Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Guaranteed yarn quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

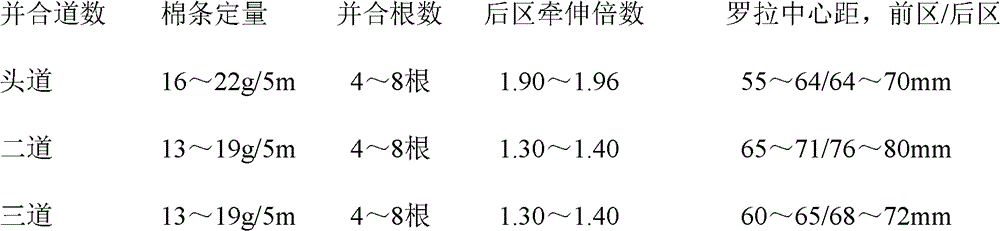

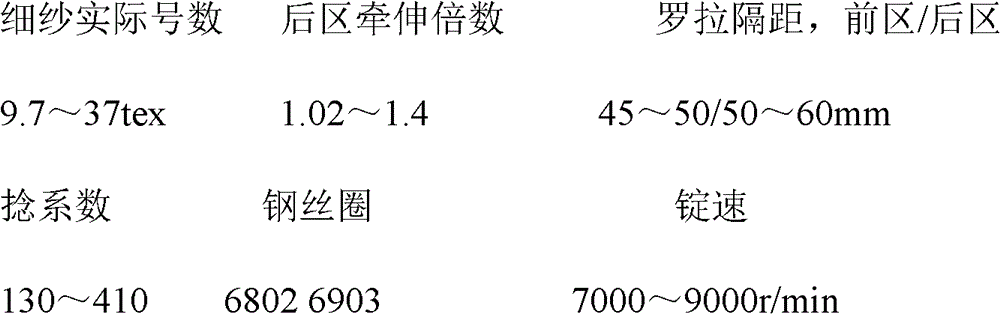

Ultra-high-count pure cotton combing yarn and spinning technology of ultra-high-count pure cotton combing yarn

ActiveCN103334190APromote maturityAmerican cotton has high strengthContinuous processingCombing machinesYarnFiber

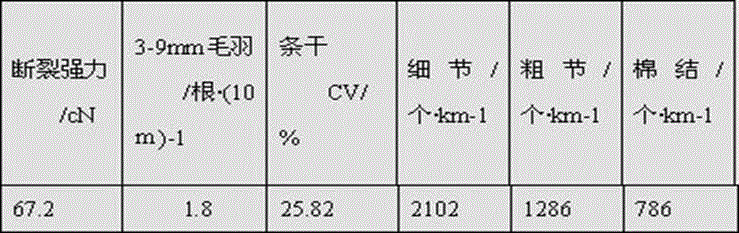

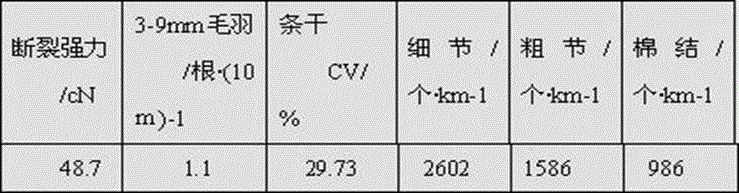

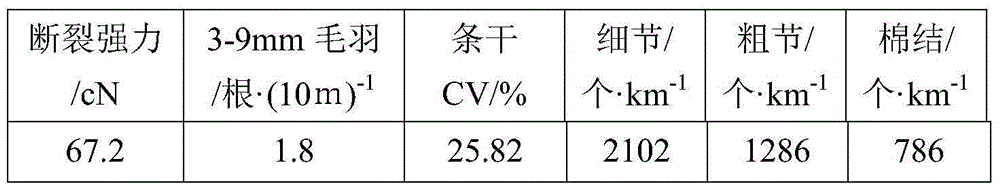

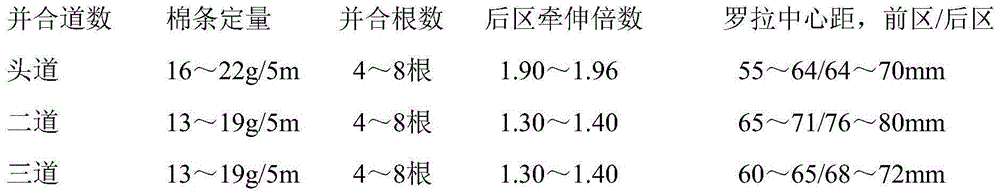

The invention discloses ultra-high-count pure cotton combing yarn and a spinning technology of the ultra-high-count pure cotton combing yarn. Raw cotton comprises, by weight, 15%-25% of Egypt cotton, 25%-35% of American cotton and 40%-50% of Xinjiang long stapled cotton, wherein the Egypt cotton, the American cotton and the Xinjiang long stapled cotton are blended to spin 200S to 300S pure cotton yarn. The spinning technology includes the following steps that the first procedure of blowing-carding, the second procedure of combing, the third procedure of drawing, the fourth procedure of roving yarn, the fifth procedure of spun yarn and the sixth procedure of spooling. With the blending scheme, the raw cotton can integrate the advantages of high fineness and good maturity of the Egypt cotton, the advantages of high strength and non-existing abnormal fibers of the American cotton, the advantage of large length of the Xinjiang long stapled cotton and the like. The raw cotton reaches the requirements for the fiber length, the length CV value, the Micronaire value, the fineness, the strength and other performance indexes of raw cotton in producing ultra-high-count yarn. According to the spinning technology of the ultra-high-count pure cotton combing yarn, the ultra-high-count yarn can be produced under a large ration of roving yarn, the spinning efficiency is improved and meanwhile, quality of resultant yarn is ensured.

Owner:傲丝生态(中国)有限公司

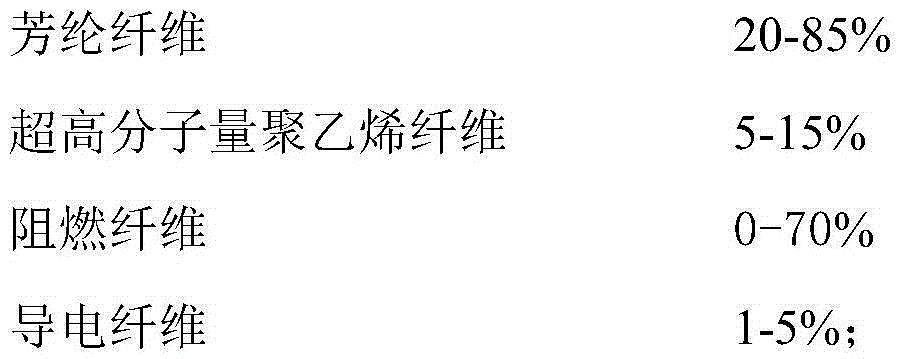

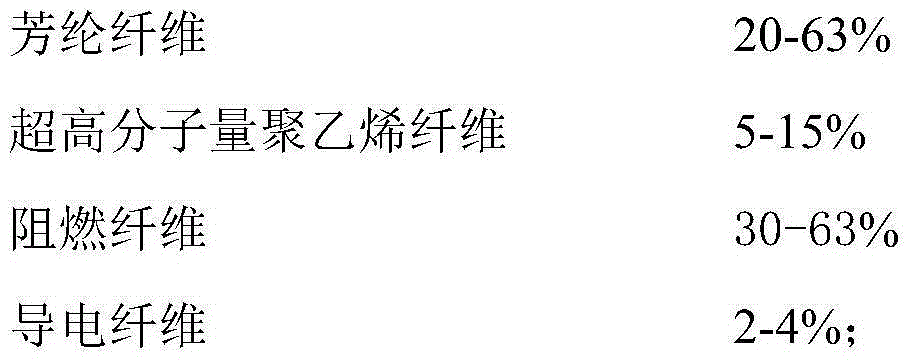

Blended yarn containing polytetrafluoroethylene fiber and preparation method of blended yarn

The invention discloses blended yarn containing polytetrafluoroethylene fiber and a preparation method of the blended yarn. The blended yarn is prepared from, by weight, 5-80% of polytetrafluoroethylene fiber, 20-95% of flame-retardant fiber and 0-5% of conductive fiber. The blended yarn containing polytetrafluoroethylene fiber is prepared by adding a certain proportion of conductive fiber, preprocessing the raw material before spinning, adding an antistatic agent for being still standing for at least 8 hours for antistatic processing, strictly controlling the technological conditions of all the procedures in the processing process, and controlling the temperature and relative humidity of the carding, drawing, roving and spinning procedures. The severe static problem during spinning of polytetrafluoroethylene fiber is effectively solved, and yarn quality is ensured.

Owner:SHANGHAI IBENA TEXTILE PROD

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

Three-in-one yarn fast bleaching method

ActiveCN101429726AStable bleaching qualityLess hairyBleaching apparatusLiquid/gas/vapor yarns/filaments treatmentYarnPeroxide process

The invention relates to a three-in-one yarn quick bleaching method, which combines with characteristics of high temperature, high pressure, low water level scouring and bleaching in one bath process and ultra-short flow, wherein in the whole scouring and bleaching process for yarns, the temperature is between 110 and 130 DEG C, the pressure is 1.5 to 3.0bar, the bath ratio is between 1 to 3 and 1 to 7, the rotating speed of a main pump of a dyeing cylinder is 600 to 1,300rpm, the scouring and bleaching time is 10 to 30 minutes and the water adding time is 3 to 4 times, meanwhile, an optimized high-temperature and high-pressure hydrogen peroxide process is used. The yarns processed through the method have remarkable reduction in strength loss and hair feather, the production cost, processing time, sewage discharge and energy consumption of scouring and bleaching white yarns are reduced greatly since the characteristics of high temperature, high pressure, low water level scouring and bleaching in one bath process and ultra-short flow are used.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

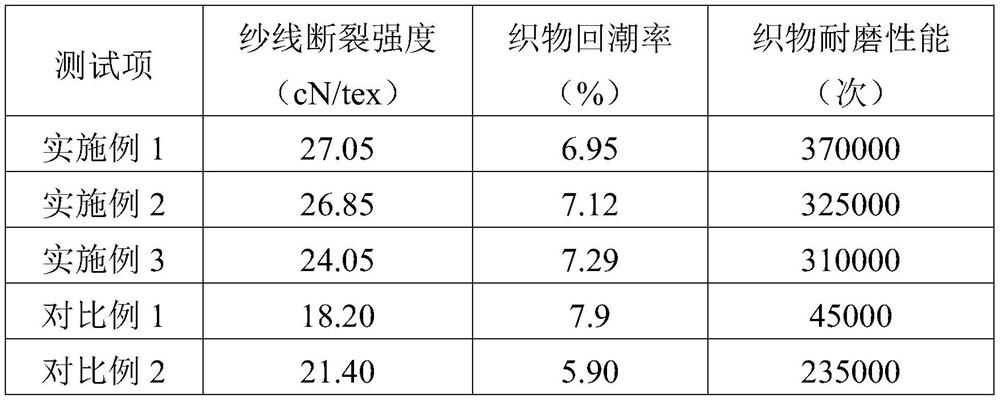

Blended yarn of polyamide fiber and cotton as well as preparation method and application of blended yarn

The invention provides a blended yarn of polyamide fiber and cotton as well as a preparation method and application of the blended yarn. The blended yarn comprises, by weight, 10-90 parts of polyamide56 fibers and 10-90 parts of cotton fibers, preferably, 20 to 50 parts by weight of polyamide 56 fiber and 50 to 80 parts by weight of cotton fiber, wherein the total weight of the polyamide 56 fibers and the cotton fibers accounts for 10-100 wt% of the total weight of the blended yarn, and / or the breaking strength of the polyamide 56 fiber is greater than 5.5 cN / dtex. Fabric prepared from the blended yarn can greatly improve the wear resistance and durability of the fabric while maintaining good moisture absorption, softness and comfort, and is suitable for the application field with high requirements for the wear resistance and comfort of the fabric.

Owner:CATHAY R&D CENT CO LTD +1

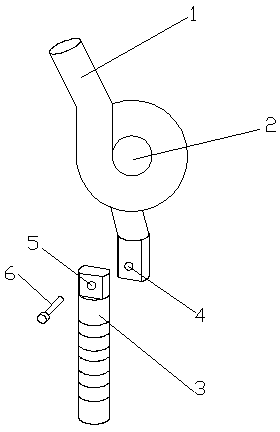

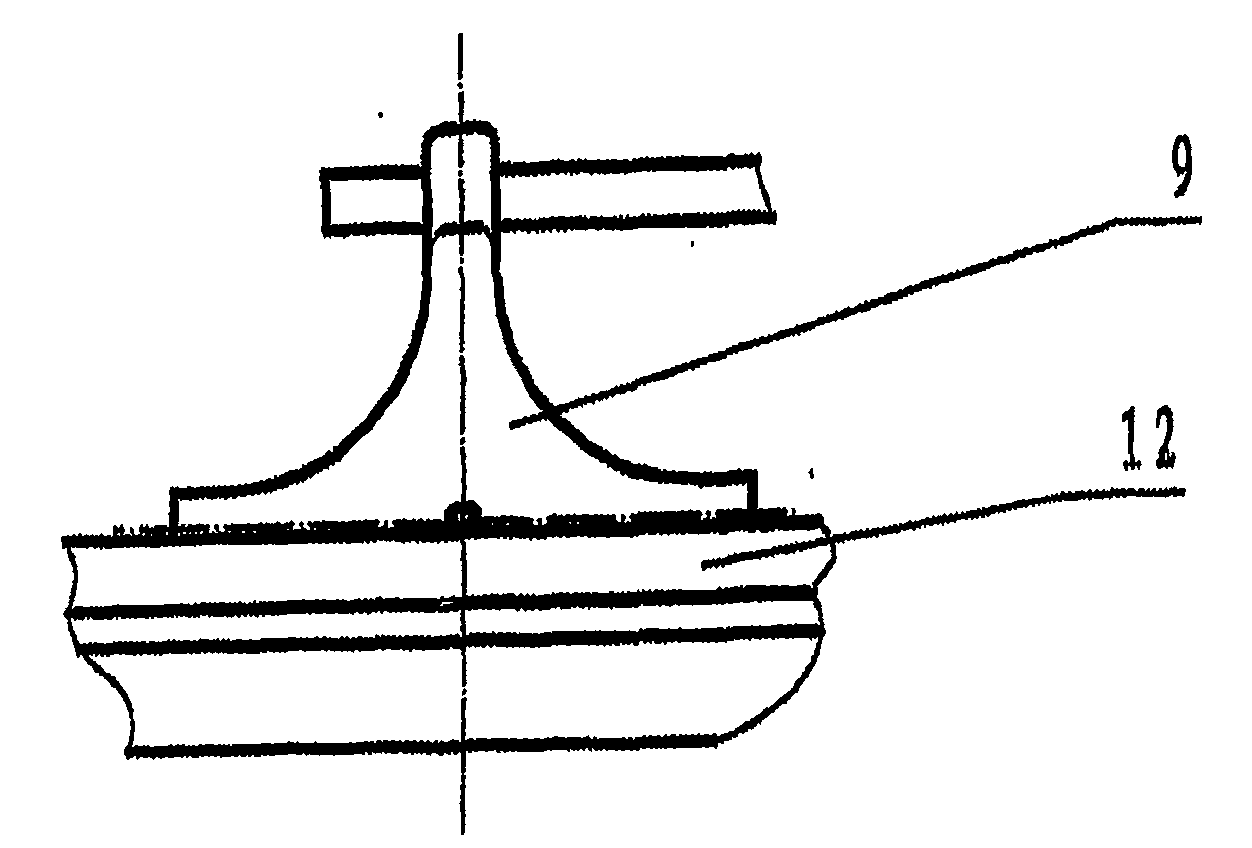

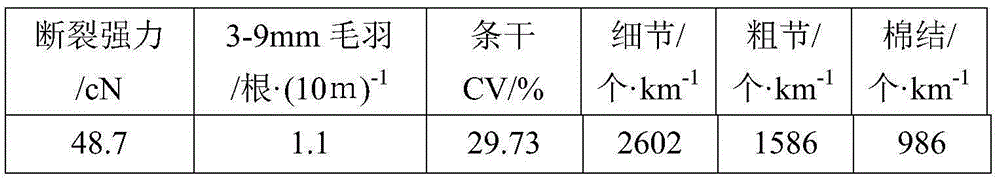

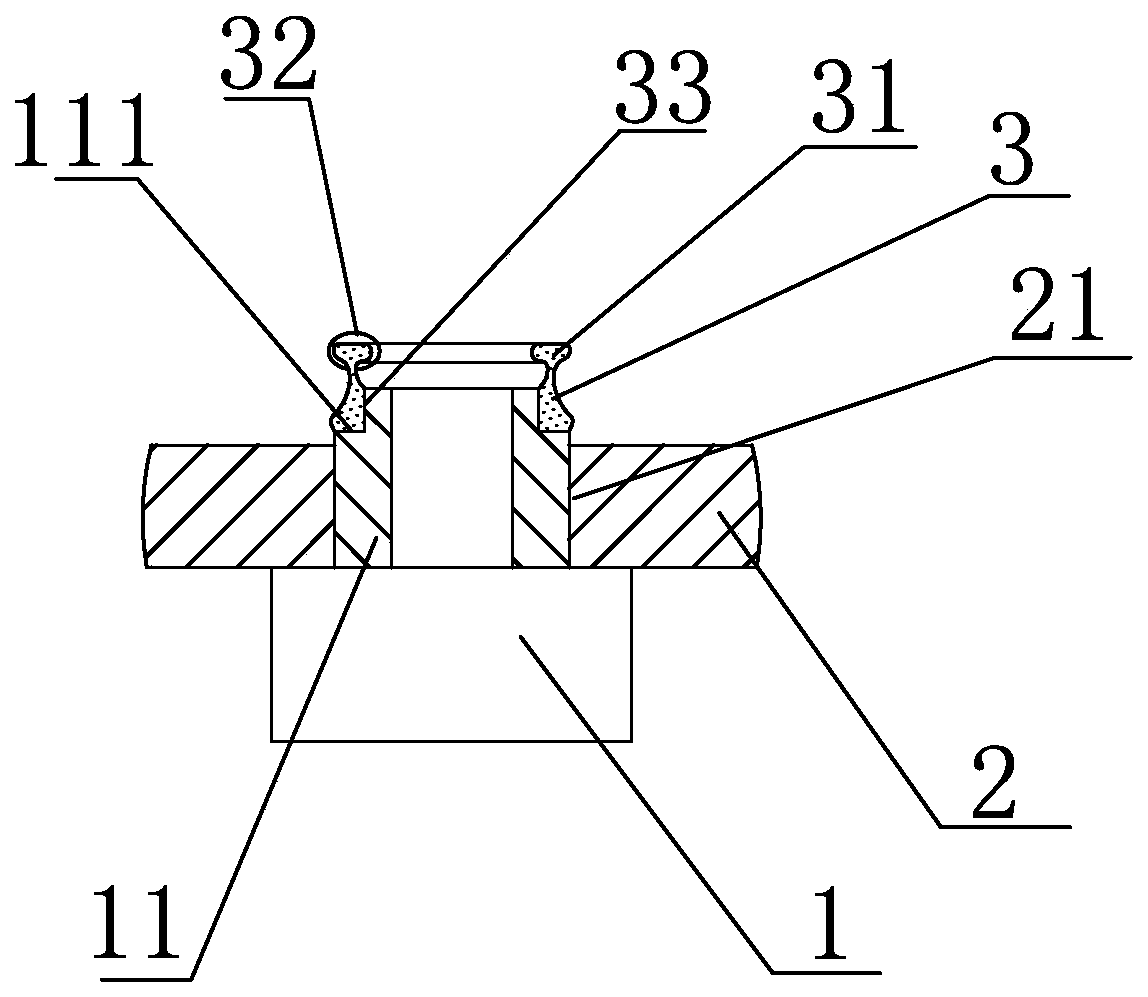

Yarn guide hook

InactiveCN103710802AMeet needsGuaranteed yarn qualityTextiles and paperYarnArchitectural engineering

