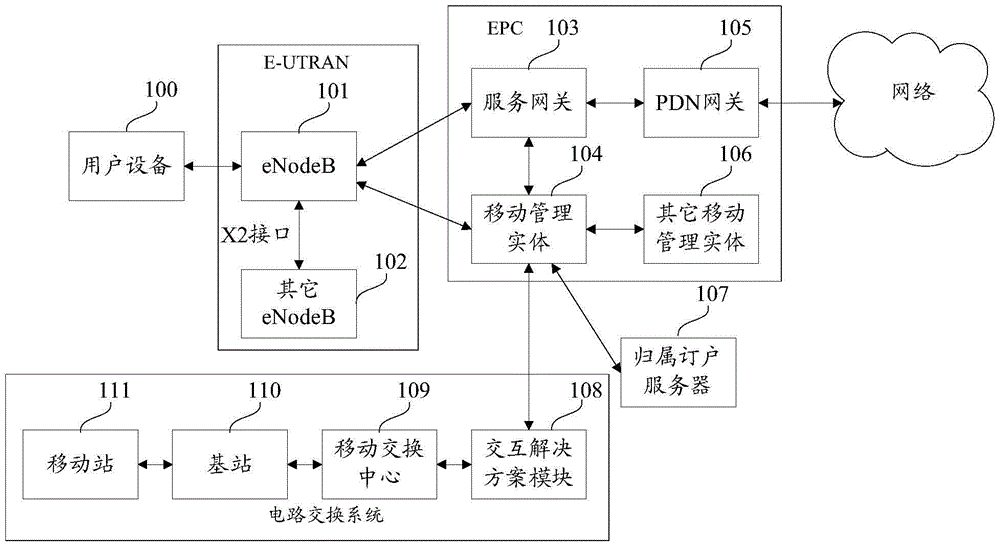

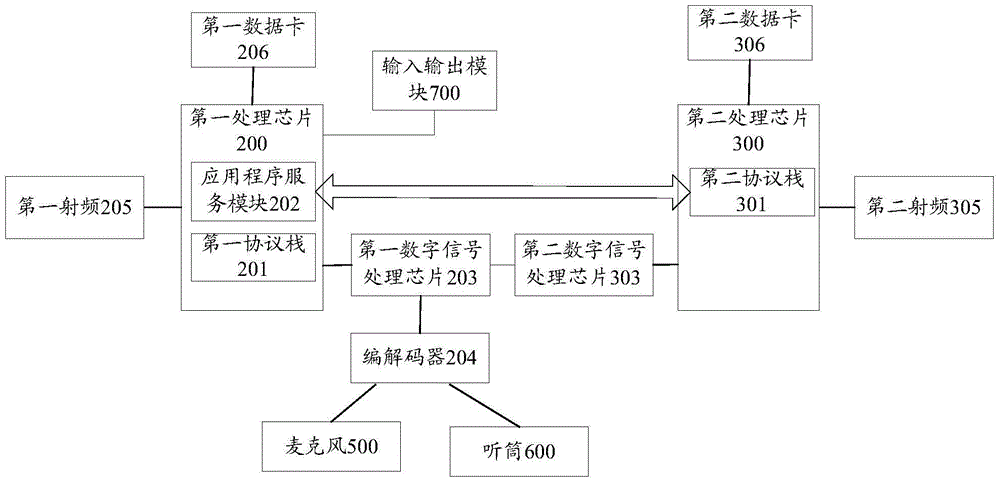

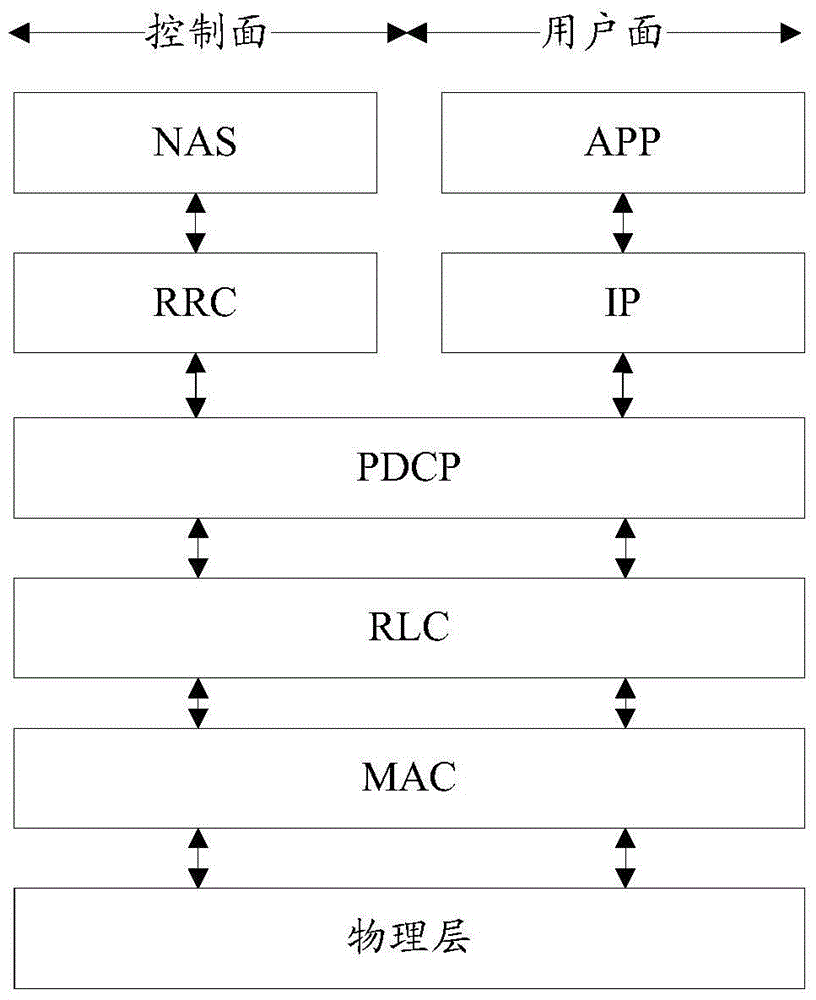

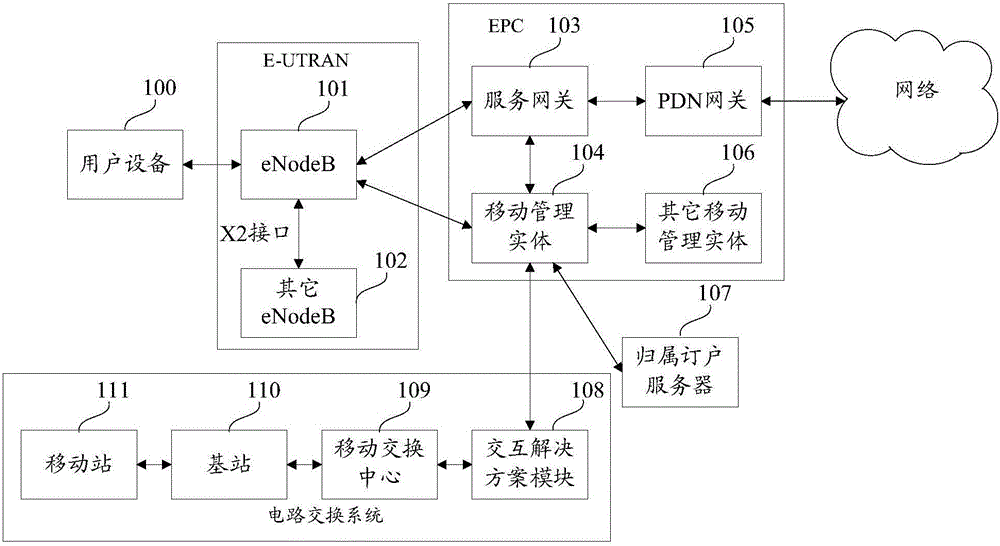

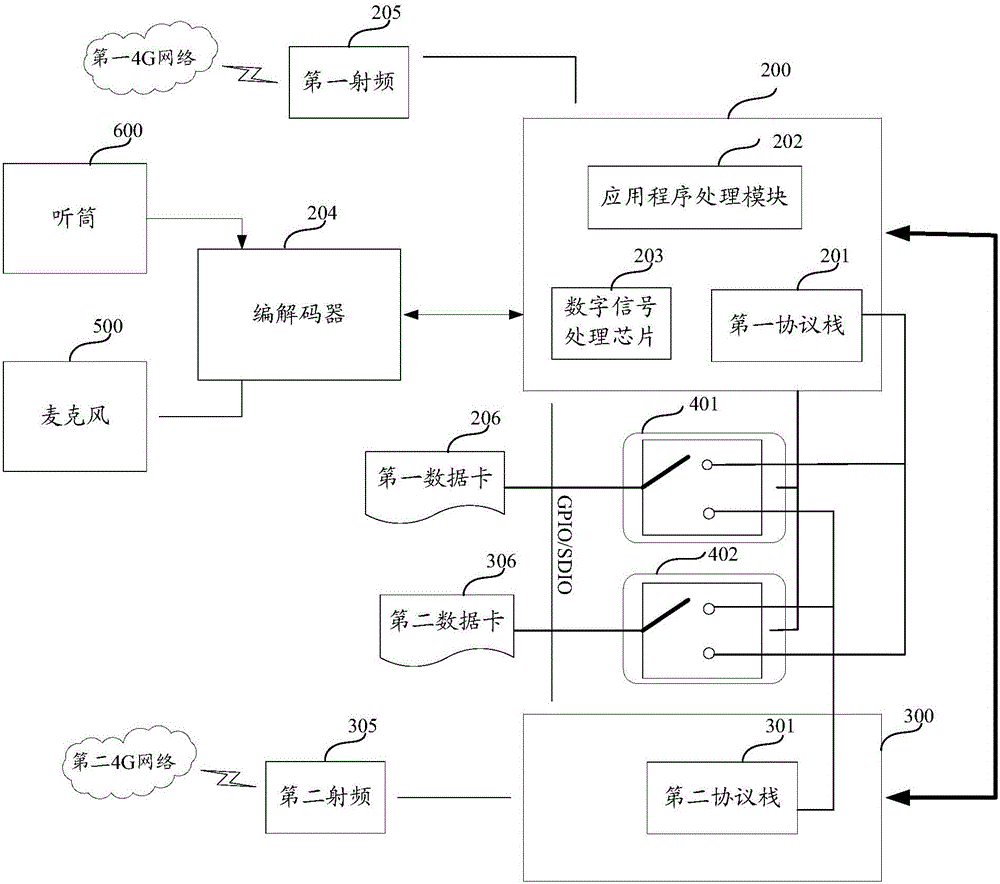

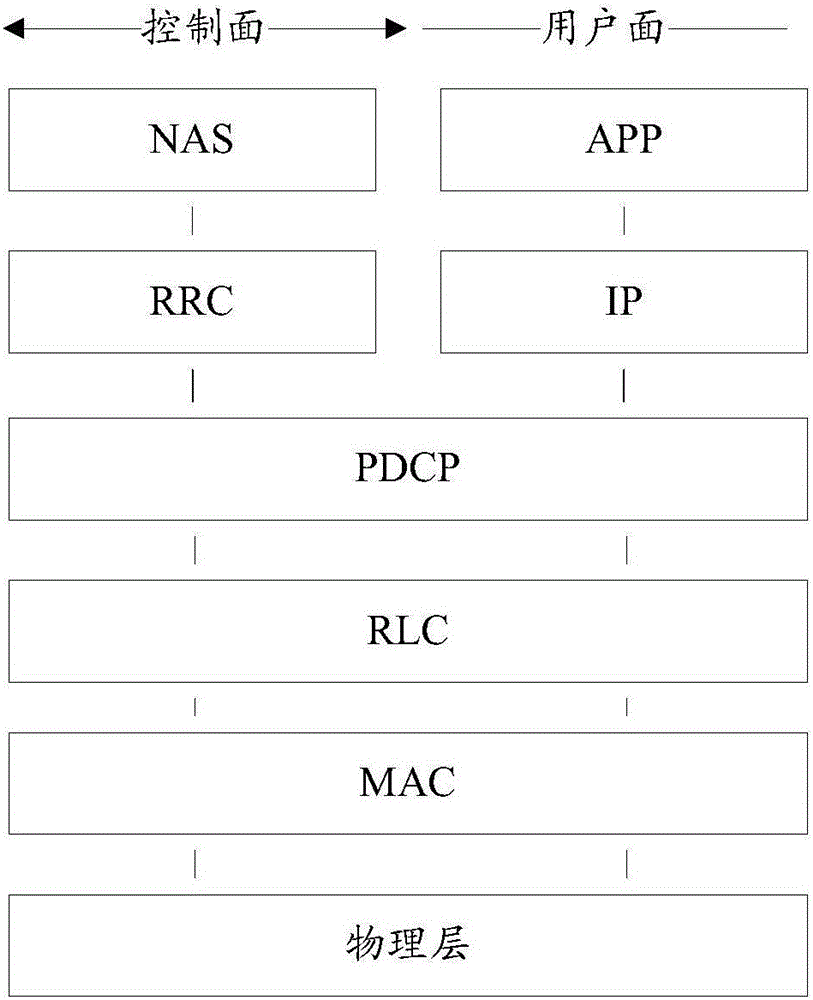

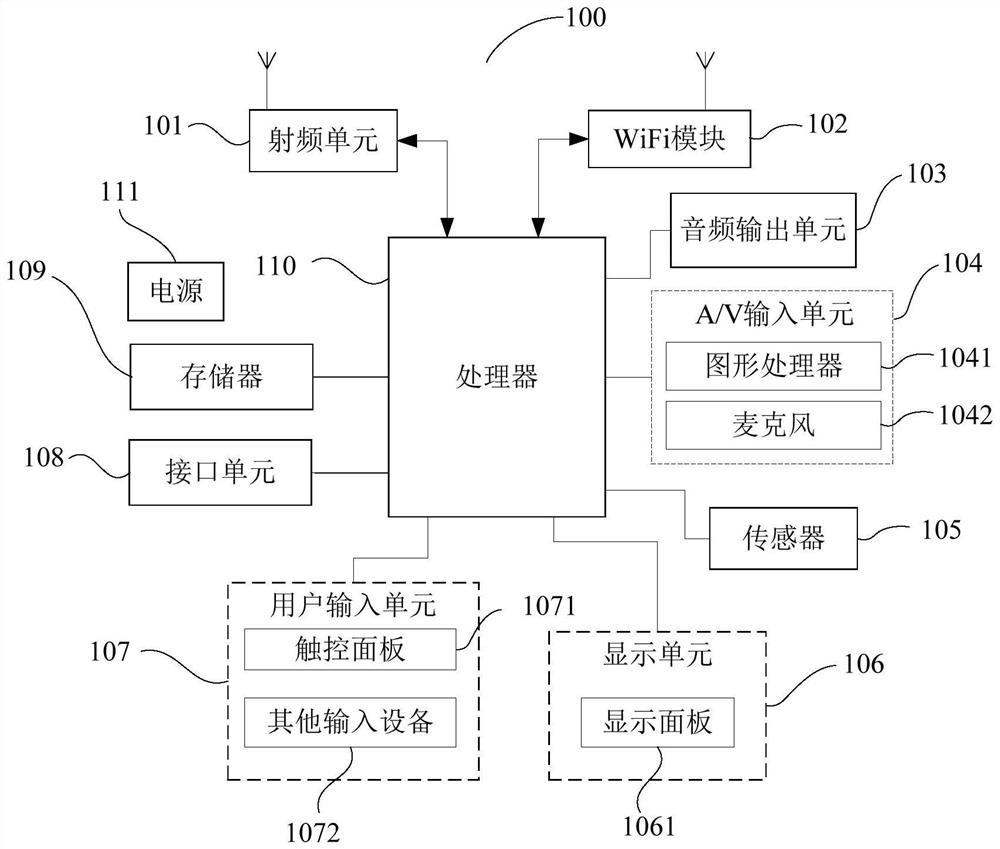

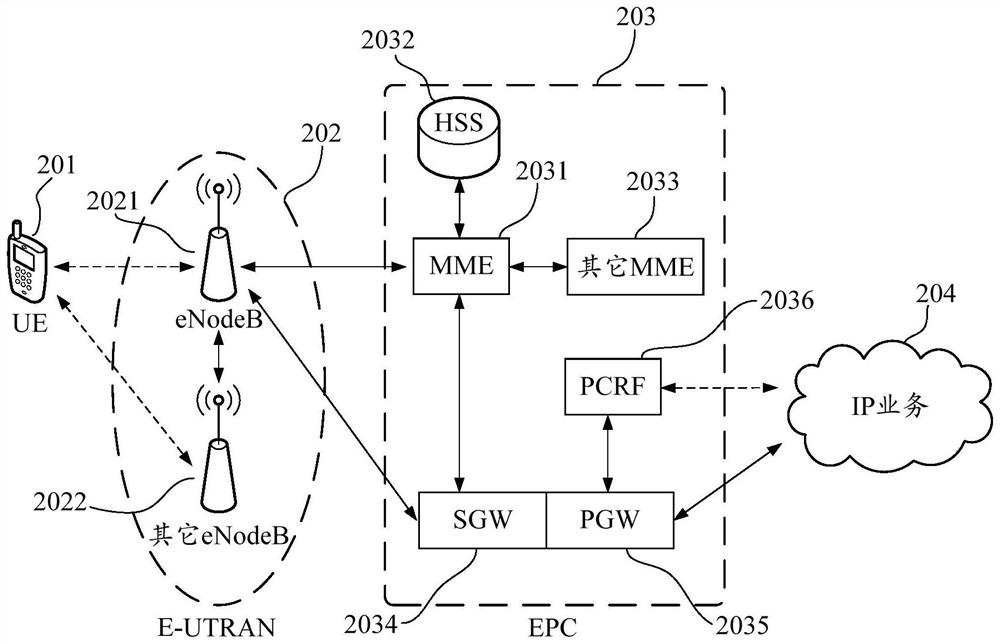

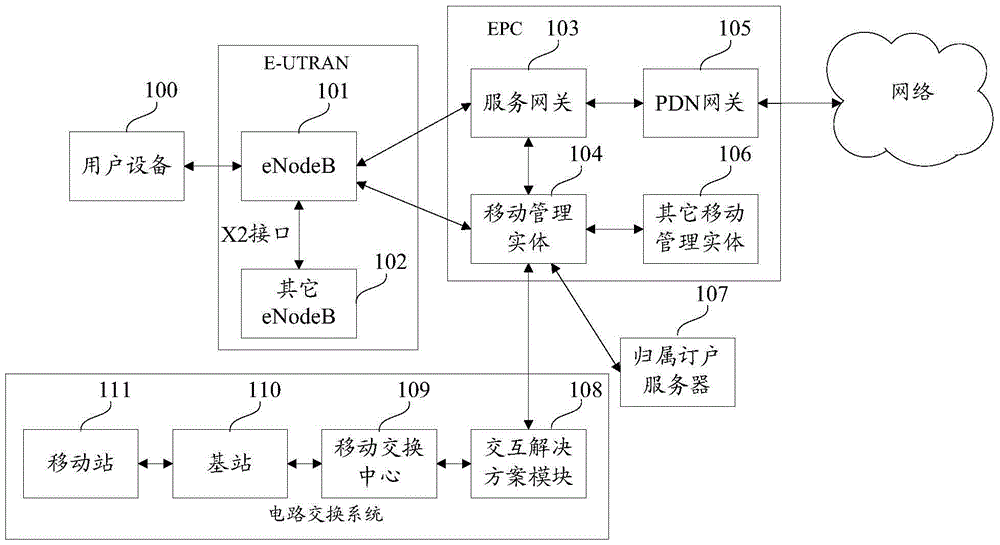

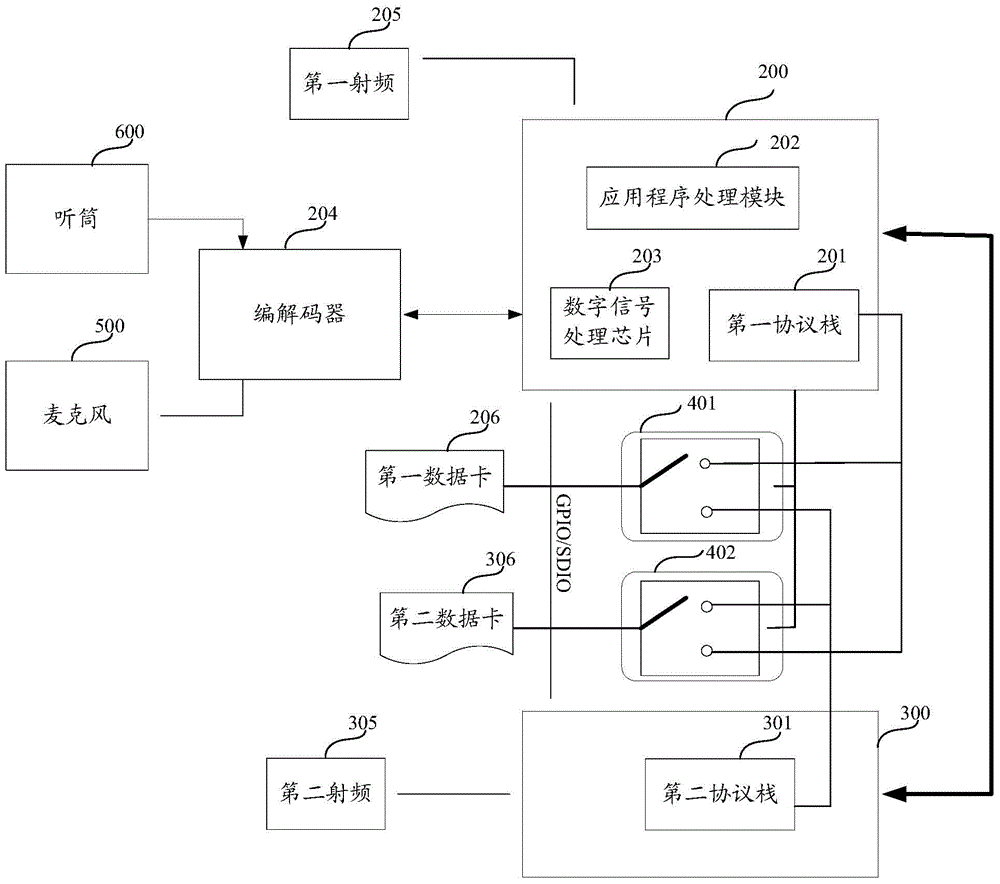

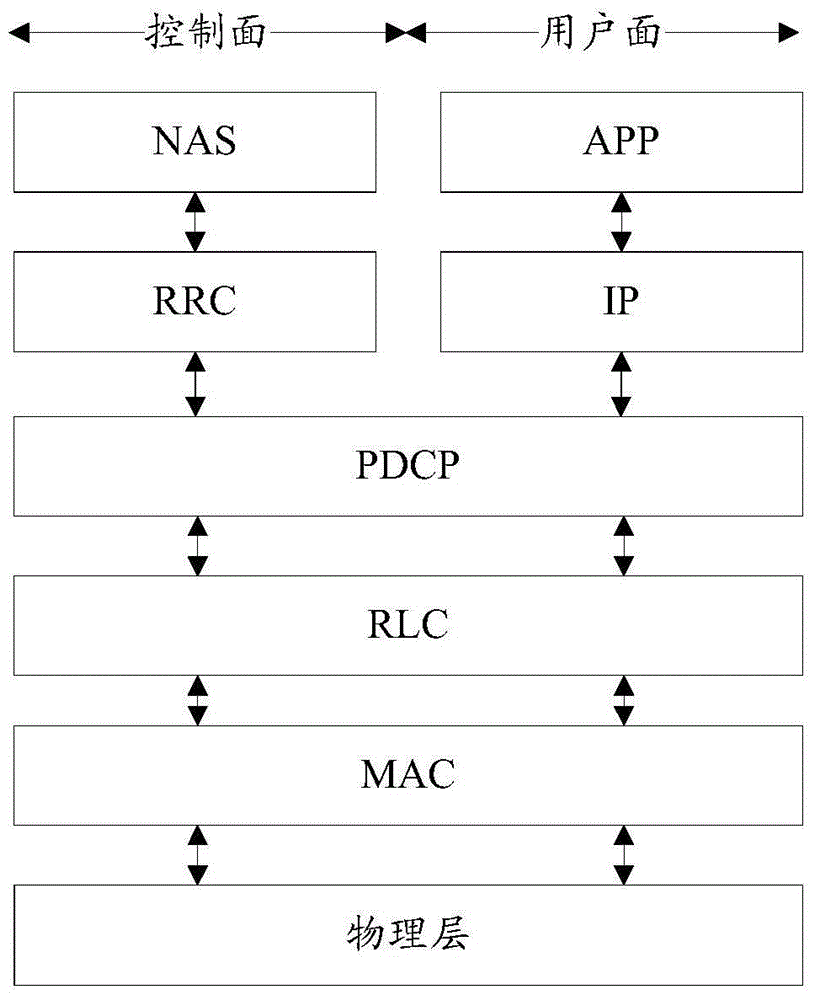

Network speed increasing device and method

InactiveCN105744570AImprove enhancement efficiencyIncrease internet speedNetwork traffic/resource managementConnection managementReal-time computingInternet access

The invention discloses a network speed increasing device. The network speed increasing device comprises a first determining module, an acquisition module and a first starting module, wherein the first determining module is used for determining whether a terminal starts a network speed increasing mode or not currently when a network speed increasing instruction is received; the acquisition module is used for acquiring Internet access channels corresponding to networks which can be connected in the terminal if the network speed increasing mode is started currently; and the first starting module is used for starting the acquired Internet access channels in order to increase a network speed of the terminal. The invention also discloses a network speed increasing method. Through the adoption of the network speed increasing device and method, the network speed increasing efficiency is increased.

Owner:NUBIA TECHNOLOGY CO LTD

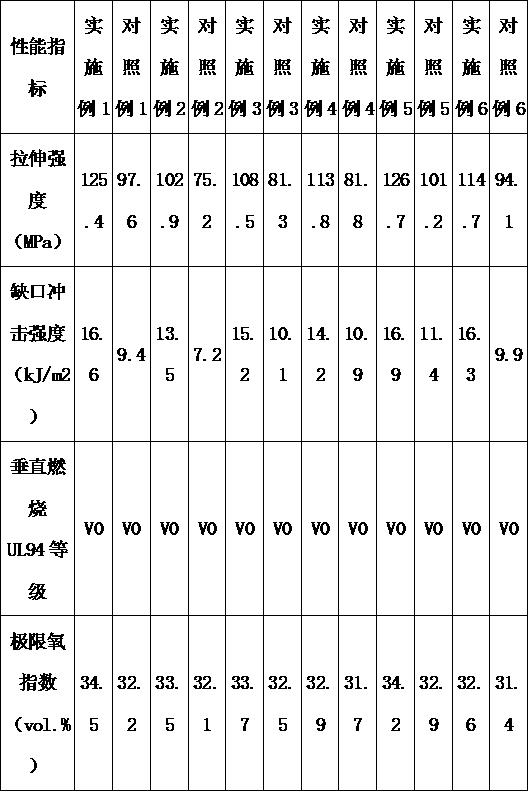

Efficient reinforced halogen-free flame retardant functional master batch for direct injection molding of PBT and preparation method of efficient reinforced halogen-free flame retardant functional master batch

ActiveCN109370175ASolve the technical problem of mismatching processing temperatureImprove enhancement efficiencyGlass fiberAntioxidant

