Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Guaranteed Tolerance Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

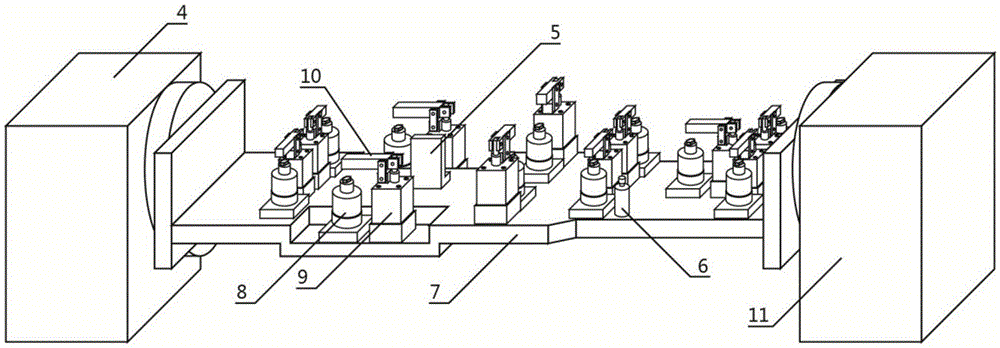

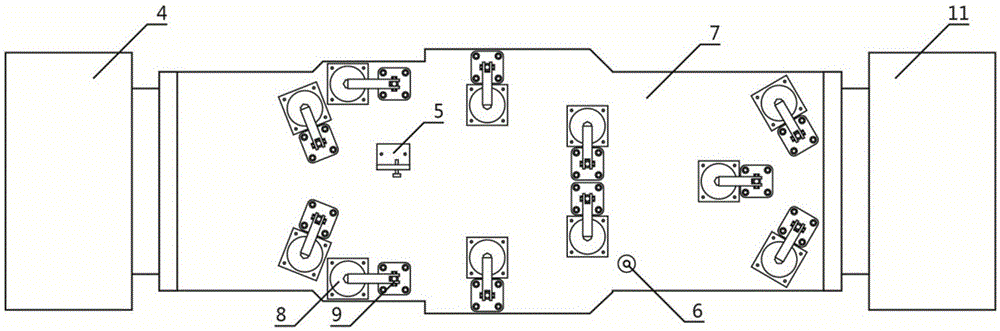

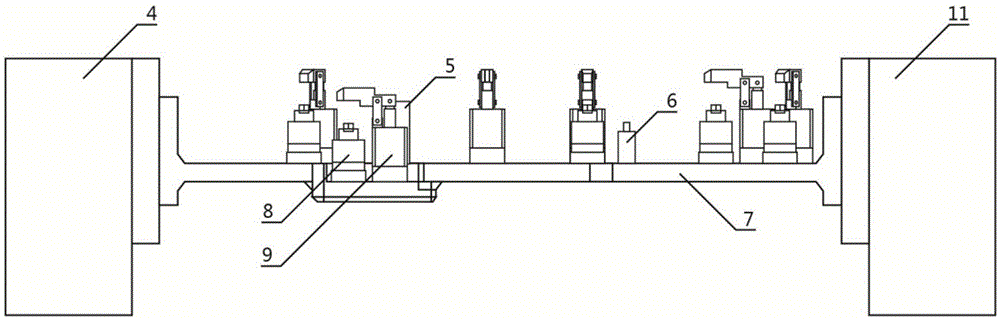

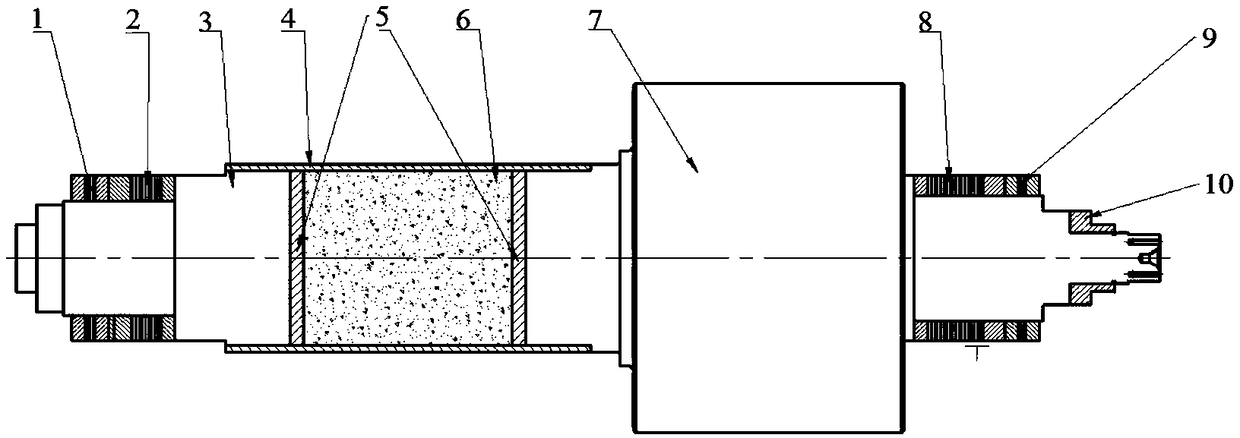

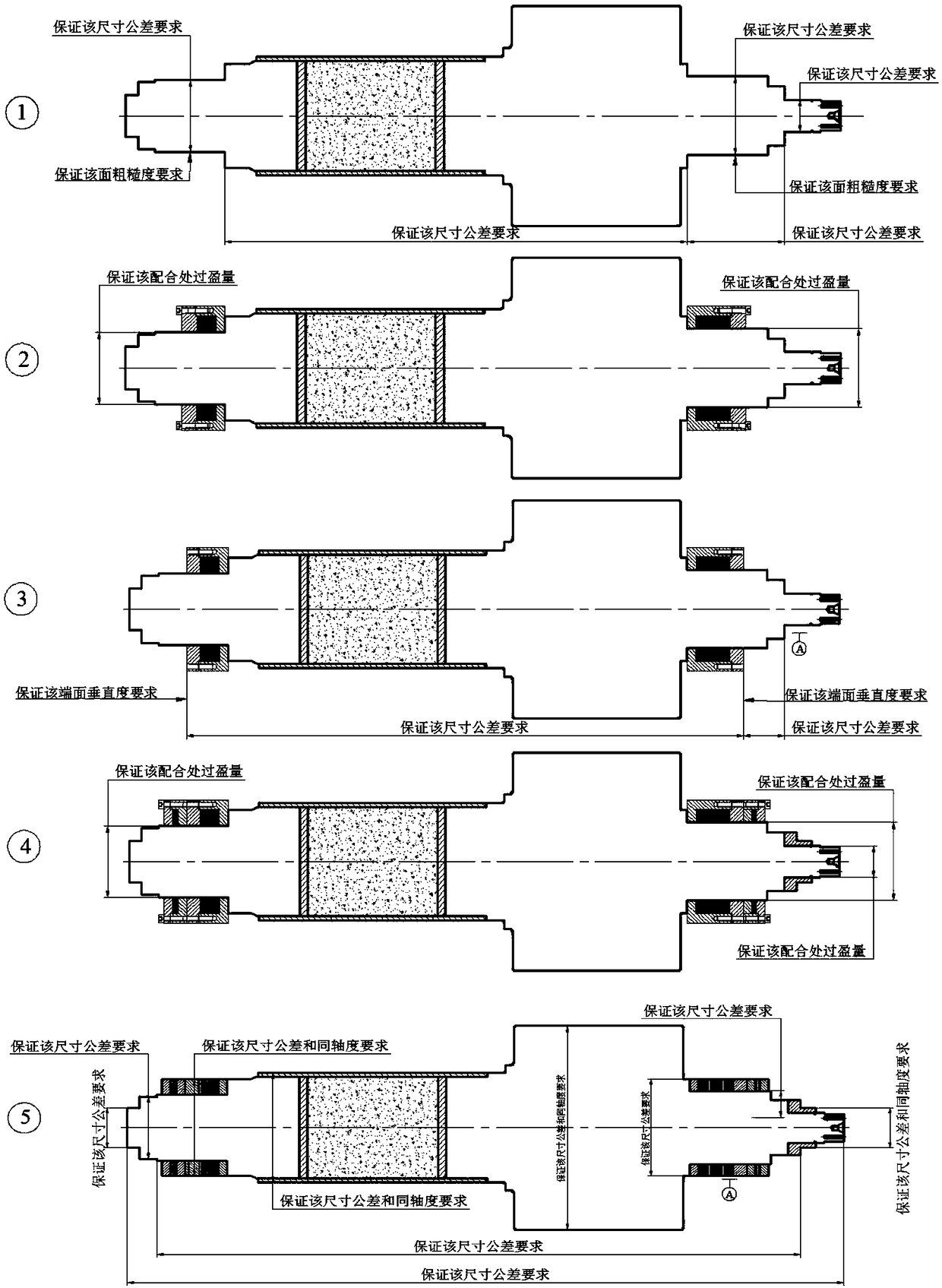

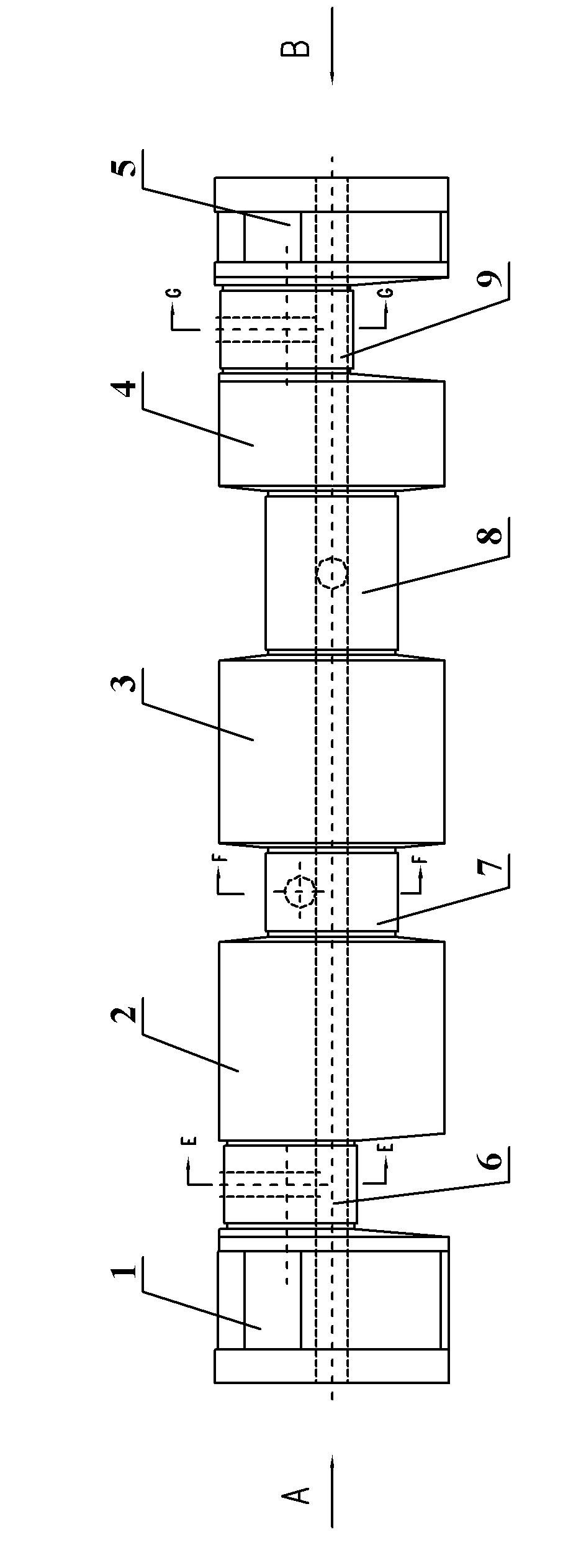

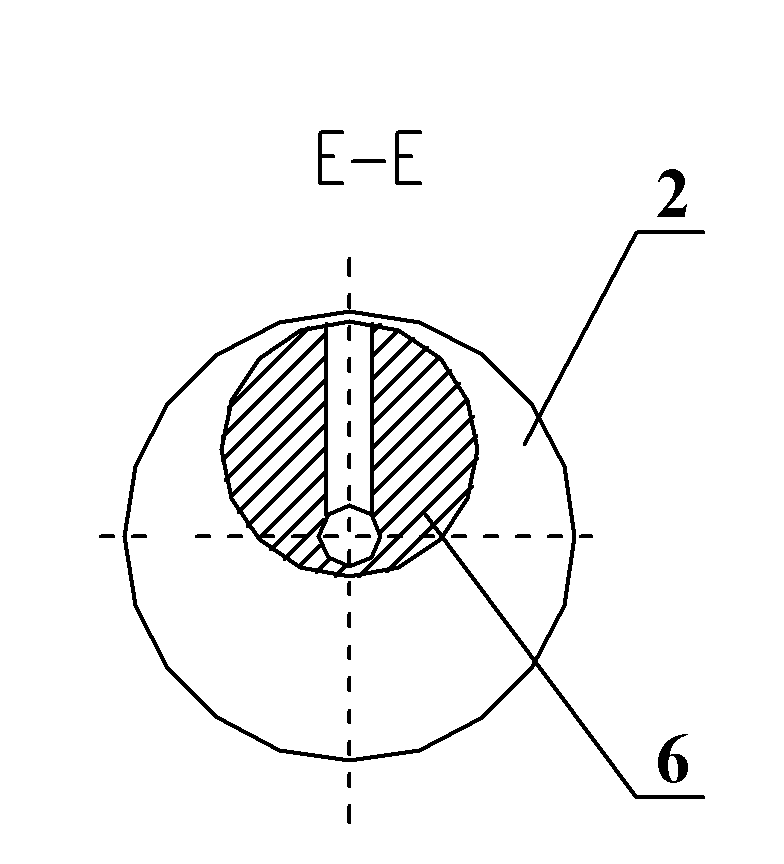