The invention discloses a yarn guide hook which comprises a yarn guide rod and a fixing rod. The middle of the yarn guide rod is rolled to form an annular yarn passing channel, the lower end of the yarn guide rod is flat, the flat lower end of the yarn guide rod is provided with a first threaded hole, the upper end of the fixing rod is also flat, the flat upper end of the fixing rod is provided with a second threaded hole, and the yarn guide rod is connected with the fixing rod due to the fact that the first threaded hole in the lower end of the yarn guide rod and the second threaded hole in the upper end of the fixing rod are matched with a fastener. The rod wall of the fixing rod is provided with threads, and the fixing rod is fixed to a yarn guide plate through the threads. In the yarn spinning process, if the yarn guide angle needs to be adjusted, the fastener can be unscrewed, the yarn guide rod is rotated to be at the needed angle, then the fastener is screwed, adjustment of the angle of the yarn guide hook is finished, requirements of different spinning machines and yarns for the yarn guide angle are met, and yarn weaving quality is guaranteed.

Owner:吴江金名来丝绸进出口有限公司

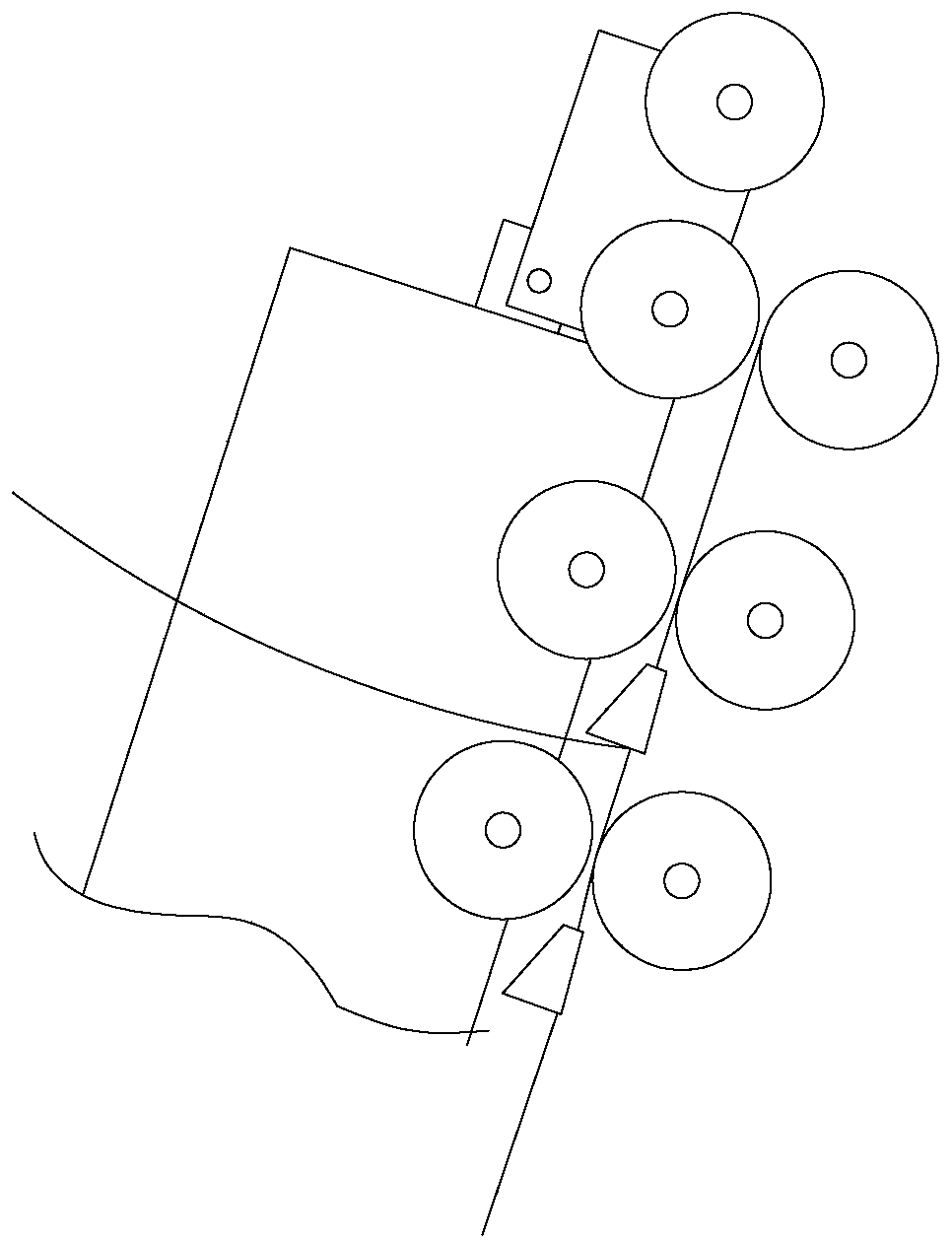

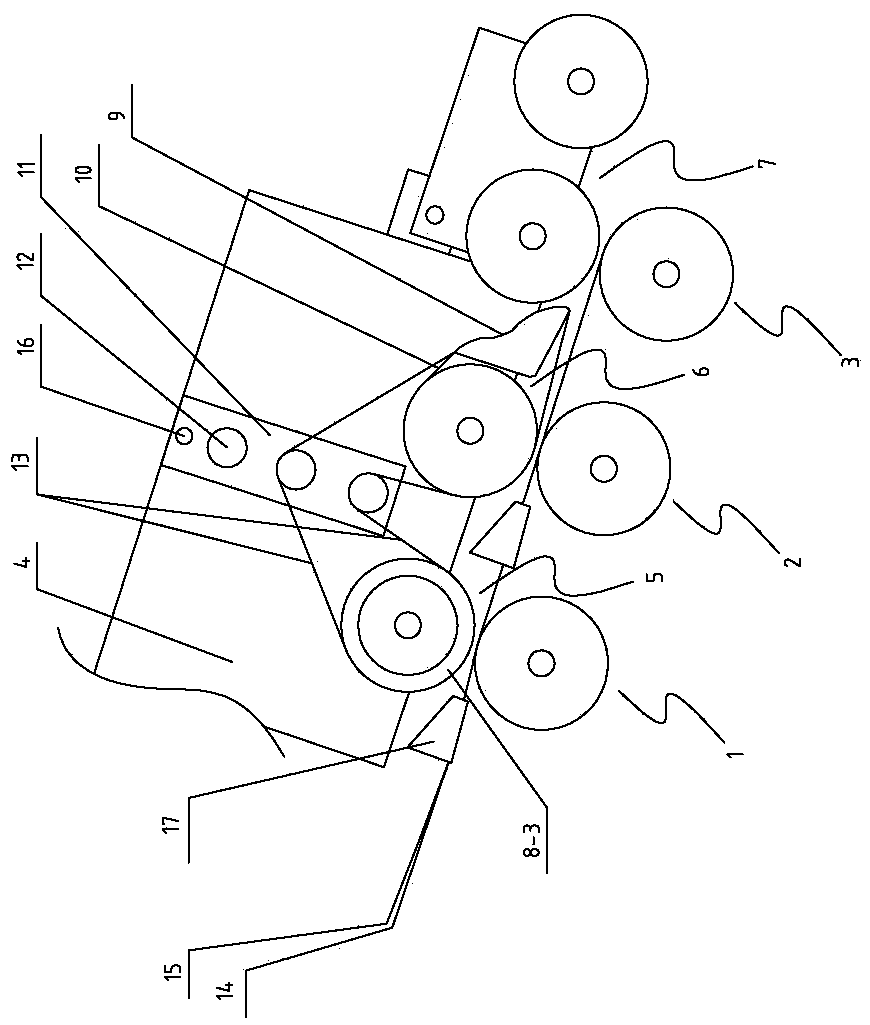

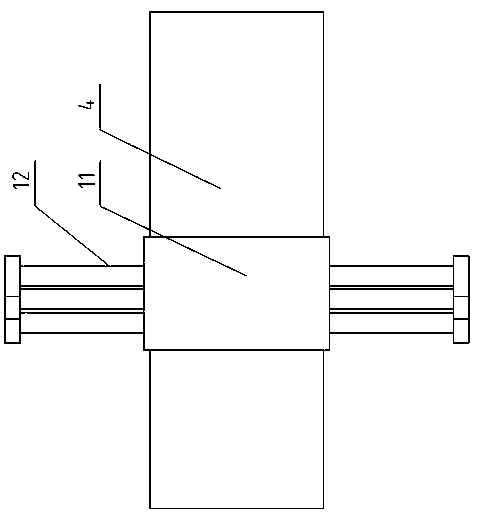

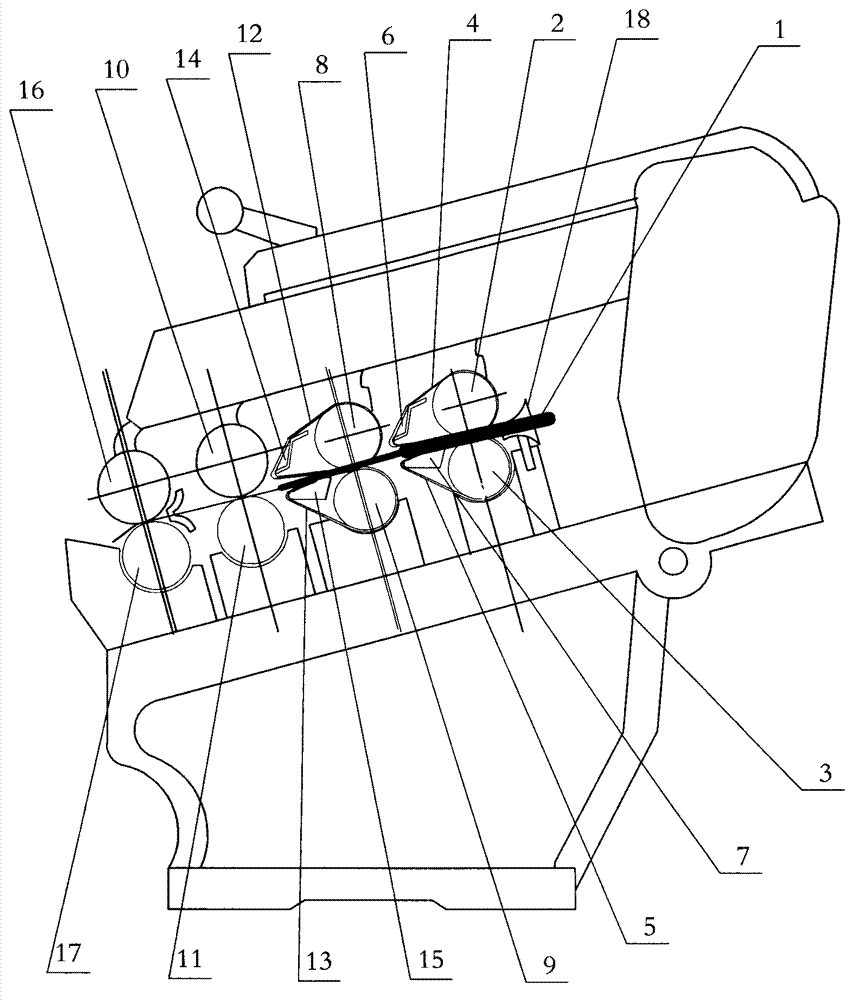

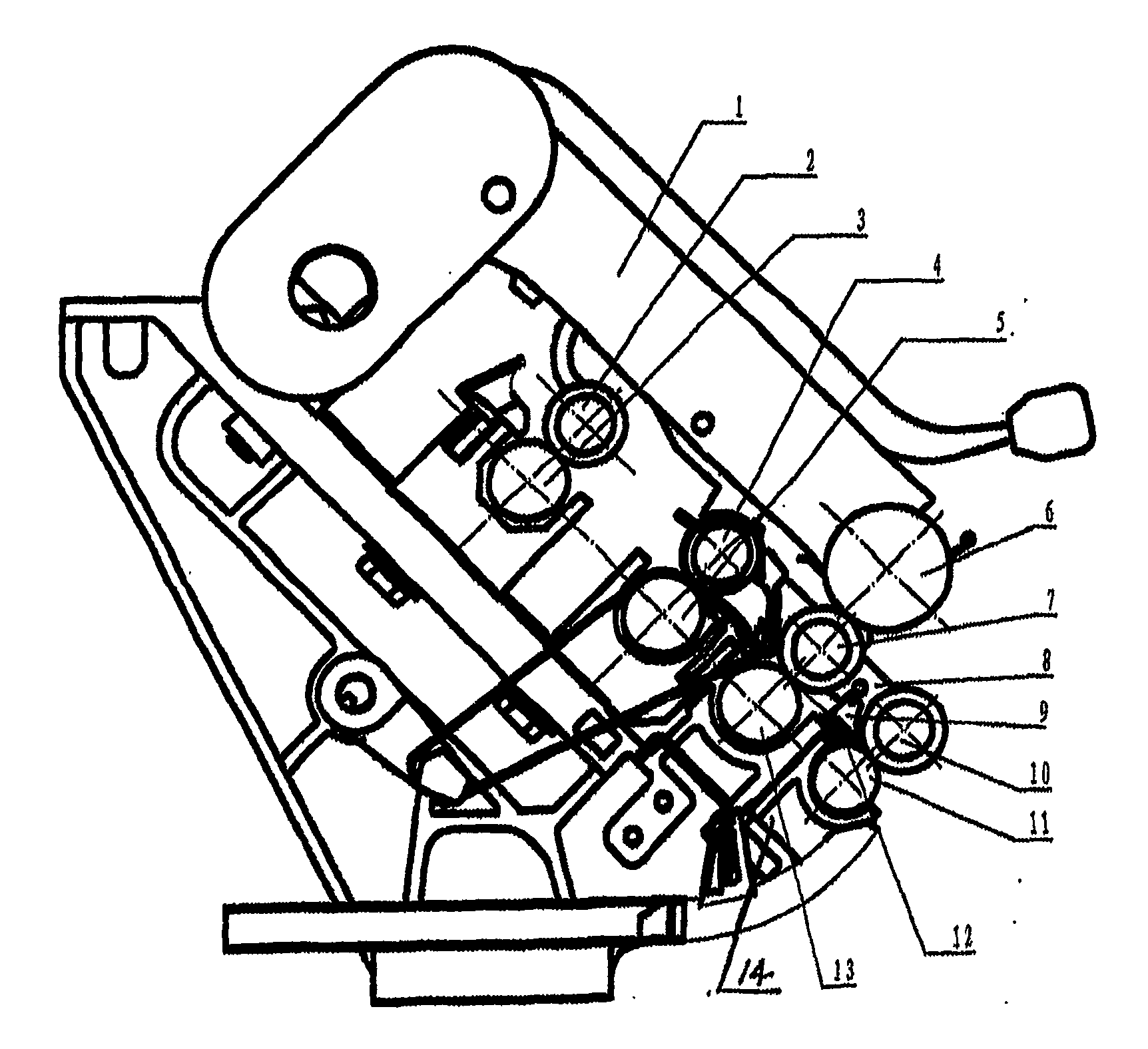

Special drafting spinning mechanism for spinning frame

The invention relates to the technical field of spinning frame equipment, in particular to a special drafting spinning mechanism for a spinning frame. The technical scheme includes that a rear roller,a middle roller and a front roller can be controlled and driven by individual motors, a cradle is arranged on upper sides of the rear roller, the middle roller and the front roller, at least one endof each roller body is provided with a large-diameter section and a small-diameter section, the widths of the large-diameter sections correspond to the widths of the small-diameter sections, the large-diameter sections and the small-diameter sections on a first upper leather roller and a second upper leather roller are correspondingly arranged in a staggered manner, the second upper leather rolleris mounted on an upper pin of the cradle in a fixedly connected manner, a first leather collar is wound on a leather roller wheel of the second upper leather roller and the upper pin, a tension frameis mounted on the cradle, at least two tensioning rods at different heights are mounted on the tension frame, one end of a second leather collar is wound on a leather roller wheel of the first upperleather roller, the other end of the second leather collar is wound on the small-diameter sections of the second upper leather roller, the middle of the second leather collar is tensioned on the two corresponding tensioning rods, and the first upper leather roller is supported by the second leather collar in a suspended manner. The special drafting spinning mechanism has the advantages that the leather collars and yarns can be conveniently accurately controlled, drafting can be effectively guaranteed, the leather collars can be prevented from slipping or dropping, and the quality of the yarnsand the spinning efficiency can be improved.

