Deep-hole boring machine for machining roller shell of roller of cast rolling machine

A roll sleeve, casting and rolling mill technology, applied in metal processing machinery parts, metal processing equipment, parts of boring machines/drilling machines, etc. The effect of increased depth and efficiency, smaller overall equipment size, and increased drive torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

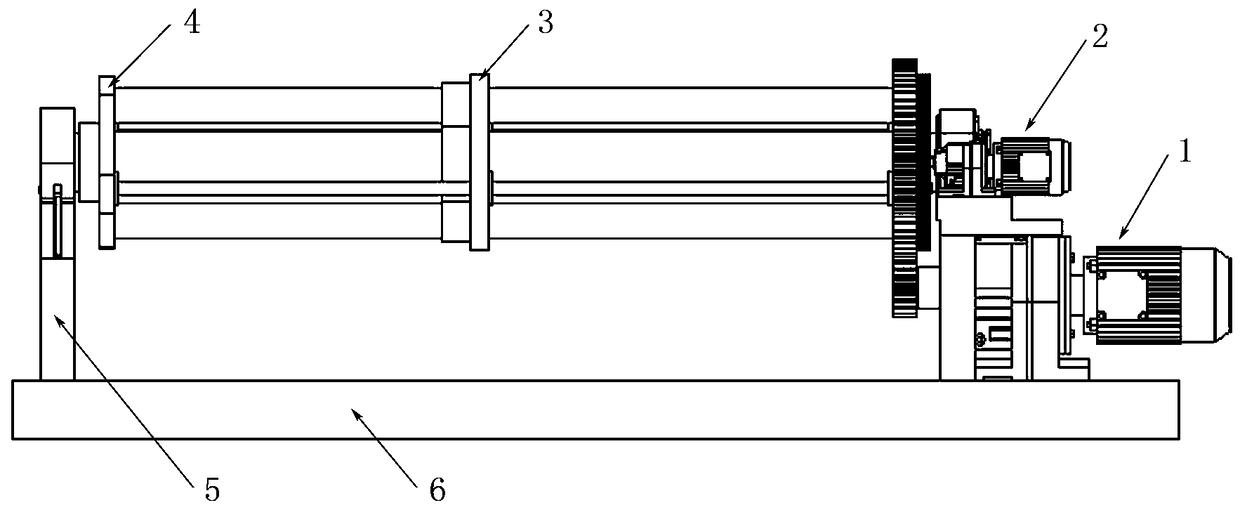

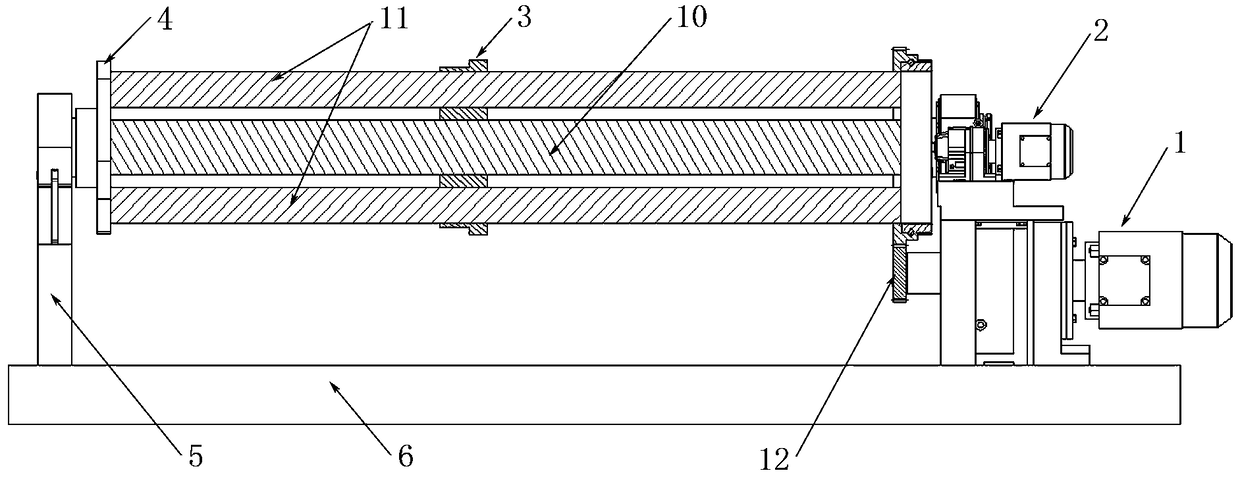

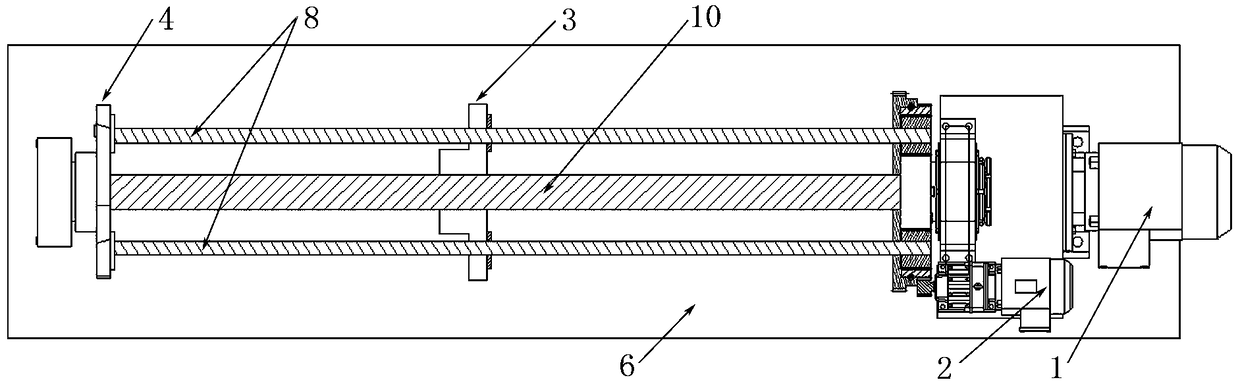

[0026] refer to Figure 1 to Figure 5 , a deep hole boring machine for processing roll sleeves of casting and rolling mills, comprising a base 6, a frame 5, a main boring bar 10, an auxiliary boring bar 11, a boring tool holder 3 and a feed screw 14; the frame 5 is fixedly arranged on base 6;

[0027] Both ends of the main boring bar 10 are rotatably supported by the frame 5, one end of the main boring bar 10 is fixedly connected with a support plate 4, and the other end of the main boring bar 10 is fixedly connected with a boring bar driving gear 13, and the supporting plate 4 and the boring bar driving gear 13 are both Located between the two support points of the main boring bar 10, there are two auxiliary boring bars 11 that are symmetrically and evenly distributed around the main boring bar 10 centered on the axis line of the main boring bar 10, and the two ends of the auxiliary boring bar 11 are respectively fixedly connected to the The supporting plate 4 and the boring...

Embodiment 2

