Compact-spinning cradle pressurizing device

A pressurizing device and compact spinning technology, which is applied in textile machinery accessories and new fields of compact spinning, can solve the problems affecting the pressure consistency of compact spinning top rollers, the front top rollers cannot achieve spinning effect, and affect the quality of yarns, etc. Achieve the effect of simple structure, convenient assembly and disassembly, and guaranteed yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

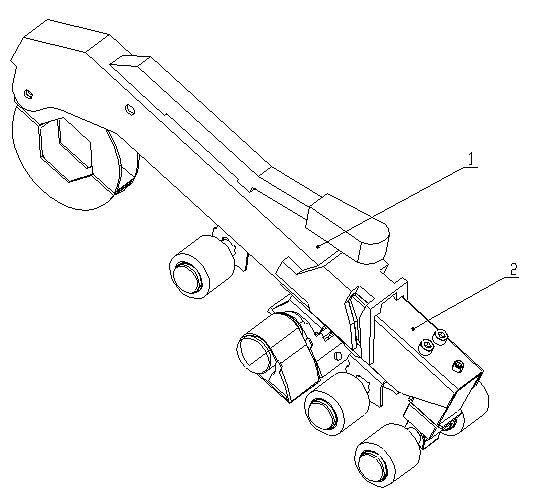

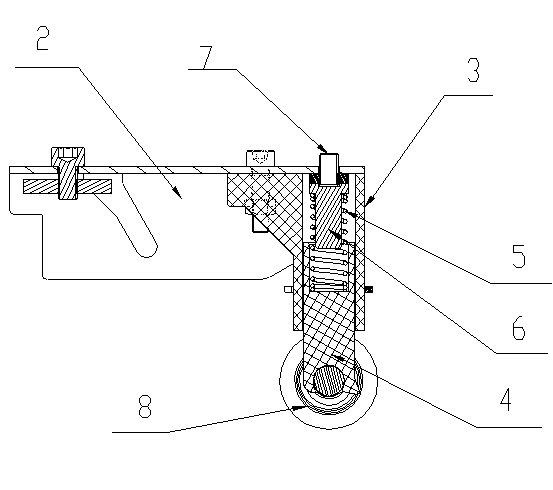

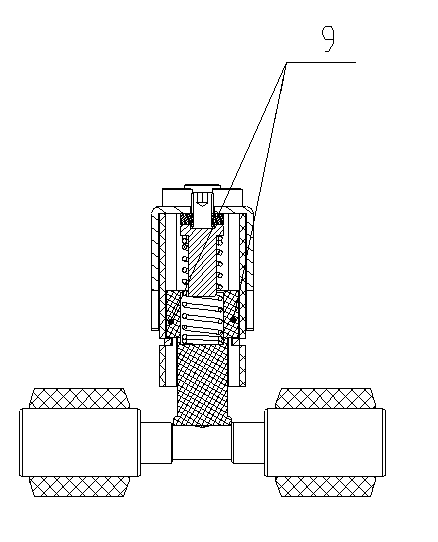

[0022] see figure 1 — Figure 4 , the present invention relates to a compact spinning cradle pressure device, which includes a cradle 1 and a pressure device connected to the cradle 1, the pressure device includes a connecting piece 2 and a top roller claw fixing seat 3, the One end of the connecting piece 2 is clamped with the cradle 1, and the top roller claw fixing seat 3 is fixed vertically downward on the other end of the connecting piece 2, and a top roller is inserted into the top roller claw fixing seat 3 Claw 4, the head of the top roller claw 4 exposes the top roller claw fixing seat 3, inserts a spring 5 in the upper circular hole of the top roller claw 4, and inserts a positioning pin at the top of the spring 5 Shaft 6, the upper part of the positioning pin shaft 6 is fixed on the connecting piece 2 through the adjusting nut 7, and the adjustment of the compression amount of the spring 5 can be realized through the adjusting nut 7 and the positioning pin shaft 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com