The invention belongs to the technical field of plastic modification and processing, and particularly relates to efficient reinforced halogen-free flame retardant functional master batch capable of being directly applied to injection molding processing of PBT products and a preparation method of the efficient reinforced halogen-free flame retardant functional master batch. The multifunctional master batch is formed by a master batch body A and a master batch body B which are combined, and the master batch body A is prepared from the following components in percentage by mass: 50.0-70.0% of glass fiber, 20.0-40.0% of high-liquidity PBT resin, 5.0-10.0% of acrylic acid diglycidyl ether graft elastic ionomer, and 0.1-0.3% of antioxidant. Compared with traditional plastic functional master batch, the prepared functional master batch has the advantages that modifying effect mutual damage caused by mutual shear abrasion of the glass fiber and a fire retardant in the processing process of reinforced halogen-free flame retardant PBT resin modifying systems is avoided, meanwhile the problem that the processing temperatures of the two modifying systems are not matched is solved, and the modifying effects of the two modifying systems are remarkably enhanced; and the master batch has the advantages of being easy to disperse and process, and can be easily mixed with the PBT resin in proportion for injection molding, and an excellent modifying effect is achieved.

Owner:江苏万纳普新材料科技有限公司

Device and method for enhancing network speed

InactiveCN105828389AImprove enhancement efficiencyIncrease internet speedNetwork traffic/resource managementConnection managementEmbedded systemComputer network

Owner:NUBIA TECHNOLOGY CO LTD

High-efficiency reinforced halogen-free flame retardant functional masterbatch for polyoxymethylene direct injection molding and preparation method thereof

ActiveCN109535642BSolve the technical problem of mismatching processing temperatureAvoid damagePolyoxymethyleneMasterbatch

The invention belongs to the technical field of plastic modification and processing, and in particular relates to a high-efficiency enhanced halogen-free flame-retardant functional masterbatch and a preparation method thereof which can be directly applied to injection molding of polyoxymethylene products; the functional masterbatch is composed of A and B two It is composed of two kinds of masterbatches. The mass percentage of A masterbatch is as follows: glass fiber 50.0~70.0 wt.%, high flow polyoxymethylene 22.0~40.0 wt.%, polyoxyethylene 5.0~7.0 wt.%, polytetrafluoroethylene Powder 1.0~3.0 wt.