Owner:WUXI HENGJIU ELECTRICAL TECH

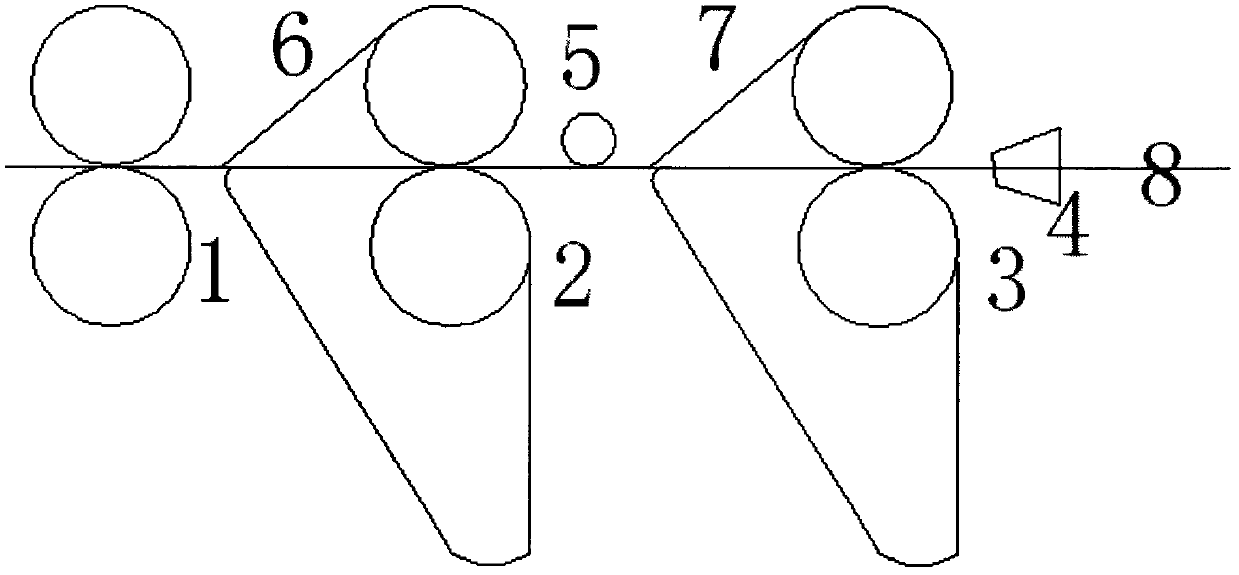

Fly frame drafting device adapting to large draft ratios

InactiveCN103088481AReliable controlRealization of large drafting multiplesDrafting machinesYarnDevice form

The invention discloses a fly frame drafting device adapting to large draft ratios. The device is of a four-roller four-short-apron drafting mode and is provided with a vice drafting area, a main drafting area and a distribution area, wherein the main drafting area and the vice drafting area are respectively provided with a double-short-apron drafting device formed by an upper apron, a lower apron, an upper pin and a lower pin. According to the fly frame drafting device, due to the fact that the vice drafting area is provided with double short aprons, two apron drafting areas exist in common, a mode that a traditional drafting device is provided with two rollers simple drafting areas and a double-short-apron drafting area is broken through, large draft ratio production of a fly frame is achieved, and a roving procedure can be smoothly achieved when spinning of cotton yarns with the density equal to or over 150 s is carried out. The fly frame drafting device can adapt to the large draft ratios ranging from 12 to 20 on the premise that spinning quality is guaranteed.

Owner:ANHUI HUAMAO TEXTILE

Drafting device with four rollers in ring spinner

InactiveCN100545331CIncrease the total draft multipleSolve the problem of high hairiness in spun yarnDrafting machinesContinuous wound-up machinesYarnQuality assurance

Owner:JINGWEI TEXTILE MASCH CO LTD

Yarn spinning technology for semi-worsted and blended colored yarn and yarn

InactiveCN104878493AImprove insulation effectIncrease elasticityBleaching apparatusYarnCardingWorsted

The invention relates to a yarn spinning technology for semi-worsted and blended colored yarn and the yarn prepared with the technology. The technological steps mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise cotton fiber, nylon fiber and viscose fiber. The cotton fiber is treated with a more efficient bleaching method, meanwhile, nylon and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are improved; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

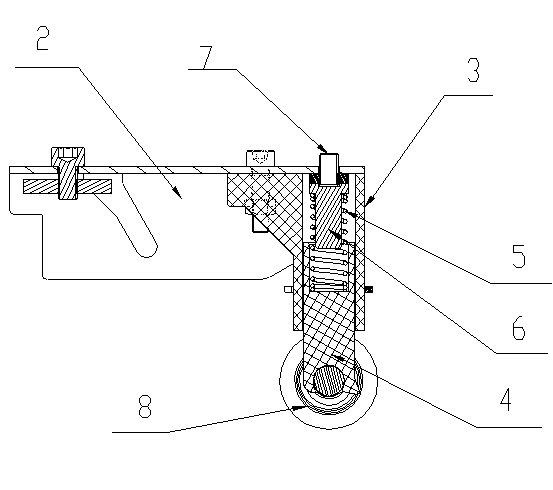

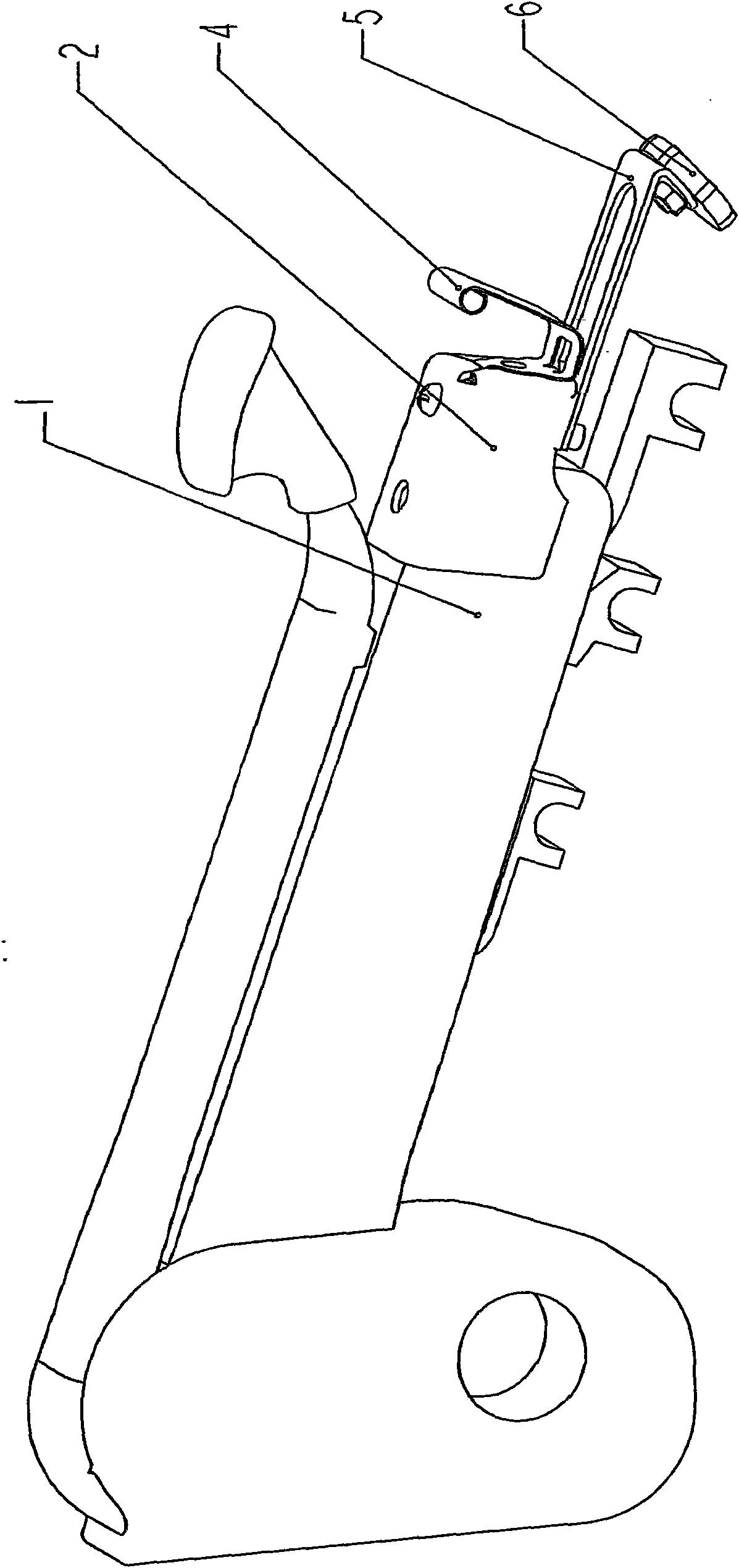

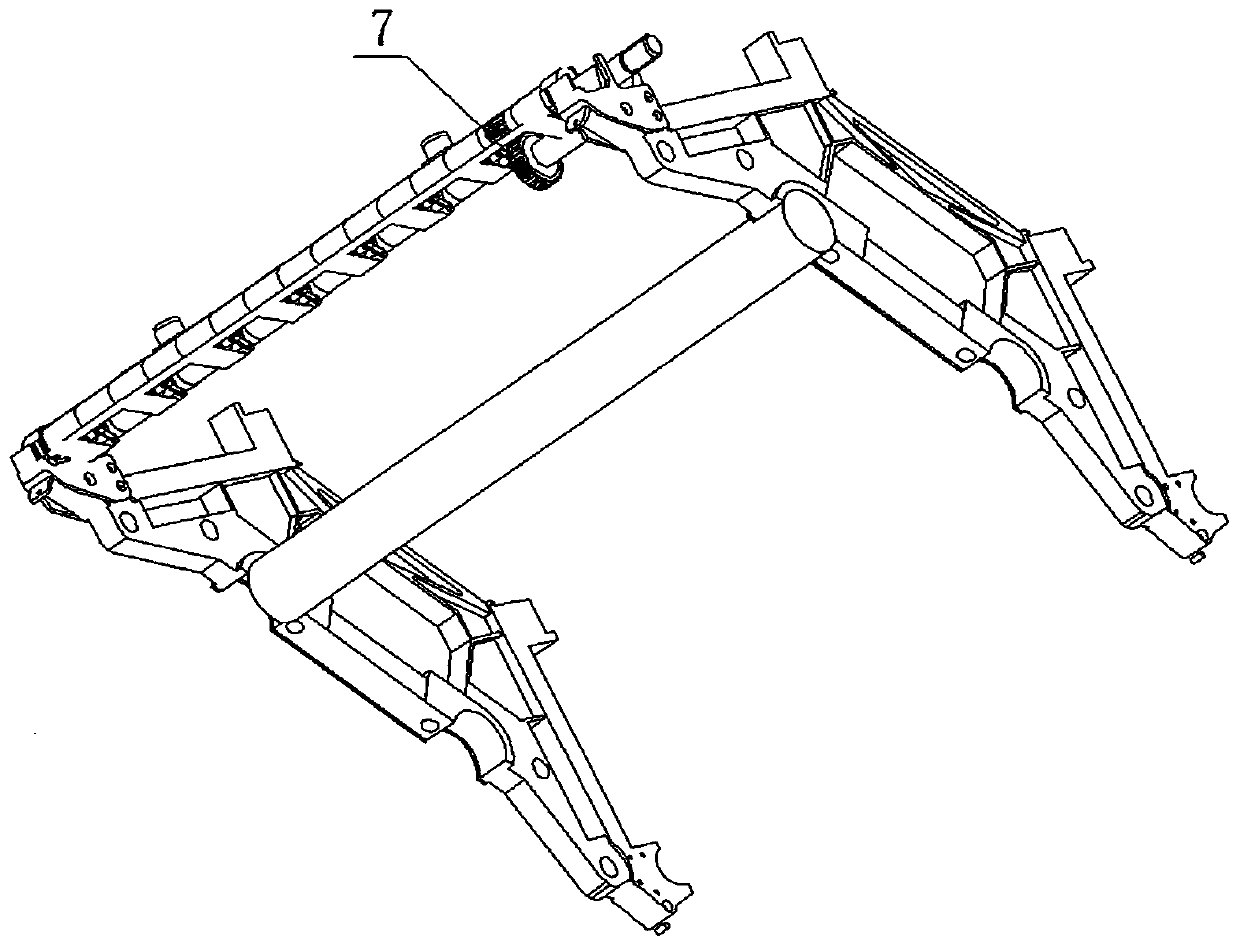

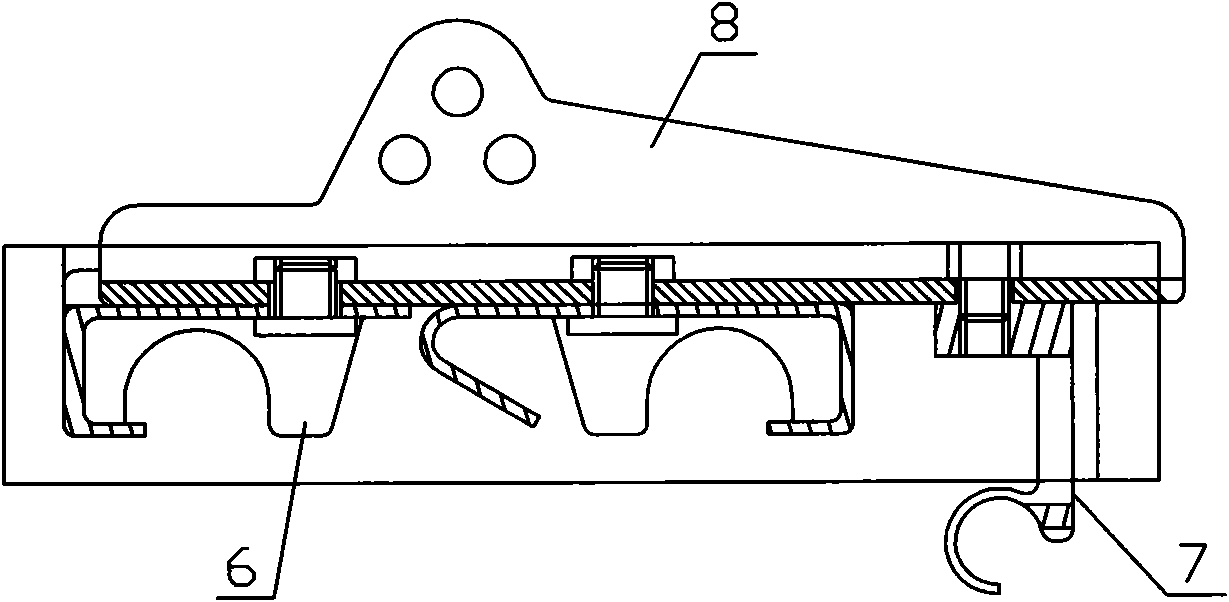

Compact-spinning cradle pressurizing device

InactiveCN102864530APressure effectSimple structureDrafting machinesEngineeringMechanical engineering

The invention relates to a compact-spinning cradle pressurizing device comprising a cradle (1) and a pressurizing device connected with the cradle. The compact-spinning cradle pressurizing device is characterized by comprising a connector (2) and a roller clamping jaw fixing base (3); wherein one end of the connector is connected with the cradle in a blocking manner; the roller clamping jaw fixing base is vertically fixed on the other end of the connector; a roller clamping jaw (4) is fixed in the roller clamping jaw fixing base; a spring (5) is inserted in a circular hole in the upper part of the roller clamping jaw; a locating pin shaft (6) is inserted on the upper part of the spring; and the upper part of the locating pin shaft is fixed on the connector by an adjusting nut (7). The compact-spinning cradle pressurizing device provided by the invention is simple in structure and convenient to assemble and disassemble, and is capable of independently pressurizing by using the spring, so that the yarn quality is ensured.

Owner:江阴市华方新技术科研有限公司

Super-high-draft device

The invention relates to a super-high-draft device which comprises a front roller, a middle roller, a rear roller, a pressure bar, a bell mouth and leather collars, and is characterized in that a pressure bar is additionally mounted in a rear zone of the conventional draft device and the leather collar is additionally mounted on the rear roller, so that the friction field of the rear zone is increased, and control of floating fibers in the rear draft zone is strengthened. Harmful feathers are reduced, and the draft multiple is improved.

