Vane pump

A vane pump, pump cavity technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve problems such as vane damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

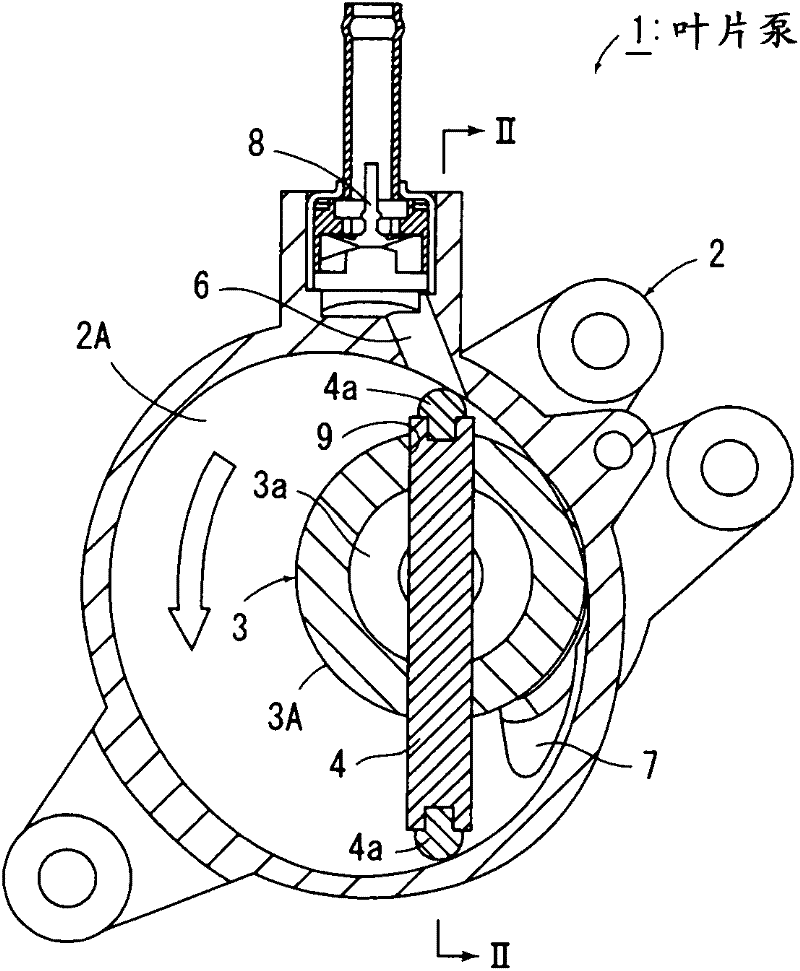

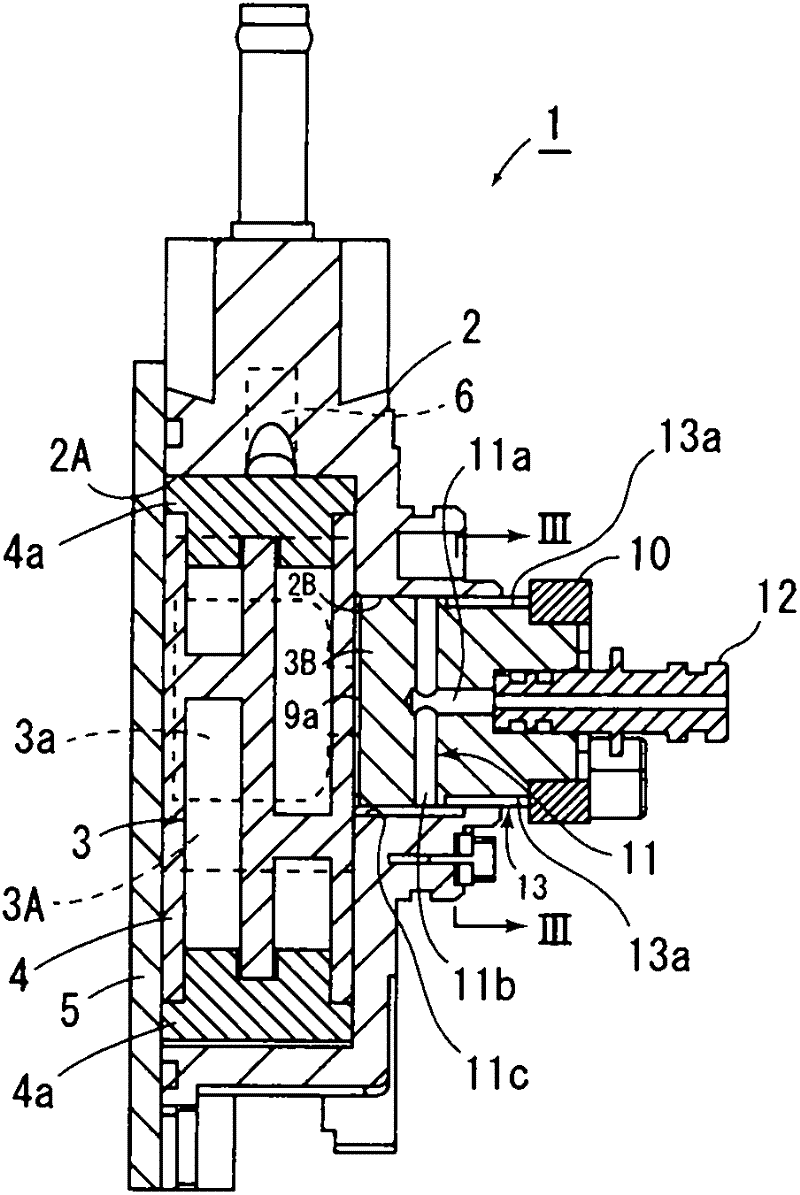

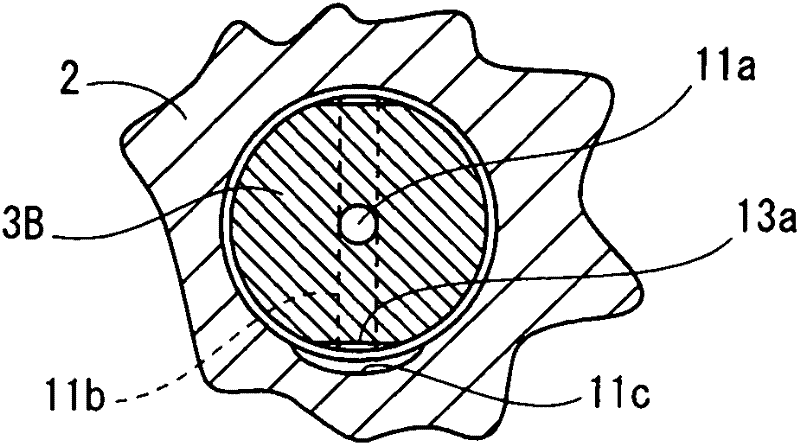

[0031] The invention is described below with respect to the illustrated embodiments, figure 1 , figure 2 The vane pump 1 according to the present invention is shown, and the vane pump 1 is fixed to the side of an engine of an unillustrated automobile to generate a negative pressure to a force multiplying device of an unillustrated brake device.

[0032] This vane pump 1 is provided with: a casing 2 formed with a substantially circular pump chamber 2A, a rotor 3 rotated by a driving force of an engine at a position eccentric with respect to the center of the pump chamber 2A, and The vane 4 that divides the pump chamber 2A into a plurality of spaces, and the cover 5 that closes the pump chamber 2A.

[0033] On the above-mentioned casing 2, an air intake passage 6 communicating with the force-multiplier device of the above-mentioned brake is respectively provided above the pump chamber 2A to attract gas from the force-double device, and an air intake channel 6 is provided below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com