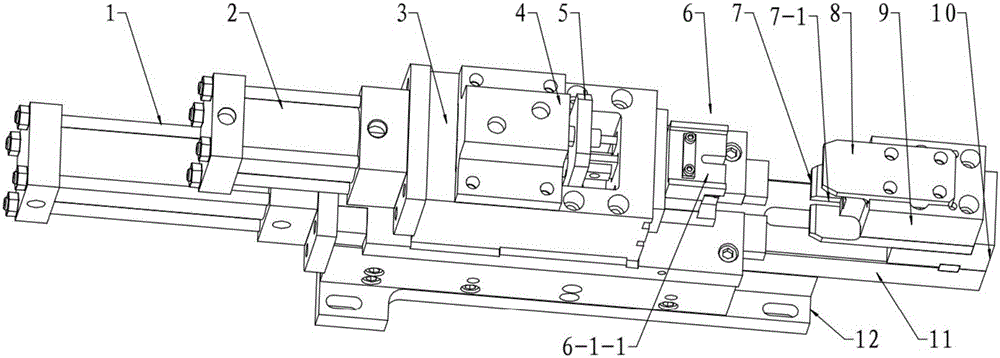

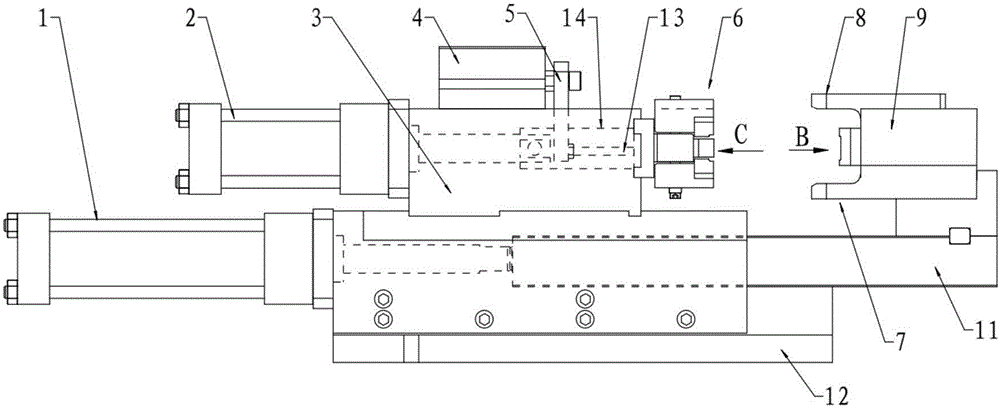

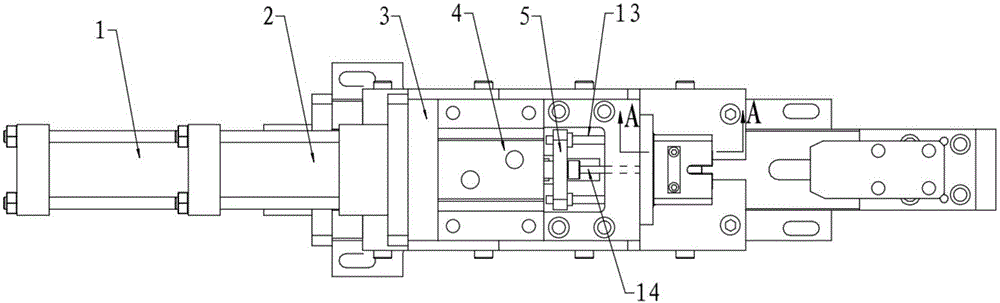

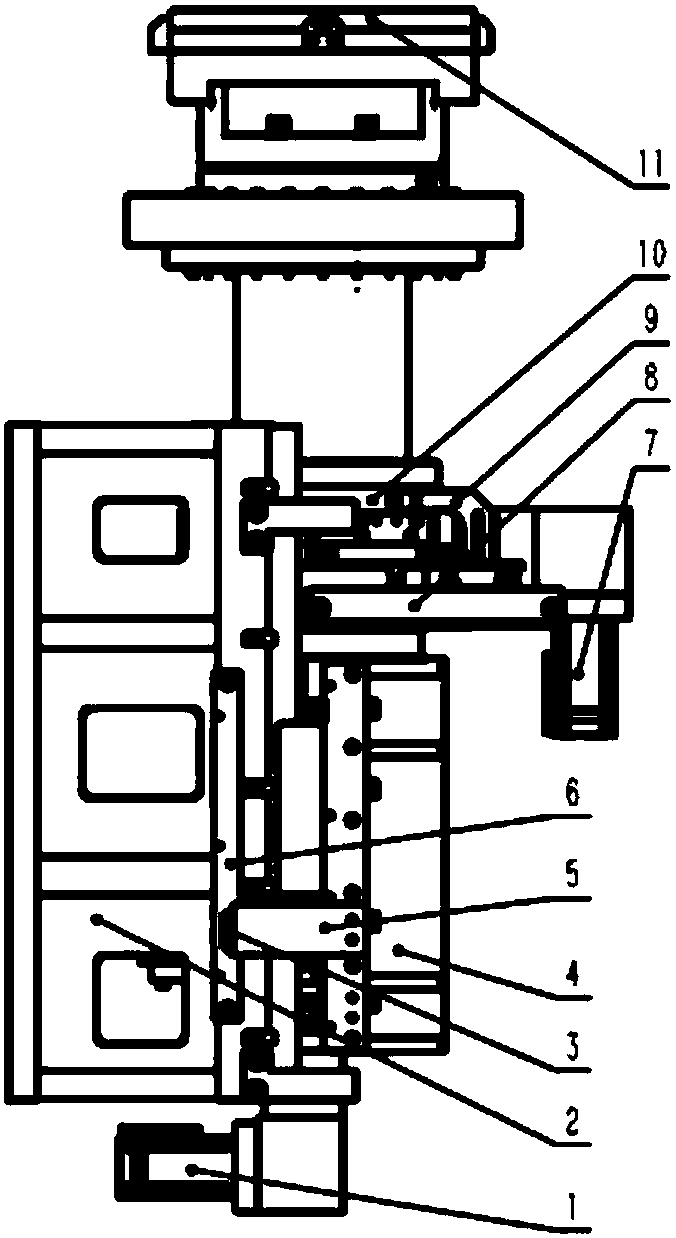

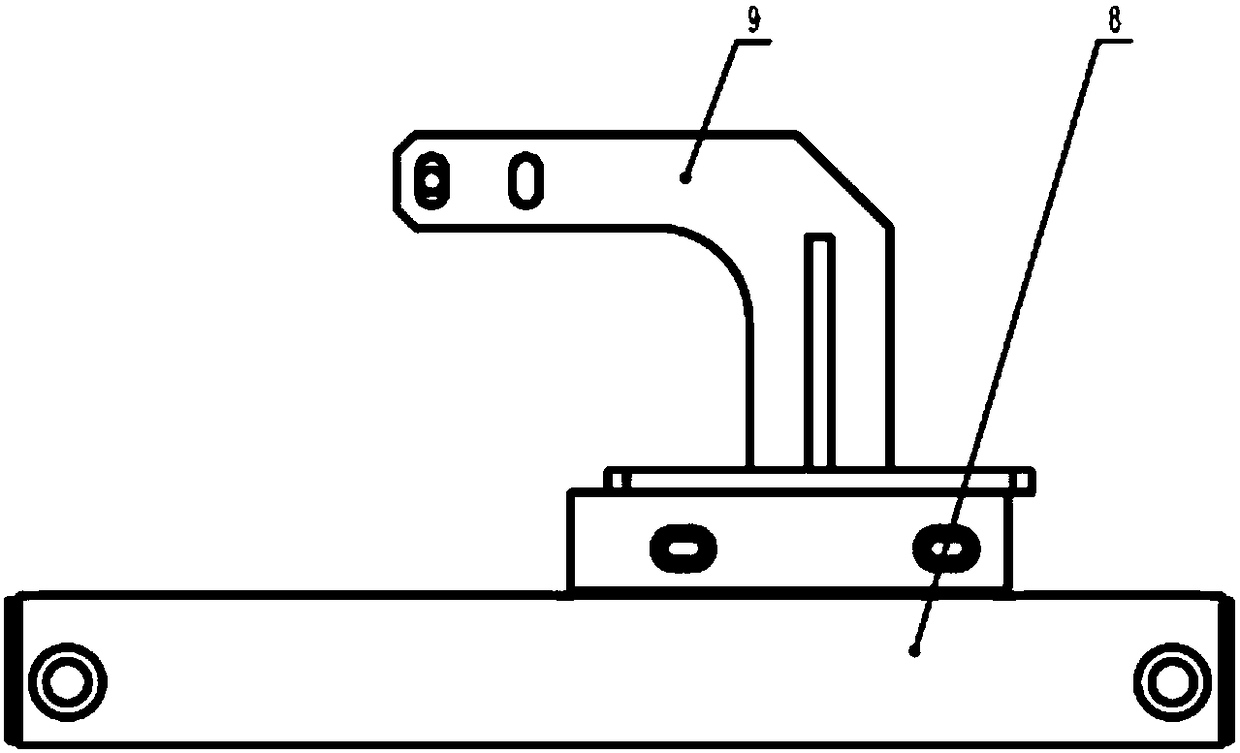

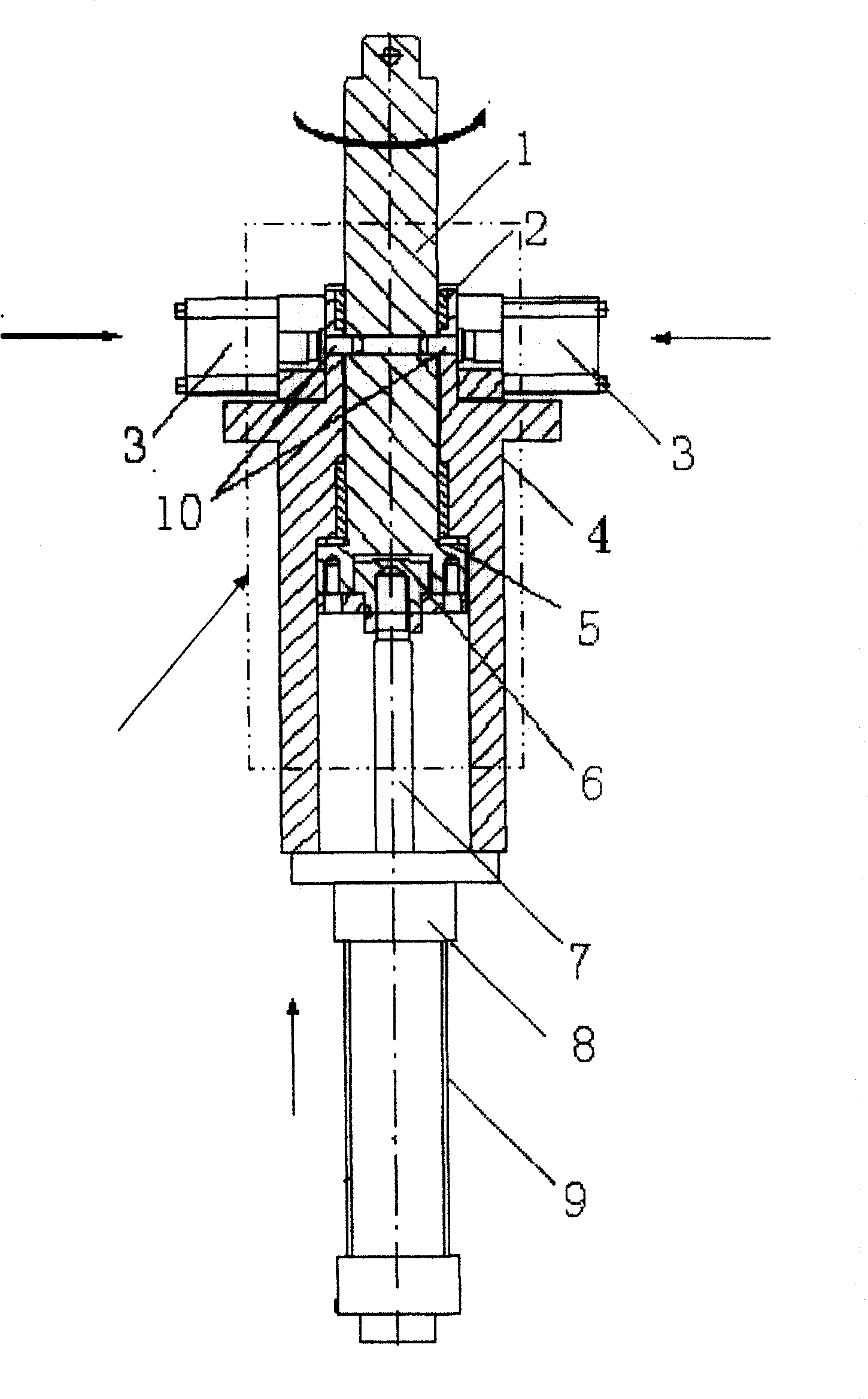

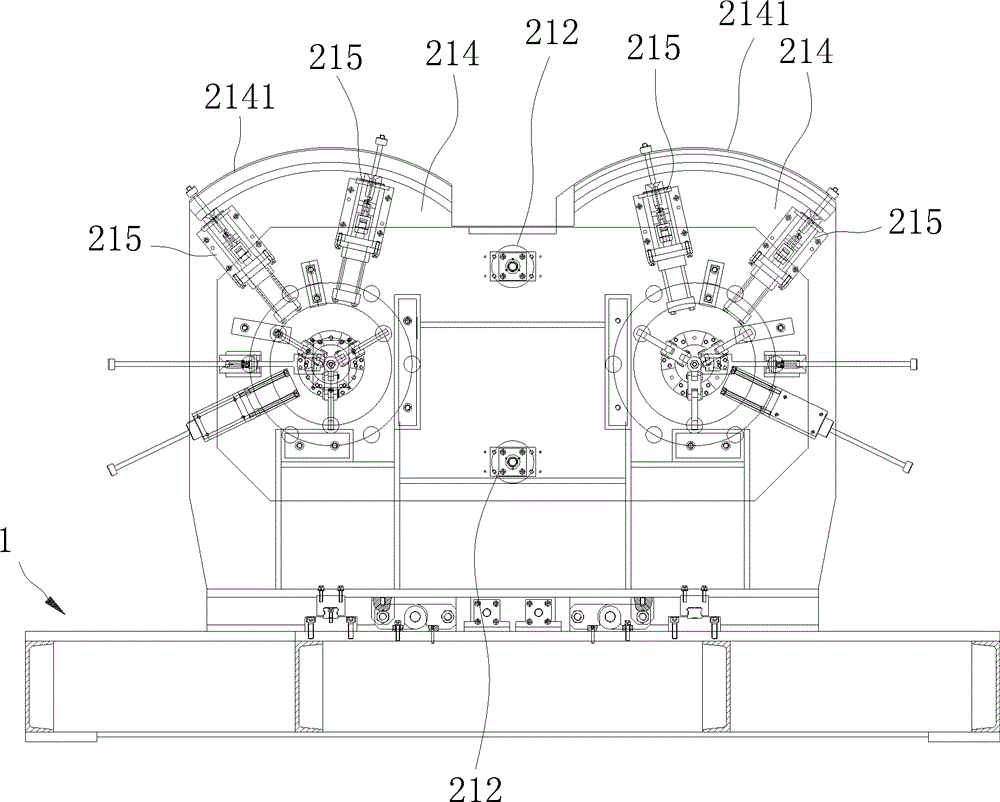

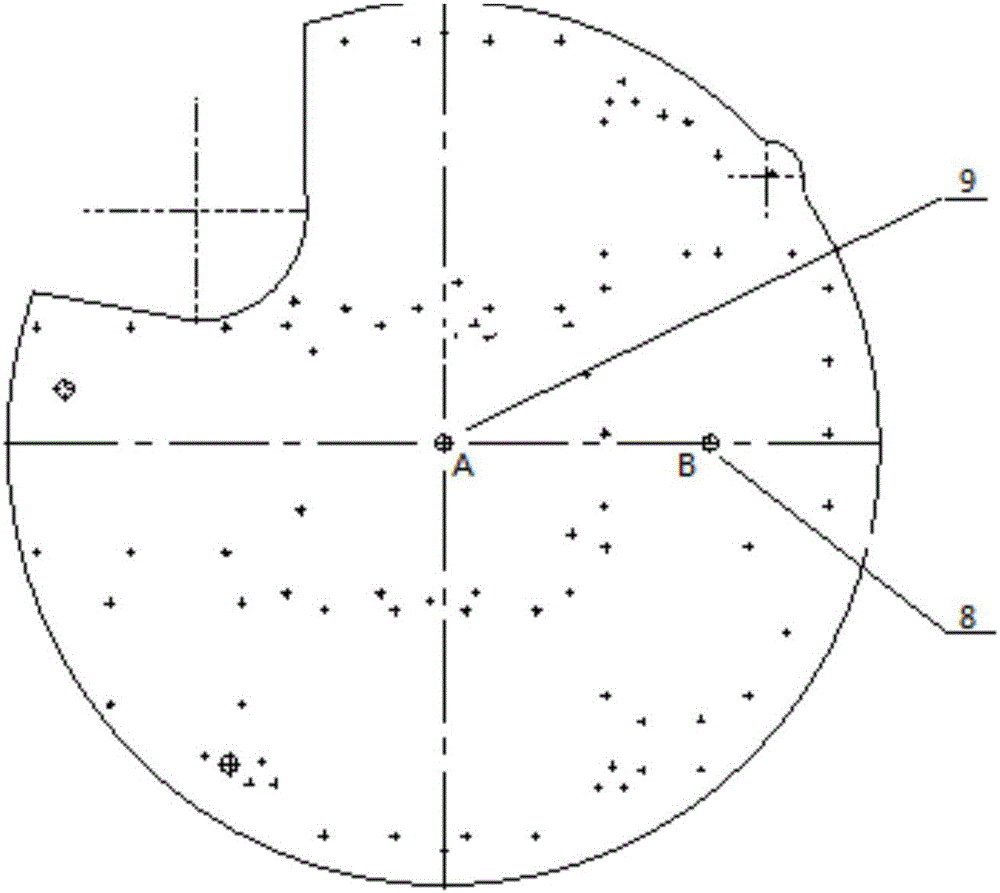

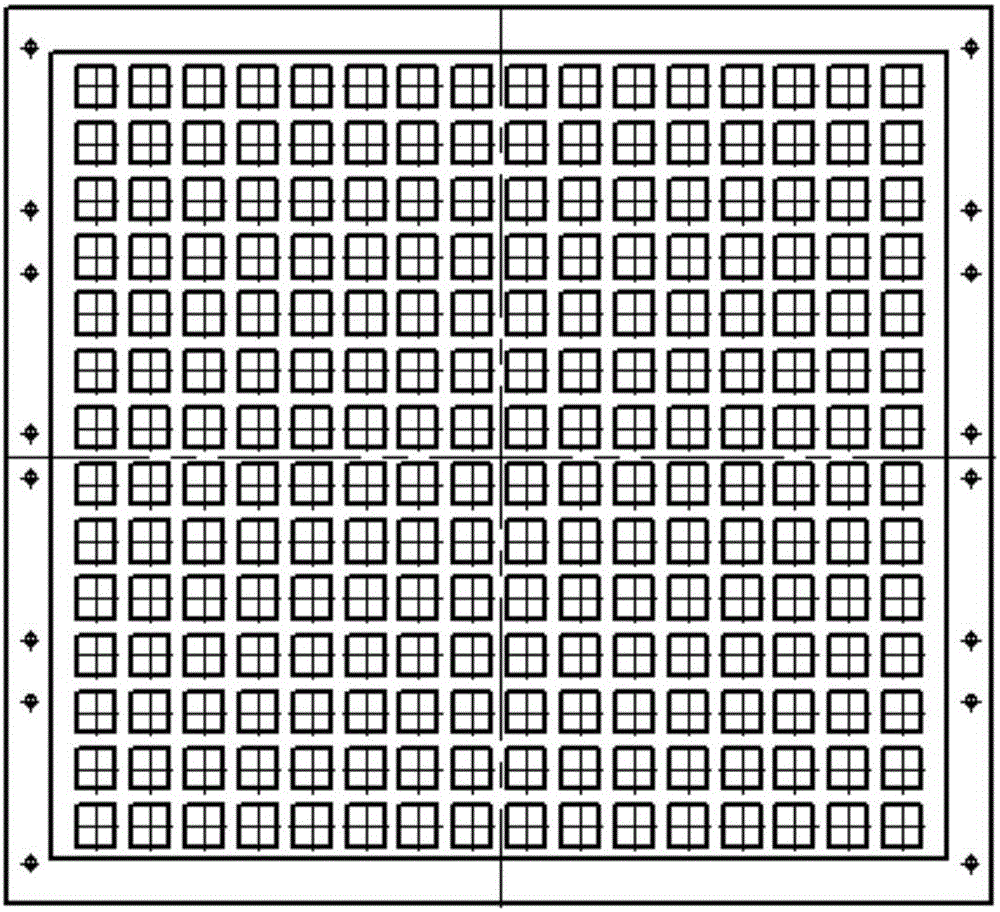

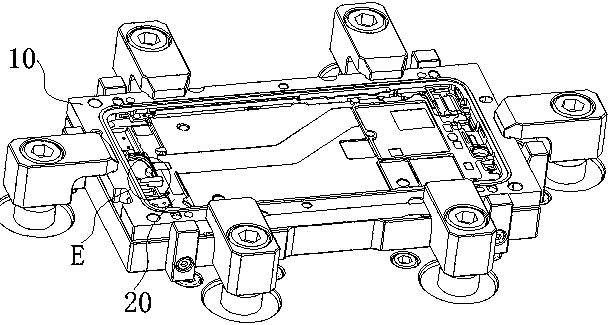

