Compact spinning pressurizing device

A pressurizing device and compact spinning technology, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve problems such as affecting yarn quality, and achieve the effect of ensuring yarn quality, stable performance and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

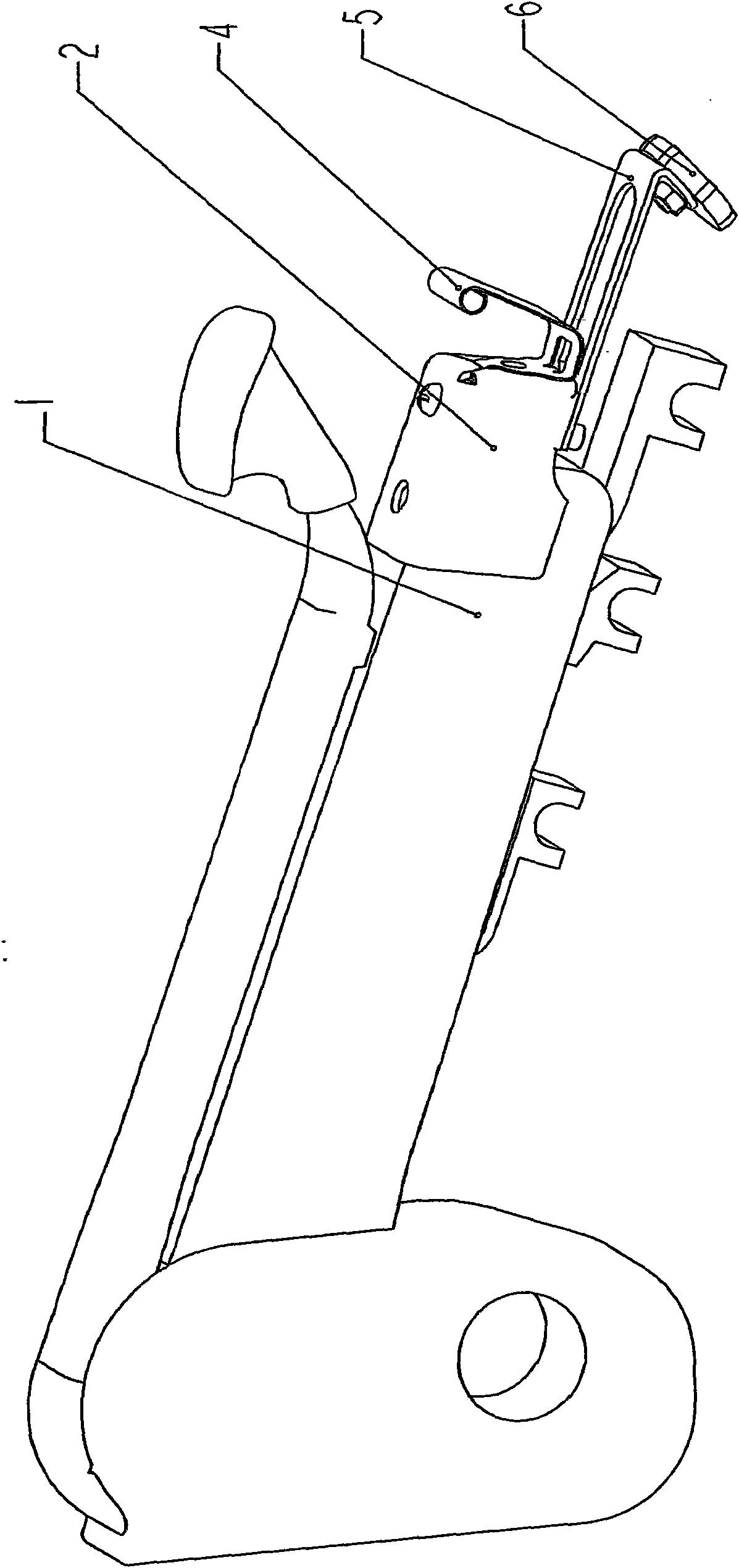

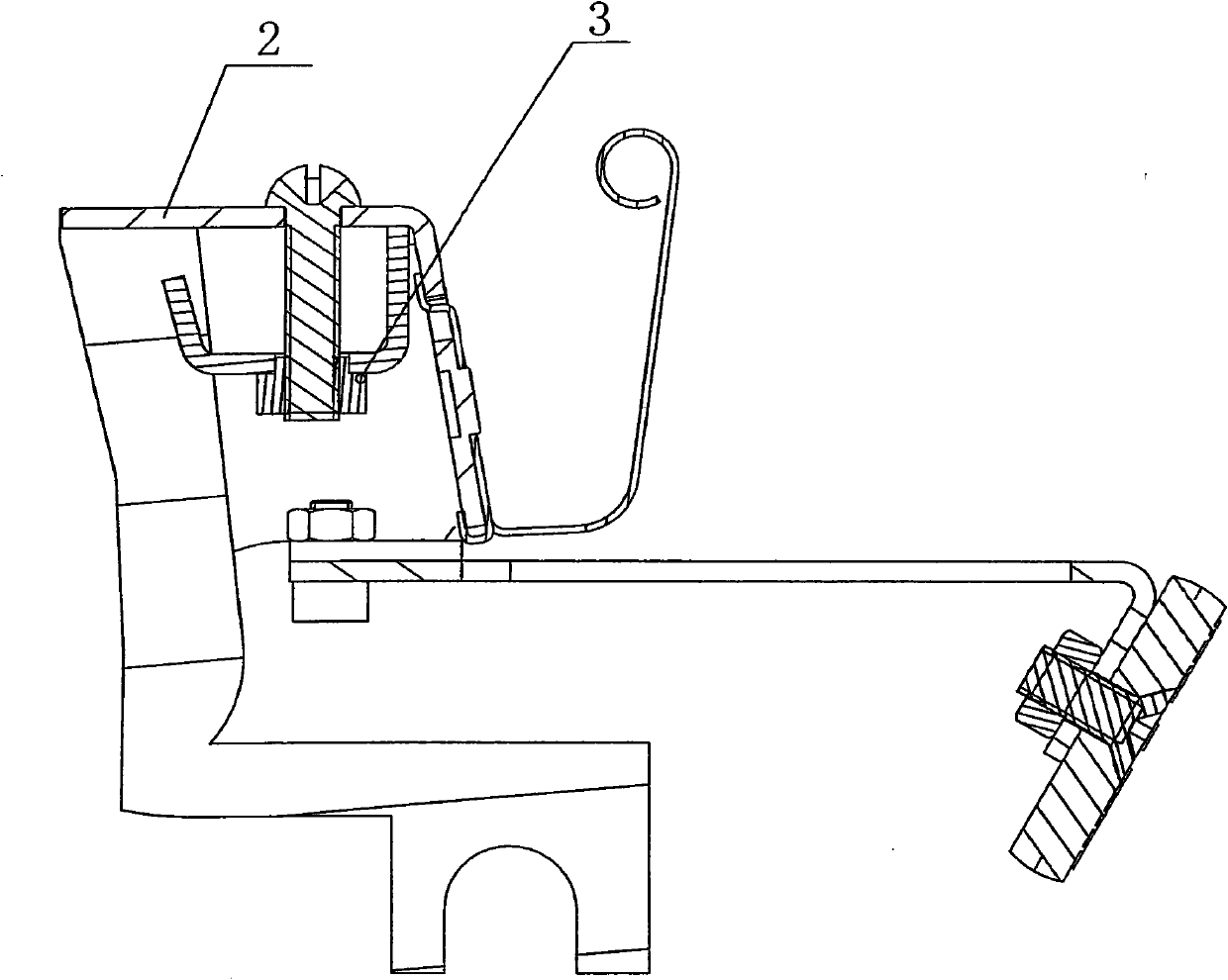

[0015] see figure 1 , The compact spinning pressurizing device that the present invention relates to is to utilize the hole on the original cradle 1 on the cradle 1 to add a pressurizing adjustment device. The pressure adjustment device includes a positioning piece combination part 3 , a spring piece 5 , a positioner 2 and a pressure piece 6 . The specific production method is: remove the cashmere stick spring 4 on the cradle 1, connect the spacer joint 3 with the hole on the cradle 1, place the spacer joint 3 inside the locator 2, and connect it with the locator 2. Screw connection, one end of the spring leaf 5 is connected with the locator 2 by screws, and the other end of the spring leaf 5 is connected with the pressure sheet 6 by screws.

