Molded article

A molding product, thermoplastic resin technology, applied in the direction of hoisting device, coupling device, lighting and heating equipment, etc., can solve the problems of easy to corrode mold, complicated steps, limited cost reduction, etc., achieve high strength, dimensional accuracy, manufacturing Cost reduction and excellent acoustic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0228] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited by these examples. The materials used are shown below.

[0229]

[0230] (1) Thermoplastic resin

[0231] ・Thermoplastic resin A: High-density polyethylene [MFR=5g / 10min (190°C / 2.16kg), density=0.953g / cm 3 ]

[0232] ・Thermoplastic resin B: Ethylene-propylene copolymer [ethylene content rate: 16% by mass, MFR (190°C / 2.16kg) = 1.4g / 10min, density = 0.862g / cm 3 ]

[0233] ・Thermoplastic resin C: Ethylene-octene copolymer [MFR=1.0g / 10min (190°C / 2.16kg), density=0.870g / cm 3 ]

[0234] (2) Cellulose

[0235] Cellulose A: KC Flock W-200 [trade name: powdered cellulose manufactured by Nippon Paper Co., Ltd., with an average particle diameter of about 32 μm]

[0236] - Cellulose B: LIGNOCEL C-120 [trade name J RETTEN MAIER & Sons Co., Ltd., particle size 70-150 μm]

[0237] (3) Ionic compounds

[0238] ・Ionic compound A: 1-butyl-3-methylimid...