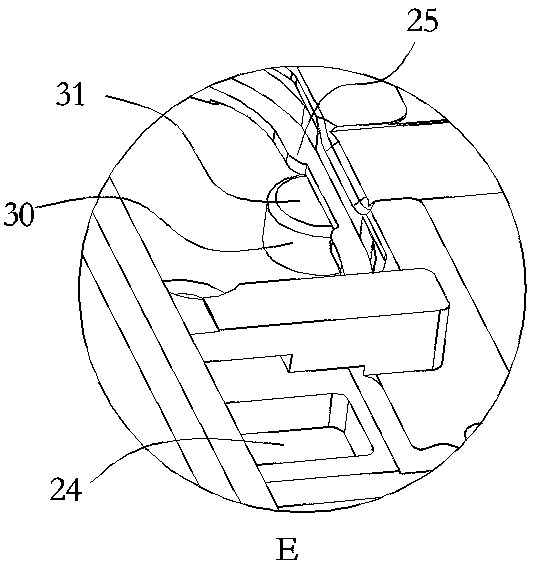

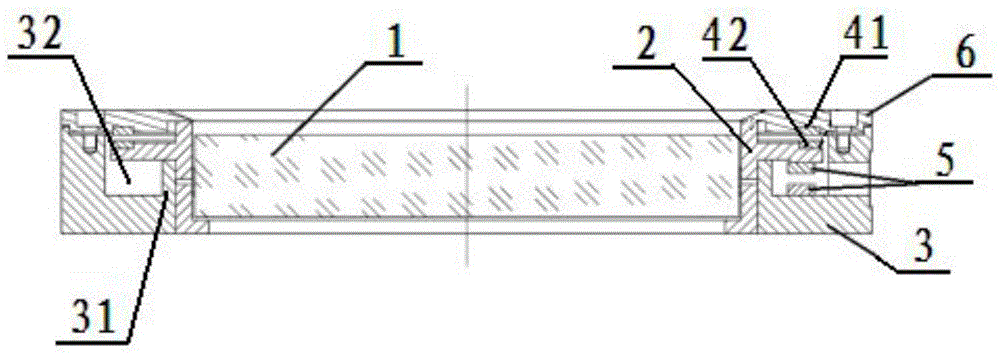

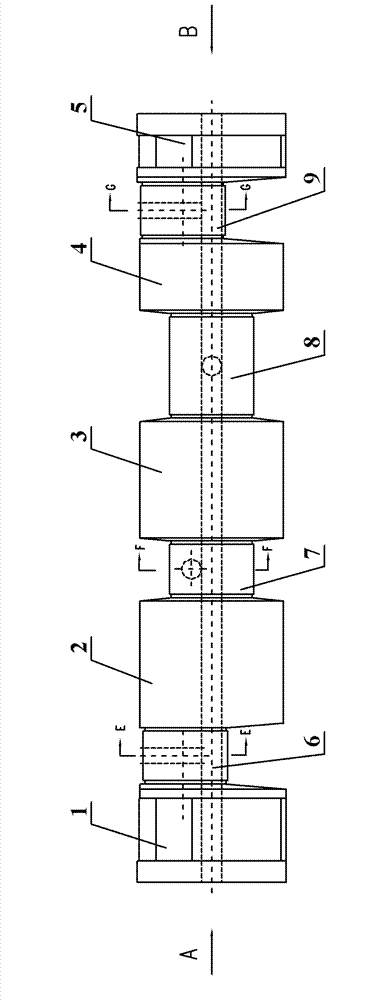

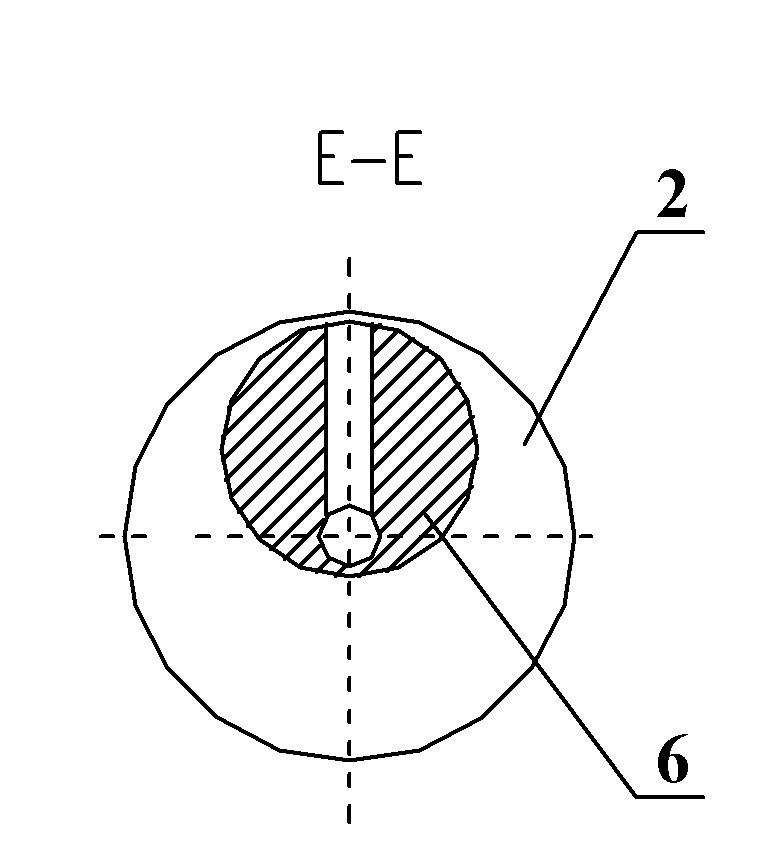

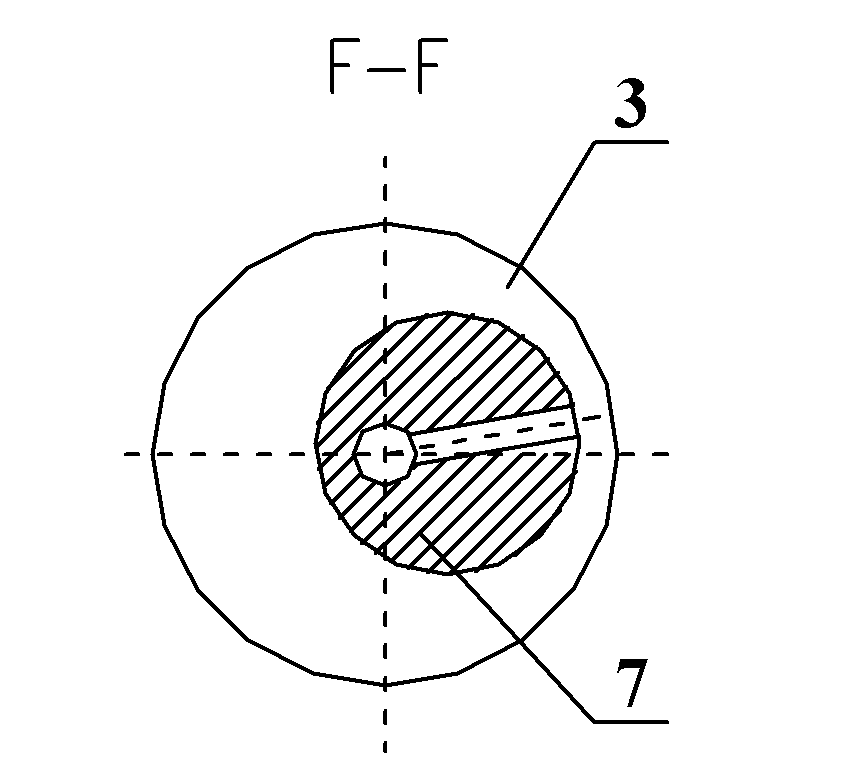

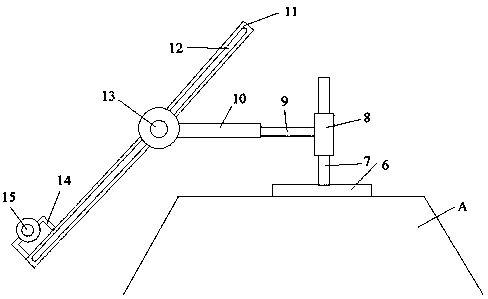

Four-axis linkage machining mechanism of numerical-control machining center and operating method of four-axis linkage machining mechanism