%, Antioxidant 0.1~0.3 wt.%. Compared with the traditional plastic functional masterbatch, the functional masterbatch prepared by the present invention avoids the processing of polyoxymethylene in the enhanced halogen-free flame retardant modification system. During the process, the decomposition of the flame retardant and the matrix resin is caused by the mutual shear friction and heat generation between the glass fiber and the flame retardant, and at the same time solves the problem of mutual loss of modification performance caused by the mismatch of the processing temperature of the above two modification systems. Significantly enhanced the modification efficiency of both.

Owner:江苏万纳普新材料科技有限公司

A high-efficiency enhanced flame-retardant functional masterbatch for nylon 6 direct injection molding and its preparation method

ActiveCN109535701BGood modification effectSolve the technical problem of mismatching processing temperatureIonomerGlass fiber

Owner:江苏万纳普新材料科技有限公司

Preparation method and application of XNBR modified graphene oxide composite filler

PendingCN114573873AImprove enhancement efficiencyStrong combinationSustainable biological treatmentSilane couplingGraphite oxide

The invention discloses a preparation method of XNBR modified graphene oxide composite filler. The method comprises the following steps: modifying graphene oxide by adopting a sulfur-containing silane coupling agent to obtain modified graphene oxide; uniformly stirring and mixing the modified graphene oxide and XNBR latex according to a weight ratio of (5-10): (100-300), and drying at 60-80 DEG C until no liquid is left to obtain a modified graphene oxide / XNBR composite material; and carrying out thin passing on the modified graphene oxide / XNBR composite material on a double-roller open mill, and carrying out hot pressing in a mold to obtain the XNBR modified graphene oxide composite filler. The preparation method is simple, the obtained composite filler is safe, environmentally friendly and good in reinforcing effect, the strength of a rubber product can be improved, the processing performance of a rubber material is improved, the dimensional stability and the physical performance are improved, and the rubber product is endowed with good abrasion resistance, tearing resistance and other performance.

