Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "High drive torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

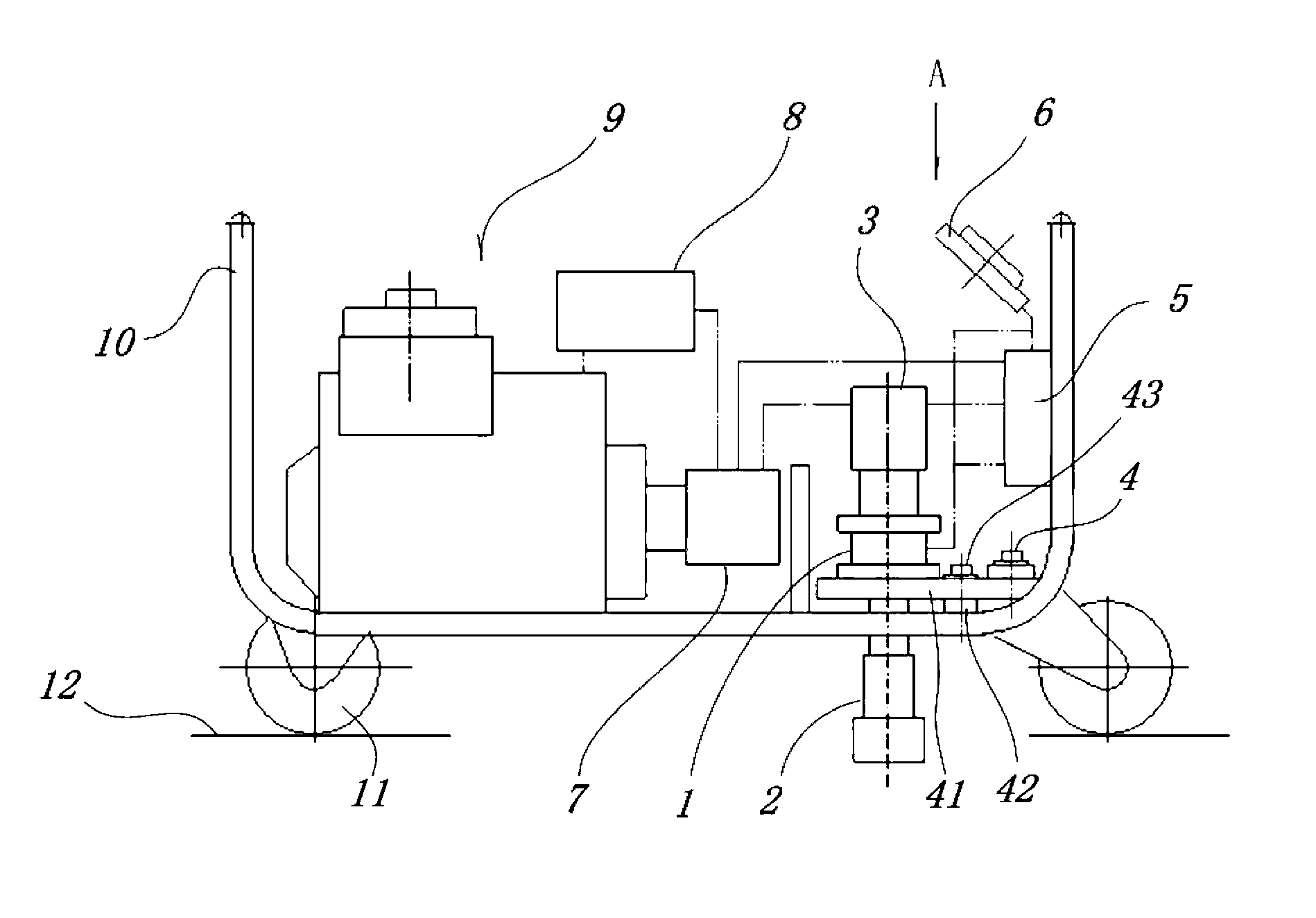

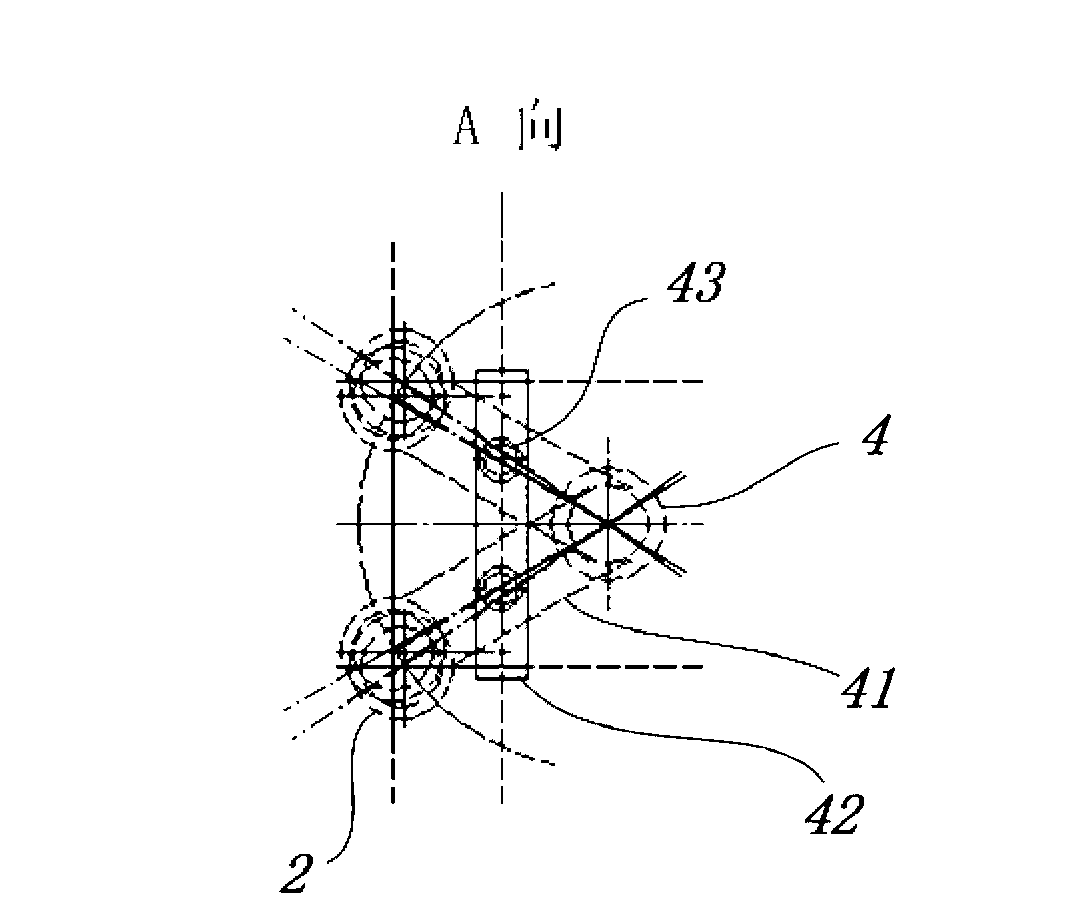

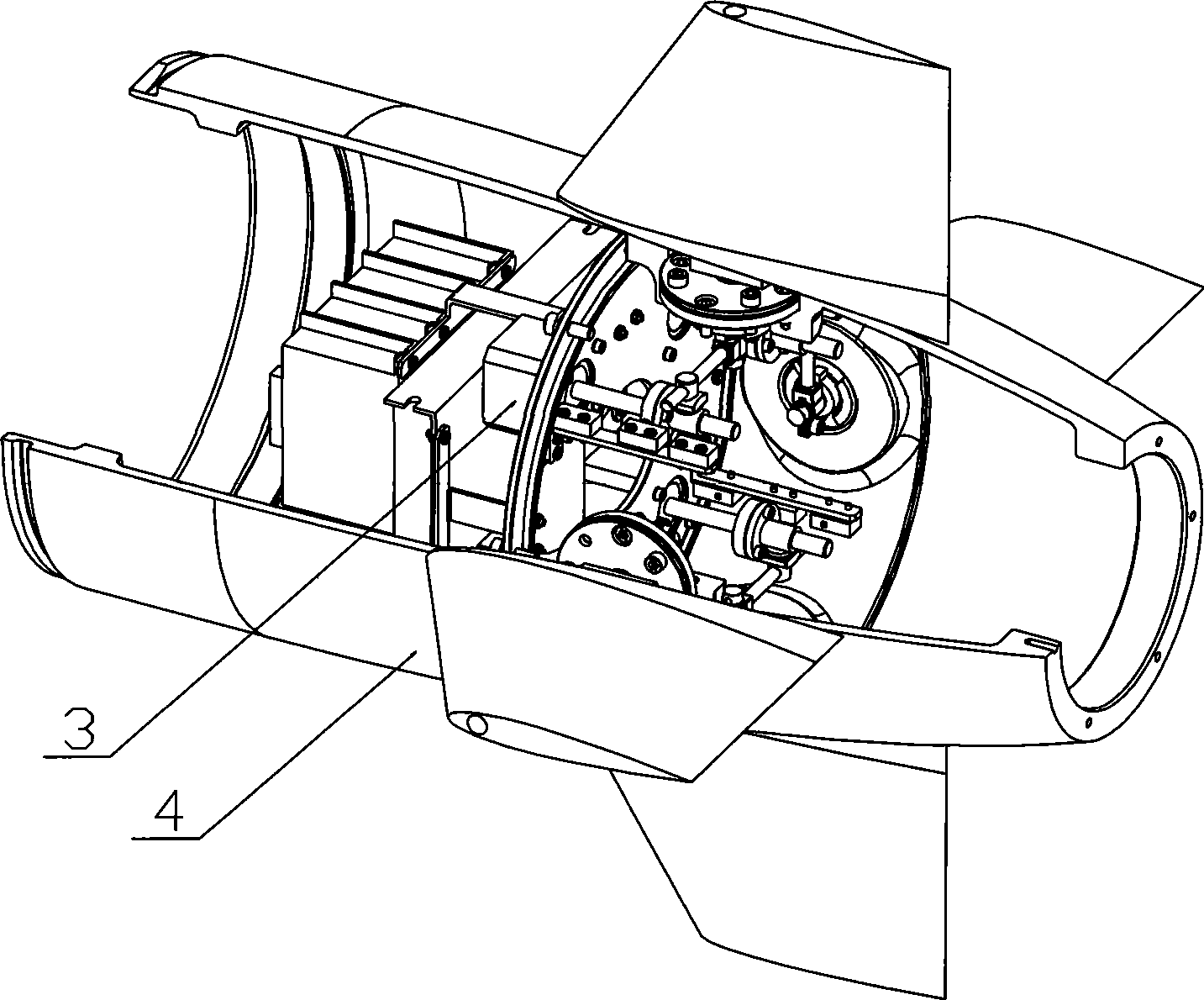

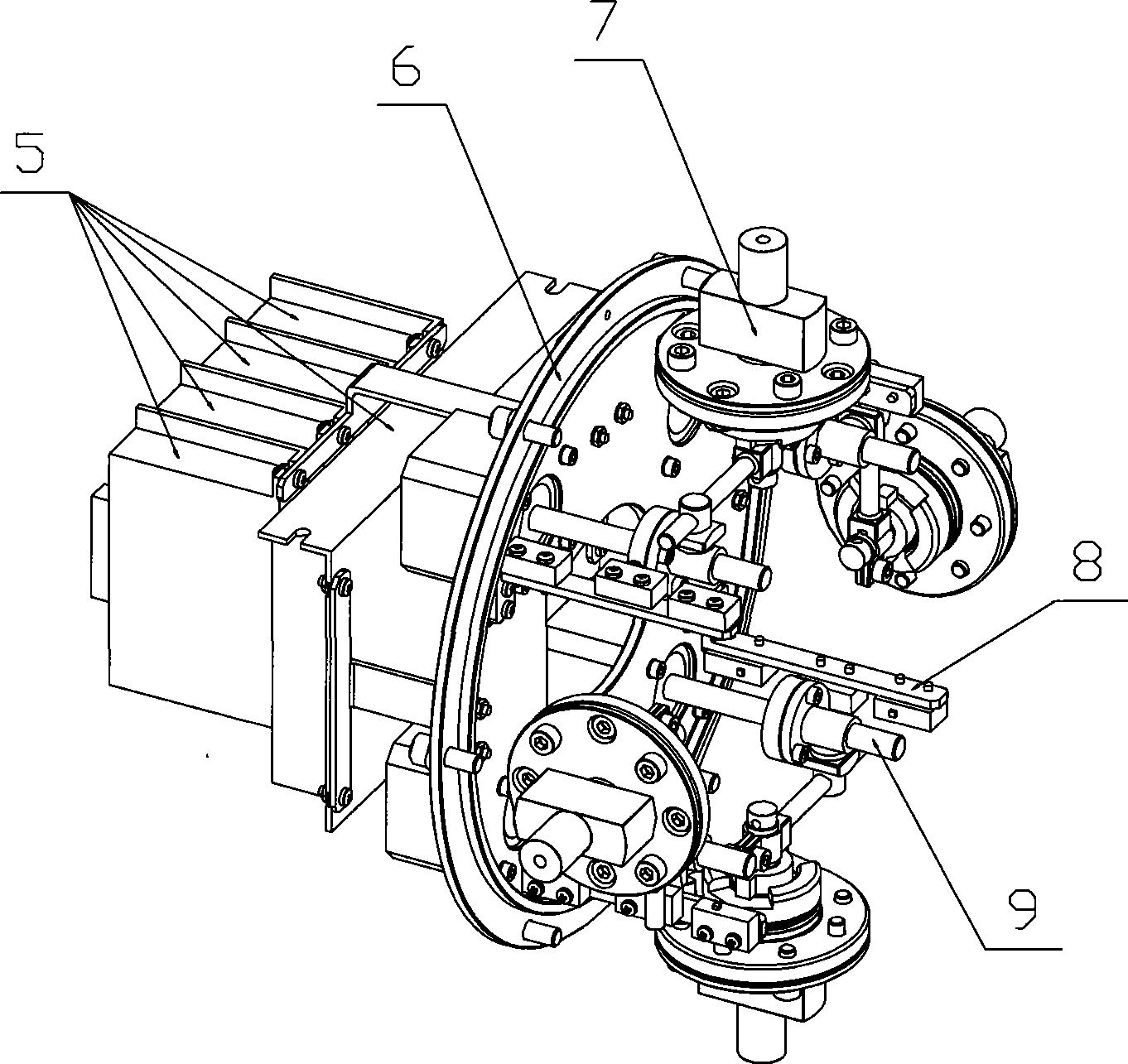

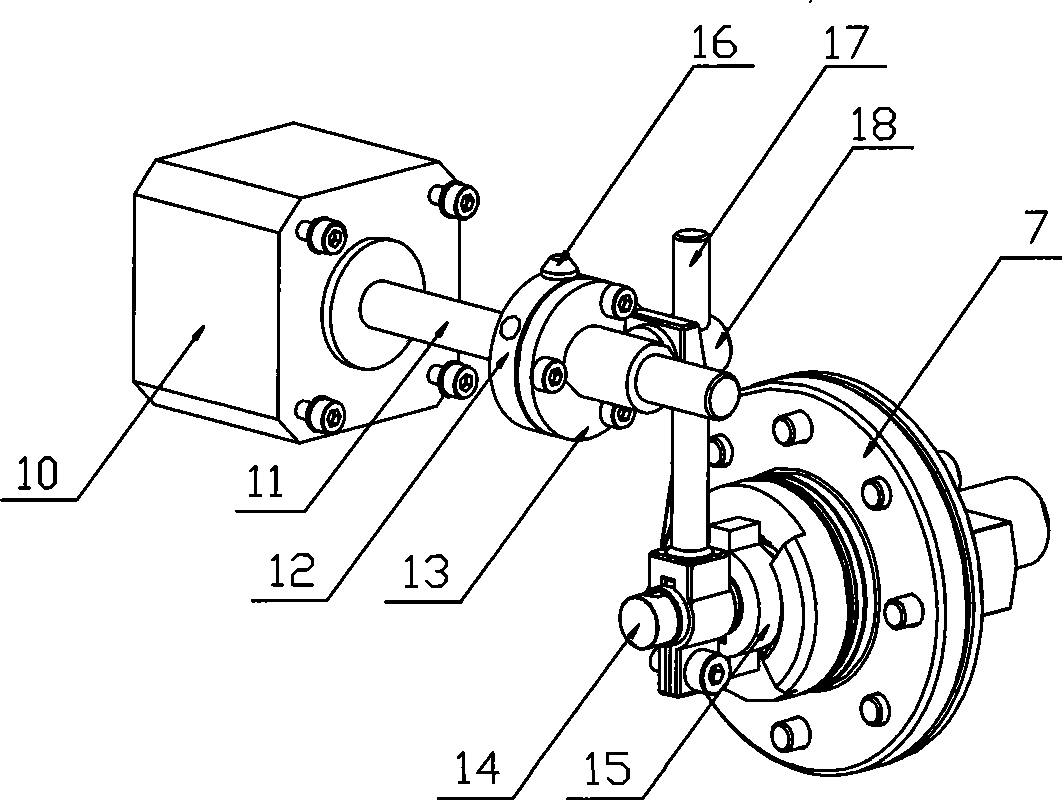

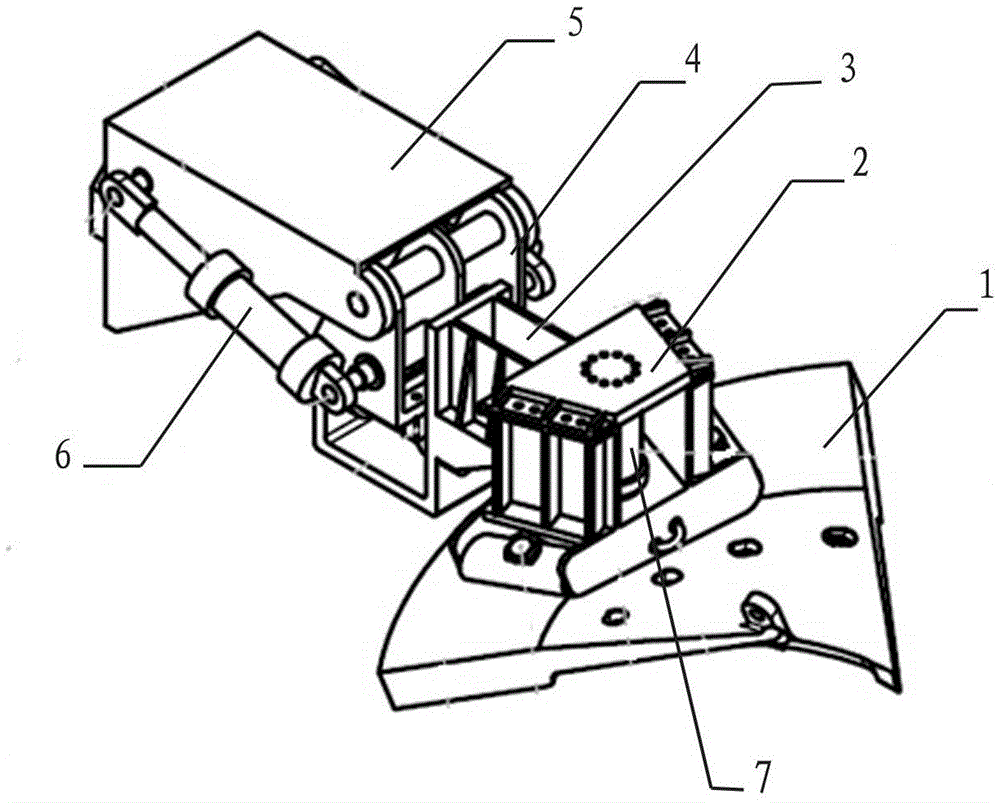

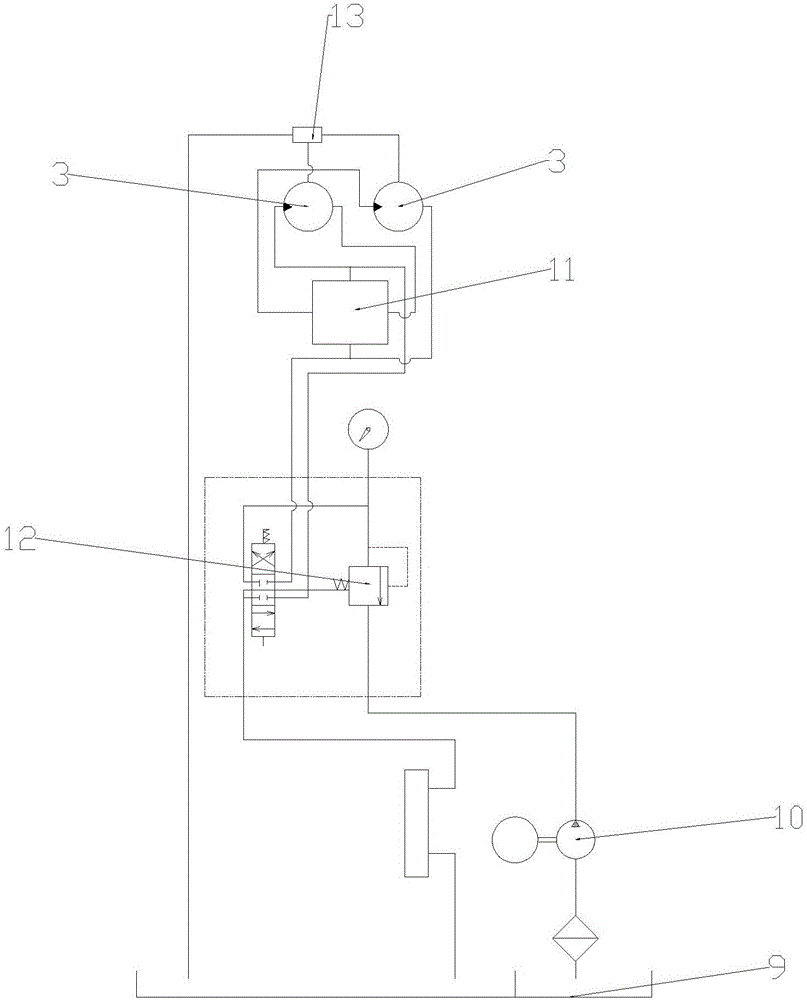

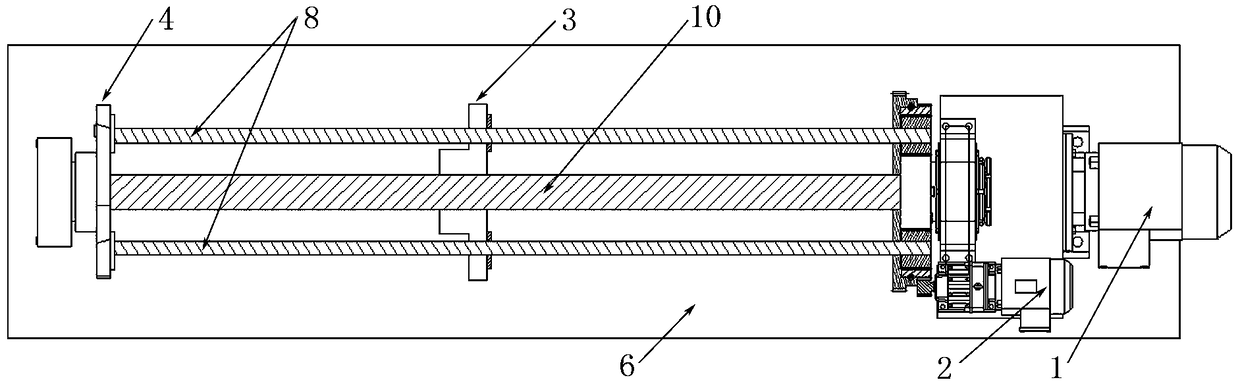

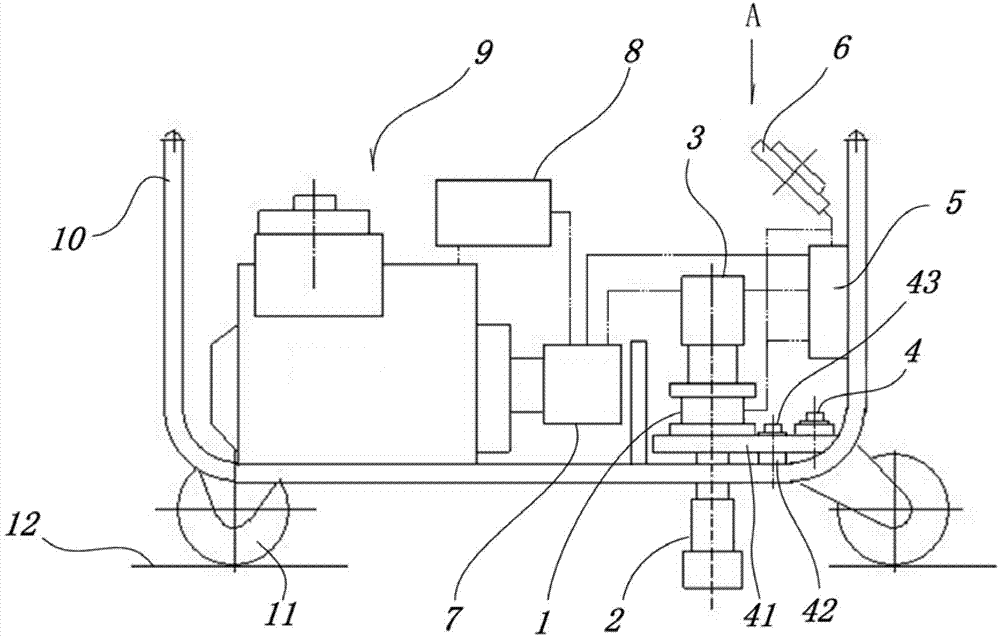

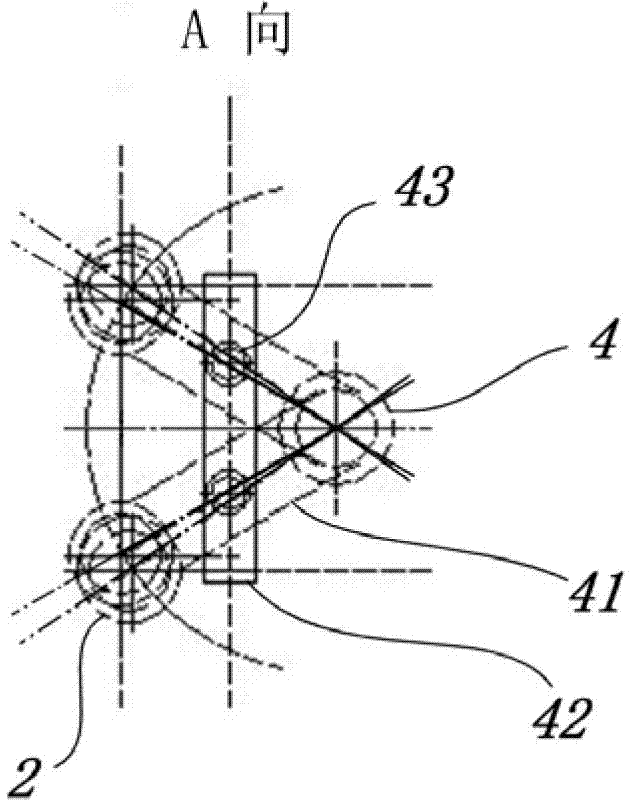

High-precision intelligentized rail fastener bolt wrench and operating method thereof

ActiveCN103128539ASimple structureImprove reliabilityMetal working apparatusTorque sensorVehicle frame

The invention provides a high-precision intelligentized rail fastener bolt wrench and an operating method of the high-precision intelligentized rail fastener bolt wrench. A power system is arranged on a vehicle frame and transports driving power to a hydraulic motor through an oil pump and a control valve component. The vehicle frame is further provided with a working system, and the working system comprises two groups of working devices which are vertically arranged. Each group of working devices comprise a bolt sleeve and a hydraulic motor which drives the bolt sleeves to rotate, and the bolt sleeves are connected in a coaxial mode. A torque sensor is arranged between the bolt sleeve and the hydraulic motor in series, the torque sensor is connected with a torque measurement and control instrument, and the torque sensor transmits a torque state to the torque measurement, controls instrument and further controls a torque output state of the hydraulic motor. When screwing operation is conducted and the torque sensor detects an instant torque value which is identical with the set torque value, the hydraulic motor stops screwing. When the screwing operation is conducted and an existing bolt torque exceeds the set value, the working device reversely unscrews and unloads the bolt, then screws the bolt and sets a value. The high-precision intelligentized rail fastener bolt wrench is simple and reliable in structure, and two groups of working devices independently work and do not influence each other.

Owner:陆亦群

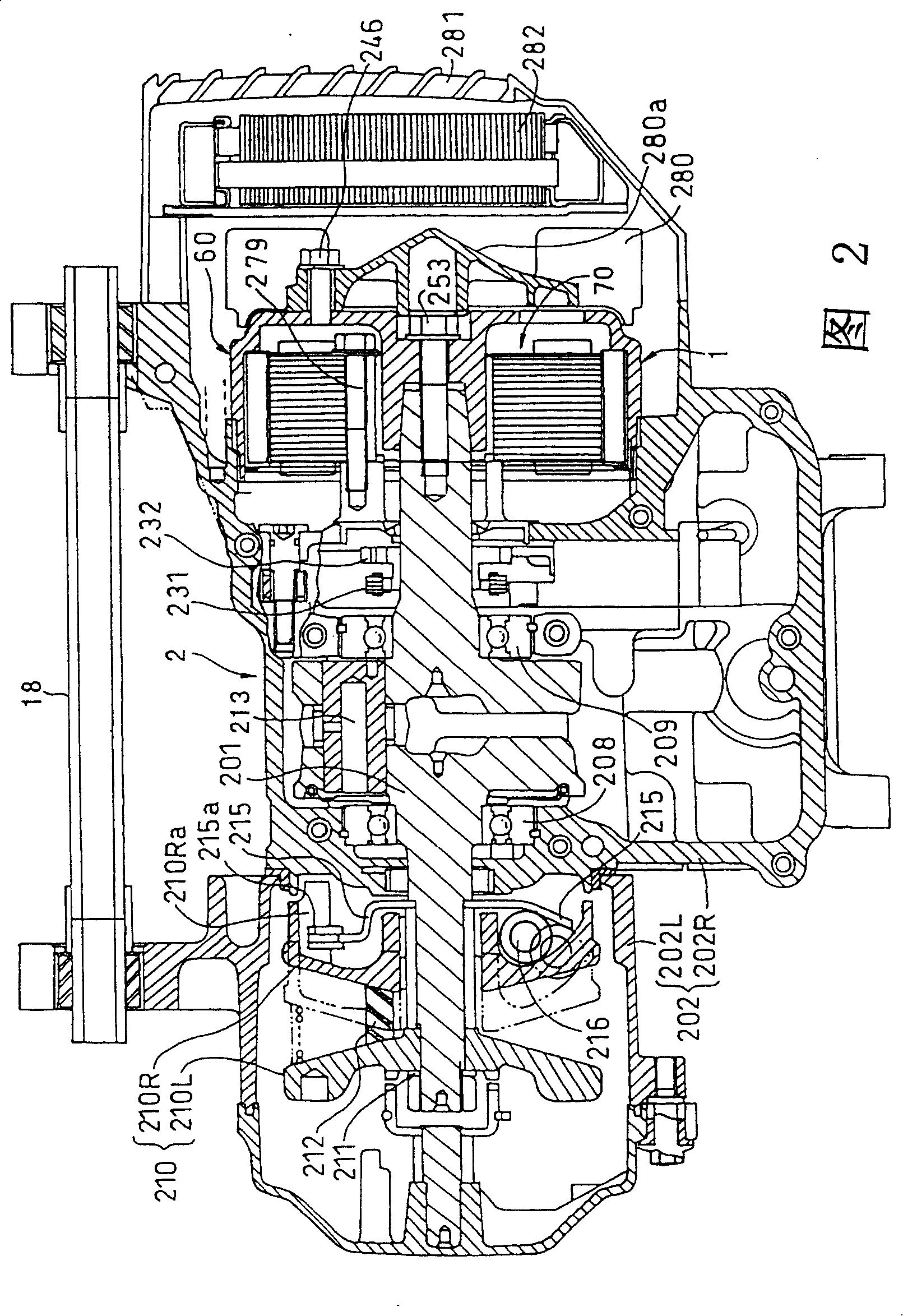

Drive arrangement

ActiveUS9255633B2High drive torqueEasy constructionDifferential gearingsMotor depositionElectric machineEngineering

In a drive arrangement for wheels of a motor vehicle which are driven by an electric machine via a differential, an electric machine which has a ring shaped rotor drives a drive element of the differential, whose output shafts output to the wheels of the motor vehicle. The ring shaped rotor of the electric machine outputs to the input element of the differential via a gear mechanism and the differential is integrated in the rotor thereby allowing for a structurally compact construction and enabling favorable transmission ratios.