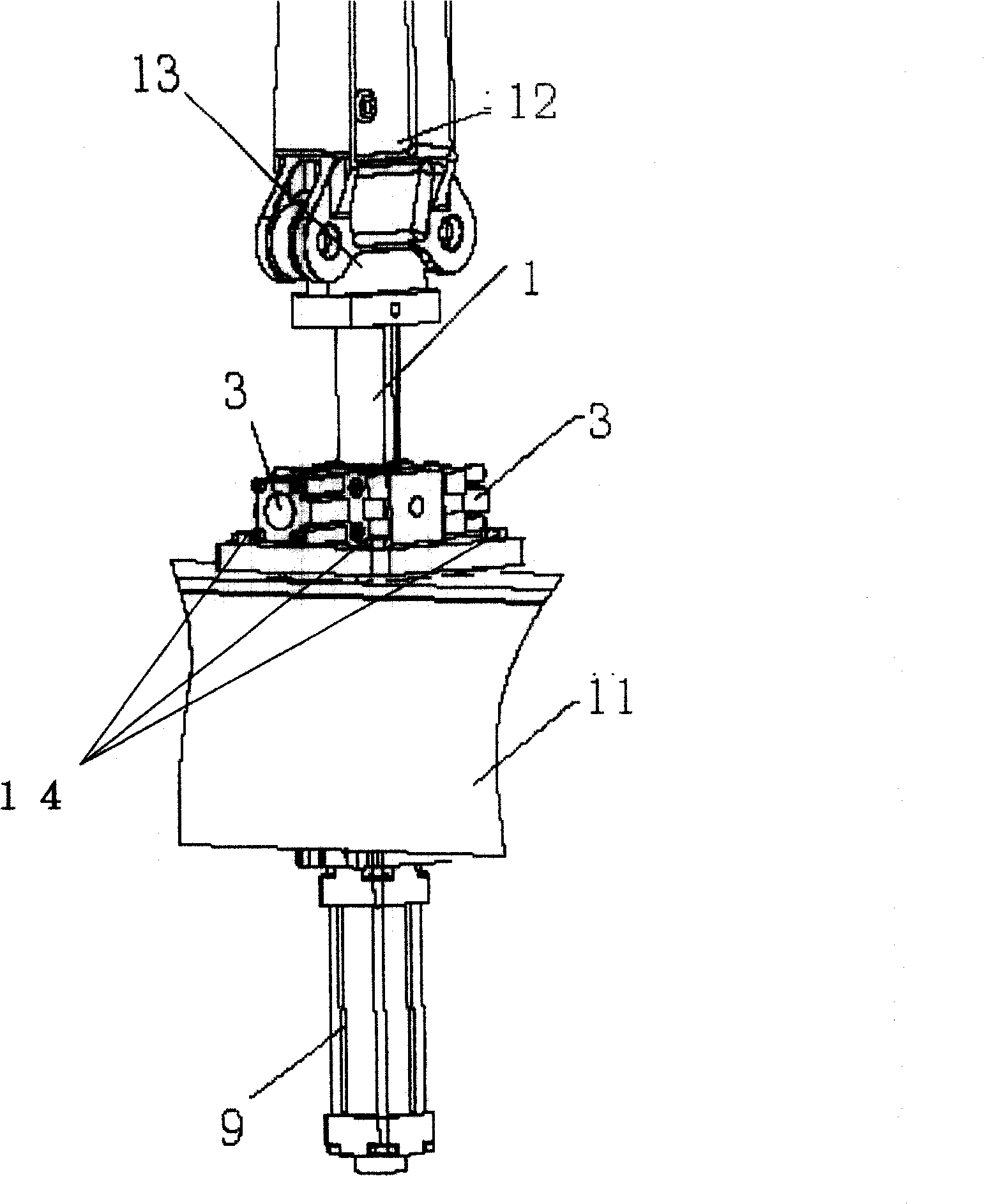

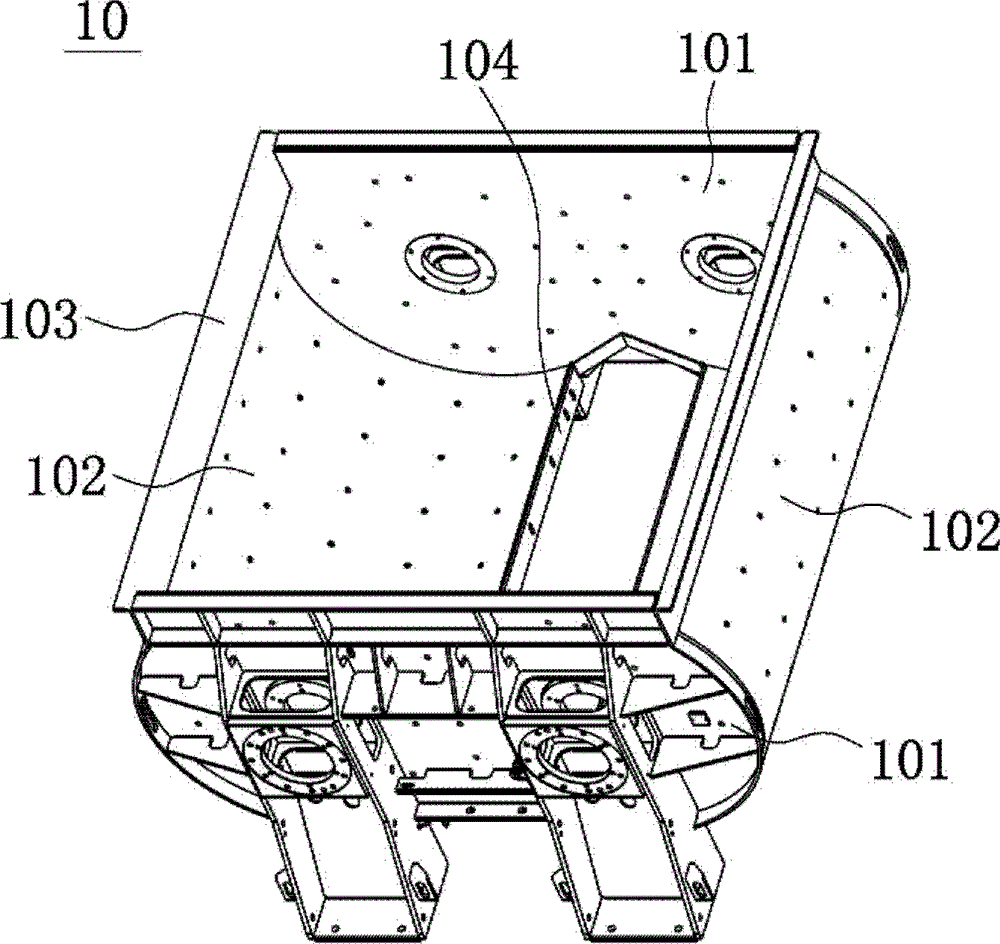

InactiveCN105643294ASolve the problem of difficult clampingEasy to processLarge fixed membersPositioning apparatusNumerical controlMachine parts

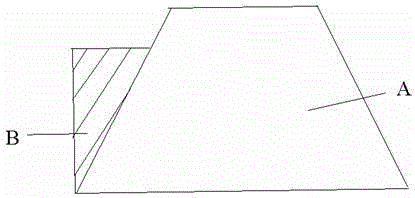

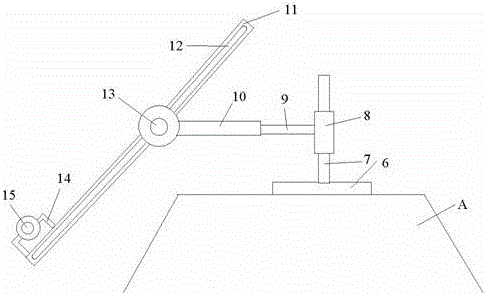

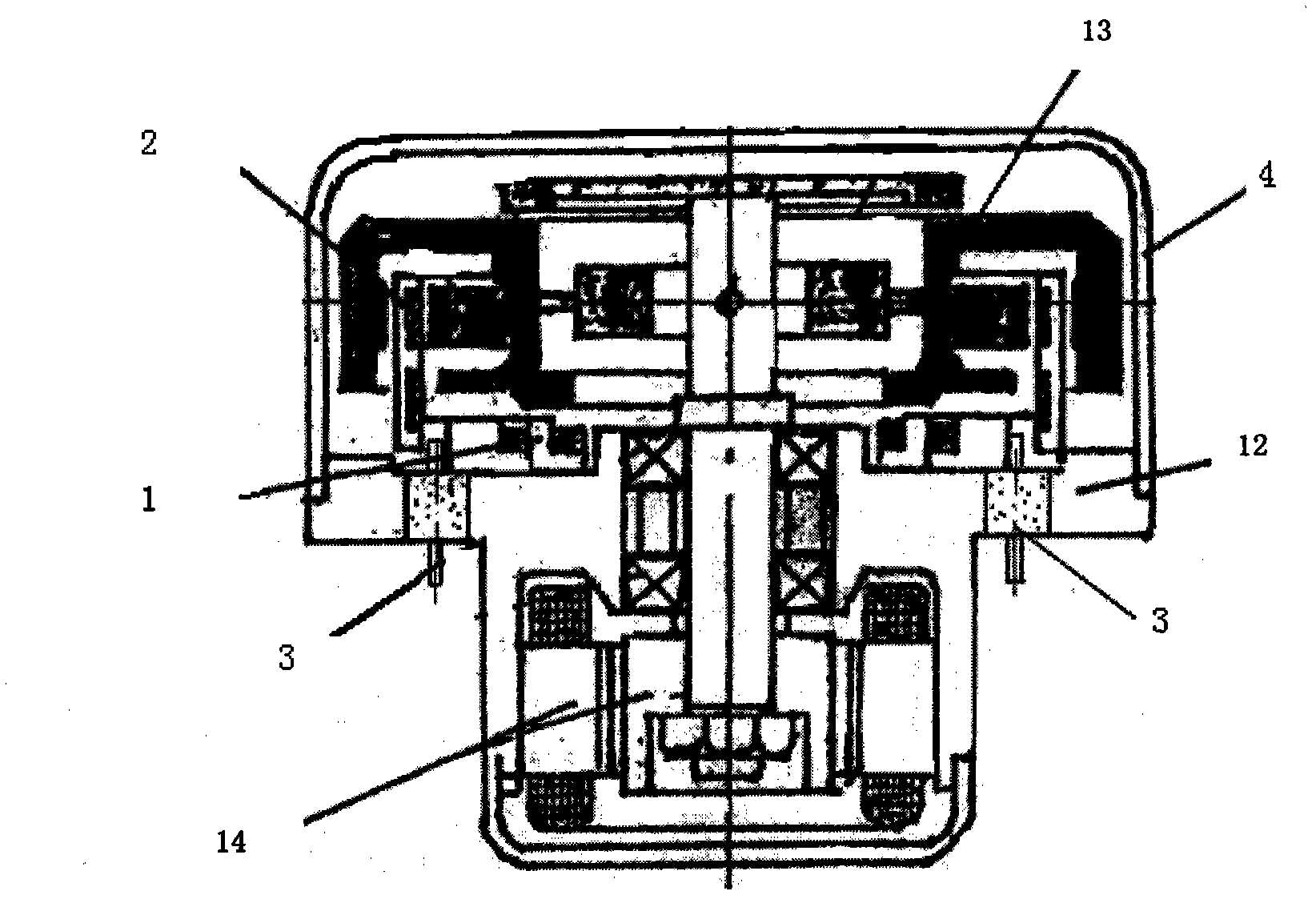

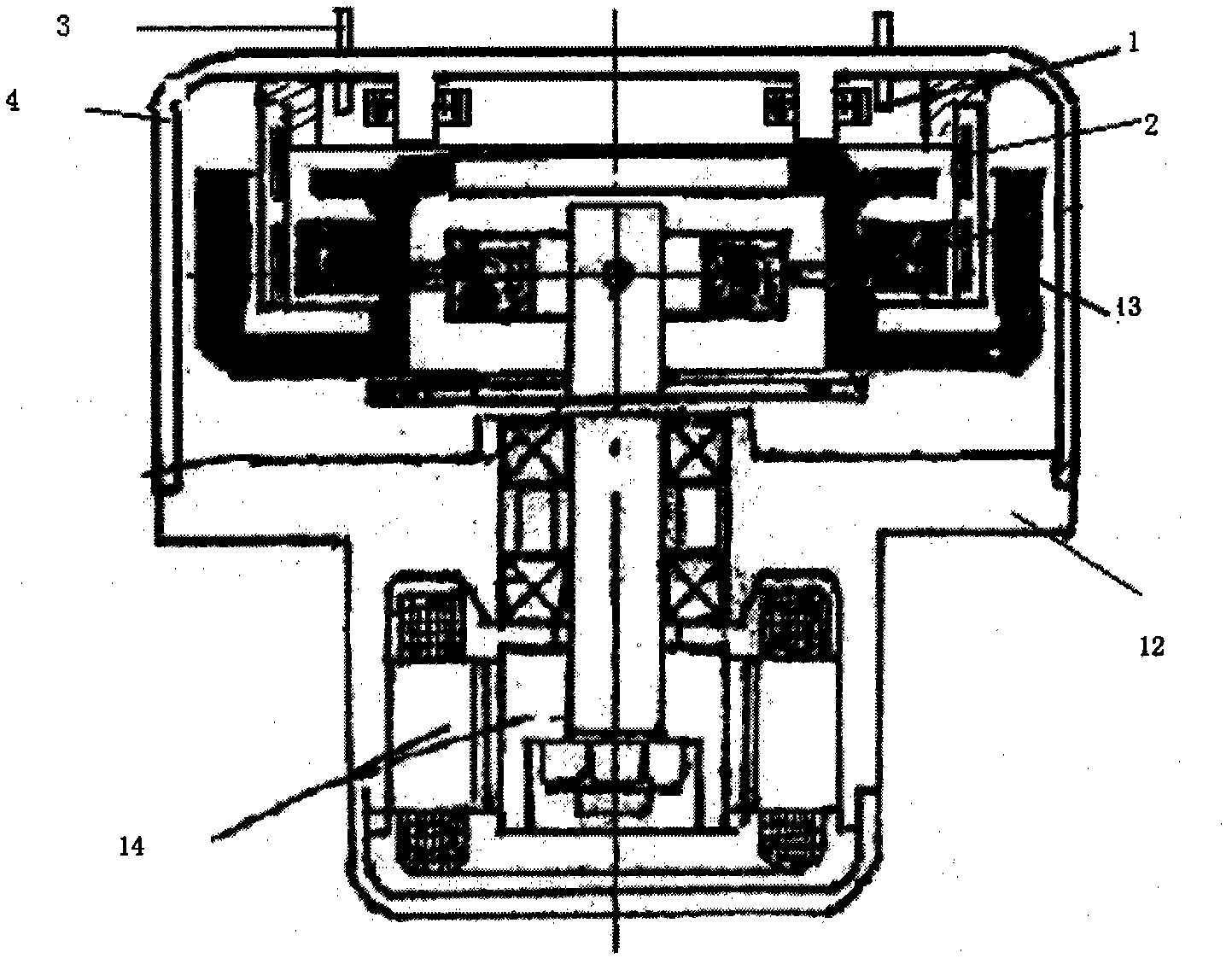

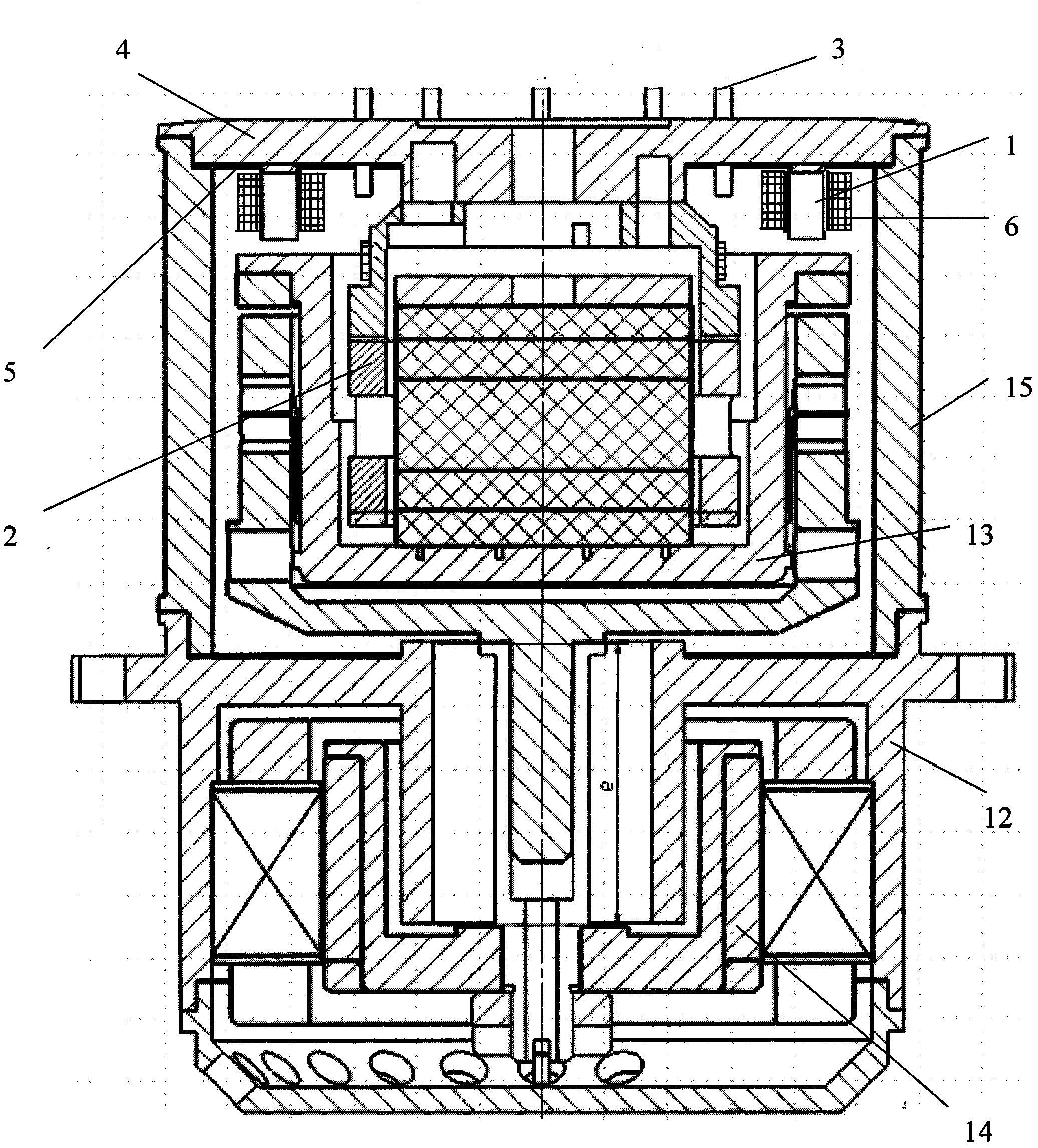

The invention provides a four-axis linkage machining mechanism of a numerical-control machining center and an operating method of the four-axis linkage machining mechanism. According to the technical scheme, the four-axis linkage machining mechanism of the numerical-control machining center comprises an operation chamber, a machining spindle and a machining table; the machining table is composed of a rotary table tailstock, a main part positioning device, an auxiliary part positioning device, a clamp body and a rotary table body; and a plurality of hydraulic supporting cylinders and a plurality of hydraulic pressing cylinders are further arranged on the clamp body. By the adoption of the four-axis linkage machining mechanism, the problems that a workpiece cannot be clamped easily, multiple procedures are needed for machining, and the precision is difficult to control are mainly solved, and a machining mode requiring multiple machine tools is changed, so that the numerical-control machining mechanism which can achieve rapid machining and high-precision machining and simplify machining procedures is obtained. The four-axis linkage machining mechanism is suitable for machining parts which are huge in boundary dimension, light and thin in structure and prone to deformation, and thus the phenomenon that clamping is difficult is avoided. The mechanism has a strict form and location tolerance requirement, the requirements for assembly and detail treatment of a system are improved, and the effect that the stability of the product quality and high efficiency are still kept in long-time continuous production is guaranteed.

