A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for nylon 6 direct injection molding and its preparation method

A technology of injection molding and functional masterbatch, applied in the field of high-efficiency reinforced halogen-free flame retardant functional masterbatch and its preparation, can solve problems such as mismatching processing temperature, and achieve enhanced enhancement efficiency, improved modification efficiency, and high flow characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

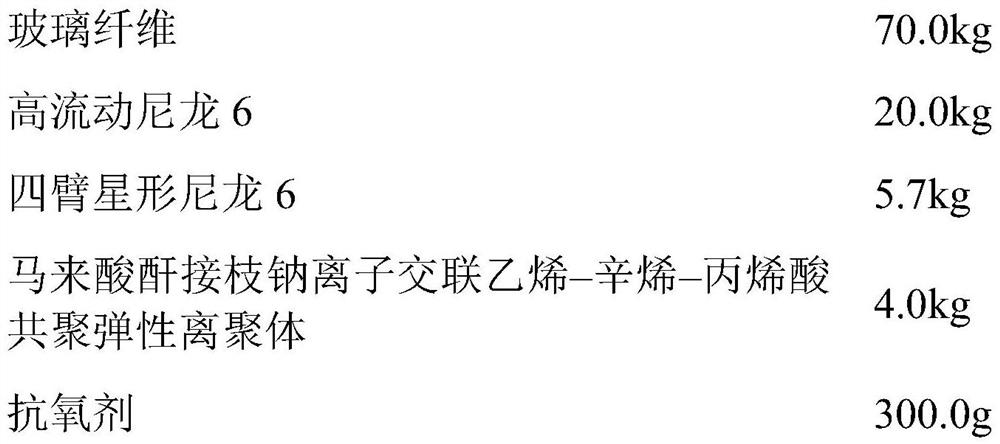

[0036] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for nylon 6 direct injection molding, which is composed of two masterbatches A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0037]

[0038] Antioxidant is 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name is antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

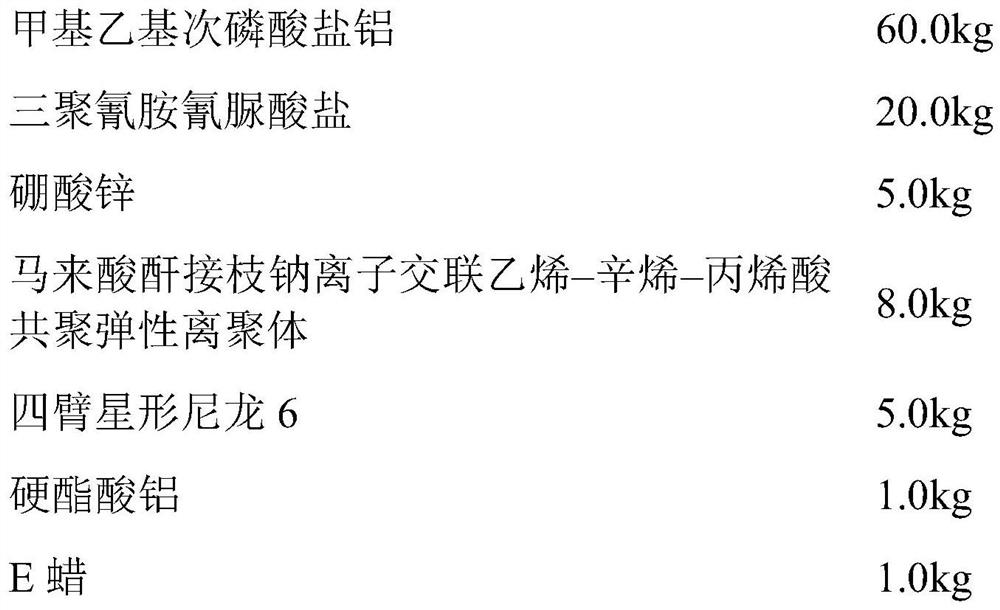

[0039] The mass ratio of the raw materials of the B masterbatch is as follows:

[0040]

[0041] The preparation method of A masterbatch is as follows: Weigh all the raw materials according to the above-mentioned mass ratio requirements, and then cross-link high-flow nylon 6 and maleic anhydride grafted sodium ion cross-linked ethylene-octene-acrylic acid copolymerized elastic ionomer pellets and four-arm star-shaped nylon 6 and antioxidant powder are put into differen...

Embodiment 2

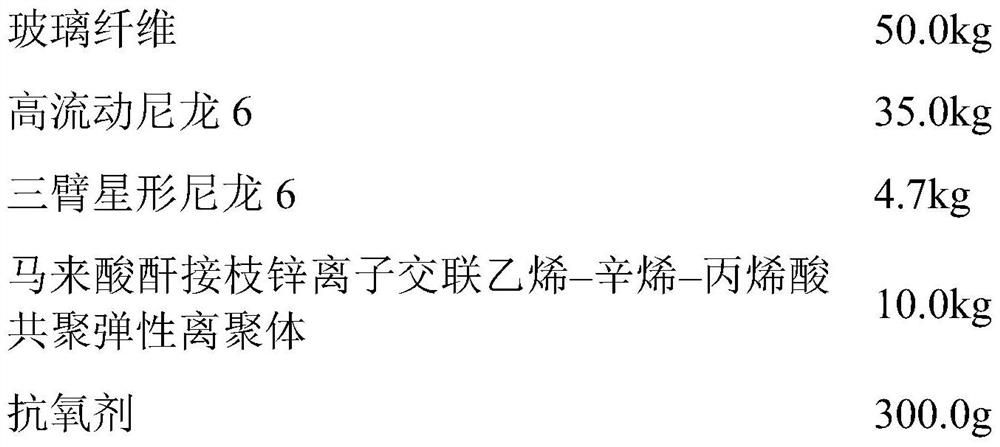

[0044] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for nylon 6 direct injection molding, which is composed of two masterbatches A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0045]

[0046] Antioxidant is 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name is antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

[0047] The mass ratio of the raw materials of the B masterbatch is as follows:

[0048]

[0049]

[0050] The preparation method of A masterbatch is as follows: Weigh all the raw materials according to the above mass ratio requirements, and then cross-link high-flow nylon 6 and maleic anhydride grafted zinc ions into two kinds of pellets of ethylene-octene-acrylic acid copolymerized elastic ionomer and three-arm star-shaped nylon 6 and antioxidant powder are put int...

Embodiment 3

[0053] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for nylon 6 direct injection molding, which is composed of two masterbatches A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0054]

[0055] Antioxidant is 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name is antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

[0056] The mass ratio of the raw materials of the B masterbatch is as follows:

[0057]

[0058]The preparation method of A master batch is as follows: Weigh all the raw materials according to the above mass ratio requirements, and then cross-link the high-flow nylon 6 and maleic anhydride grafted barium ion cross-linked ethylene-octene-acrylic acid copolymerized elastic ionomer pellets and three-arm star-shaped nylon 6 and antioxidant powder are put into different hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com