Auxiliary gas path drying device and braking system

A drying device and brake system technology, which is applied in the direction of air handling devices, brakes, brake components, etc., can solve the problems of adverse effects of the main air circuit, rust of parts, insufficient pressure of the main air circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

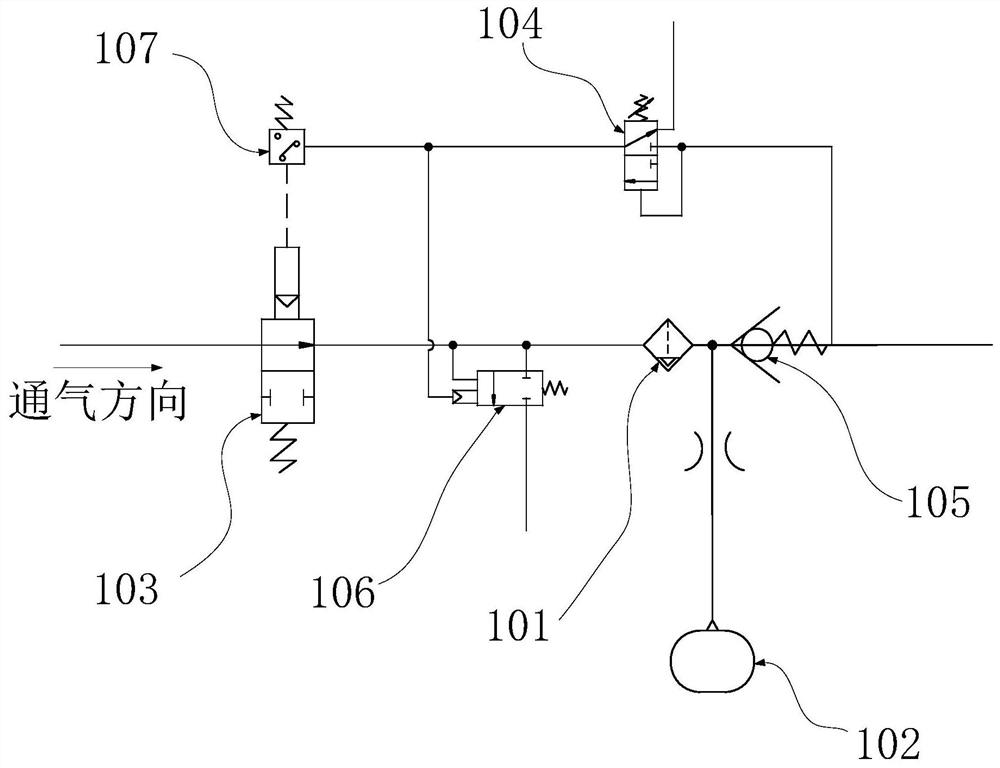

[0039] Please refer to figure 1 , this embodiment provides an auxiliary gas path drying device, which includes a first molecular sieve 101, a first regeneration cylinder 102, a first exhaust valve 106 and a control valve 103, and the first exhaust valve 106 and the first regeneration cylinder 102 are respectively Communicated with the first molecular sieve 101, the control valve 103 is arranged on the side of the air inlet of the first molecular sieve 101, and the control valve 103 is switched to a closed state when the pressure of the gas path exceeds the first threshold.