Owner:TIANJIN HUATIAN CENTURY MACHINERY

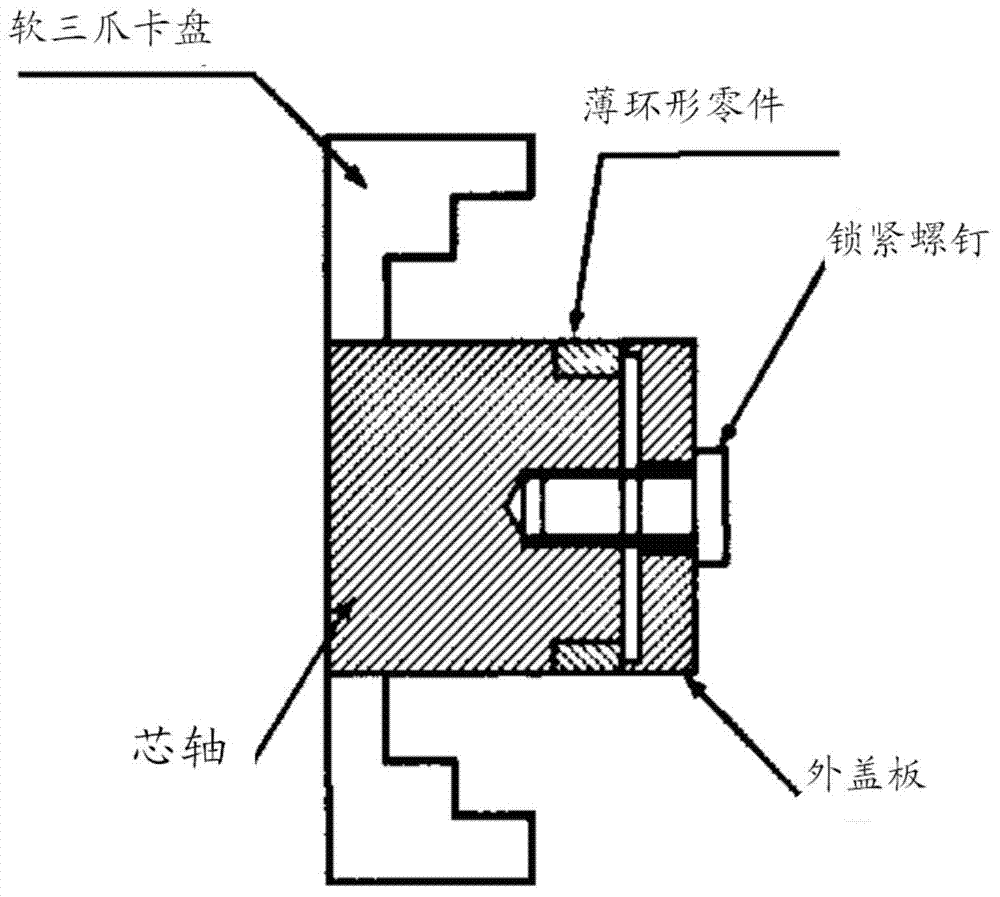

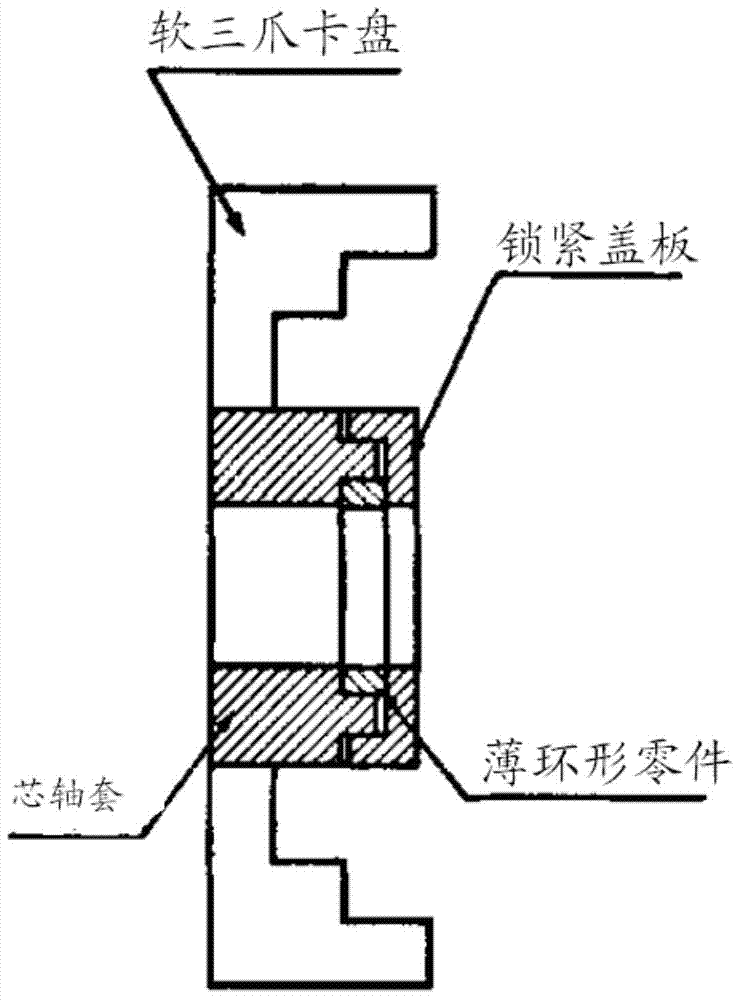

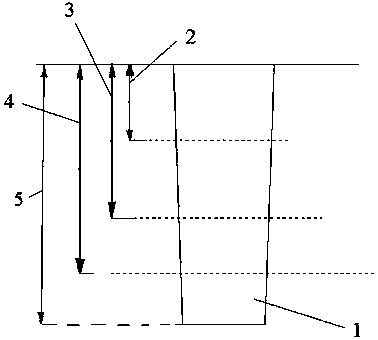

Processing technology for thin annular parts

InactiveCN103692159AEliminate internal stressGuaranteed Tolerance RequirementsMechanical engineering

The invention discloses a processing technology for thin annular parts. The problems that the out-of-tolerance of size and geometric tolerance of the thin annular parts is easily caused in the traditional processing technology are solved. The processing technology for thin annular parts comprises the following steps of: installing a core shaft, and turning an outer circle; sleeving the outer circle and turning an inner circle; carrying out aging treatment. The processing technology for the thin annular parts is reasonable, and the finishing quality of the thin annular parts is improved.