Owner:AUDI AG

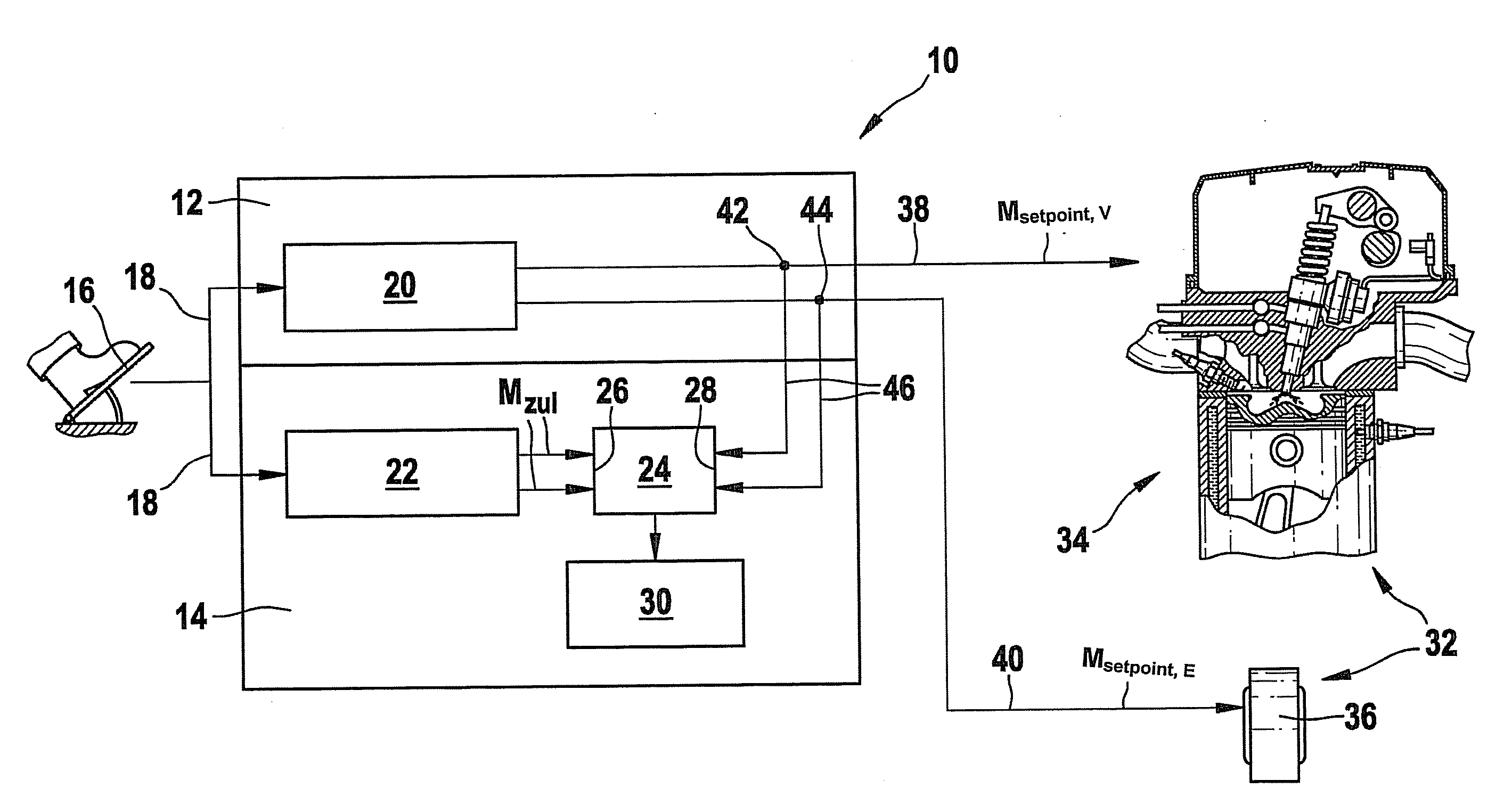

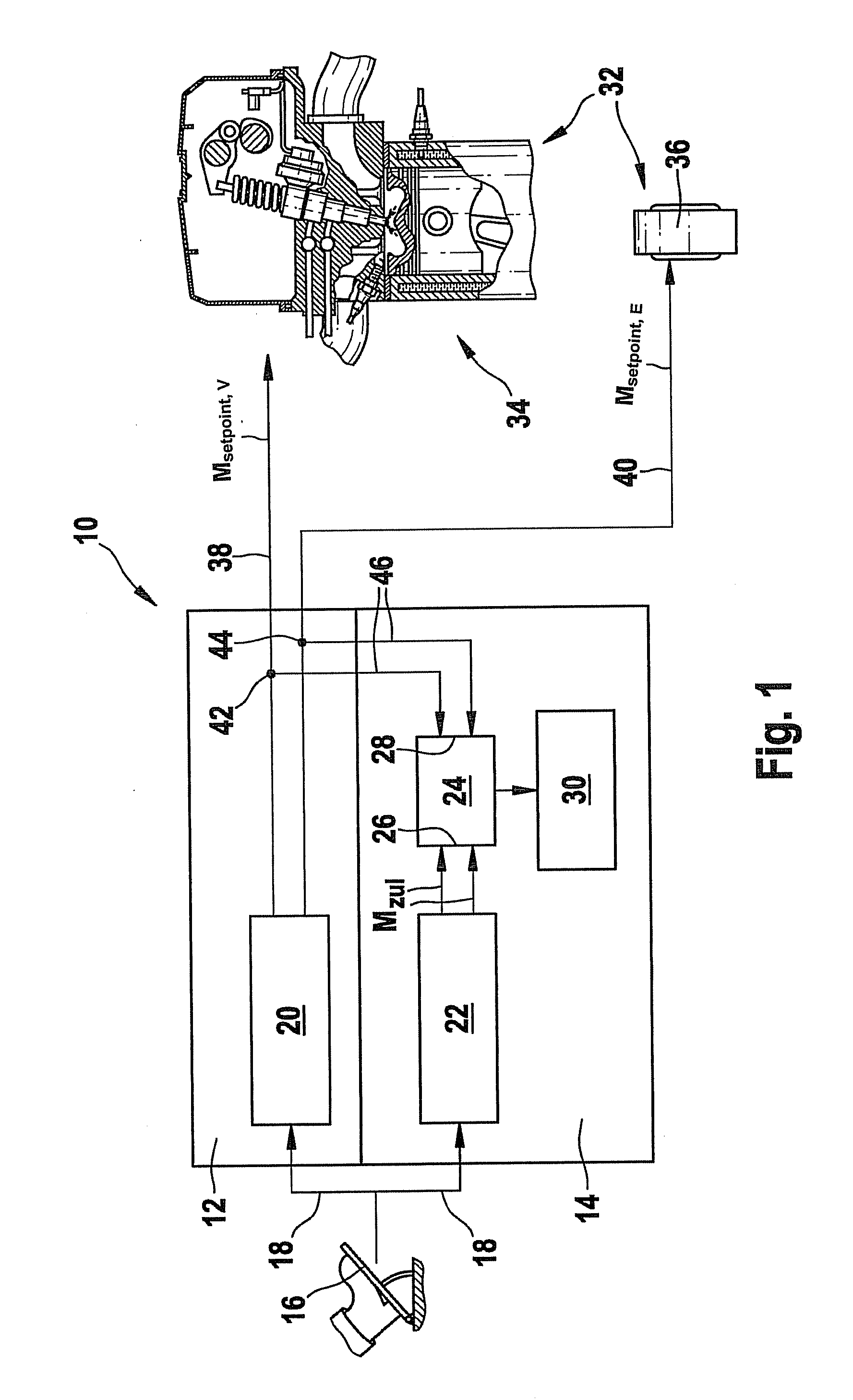

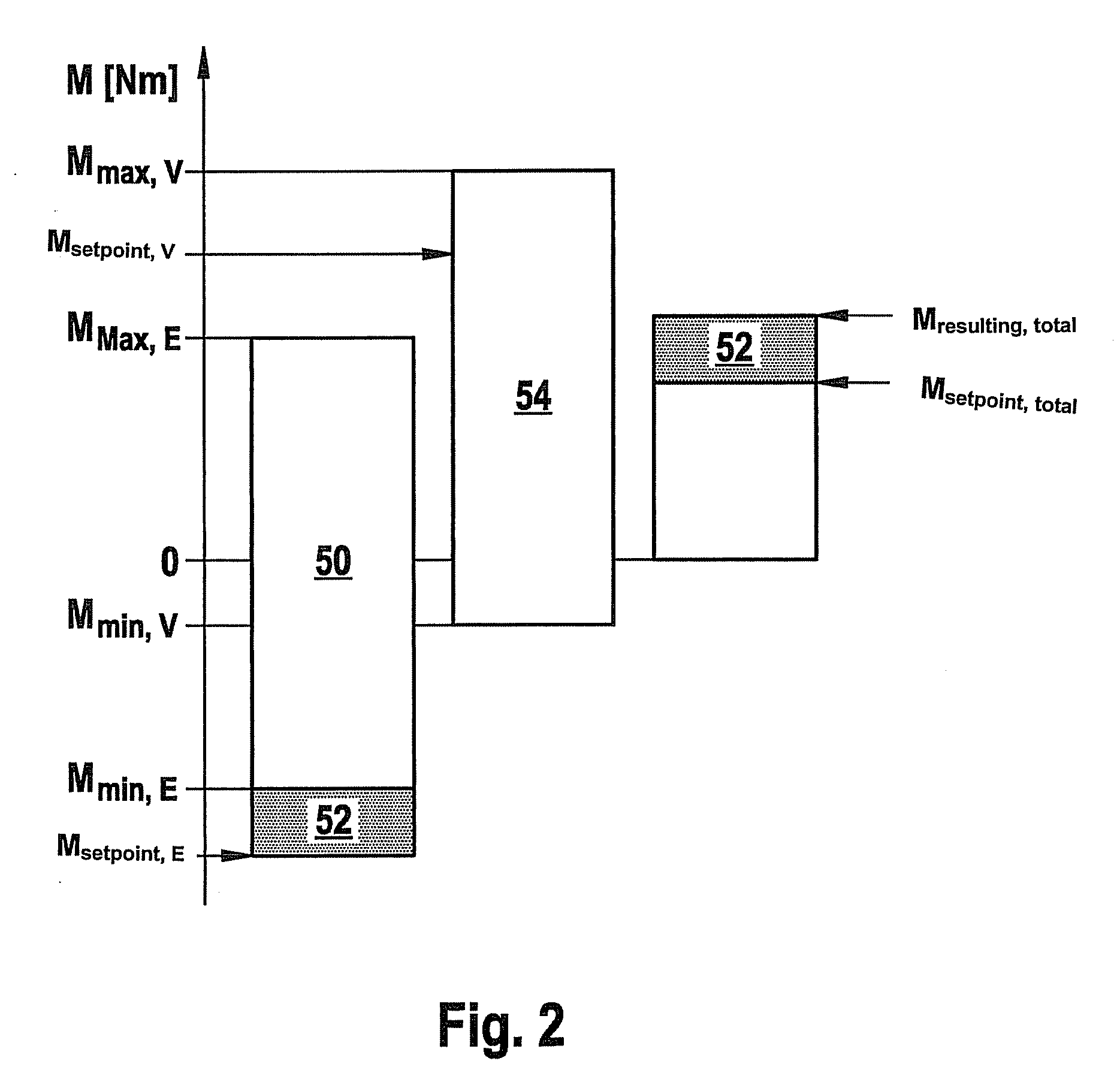

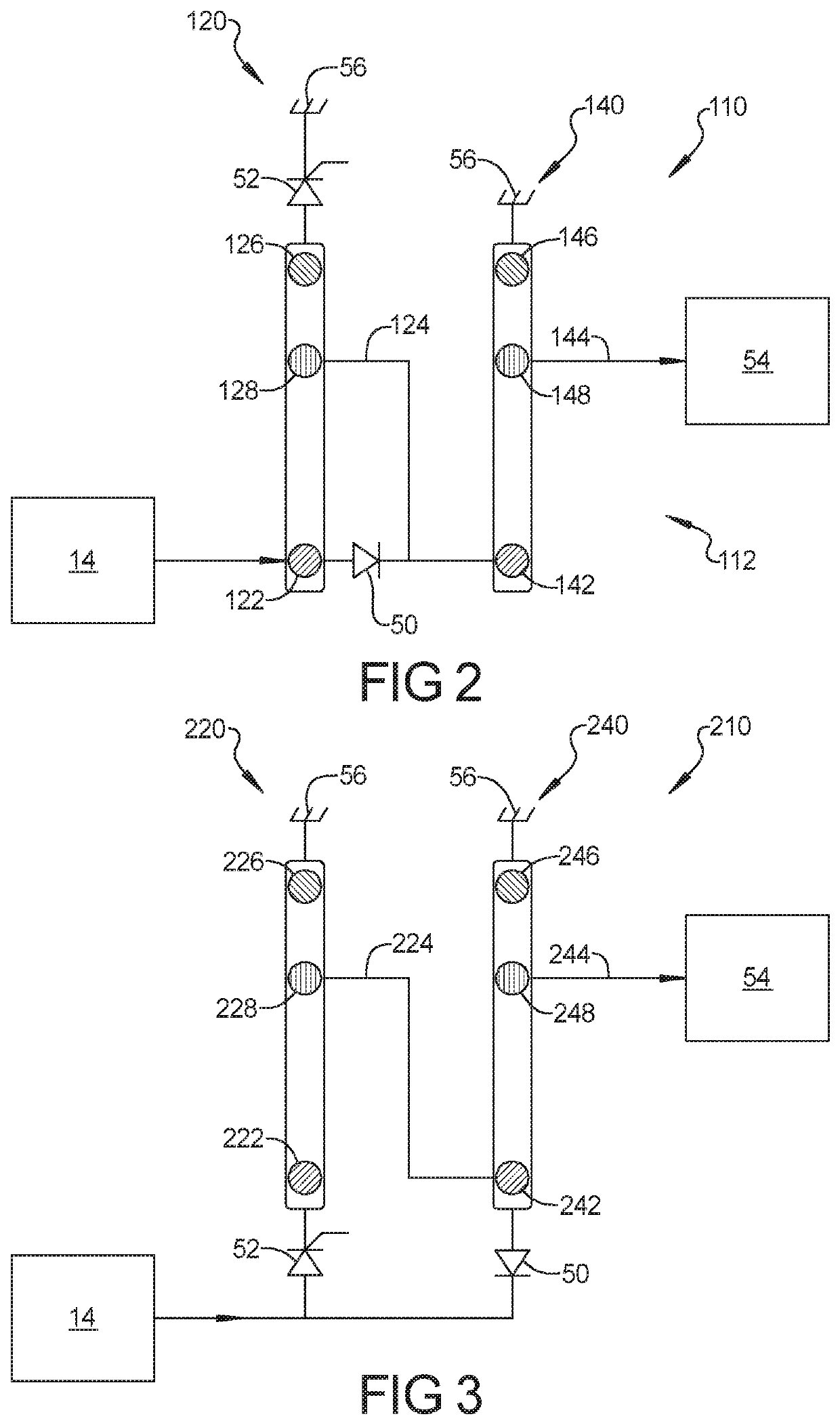

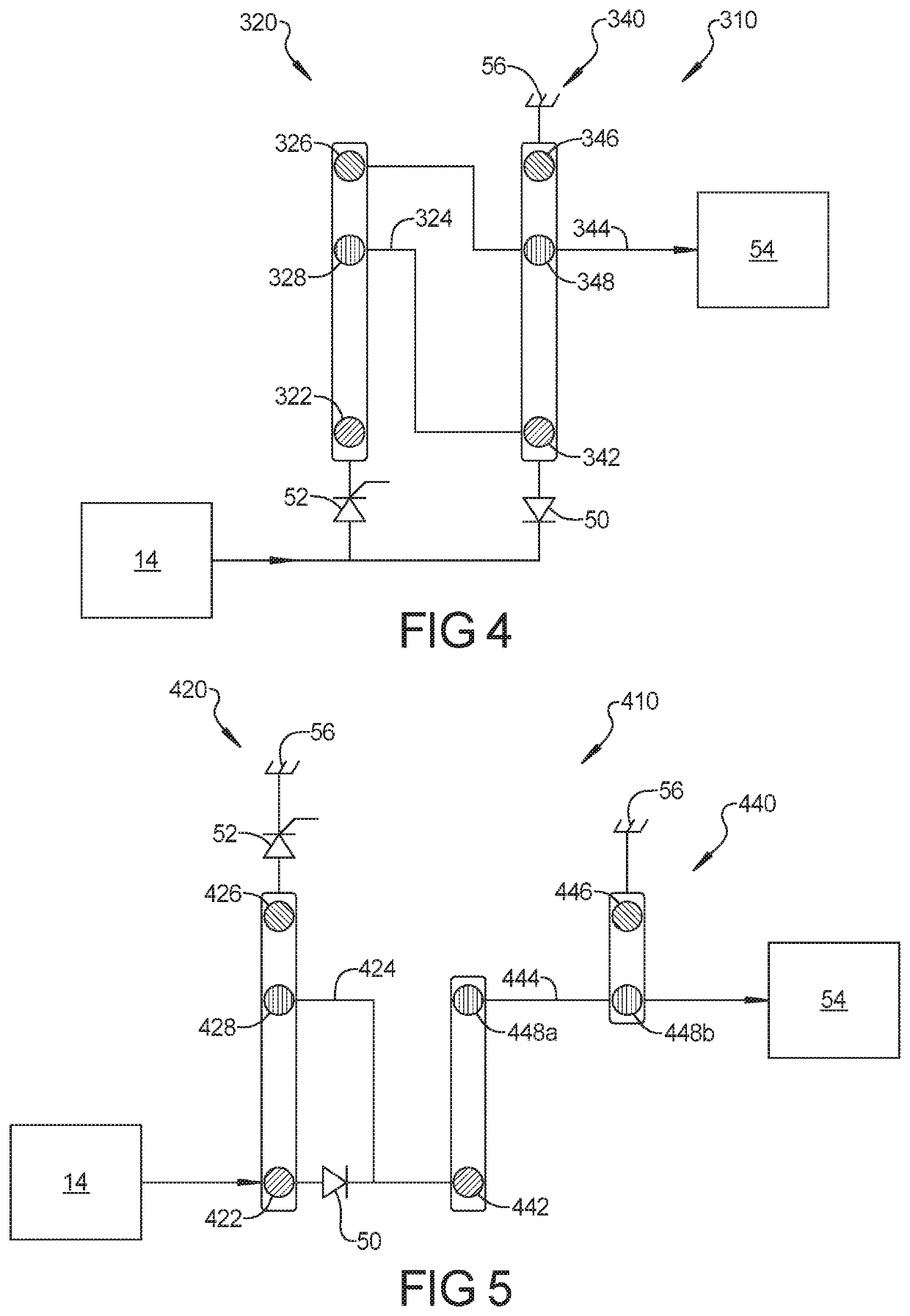

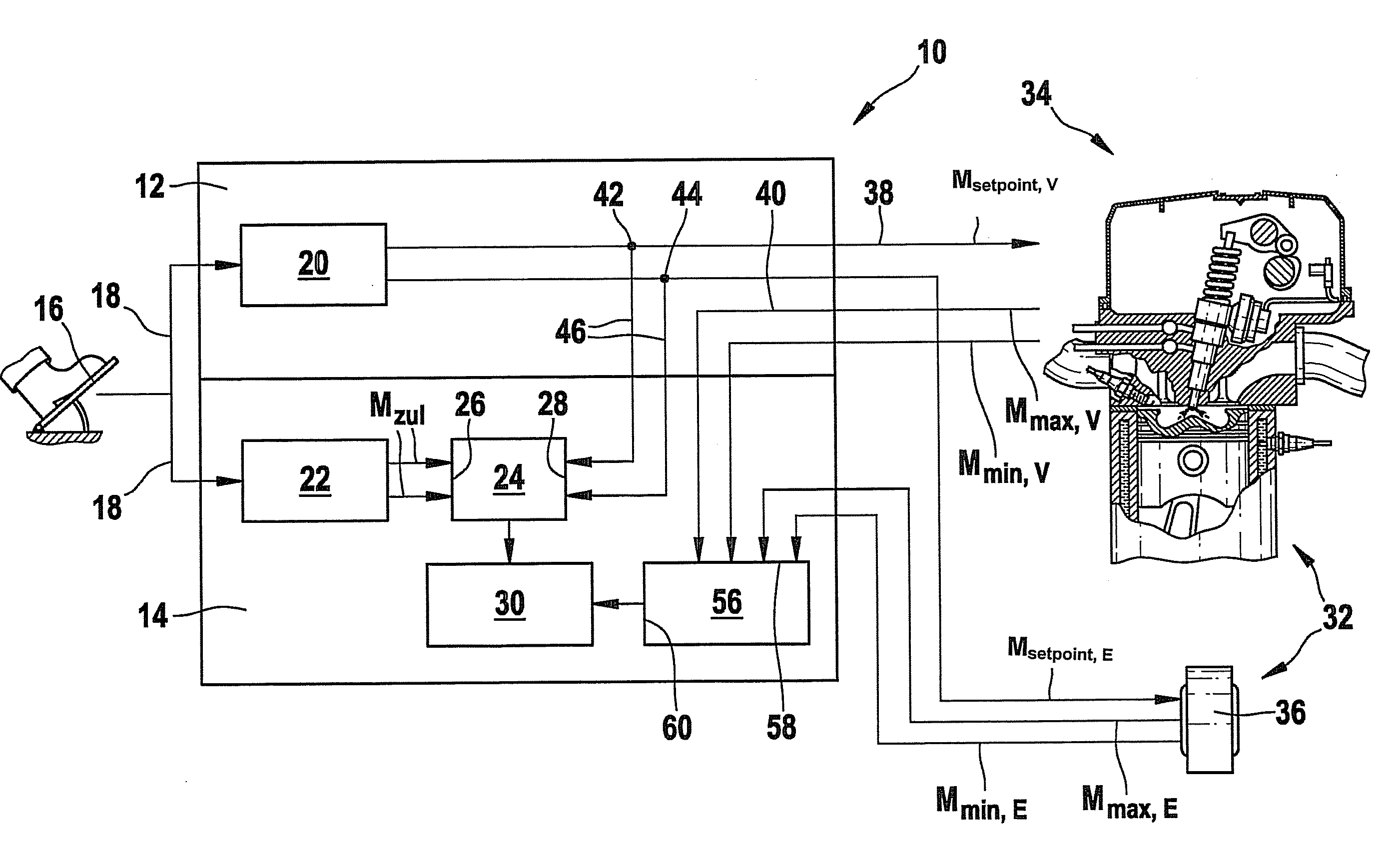

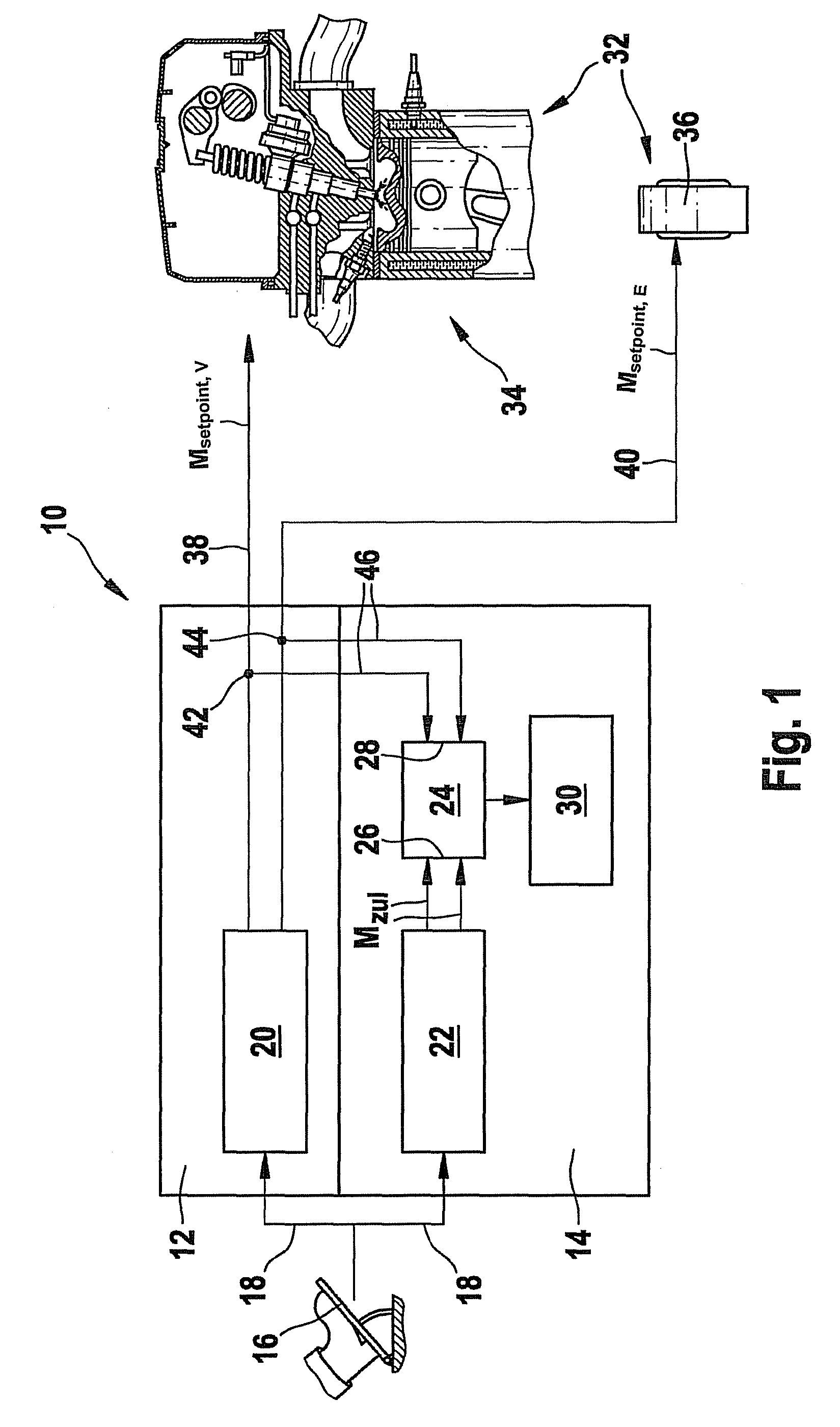

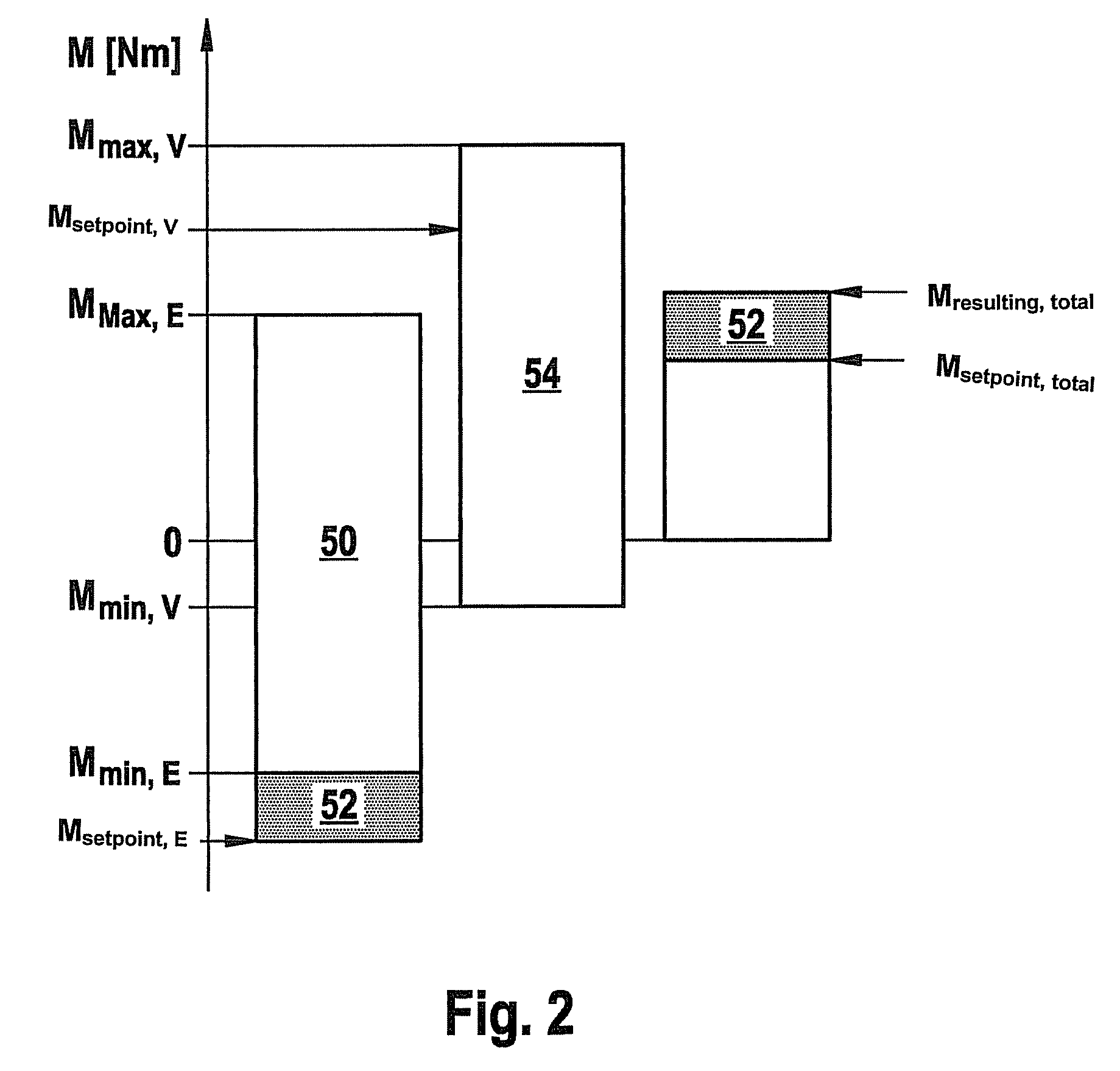

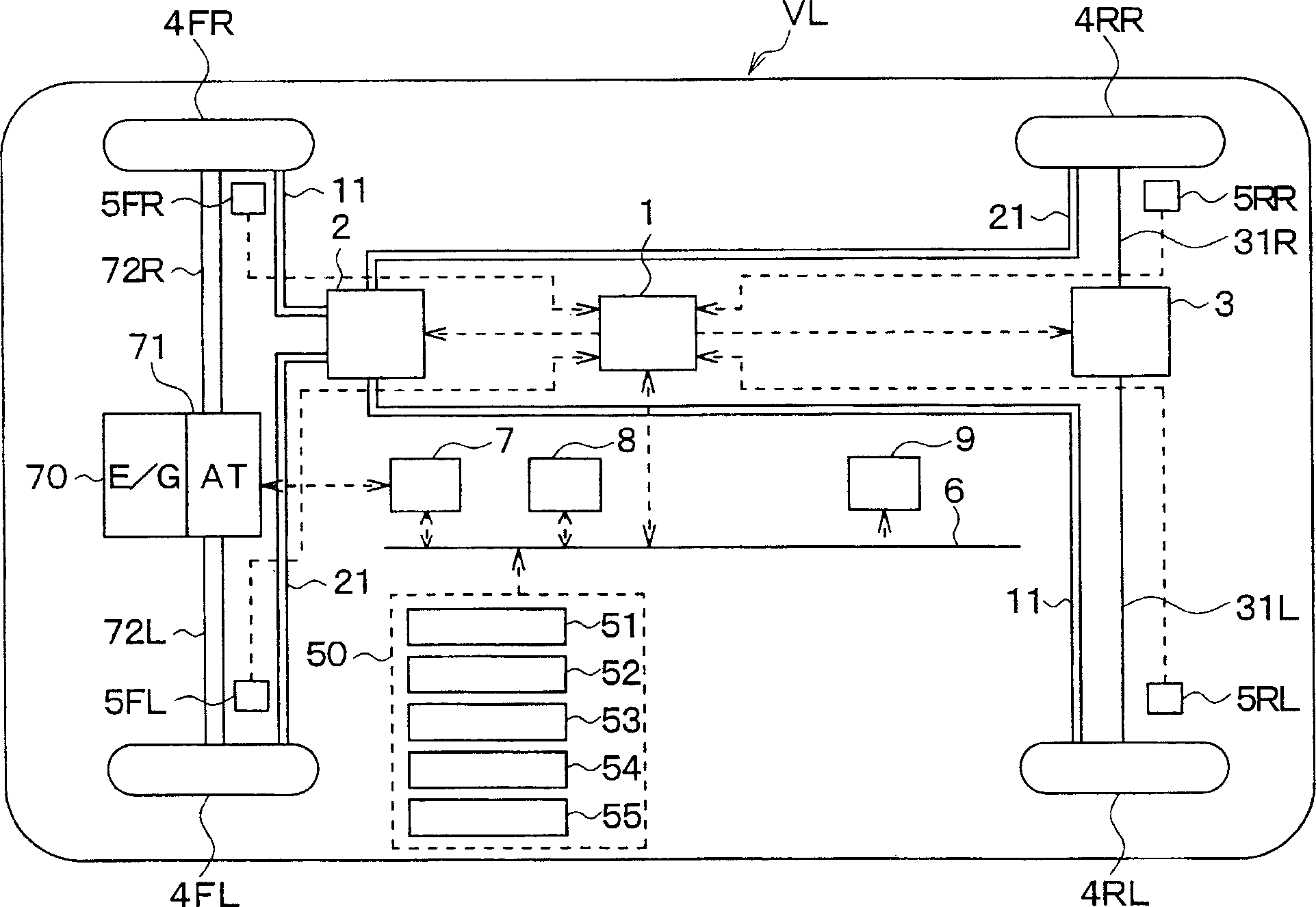

Method for monitoring multi-motor drive

ActiveUS20100042276A1High drive torqueImprove controllabilityVehicle testingRegistering/indicating working of vehiclesMotor driveElectric machine

A method for controlling a vehicle drive unit, which comprises at least two individual drives, at least one of which is able to provide a negative torque. A vehicle control unit is provided, within which a continuous torque comparison is performed within a monitoring level. A permissible torque is ascertained therein. Using a torque range checker it is established whether ascertained setpoint torques lie within torque ranges of the at least two individual drives.

Owner:ROBERT BOSCH GMBH

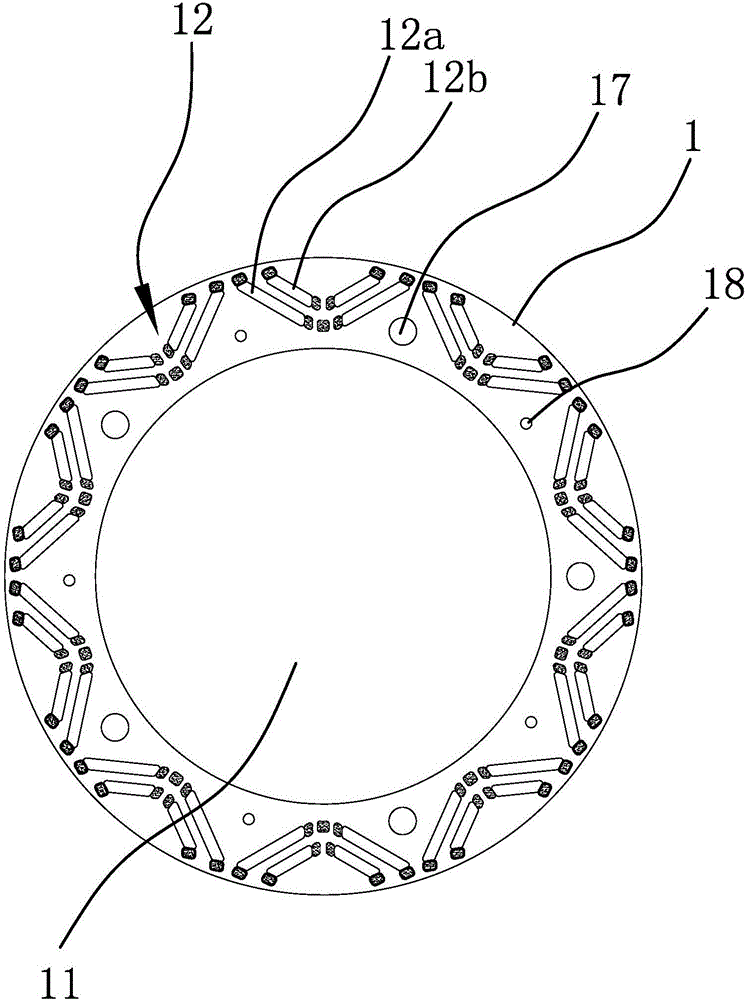

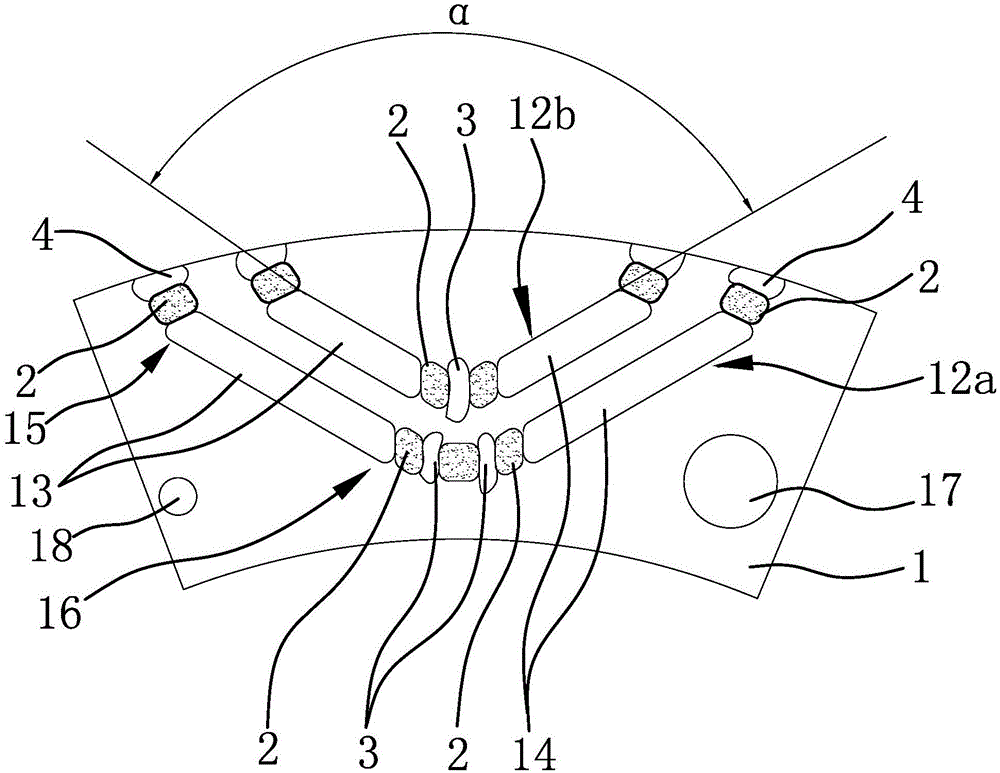

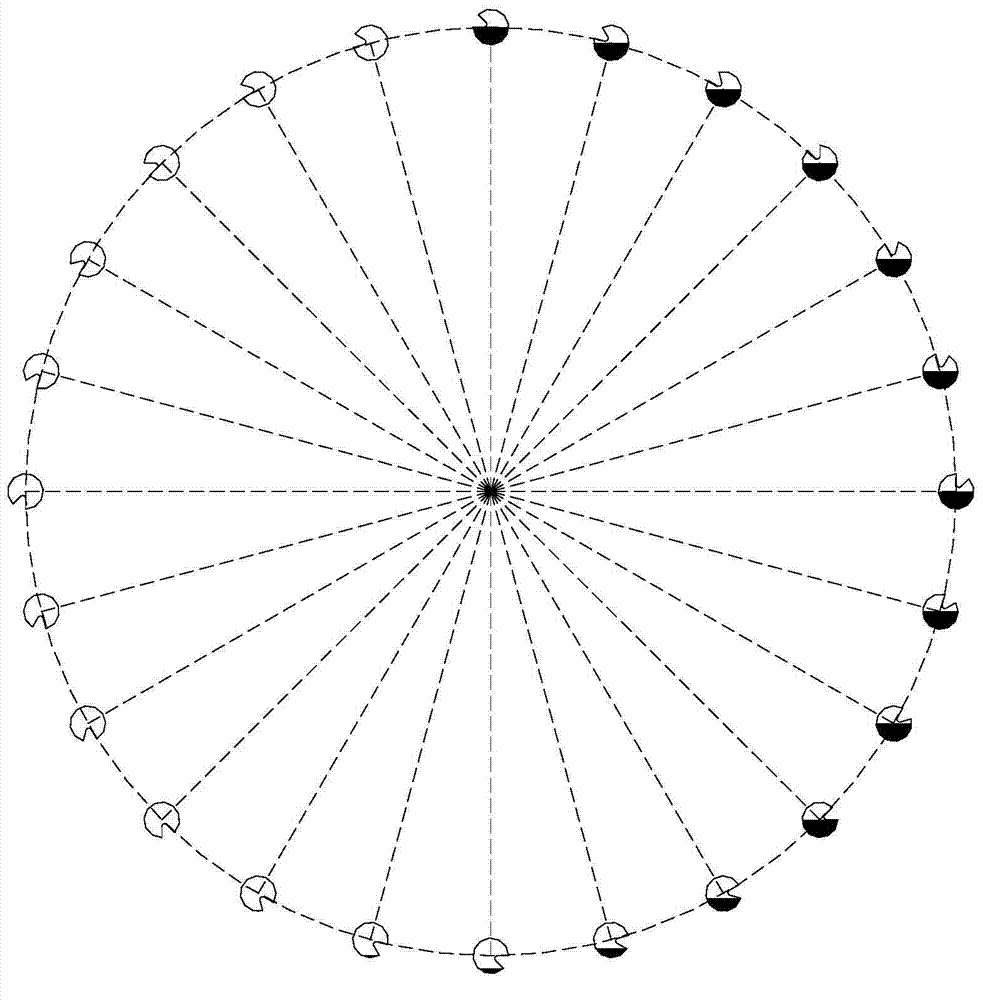

Punching sheet structure of permanent-magnet motor

PendingCN106787316AHigh drive torqueStrong and weak magnetic speed expansion capabilityMagnetic circuit rotating partsEngineeringSheet structure

The invention provides a punching sheet structure of a permanent-magnet motor, belongs to the technical field of motor manufacturing. By the punching sheet structure, the technical problems of small patented output and the like of an existing permanent-magnet motor are solved. The punching sheet structure comprises a round disc-shaped sheet body, wherein a plurality of V-shaped grooves are formed in the sheet body, a plurality of U-shaped grooves are further formed in the sheet body and are in one-to-one correspondence to the V-shaped groove, each pair of U-shaped groove and V-shaped groove forms a group of magnetic steel grooves, the magnetic steel grooves are distributed around the circumferential direction of the sheet body at intervals, openings of the U-shaped grooves and the V-shaped grooves face a peripheral surface of the sheet body, the U-shaped grooves are arranged between the