Owner:JIANGNAN UNIV

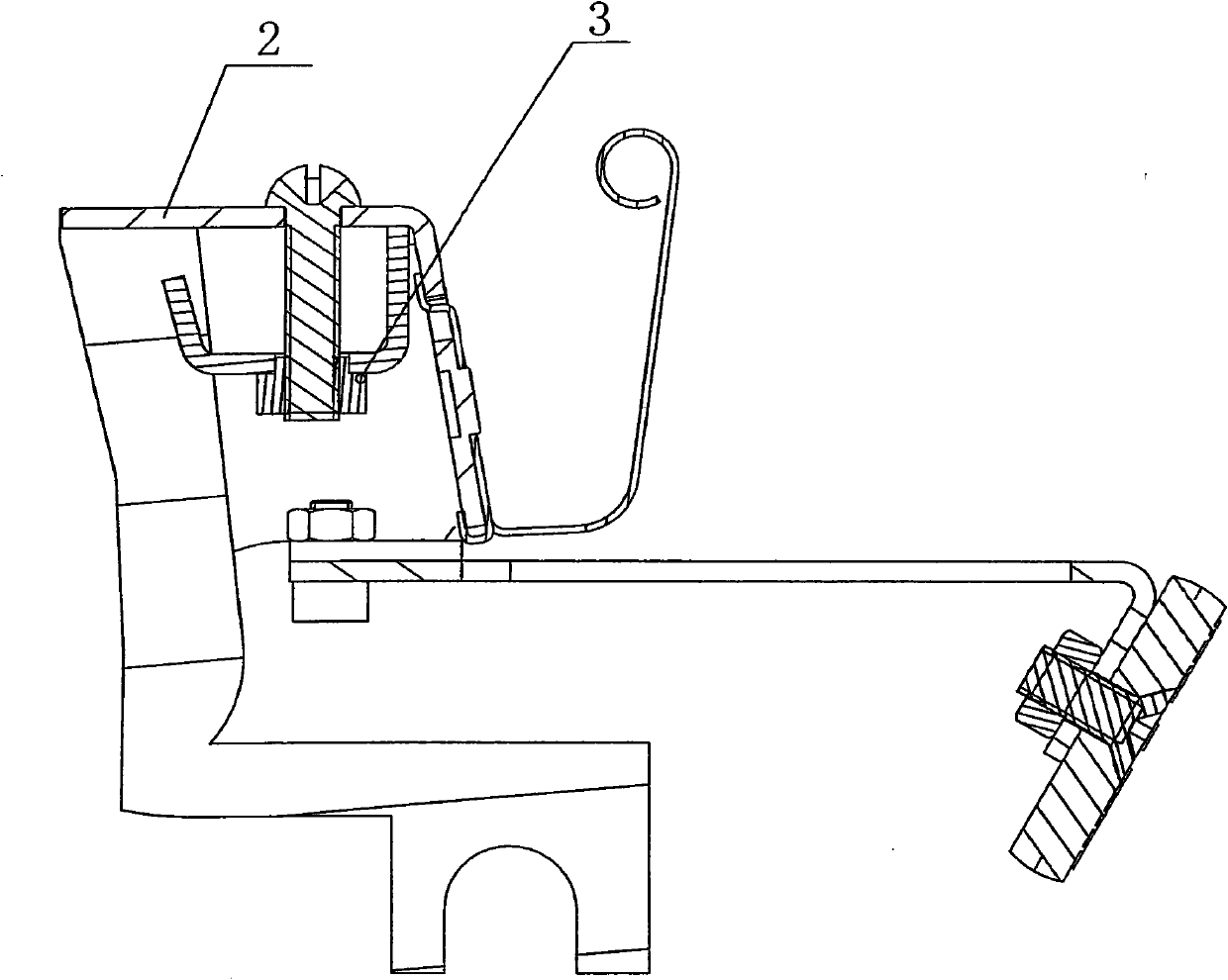

Compact spinning pressurizing device

InactiveCN102021690AGuaranteed yarn qualityNot affected by external factorsDrafting machinesMechanical engineeringTextile

The invention relates to a compact spinning pressurizing device which belongs to the technical field of parts of textile machinery and comprises a cradle (1) and a velvet roll spring (4) arranged on the cradle (1), wherein a hole is arranged on the cradle (1). The compact spinning pressurizing device is characterized in that a pressurizing regulating device is additionally arranged on the hole of the cradle (1) and comprises a positioning sheet combining member (3), a spring piece (5), a positioner (2) and a pressurizing sheet (6), wherein the positioning sheet combining member (3) is connected with the hole on the cradle (1) and positioned at the inner side of the positioner (2) as well as connected with the positioner (2), one end of the spring piece (5) is connected with the positioner (2) and the other end is connected with the pressurizing sheet (6). The pressurizing device can ensure that the pressure of the pressurizing sheet to a small roll is not influenced by outside and is basically kept unchangeable.

Owner:江阴市华方新技术科研有限公司

A kind of extra-high-count pure cotton combed yarn and its spinning process

ActiveCN103334190BPromote maturityAmerican cotton has high strengthContinuous processingCombing machinesYarnFiber

The invention discloses ultra-high-count pure cotton combing yarn and a spinning technology of the ultra-high-count pure cotton combing yarn. Raw cotton comprises, by weight, 15%-25% of Egypt cotton, 25%-35% of American cotton and 40%-50% of Xinjiang long stapled cotton, wherein the Egypt cotton, the American cotton and the Xinjiang long stapled cotton are blended to spin 200S to 300S pure cotton yarn. The spinning technology includes the following steps that the first procedure of blowing-carding, the second procedure of combing, the third procedure of drawing, the fourth procedure of roving yarn, the fifth procedure of spun yarn and the sixth procedure of spooling. With the blending scheme, the raw cotton can integrate the advantages of high fineness and good maturity of the Egypt cotton, the advantages of high strength and non-existing abnormal fibers of the American cotton, the advantage of large length of the Xinjiang long stapled cotton and the like. The raw cotton reaches the requirements for the fiber length, the length CV value, the Micronaire value, the fineness, the strength and other performance indexes of raw cotton in producing ultra-high-count yarn. According to the spinning technology of the ultra-high-count pure cotton combing yarn, the ultra-high-count yarn can be produced under a large ration of roving yarn, the spinning efficiency is improved and meanwhile, quality of resultant yarn is ensured.

Owner:傲丝生态(中国)有限公司

Active rotating steel collar

PendingCN109763220AIncrease the diameterReduce the relative angular velocityTextiles and paperYarnAngular velocity

The invention relates to an active rotating steel collar. The steel collar is structurally characterized in that a hollow shaft motor is fixedly connected with a steel collar plate, a through hole isformed in the steel collar plate, a central shaft of a hollow rotating shaft of the hollow shaft motor penetrates the center of the through hole, the steel collar body is fixedly connected with the outer end of the hollow rotating shaft, a runway is arranged on the steel collar body, and a traveler is arranged on the runway. The steel collar has the advantages that the relative angular velocity ofthe traveler and the steel collar is reduced, the breakage rate is reduced by about 45%, and production efficiency is improved; the spindle speed can be increased by 50%, the front roller speed withthe same twist is also increased by 50%, and the single spindle output of a spinning frame is increased by 50% or higher; the diameter of the steel collar is increased, the cop capacity is increased,the doffing frequency is reduced, and the number of doffing workers is reduced; the service life of the traveler is greatly prolonged by 1-2 months, and labor intensity of the workers is reduced; when the variety of products is changed, all that is required is to change the rotating speed of the steel collar, the traveler is not needed to be changed, and the workload of knitters is reduced; yarndamage caused by heating of the traveler is reduced, and yarn quality is ensured.

Owner:江苏格罗瑞节能科技有限公司

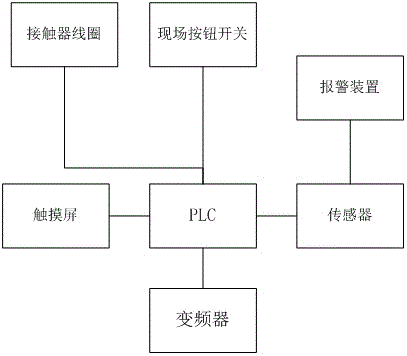

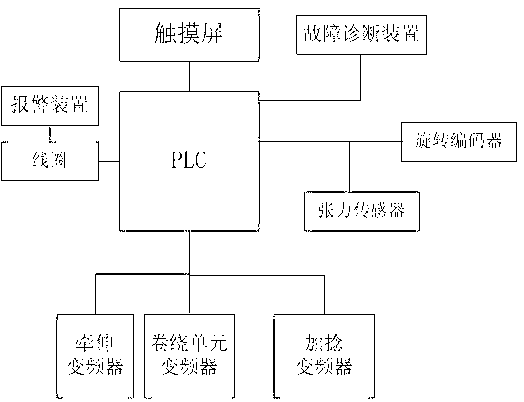

Control system for spinning machine

InactiveCN102945014AGuaranteed yarn qualityReduce manufacturing costTextiles and paperProgramme control in sequence/logic controllersFrequency changerYarn

The invention discloses a control system for a spinning machine. The control system comprises a touch screen, a frequency converter, a PLC (Programmable Logic Controller), a contactor coil, a field button switch and a sensor, wherein the touch screen and the frequency converter are respectively connected with the PLC; and the contactor coil, the field button switch and the sensor are respectively connected with the PLC. The PLC, the touch screen and the frequency converter form a frequency conversion and speed regulation system, so the control system provided by the invention has the advantages of intelligence, multiple functions, safety, reliability, guaranteed quality of finished yarns and reduced production cost.