Owner:CHANGZHOU UNIV

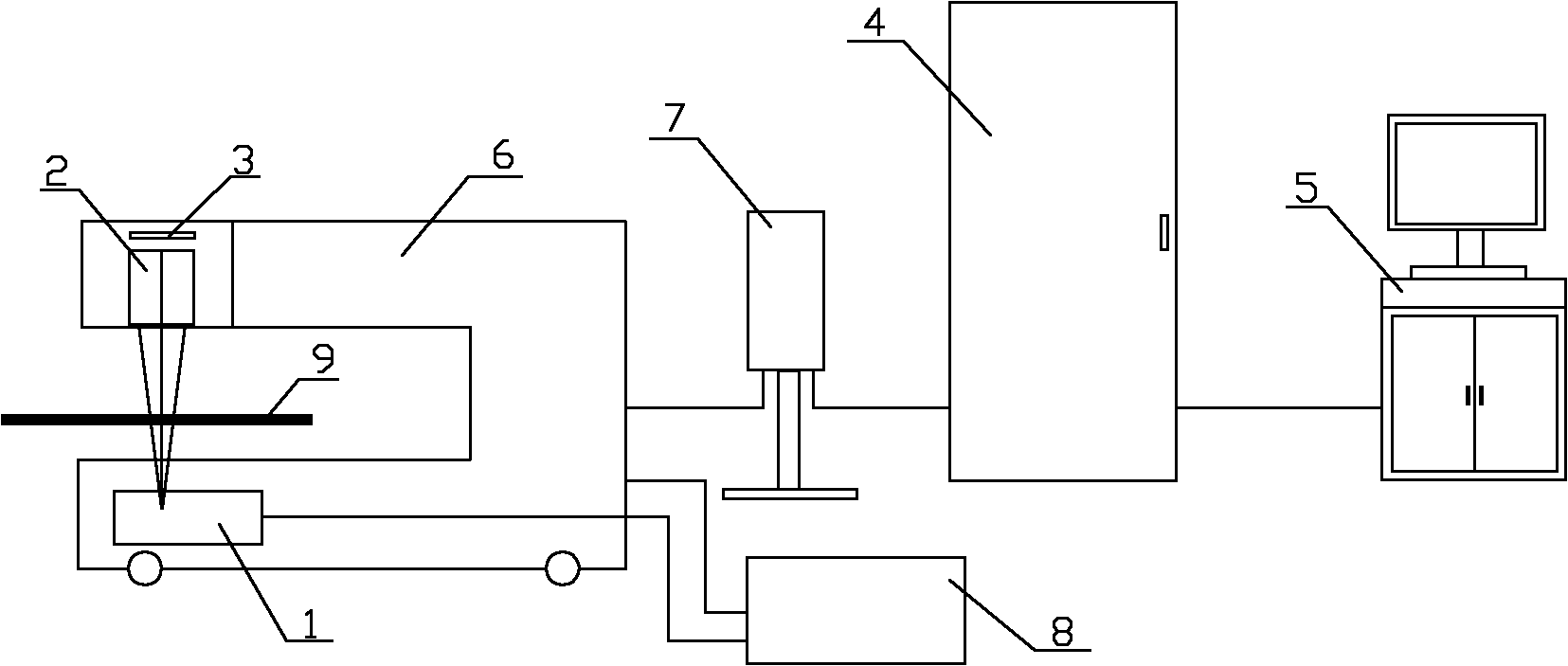

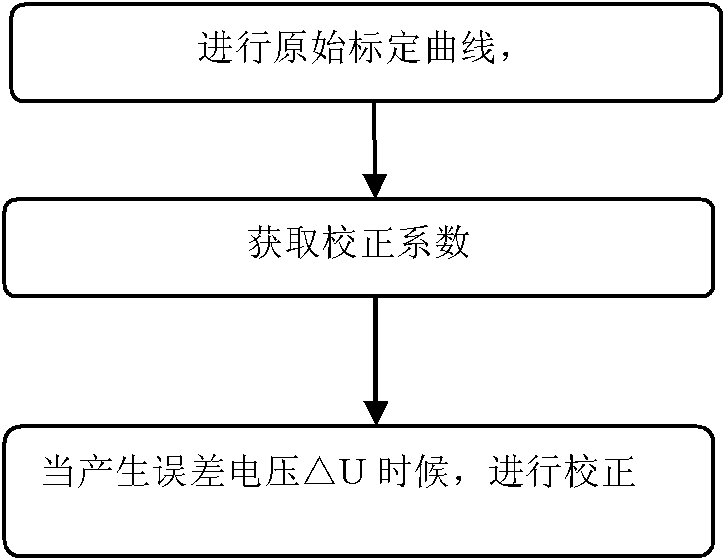

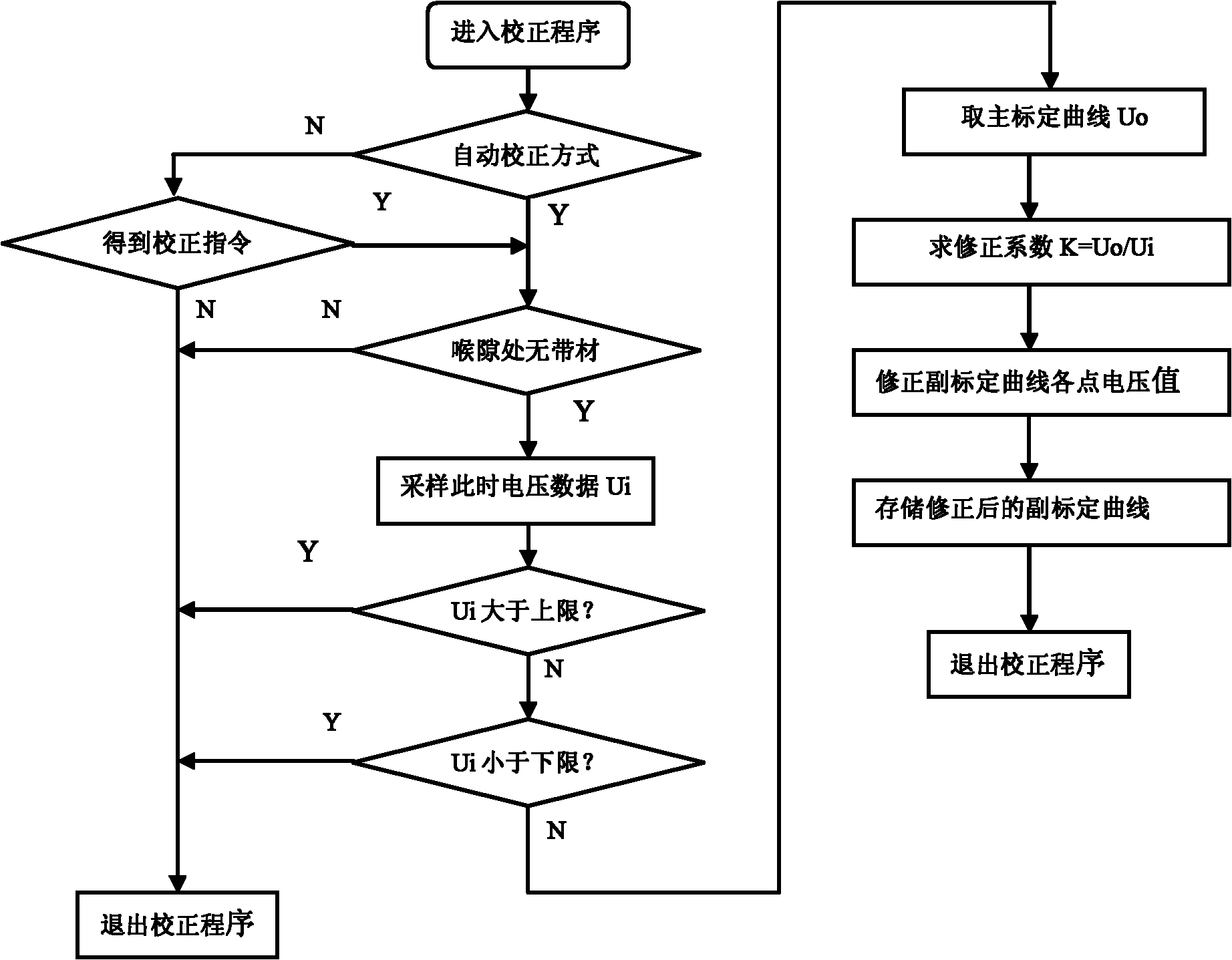

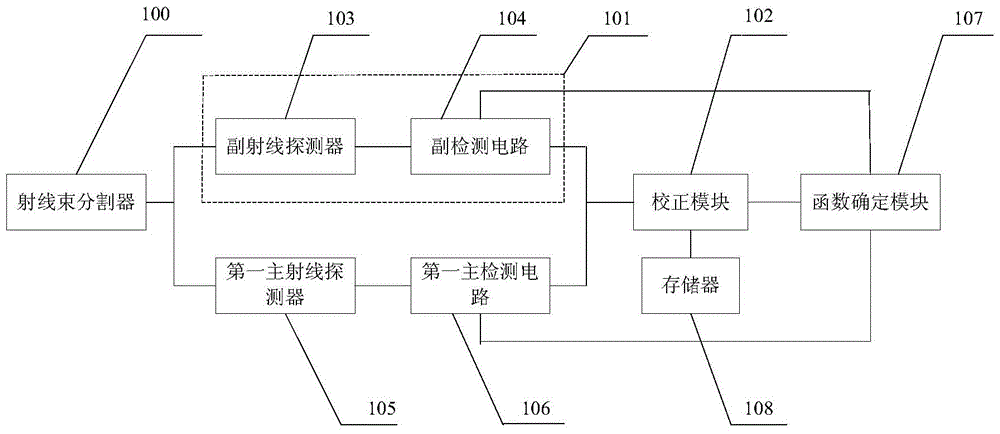

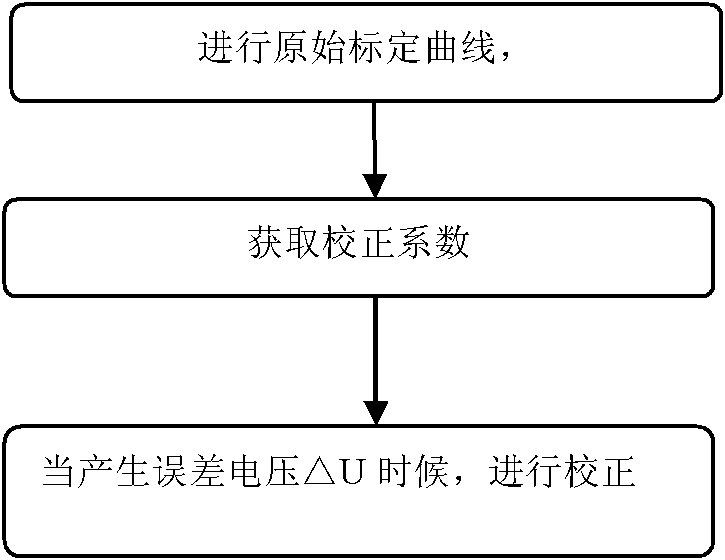

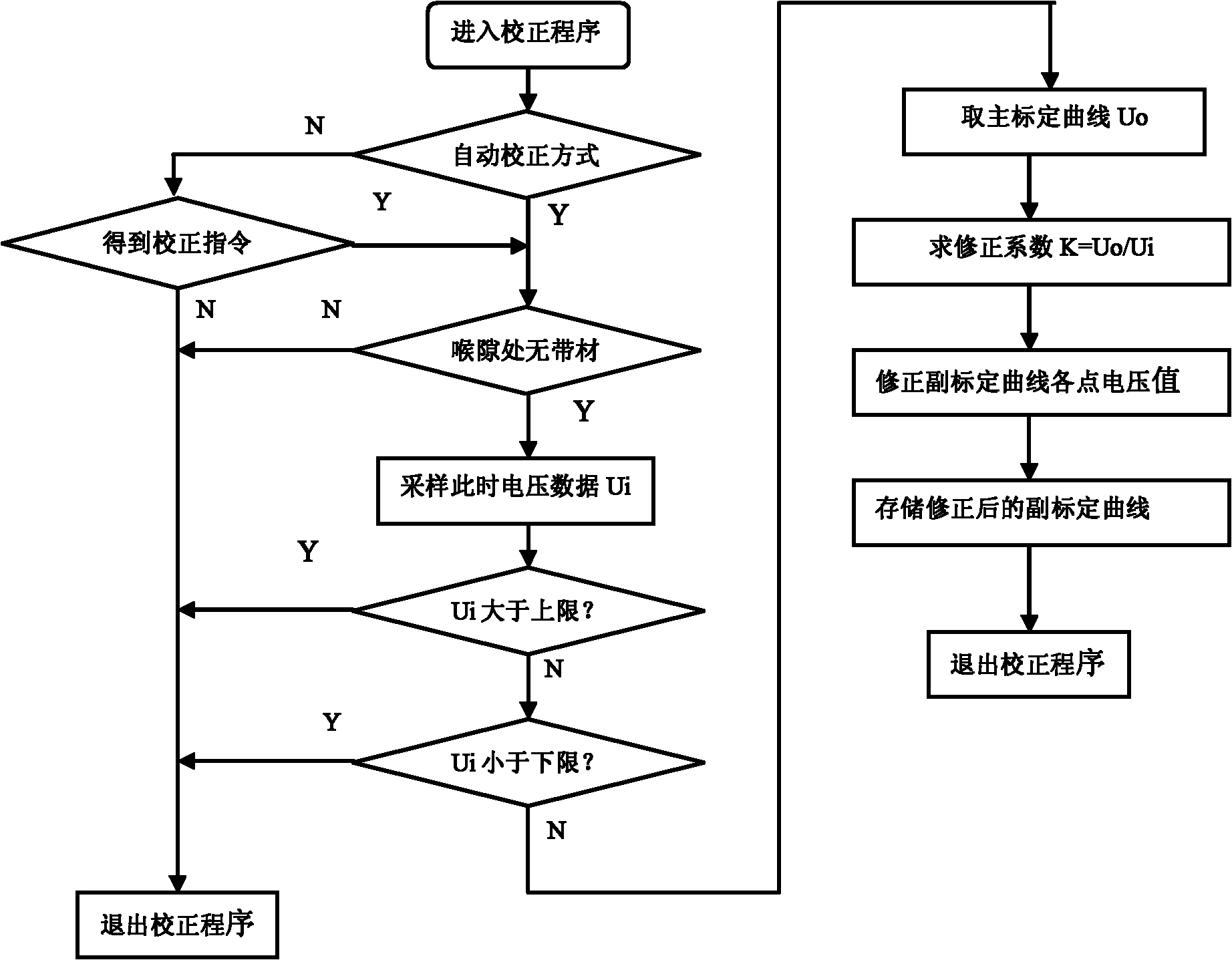

Ray-type thickness gauge and calibration method thereof

InactiveCN102564361AEliminate errorsIncrease productivityUsing wave/particle radiation meansControl systemCorrection method

Owner:BEIJING ARITIME INTELLIGENT CONTROL

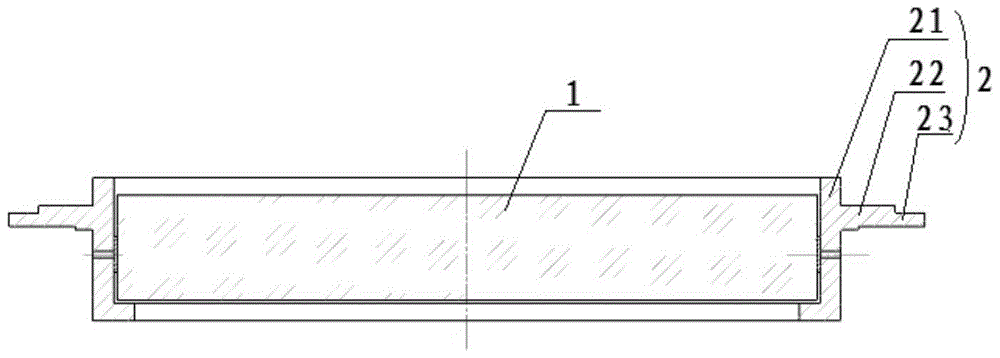

Novel magnetic suspension energy storage flywheel rotor

InactiveCN109510382AIncrease speedIncrease the lengthMagnetic circuit rotating partsMechanical energy handlingMagnetic bearingHigh intensity

The invention discloses a novel magnetic suspension energy storage flywheel rotor. The novel magnetic suspension energy storage flywheel rotor is composed of a motor rotor, a magnetic bearing rotor, aflywheel upper shaft and a flywheel lower shaft; the motor rotor is adhered to the flywheel upper shaft and the flywheel lower shaft through a magnetic steel partition plate, and is connected with anon-magnetic alloy steel sheath, so that tensile stress generated by a centrifugal force during high-speed rotation can be offset; high-strength laminations are adopted as the laminations of the magnetic bearing rotor, and a high lamination coefficient is ensured so that the magnetic bearing rotor can withstand the centrifugal force generated by the high-speed rotation of the flywheel rotor; a speed sensor is integrated at a position close to the magnetic bearing rotor, and therefore, the detection accuracy of the sensor can be improved. The novel magnetic suspension energy storage flywheel rotor of the present invention is a comprehensive design based on rotor structural strength, dynamic characteristics and electromagnetic characteristics.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Method for processing crankshaft of multiaxial warp knitting machine

The embodiment of the invention discloses a method for processing a crankshaft of a multiaxial warp knitting machine. The crankshaft comprises a spindle diameter and a connecting rod diameter. The connecting rod diameter is connected with the spindle diameter. The method comprises the following steps of: step A: processing a raw material through the steps of drilling a first center hole, roughly turning, hardening and tempering, and fine turning an outer diameter to obtain a polished shaft; step B: respectively drilling a second center hole of the crankshaft and a third center hole of the connecting rod diameter at the opposite positions at both ends of the polished shaft, drilling a process positioning hole at the position at a distance of 20mm from the first center hole, carrying out fine turning on the spindle diameter and the connecting rod diameter according to the process positioning hole, the second center hole and the third center hole, and carrying out milling and rough grinding to obtain a semi-finished product; and step C: carrying out high-frequency quenching on the semi-finished product, drilling and reaming pin holes at both ends of the semi-finished product and carrying out fine grinding processing to obtain a finished product. In the embodiment of the invention, when the outer diameter, the spindle diameter and the connecting rod diameter are subjected to fine turning, positioning is carried out through the process positioning hole and the respective center holes, so that when the outer diameter, the spindle diameter and the connecting rod diameter are processed, the requirement on a tolerance of the eccentricity of the connecting rod diameter and the spindle diameter of the crankshaft can be guaranteed.