V-shaped grooves and a shaft hole, and magnetic isolation bridges are arranged at lower ends of the U-shaped grooves and lower ends of the V-shaped grooves. In the punching sheet structure, each group of magnetic steel grooves comprise the U-shaped groove and the V-shaped groove which are arranged correspondingly, the U-shaped groove and the V-shaped groove are divided into two layers along a radial direction, thus, the magnetic resistance of a direct-axis magnetic path of the motor is increased, the magnetic conduction is reduced, the direct-axis inductance is reduced, the difference value between a quadrature-axis inductance and the direct-axis inductance is increased, the magnetic resistance torque of the motor is increased, and the output of the motor is increased.

Owner:WENLING JIUZHOU ELECTROMECHANICAL

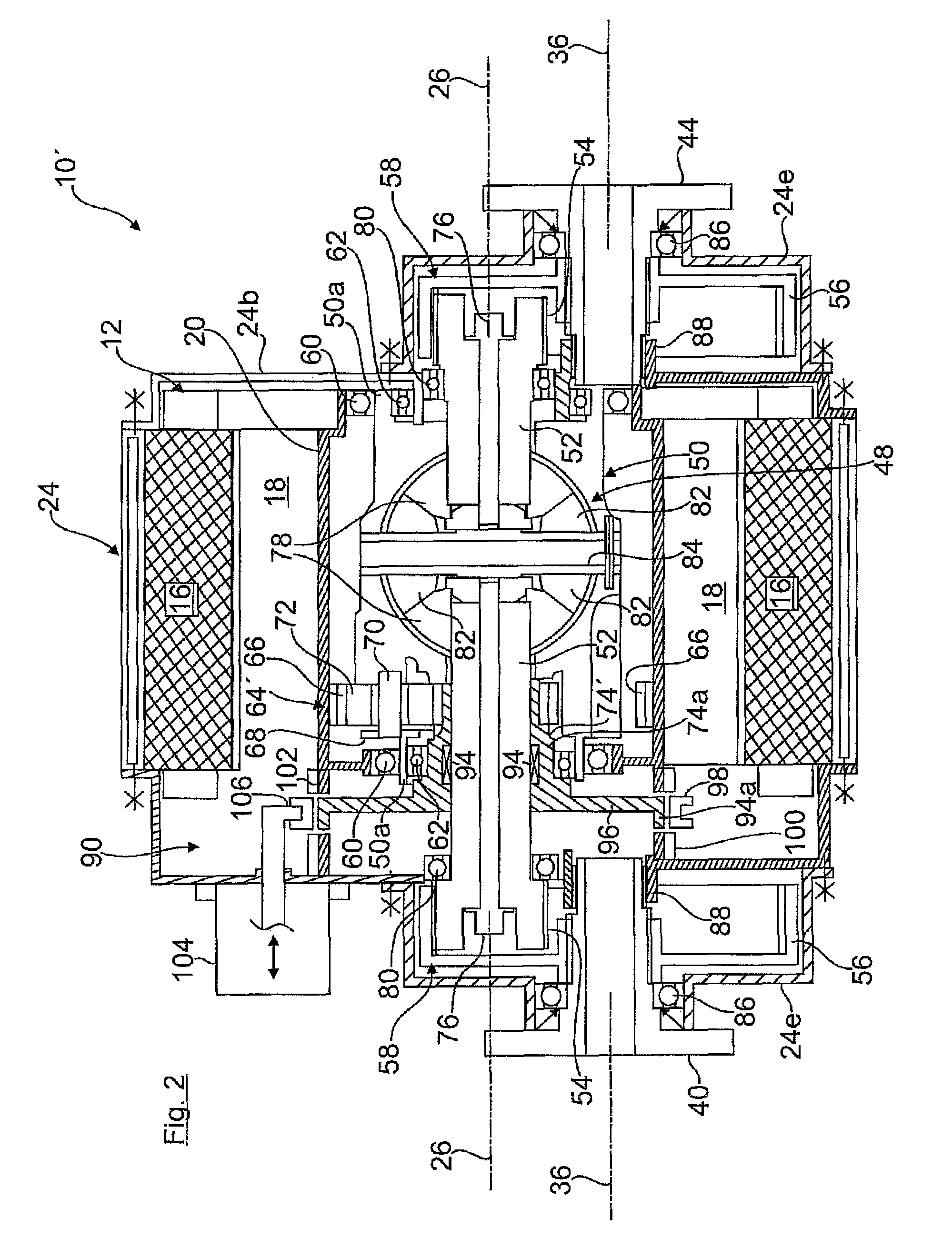

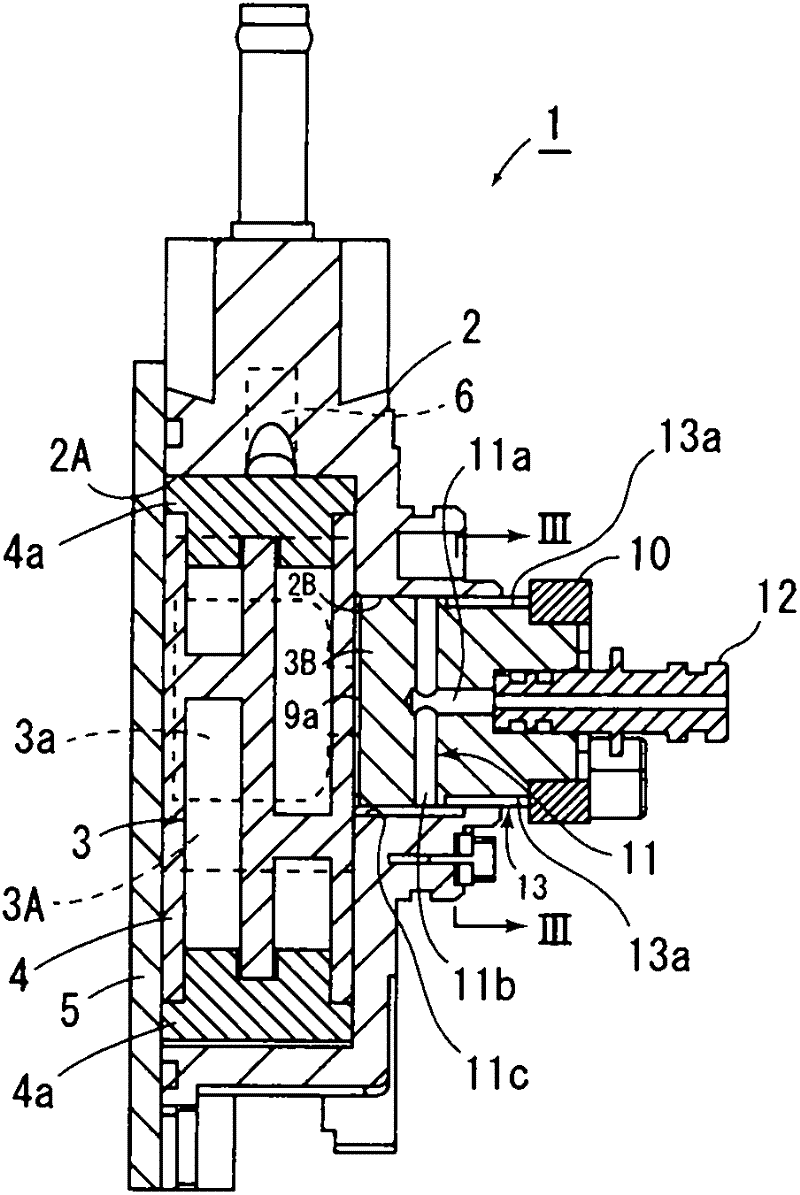

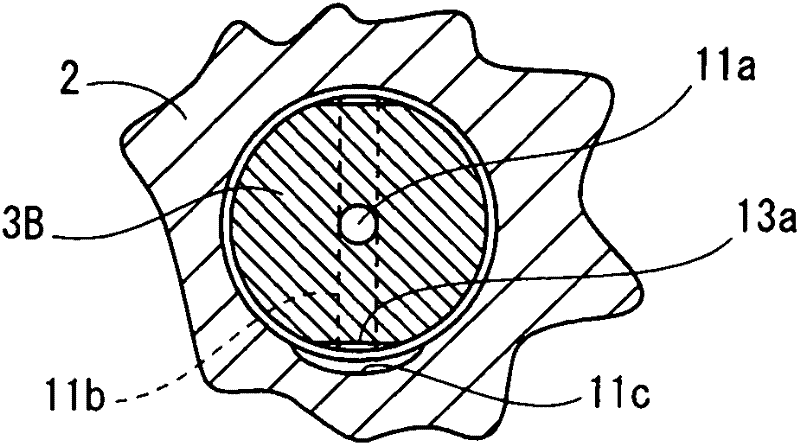

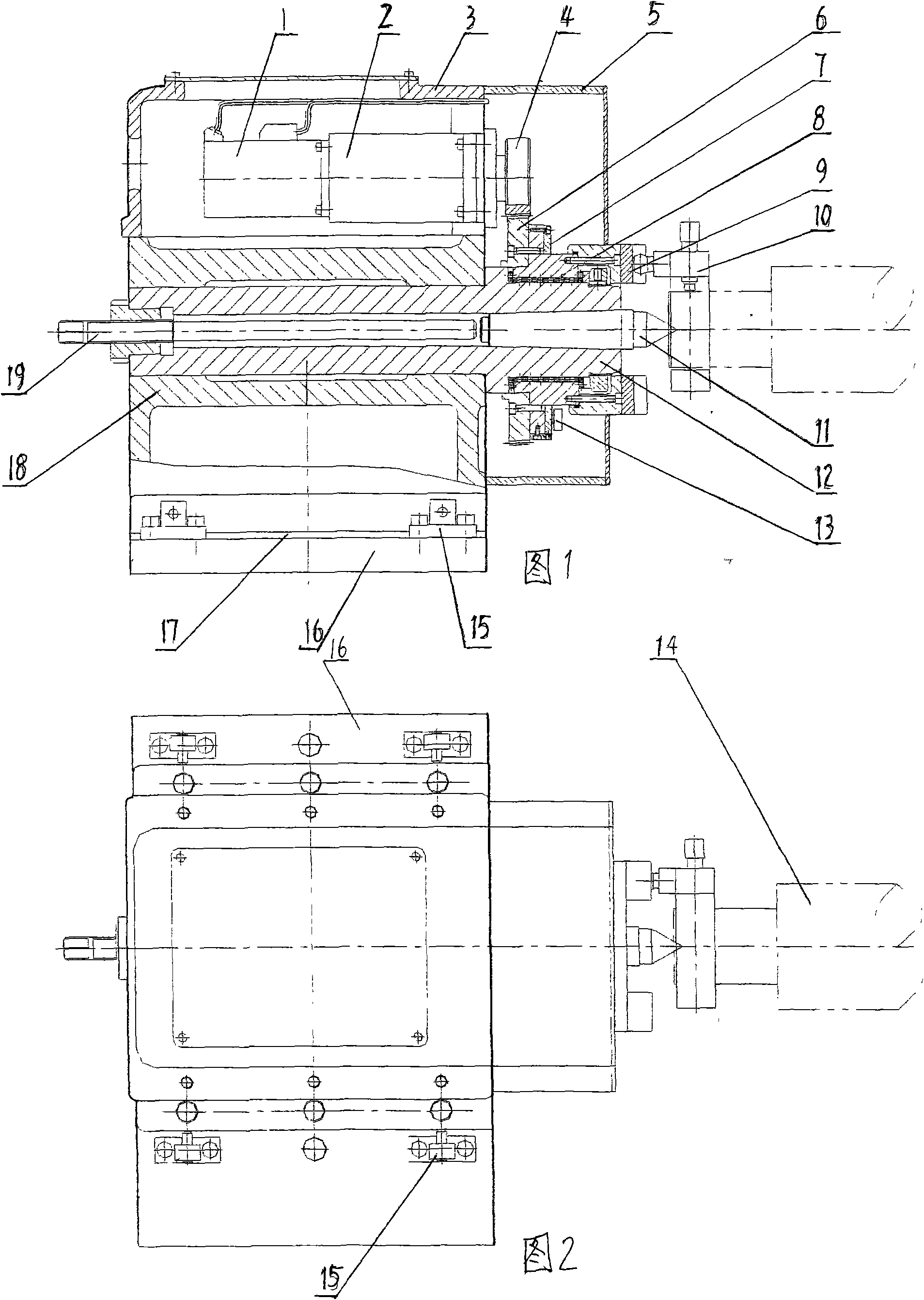

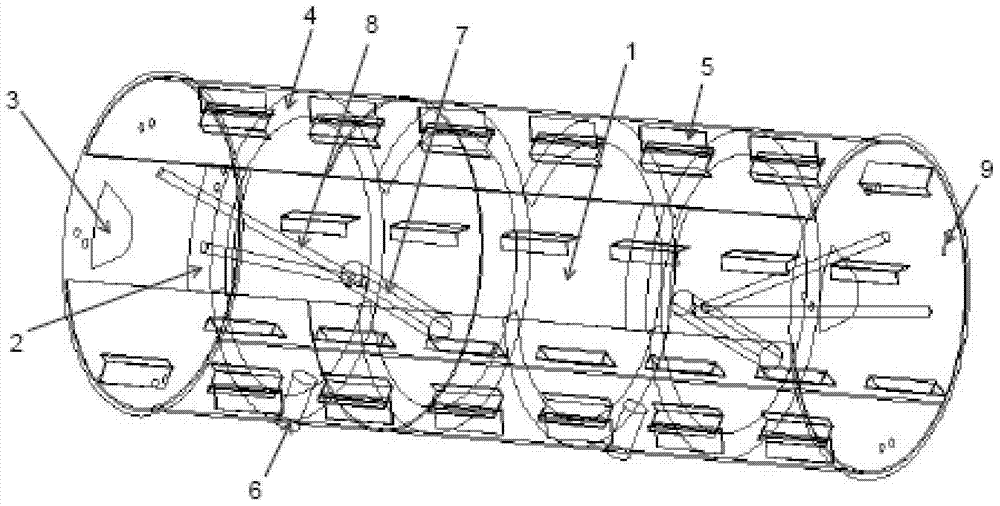

Cutter drive device of eccentric multi-axial type tunnelling machine

The invention is a kind of cutter plate driving device for eccentric multi spindle development machine, which belongs to building mechanical field. The sealing way of sand in the invention is: there sets a double sealing of maze sealing and the first teeth sealing between the bearing bracket base and the eccentric spindle, there sets a double sealing of maze sealing and the second teeth sealing between the bearing base and the eccentric spindle. The driving device hydraulic motor and the decelerator base are connected with one end of the bearing base through bolt. The decelerator output small gear spindle engages with the gear, the gear is covered in the eccentric spindle and connected with flat key, the second bearing and the third bearing in the bearing base are set on the neck part of the eccentric spindle, the first bearing in the bearing base is supported on another neck part of the eccentric spindle, the two ends of the eccentric spindle are fixed through a round bolt and stopping cushion to limit the axial movement of eccentric spindle. The invention reduces the project cost greatly and shortens the constructing period.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

