High-precision angular indexing dynamic measuring spindle system

A dynamic measurement and angular indexing technology, applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve the problem of difficult to achieve micron-level accuracy, inability to angular indexing measurement and high-precision angular indexing measurement, single function, etc. To solve the problem, to achieve the effect of concise system working link, high rotation accuracy of main shaft system, and high accuracy of circumferential indication value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

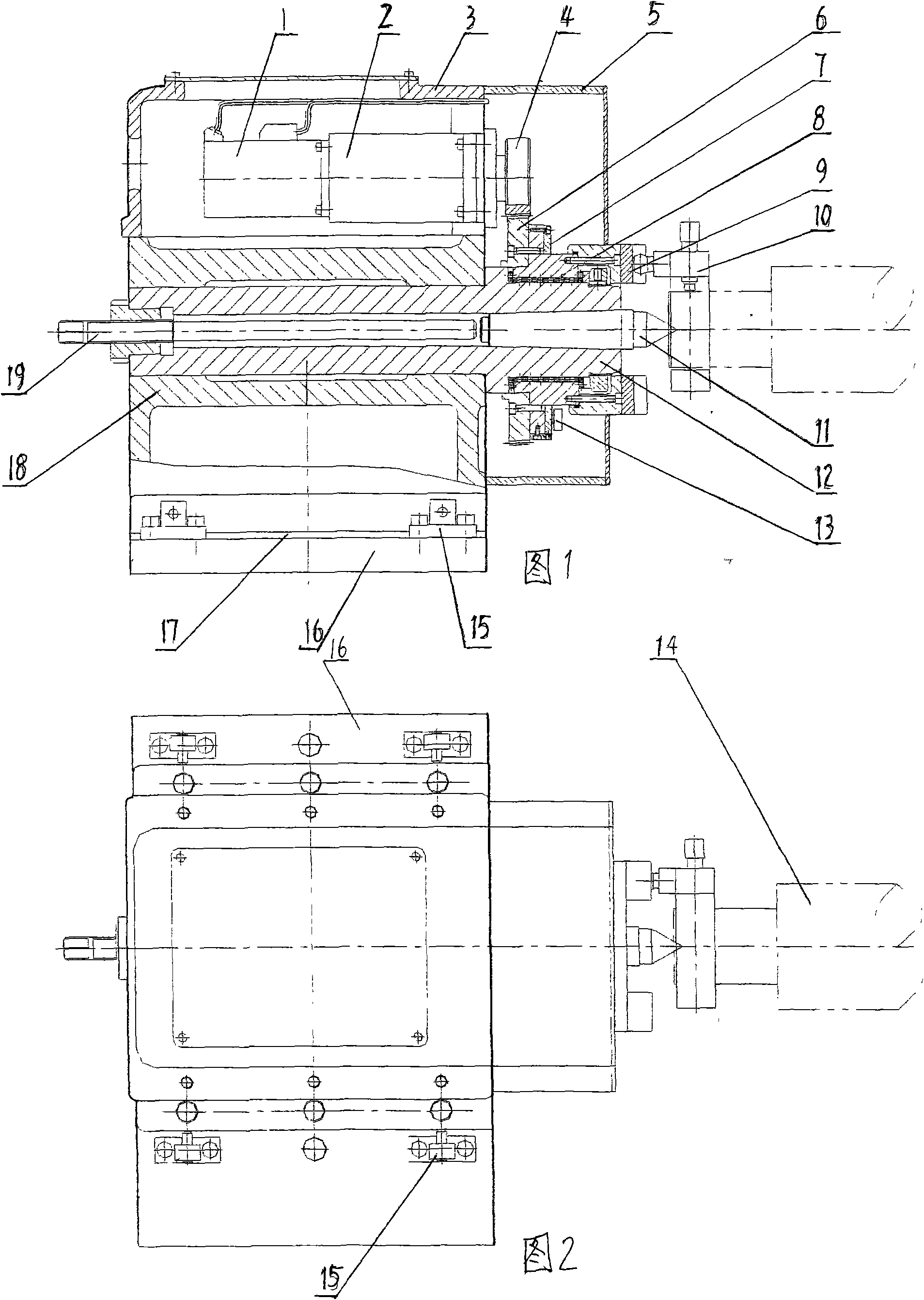

[0020] Such as figure 1 , figure 2 As shown, the drive system is composed of drive motor 1, reducer 2 and pinion gear set 4. Given the rated speed and corresponding driving torque under computer control, this driving system can obtain a larger reduction ratio by combining with the large gear set 6, so that a larger driving torque can be obtained.

[0021] The dense ball bearing system with precision grating disc is composed of large gear set 6, precision grating disc 7, dense ball bearing set 8, dial set 9, Morse top 11 and spindle 12. The mandrel 12 is assembled and fixed on the lower casing 18, and the center hole of the mandrel is tightly fitted with the Morse top 11, and the precision grating disc 7 is installed on the large gear set 6, and is set on the mandrel 12 through the dense ball bearing set 8, The dense bead shaft system can control the interference fit of the mandrel 12 through technological methods, so as to ensure that the precision grating disc 7 and the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com