Owner:WUJIANG JIEJIE WEAVING

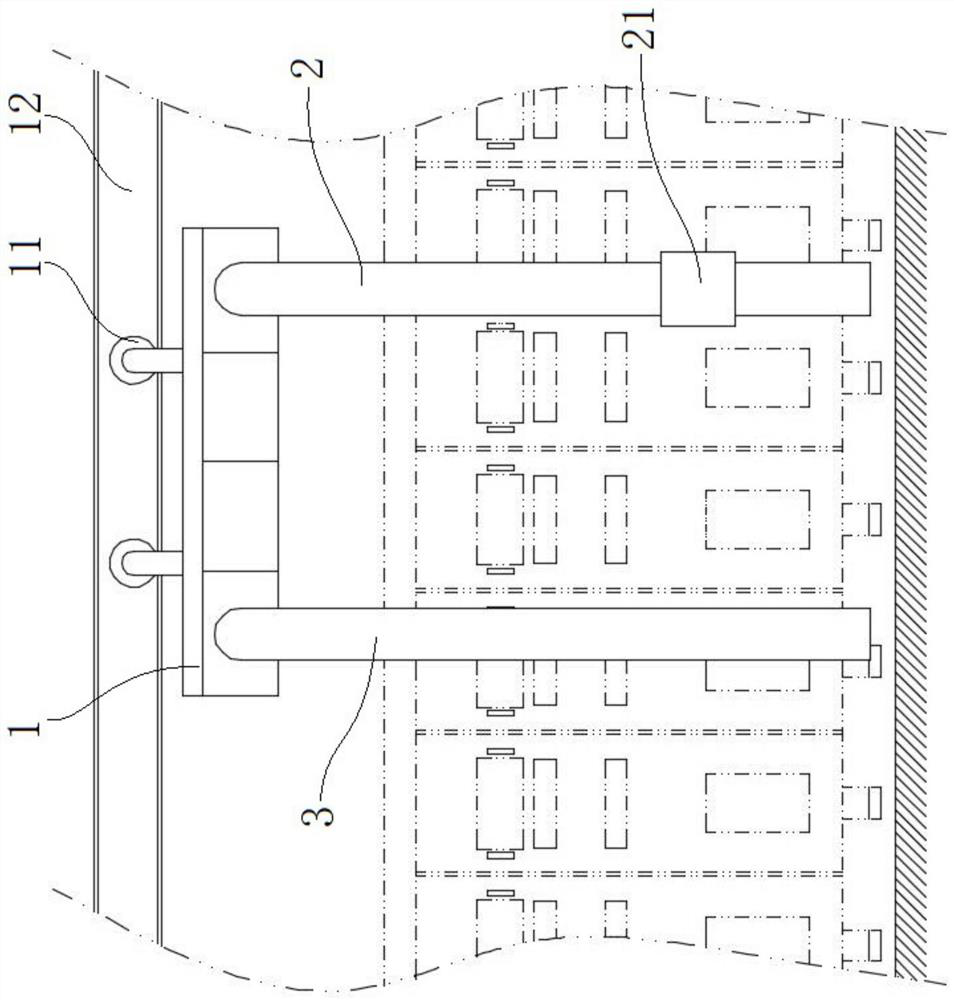

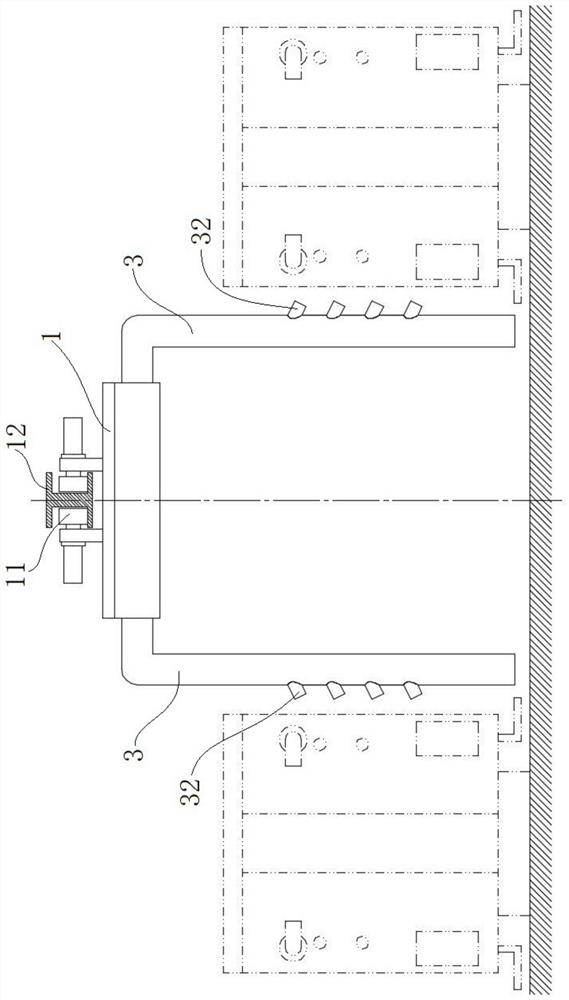

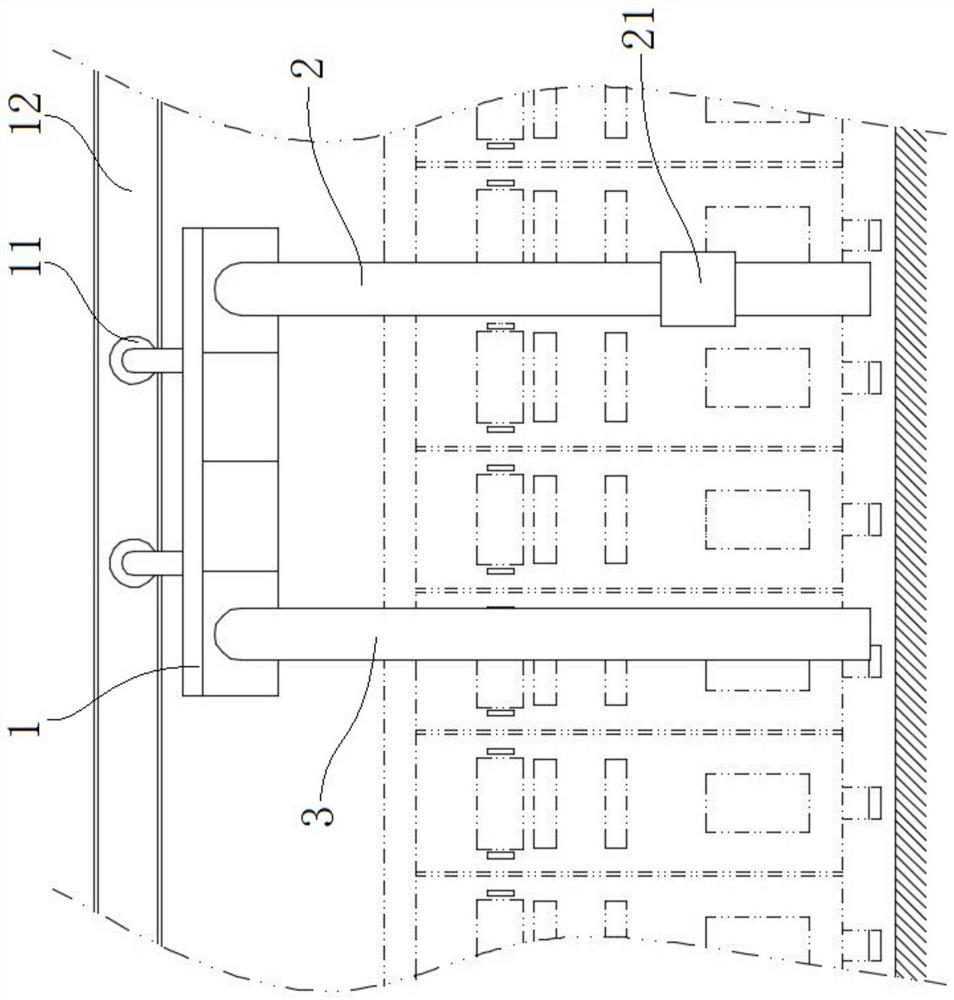

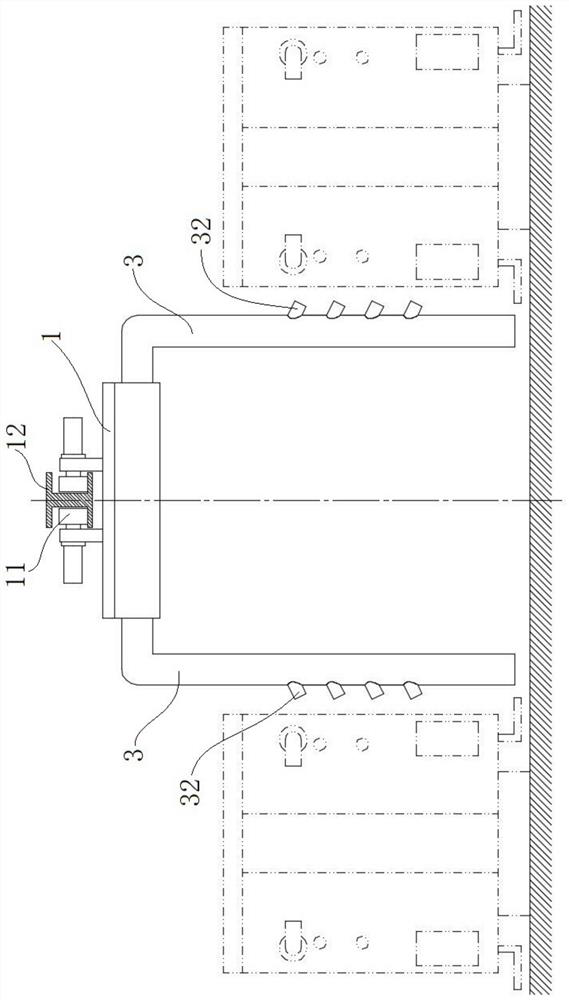

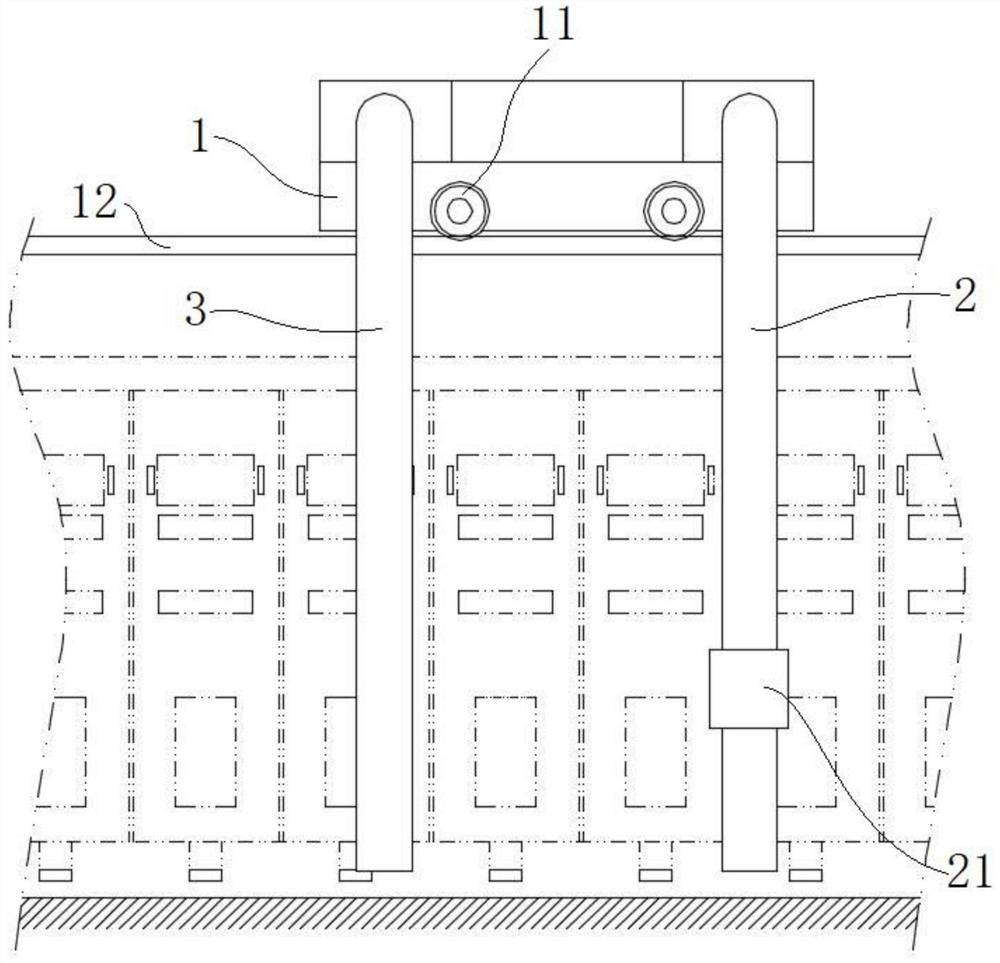

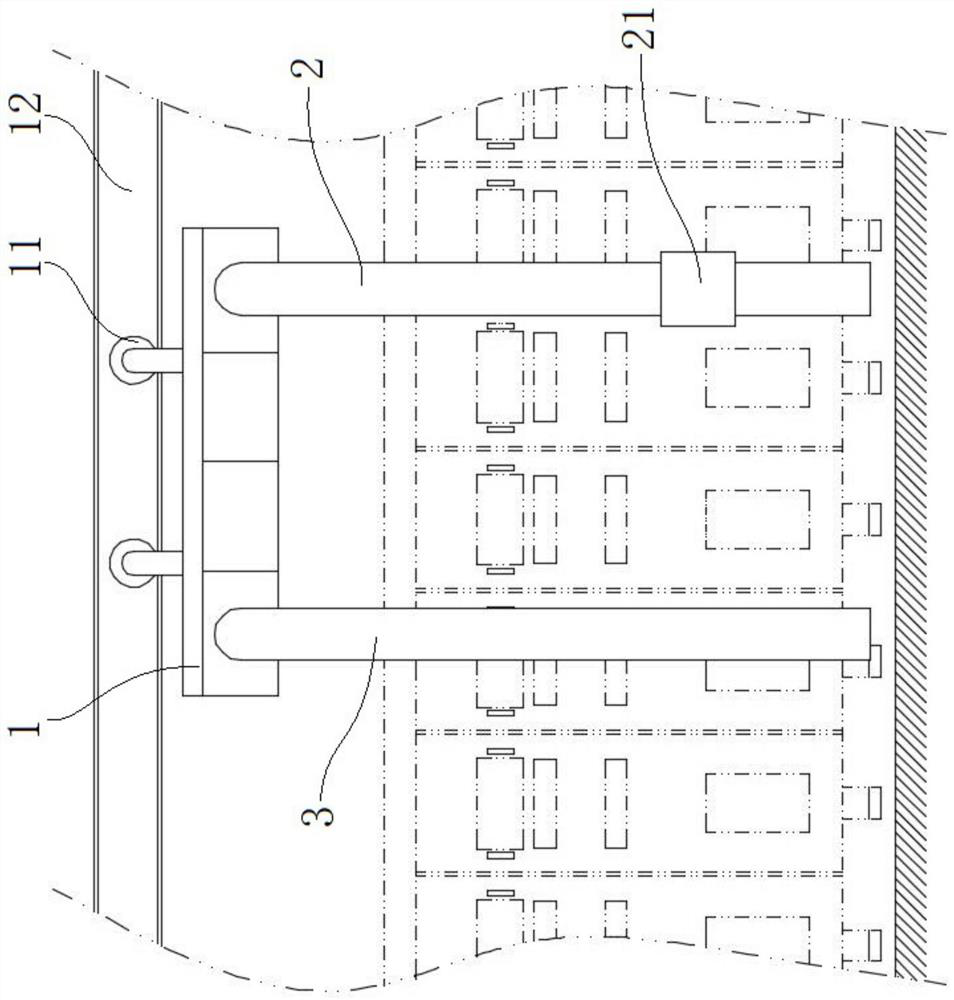

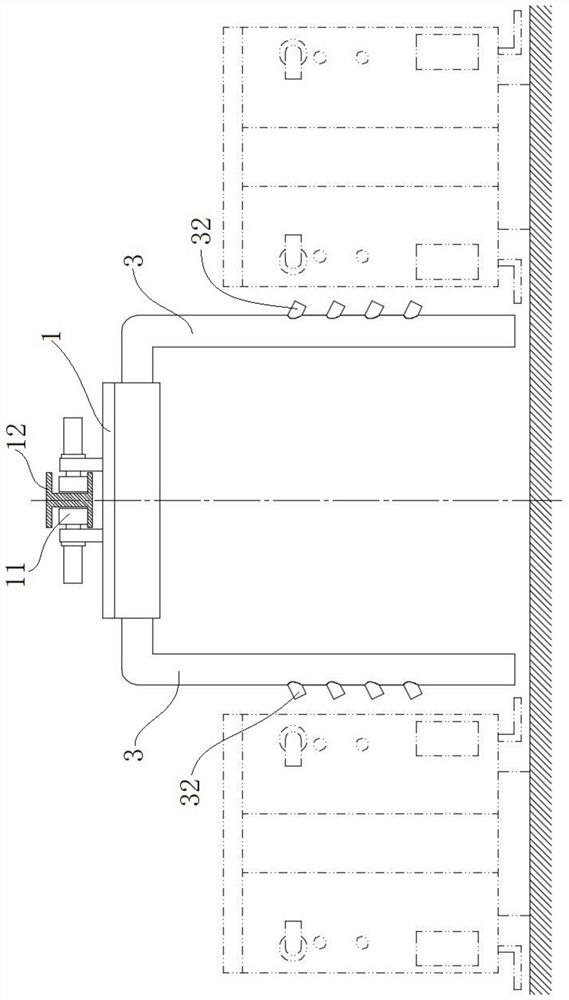

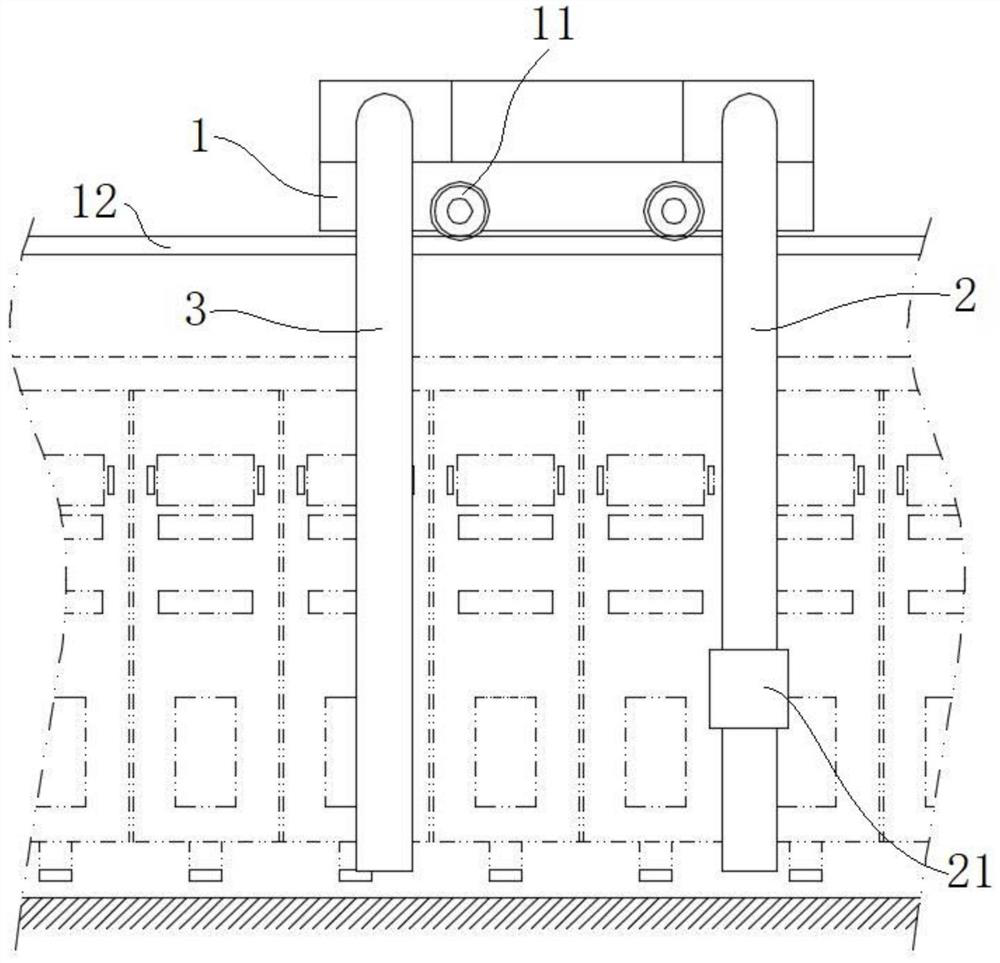

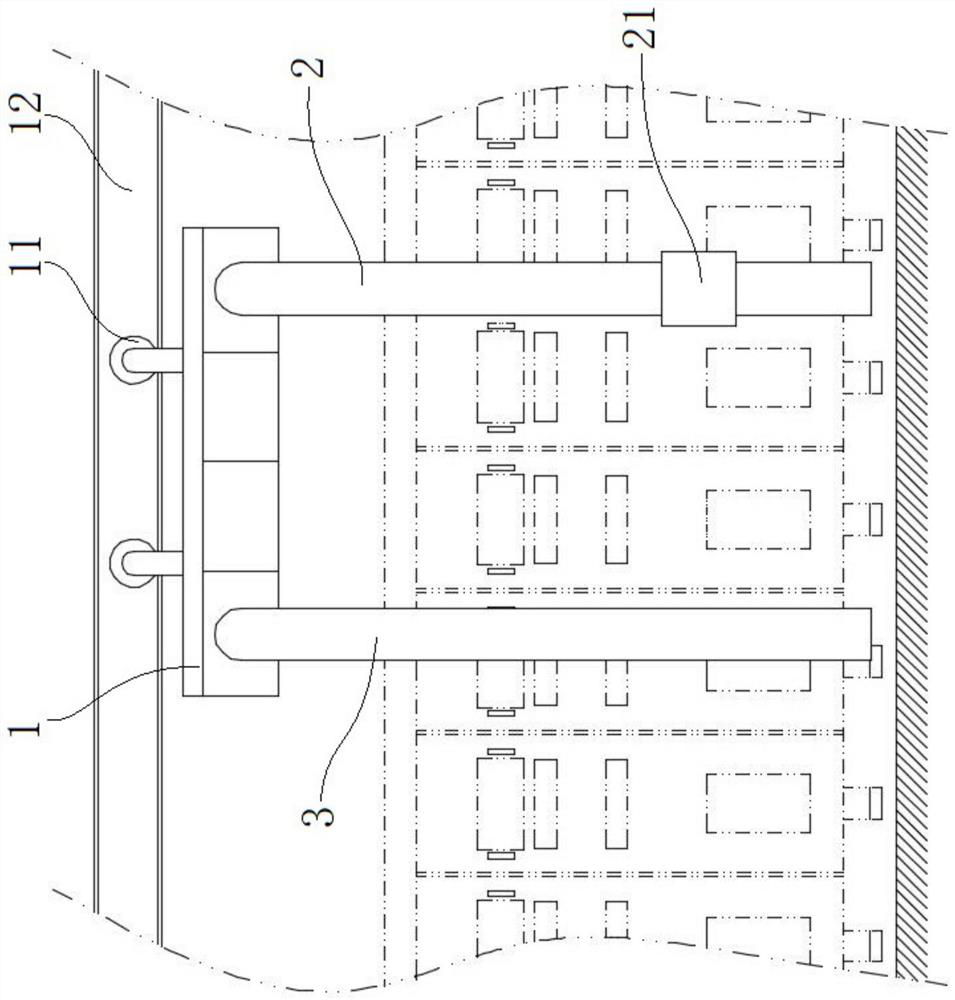

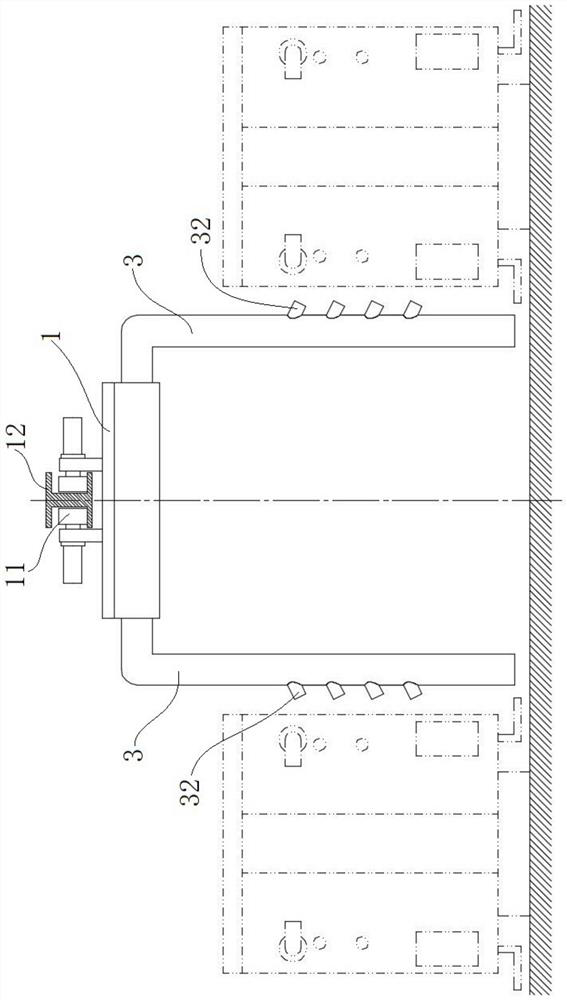

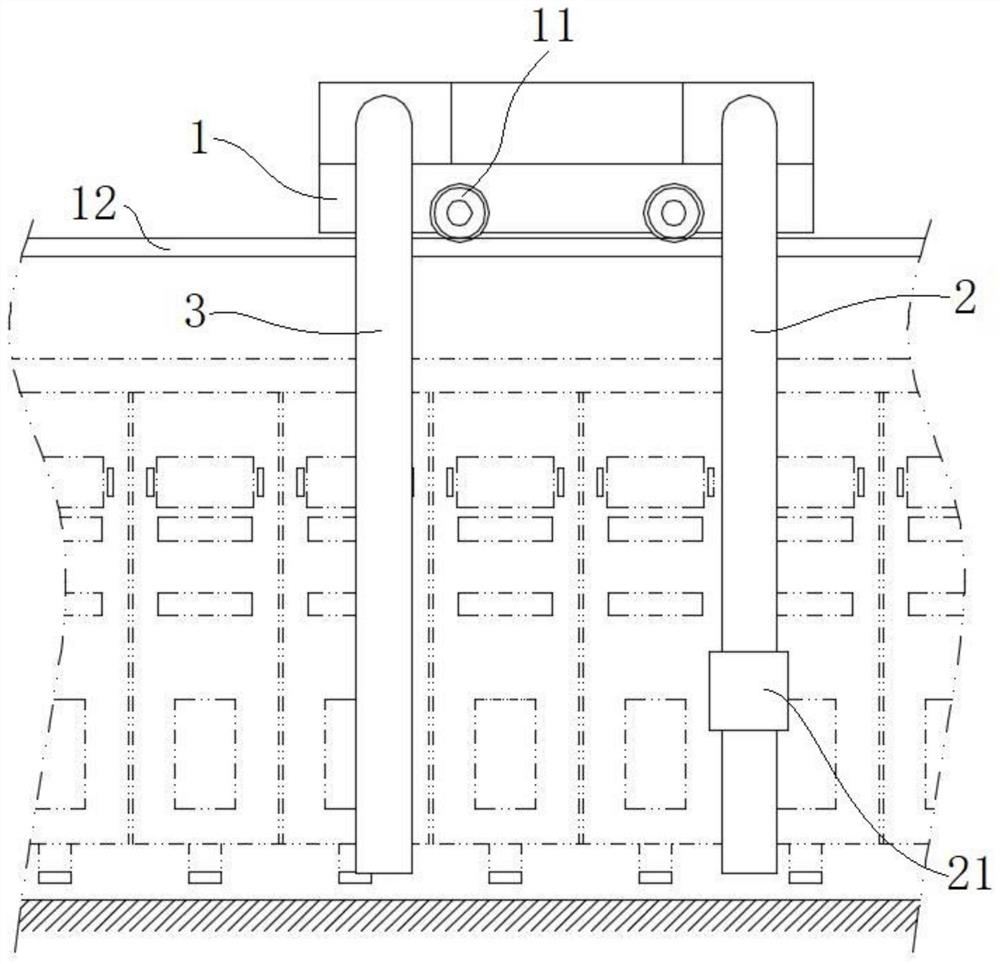

Temperature and humidity precise control system for textile workshop

ActiveCN112783237AIncrease flow rateImprove uniformityTotal factory controlSimultaneous control of multiple variablesYarnAutomatic control

The invention discloses a temperature and humidity precise control system for a textile workshop. The temperature and humidity precise control system comprises an inspection robot, a temperature and humidity control part and a temperature and humidity centralized electric control part; the inspection robot can slowly move in the moving direction of a production line, the temperature and humidity control part comprises an air inlet pipeline, an air outlet pipeline, a temperature rising control device, a humidity rising control device and a mixing device which are installed on the vehicle body of the inspection robot, and an air pump is arranged at the input end of the air inlet pipeline; and a plurality of air blowing pipe ends communicated and connected with the air outlet pipeline are arranged on the air outlet pipeline corresponding to the product processing position of a production line production unit. According to the temperature and humidity precise control system for the textile workshop, the circulation direction of low-flow-speed air sucked into the air inlet pipeline can be controlled through real-time feedback of the temperature sensor II and the humidity sensor II, and precise and automatic control over the temperature and humidity of air within the local range around a production line is achieved, so the yarn forming quality is further guaranteed; and the system is particularly suitable for textile workshops with strict requirements on temperature and humidity.