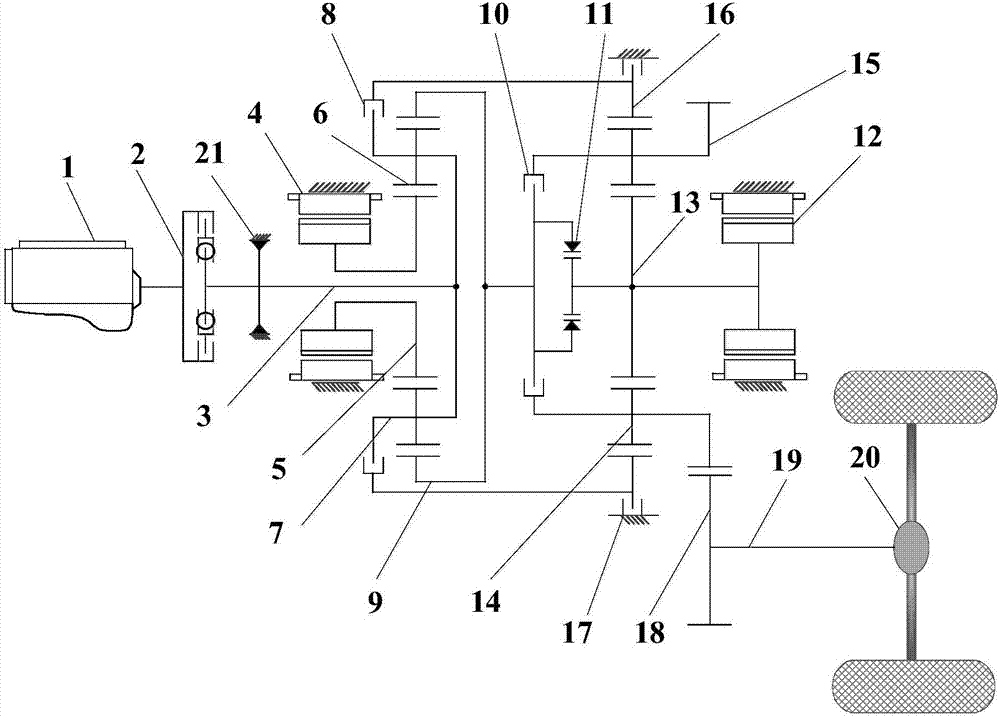

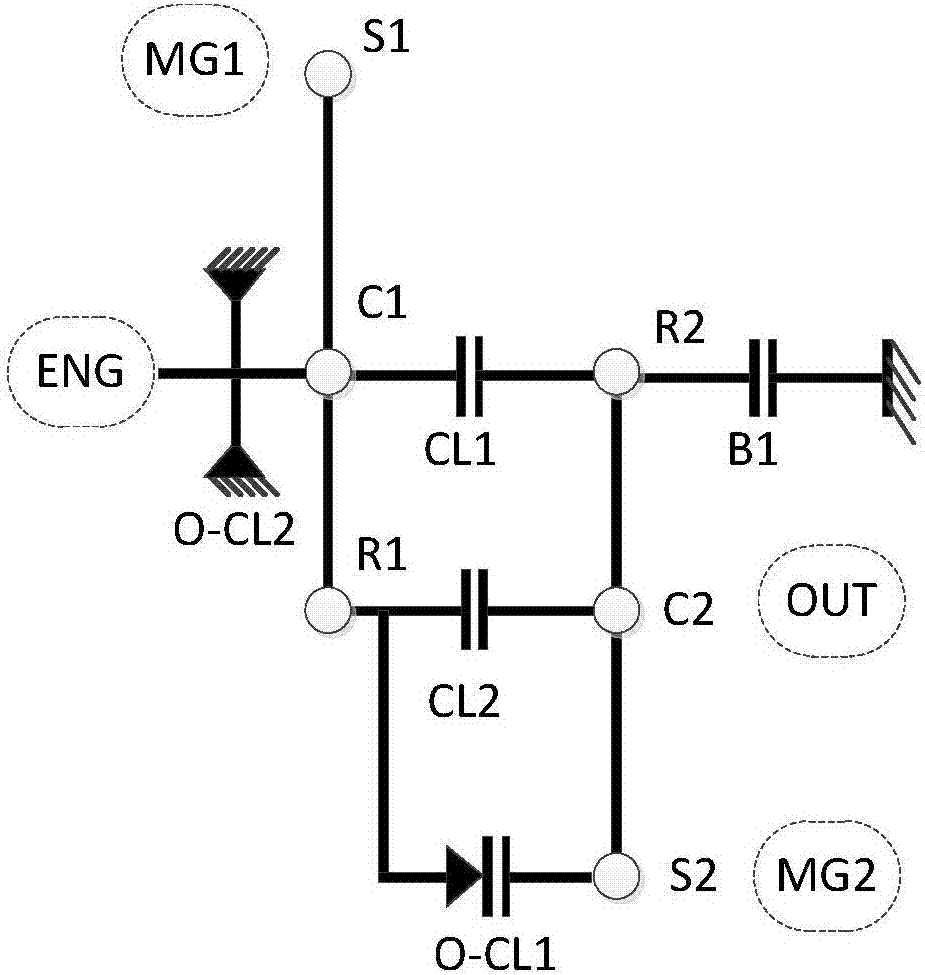

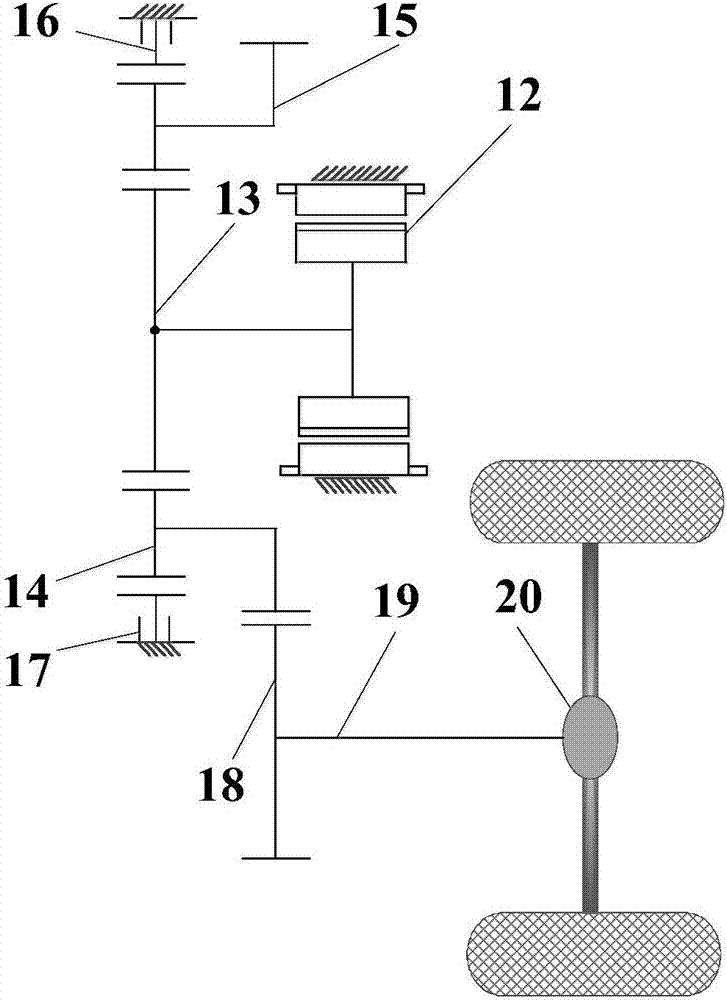

Planetary gear series-parallel twin-mode hybrid vehicle drive system

InactiveCN106976390AEliminate idle fuel consumptionImprove fuel economyHybrid vehiclesGas pressure propulsion mountingLow speedElectric machine

The invention discloses a planetary gear series-parallel twin-mode hybrid vehicle drive system and relates to the technical field of vehicles. The system comprises an engine, a front planetary gear train, a rear planetary gear train, a first clutch, a second clutch, an overrun clutch, a backstop, a brake, a first motor and a second motor. Conversion among different working modes can be achieved through combination and separation of the clutches and the brake. The system is compact in structural design, the power grades of the motors are effectively decreased, the sizes of the motors are reduced, the slope climbing performance of the vehicle in a pure electric mode is improved, and the low-speed performance of the vehicle in the pure electric mode is improved; the defect that parasitic power is generated when the vehicle travels in a high-speed area is overcome, the high-efficiency range of a hybrid power system is enlarged, and the economic efficiency of the vehicle is improved; and the problems that the acceleration performance of the vehicle is poor and the slope climbing capability is limited in a low-speed area are solved, and the dynamic property and the economic efficiency of the vehicle are improved.

Owner:JILIN UNIV

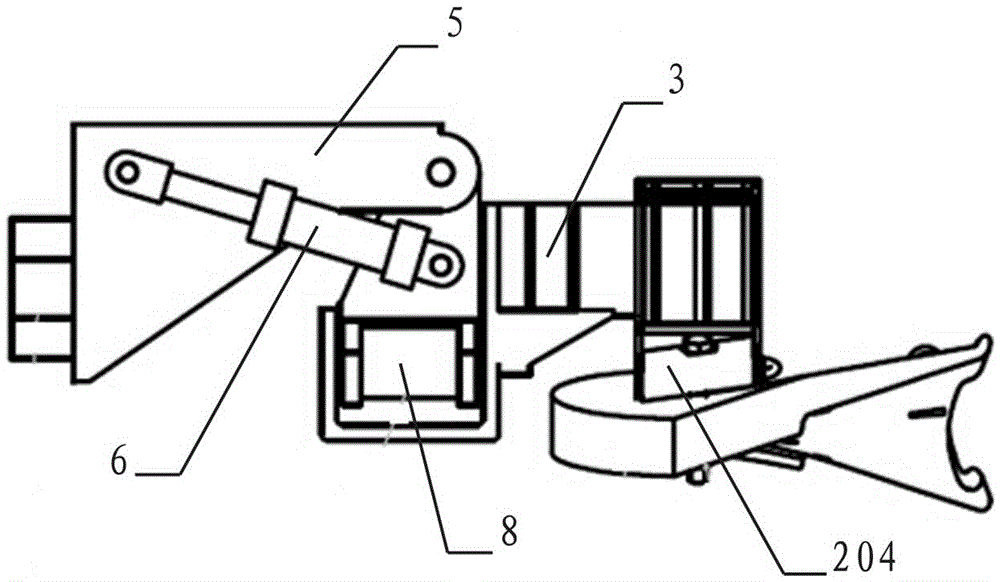

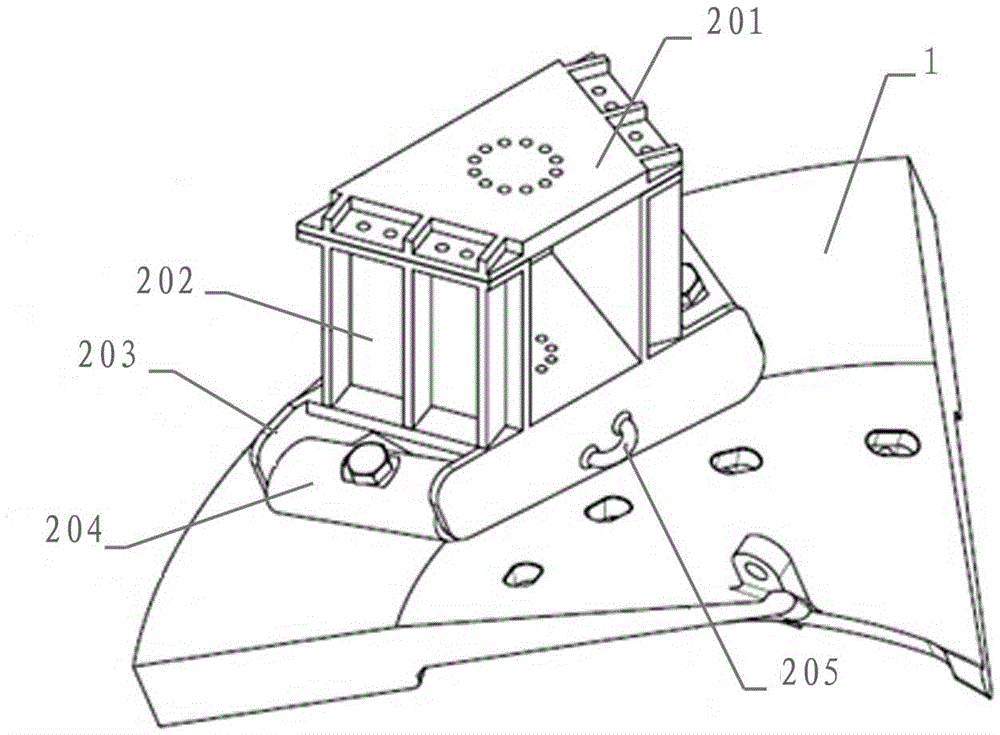

Underwater tail vane turning die and underwater navigation device containing the same

InactiveCN101508336AReduce frictional resistanceStrong pressure capacityEngine sealsUnderwater vesselsUnderwater navigationRudder

The invention discloses an underwater stern rudder steering module, which comprises a steering mechanism fixedly connected with a rudder. The steering mechanism is arranged in a stern shell and comprises a rudder shaft which extends out of the stern shell and is fixedly connected with the rudder shaft; a sealed structure is arranged between the rudder shaft and the stern shell; the steering mechanism also comprises a motor, a screw rod connected with an output shaft of the motor, a screw nut arranged on the screw rod, a rotating seat fixedly connected with the screw nut, a vertically outward rotating part connected with the rotating seat, and a deflector rod inserted in the rotating part and fixedly connected with the rudder shaft; and the steering mechanism is fixedly connected to a fixed disk which is fixedly connected with the stern shell, and the fixed disk is fixedly connected with a control device of the steering mechanism. The invention also discloses an underwater running vehicle comprising the underwater stern rudder steering module. The underwater stern rudder steering module adopts a linkage mechanism and mechanical seal to realize stern rudder steering, and adopts the modularization design to ensure that the module has small volume and a compact structure which is easy to replace, dismount and mount; and the structure is simple and reliable, the driving torque is large, and the sealed structure has small frictional resistance and strong bearing capacity.

Owner:TIANJIN UNIV

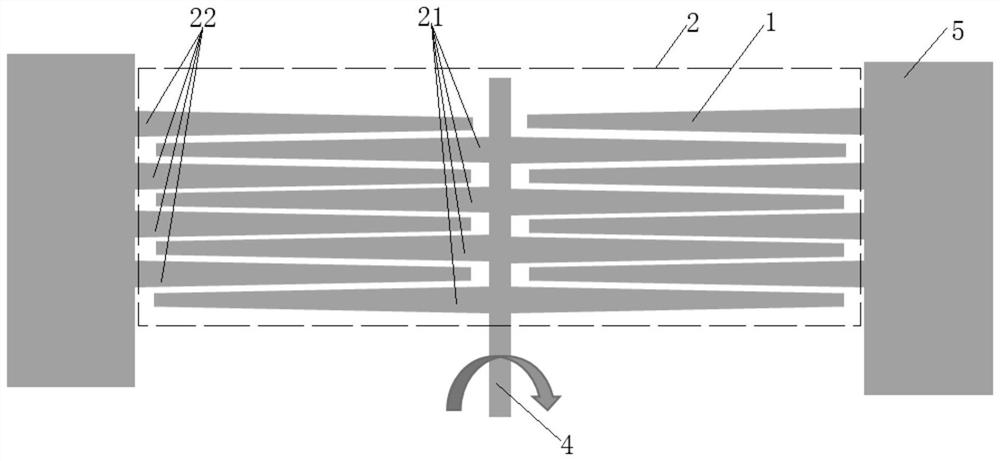

Mash seam welding method and device

ActiveCN103108719AIncreased pressure bearing shareIncrease the pressure differenceElectrode featuresWelding electric supplySeam weldingUltimate tensile strength

In order that in mash seam welding for metal plates with a thickness exceeding 2 mm, the joint strength is stabilized, the difference in the level of a joint part is reduced, high joint strength and reliability are ensured, and therefore metal plates with a thickness exceeding 4.5 mm can be also joined, two metal plates (5, 6) are grasped by first and second graspers (7, 8), respectively, ends of the two metal plates (5, 6) are overlapped , an overlap (L) therebetween is pressurized by a pair of upper and lower electrode wheels (1, 2) and continuously welded while a welding current is being passed to thereby join the two metal plates. While the overlap (L) is continuously welded while the welding current is being passed, welding pressure to be applied to the upper and lower electrode wheels (1, 2) is controlled such that upper and lower pressing forces acting on the overlap become equal.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

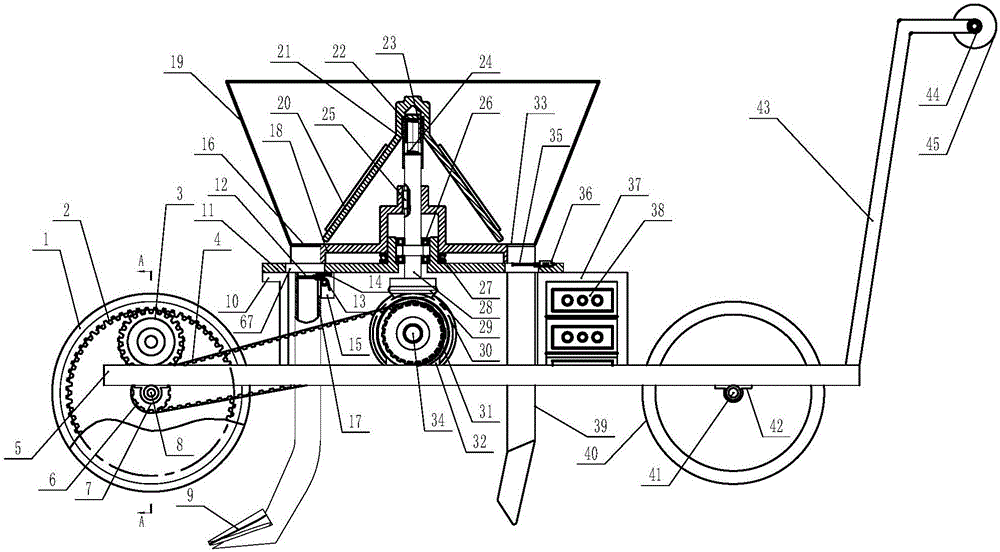

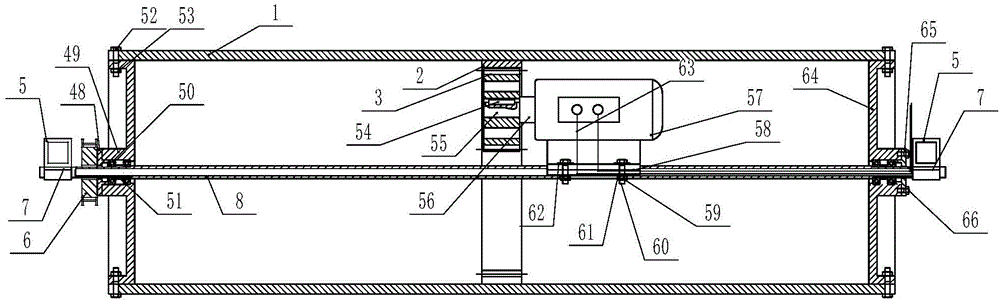

Horizontal rotating disk-type electric potato planting machine capable of realizing missing seeding compensation

InactiveCN106385887AMeet the requirements of precision plantingSimple structurePotato plantersFurrow making/coveringDrive shaftAgricultural engineering

The invention discloses a horizontal rotating disk-type electric potato planting machine capable of realizing missing seeding compensation. The horizontal rotating disk-type electric potato planting machine comprises a machine frame, a driving part, a soil covering pressing wheel, and a planting mechanism; the driving part is supported by the front end of the machine frame; the soil covering pressing wheel is supported by the back end of the machine frame; the planting mechanism comprises a seed discharging transmission shaft, a seed box base plate, and a floating seed scattering plate; the seed discharging transmission shaft is supported by the machine frame; the power output end of the driving part is connected with the seed discharging transmission shaft via coupling transmission; a horizontal seed distributing rotating disk is supported by the upper end of the seed box base plate; a rotating disk driving shaft fixedly connected with the horizontal seed distributing rotating disk is supported by the seed box base plate; transmission of the seed discharging transmission shaft and the rotating disk driving shaft is realized via engagement transmission of bevel gears; and the floating seed scattering plate is connected with the top of the rotating disk driving shaft via an elastic link device. The horizontal rotating disk-type electric potato planting machine is compact in structure, reliable in transmission, and high in seed discharging accuracy; can be moved conveniently in field, possesses relatively wide planting distance adjusting range, and is capable of satisfying agricultural requirements of potato precision planting in mountain slope or other small lands.

Owner:ZHEJIANG FORESTRY UNIVERSITY

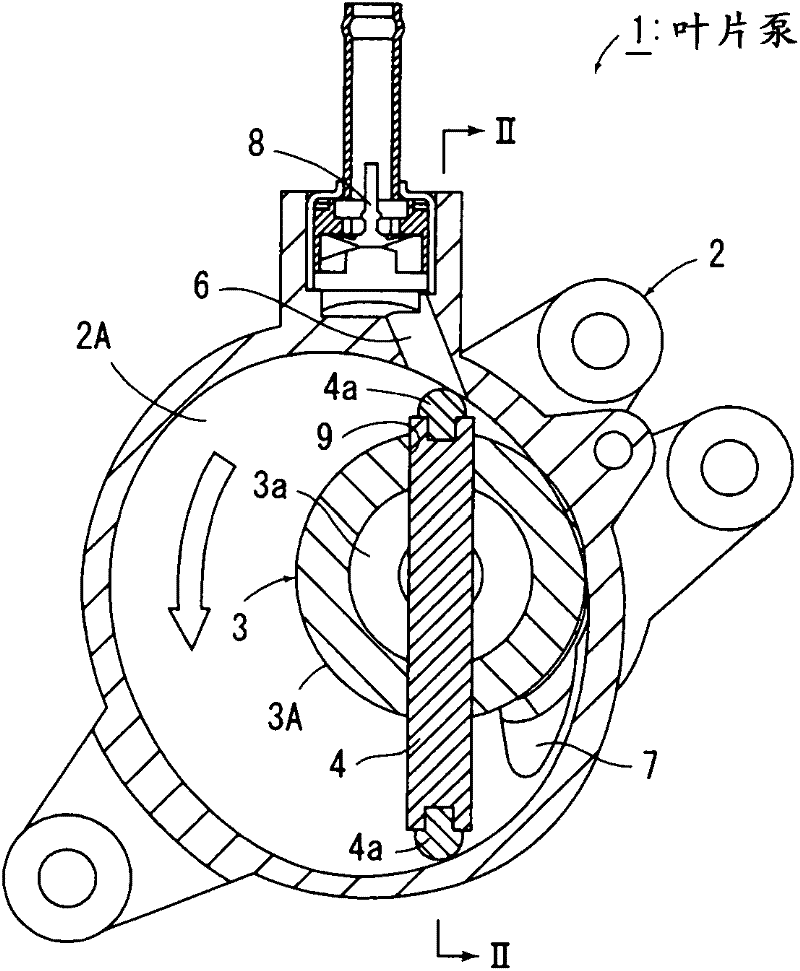

Vane pump

InactiveCN102365461AConsistent widthAvoid inhalationRotary piston pumpsRotary piston liquid enginesPump chamberEngineering

Owner:TAIHO INDUSTRIES CO LTD

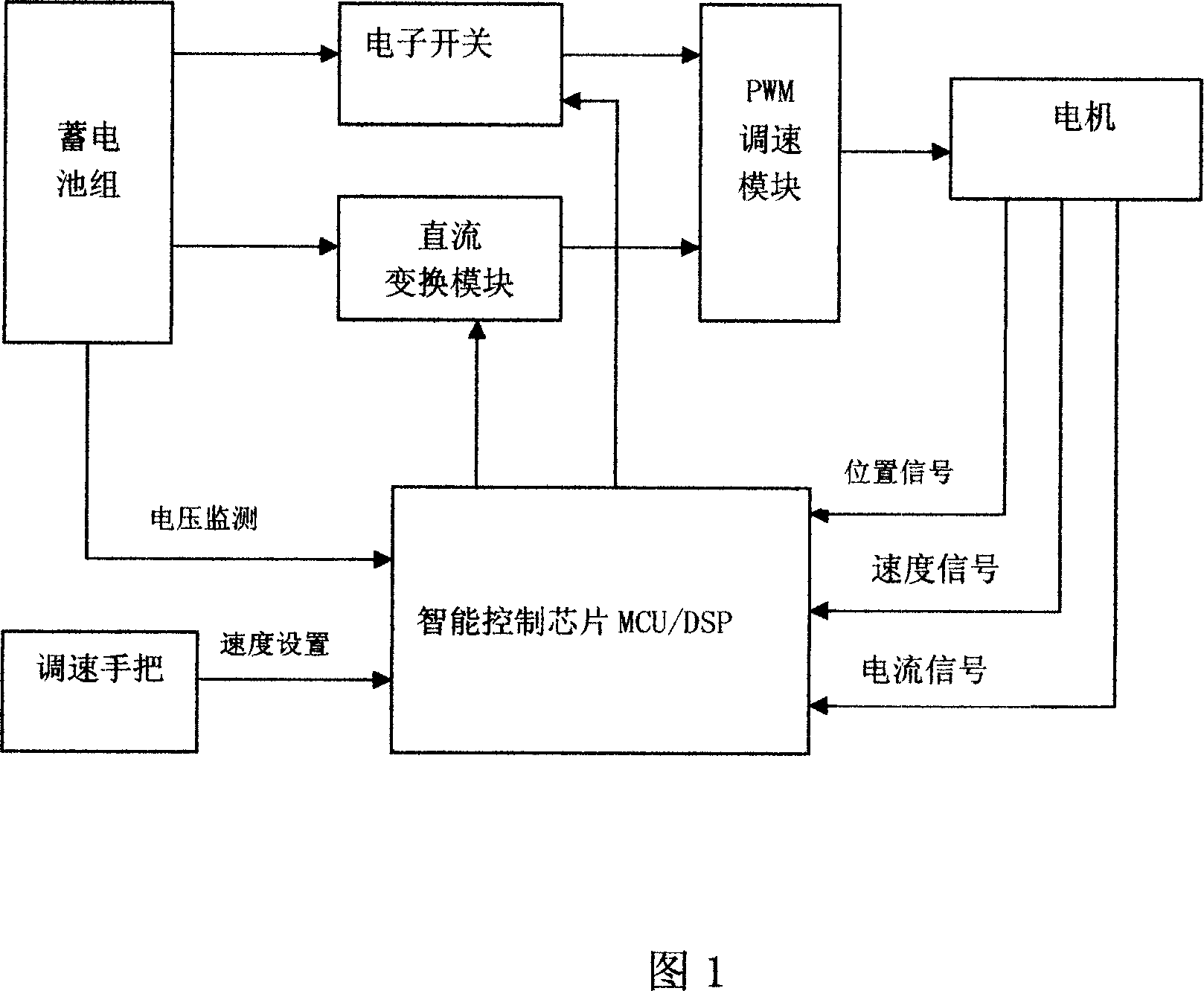

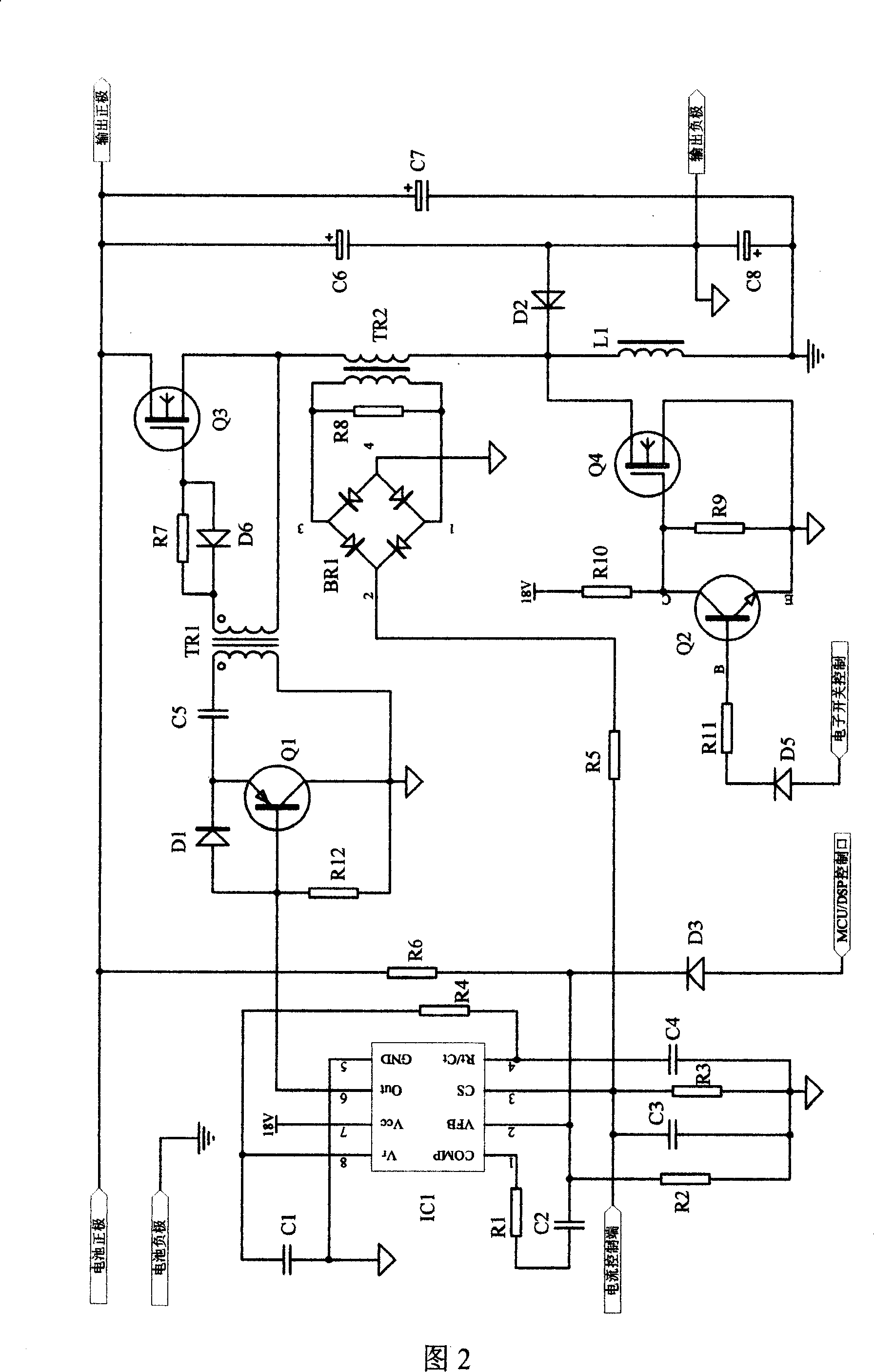

Control method and device for increasing DC brushless motor speed

InactiveCN101026353AGuaranteed operating efficiencyProtect normal use conditionsField or armature current controlBrushless motorsElectric machine

Detecting rotation speed of motor, working current and voltage, the invention controls motor to operate at following states: (1) working current of motor larger than setting value, using voltage output from accumulator as voltage for supplying to motor; (2) voltage of battery smaller than setting value, keeping voltage output from accumulator as voltage for supplying to motor; (3) working current of motor not larger than setting value, voltage of battery not smaller than setting value; when voltage signal detected from rotating handle for speed adjustment is in maximum, the disclosed method converts voltage of accumulator storage battery to obtain voltage of transformation V2, and using summation of V2 and output voltage V1 from accumulator storage battery as working voltage of motor. Thus, rotation speed of motor reaches to (V1+V2) / V1 time of former rotation speed.

