Special drafting spinning mechanism for spinning frame

A spinning frame and drafting technology, which is applied in the field of special drafting and spinning mechanisms for spinning frames, can solve problems such as low spinning efficiency, apron drop, tailing, etc., and achieve the effect of improving yarn quality and spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

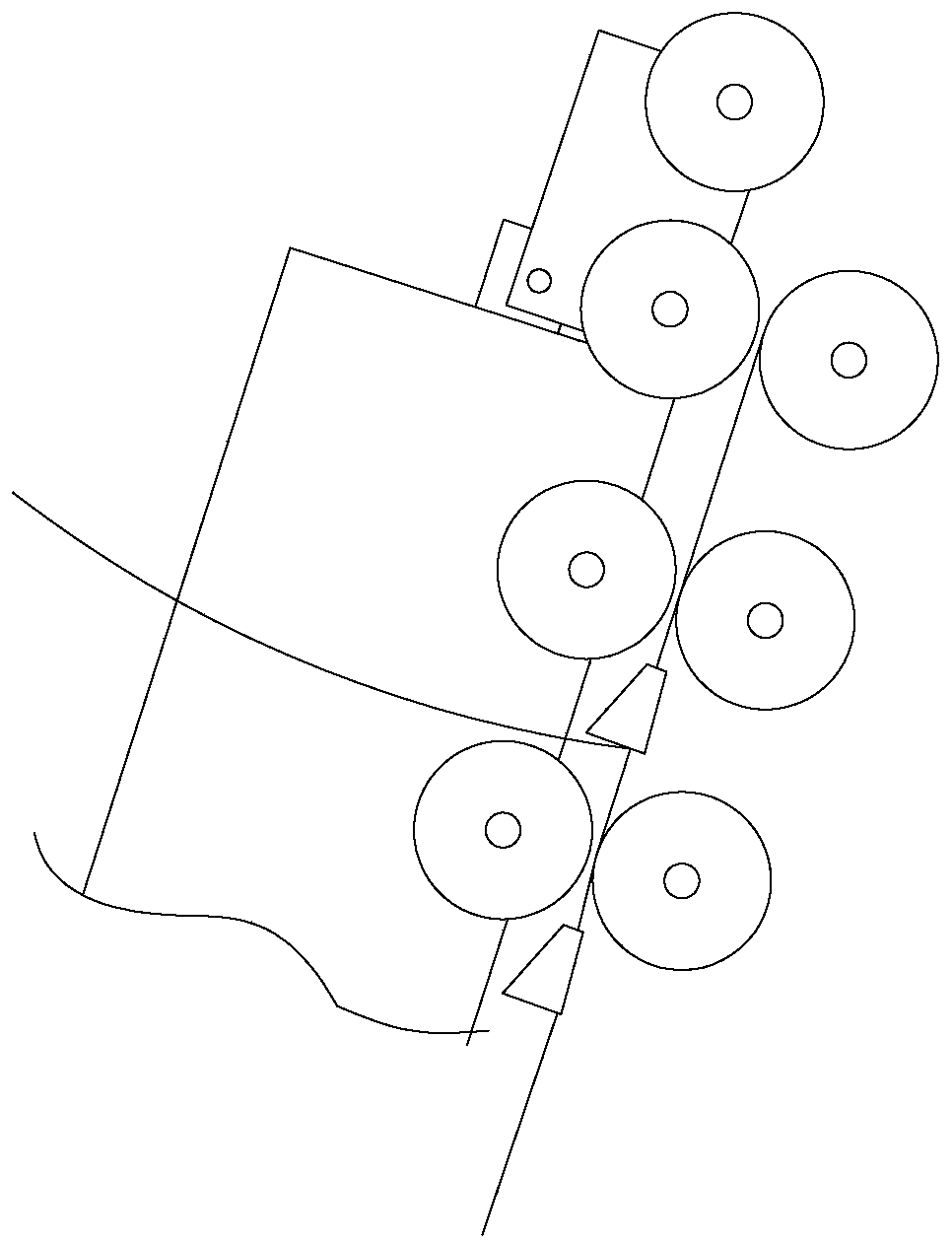

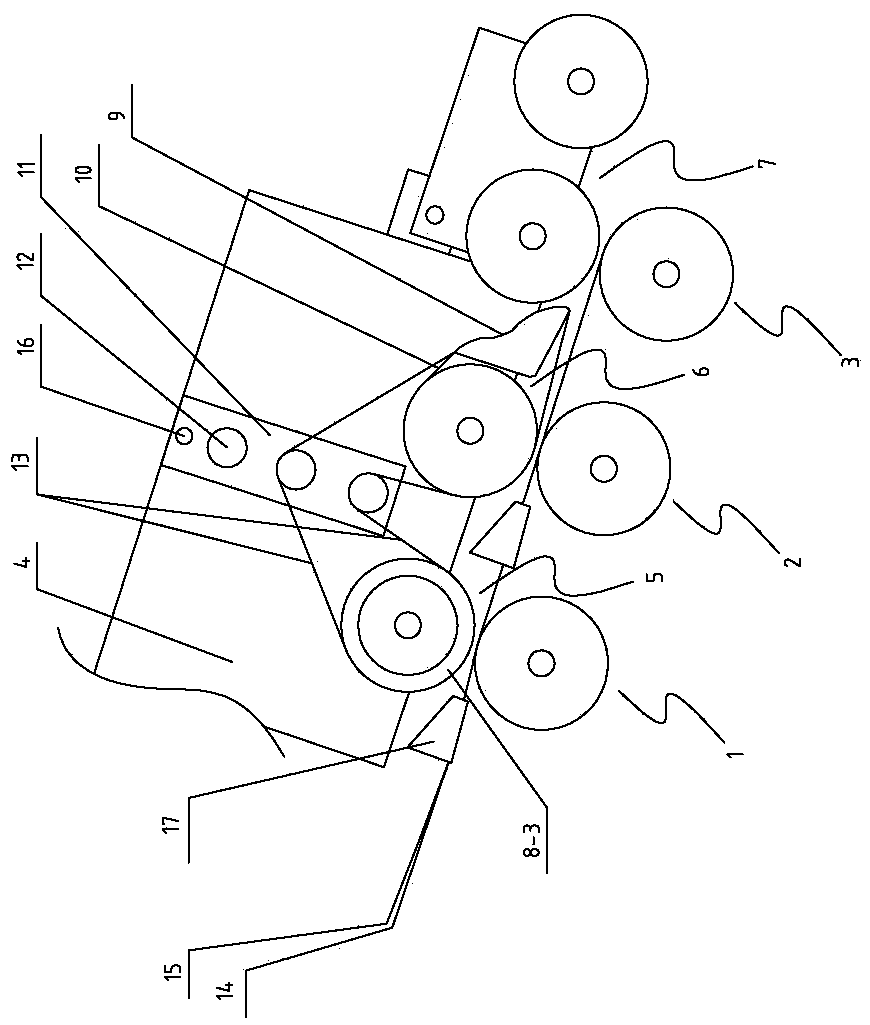

Image

Examples

Embodiment Construction

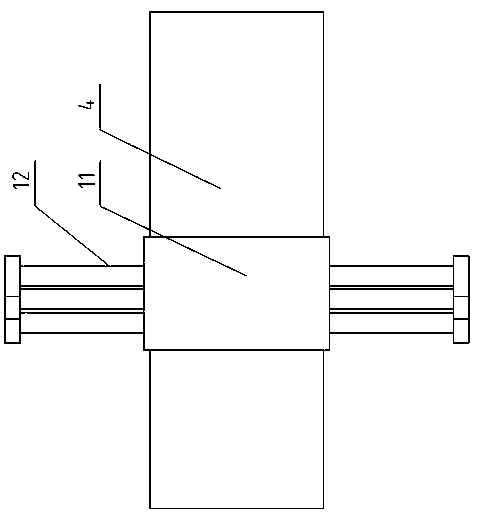

[0020] see Figure 2 to Figure 7 As shown, a special drafting spinning mechanism for spinning frame includes a rear roller 1, a middle roller 2 and a front roller 3 arranged in sequence. The rear roller 1, the middle roller 2, and the front roller 3 are driven by separate motors respectively. , The rear roller 1, the middle roller 2, the front roller 3 is provided with a cradle 4, and the cradle 4 is provided with a first top roller 5 and a second top roller 6 corresponding to the rear roller 1, the middle roller 2, and the front roller 3 respectively. , The third top roller 7, the first top roller 5 and the second top roller 6 each include a roller body 8. Both ends of the roller body 8 are provided with a large diameter section 8-1 and a small diameter section 8-2 corresponding to the width. The section 8-1 is equipped with a top roller wheel 8-3. The large-diameter section 8-1 and the small-diameter section 8-2 of the first top roller 5 and the second top roller 6 are stagge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com