Air pressure dustless godet roller device

A godet wheel and air pressure technology, applied in textiles and papermaking, etc., can solve problems such as unevenness of core-spun yarn, affecting yarn quality, and inability to rotate the godet wheel, so as to prolong service life and ensure yarn quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

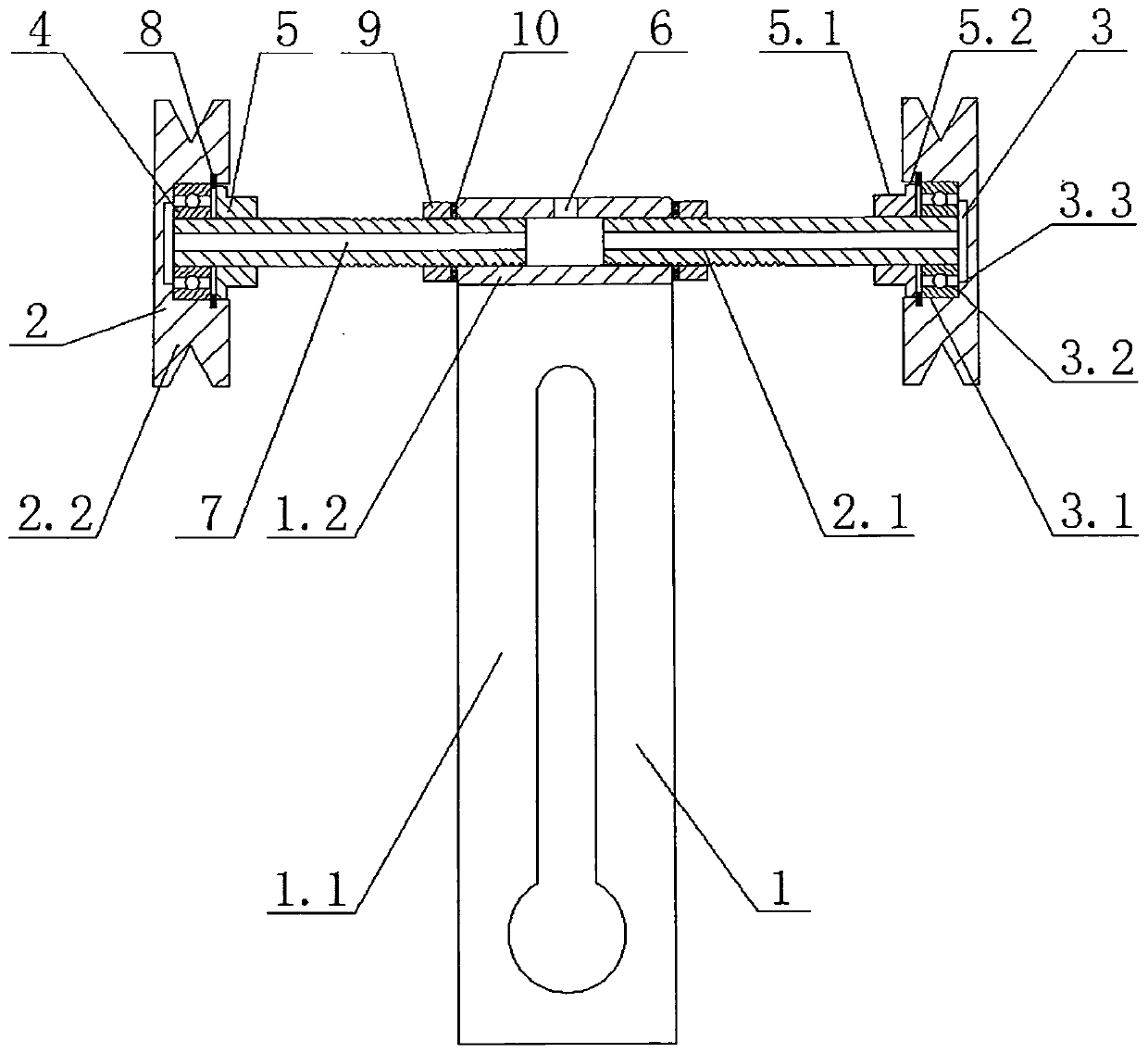

[0042] like figure 1 As shown, a pneumatic dust-free godet wheel device in this embodiment includes a fixed bracket 1 and godet wheel parts 2 arranged on both sides of the fixed bracket 1, and the fixed bracket 1 includes a bottom bracket 1.1 and a long screw Cap 1.2, the godet wheel component 2 includes an adjustment shaft 2.1, the inner end of the adjustment shaft 2.1 is connected with the long nut 1.2, the outer end of the adjustment shaft 2.1 is provided with a godet wheel 2.2, and the godet wheel 2.2 The inner side is provided with a blind hole 3, the blind hole 3 is provided with a bearing 4, the inner side of the bearing 4 is provided with a retaining ring 5, the retaining ring 5 is fixedly connected with the adjustment shaft 2.1, and the retaining ring 5 is connected with the blind hole 3 There is a gap between the inner walls, the middle part of the long nut 1.2 is provided with an air inlet 6, and the air inlet 6 communicates with the inside of the long nut 1.2, and ...