Owner:金华市绿源电动车有限公司 +1

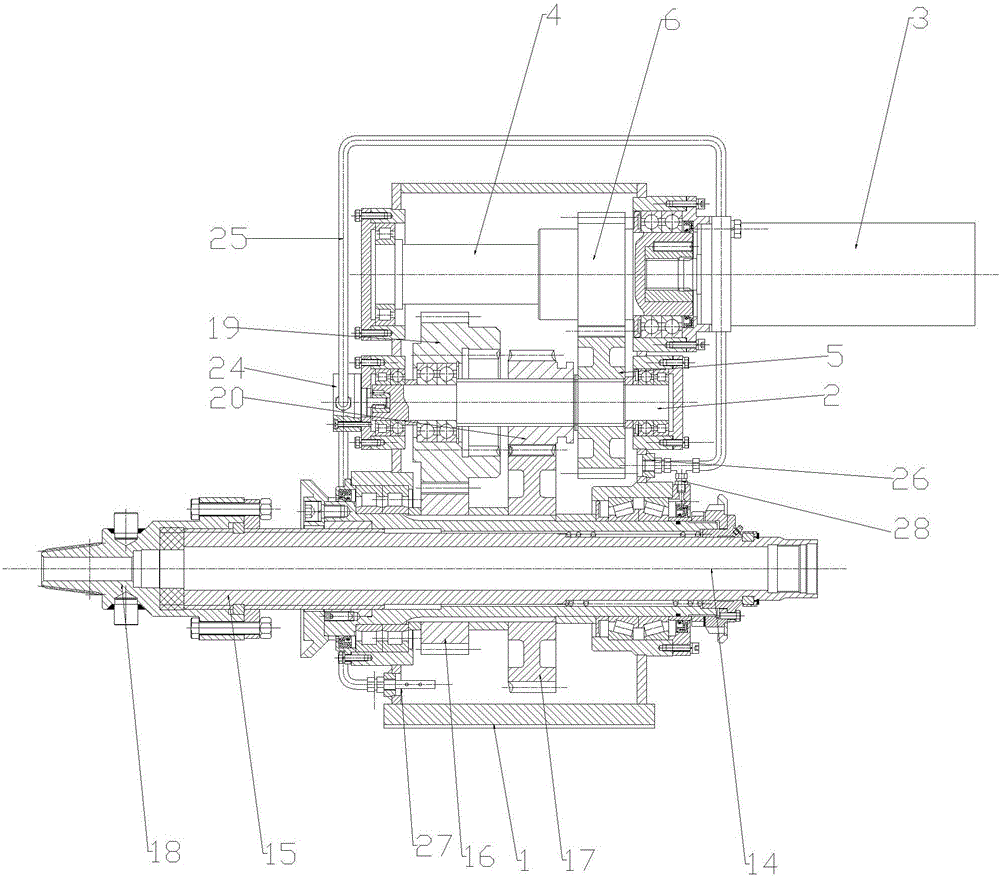

High-precision angular indexing dynamic measuring spindle system

ActiveCN101608933AAdvanced structure principleSystem working links are conciseMeasurement apparatus componentsMeasurement deviceDrive motor

The invention relates to a high-precision angular indexing dynamic measuring spindle system belonging to a precision measuring device. A mandrel (12) is fixed on a lower seat body (18), and the center is provided with a Mohs tip (11) ; a gearwheel set (6) is provided with a precision grating disc (7) which is sheathed on the mandrel by a ball bearing set (8); two sets of grating read heads (13) are arranged on the lower seat body (18) and are distributed diametrically to sample reading; a drive plate set (9), the precision grating disc (7) and the outer cover of the ball bearing set (8) are in rigid connection with the gearwheel set (6); a grip set (10) and a clamping workpiece (14) are arranged on the drive plate set (9), and a drive motor (1), a reducer (2) and a pinion wheel set (4) are arranged in an upper seat body (3) to form a drive system. The invention aims to provide the high-precision angular indexing dynamic measuring spindle system which has novel design, advanced technology, reliable structure and low manufacture cost and can be widely applied to precision measuring apparatus industry.

Owner:贵阳新天光电科技有限公司

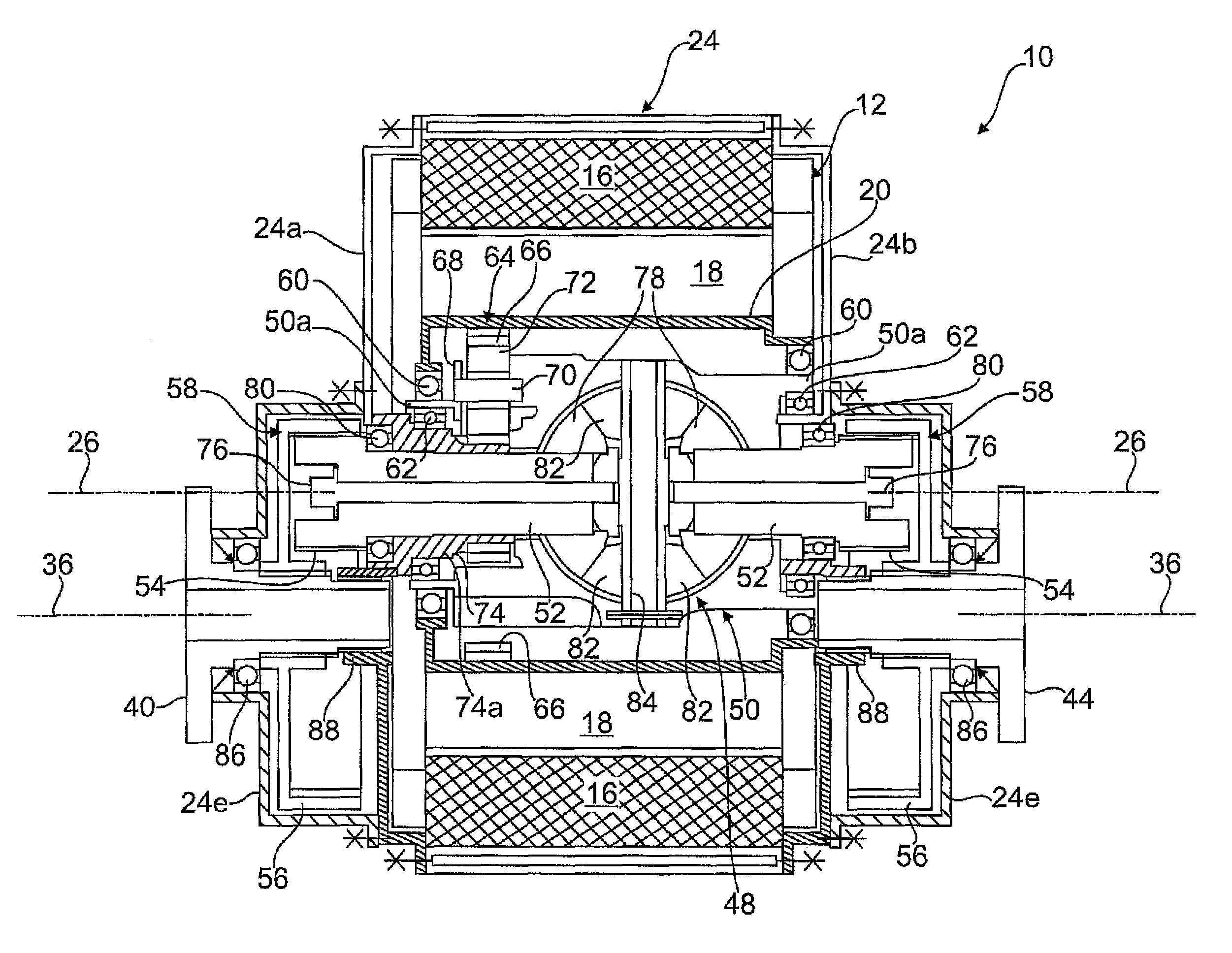

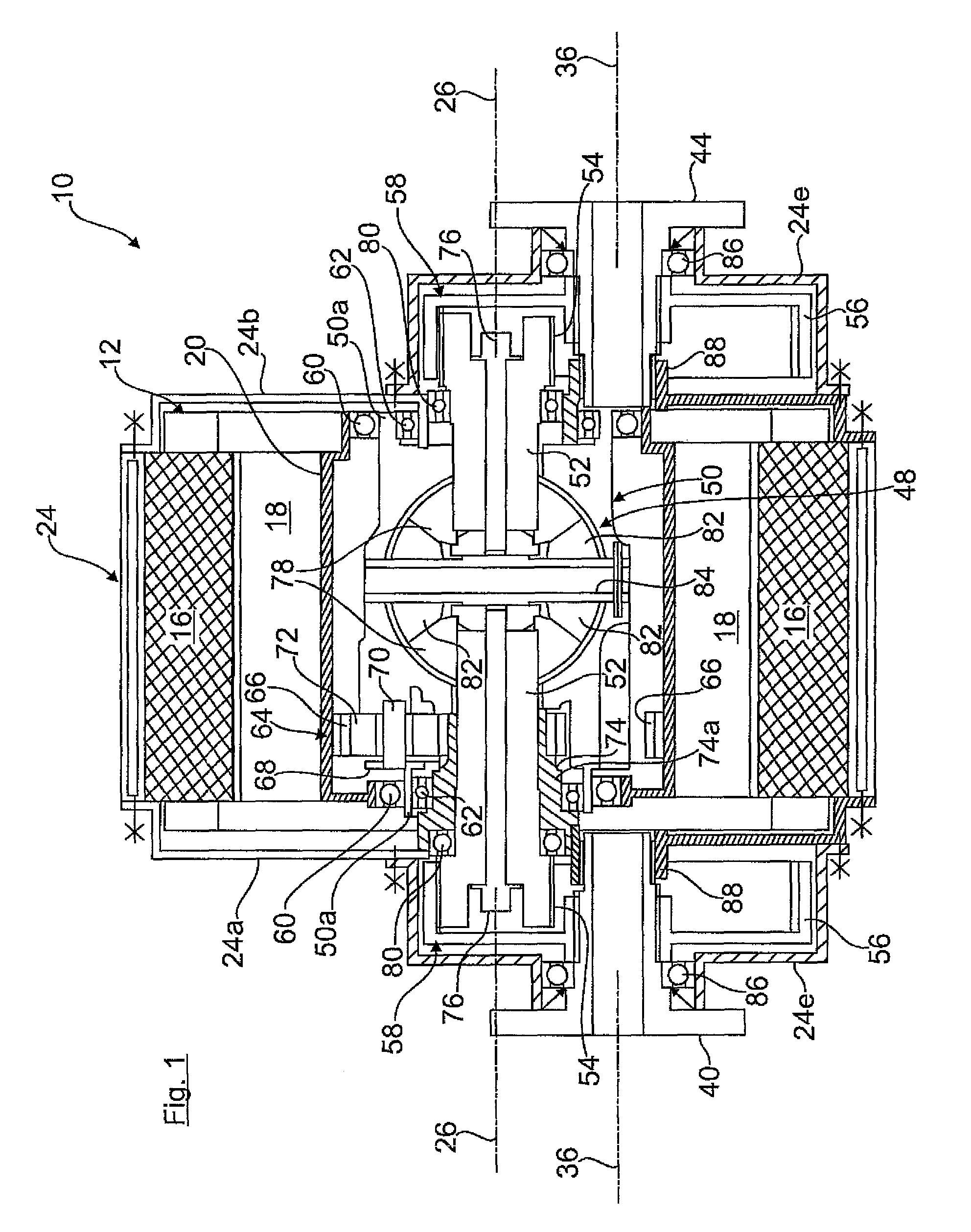

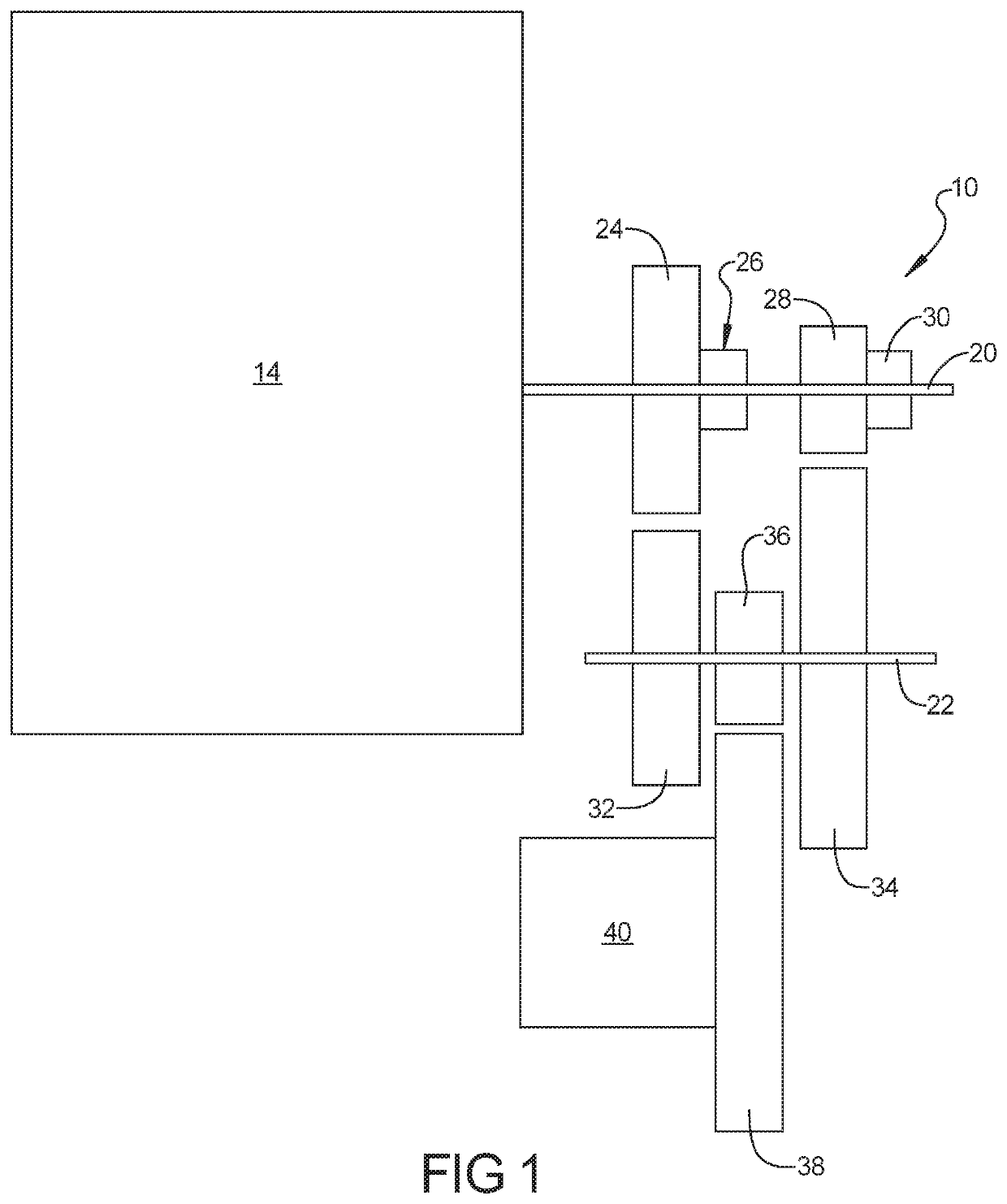

Two ratio electric drive unit

ActiveUS10533640B2Increased torque densityReduce riskToothed gearingsTransmission elementsGear wheelElectric drive

A powertrain includes an electric motor and a first planetary gear stage having a first rotatable member drivingly connected to the electric motor and at least one second rotatable member. A second planetary gear stage includes a third rotatable member drivingly connected to the at least one second rotatable member and includes at least one fourth rotatable member. One of the third rotatable member and the at least one fourth rotatable member is connected to an output member. A passive one-way clutch and a selectable one-way clutch are associated with at least one of the first and second planetary gear stages for varying operation of the first and second planetary gear stages based upon an operation state of the selectable one-way clutch and a direction of rotation of the electric motor.

Owner:GM GLOBAL TECH OPERATIONS LLC

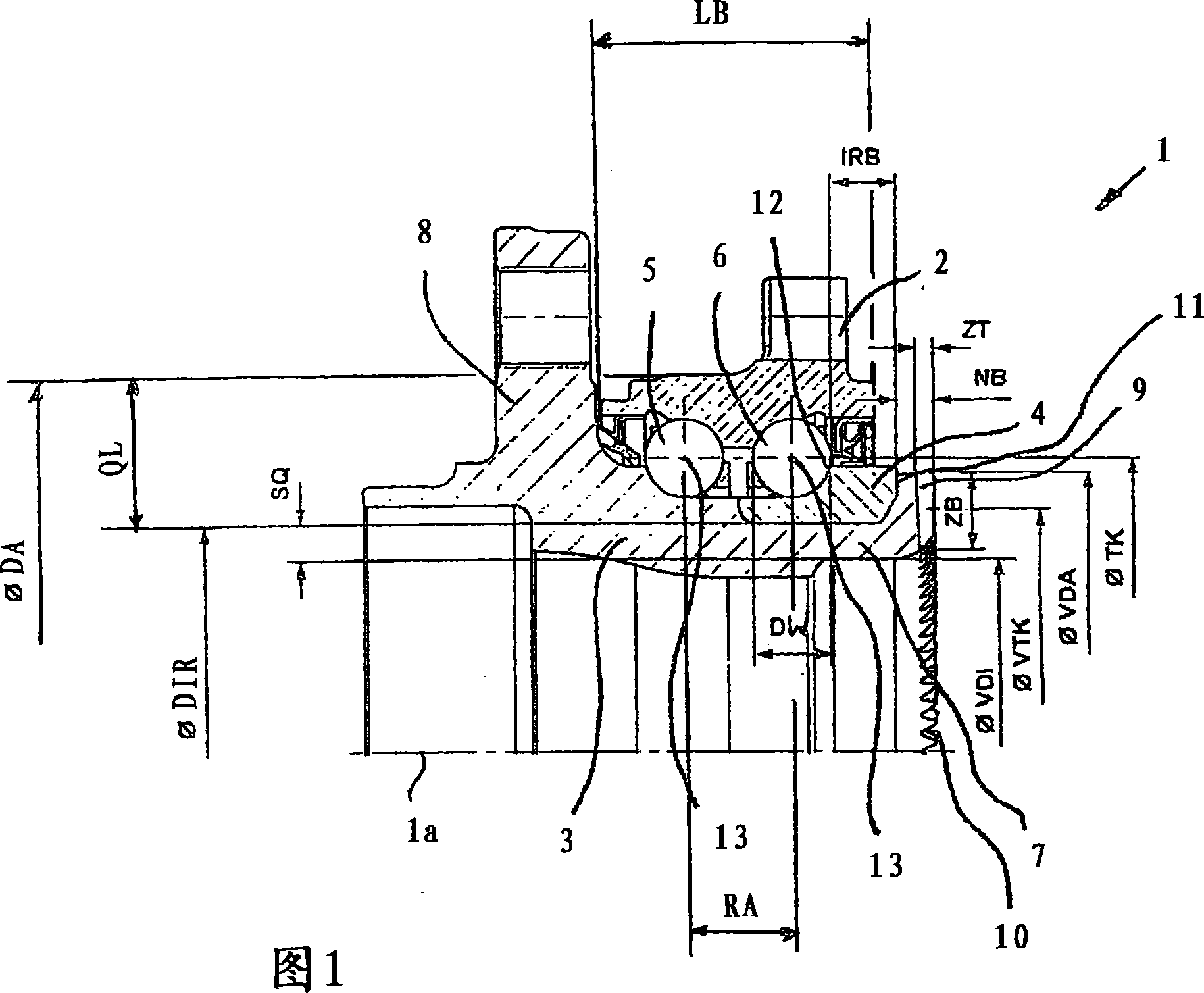

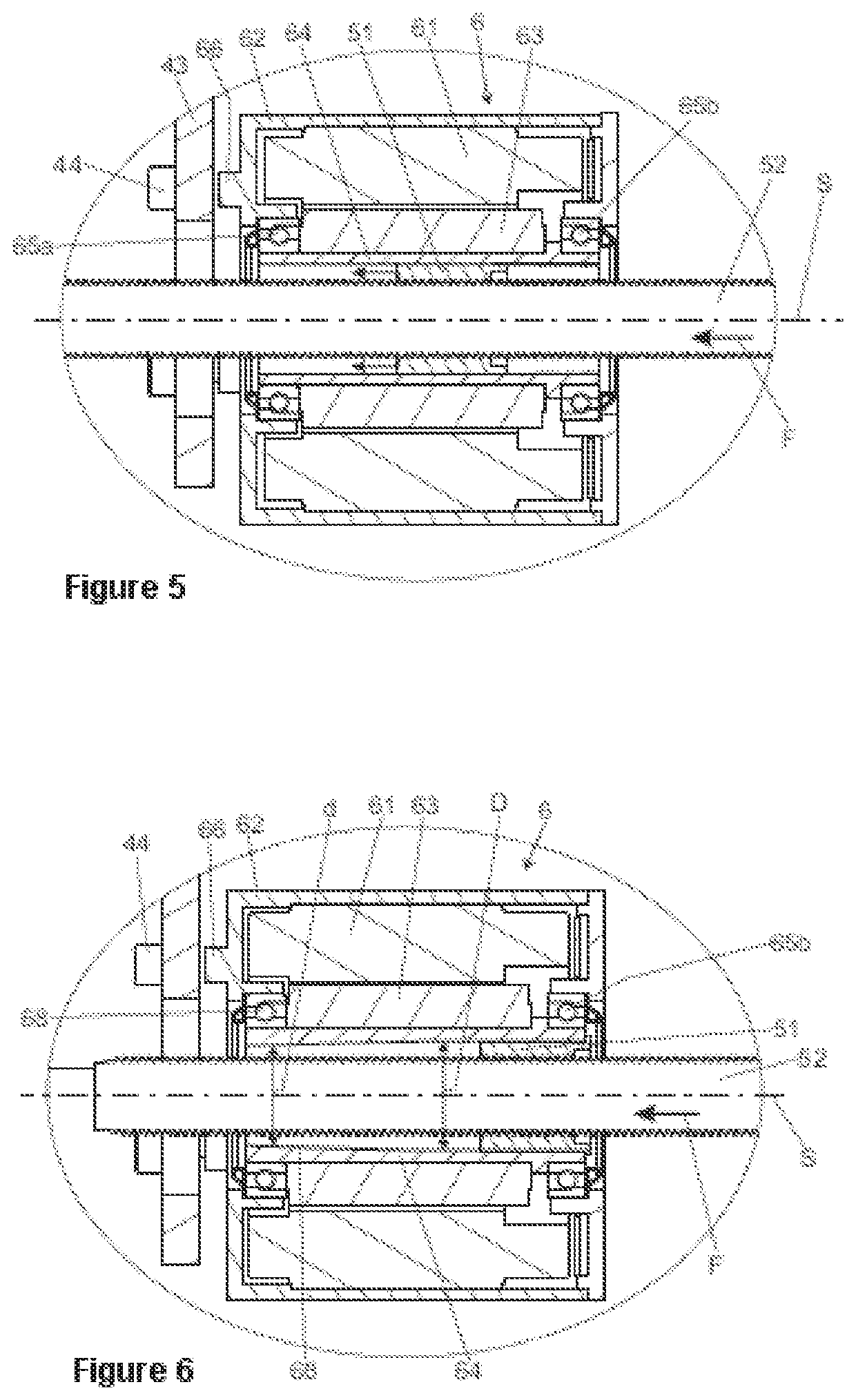

Wheel bearing arrangement having spur toothing

ActiveCN101228037ALarge diameterHigh drive torqueRolling contact bearingsHubsDriven elementEngineering

The invention relates to a wheel bearing arrangement having at least two rows of rolling bodies for supporting a wheel hub drivable by the wheel bearing arrangement via a drive element. The wheel hub is connected to the drive part; the wheel hub and the drive part mesh with each other in a form-locking manner via a pair of mutually corresponding end face gears. On the wheel bearing arrangement, in particular, the ratio of the pitch circle diameter (VTK) of the wheel bearing arrangement-side toothing to the rolling element row distance (RA) of the at least two rows of rolling elements is greater than a value of three.

Owner:SCHAEFFLER TECH AG & CO KG

Method for monitoring multi-motor drive

ActiveUS8219272B2High drive torqueImprove controllabilityVehicle testingRegistering/indicating working of vehiclesMotor driveControl theory

A method for controlling a vehicle drive unit, which comprises at least two individual drives, at least one of which is able to provide a negative torque. A vehicle control unit is provided, within which a continuous torque comparison is performed within a monitoring level. A permissible torque is ascertained therein. Using a torque range checker it is established whether ascertained setpoint torques lie within torque ranges of the at least two individual drives.

Owner:ROBERT BOSCH GMBH

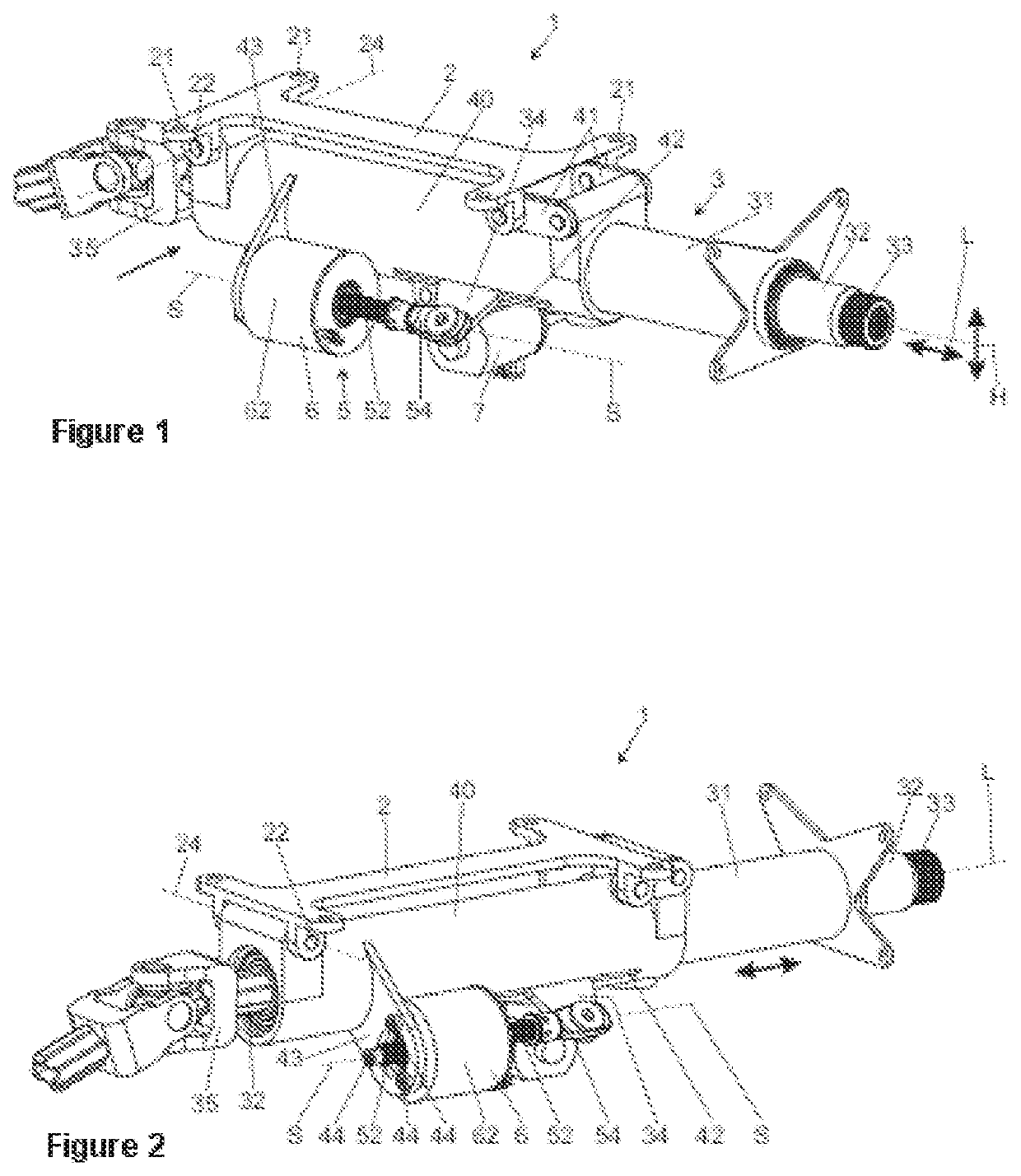

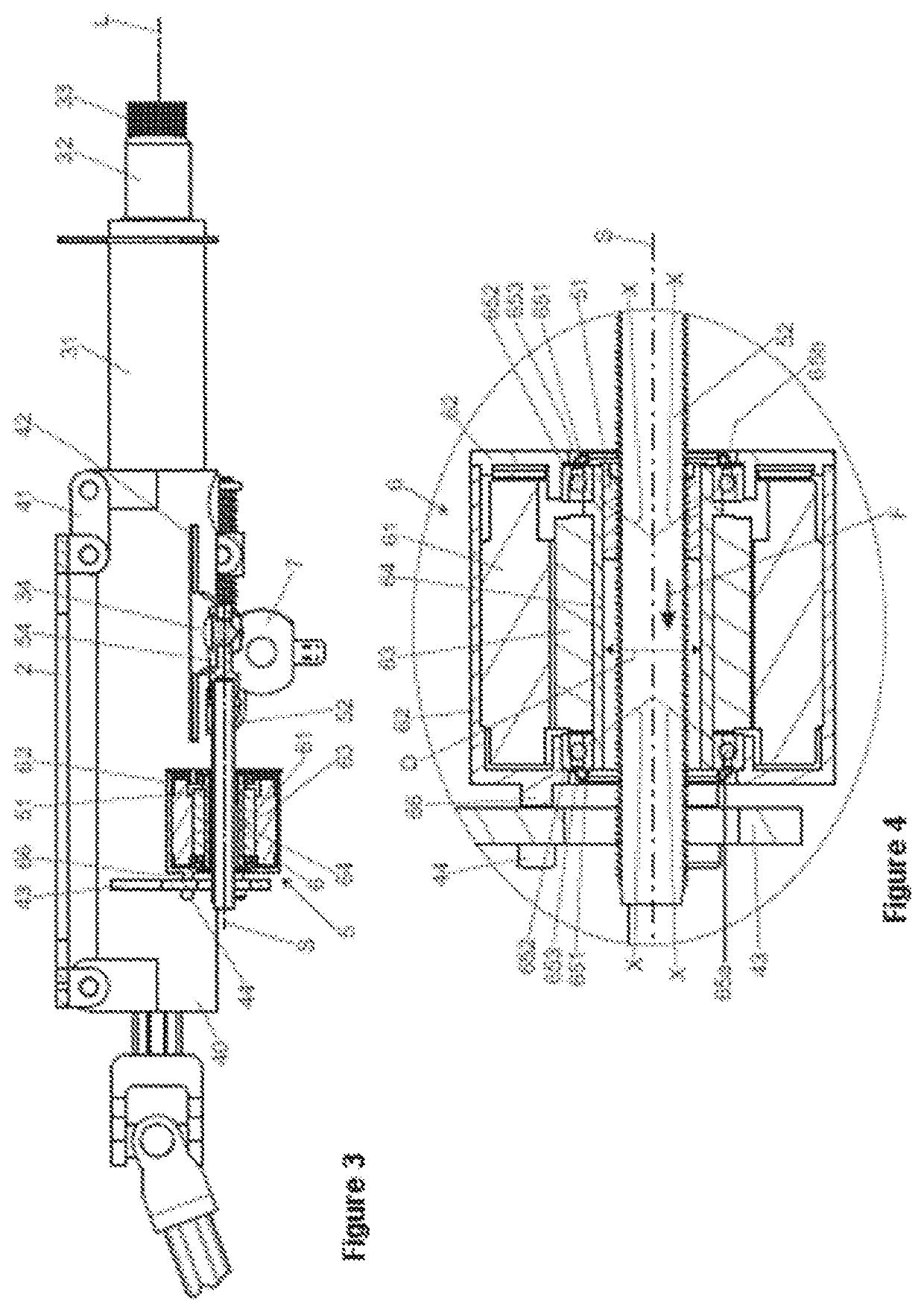

Mechanical arm used for replacing spiral liner plate

ActiveCN105643655AImprove mechanizationHigh degree of automationJointsWork holdersVertical planeRobot hand

