Film bulk acoustic resonator and method for manufacturing same

A thin-film bulk acoustic wave and resonator technology, applied to electrical components, impedance networks, etc., can solve problems such as poor thickness uniformity and affect the resonant frequency of thin-film bulk acoustic wave resonators, and achieve a highly consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

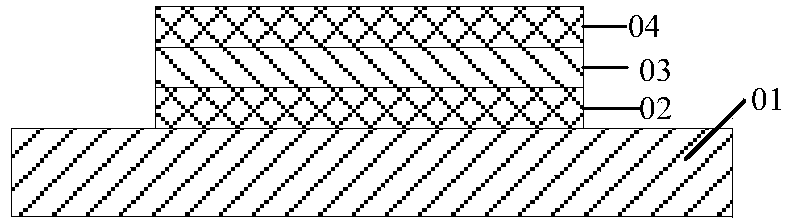

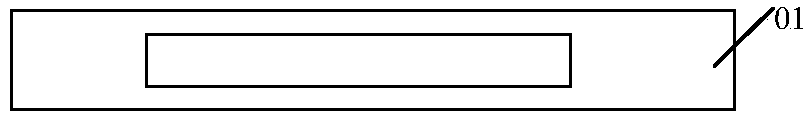

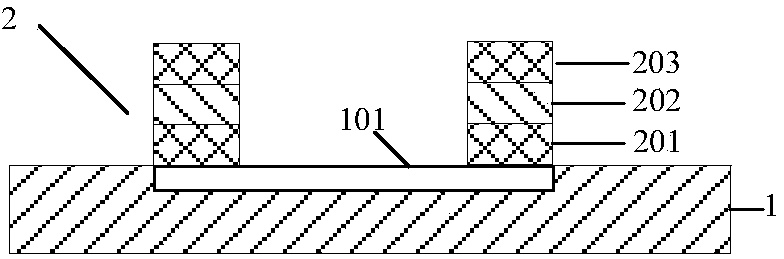

[0053] This embodiment provides a thin film bulk acoustic resonator, such as Figure 2a As shown, it includes a substrate layer 1 and an annular functional layer 2 prepared on the substrate layer 1; the annular functional layer 2 includes a first electrode 201 along a direction away from the substrate layer 1, a piezoelectric material layer 202 and a second Two electrodes 203 ; an air cavity 101 is set on the substrate layer 1 , and the area of the air cavity 101 in the lateral direction is larger than the area surrounded by the outer boundary of the annular functional layer 2 . The horizontal direction mentioned here refers to the direction parallel to the first electrode 201 , that is, the direction perpendicular to the direction of the applied electric field.

[0054] combine Figure 2b to Figure 2d In this embodiment, the annular structure of the annular functional layer 2 includes but is not limited to a circular annular structure, a square annular structure, and a pol...

Embodiment 2

[0066] This embodiment provides a method for preparing a thin film bulk acoustic resonator, including the following steps:

[0067] S1: select the substrate substrate to obtain the substrate layer 1.

[0068] S2: Prepare ring-shaped functional layer 2: prepare ring-shaped first electrode 201 , ring-shaped piezoelectric material layer 202 and ring-shaped second electrode 203 on the substrate layer 1 .

[0069] S3: At the position below the first electrode 201 on the substrate layer 1, etch away the base material of the substrate to form an air cavity 101, the area of the air cavity 101 is larger than that of the annular functional layer 2 in the lateral direction The area enclosed by the outer boundary.

[0070] After the step S3 is completed, an air cavity 101 is formed under the annular functional layer 2, and when the air cavity is formed by etching, two or more fixing feet 4 will be reserved for the annular functional layer 2 fixed. The positions and numbers of the fix...

Embodiment 3

[0089] This embodiment provides a filter and an oscillator using the thin film bulk acoustic resonator described in Embodiment 1. And a radio frequency module, including a duplexer or a multiplexer, the thin film bulk acoustic resonator in the duplexer or the multiplexer adopts the thin film bulk acoustic resonator described in Embodiment 1 or Embodiment 2.

[0090]Among them, the filter realizes functions such as image elimination, parasitic filtering and channel selection in the wireless transceiver device. The filter made by FBAR device has the characteristics of high quality factor and easy realization of miniaturization. In order to improve frequency selectivity, more combinations of FBAR devices with resonators with different resonant frequencies are required. Currently, Figure 5 The ladder structure shown.

[0091] There is a wide demand for low-jitter clocks and oscillators in wired and wireless communications. Oscillators based on FBAR devices have advantages in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com