Embodiment 2

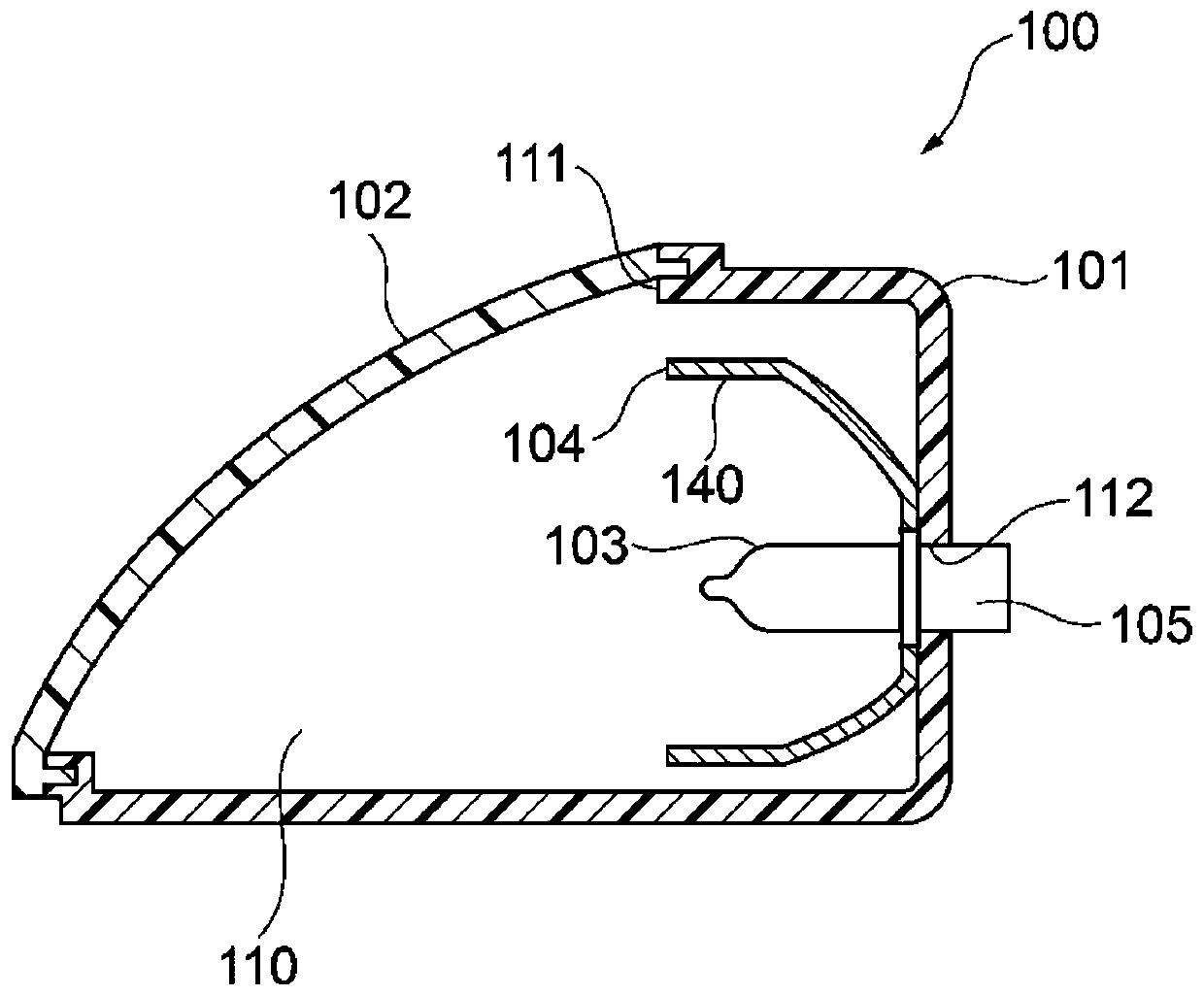

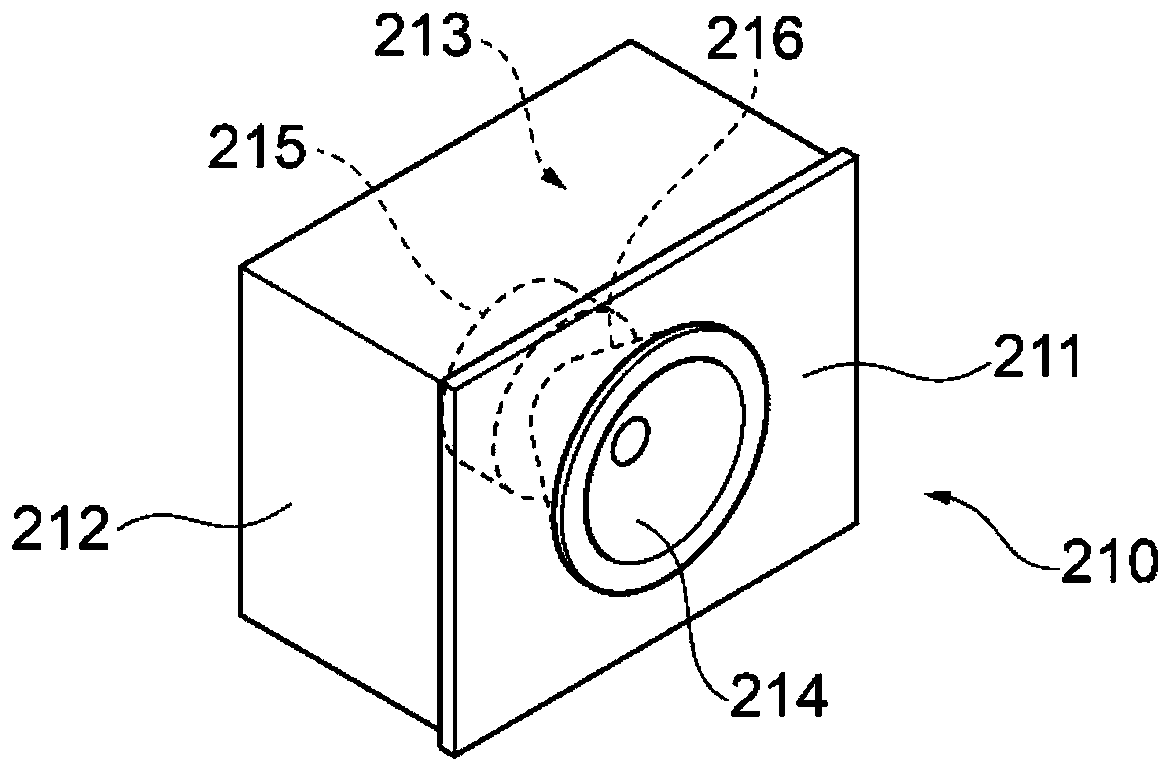

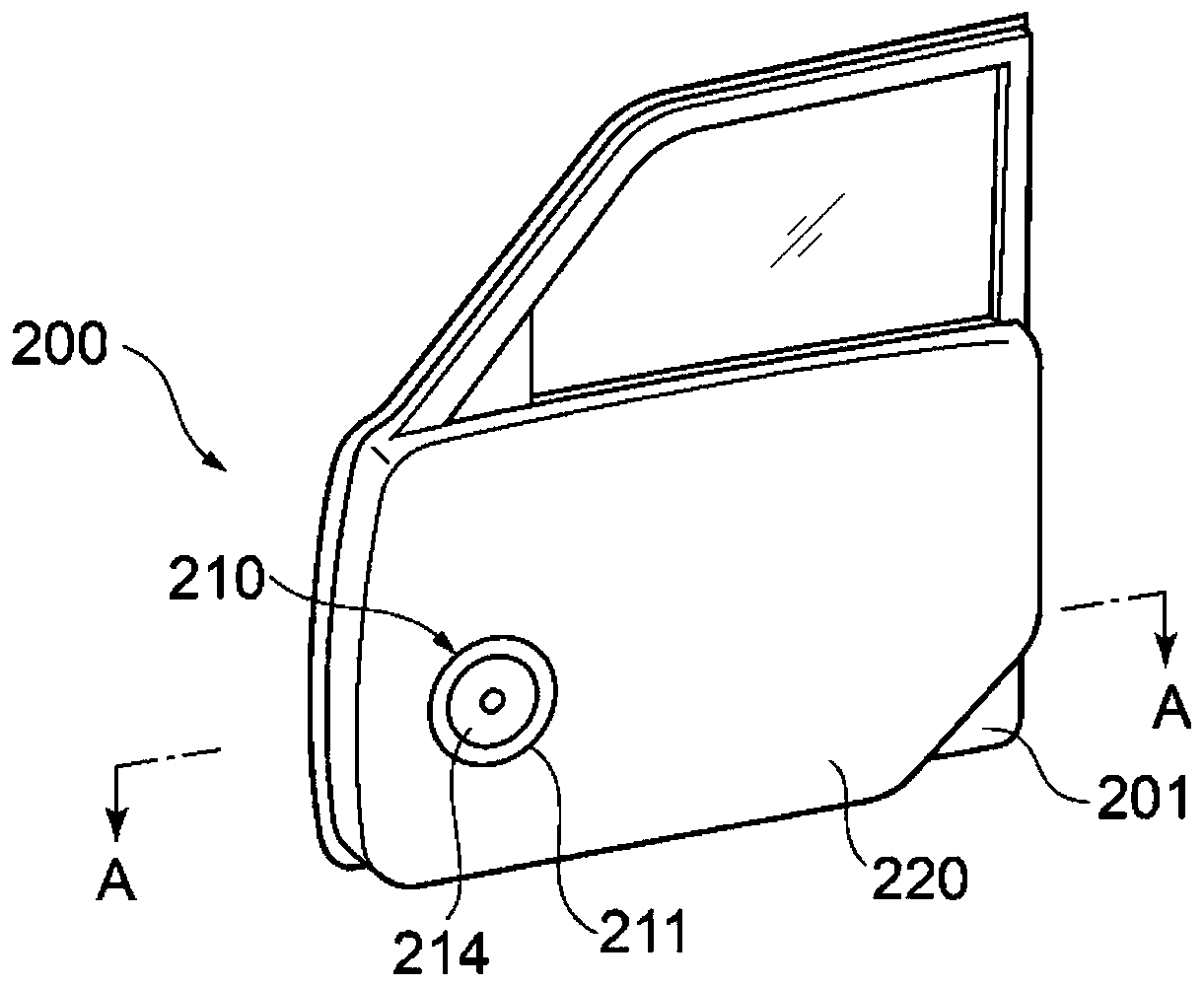

[0252] The cellulose-reinforced thermoplastic resin composition containing one type of thermoplastic resin obtained in 2) was produced without performing the step 3) of Example 1. Then, using this cellulose-reinforced thermoplastic resin composition, a lamp body was fabricated by the same method as in step 4) of Example 1.

Embodiment 3

[0254] In the step 1) of Example 1, 0.1 parts by mass of the ionic compound A was mixed with 99.9 parts by mass of the cellulose A, and in the step 2), the thermoplastic resin A and B were used instead of the thermoplastic resin B according to A cellulose-reinforced thermoplastic resin composition containing two types of thermoplastic resins was prepared in the same manner as in Example 2 except that the resins mixed so that the mass ratio was 499:1. Then, using this cellulose-reinforced thermoplastic resin composition, a lamp body was fabricated by the same method as in step 4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com