[0034] refer to Figure 1 to Figure 5 , a deep-hole boring machine for processing roll sleeves of casting and rolling mills. Compared with Embodiment 1: the supporting part of the ring gear 7 is still rotated and arranged in the cylindrical accommodation space of the boring bar drive gear 13, but no bearings are used, and It is to directly use the steel ball 15 (such as Figure 5shown) to perform axial and radial positioning so that the two can only rotate relative to each other, that is, the inner wall of the cylindrical accommodation space of the boring bar driving gear 13 and the outer periphery of the supporting part of the ring gear 7 are correspondingly provided with annular grooves, and the steel balls 15 is arranged in the annular groove to realize the axial and radial positioning between the cylindrical accommodation space of the boring rod driving gear 13 and the support part of the ring gear 7 (that is, compared with Embodiment 1, the rod driving gear 13 cylinder T...

Embodiment 3

[0036] refer to Figure 1 to Figure 4 as well as Figure 6 , a deep hole boring machine for processing roll sleeves of casting and rolling mills. The difference from Embodiment 1 is that the ring gear 7 is not installed in the boring bar driving gear 13 for rotation, but adopts such as Figure 4 In the shown structure, the side of the ring gear 7 facing away from the boring bar driving gear 13 is provided with a boring bar driving gear hub, and the boring bar driving gear hub is rotatably arranged on the main boring bar 10 .

[0037] In the above embodiments, the rotary motion of the feed screw 14 is divided into the motion of following the main boring bar 10 (or the boring bar driving gear 13) around the axis of the main boring bar 10 and the rotation around the axis of the feed screw 14 itself. Among them, the power transmission direction of the revolution movement of the feed screw 14 is: boring bar motor 1 → boring bar motor output gear 12 → boring bar driving gear 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com