Embodiment 2

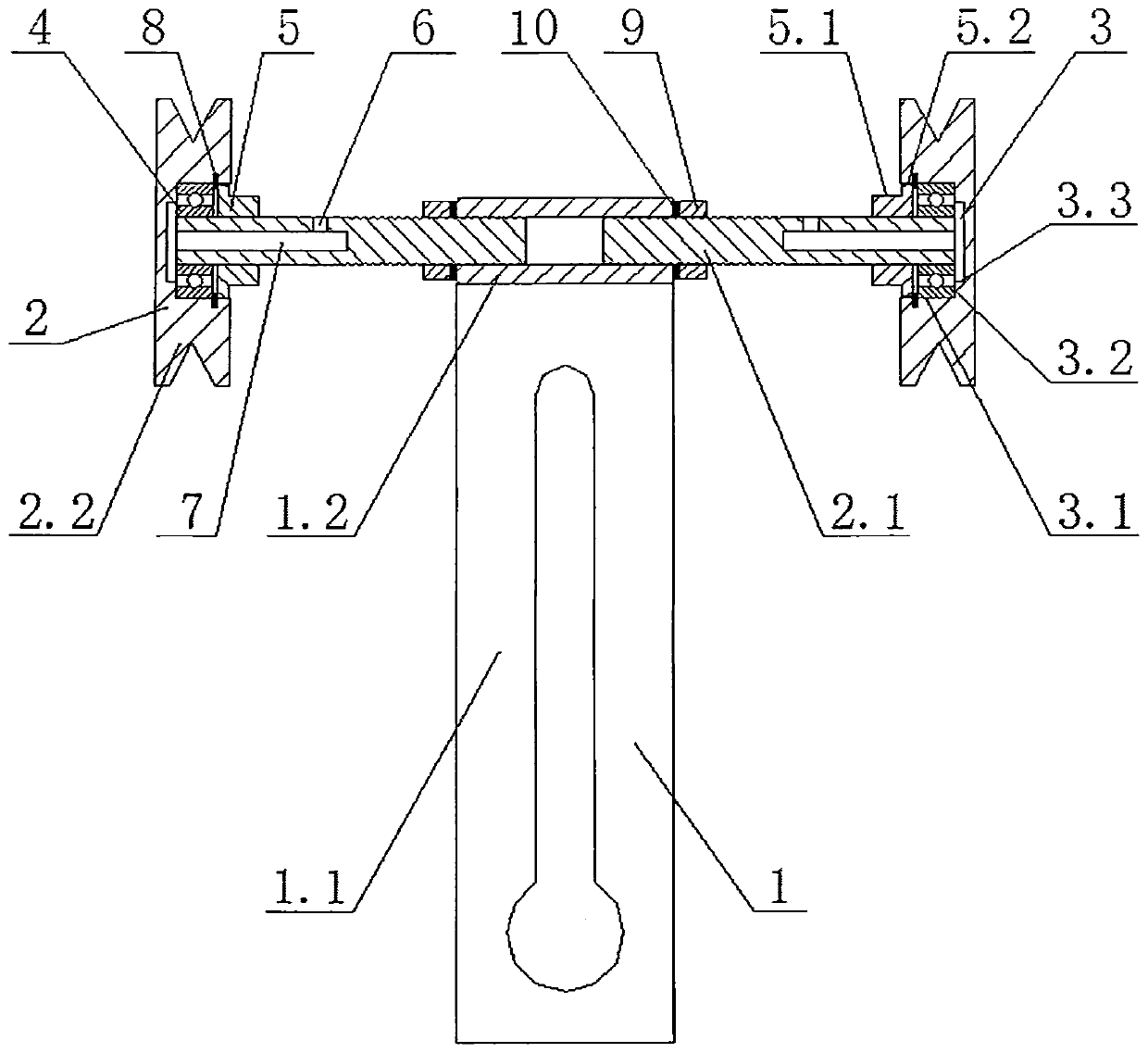

[0053] like figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the outer end of the adjustment shaft 2.1 is provided with an air intake channel 7 inwardly, and the air intake channel 7 extends to the middle part of the adjustment shaft 2.1, and the middle part of the adjustment shaft 2.1 is opened There is a compressed air inlet 6 , and the compressed air inlet 6 communicates with the air intake passage 7 .

[0054] working principle:

[0055] The compressed air inlet in the middle of the long nut or in the middle of the adjusting shaft is connected to an external air compressor. The compressed air enters from the compressed air inlet, then flows outward along the air intake channel in the center of the adjusting shaft, and finally enters the inner section of the blind hole of the godet wheel , and then the compressed air flows out through the gap between the bearing, the gap between the retaining ring and the circlip, and the gap between the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com