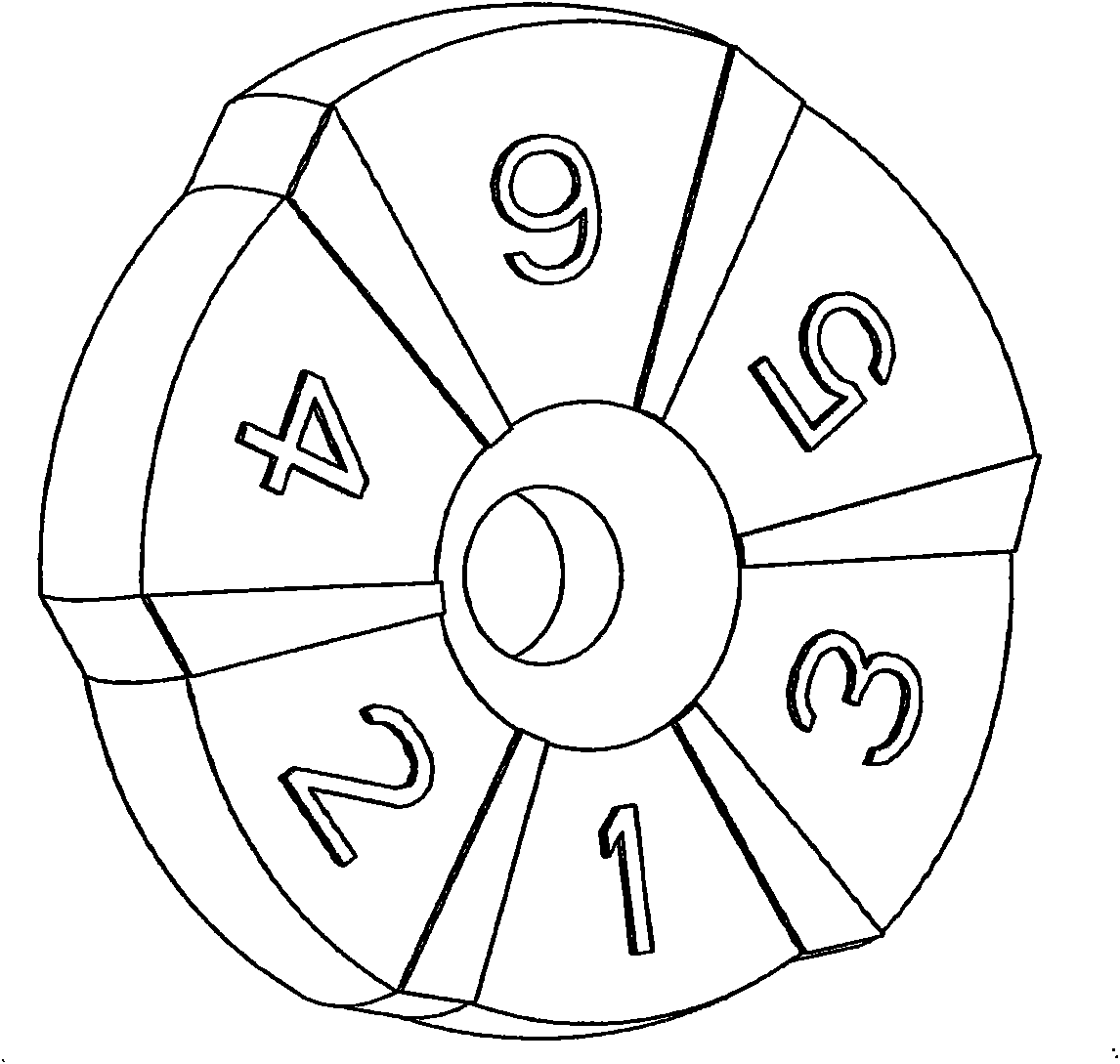

[0016] Such as Figure 4 The cradle assembly of the yarn pneumatic gathering device shown, the pressure of the rubber roller 8 on the front roller 7 and the pressure of other rubber rollers on the rear roller are determined by the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com