FRCM plate prestress applying and loss monitoring process and product thereof

A monitoring process and prestressing technology, applied in force/torque/work measuring instruments, measuring devices, building reinforcements, etc., can solve the problems of single fiber bundle anchorage, poor shear resistance of carbon fiber materials, high cost, etc., to achieve increased Large contact area and roughness, convenient prestress loss monitoring, and the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The operating methods not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

[0066] Such as Figure 2 to Figure 9 As shown, this embodiment takes carbon fiber bundles as an example, and the FRCM plate prestressing and loss monitoring process includes steps:

[0067] 1) formwork, laying and assembly:

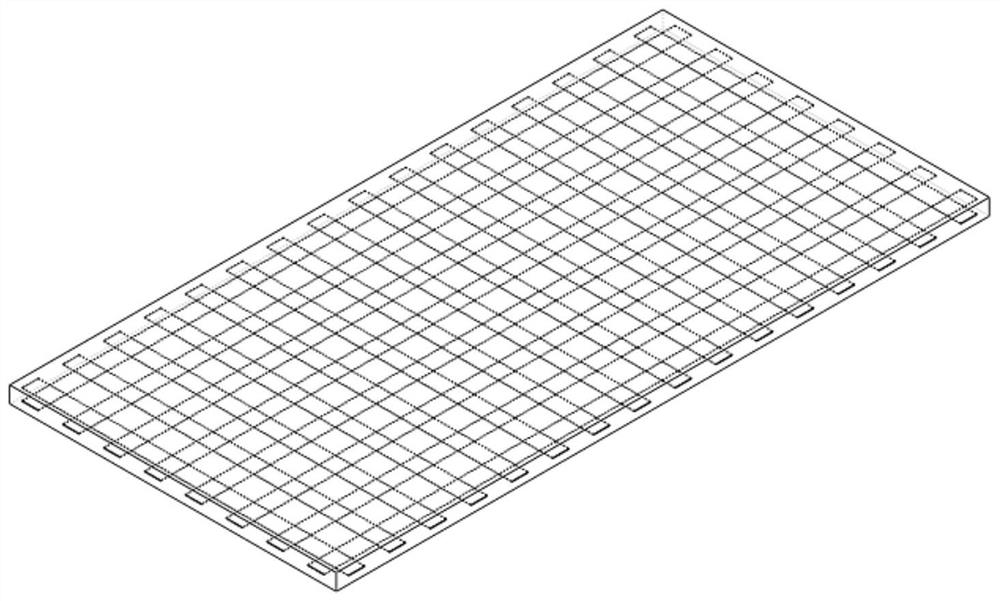

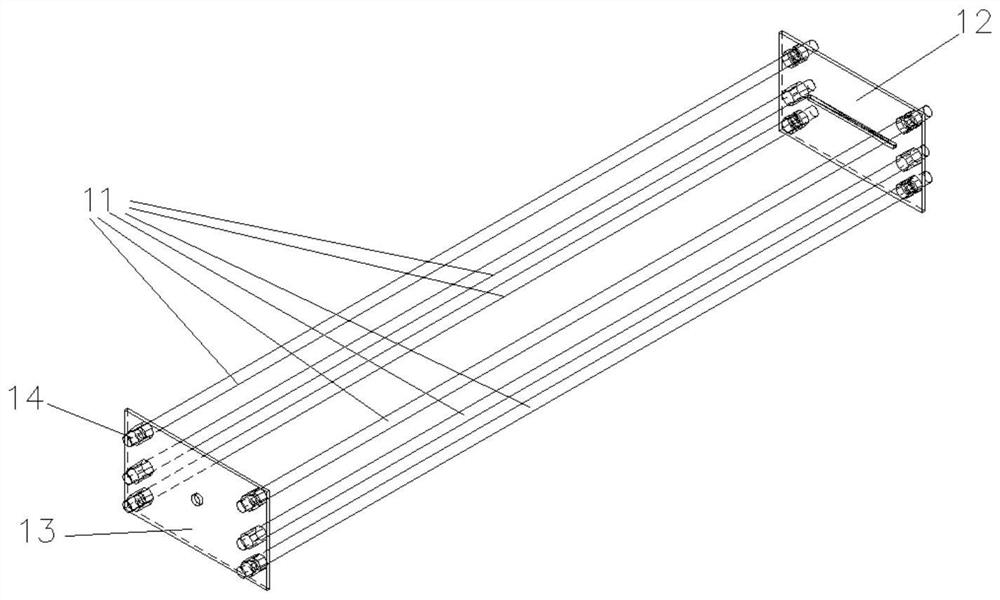

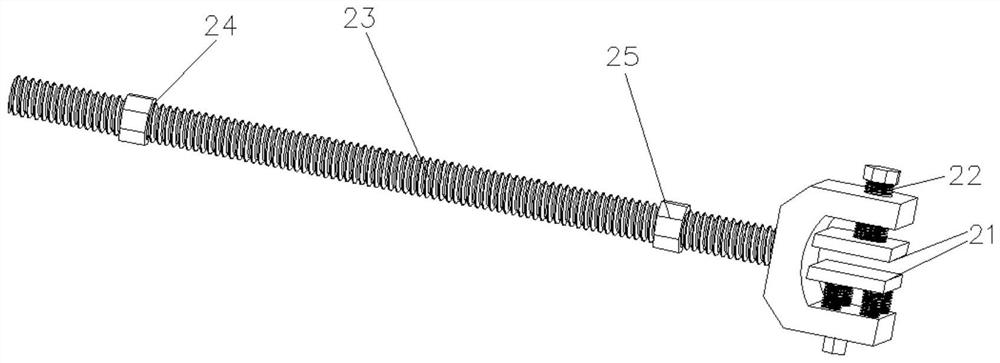

[0068] Six axial bearing rods 11 and first bolts 14 are used to fixedly connect the opposite end baffles 12 with holes and the end baffles 13 with holes to form a cuboid cavity with a length of 2400 mm and a width of 500 mm. A plurality of molds can be arranged in the cuboid mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com