Owner:徐州嘉搏纺织股份有限公司

Auxiliary device for compact siro spinning yarn and method for compact siro spinning yarn

ActiveCN106676689BAvoid getting tangled into oneIncrease friction areaDrafting machinesYarnEngineering

Owner:XINJIANG YIDA TEXTILE +3

Wool fabric roving machine

InactiveCN102995194ASatisfy the parameter settingSatisfy revealingTextiles and paperYarnType frequency

The invention discloses a wool fabric roving machine, which is characterized by comprising a touch screen, a coil, a tension sensor, a rotary encoder, a frequency converter and a PLC (Programmable Logic Controller), wherein the touch screen, the coil, the tension sensor, the rotary encoder and the frequency converter are connected with the PLC; and the frequency converter comprises a drafting frequency converter, a frequency converter of a coiling unit and a twisting frequency converter. With the adoption of the wool fabric roving machine disclosed by the invention, rough yarns are synchronously coiled, drafted and twisted by using a multi-click variable-frequency type frequency speed adjusting system controlled by the PLC; a high-precision tension sensor is selected for detecting tension of the rough yarns online; the output frequency of the coiling frequency converter is controlled; the rotation speed of a coiling motor is adjusted; the tension of the rough yarns keeps stable; parameters of a twist gear and lift stroke variation of a keel can be detected through the rotary encoder; the lifting of the keel is controlled; the requirements of setting and displaying parameters and monitoring a production process of the wool fabric roving machine can be met; and the wool fabric roving machine is multifunctional, safe, reliable, and convenient to operate and display.

Owner:WUJIANG JIEJIE WEAVING

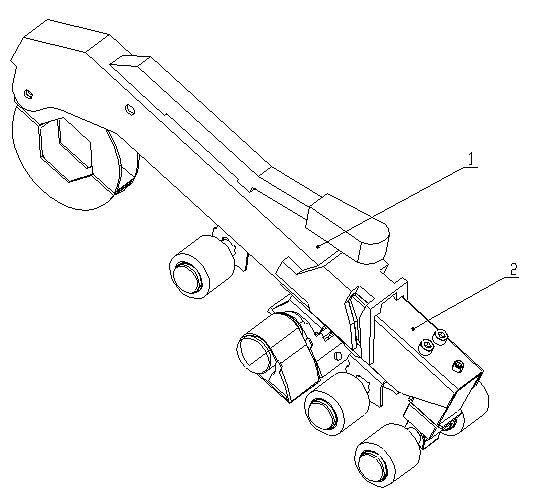

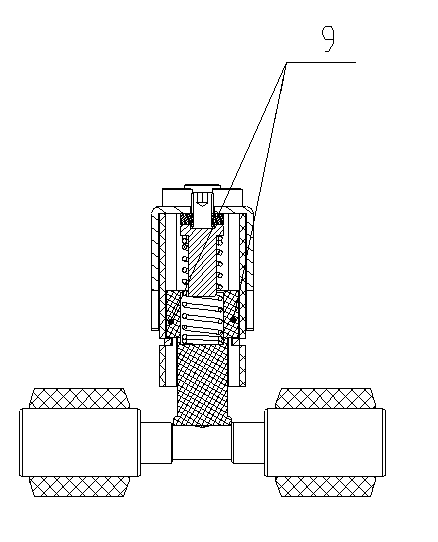

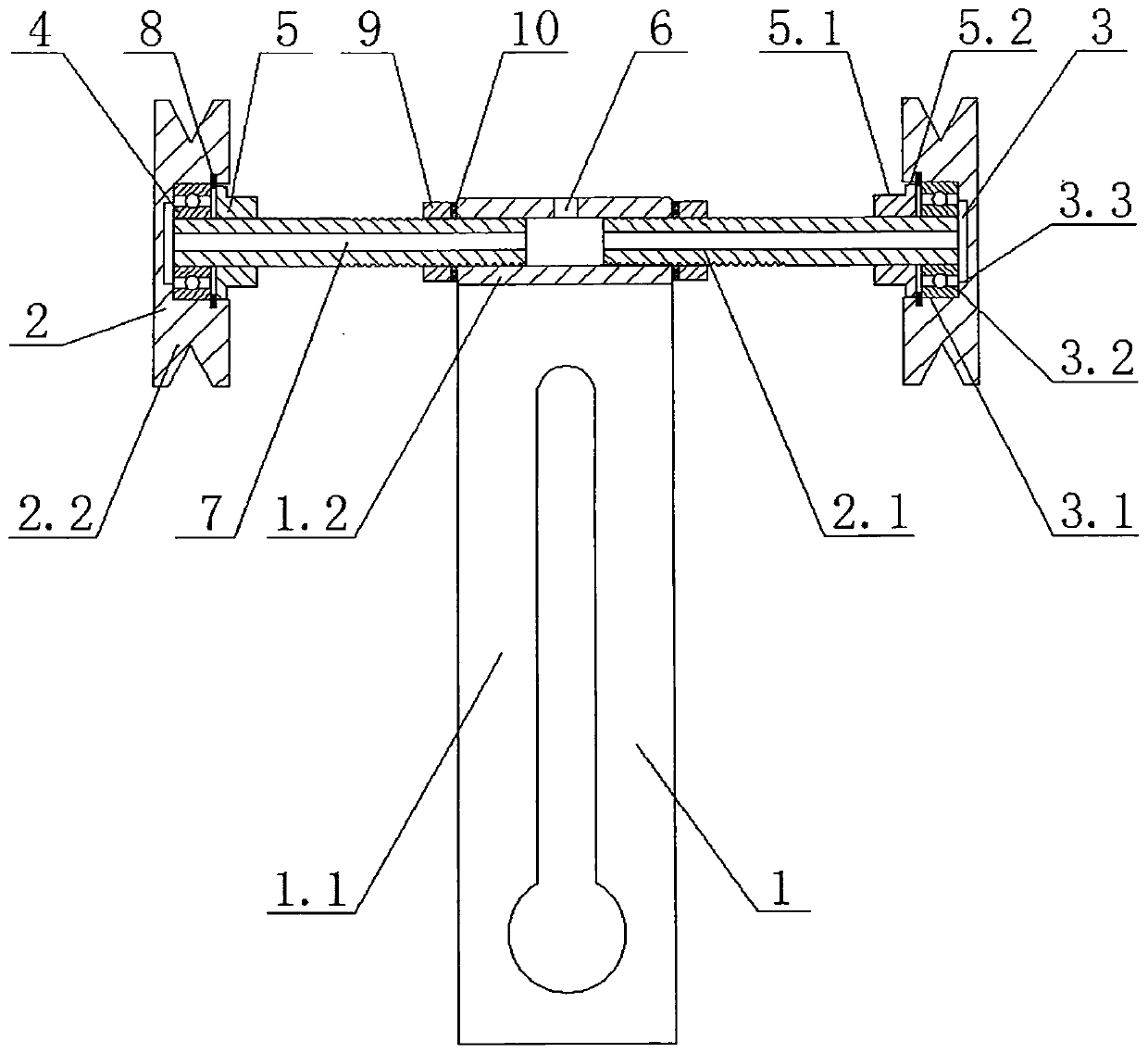

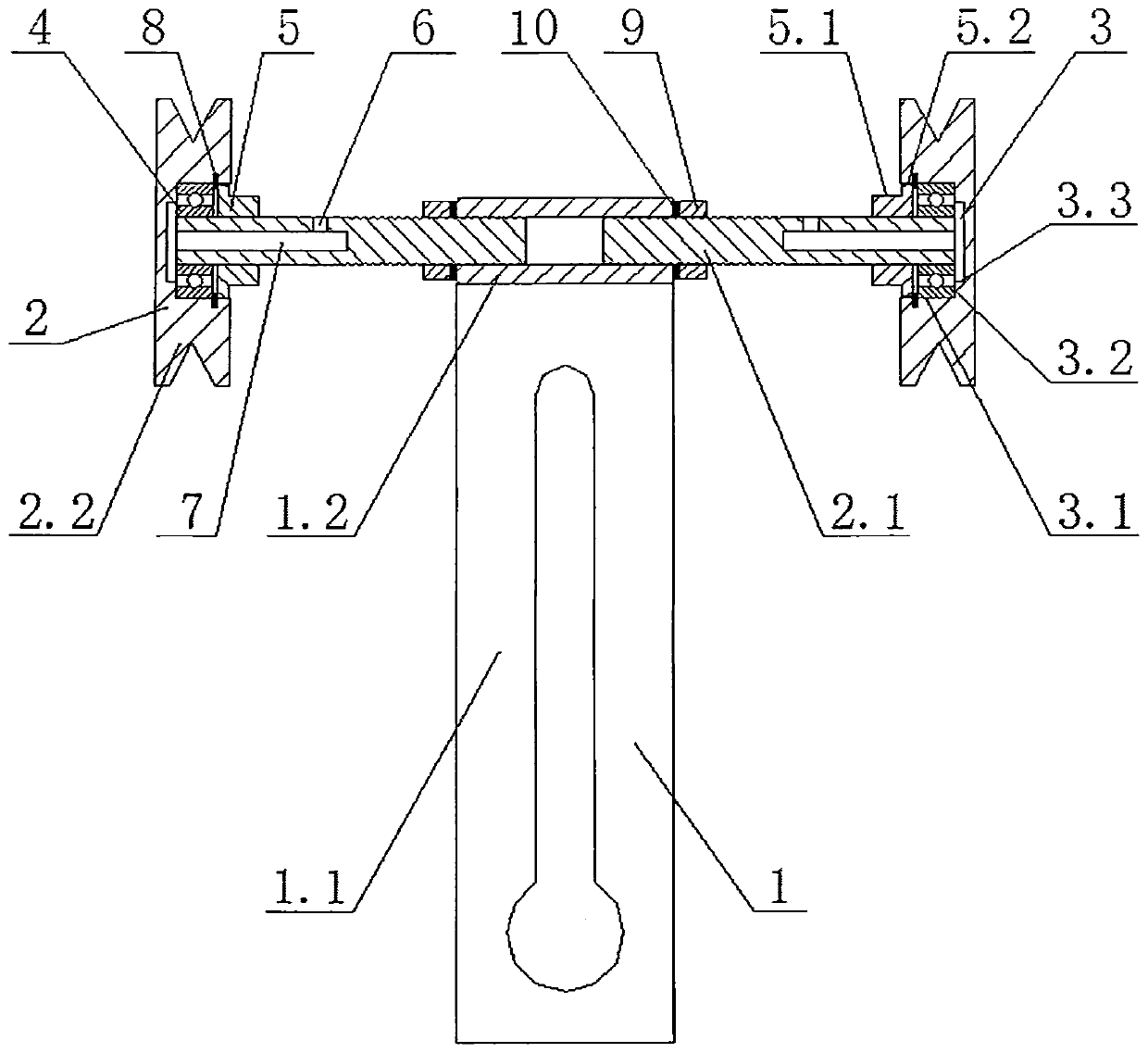

Air pressure dustless godet roller device

The invention relates to an air pressure dustless godet roller device. The air pressure dustless godet roller device comprises a fixed bracket (1) and godet roller parts (2) arranged at both sides ofthe fixed bracket (1); godet rollers (2.2) are arranged at the outer ends of regulation shafts (2.1); blind holes (2.3) are formed inside the godet rollers (2.2); bearings (4) are arranged in the blind holes (3); check rings (5) are arranged inside the bearings (4); the check rings (5) are fixedly connected with the regulation shafts (2.1); a compressed air inlet (6) is formed at the middle part of a long nut (1.2); the compressed air inlet (6) communicates with the inside of the long nut (1.2); and air inlet passages (7) penetrating the entire regulation shafts (2.1) are formed at the centersof the regulation shafts (2.1). The air pressure dustless godet roller device disclosed by the invention can effectively prevent short threads flying battings and floating dust in the air from entering the insides of the bearings so as to greatly prolong the service lives of the godet roller parts and effectively ensure final yarn forming quality.

