Efficient reinforced halogen-free flame retardant functional master batch for direct injection molding of PBT and preparation method of efficient reinforced halogen-free flame retardant functional master batch

A technology of injection molding and functional masterbatch, applied in the field of high-efficiency reinforced halogen-free flame retardant functional masterbatch and its preparation, can solve the problems of decreased fiber aspect ratio, temperature mismatch, etc. Enhanced efficiency, excellent dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

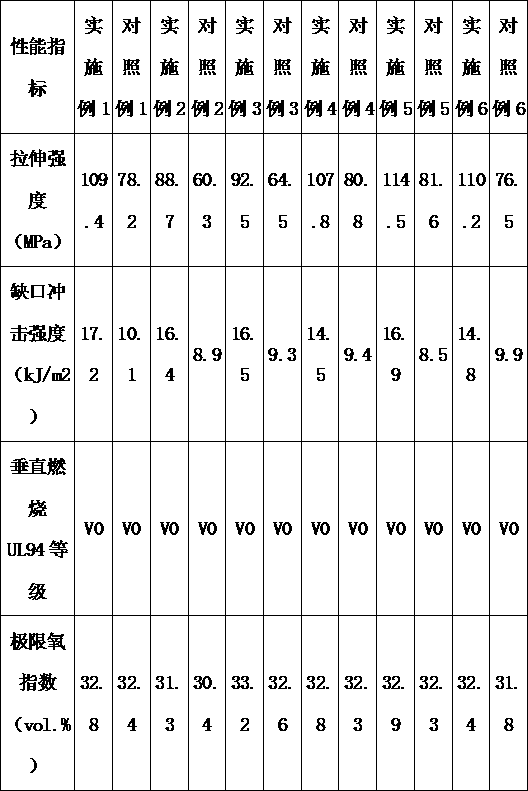

Examples

Embodiment 1

[0036] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for direct injection molding of PBT resin, which is composed of two masterbatches A and B, and the quality ratio of the raw materials of the A masterbatch is as follows:

[0037] glass fiber

70.0kg

High Flow PBT Resin

20.0kg

Acrylic acid diglycidyl ether grafted sodium ion crosslinked ethylene-octene-acrylic acid copolymer elastic ionomer

9.7kg

300.0g

[0038] The antioxidants are 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name Antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

[0039] The mass ratio of the raw materials of the B masterbatch is as follows:

[0040] Aluminum methyl ethyl hypophosphite

60.0kg

Melamine cyanurate

25.0kg

Acrylic acid diglycidyl ether grafted sodiu...

Embodiment 2

[0044] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for direct injection molding of PBT resin, which is composed of two masterbatches A and B, and the quality ratio of the raw materials of the A masterbatch is as follows:

[0045] glass fiber

50.0kg

High Flow PBT Resin

40.0kg

Acrylic acid diglycidyl ether grafted with zinc ions to crosslink ethylene-octene-acrylic acid copolymer elastic ionomer

9.7kg

300.0g

[0046] The antioxidants are 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name Antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

[0047] The mass ratio of the raw materials of the B masterbatch is as follows:

[0048] Ammonium polyphosphate

40.0kg

Melamine cyanurate

45.0kg

Embodiment 3

[0052] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for direct injection molding of PBT resin, which is composed of two masterbatches A and B, and the quality ratio of the raw materials of the A masterbatch is as follows:

[0053] glass fiber

60.0kg

High Flow PBT Resin

30.7kg

Acrylic acid diglycidyl ether grafted barium ion crosslinked ethylene-octene-acrylic acid copolymer elastic ionomer

9.0kg

antioxidant

300.0g

[0054] The antioxidants are 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name Antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

[0055] The mass ratio of the raw materials of the B masterbatch is as follows:

[0056] aluminum diethyl hypophosphite

35.0kg

25.0kg

25.0kg

Acrylic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com