Tool for positioning pressure bars at back zone of V-shaped drafting machine of F1508 spinning frame

A spinning frame and pressure bar technology, which is applied in spinning frames, drafting equipment, textiles and papermaking, etc., can solve the problems of inconvenient operation, inability to ensure the consistency of the pressure bar position, time-consuming, etc., and achieves easy operation and high work efficiency. , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

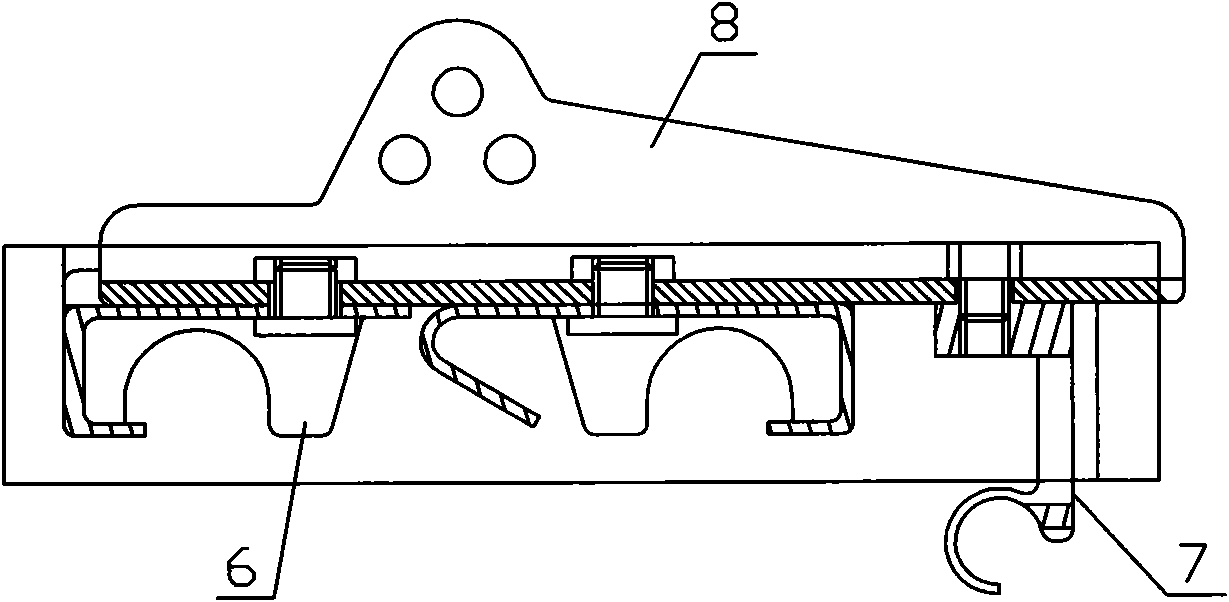

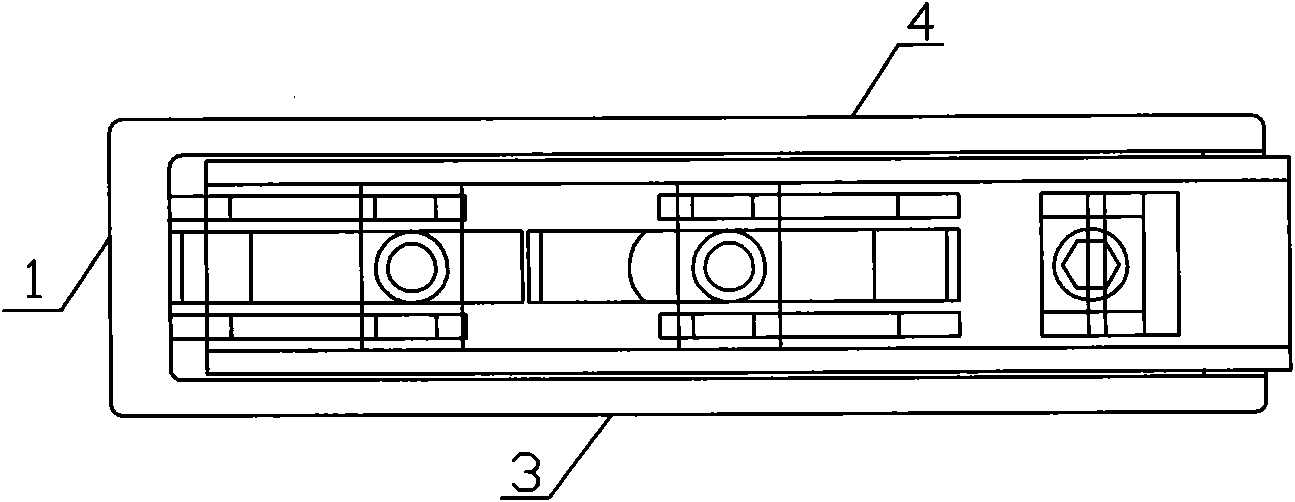

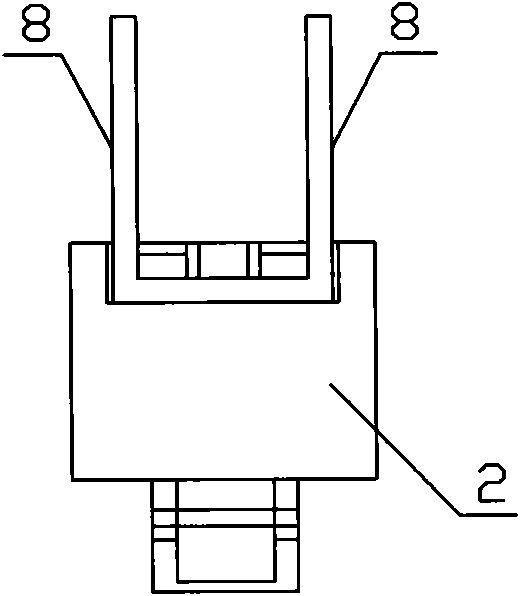

[0013] Depend on Figure 4 , Figure 5 , Figure 6 , Figure 7 It can be seen that the pressure bar positioning tool in the rear area of the F1508 spinning frame "V" drafting machine of the present invention is made of steel material, and its front baffle 1, rear baffle 2, left baffle 3 and right baffle 4 are fixed Connected into a rectangular frame, the upper and lower sides are hollow, the size is 96CM*23CM*19CM (length*width*height), the thickness is 3CM, the height of the rear baffle 2 is lower than the front baffle 1, so that the rear end of the rectangular frame A notch is formed in the upper part. The inner sides of the left baffle 3 and the front half of the right baffle 4 are all fixedly connected to the inner baffle 5, the distance between the inner baffle 5 and the front baffle 1 is 10CM, and the size is 22CM*15CM*2CM (length*width*thickness). The height of the baffle plate 5 is the same as that of the rear baffle plate 2 .

[0014] see figure 1 , figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com