Owner:江阴市名闻机械有限公司

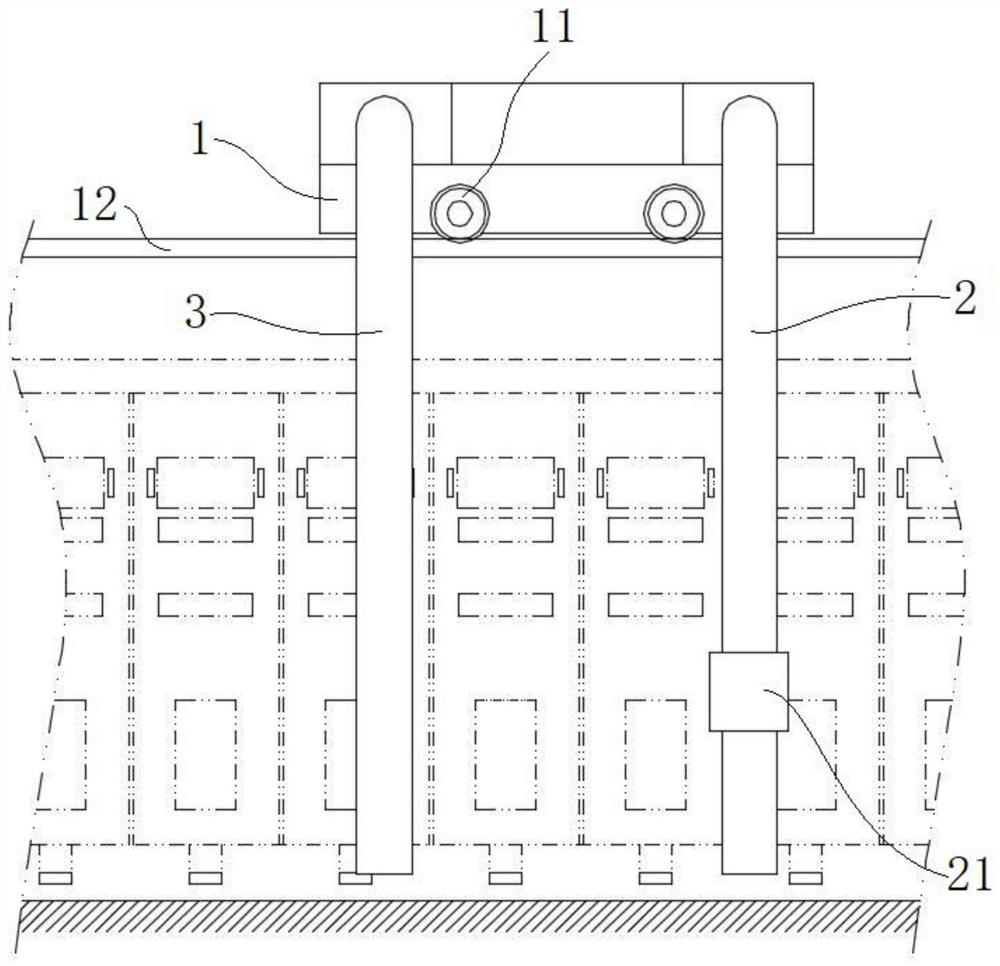

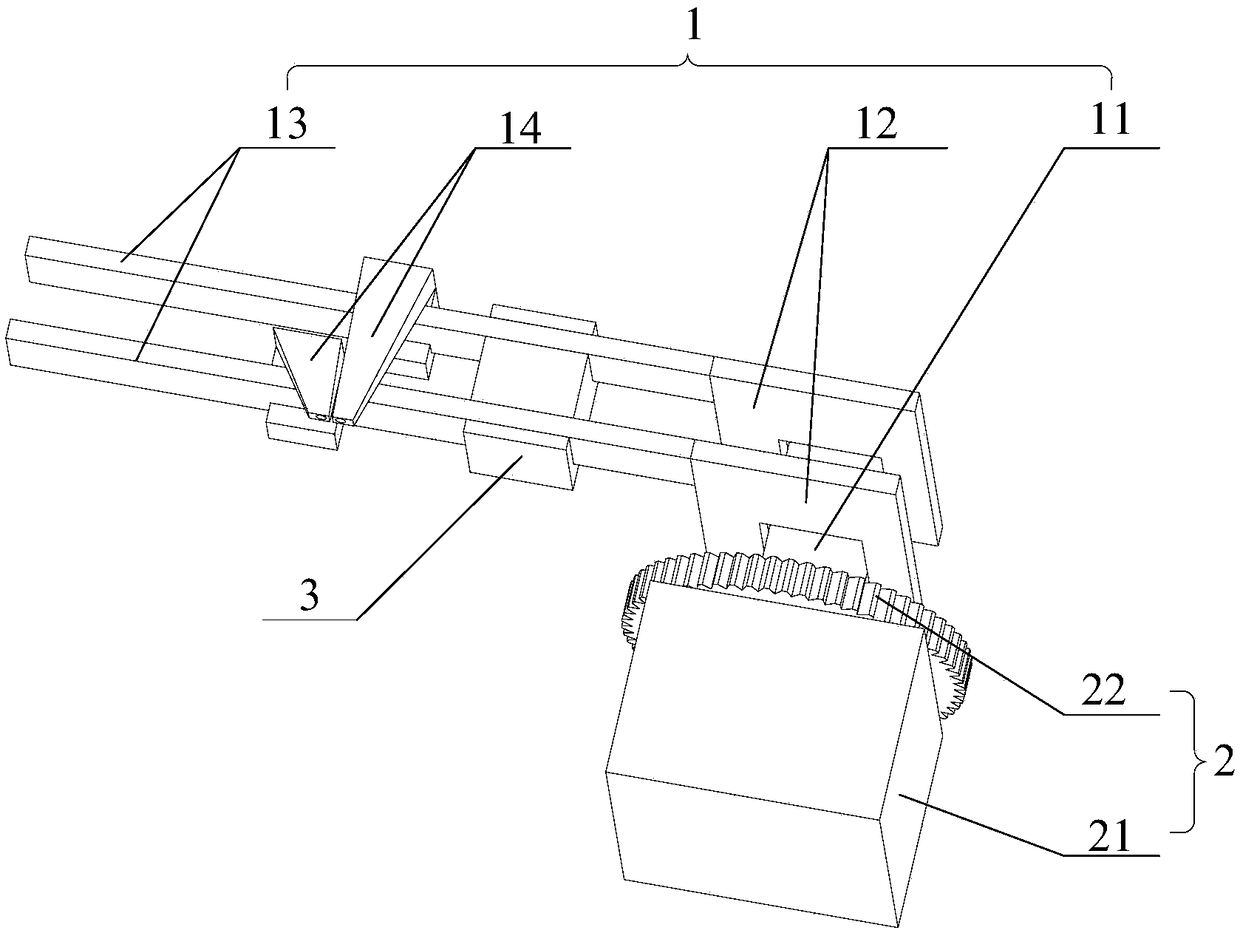

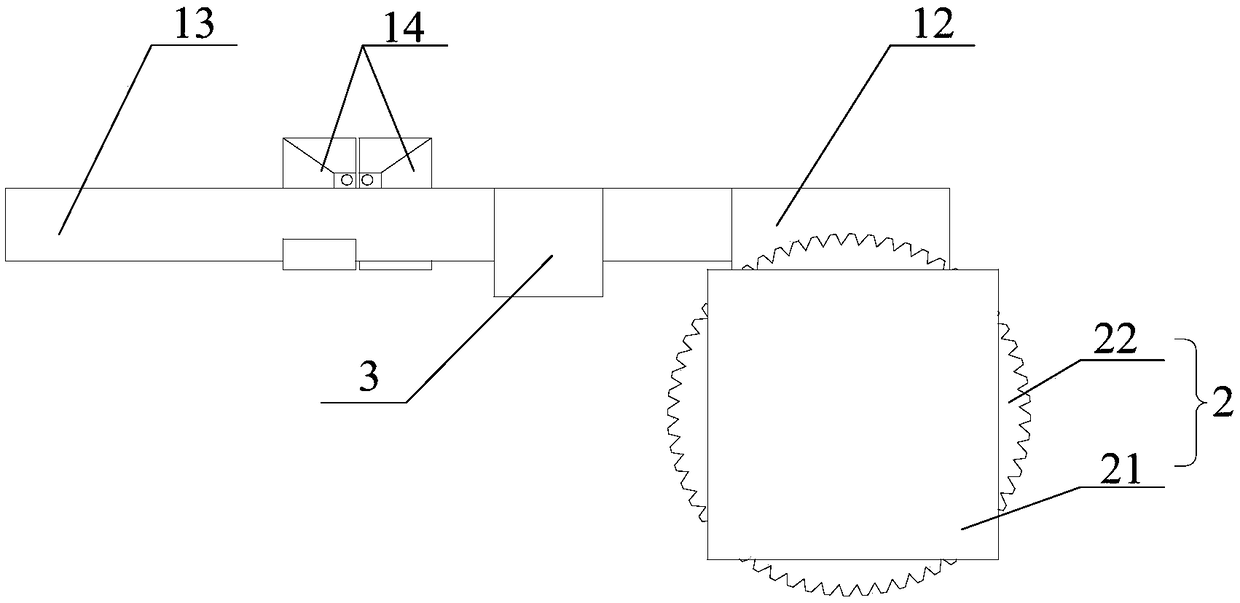

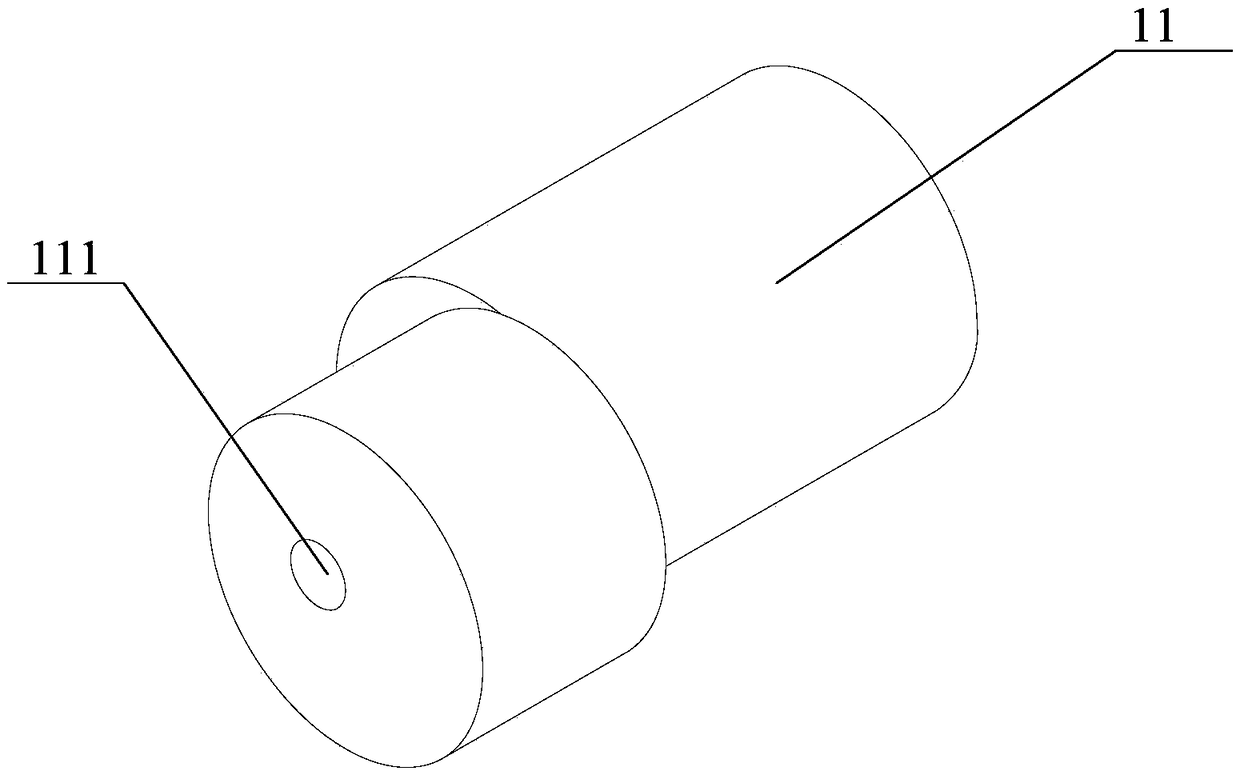

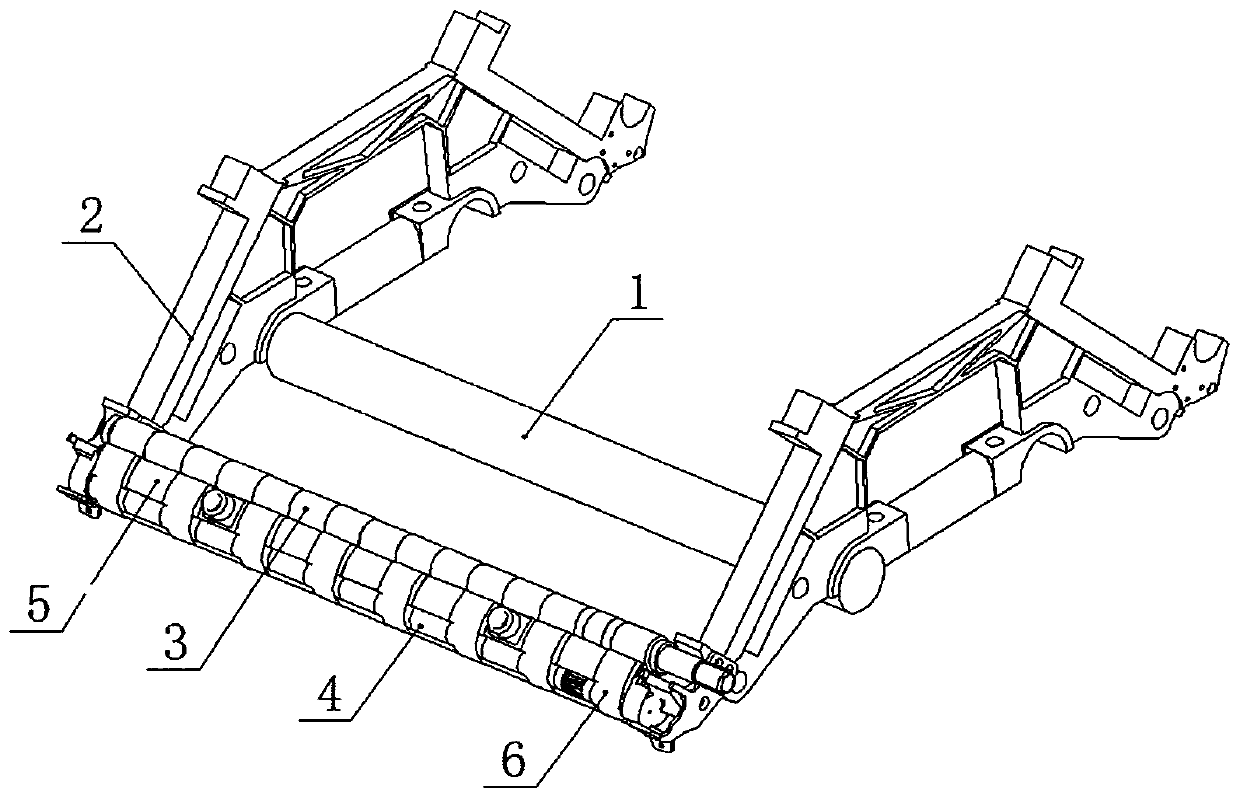

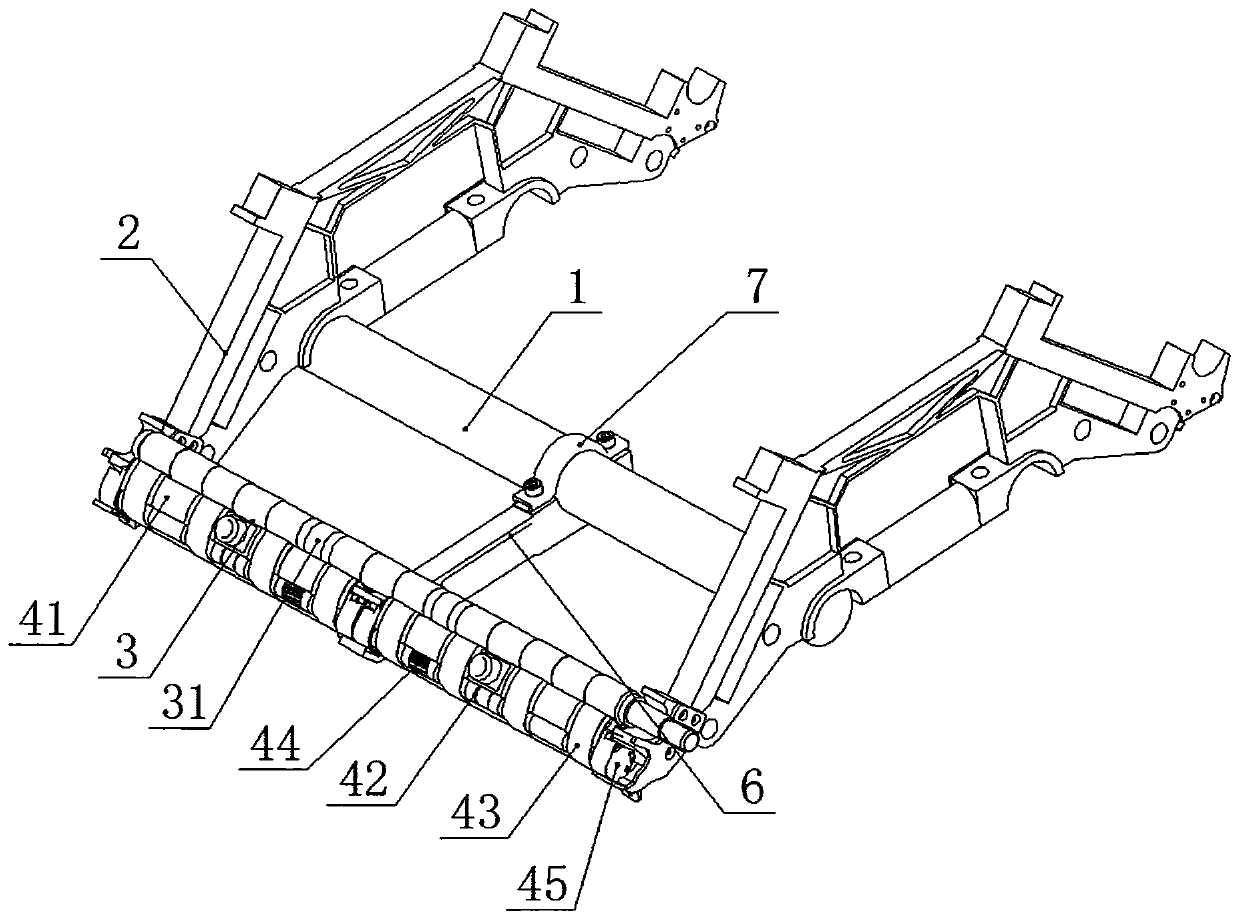

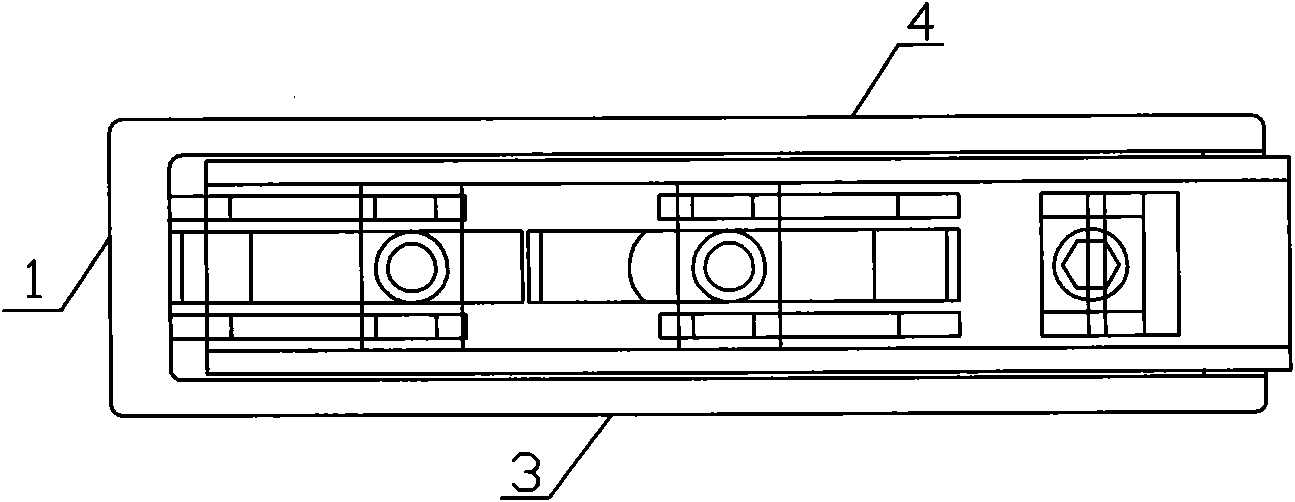

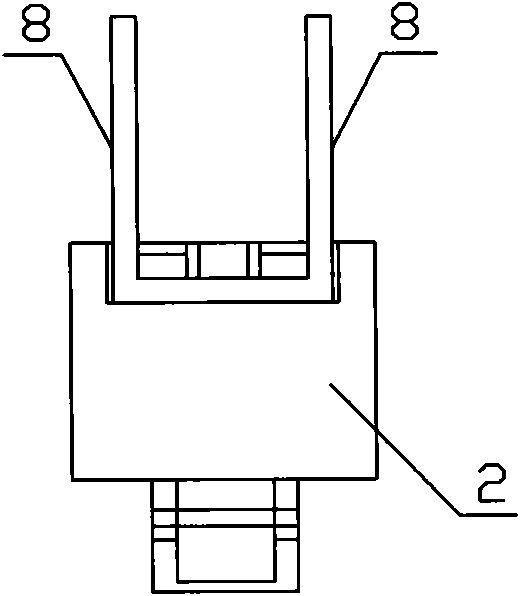

Transmission supporting mechanism for compact spinning carrier gear

InactiveCN111005100AEliminate manufacturing errorsReduce manufacturing costPortable liftingDrafting machinesYarnSpinning

The invention relates to a transmission supporting mechanism for a compact spinning carrier gear. The transmission supporting mechanism comprises a circular machine beam (1), wherein the circular machine beam (1) is provided with left and right roller seats (2); a front roller (3) is arranged between the front portions of the left and right roller seats (2); left and right gathering mechanisms (4)are arranged below the front roller (3); a support arm (6) is arranged in the middle of the circular machine beam (1) forwardly; one end of the gathering mechanism (4) is placed at the front end of the support arm (6), and the other end of the gathering mechanism (4) is arranged at the front part of the left roller seat or the right roller seat (2). The front roller drives left and right gathering small rollers through the left and right compact spinning carrier gears respectively, so that the load borne by the compact spinning carrier gear is greatly reduced, the compact spinning carrier gear is not prone to being damaged, the service life is greatly prolonged, the maintenance cost of a user is reduced, stable transmission is ensured, and the yarn quality is effectively guaranteed.

