Wheel bearing arrangement having spur toothing

A technology of wheel bearings and end teeth, which is applied in the direction of rotating bearings, bearings, wheels, etc., can solve the problem of wheel train tipping and other problems, and achieve the effect of large diameter and high driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

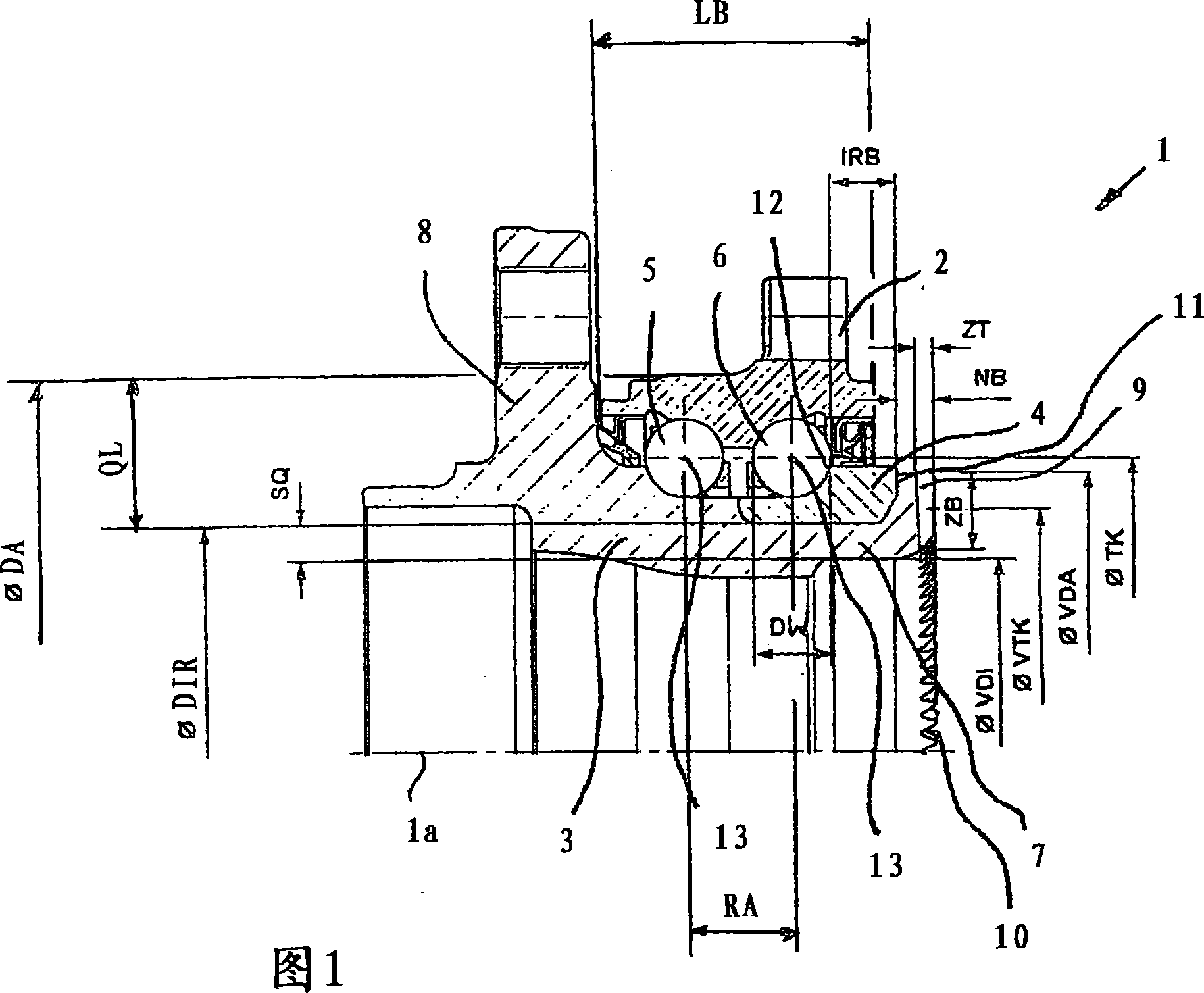

[0055] Figure 1 shows an embodiment of the invention.

[0056] The wheel bearing arrangement 1 is formed from a vehicle-side flange 2 , a hub 3 with a wheel flange 8 , an inner ring 4 and two rows 5 , 6 of rolling bodies. In this case the balls 12 of the two rows 5 and 6 are arranged around the axis of rotation of the wheel bearing unit 1 with a pitch circle of diameter TK. The pitch circle extends through the ball center 13 .

[0057] The inner ring 4 rests on a hollow section 7 with a wall thickness SQ. This section 7 has an inner diameter VDI. A collar 9 is formed integrally with section 7 of hub 3 . The collar 9 is located radially away from the segment 7 and has an outer diameter VDA on the outside.

[0058] The wheel bearing arrangement 1 , here the inclined ball bearing arrangement, is clamped via the collar 9 . To this end, the collar 9 bears axially against the end face 11 of the inner ring 4 in the direction of the end toothing 10 . The width IRB of the shoulde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com