Owner:深圳石墨烯创新中心有限公司

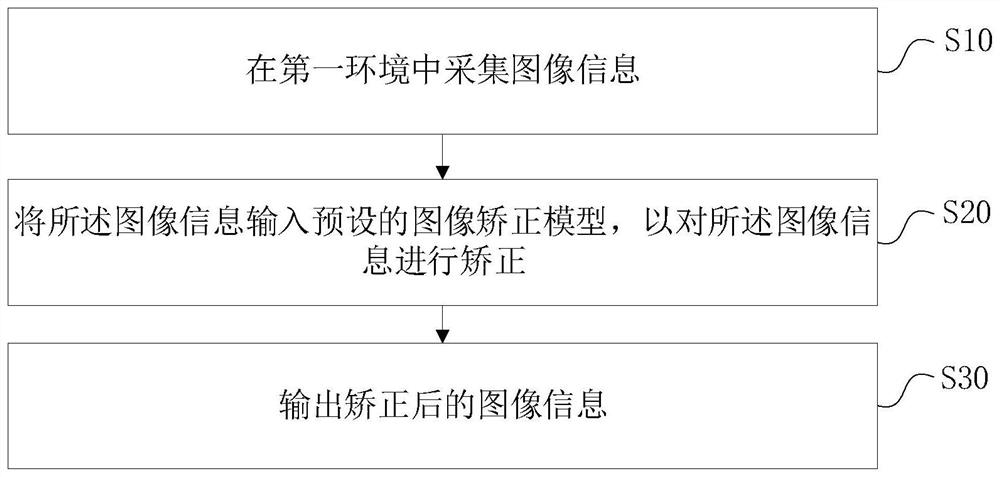

Image processing method, intelligent terminal and storage medium

PendingCN114820382AImprove enhancement efficiencySolve the problem of low enhancement efficiencyImage enhancementImage analysisImaging processingRadiology

The invention provides an image processing method, an intelligent terminal and a storage medium, and the image processing method can be applied to the intelligent terminal, and comprises the following steps: collecting image information in a first environment; inputting the image information into a preset image correction model to correct the image information; and outputting the corrected image information. According to the invention, the image information collected in the first environment is input into the preset image correction model, so that the image information is corrected, and the enhancement efficiency of the image is improved.

Owner:SHANGHAI TRANSSION CO LTD

Efficient enhanced flame-retardant multifunctional master batch for direct injection molding of PBT

ActiveCN109486131AGood modification effectSolve the technical problem of mismatching processing temperatureGlass fiberIonomer

The invention belongs to the technical fields of plastic modification and processing and particularly relates to an efficient enhanced flame-retardant multifunctional master batch which can be directly applied to the direct injection molding of PBT products and a preparation method of the master batch. The multifunctional master batch is formed by the combination of a master batch A and a master batch B, wherein the master batch A contains the following components in percentage by weight: 50.0wt%-70.0wt% of glass fibers, 15.0wt%-30.0wt% of high-flow PBT resin, 5.0wt%-10.0wt% of diglycidyl ether acrylate grafted elastic ionomer and 0.1wt%-0.3wt% of an antioxidant. Compared with a traditional plastic functional master batch, the prepared functional master batch has the advantages that the mutual loss of the modification effects caused due to the mutual shear loss between the glass fibers and the flame retardant in the processing process of an enhanced bromine-series PBT resin modification system is avoided, the problem that the processing temperatures of two modification systems are not matched is solved, and the modification effects of the two systems are remarkably improved; and the multifunctional master batch has the characteristics of easiness in dispersion and processing and can be subjected to injection molding after being simply mixed with PBT resin in proportion, and anexcellent modification effect is achieved.

