Fly frame drafting device adapting to large draft ratios

A drafting device and roving frame technology, which is applied to spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of small cross-sectional area of cotton yarn and the inability of roving drafting device to meet the requirements, and achieve strong control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

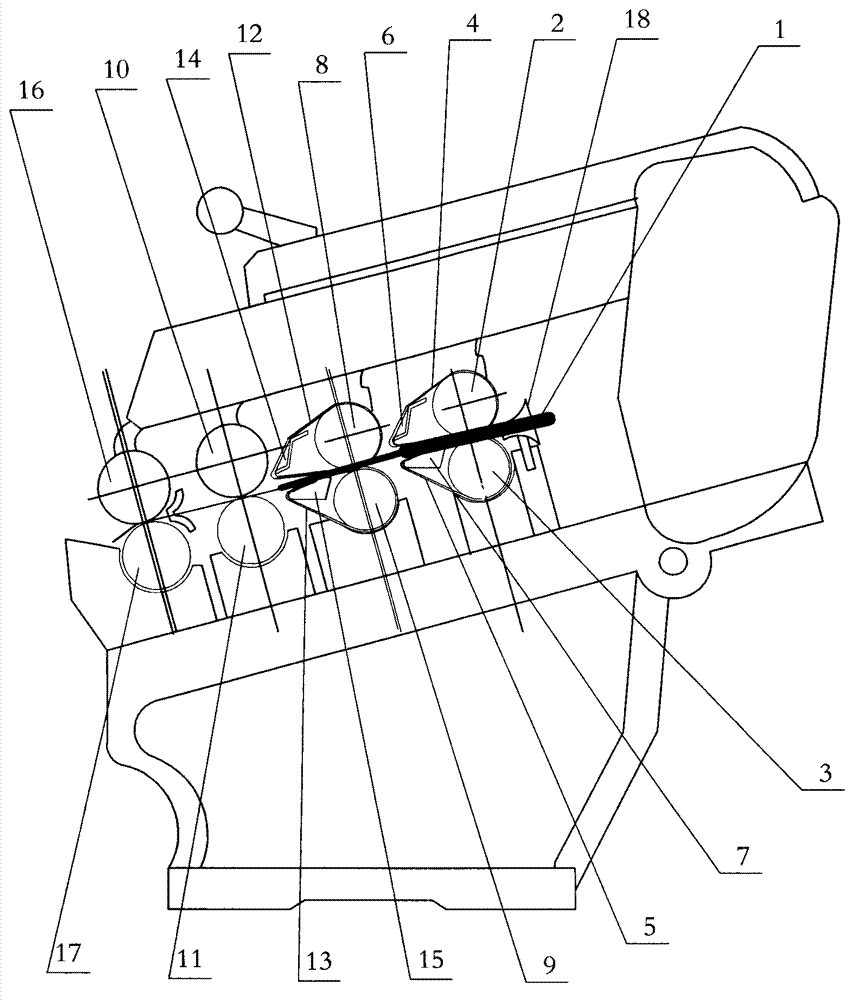

[0008] Depend on figure 1 It can be seen that the drafting device of the roving frame of the present invention is a four-roller four-short apron drafting type, and is provided with three drafting areas: an auxiliary drafting area, a main drafting area, and a finishing area. According to the feeding direction of the sliver 1, the first drafting zone when the sliver 1 enters the drafting device is the secondary drafting zone; the secondary drafting zone is composed of a pair of rollers, and the top roller 2 is a rubber roller naked apron roller, The bottom roller 3 is a steel knurled roller; the secondary drafting area is provided with a double short apron drafting device consisting of an upper apron 4, a lower apron 5, an upper pin 6 and a lower pin 7. The second drafting zone is the main drafting zone, which is composed of two pairs of rollers. The upper roller 8 adjacent to the secondary drafting zone is a rubber roller naked apron roller, and the lower roller 9 is a steel kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com