Owner:江阴市华方新技术科研有限公司

Aramid fiber and ultra-high molecular weight polyethylene blended yarn and production method thereof

Owner:SHANGHAI IBENA TEXTILE PROD

Temperature and humidity accurate control method for textile workshop

ActiveCN112799450AIncrease flow rateImprove uniformityTotal factory controlSimultaneous control of multiple variablesYarnAutomatic control

The invention discloses a temperature and humidity precise control method for a textile workshop. A temperature and humidity precise control system comprises an inspection robot, a temperature and humidity control part and a temperature and humidity centralized electric control part. The inspection robot can slowly move in the moving direction of the production line, the temperature and humidity control part comprises an air inlet pipeline, an air outlet pipeline, a temperature rising control device, a humidity rising control device and a mixing device which are installed on a vehicle body of the inspection robot, and an air pump is arranged at the input end of the air inlet pipeline; and a plurality of air blowing pipe ends communicated and connected with the air outlet pipeline are arranged on the air outlet pipeline corresponding to the product processing position of the production line production unit. The circulating direction of low-flow-speed air sucked into the air inlet pipeline is controlled through real-time feedback of a temperature sensor II and a humidity sensor II, accurate and automatic control over the air temperature and humidity within the local range around the production line is achieved, so the yarn forming quality is further guaranteed, and the method is particularly suitable for textile workshops with strict requirements on temperature and humidity.

Owner:徐州嘉搏纺织股份有限公司

Tool for positioning pressure bars at back zone of V-shaped drafting machine of F1508 spinning frame

The invention discloses a tool for positioning pressure bars at the back zone of a V-shaped drafting machine of an F1508 spinning frame. As for the tool, four baffle plates are fixedly connected into a rectangular frame, a rear baffle plate is higher than a front baffle, the inner sides of the first half parts of a left baffle plate and a right baffle plate are fixedly connected with an inner baffle plate, and the inner baffle plate has the same height as the rear baffle plate. A fixed component (three-shift tiger claw) is arranged in the middle of the positioning tool in the invention, and the screws on the fixed component are tightly screwed by a wrench, thereby ensuring the consistency and straightness of the positions of pressure bars at the back zone without deflection, thus the stability of spinning quality is greatly improved, the operation is convenient, the working efficiency is high and the effect is obvious.

Owner:ANHUI HUAMAO TEXTILE

A method for precise control of temperature and humidity in textile workshops

ActiveCN112799450BIncrease flow rateImprove uniformityTotal factory controlSimultaneous control of multiple variablesYarnAutomatic control

The invention discloses a precise temperature and humidity control method for a textile workshop. The temperature and humidity precise control system includes an inspection robot, a temperature and humidity control part and a temperature and humidity centralized electric control part; the inspection robot can move slowly along the direction of the production line, and the temperature and humidity The humidity control part includes an air intake pipeline, an air outlet pipeline, a temperature rise control device, a humidity rise control device and a mixing device installed on the vehicle body of the inspection robot. The product processing position of the production line production unit is provided with a plurality of blowing pipe ends connected with the air outlet pipeline. The present invention controls the circulation direction of the low-velocity air sucked into the air intake pipeline through the real-time feedback of the temperature sensor II and the humidity sensor II, and realizes precise and automatic control of the air temperature and humidity in a local area around the production line, thereby further ensuring the yarn quality , especially suitable for textile workshops with strict requirements on temperature and humidity.

Owner:徐州嘉搏纺织股份有限公司

Flame-retardant wool blended yarn and production method thereof

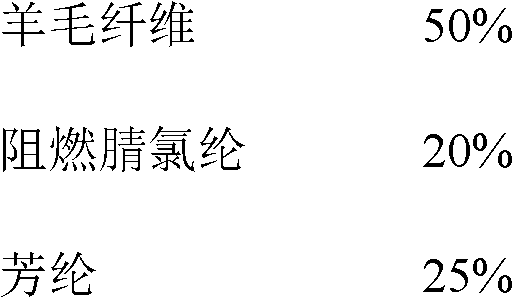

The invention provides inflaming retarding wool cross-blended yarn and a production method thereof. The inflaming retarding wool cross-blended yarn is characterized by comprising the following components by weight: 20 to 50 % of wool fiber, 20 to 50 % of inflaming retarding nitrile polyvinyl chloride fibre, 10 to 40 % of aramid and 1 to 5 % of conductive fiber. As the wool, the fibre aramid and the inflaming retarding nitrile polyvinyl chloride fibre are easy to produce static electricity, the yarn reduces the static electricity phenomenon through two aspects: the first one is to mix a certain proportion of conductive fiber, and the second one is to carry out pretreatment on the raw materials before the spinning, adding wool oil, and still standing to carry out well-being process. During the preparing process, the technology condition of each process is strictly controlled; the temperature and the relative humidity of cotton carding, drawing, roving and spinning processes are controlled; the serious static electricity problems of the wool, the inflaming retarding acrylon and the aramid during the spinning can be well solved; the strong rigidity of the aramid fibre can be overcome; the yarn quality is ensured.

Owner:SHANGHAI IBENA TEXTILE PROD

Organic cotton and wool blended knitted fabric and preparation method thereof

The invention relates to the technical field of textiles, in particular to an organic cotton and wool blended knitted fabric and a preparation method thereof. The organic cotton and wool blended knitted fabric adopts organic cotton fibers and wool fibers as spinning raw materials, and the blending mass ratio of the organic cotton fibers to the wool fibers is 8:2; the organic cotton fibers with main fiber length of about 31 mm are selected, spinning is conducted through a poly-spinning process, and the twist coefficient of spun yarn is 390-410; the fabric adopts combined rib stitches, the transverse density is 78 / 10 cm, and the longitudinal density is 40.9 / 10 cm. The organic cotton and wool blended knitted fabric and the preparation method thereof have the advantages that the developed fabric has good comfort, the soft hand feeling of cotton and the softness, fluffiness and bright color of wool, and pilling and wrinkling do not easily occur.

Owner:JIANGYIN XIANGFEI APPAREL

Method for accurately controlling temperature and humidity of air around textile production line

InactiveCN114510096AIncrease flow rateImprove uniformityTotal factory controlSimultaneous control of multiple variablesYarnAutomatic control

The invention discloses a method for accurately controlling the temperature and humidity of air around a textile production line. A system for accurately controlling the temperature and humidity comprises an inspection robot, a temperature and humidity control part and a temperature and humidity centralized electric control part, the inspection robot can slowly move in the moving direction of the production line, the temperature and humidity control part comprises an air inlet pipeline, an air outlet pipeline, a temperature rising control device, a humidity rising control device and a mixing device which are installed on a vehicle body of the inspection robot, and an air pump is arranged at the input end of the air inlet pipeline; and a plurality of air blowing pipe ends communicated and connected with the air outlet pipeline are arranged on the air outlet pipeline corresponding to the product processing position of the production line production unit. The circulating direction of low-flow-speed air sucked into the air inlet pipeline is controlled through real-time feedback of the temperature sensor II and the humidity sensor II, accurate and automatic control over the air temperature and humidity within the local range around the production line is achieved, and therefore the yarn forming quality is further guaranteed; and the device is particularly suitable for textile workshops with strict requirements on temperature and humidity.

Owner:XUZHOU JIABO TEXTILE CO LTD

Differential anti-overlap micromotion mechanism of rotor spinning machine

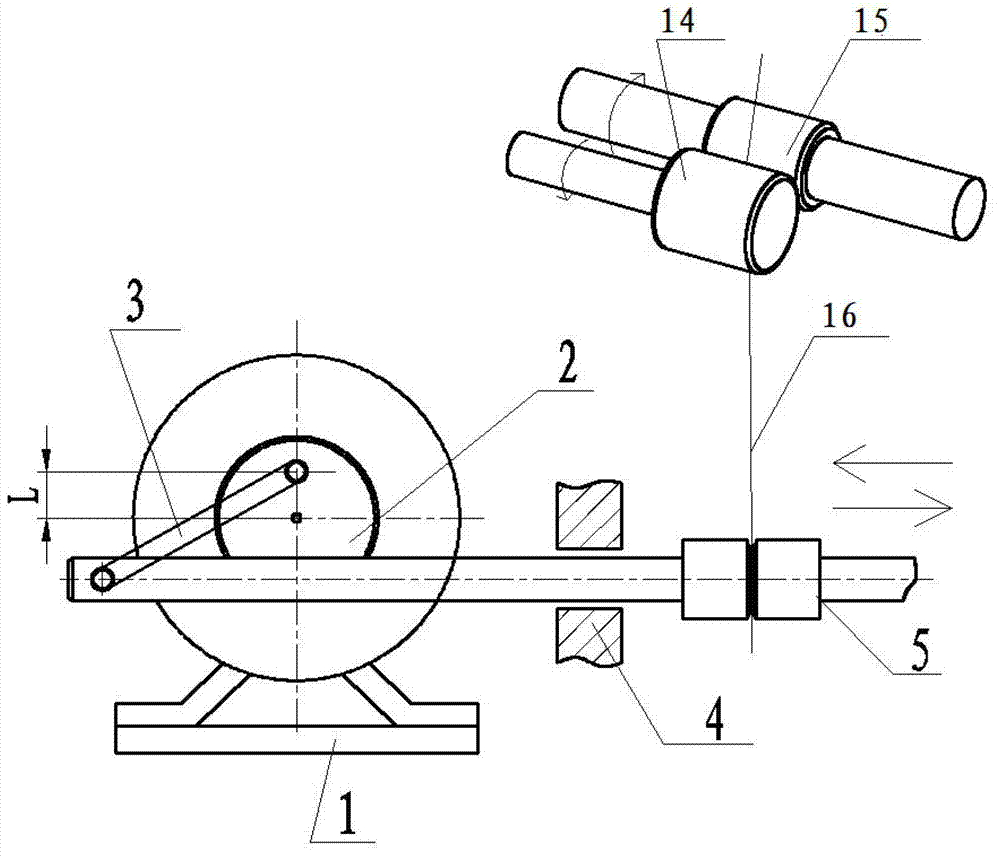

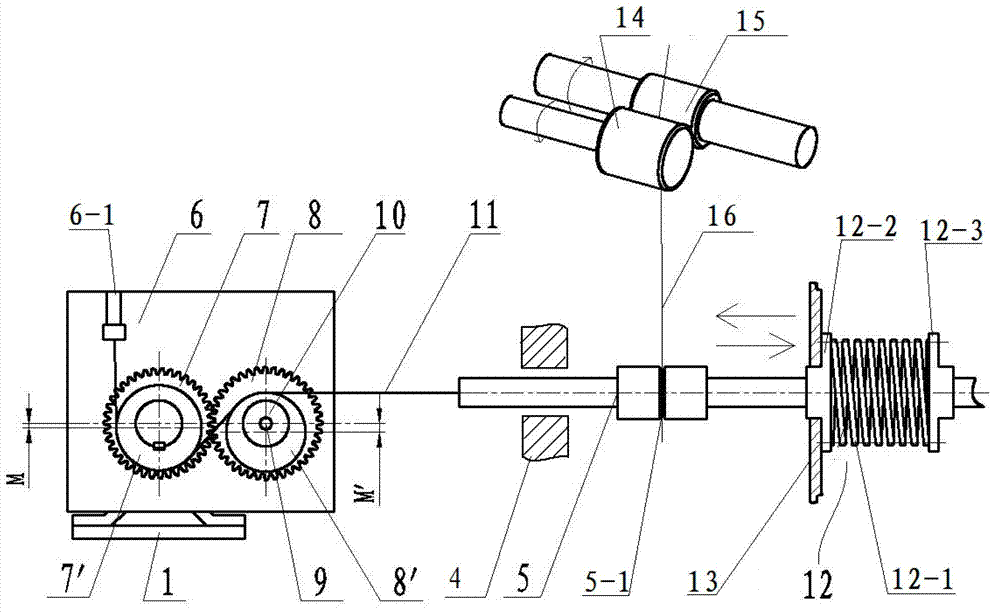

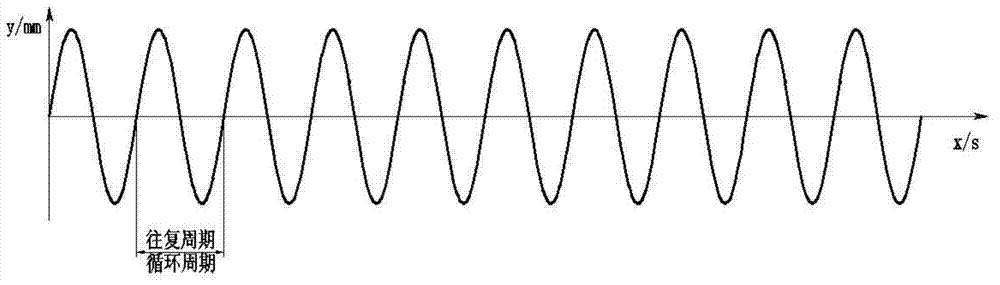

InactiveCN102787400BExtend the intervalGuaranteed yarn qualityContinuous wound-up machinesOpen-end spinning machinesReducerEngineering

The invention relates to a differential anti-overlap micromotion mechanism of a rotor spinning machine. The differential anti-overlap micromotion mechanism comprises a horizontally-arranged micromotion rod, wherein a right end of the micromotion rod penetrates through a wall plate and an end head of the micromotion rod is provided with an elastic tension device; the left side of the micromotion rod is provided with a micromotion seat, the micromotion seat is installed with a reducer and a left gear and a right gear which are arranged in parallel and mutually engaged; the gear coaxially connected with the reducer is a driving gear and the other gear is a driven gear; end faces of the two gears on the same side are respectively provided with a driving eccentric boss with an eccentric arm of M and a driven eccentric boss with the eccentric arm of M'; a fixed seat is installed at a top end of the micromotion seat on the left side upper part of the left gear, and the lower part of the fixed seat is connected with a micromotion belt; the micromotion belt is intertwined from the lower end of the left eccentric boss to the upper end of the right eccentric boss and is fixedly connected with the left end of the micromotion rod.

Owner:上海捷春进出口贸易有限公司

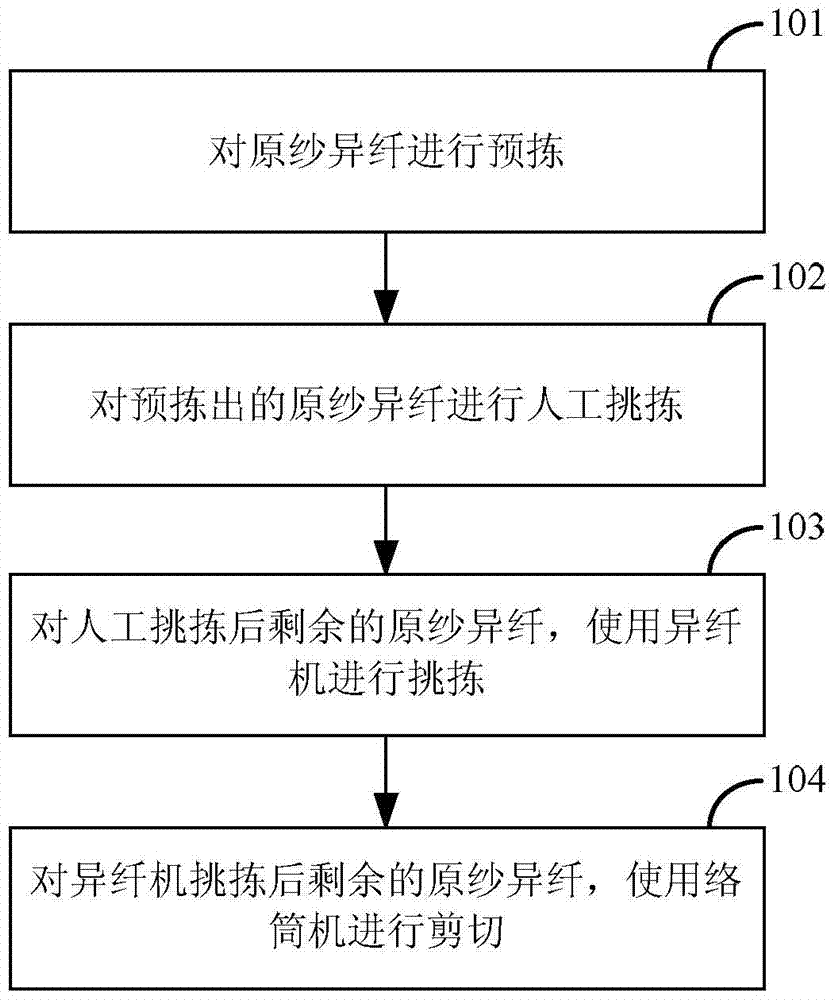

Method for controlling foreign matter in raw yarn and method for determining the amount of foreign matter in raw yarn

ActiveCN105648543BThe data is up to standard and relatively stableGuaranteed yarn qualityMechanical treatmentYarnWinding machine

The invention discloses a method for controlling base yarn foreign fibers and a method for determining the quantity of the base yarn foreign fibers. The method for controlling the base yarn foreign fibers includes the steps that the base yarn foreign fibers are pre-sorted; the pre-sorted base yarn foreign fibers are manually sorted; the base yarn foreign fibers left after manual sorting are sorted through a foreign fiber machine; the base yarn foreign fibers left after sorting through the foreign fiber machine are sheared through a winding machine. The method for determining the quantity of the base yarn foreign fibers includes the steps that after the base yarn foreign fibers are pre-sorted, the pre-sorting quantity of the base yarn foreign fibers is obtained; after the pre-sorted base yarn foreign fibers are manually sorted, the manual sorting-out quantity is obtained; after the base yarn foreign fibers left after manual sorting are sorted through the foreign fiber machine, the sorting-out quality of the foreign fiber machine is obtained; after the base yarn foreign fibers left after sorting through the foreign fiber machine are sheared through the winding machine, the shearing quantity of the winding machine is obtained; the remaining base yarn foreign fiber quantity is obtained by subtracting the manual sorting-out quantity, the sorting-out quantity of the foreign fiber machine and the shearing quantity of the winding machine from the pre-sorting quantity of the base yarn foreign fibers. The base yarn foreign fibers can be effectively controlled, and the remaining base yarn foreign fiber quantity is accurately calculated.

Owner:XINJIANG YIDA TEXTILE +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com