The invention discloses a mechanical arm used for replacing a spiral liner plate. The mechanical arm comprises a linking tool, a pitching joint, a spiral curved surface attaching joint and an installation hole positioning joint. The spiral liner plate to be replaced is fixed to the linking tool. The pitching joint comprises a pitching connecting plate and a support, and the pitching action of the pitching joint is controlled by a drive mechanism arranged between the pitching connecting plate and the support. The spiral curved surface attaching joint comprises a tool connecting mechanism and a rotating mechanism I. The linking tool is connected to the tool connecting mechanism. The rotating mechanism I drives the linking tool to rotate. The installation hole positioning joint is composed of a rotating mechanism II arranged on the linking tool. The linking tool is driven to rotate in the horizontal plane. Pitching rotation, rotation in the horizontal plane and rotation in the vertical plane of the mechanical arm are completed through the coordination of the three joints, the posture of the spiral liner plate is adjusted gradually so that the spiral liner plate can be well attached to a spiral supporting plate of a vertical stirring mill and an installation hole can be positioned, and the mechanization and automation degree of replacing the spiral liner plate is greatly improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

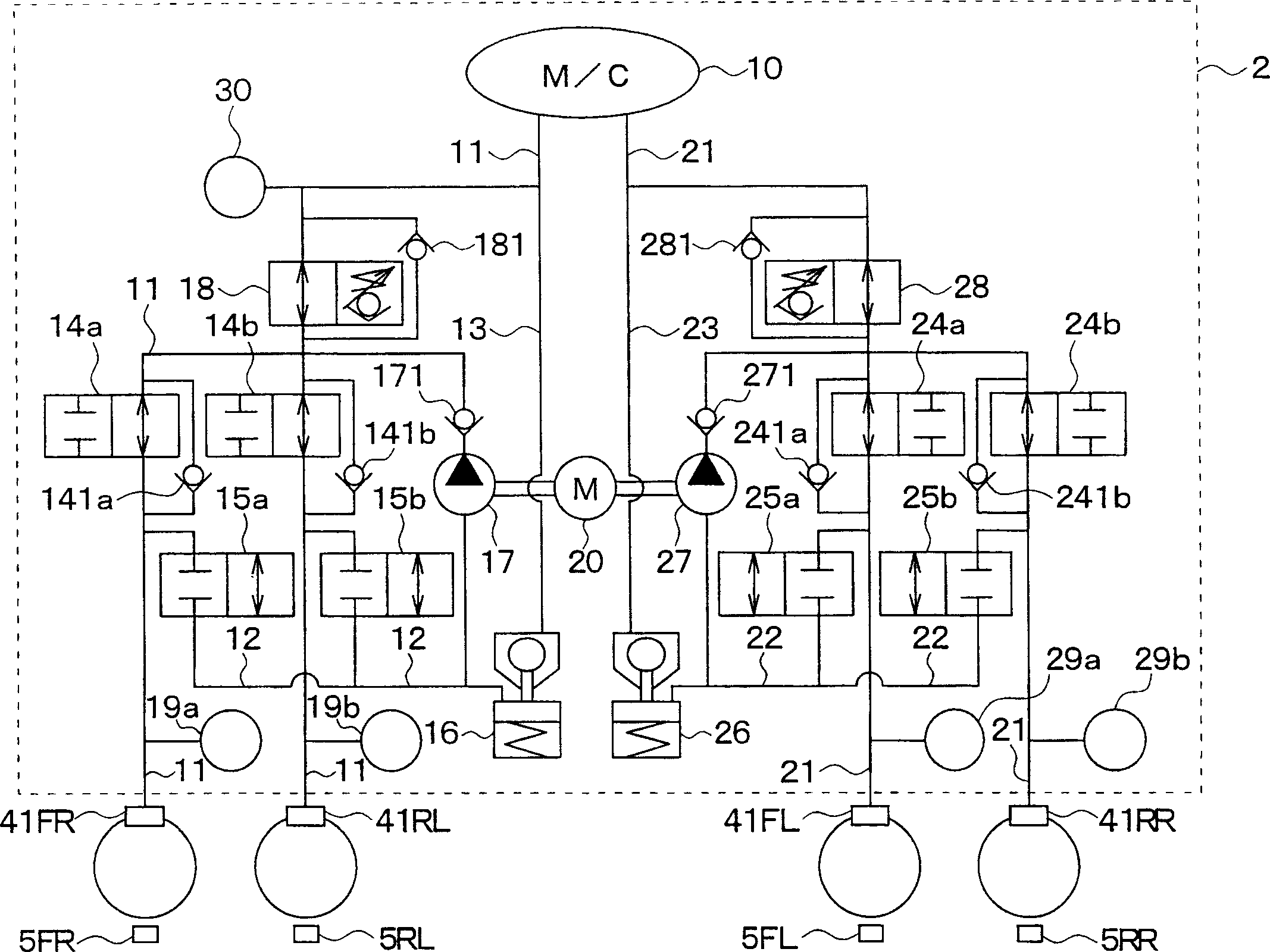

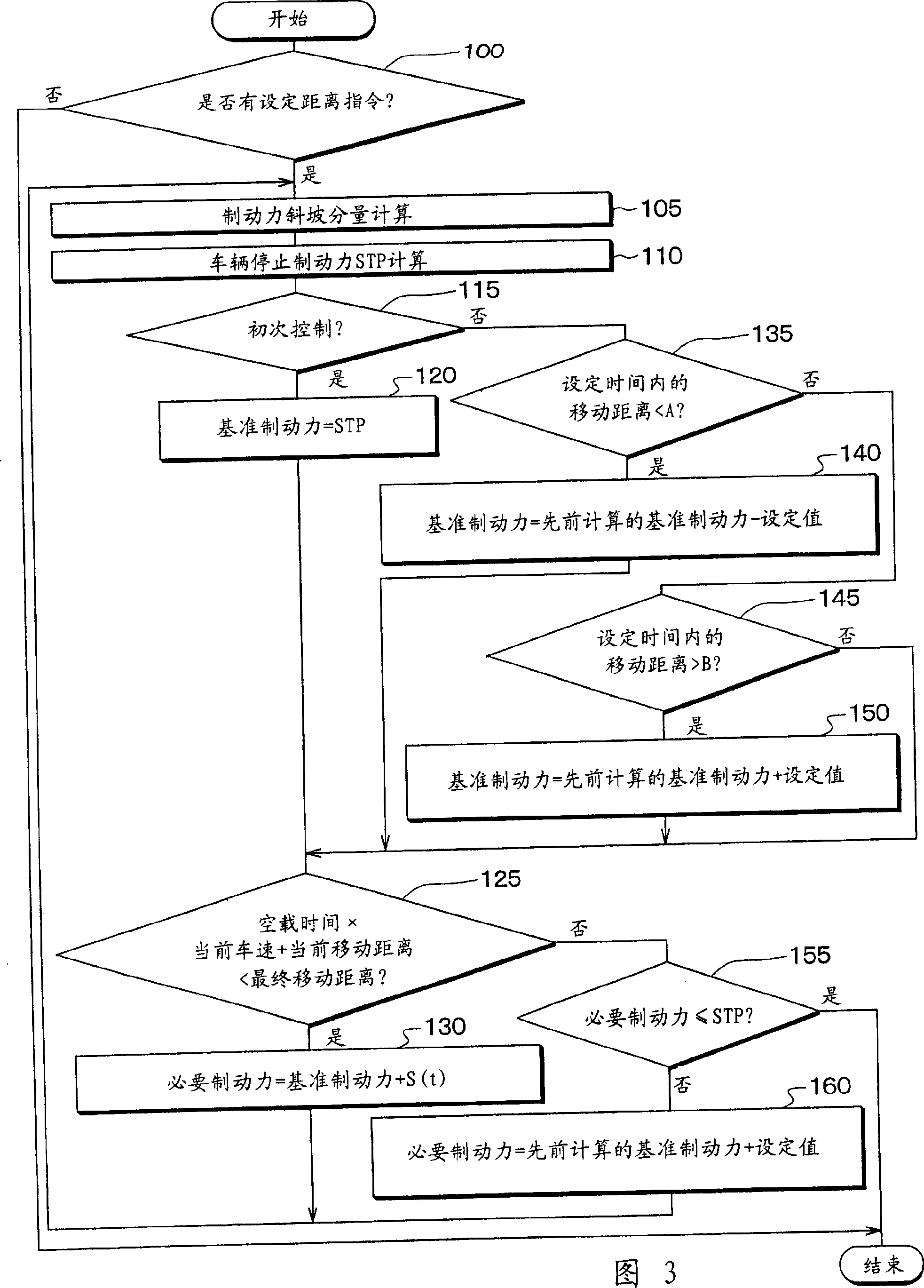

Vehicle running control device for running extremely low speed to stop

InactiveCN1904331AHigh drive torqueGreat driving forceEngine controllersMachines/enginesLow speedEngineering

The distance from the vehicle stop position to the target parking position is determined as the set distance. Then, the vehicle moves by gradually reducing the necessary braking force including the oscillation braking force. Thus, it is possible to run an engine-driven vehicle at an extremely low speed regardless of whether a motor is provided.

Owner:ADVICS CO LTD

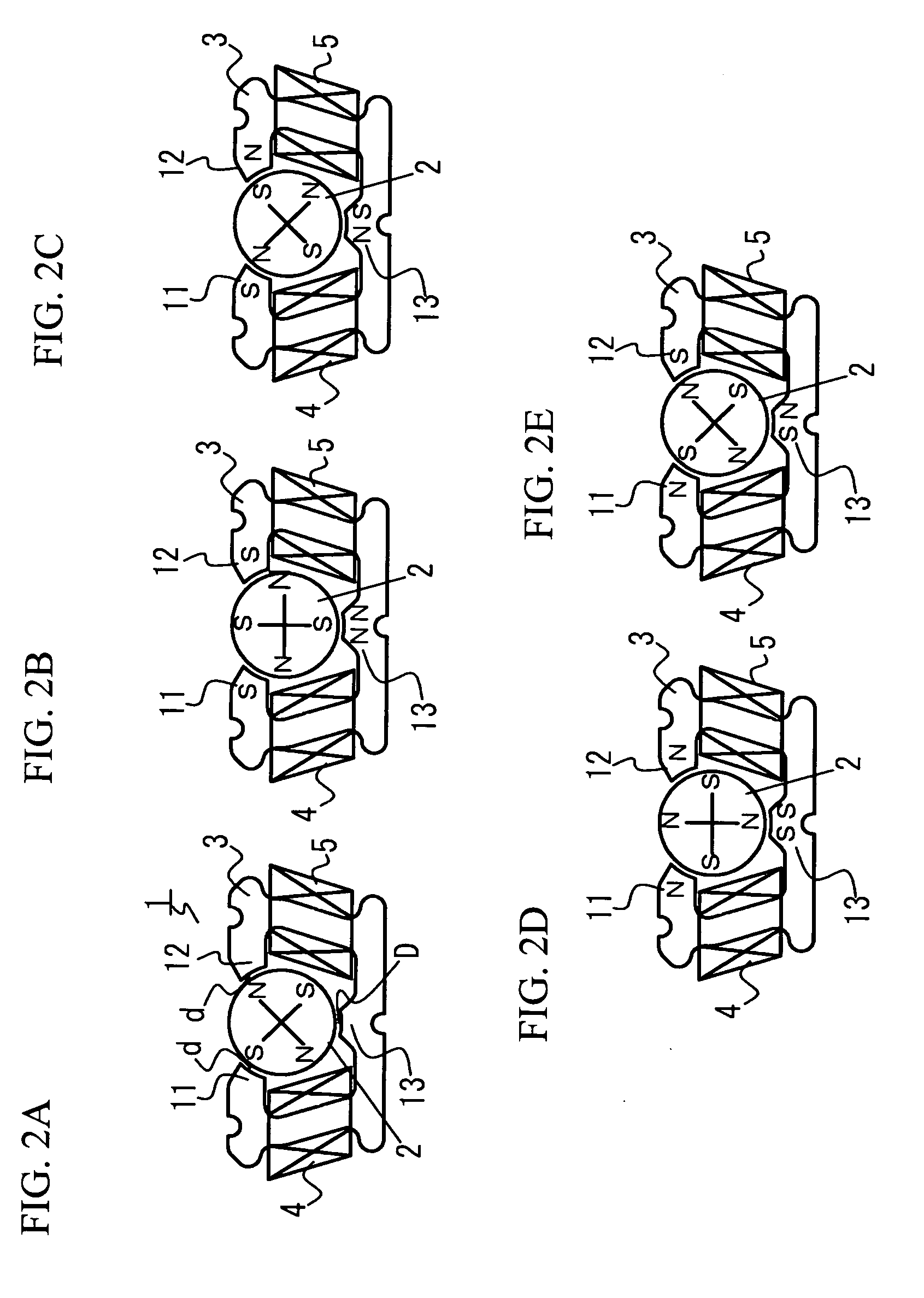

Step motor

ActiveUS20060226716A1Average power consumptionWeaken the magnetic fieldsMagnetic circuit stationary partsMaster clocksMagnetic polesAtomic physics

A step motor includes a rotor having four magnetic poles, a first magnetic pole magnetically excited by a first coil, a second magnetic pole magnetically excited by a second coil, and a third magnetic pole magnetically excited by the first coil and the second coil. A gap between the third magnetic pole and the rotor is smaller than that between the first magnetic pole and the rotor and that between the second magnetic pole and the rotor. In the step motor, it is possible to intensify the influence, on the rotor having four poles, of the magnetic fields created from three magnetic poles. Accordingly, this can weaken the magnetic fields set up from the first magnetic pole and the second magnetic pole, which tend to intensify the influence on the rotor, enabling the torque smaller at the time of the rotation start of the rotor.

Owner:SEIKO INSTR INC

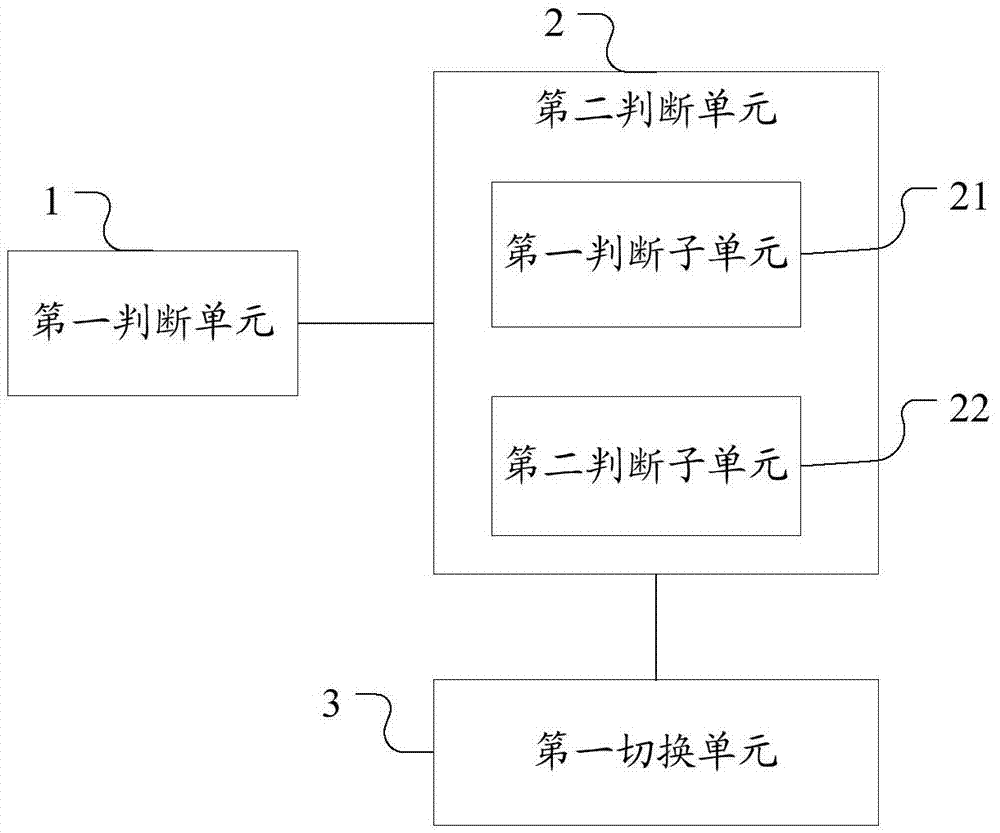

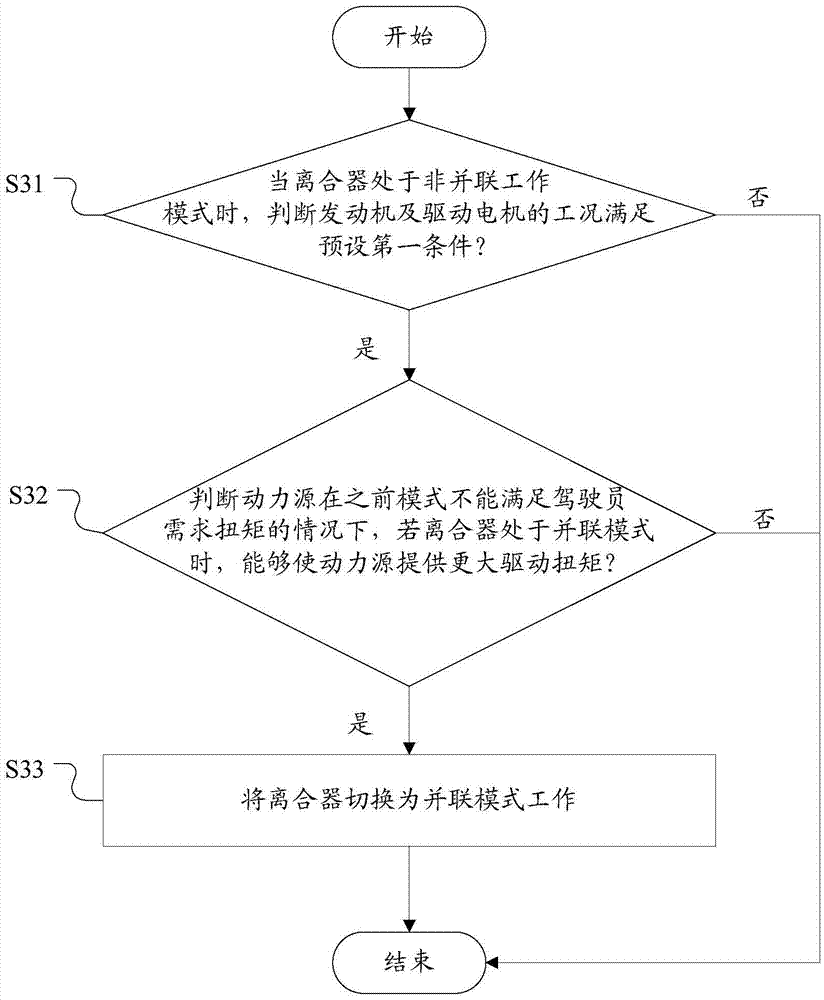

HCU and clutch work mode switching control method

The invention provides an HCU and clutch work mode switching control method. The method comprises the steps of when a clutch is in the non-parallel work mode, determining whether the work conditions of an engine and a drive motor meet a first preset condition; when the work conditions of the engine and the drive motor meet a first preset condition, determining that a power source cannot meet the torque needed by a driver in the previous condition, if the clutch is in the parallel work condition, determining whether the power source can be made to provide a bigger drive torque, or determining whether the power source efficiency and the automobile noise and vibration conditions meet a second preset condition; when it is determined that the clutch is in the parallel work mode, the power source can provide a bigger drive torque, or the power source efficiency and the noise and vibration conditions meet the second condition, switching the clutch to the parallel work mode. The use of the technical scheme can make sure that the automobile has full power, enhances the driving safety, avoid the occurrence of resonance, and reduces noise.

Owner:SAIC MOTOR

Trapezoidal comb tooth, electrostatic comb tooth driver and MEMS scanning mirror

PendingCN112255781AIncrease logarithmIncrease vertical electrostatic forceOptical elementsChip sizeComb drive

The invention discloses a trapezoidal comb tooth; the width of the root of the trapezoidal comb tooth is larger than that of the head of the trapezoidal comb tooth, and the width of the trapezoidal comb tooth is monotonously reduced from the root of the trapezoidal comb tooth to the head of the trapezoidal comb tooth. Due to the trapezoidal comb tooth design, the width of the comb tooth root is larger than that of the comb tooth head, and the rigidity of the comb tooth root can be greatly improved under the condition that the average width of the comb teeth is kept unchanged; under the condition of a fixed chip size, compared with a rectangular comb tooth structure in the prior art, the trapezoidal comb tooth structure has the advantages that the driving torque of a comb tooth driver can be greatly improved, the driving angle is increased, or the size of the chip is reduced, the driving voltage is reduced, the technical performance of the chip is greatly improved, and the cost of the chip is reduced.

Owner:苏州小优智能科技有限公司

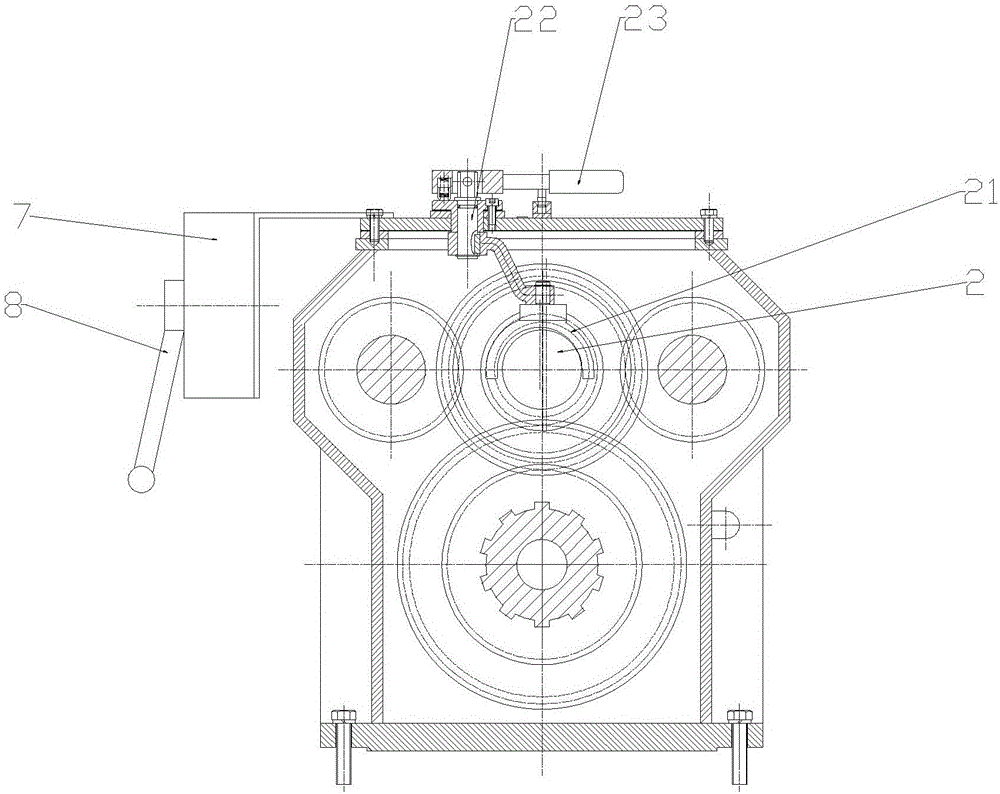

High-torque double-motor double-speed rotating power head

InactiveCN106223838AExtend your lifeHigh drive torqueConstructionsRotary drillingHydraulic motorGear wheel

The invention relates to a rotary power head, in particular to a high-torque double-motor double-speed rotating power head, and belongs to the technical field of the drilling power head device. The rotating power head comprises a power box, the power box has a spline shaft in the center, and hydraulic motors are connected with one end of gear shafts on the left and right sides of the spline shaft, and drive the gear shafts. The hydraulic motors on the left and right sides of the spline shaft are connected to a hydraulic motor control handle via a hydraulic motor control assembly which can control the two hydraulic motors to operate independently or simultaneously. The high-torque double-motor double-speed rotating power head has the advantages of simple, compact and reasonable structure, and has the hydraulic and mechanical double shifting and many shift gears so that the rotary speed range is wide and suitable for various use conditions. The self-lubricating mechanism prolongs the life of the gear and the bearing, and the driving torque of the double motor is greatly increased.