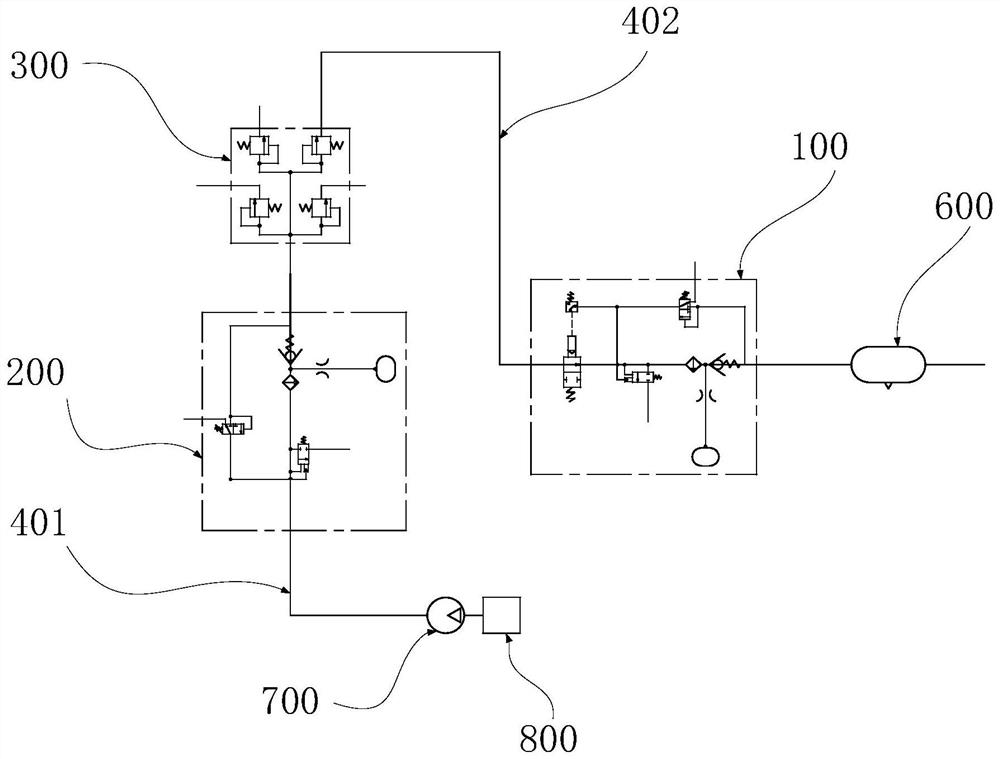

[0040] Such as figure 2 As shown, the auxiliary air path drying device 100 provided in this embodiment can be applied to the brake system, and can be applied to the auxiliary air path 402 of the brake system to dry the gas in the auxiliary air path 402, even in the manufacturing The main gas path 401 of the dynamic system has already been equipped with drying equipment, and the auxiliary gas path drying ...

no. 2 example

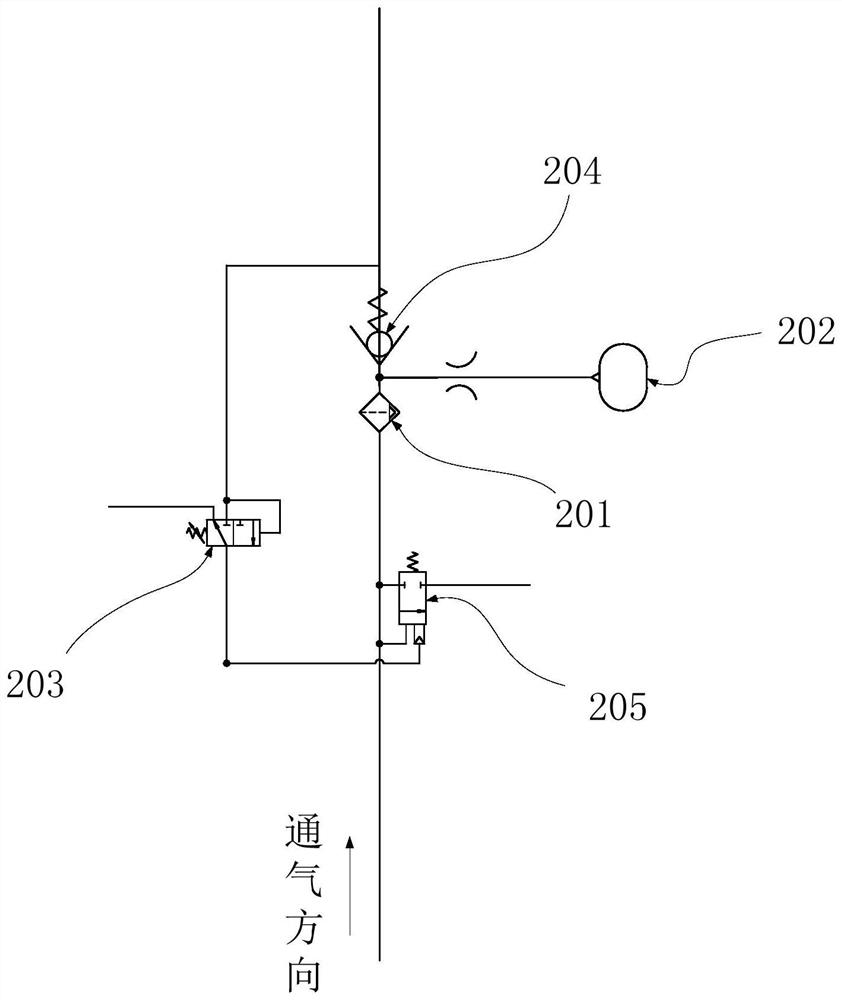

[0053] Such as figure 2 and image 3 As shown, this embodiment provides a brake system, which includes a main air circuit 401 and an auxiliary air circuit 402, and the auxiliary air circuit 402 is provided with the auxiliary air circuit drying device 100 provided in the first embodiment above.

[0054] Since the auxiliary air path 402 is provided with the auxiliary air path drying device 100, in the braking system provided by this embodiment, the gas in the auxiliary air path 402 can be dried without affecting the gas in the main air path 401. pressure.

[0055] Further, an air storage tank 600 may also be provided in the auxiliary air passage 402. The air storage tank 600 is arranged on the auxiliary air passage 402 at the side of the gas outlet of the auxiliary air passage drying device 100, and is dried by the auxiliary air passage drying device 100. The final gas enters the gas storage tank 600. The gas storage tank 600 can temporarily store gas, and the gas in the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com