Aramid fiber and ultra-high molecular weight polyethylene blended yarn and production method thereof

An ultra-high molecular weight, blended yarn technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of easy generation of hair balls, poor anti-pilling performance, difficult to remove hair balls, etc., to ensure yarn quality, overcome Strong rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

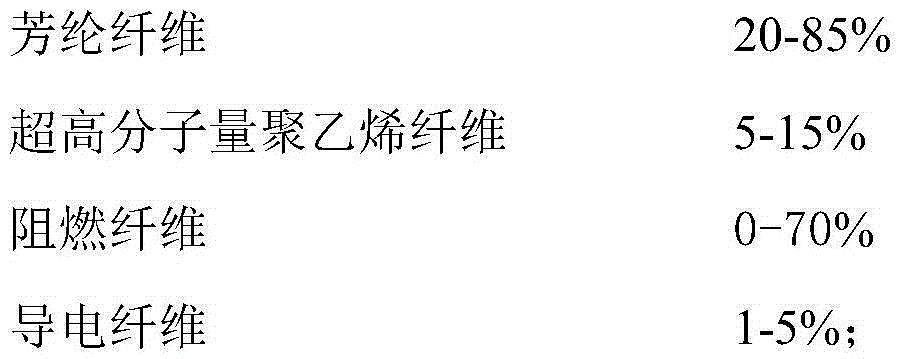

[0044] Formula: (weight percent)

[0045] Aramid fiber 85%

[0046] Ultra-high molecular weight polyethylene fiber 13%

[0047] Conductive fiber 2%

[0048] 2% antistatic agent based on the total weight of ultra-high molecular weight polyethylene fibers, aramid fibers and conductive fibers;

[0049] The yarn number is 21tex;

[0050] The ultra-high molecular weight polyethylene fiber is selected from the fiber of Sinopec Yizheng Chemical Fiber Co., Ltd., with a molecular weight between 1 million and 5 million;

[0051] Described conductive fiber is the nylon that inner core is graphite carbon, adopts the product that DuPont's trade mark is P140;

[0052] The antistatic agent is selected from the TS-YK3 antistatic agent of Dongguan Tiansheng Chemical Technology Co., Ltd.

[0053] Preparation:

[0054] (1) Raw material pretreatment:

[0055] Spray the antistatic agent evenly on the aramid fiber and ultra-high molecular weight polyethylene fiber, and let it stand for 24 ho...

Embodiment 2

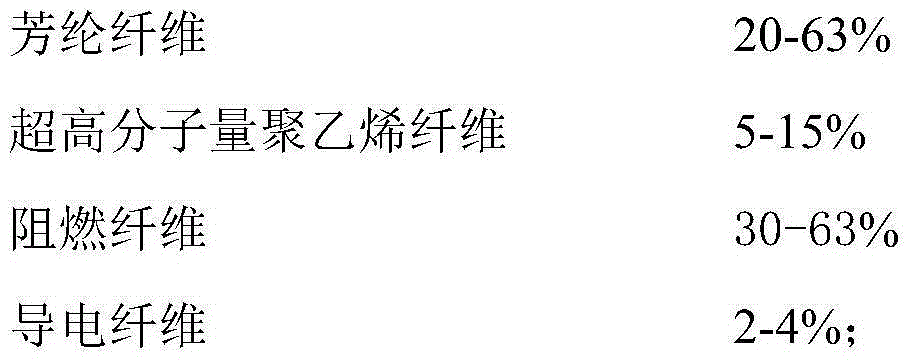

[0072] formula:

[0073]

[0074] 1.5% antistatic agent based on the total weight of aramid fiber, ultra-high molecular weight polyethylene fiber, flame-retardant viscose and conductive fiber;

[0075] The yarn number is 37tex

[0076] The ultra-high molecular weight polyethylene fiber is selected from the fiber of Sinopec Yizheng Chemical Fiber Co., Ltd., with a molecular weight between 1 million and 5 million;

[0077] Described conductive fiber is the nylon that inner core is graphite carbon, adopts the product that DuPont's trade mark is P140;

[0078] The antistatic agent is selected from the TS-YK3 antistatic agent of Dongguan Tiansheng Chemical Technology Co., Ltd.

[0079] Preparation:

[0080] (1) Raw material pretreatment:

[0081] Spray antistatic agent evenly on aramid fiber, ultra-high molecular weight polyethylene, flame-retardant viscose and conductive fiber, and let it stand for 16 hours to carry out health-preserving treatment;

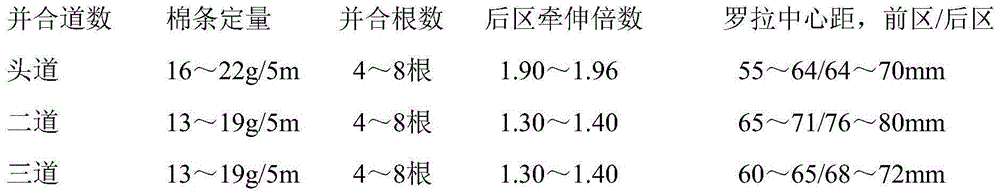

[0082] (2) Cotton blen...

Embodiment 3

[0097] formula:

[0098]

[0099] 2% antistatic agent based on the total weight of aramid, flame-retardant viscose fiber, ultra-high molecular weight polyethylene fiber and conductive fiber;

[0100] The yarn number is 14.6tex

[0101] The ultra-high molecular weight polyethylene fiber is selected from the fiber of Sinopec Yizheng Chemical Fiber Co., Ltd., with a molecular weight between 1 million and 5 million;

[0102] Described conductive fiber is the nylon that inner core is graphite carbon, adopts the product that DuPont's trade mark is P140;

[0103] The antistatic agent is selected from the TS-YK3 antistatic agent of Dongguan Tiansheng Chemical Technology Co., Ltd.

[0104] Preparation:

[0105] (1) Raw material pretreatment:

[0106] Spray the antistatic agent evenly on the aramid fiber, ultra-high molecular weight polyethylene, flame-retardant viscose and conductive fiber, and let it stand for 24 hours for health treatment;

[0107] (2) Cotton blending step: S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com