Continuous preparation device for conductive micro-nano material modified prepreg

A preparation device and a technology for prepreg, which are applied in the field of micro-nano modified composite material preparation to achieve the effects of improving comprehensive performance, enhancing enhancement efficiency and solving the problem of random dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

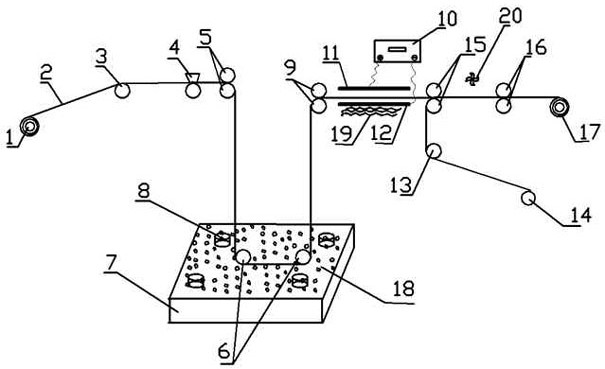

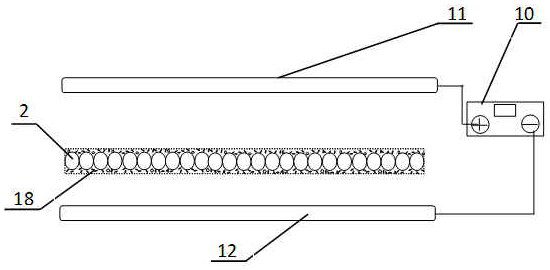

[0021] Such as figure 1 As shown, the oriented conductive micro-nano material / fiber-reinforced resin-based prepreg continuous preparation device of the present invention is a horizontally arranged structure, including a fiber tow winding roller 1, a fiber conveying guide roller 3, a fiber tow unrolling device 4, The first conveying roller group 5, the fiber dipping device, the prepreg thickness adjusting roller group 9, the electric field device, the heating device 19, the release paper traction roller 13, the release paper roll roller 14, the second conveying roller group 15 , cooling device 20, traction roller group 16 and winding device 17.

[0022] Among them, the fiber impregnation device includes fiber impregnation glue tank 7, impregnation glue groove roller group 6, ultrasonic probe 8, conductive micro-nano material / resin glue 18; the diameter of conductive micro-nano material / resin glue 18 is 5-30nm A mixed solution of carbon nanotubes and epoxy resin with a length o...

Embodiment 2

[0030] The difference with Example 1 is:

[0031] The dipping rubber tank roller group 6 is composed of 3 glass guide rollers placed in a square shape, and the distance between adjacent guide rollers is 90mm.

[0032] There are 3 groups of prepreg thickness adjusting roller groups 9 .

[0033] For the electric field device, the length of the positive electrode plate 11 and the negative electrode plate 12 is 150 cm, the width is the same as that of the prepreg material, the distance is 10 cm, and the material is copper.

Embodiment 3

[0035] The difference with Example 1 is:

[0036] The impregnated rubber groove roller group 6 is composed of 5 glass guide rollers arranged in an M shape, and the distance between adjacent guide rollers is 80 mm.

[0037] There are 5 groups of prepreg thickness regulating roller groups 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com