A kind of extra-high-count pure cotton combed yarn and its spinning process

An ultra-high-count, pure cotton technology, applied to combing machines, yarns, spinning machines, etc., can solve the problems of high yarn quality requirements, high-count yarn difficulty, and easy broken ends, etc., to achieve high-strength American cotton, Guarantee the effect of yarn quality and fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

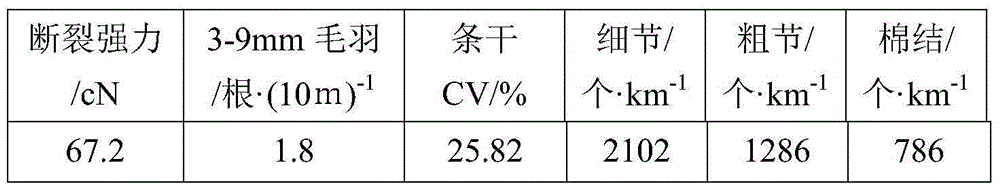

Embodiment 1

[0028] Example 1: Take the pure cotton combed 2.7tex yarn installed on the TH558 four-roller ultra-large draft ring spinning frame as an example, and the raw cotton is 22% Egyptian cotton, 33% American cotton, and 45% Xinjiang cotton. The long-staple cotton is mixed, and the specific process steps are as follows:

[0029] (1) Blowing and carding unit:

[0030] The technological process includes: bale grabbing, first cotton opening, cotton blending, second cotton opening, impurity removal, and carding.

[0031] Using Trützschler blowing carding unit, the specific equipment and process are as follows:

[0032] BDT, BOBA, AFC double-axis flow opener, LvSA heavy object separator, MM6 multi-compartment mixing box, CVT opener, DX multi-tube cyclone dust collector, FBK fine impurity remover, TC03 type carding machine.

[0033] The AFC type double-axial flow opener adopts the comb beater with a speed of 950r / min, the speed of the licker-in roller of the CVT opener is 600r / min, the di...

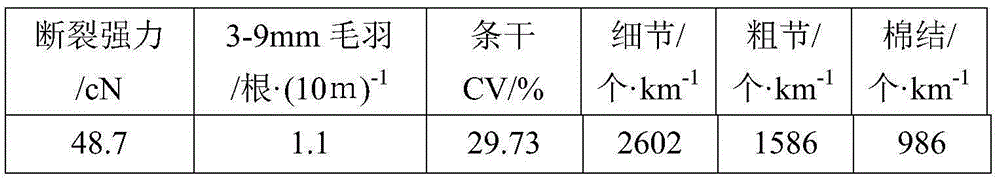

Embodiment 2

[0056] Example 2: Taking the addition of a fully polyspun device on the TH558 four-roller ultra-large draft ring spinning frame as an example, the pure cotton combed 1.9tex yarn is used as an example, and the raw cotton is 20% Egyptian cotton, 30% American cotton, and 50% Xinjiang cotton. The long-staple cotton is mixed, and the specific process steps are as follows:

[0057] (1) Blowing and carding unit:

[0058] The technological process includes: bale grabbing, first cotton opening, cotton blending, second cotton opening, impurity removal, and carding.

[0059] Using Trützschler blowing carding unit, the specific equipment and process are as follows:

[0060] BDT, BOBA, AFC double-axis flow opener, LvSA heavy object separator, MM6 multi-compartment mixing box, CVT opener, DX multi-tube cyclone dust collector, FBK fine impurity remover, TC03 type carding machine.

[0061] The AFC type double-axial flow opener adopts the comb beater with a speed of 950r / min, the speed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com