Owner:JIANGSU WUXI MINERAL EXPLORATION MASCH GENERAL FAB CO LTD

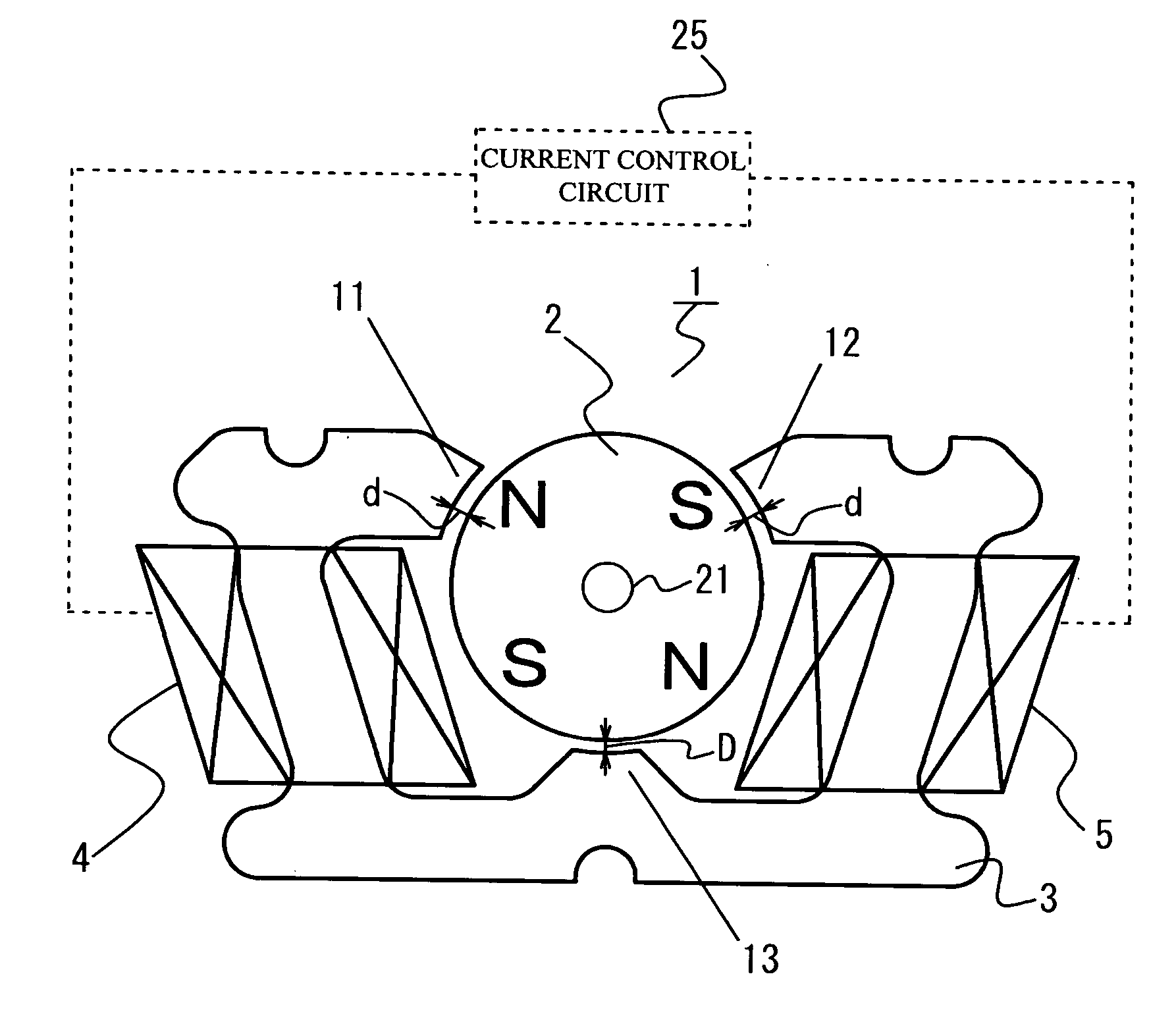

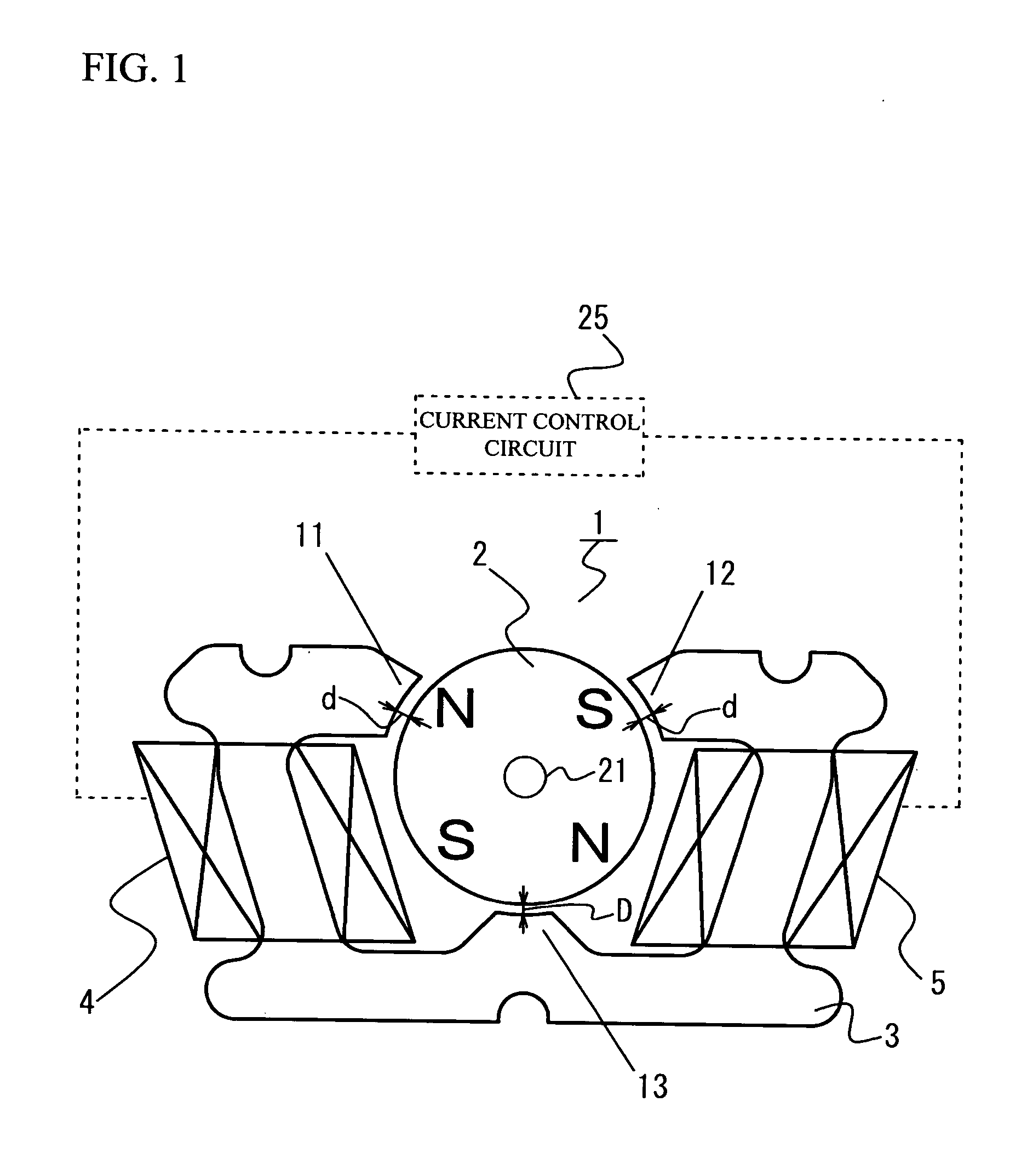

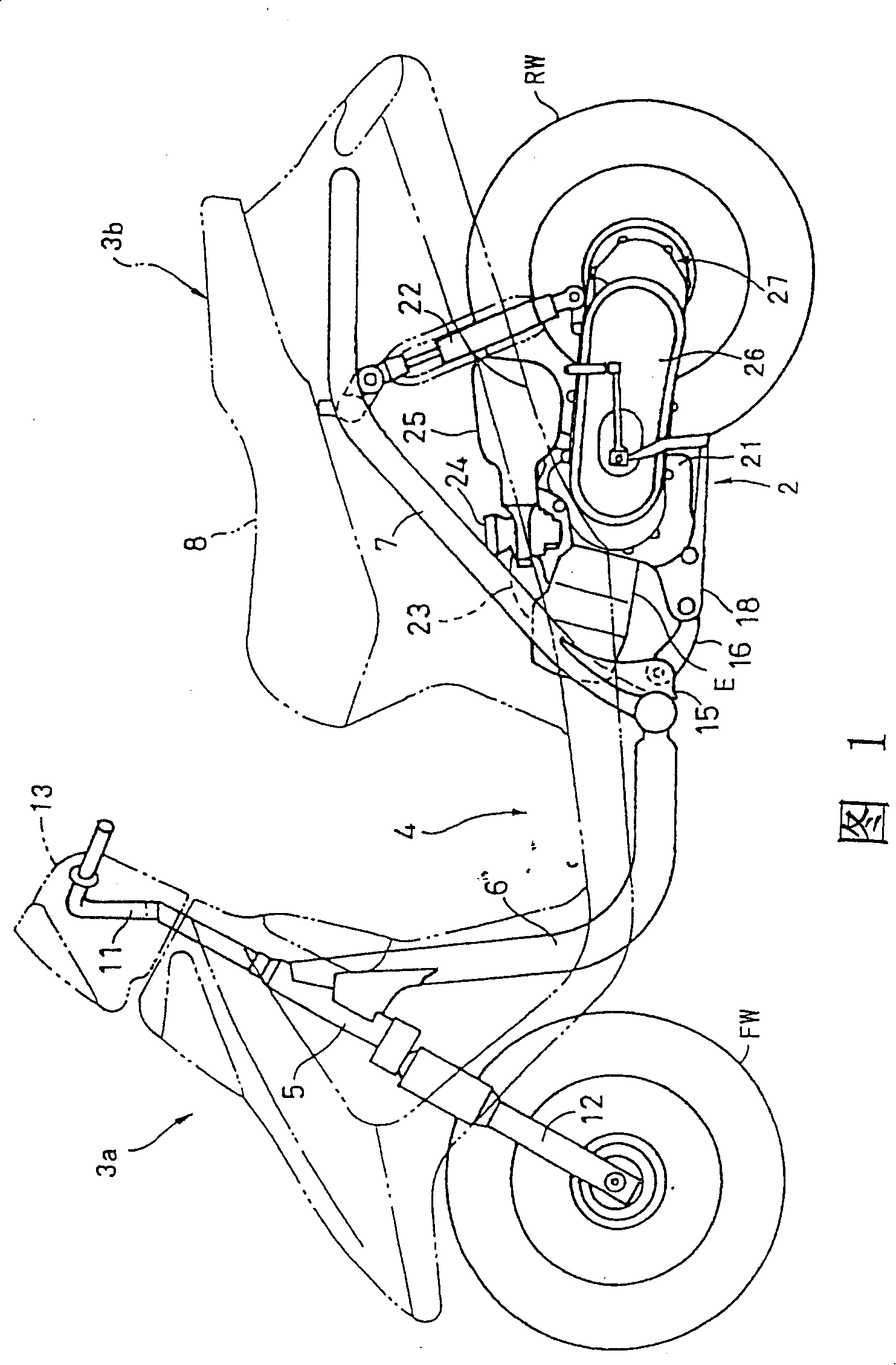

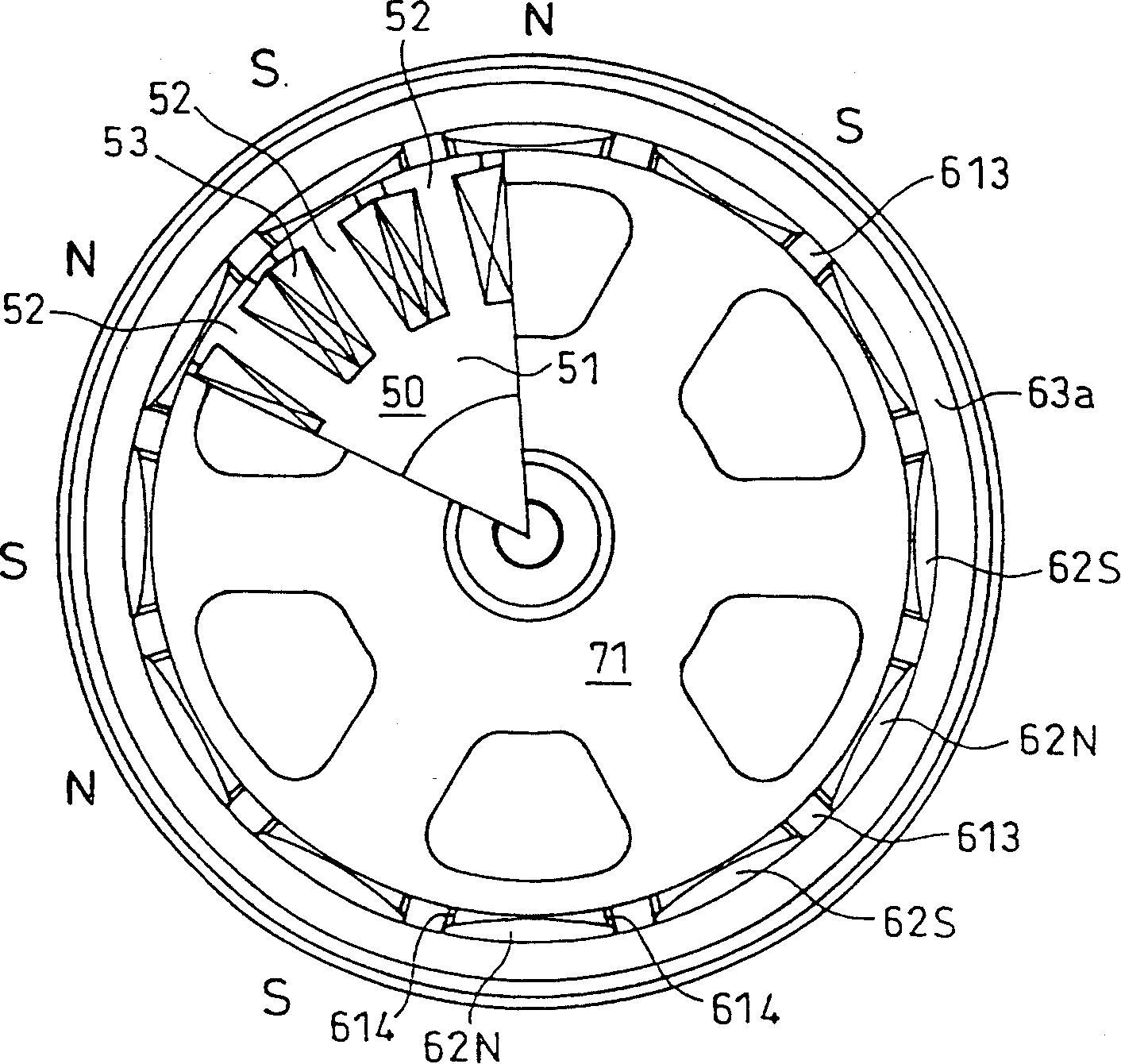

Permanent-magnet rotary motor

InactiveCN100380790CHigh active ingredientHigh drive torqueSpeed controllerMagnetic circuit rotating partsStarter generatorEngineering

The invention provides a permanent magnet rotary electric motor as a starter-generator apparatus with which high driving torque is obtained when it functions as a starter motor whereas the driven torque can be suppressed low when it functions as a generator. The permanent magnet rotary electric motor includes a stator 50 and a winding 53 on the stator, and a substantially cylindrical rotor yoke 61 including a plurality of permanent magnets 62 disposed along a circumferential direction and rotatable around the stator 50 and wherein the rotor yoke 61 has a commutating pole portion 613 between each adjacent ones of the permanent magnets 62, is constructed such that a gap 612, 614 is provided at a portion between each of the permanent magnets 62 and the rotor yoke 61.

Owner:HONDA MOTOR CO LTD

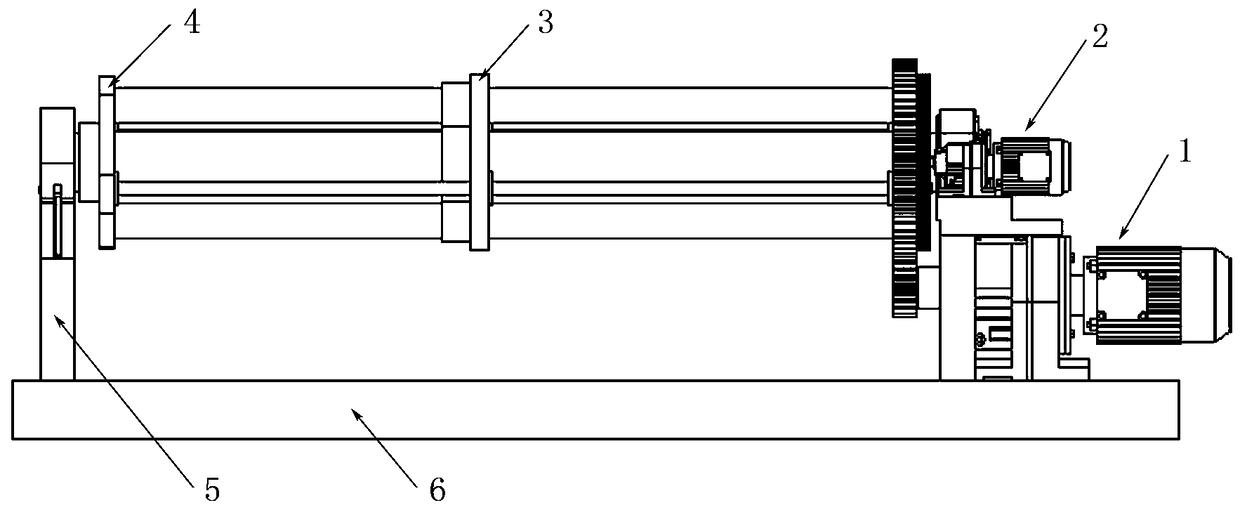

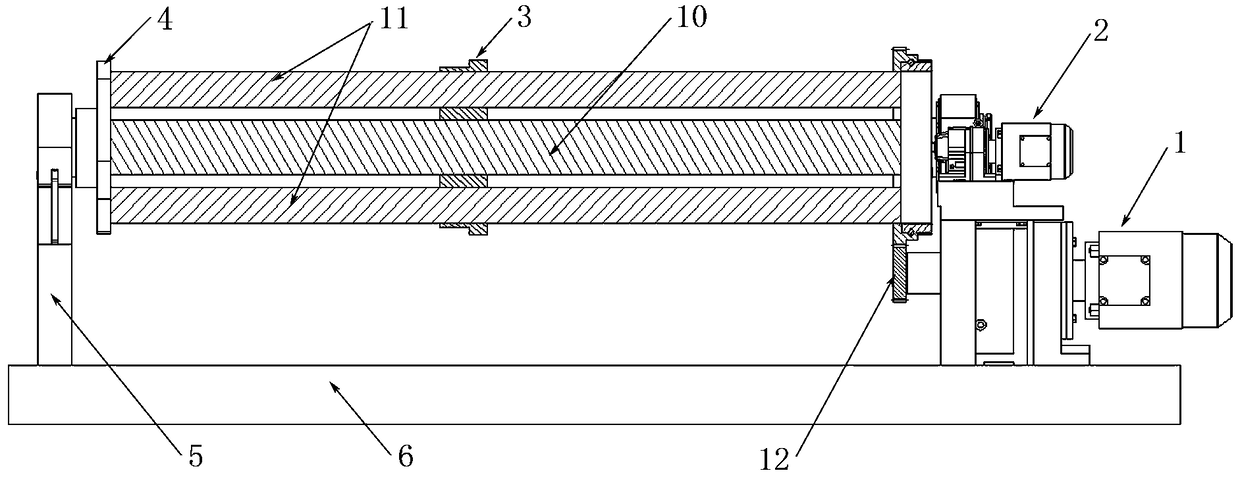

Deep-hole boring machine for machining roller shell of roller of cast rolling machine

PendingCN108655462ASolve technical problems with saggingSimple structureFeeding apparatusBoring/drilling componentsDeep holePower consumption

The invention relates to the technical field of deep-hole boring machines, in particular to a deep-hole boring machine for machining a roller shell of a roller of a cast rolling machine. An independent variable frequency motor is adopted as a lead screw motor to drive feed lead screws, and in combination with a boring rod motor, stepless variable speed control over axial feeding of a boring cuttershaft is jointly achieved; and by the adoption of a gear ring simultaneously provided with inner teeth and outer teeth, synthesis motion of rotation of the feed lead screws around the axes of the feed lead screws and rotation of the feed lead screws around the axial line of a main boring rod is achieved. The technical problem of drooping of the boring rod is solved through two-end supporting. Thedeep-hole boring machine is simple in structure, relatively small in equipment total volume, low in power consumption and high in machining efficiency.

Owner:洛阳广纬精工科技有限公司

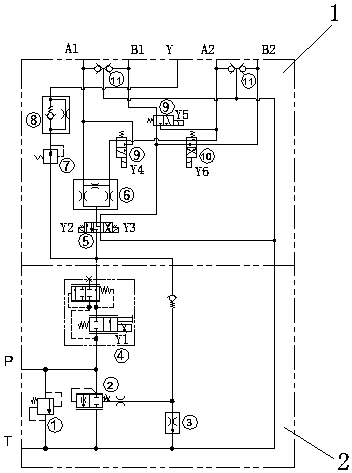

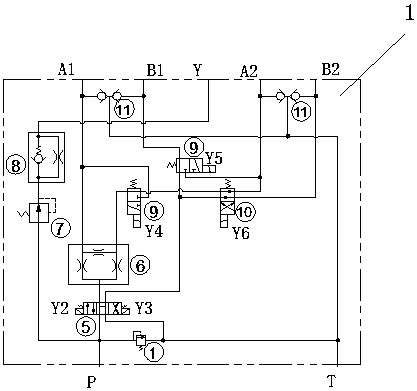

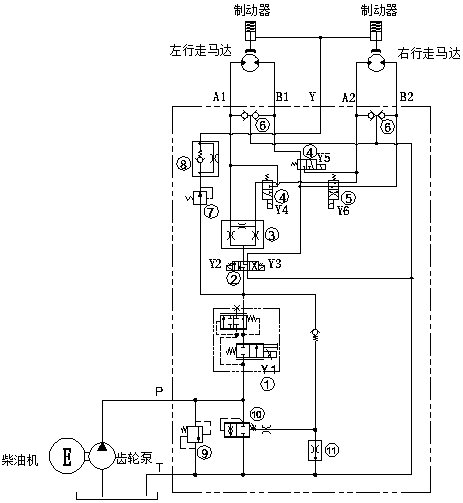

Control valve and control system of crawler chassis driven by hydraulic motor to travel

InactiveCN109899335ALow costHigh versatility of componentsServomotor componentsControl devicesHydraulic motorElectricity

The invention discloses a control valve and a control system of a crawler chassis driven by a hydraulic motor to travel. A speed regulation module and a logic control module are involved, wherein thespeed regulation module comprises a safety valve, a pressure compensator, a damping hole and a proportional speed regulation valve, wherein the safety valve is used for limiting the maximum working pressure, protecting a pumping set and a whole hydraulic system; the pressure compensator is used for enabling the pumping set to supply oil in the pressure and flow state required by the system all thetime, and redundant oil liquid returns to an oil tank; the damping hole is used for enabling extremely small flow of oil to exist in a valve to return through the damping hole, the consistence of thetemperature of the oil in the valve is ensured so as to increase the response speed of the system; and the proportional speed regulation valve is used for controlling the continuous output of the oilflow through continuous changing of an opening port of a proportional electric signal control valve. All elements in the control valve are all conventional valve members, are mature, reliable, universal, low in price and high in cost performance, and the control valve and the control system can obtain remarkable economic benefits.

Owner:SHANDONG KINGELEVATOR GRP CO LTD

Steering column for a motor vehicle

ActiveUS20210046970A1Less spaceSimple processSteering columnsMechanical energy handlingSteering columnElectric machinery

An adjustment drive for a motor-adjustable steering column for a motor vehicle, includes a spindle drive having a threaded spindle which engages in a spindle nut which, so as to be able to be driven in a rotating manner about the spindle axis relative to the threaded spindle, is coupled to the rotor shaft of a drive motor which has a rotor and a stator. In order to enable a compact design with minor complexity, the rotor shaft of the drive motor is configured as a hollow shaft which is disposed so as to be coaxial with the spindle axis and in which the threaded spindle is coaxially disposed.

Owner:THYSSENKRUPP PRESTA AG +1

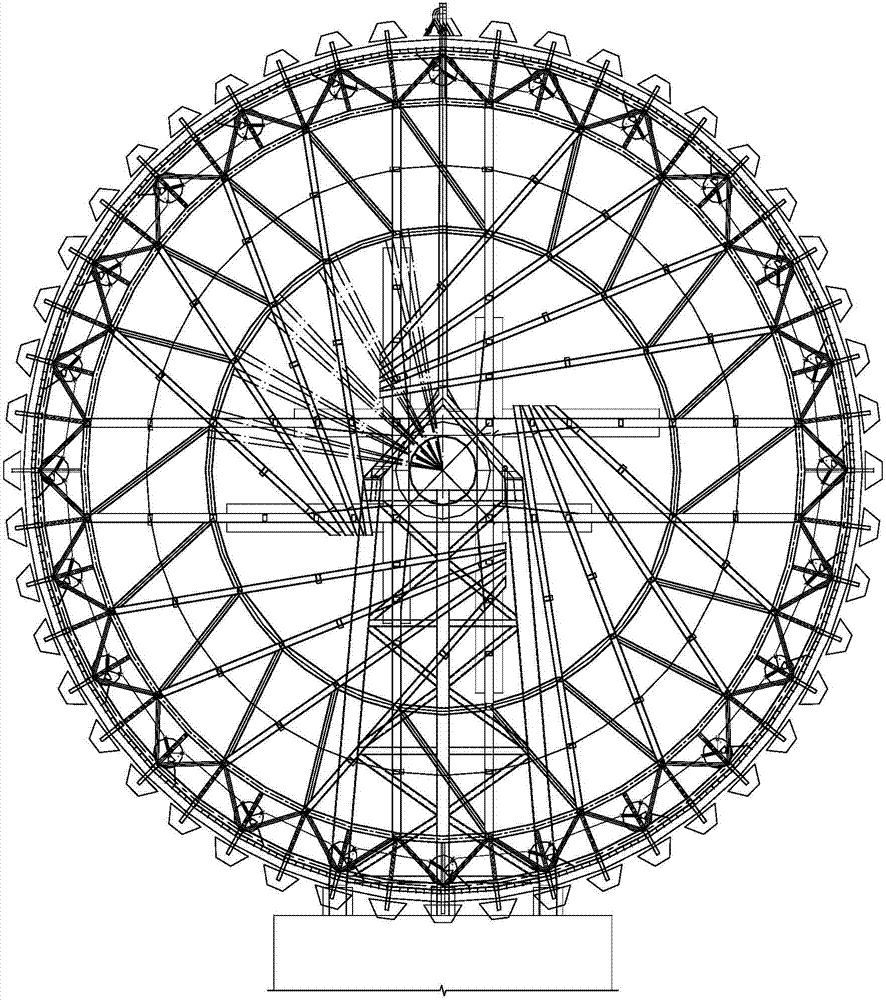

Water bucket device for driving large rotary waterwheel

ActiveCN104500311AHigh drive torqueSuppression of water injection surgeHydro energy generationEngine componentsWater wheelCommunicating vessels

The invention discloses a water bucket device for driving a large rotary waterwheel. The water bucket device comprises a barrel body, wherein a water inlet and water outlets are formed in the barrel body; the barrel body is a hollow cylinder; the water inlet is a long strip opening formed in the cylindrical surface of the barrel body; the water outlets are formed in positions, corresponding to two sides of the water inlet, in the two end surfaces of the barrel body; a plurality of vertical inner baffle plates and a plurality of transverse inner baffle plates are arranged on the inner wall of the barrel body; a reserved water inlet connecting tube and a reserved water outlet connecting tube are arranged in the barrel body. The water bucket device for driving the large rotary waterwheel disclosed by the invention has the beneficial effects that the water inlet and the water outlets in special positions are formed, so that water is filled in most of positions, capable of producing power torque, of the water bucket, and water is overflowed in positions capable of producing adverse torque, thereby forming the maximal drive torque. The vertical inner baffle plates and the transverse inner baffle plates have an effect of preventing injecting water from overflowing outwards. The reserved water inlet connecting tube and the reserved water outlet connecting tube are arranged in the barrel body, and are connected with the adjacent water bucket through communicating vessels, so that under a static state of the waterwheel, water in a high-level water bucket is transported to a low-water water bucket by virtue of the communicating vessels through height difference, and so on the waterwheel start function is realized.

