High-precision intelligentized rail fastener bolt wrench and operating method thereof

A technology for rail fasteners and bolts, applied in the field of high-precision intelligent rail fastener bolt wrenches, which can solve problems such as uneven pressure of fasteners, changes in opening characteristics, inaccuracy, etc., and achieve the effect of simplifying the structure and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

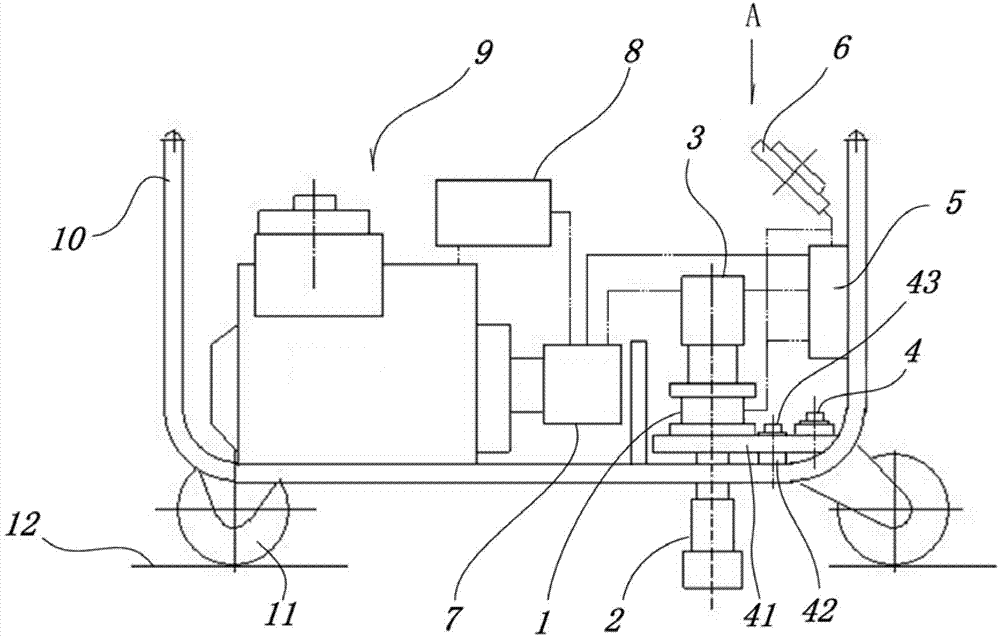

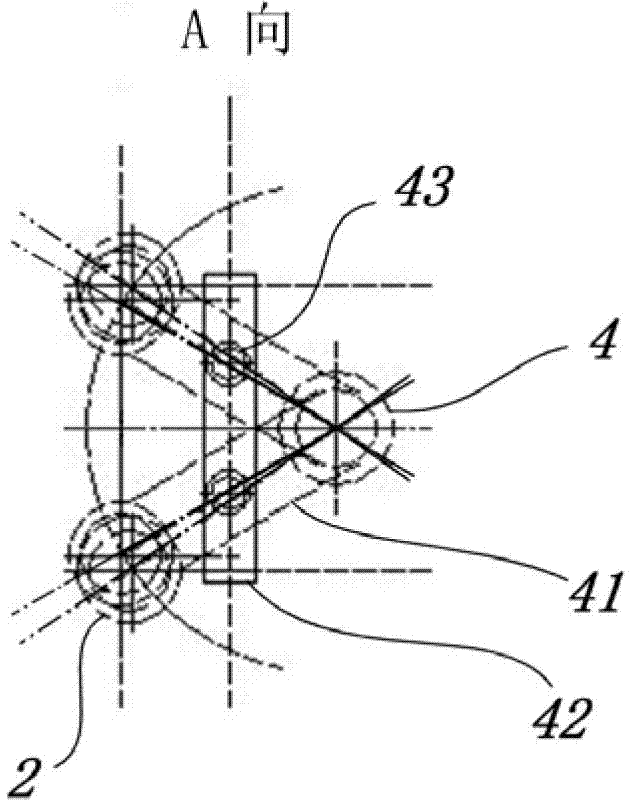

[0050] see figure 1 , the track fastener bolt high-precision intelligent wrench of the present invention has a vehicle frame 10, which is erected on the track surface 12 through a guide wheel 11; a power system 9, which uses a gasoline engine as a prime mover to drive an oil pump system, is placed on the vehicle frame 10, The oil pump and control valve assembly 7 sends hydraulic power to the hydraulic motor 3, so that the pressure and flow of the hydraulic system adapt to the working parameters of the hydraulic motor 3; the frame 10 is also provided with a working system, which includes two sets of vertically arranged working devices, Each device includes a coaxially connected bolt sleeve 2 and a hydraulic motor 3 that drives the bolt sleeve 2 to rotate, and a torque sensor 1 is connected in series between the bolt sleeve 2 and the hydraulic motor 3; the torque sensor 1 is connected to a torque controller 5, The torque sensor 1 transmits the torque state to the torque controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com