Owner:江苏万纳普新材料科技有限公司

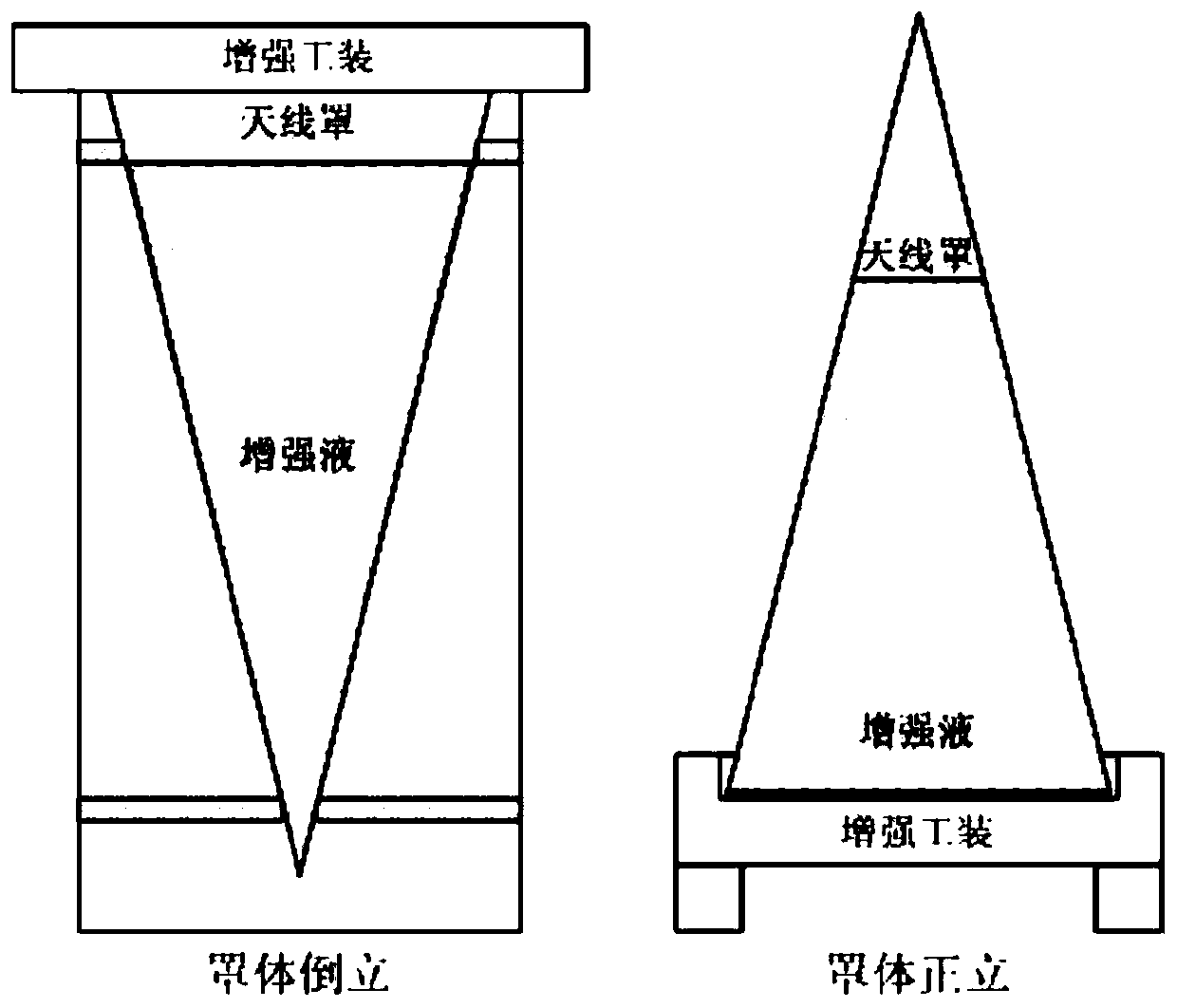

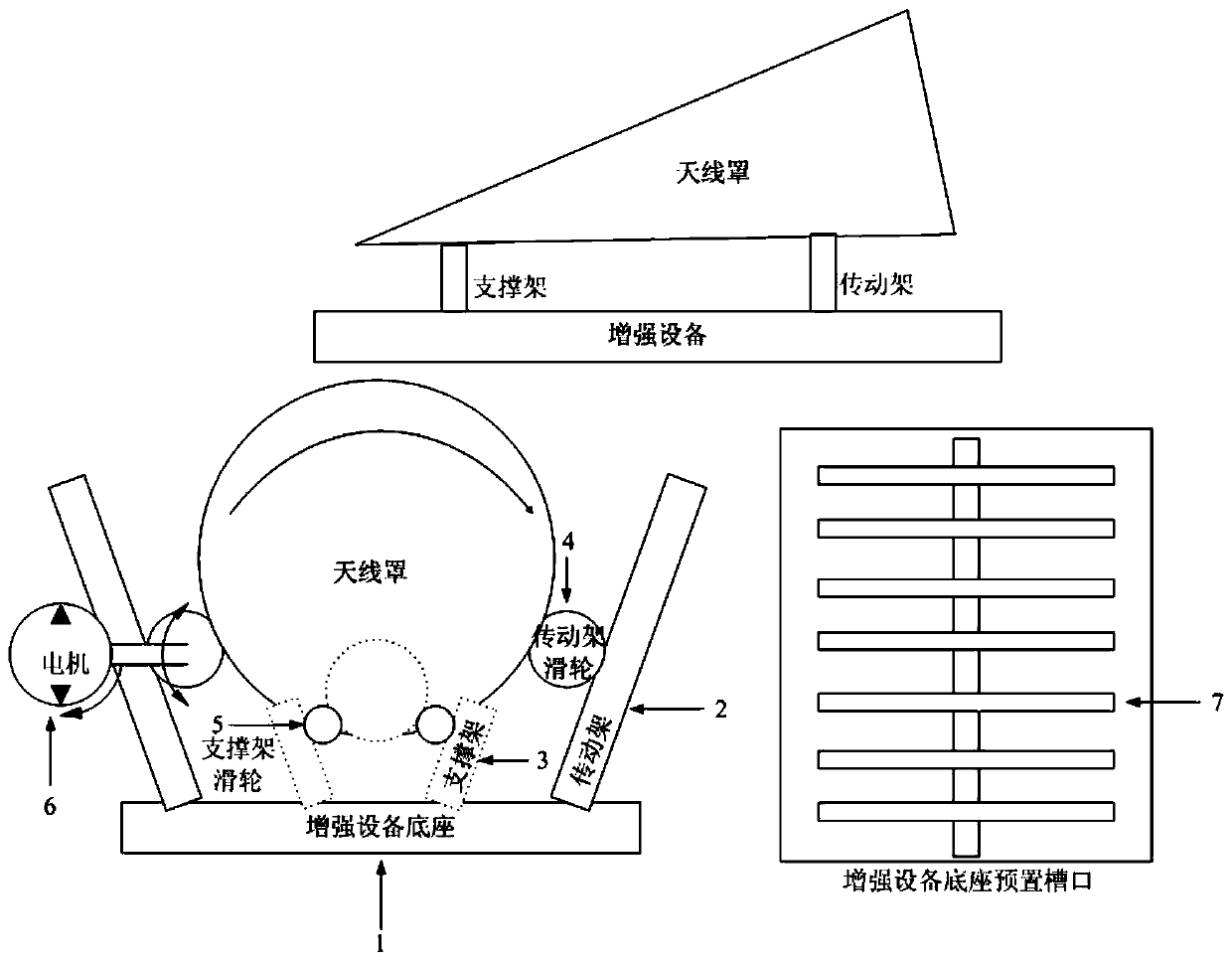

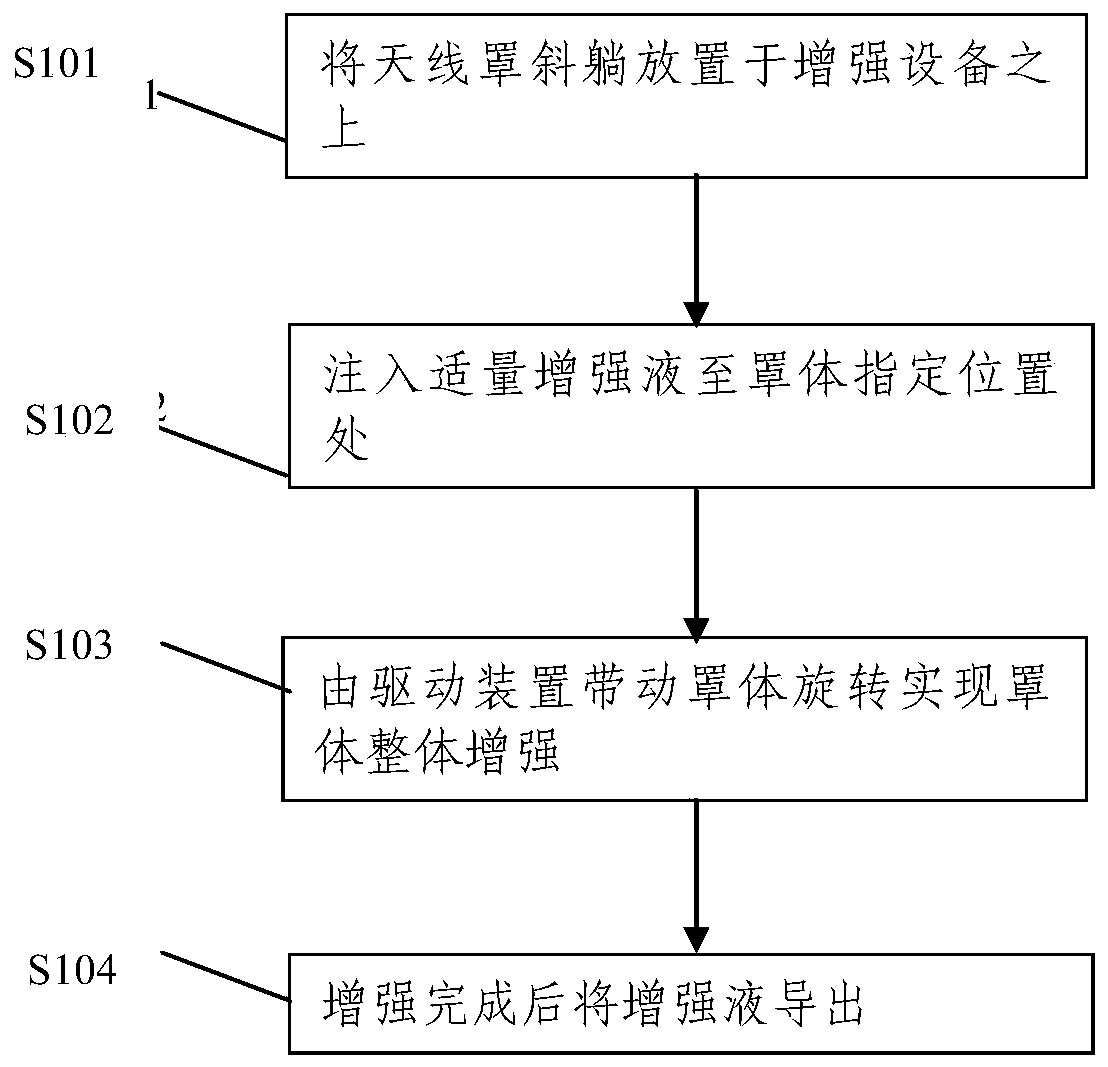

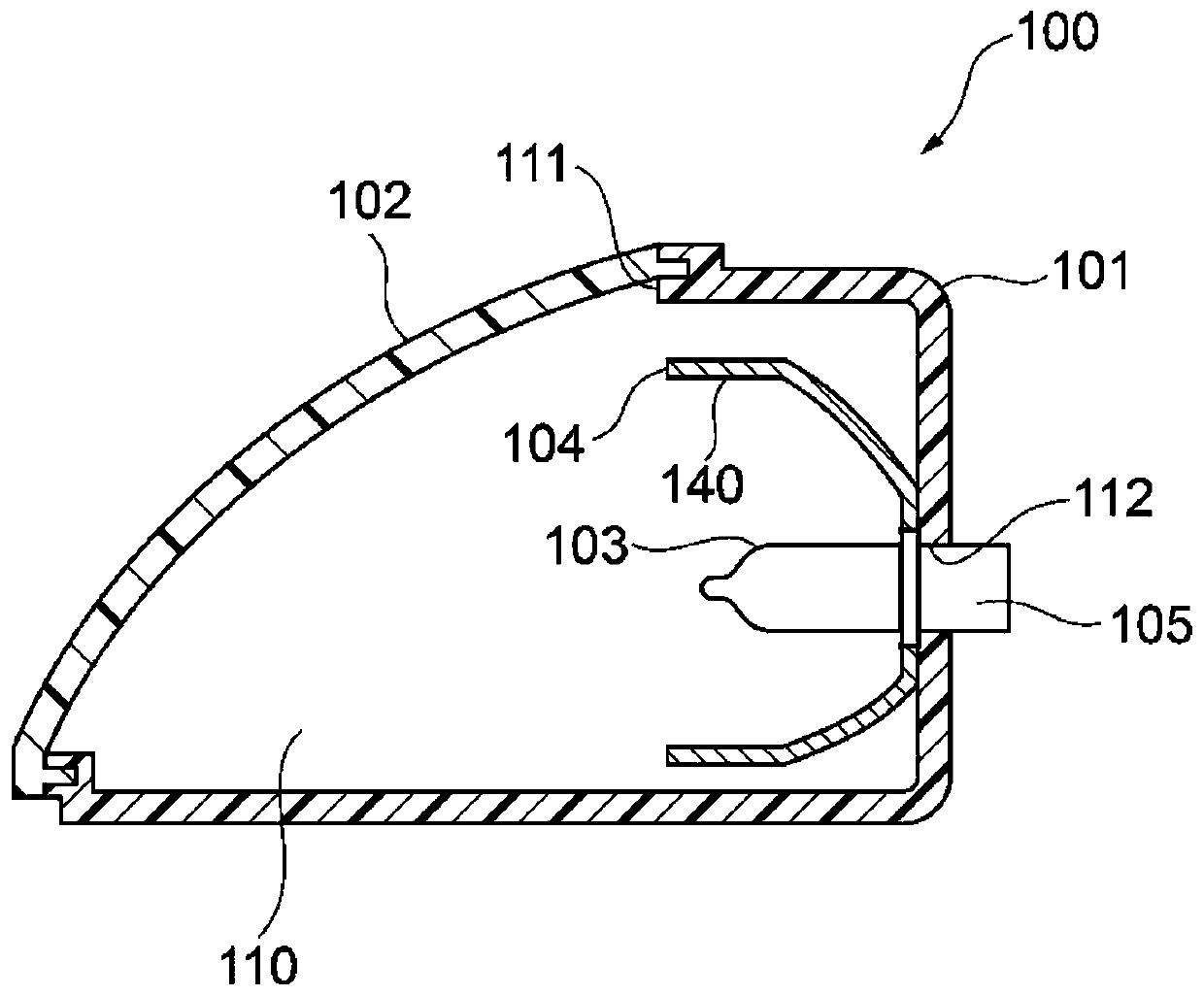

Antenna housing enhancing system and antenna housing enhancing method

InactiveCN110193449AImprove enhancement efficiencyOvercome the inefficiency of static enhancementLiquid surface applicatorsCoatingsStructural dimensionPulley

The invention discloses an antenna housing enhancing system and an antenna housing enhancing method. The antenna housing enhancing system comprises enhancing equipment. Positions of a transmission rack and a supporting rack of the enhancing equipment are adjusted through a preset notch in an enhanced equipment base to fit antenna housings of different structural dimensions. The antenna housing isobliquely placed on the enhancing equipment, the head of the antenna housing is placed on a pulley of the supporting rack, the bottom end of the antenna housing is placed on a pulley of the transmission rack, and the pulley of the transmission rack is connected to a driving device. The antenna housing enhancing method comprises the following steps: placing the antenna housing obliquely to the enhancing equipment; injecting an enhancing liquid to an appointed position of a housing body; driving the housing body to integrally enhance the housing body by a driving device; and exporting the enhancing liquid after enhancement. The antenna housing enhancing system and the antenna housing enhancing method have the advantages that the system and the method are easy to implement, the antenna housings of different structural dimensions can be enhanced only with a proper amount of the enhancing liquid, a complex process of injecting and exporting a lot of enhancing liquid in conventional methodsis avoided, and the antenna housing is enhanced dynamically by rotating the housing body, so that the low efficiency defect of static enhancing in the conventional methods is overcome, the antenna housing enhancing efficiency is improved greatly, and the system and the device are in particular suitable for large dimension antenna housings.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