Owner:大连市建筑设计研究院有限公司

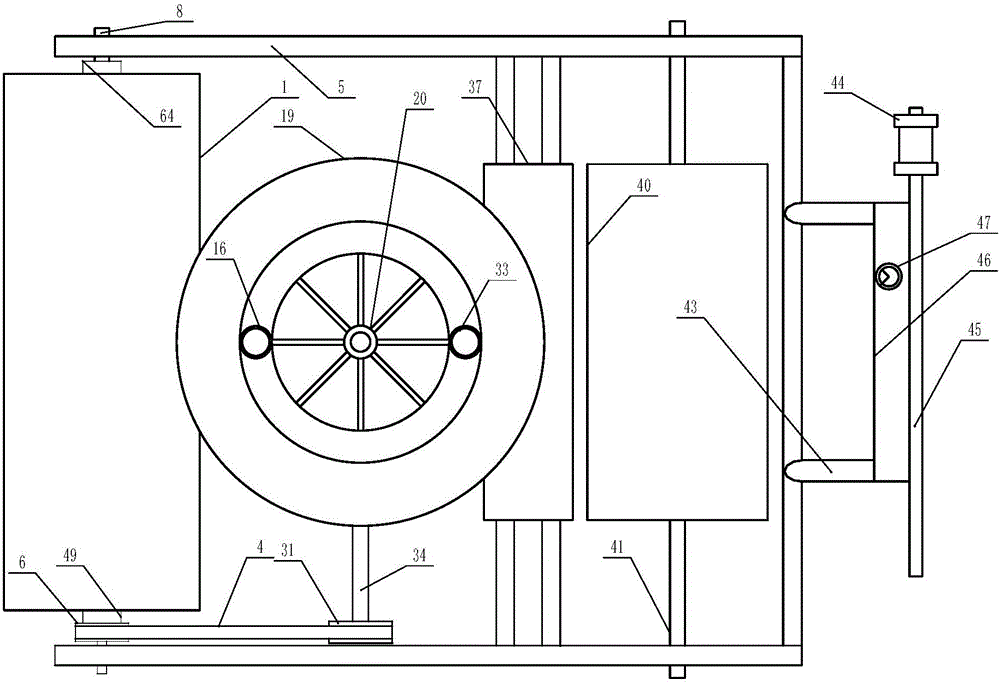

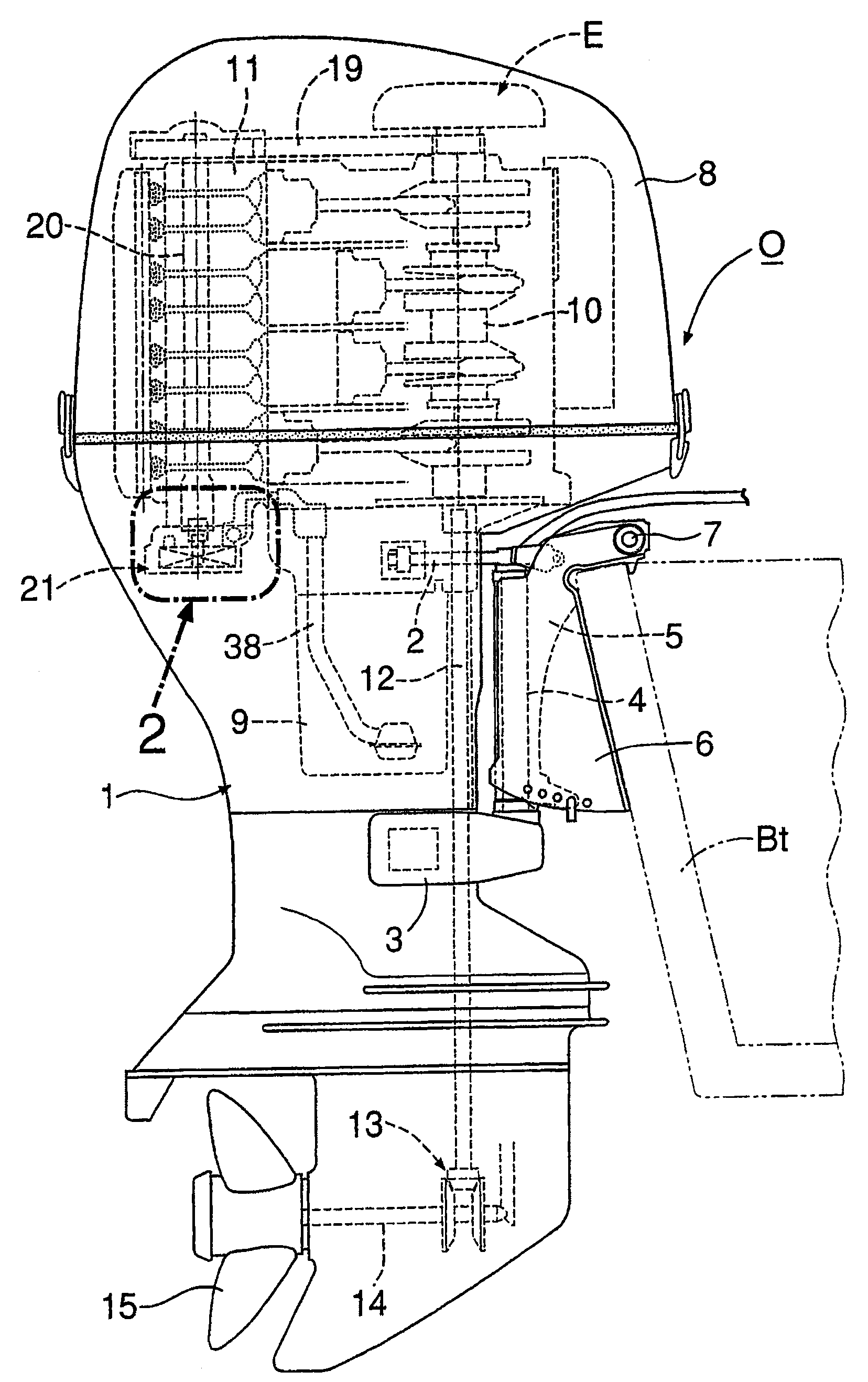

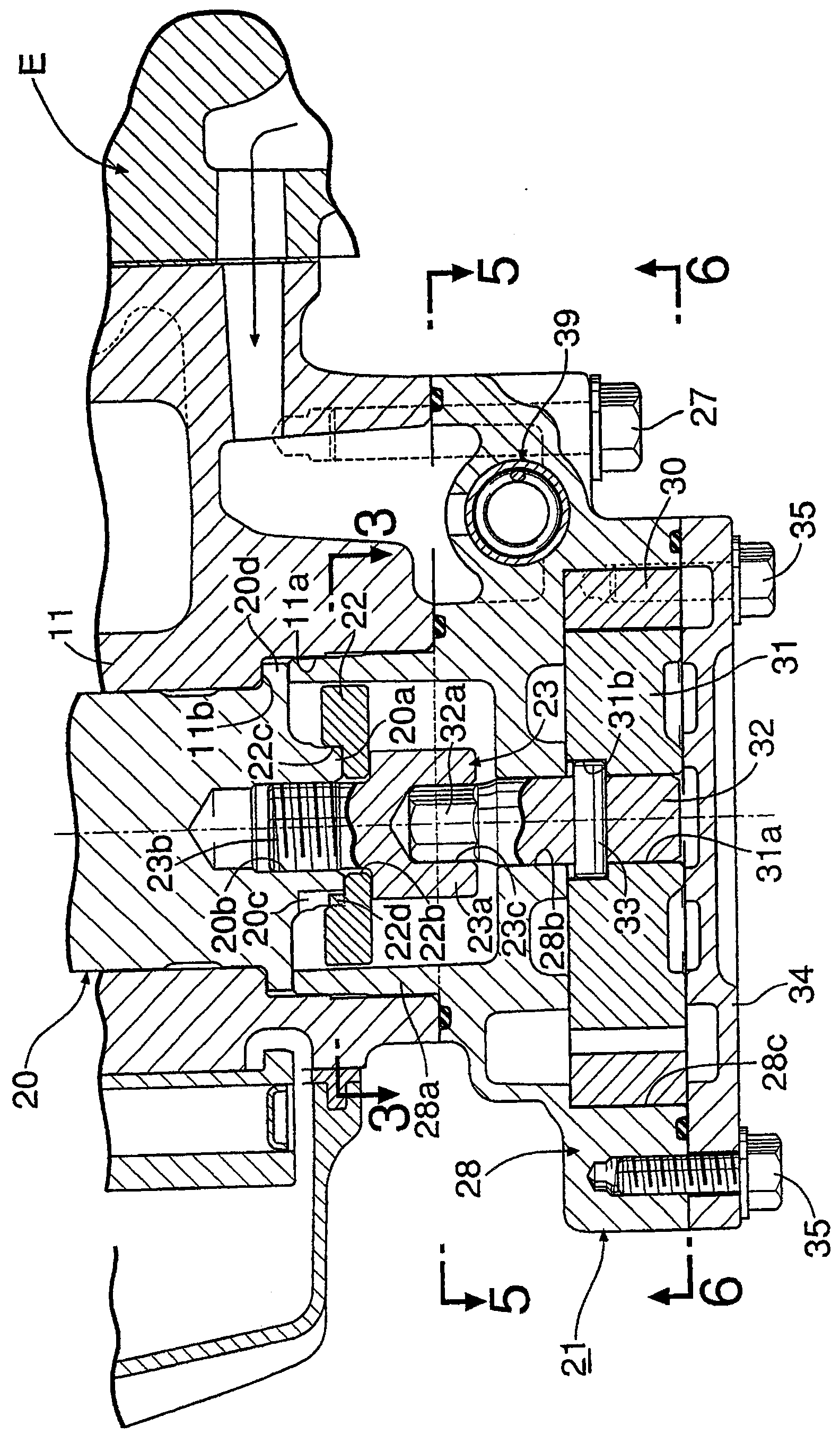

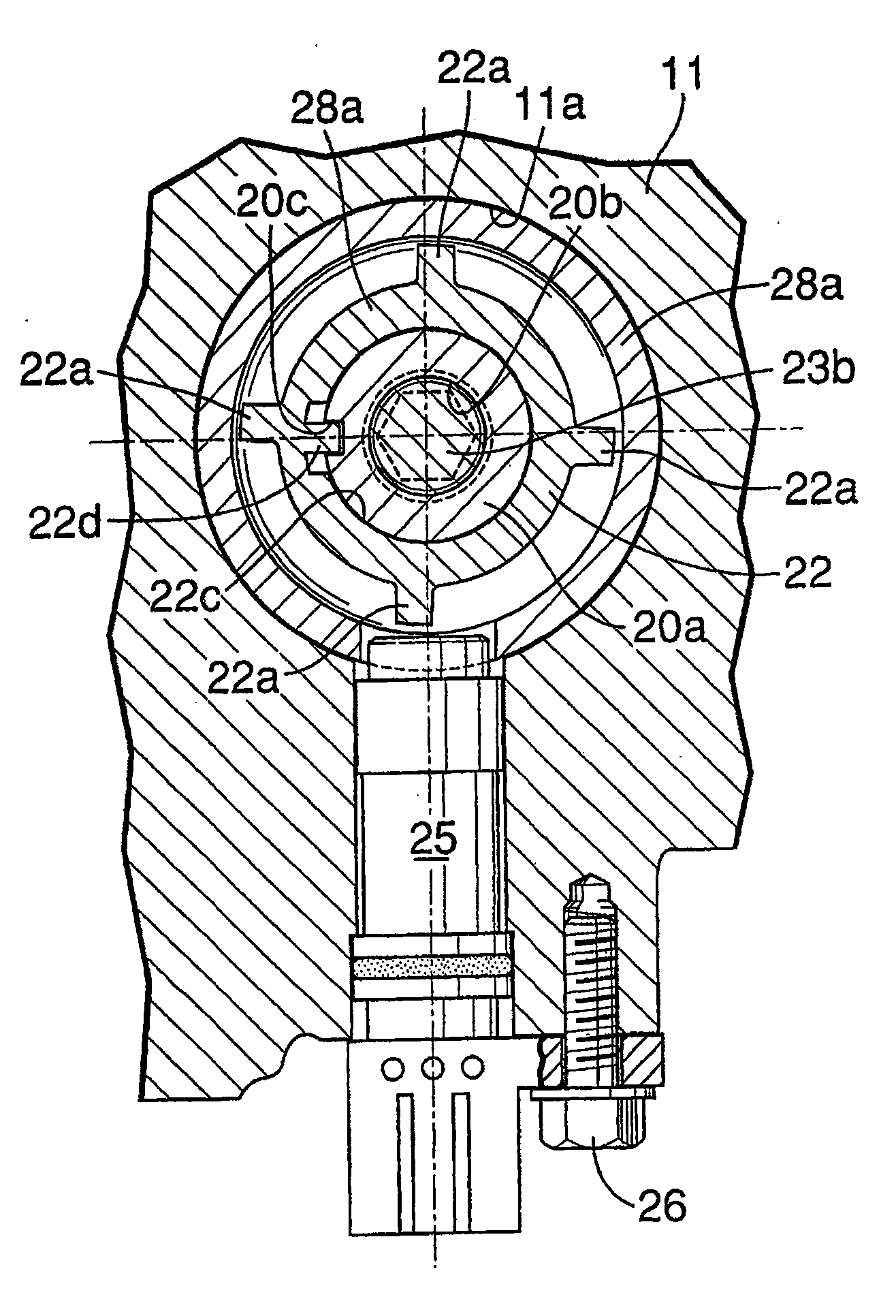

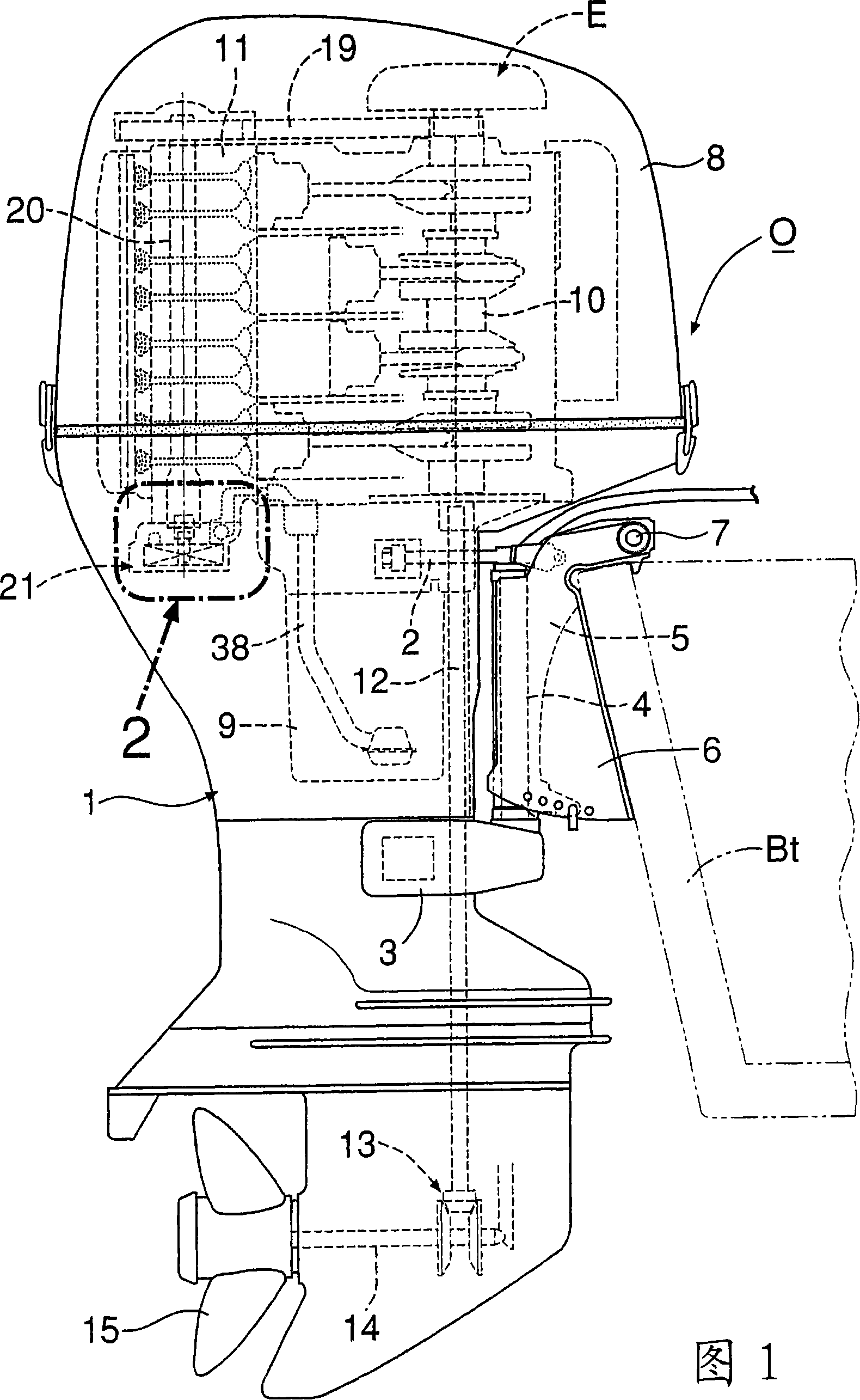

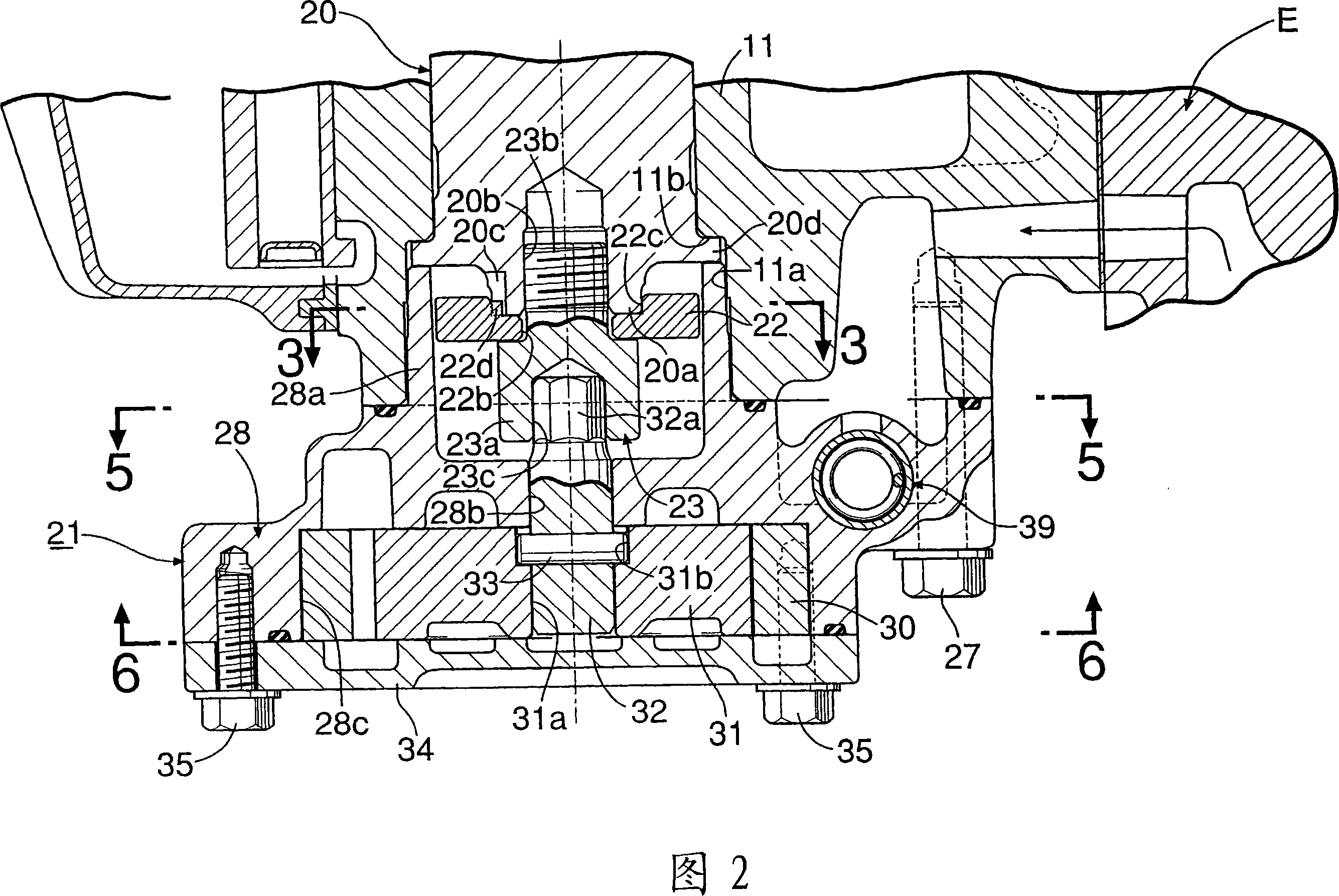

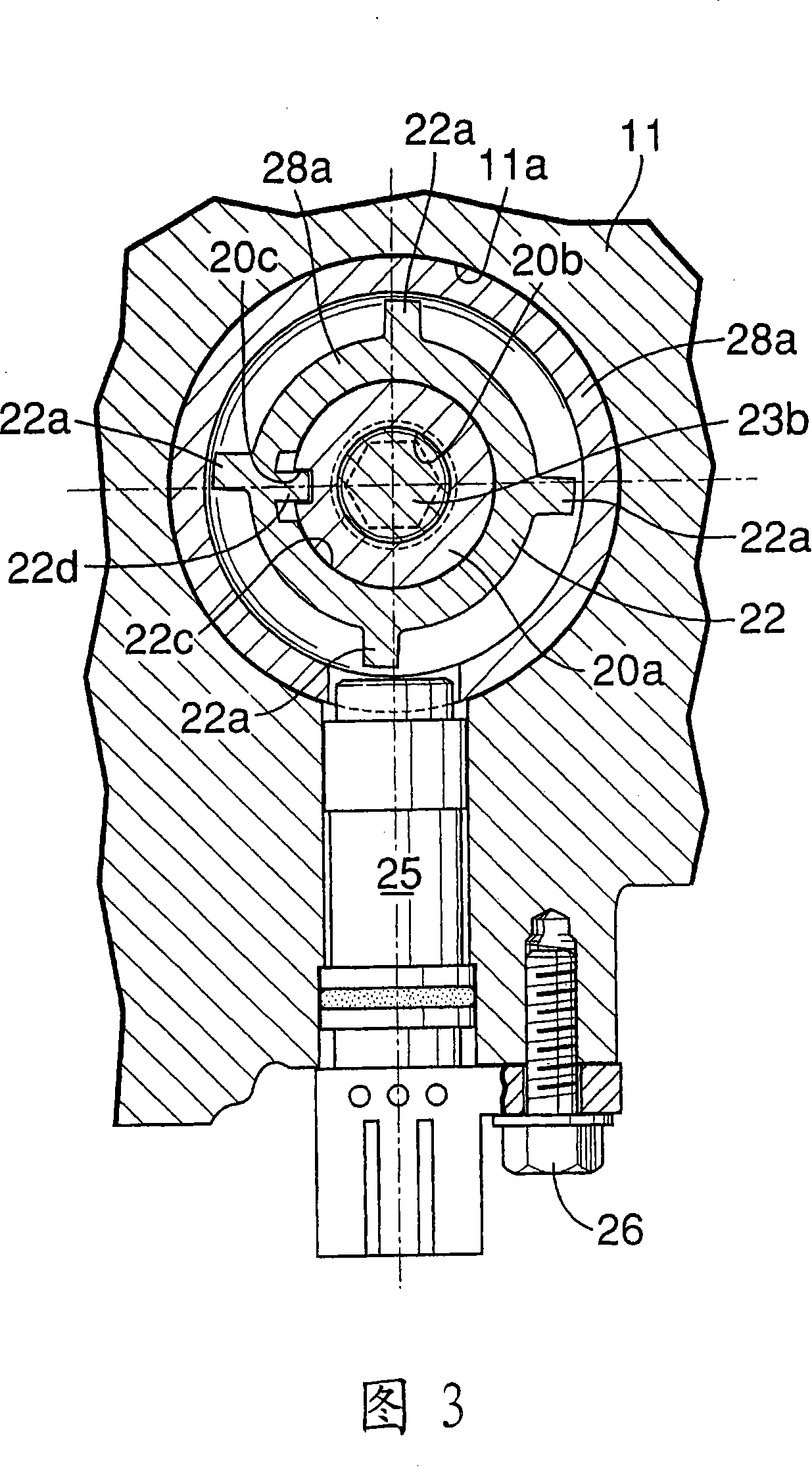

Pump driving device in engine

InactiveCN100552193CWill not effectively support surface cutsHigh drive torquePressure lubrication with lubrication pumpDrive shaftEngineering

The invention provides a pump driving device of an engine, the pump driving device of the engine controls the pump (21) installed on the engine main body (11) through the valve camshaft (20) supported on the engine main body (11). The pump shaft (32) is driven. On one end of the camshaft, the bolt (23) that passes through the pulse rotor (22) and is screwed on the camshaft is used to fix the pulse rotor. Fitting parts (23c, 32a) for mutual fitting and torque transmission are formed on the pump shaft, and the fitting part on the bolt side is formed by a corner hole (23c) for wrench fitting formed on the head part (23a) of the bolt; The fitting portion on the pump shaft side is constituted by a corner shaft portion (32a) formed at one end portion of the pump shaft. In this way, a relatively large drive torque can be transmitted from the camshaft to the pump shaft without any reduction in the effective bearing surface of the journal of the camshaft.

Owner:HONDA MOTOR CO LTD

Pump driving device in engine

InactiveCN101082292AEffective Support Surface ReductionIncreased durabilityPressure lubrication with lubrication pumpEngineeringSupport surface

To transmit large driving torque to a pump shaft from a camshaft, without substantially reducing an effective support surface of a journal part of the camshaft.The pump driving device in an engine drives the pump shaft 32 of a pump 21 installed in an engine body 11 by the camshaft 20 for a valve system supported by the engine body 11. While threadably attaching a bolt 23 having a head part 23a with a square hole 23c to one end part of the camshaft 20, a square shaft part 32a fitted to the square hole 23c is formed in one end part of the pump shaft 32, and the pump shaft 32 is driven from the camshaft 20 via these square hole 23c and square shaft part 32a.

Owner:HONDA MOTOR CO LTD

High-precision intelligentized rail fastener bolt wrench and operating method thereof

ActiveCN103128539BReduce rotation speedHigh drive torqueMetal working apparatusHydraulic motorVehicle frame

Owner:陆亦群

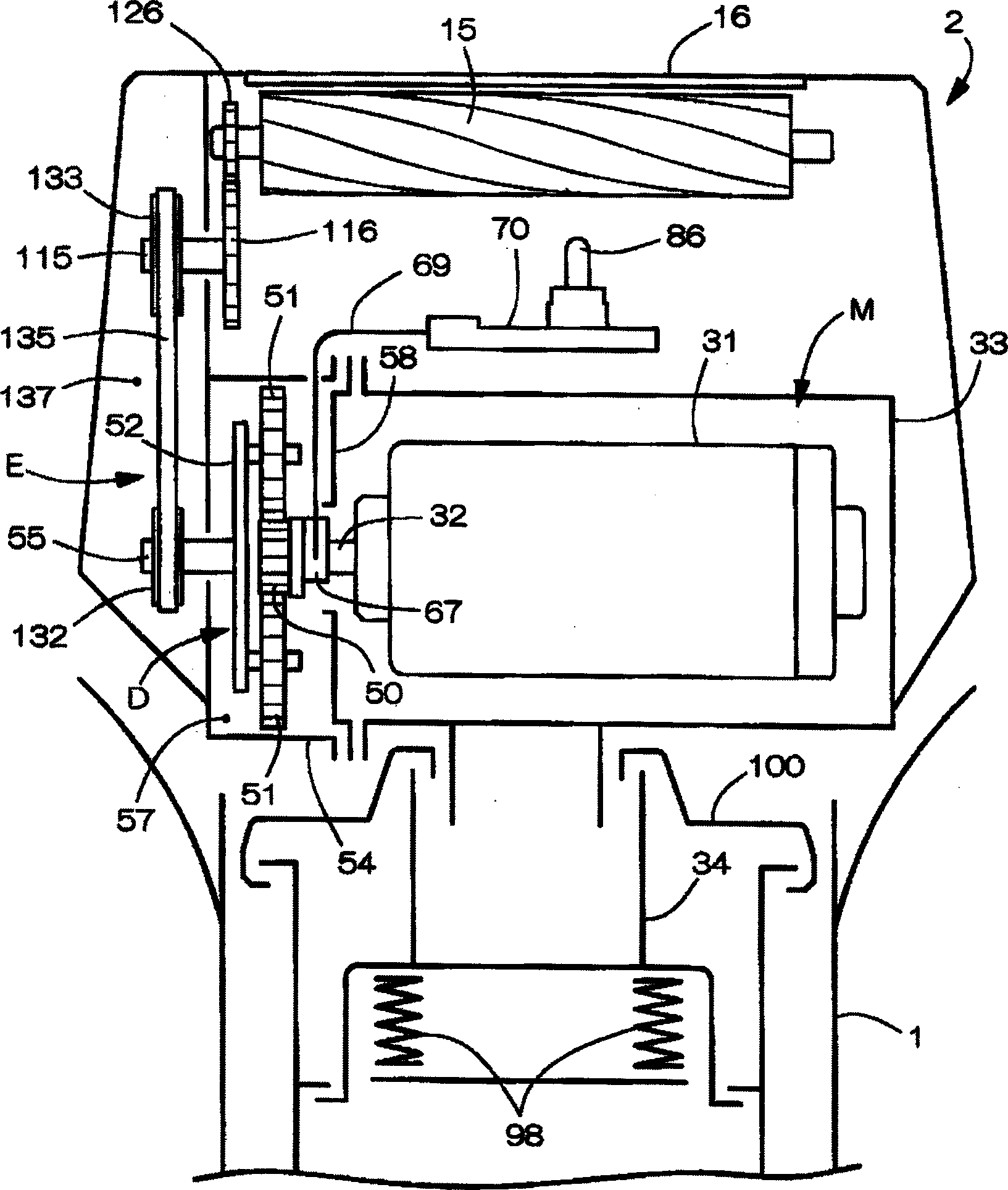

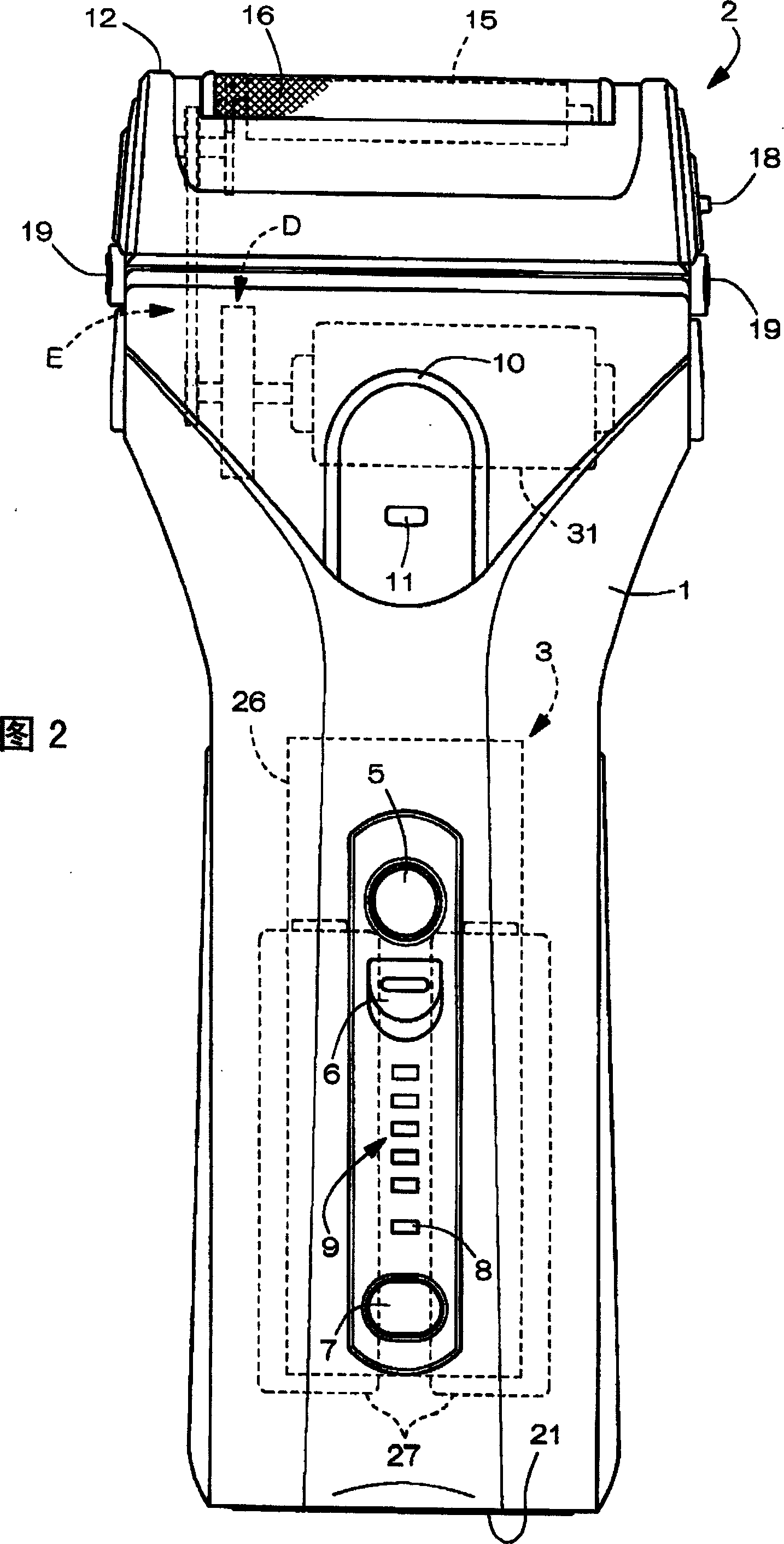

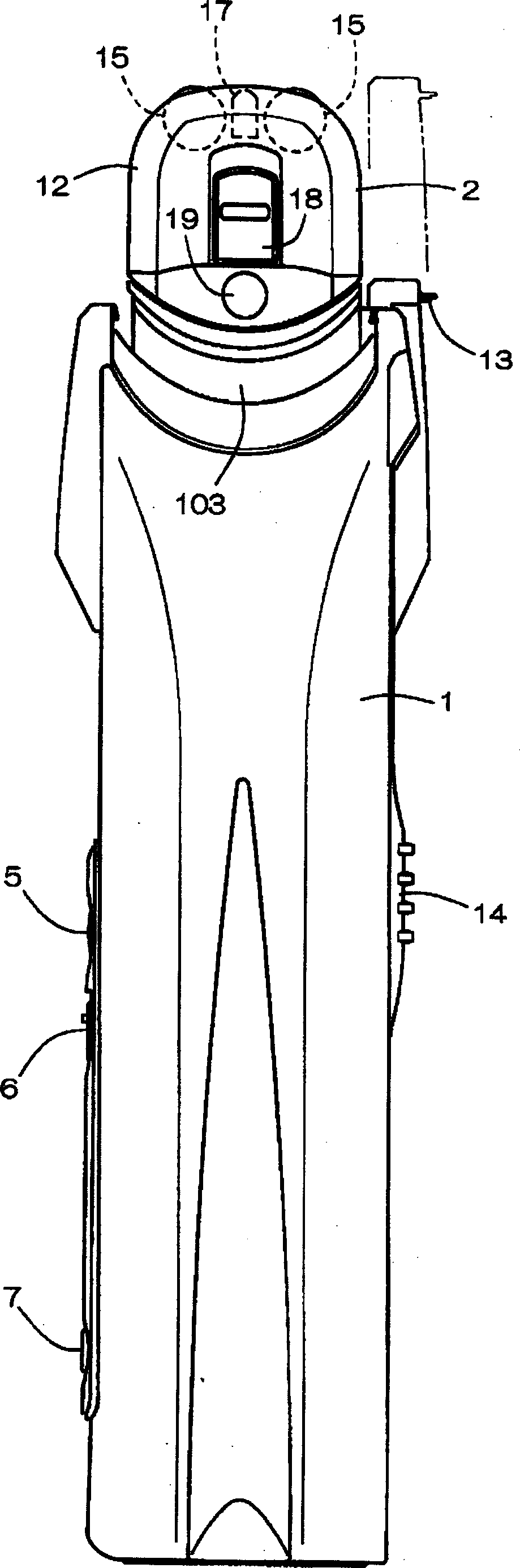

Electric shaver

InactiveCN1517189AReduce usageImprove transfer efficiencyMetal working apparatusGear wheelNoise level

The motor 31 is made into one body with a deceleration transmission mechanism D for decelerating motor power, so as to obtain one power module M. Thus, the structure of the power transmission mechanism from the motor 31 to the cutter 15 is simplified simultaneously with raising transmission efficiency. The unitized power module M is utilized as a power source for the different kinds of electric razors. Power decelerated by the deceleration transmission mechanism D is transmitted to the cutter 15 via a succeeding stage transmission mechanism E. The deceleration transmission mechanism D includes a planet gear mechanism, so as to obtain a prescribed deceleration ratio, while minimizing the engagement part of gears, to suppress the generation of gear noise. The succeeding stage transmission mechanism E includes a wrapping transmission mechanism with an endless belt 135 as a transmission element. The noise, therefor, is prevented from being generated in the succeeding stage transmission mechanism E, and a noise level is lowered in the outer part of the electric razor.

Owner:KYUSHU HITACHI MAXELL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com