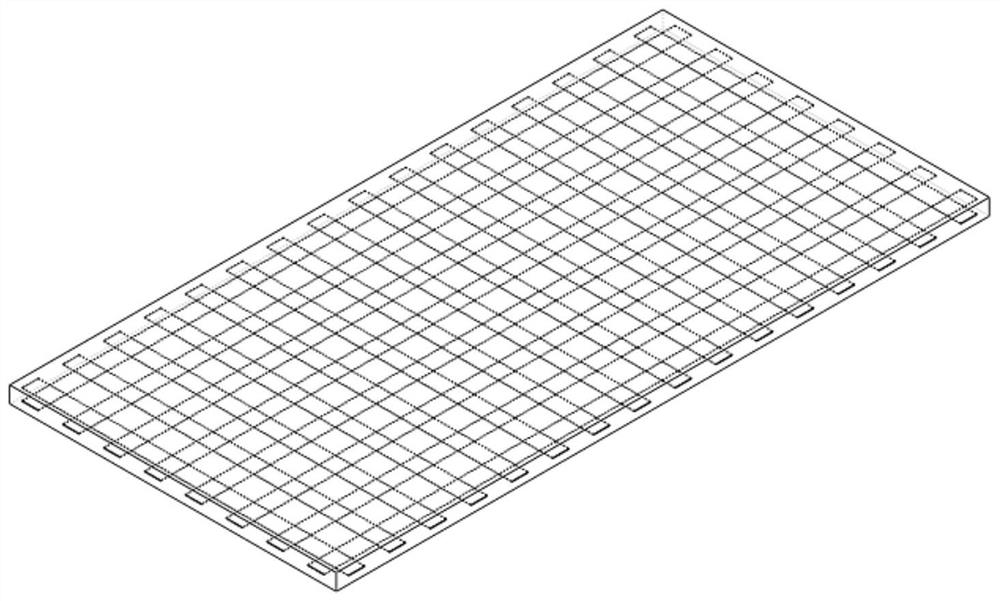

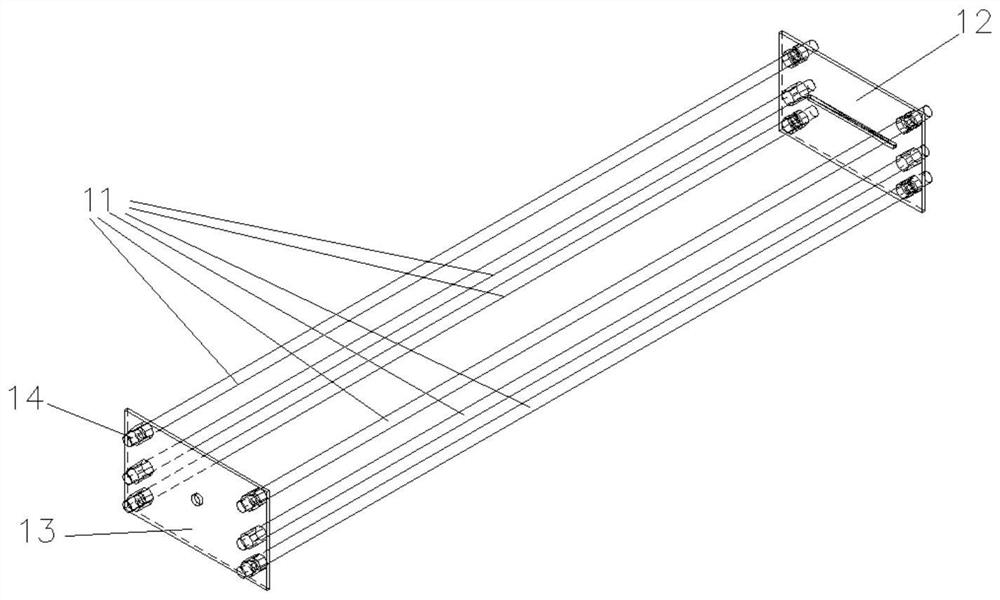

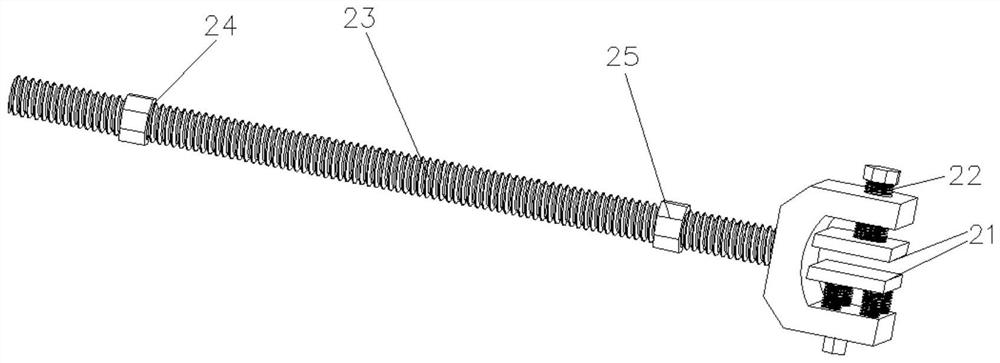

FRCM plate prestress applying and loss monitoring process and product thereof

PendingCN114396136AGood coordinationImprove enhancement efficiencyConstruction materialBuilding reinforcementsWave shapeStructural engineering

The invention discloses an FRCM plate prestress applying and loss monitoring process and a product thereof. The process comprises the following steps: laying a fiber net in a mold cavity, enabling one end of a longitudinal fiber bundle to penetrate through a second end baffle which is fixedly arranged, and then sequentially penetrating into a second load sensor and a second wave-shaped anchorage device; the other end of the first load sensor penetrates through the base plate, the first load sensor and the first sleeve in sequence and is fixedly connected with the counter-force frame and the center hole jack through the fiber bundle clamp, the clamp screw and the nut; jacking the cross-core jack to drive the fiber bundle clamp to move, tensioning the longitudinal fiber bundle until the reading of the second load sensor reaches the standard, and screwing a nut at the counter-force frame to complete tensioning; a first wave-shaped clamping piece is arranged in a first sleeve to be assembled into a first wave-shaped anchorage device, and the first wave-shaped anchorage device tightly abuts against a first load sensor; and pouring, maintaining, removing the mold, reversely rotating the nuts at the counter-force frame to perform pre-stress releasing, and cutting off the longitudinal fiber bundles to obtain the FRCM plate.

Owner:ZHEJIANG UNIV

A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for nylon 6 direct injection molding and its preparation method

ActiveCN109370210BSolve the technical problem of mismatching processing temperatureAvoid damageGlass fiberIonomer

Owner:江苏万纳普新材料科技有限公司

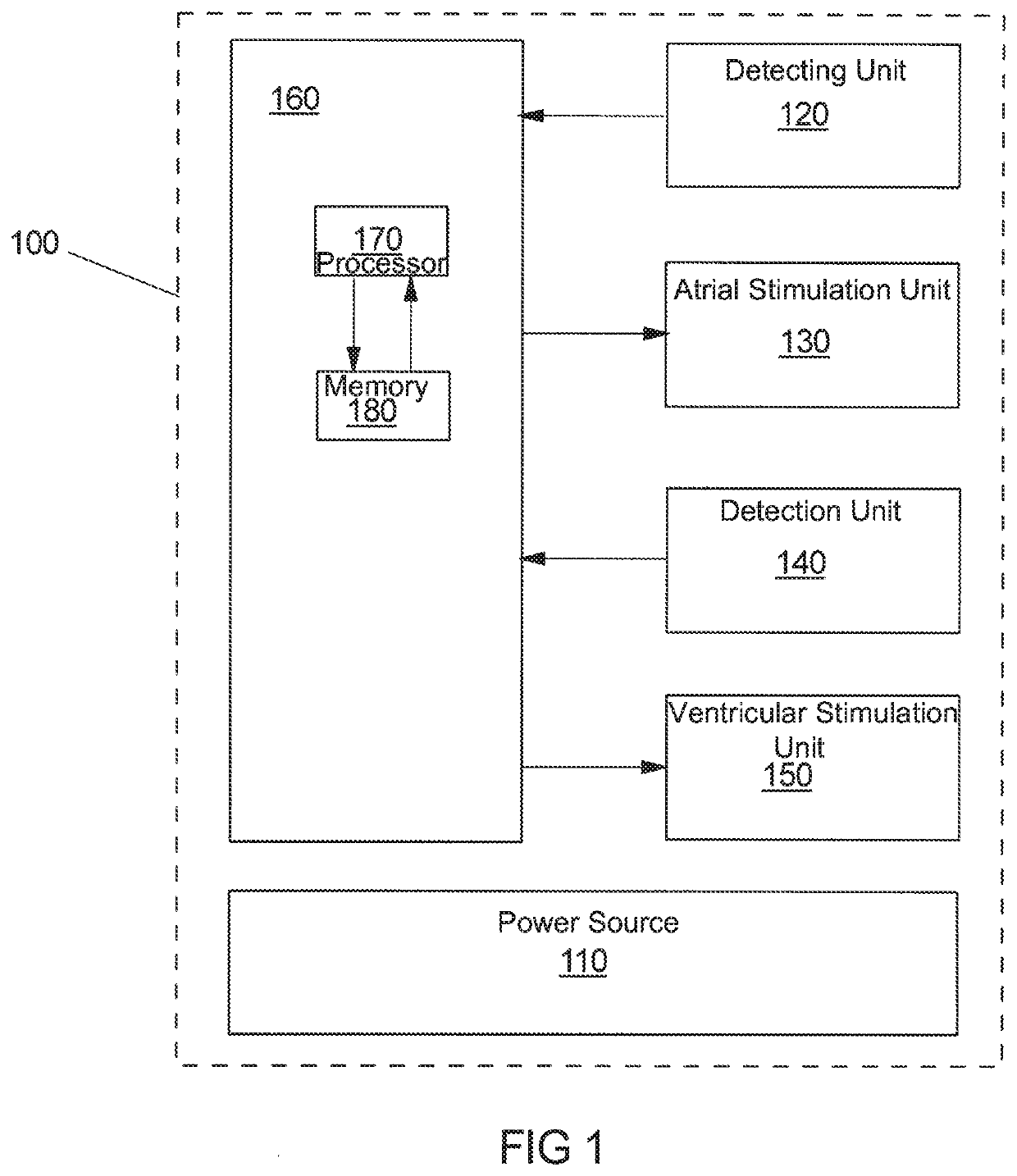

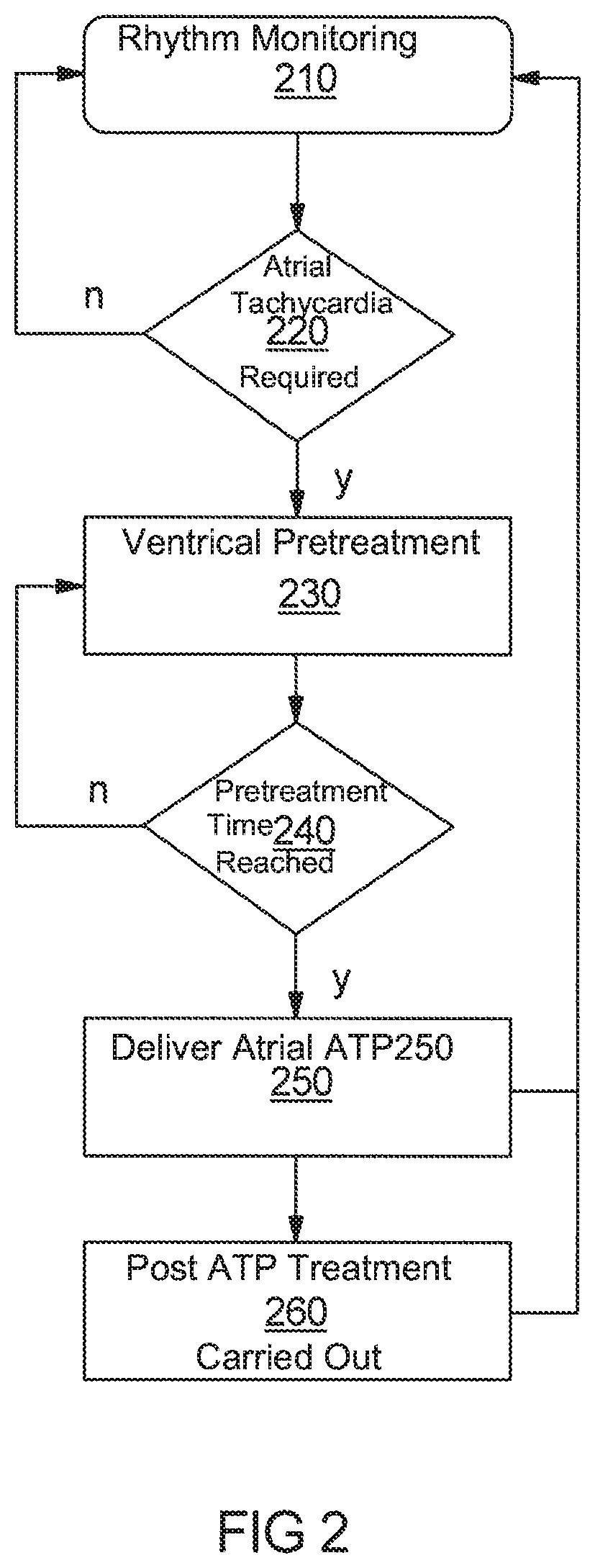

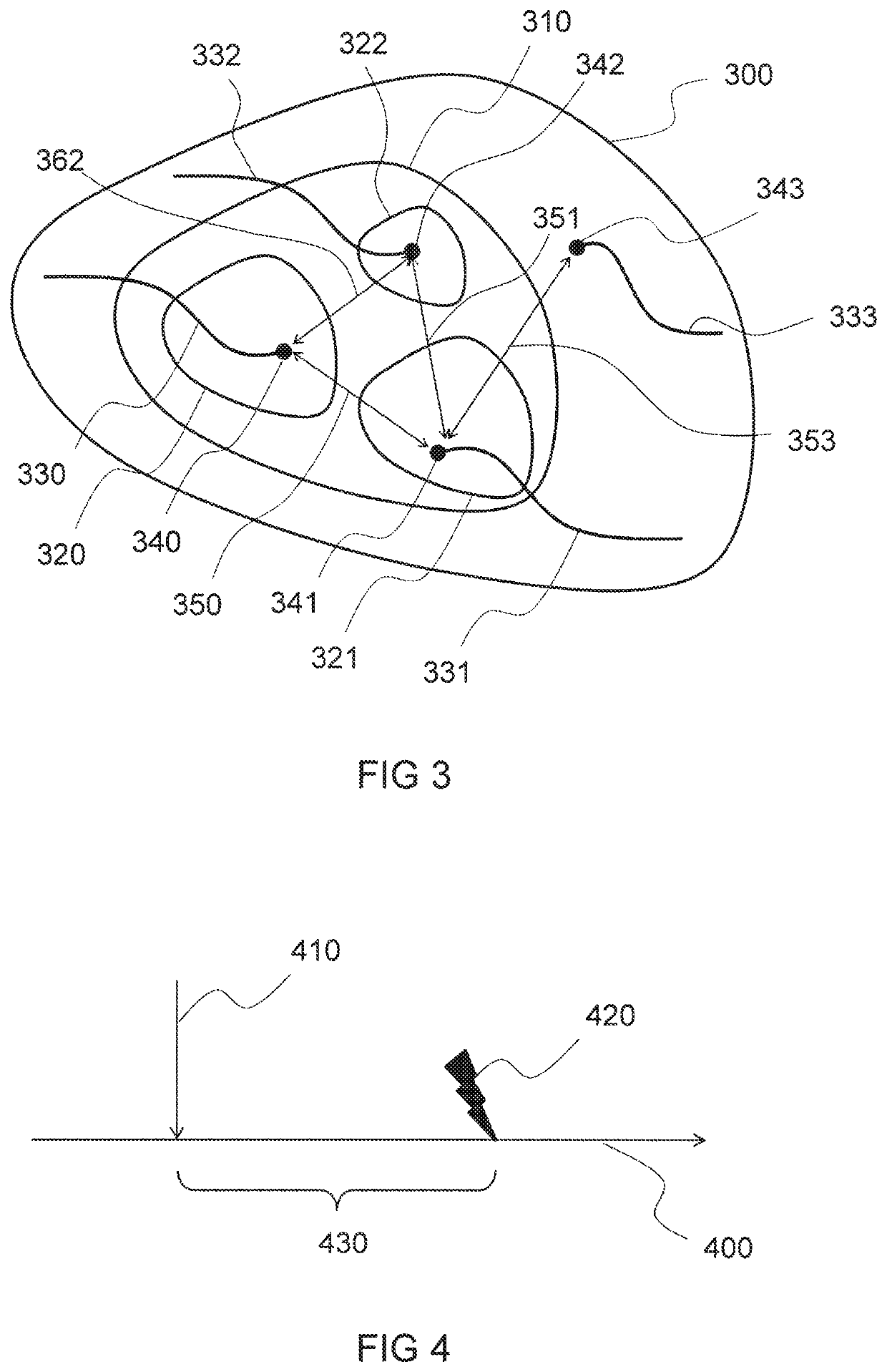

Implantable system for the diagnostic and/or theraputic treatment of a human patient or an animal patient

ActiveUS20200330779A1Extended service lifeConsider comfortTherapiesHeart defibrillatorsHuman patientTherapeutic treatment

An implantable system for the diagnostic and / or therapeutic treatment of a human or animal patient contains a processor, a memory, a treatment unit and a remote data transmission unit. The system is characterized in that the memory includes a computer-readable program which prompts the processor to carry out the following steps when the program is being executed on the processor: a) ascertaining whether a treatment functionality of the treatment unit could jeopardize a patient in whom the system was implanted if a diagnostic and / or therapeutic treatment of the patient corresponding to the treatment functionality were to be carried out; b) deactivating the treatment functionality when a potential risk for the patient was ascertained; c) receiving reactivation data by way of the remote data transmission unit; and d) reactivating the deactivated treatment functionality based on the received reactivation data.

Owner:BIOTRONIK SE & CO KG

Network speed enhancement device and method

InactiveCN105898887AImprove enhancement efficiencyIncrease internet speedConnection managementComputer hardwareInternet channel

Owner:NUBIA TECHNOLOGY CO LTD

Foam reinforced sandwich structure with fiber bundle and preparation method using sewing-thermal expansion curing molding

InactiveCN101508190BNot bentImprove enhancement efficiencyLaminationLamination apparatusFiber bundleThermal expansion

The invention discloses a reinforced foam interlayer structure with fiber bundles and a preparation method by adopting sewing-thermal expansion curing molding. according to certain pin length d1, pin pitch d3 and row pitch d2, the fiber bundles are connected up and down and sewed on a preforming body in the depth direction of the preforming body so as to realize that an upper panel, a compressed core material and a lower panel are sewed together; subsequently, at temperature of between 60 and 220 DEG C, foam core expands to produce expansion pressure of between 0.05 and 0.7 MPa; after the foam core is cured for 30 and 300 minutes at expansion pressure, the foam core is cooled and demoulded and the reinforced foam interlayer structure with fiber bundles is obtained.

Owner:BEIHANG UNIV

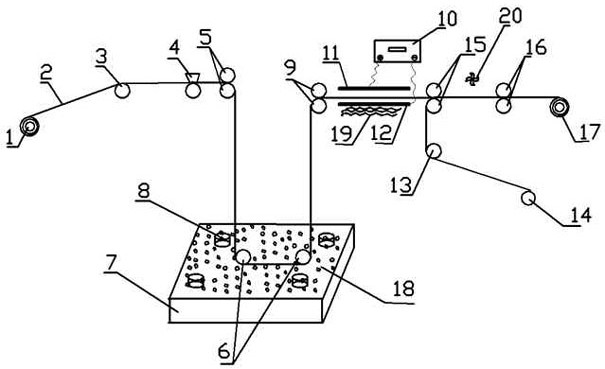

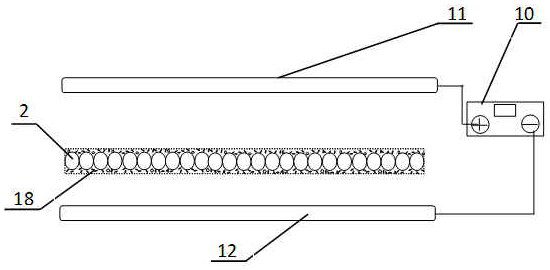

Continuous preparation device for conductive micro-nano material modified prepreg

The invention discloses a continuous preparation device for a conductive micro-nano material modified prepreg. The continuous preparation device comprises a fiber tow unfolding device, a fiber dipping glue tank, a prepreg thickness adjusting roller set, a high-voltage direct-current power supply and a prepreg winding device. An ultrasonic probe is arranged in the fiber impregnation tank, and uniform dispersion of a conductive micro-nano material in a resin glue solution is mainly realized; the high-voltage direct-current power supply is mainly used for constructing a high-strength uniform electric field, and directional control on the conductive micro-nano material is achieved through an electric field orientation method. While the yield of the conductive micro-nano material / fiber reinforced thermosetting resin-based prepreg is increased, the problems of agglomeration and random dispersion of the conductive micro-nano material in the resin are solved, and the device has a positive effect on improvement of the performance of the composite material.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

A kind of high-efficiency enhanced flame-retardant functional master batch for PBT direct injection molding and preparation method thereof

ActiveCN109486131BGood modification effectSolve the technical problem of mismatching processing temperatureGlass fiberIonomer

The invention belongs to the technical fields of plastic modification and processing and particularly relates to an efficient enhanced flame-retardant multifunctional master batch which can be directly applied to the direct injection molding of PBT products and a preparation method of the master batch. The multifunctional master batch is formed by the combination of a master batch A and a master batch B, wherein the master batch A contains the following components in percentage by weight: 50.0wt%-70.0wt% of glass fibers, 15.0wt%-30.0wt% of high-flow PBT resin, 5.0wt%-10.0wt% of diglycidyl ether acrylate grafted elastic ionomer and 0.1wt%-0.3wt% of an antioxidant. Compared with a traditional plastic functional master batch, the prepared functional master batch has the advantages that the mutual loss of the modification effects caused due to the mutual shear loss between the glass fibers and the flame retardant in the processing process of an enhanced bromine-series PBT resin modification system is avoided, the problem that the processing temperatures of two modification systems are not matched is solved, and the modification effects of the two systems are remarkably improved; and the multifunctional master batch has the characteristics of easiness in dispersion and processing and can be subjected to injection molding after being simply mixed with PBT resin in proportion, and anexcellent modification effect is achieved.

Owner:江苏万纳普新材料科技有限公司

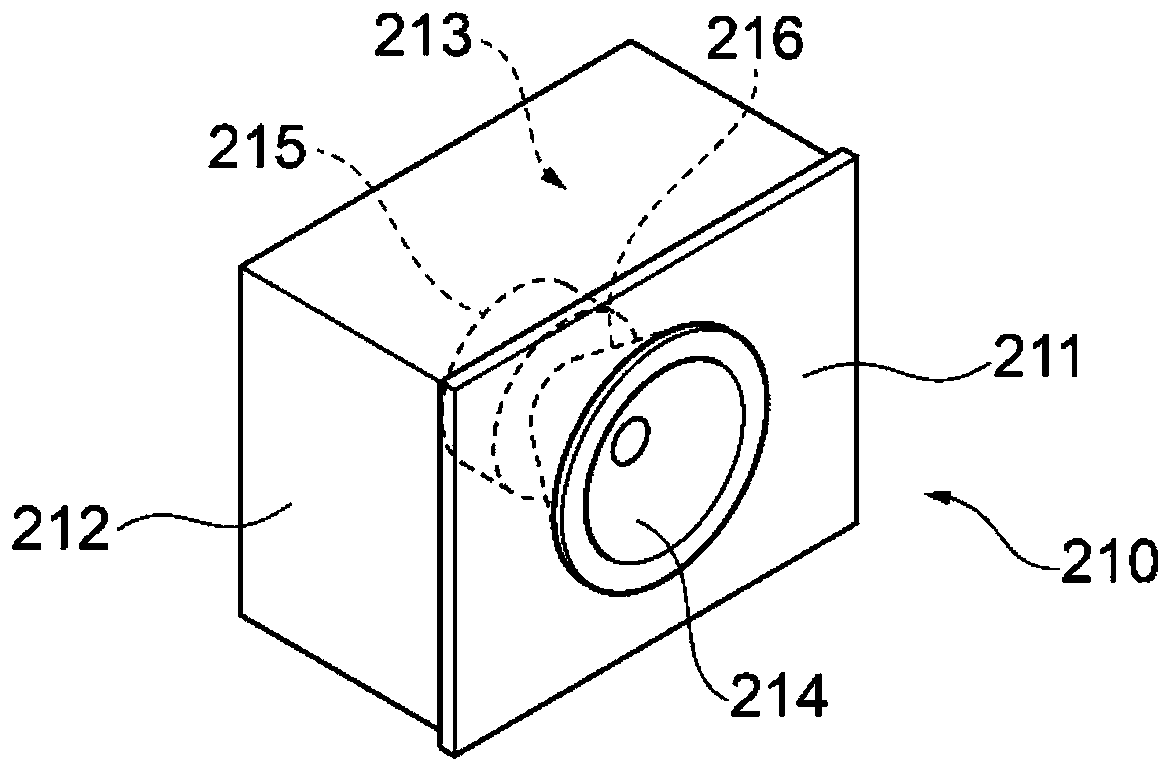

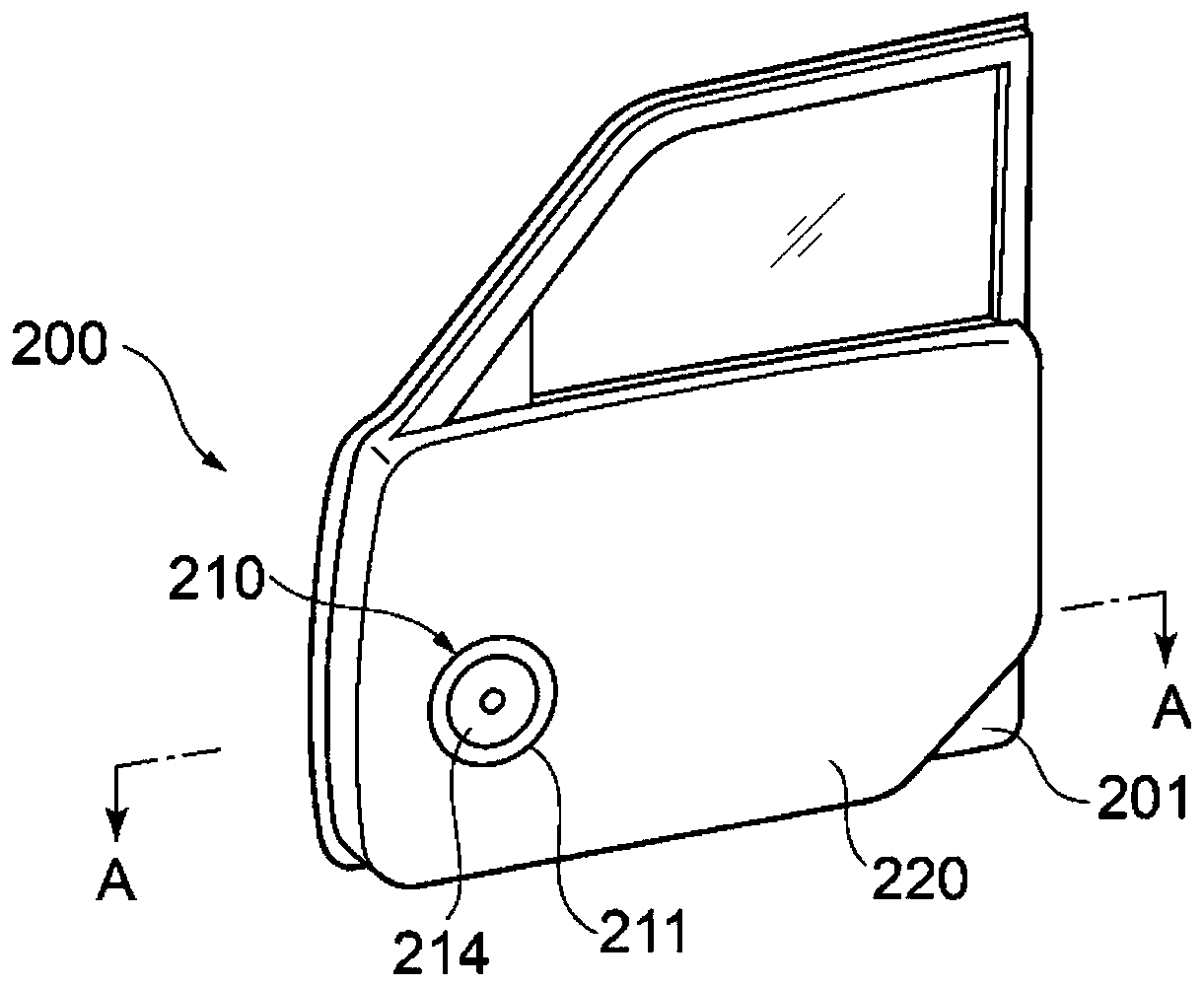

Molded article

PendingCN111183187AImprove enhancement efficiencyNo aggregationProtective devices for lightingPortable liftingCellulosePolymer science

The present invention relates to a molded article which comprises a resin part that is formed of a thermoplastic resin composition wherein refined cellulose is uniformly dispersed in a thermoplastic resin. This molded article comprises a resin part that is formed of a thermoplastic resin composition which contains a thermoplastic resin, cellulose and an ionic compound, and which is configured suchthat: the content of the cellulose is 1 to 100 parts by mass relative to 100 parts by mass of the thermoplastic resin; and the content of the ionic compound is 0.001 times or more but less than 1.000times the content of the cellulose.

Owner:FURUKAWA ELECTRIC CO LTD

A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for PBT direct injection molding and its preparation method

ActiveCN109370175BSolve the technical problem of mismatching processing temperatureImprove enhancement efficiencyPolymer scienceInjection moulding

The invention belongs to the technical field of plastic modification and processing, and particularly relates to efficient reinforced halogen-free flame retardant functional master batch capable of being directly applied to injection molding processing of PBT products and a preparation method of the efficient reinforced halogen-free flame retardant functional master batch. The multifunctional master batch is formed by a master batch body A and a master batch body B which are combined, and the master batch body A is prepared from the following components in percentage by mass: 50.0-70.0% of glass fiber, 20.0-40.0% of high-liquidity PBT resin, 5.0-10.0% of acrylic acid diglycidyl ether graft elastic ionomer, and 0.1-0.3% of antioxidant. Compared with traditional plastic functional master batch, the prepared functional master batch has the advantages that modifying effect mutual damage caused by mutual shear abrasion of the glass fiber and a fire retardant in the processing process of reinforced halogen-free flame retardant PBT resin modifying systems is avoided, meanwhile the problem that the processing temperatures of the two modifying systems are not matched is solved, and the modifying effects of the two modifying systems are remarkably enhanced; and the master batch has the advantages of being easy to disperse and process, and can be easily mixed with the PBT resin in proportion for injection molding, and an excellent modifying effect is achieved.

Owner:江苏万纳普新材料科技有限公司

A kind of high-efficiency reinforced flame-retardant functional masterbatch for direct injection molding of polypropylene and preparation method thereof

ActiveCN109535559BGood modification effectSolve the technical problem of mismatching processing temperatureGlass fiberIonomer

The invention belongs to the technical field of plastic modification and processing, and in particular relates to a high-efficiency enhanced flame-retardant functional masterbatch which can be directly applied to injection molding processing of polypropylene products and a preparation method thereof; The mass percentage composition of A masterbatch is as follows: glass fiber 50.0-70.0 wt.%, high-flow polypropylene 15.0-35.0 wt.%, elastic ionomer 5.0-10.0 wt.%, atactic polypropylene 3.0 ~6.0 wt.%, maleic anhydride grafted polypropylene 1.0~3.0 wt.%, polytetrafluoroethylene powder 1.0~3.0 wt.%, antioxidant 0.1~0.3 wt.%; the functional masterbatch of the present invention has It is easy to disperse and process, and can be simply mixed with polypropylene resin according to the ratio and then injection molded.

Owner:江苏万纳普新材料科技有限公司

A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for polypropylene direct injection molding and its preparation method

ActiveCN109486013BSolve the technical problem of mismatching processing temperatureAvoid damagePolymer sciencePolypropylene

The invention belongs to the technical field of plastic modification and processing, and in particular relates to a high-efficiency enhanced halogen-free flame-retardant functional masterbatch and a preparation method thereof which can be directly applied to injection molding of polypropylene products; the functional masterbatch is composed of A and B two A combination of masterbatches, the mass percentage of A masterbatch is as follows: glass fiber 50.0~70.0 wt.%, high flow polypropylene 15.0~35.0 wt.%, elastic ionomer 5.0~10.0wt.%, random polymer 3.0-6.0 wt.% of propylene, 1.0-3.0 wt.% of maleic anhydride grafted polypropylene, 1.0-3.0 wt.% of polytetrafluoroethylene powder, 0.1-0.3 wt.% of antioxidant; prepared by the present invention Compared with the traditional plastic functional masterbatch, the functional masterbatch avoids the modification effect caused by the mutual shear friction and heat generation between the glass fiber and the flame retardant during the processing of the enhanced halogen-free flame retardant polypropylene modification system, and solves the problem at the same time. It solves the problem of mutual loss of modification performance caused by the mismatch of the processing temperature of the above two modification systems, and significantly enhances the modification performance of the two.

Owner:江苏万纳普新材料科技有限公司

Method for enhancing optical image

ActiveCN102063702BImpact enhancementSuitable for realizationImage enhancementMarine navigationOptical image

The invention relates to a method for enhancing an optical image. The method comprises the following steps of: 1, inputting an image acquired in photoelectric navigation; 2, performing point-by-point scanning on the image, and acquiring a pixel value, namely pixel (a, b) of the current pixel point; 3, acquiring pixel values of adjacent pixel points at the top left corner, the bottom left corner, the top right corner and the bottom right corner of the current pixel point respectively; 4, solving relative difference values, namely difpix of the current pixel point and (2<n> + 2<m>) adjacent pixel points obtained in the step 3; 5, solving an absolute value of the relative difference value, namely the absolute value of difpix, comparing the absolute value with a set threshold, namely TH4, setting the pixel value of the current pixel point with a coordinate value of a (a, b) point to be the absolute value of difpix multiplying by M when the absolute value is larger than the threshold, namely the TH4, and setting the pixel value of the current pixel point with the coordinate value of the (a, b) point to be 0 when the absolute value is smaller than the threshold, namely the TH4; and 6, after performing the point-by-point scanning on the image, acquiring an enhanced contrast image. The method is easy to operate, good in enhancement effect and suitable for circuit realization, and enhancement efficiency is improved.

Owner:江苏钜芯集成电路技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com