Owner:沈阳气体压缩机制造有限公司

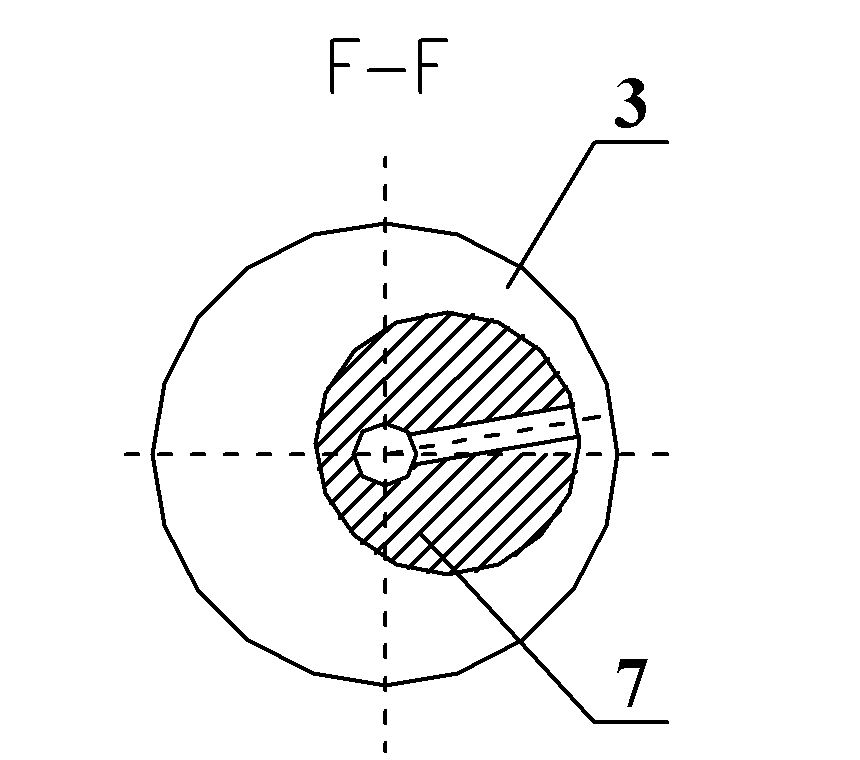

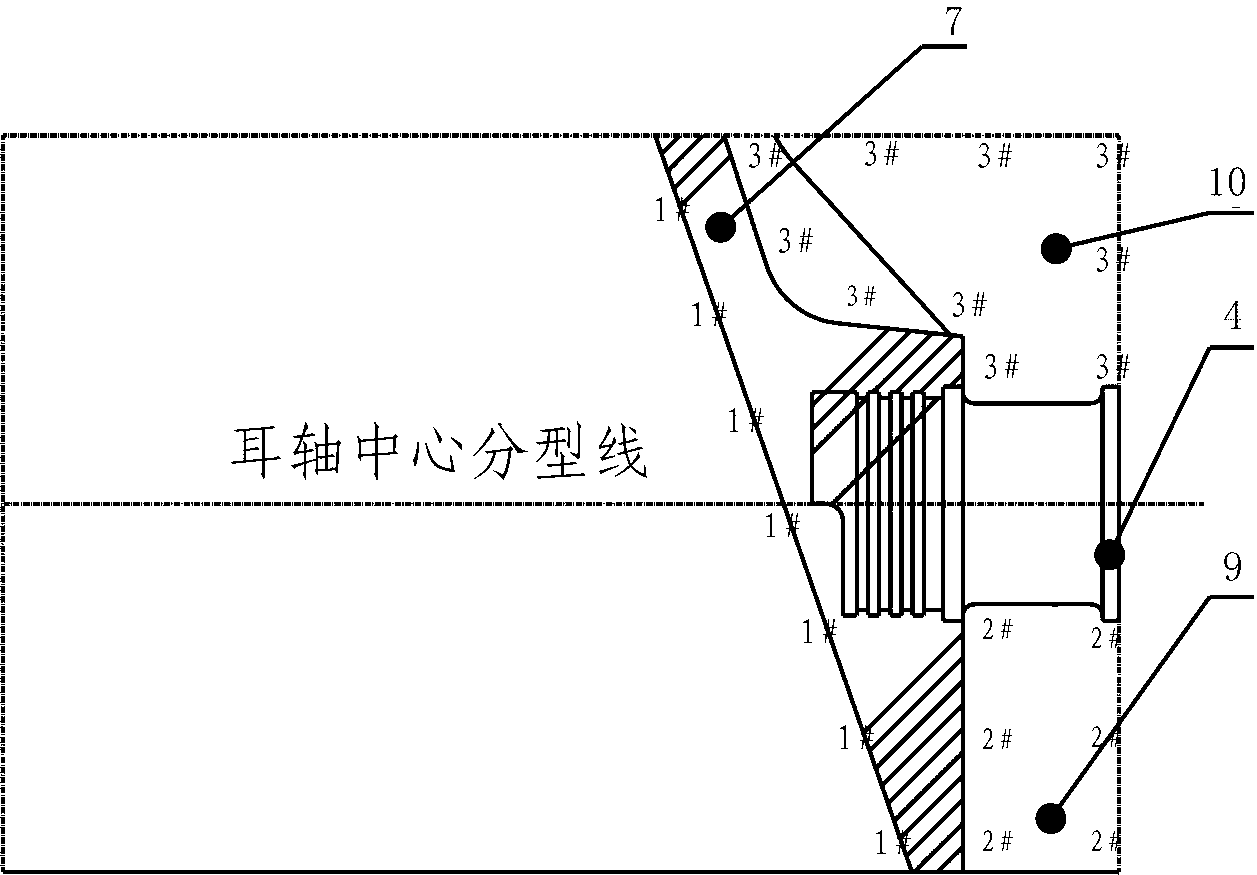

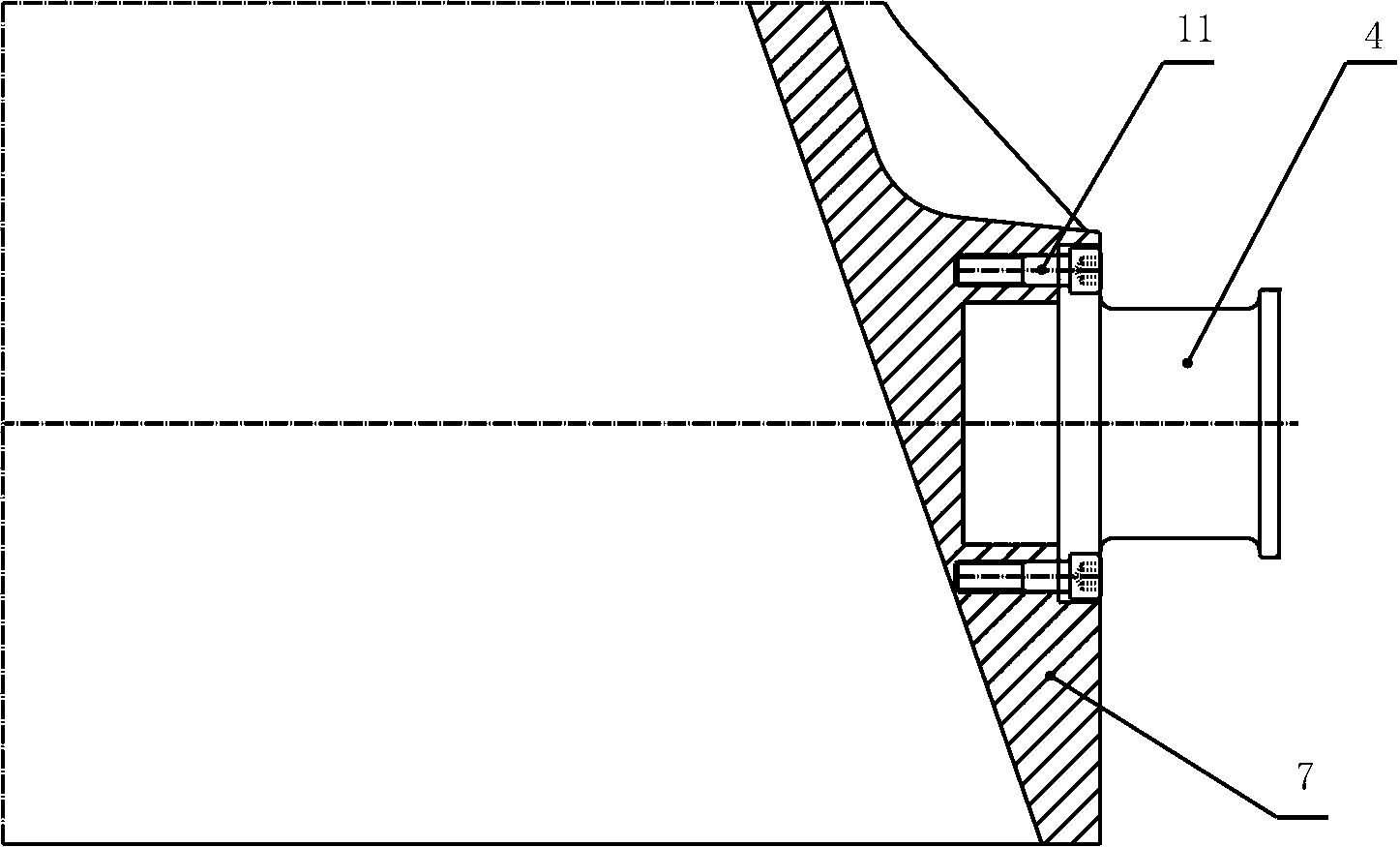

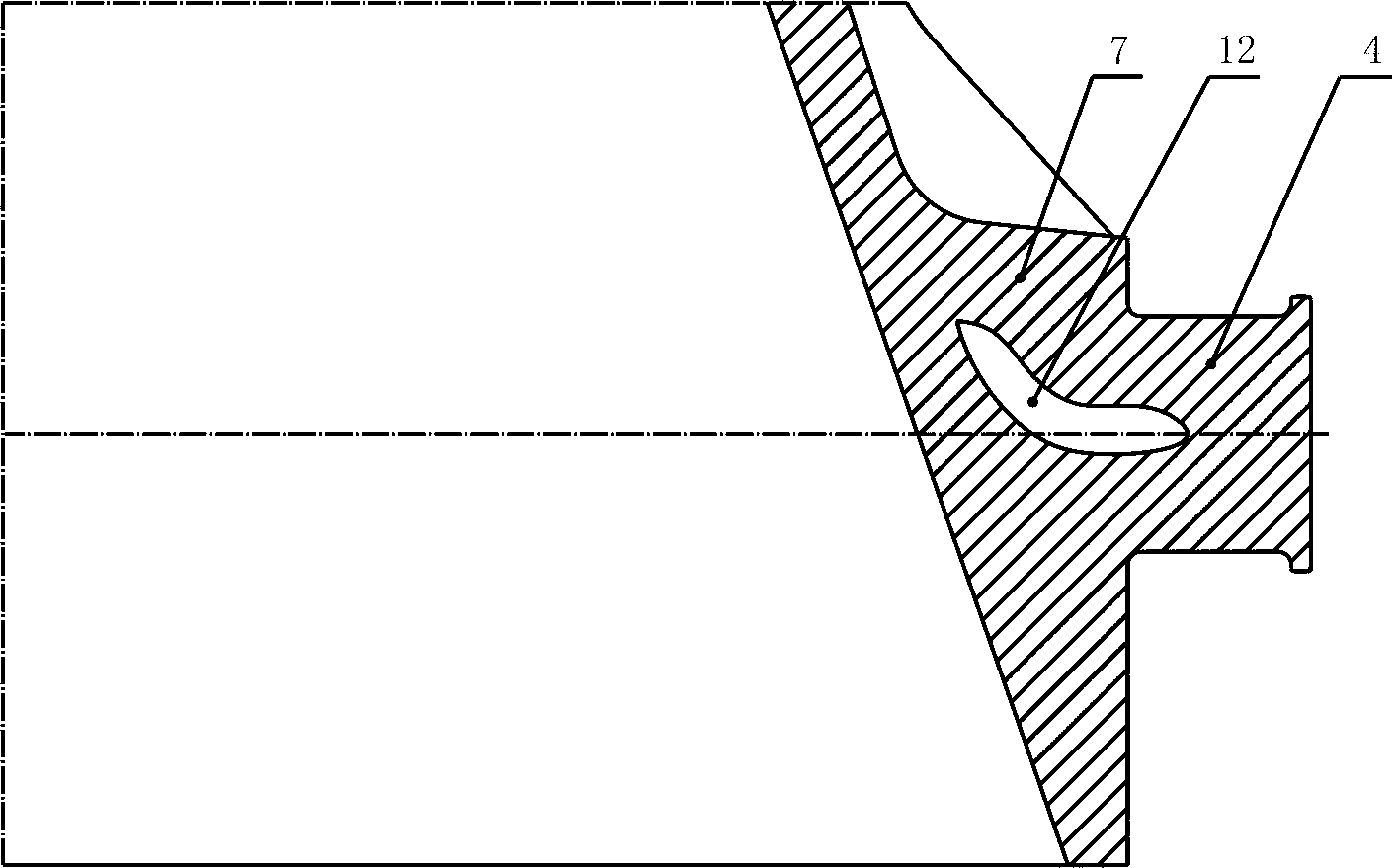

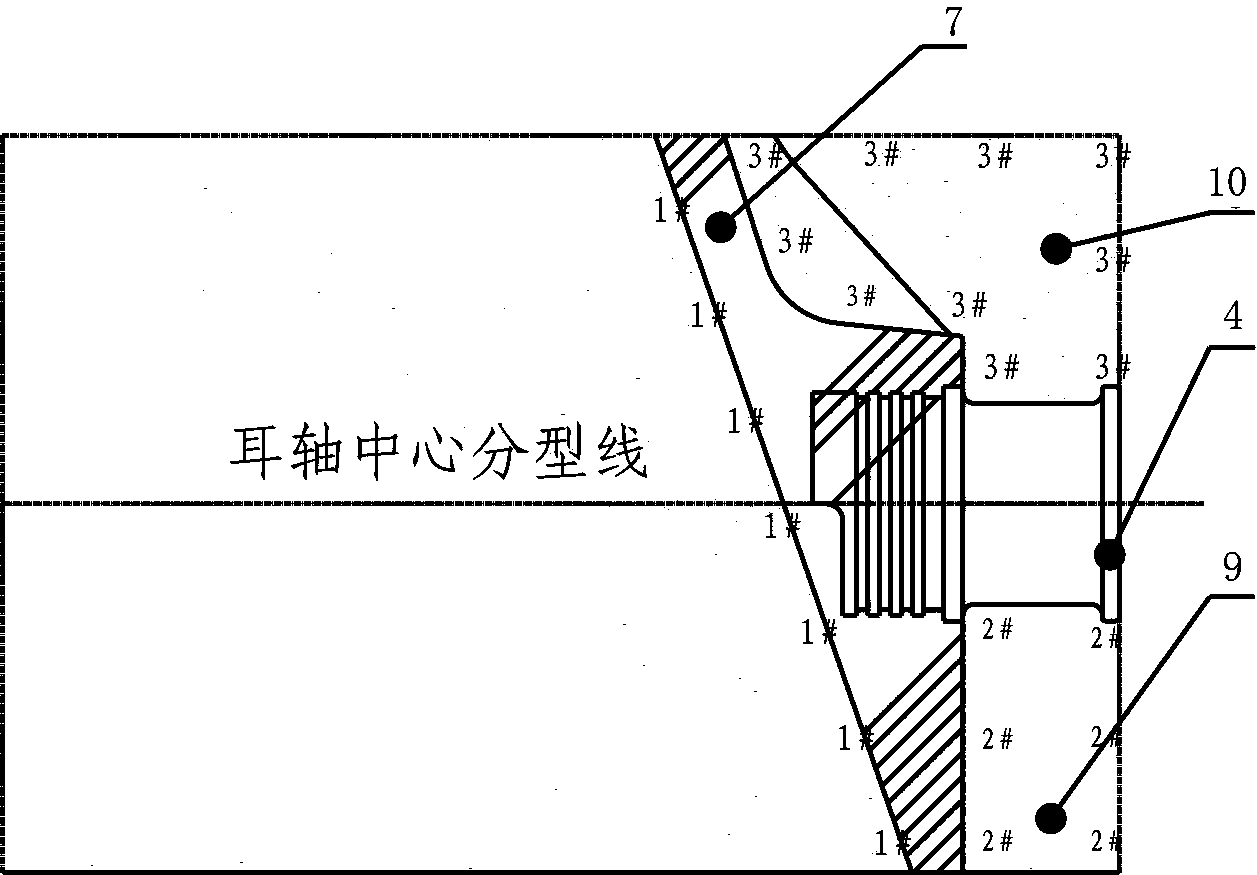

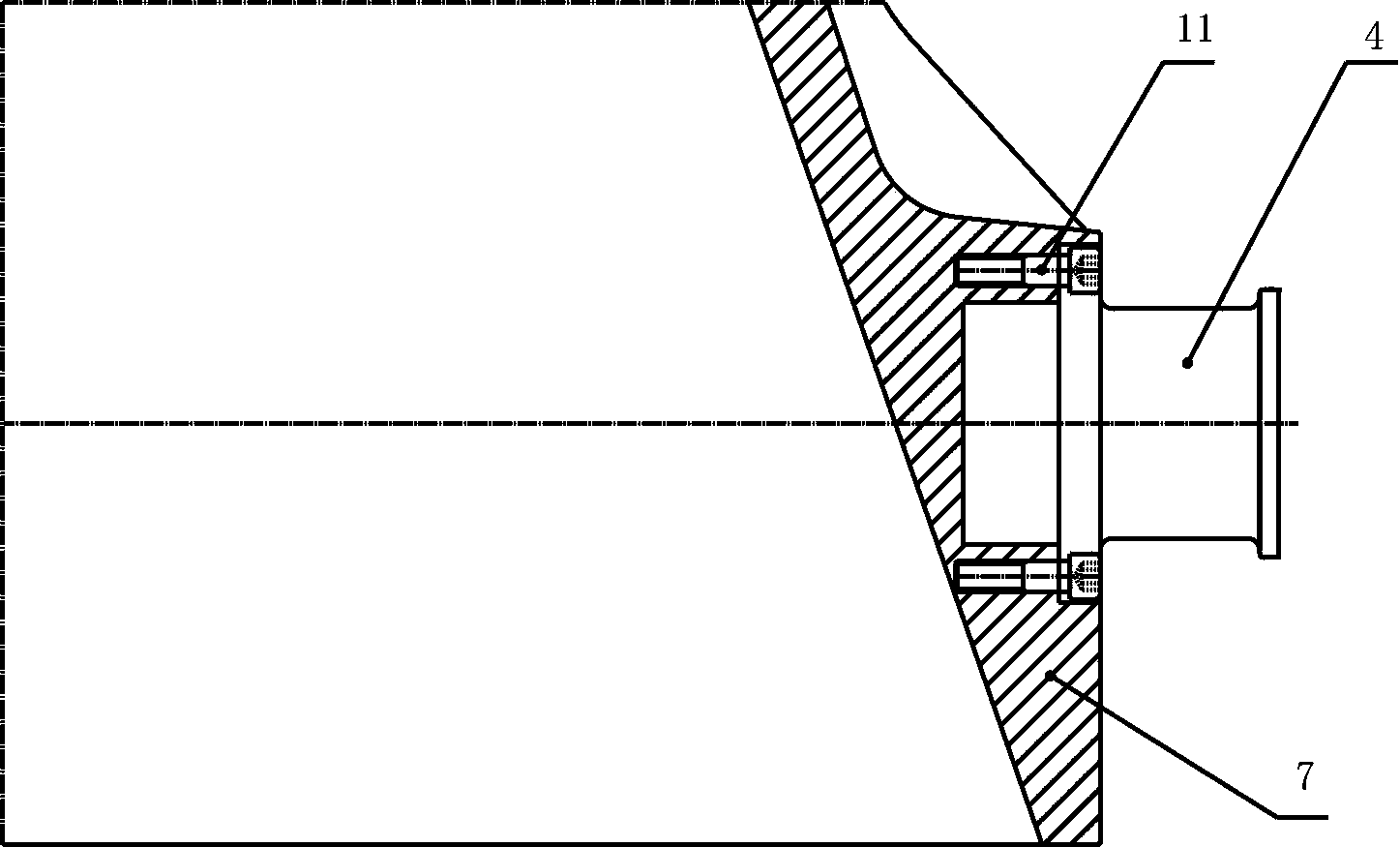

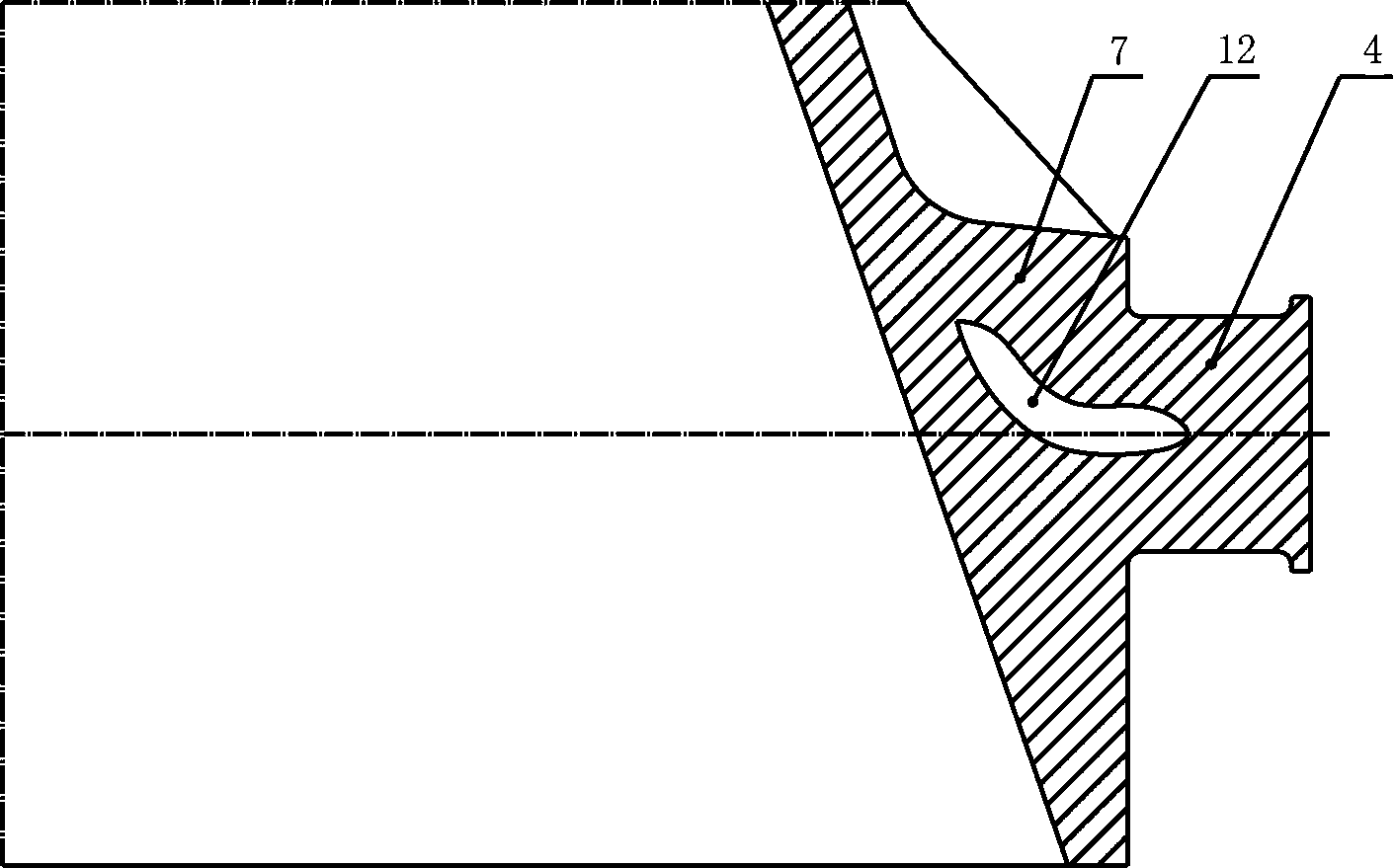

Trunnion imbedding method of metallurgical slag pot

The invention relates to a trunnion imbedding method of a metallurgical slag pot. A processed trunnion is cast on a slag pot body to complete casting of the trunnion and the slag pot body when the slag pot body is cast. The trunnion imbedding method comprises the following steps of (1) preparing an outer sand mould; namely transversely embedding the processed trunnion in the sand mould, and stretching an inside end of the trunnion into a cavity of the outer sand mould; and (2) enabling the outer sand mould to be sleeved on an inner sand mould, casting molten steel in a cavity between an outer sand mould model and an inner sand mould model, casting the trunnion on the slag pot body, removing the sand moulds after cooling, and completing the casting of the trunnion and the slag pot body. The trunnion imbedding method is simple in operation, high in work efficiency, short in production period and low in production cost.

Owner:武钢集团襄阳重型装备材料有限公司

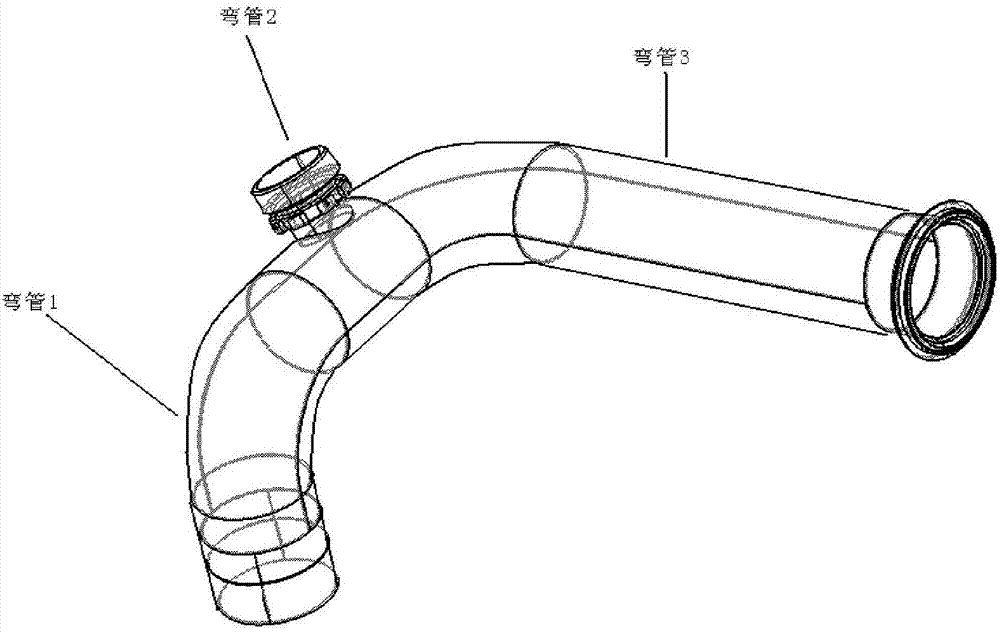

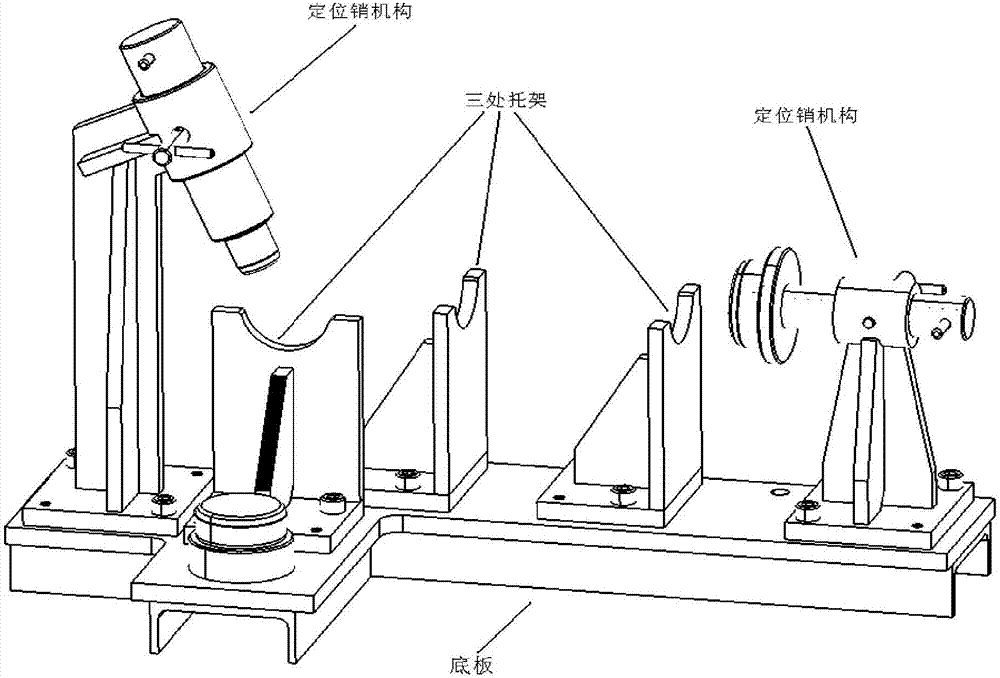

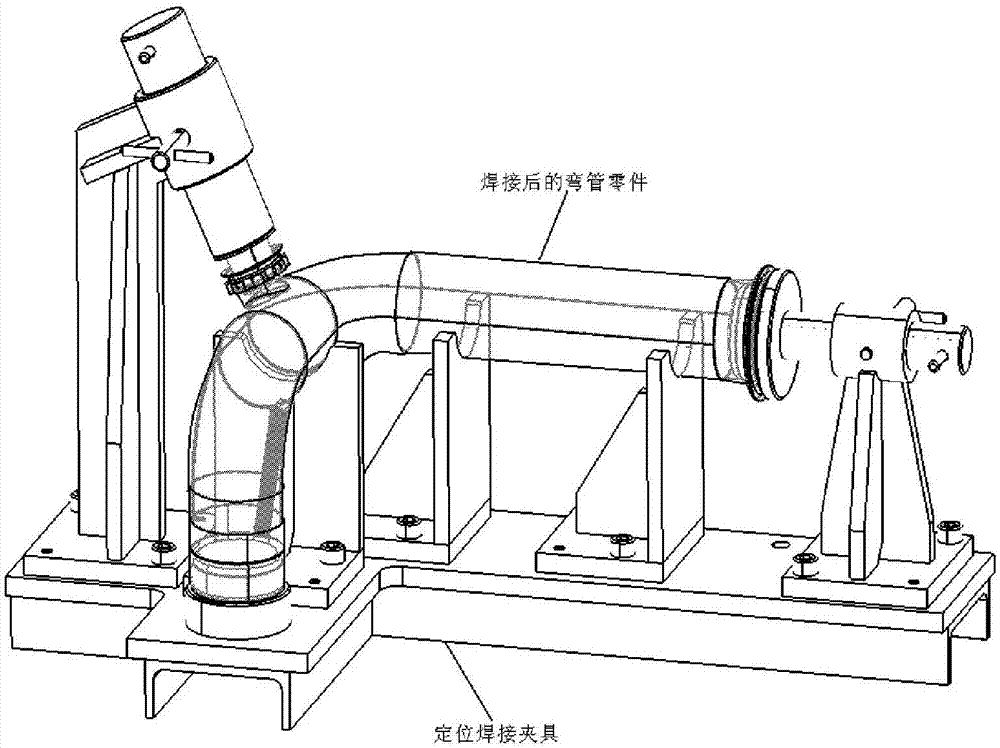

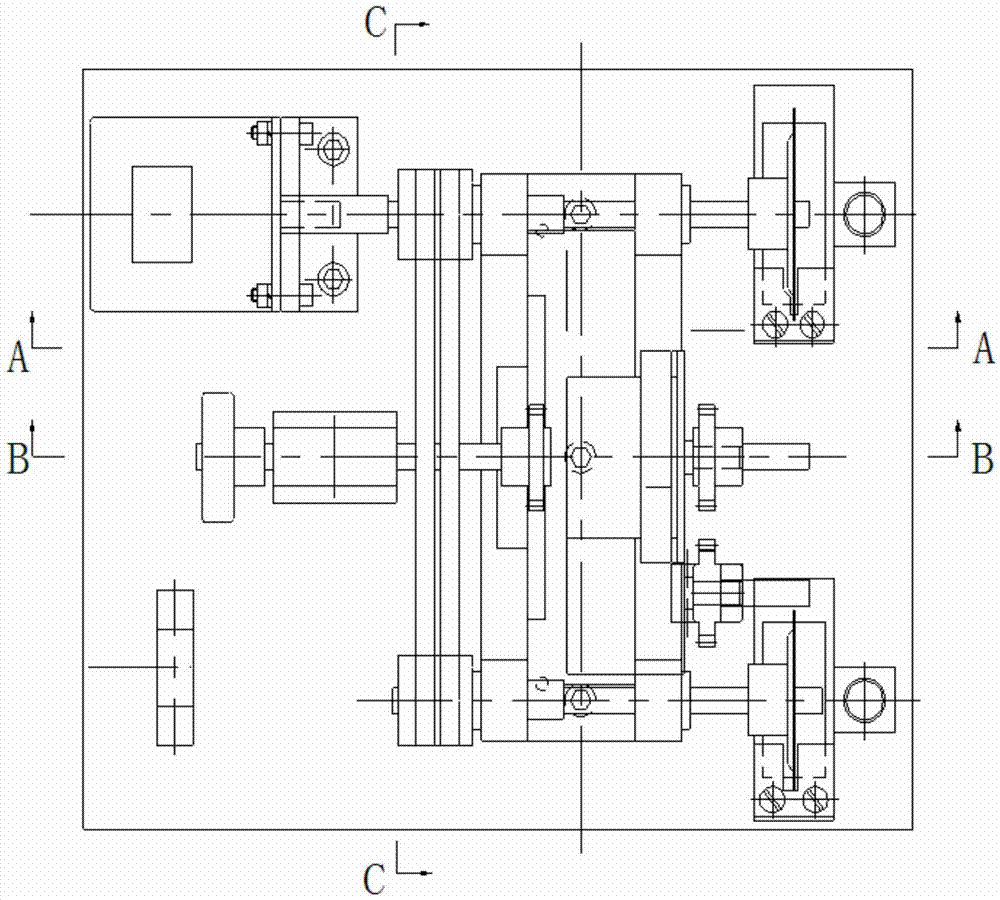

Method for machining positioning welding clamp

ActiveCN106956112AGuaranteed Tolerance RequirementsGuaranteed positional relationshipWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInternal forces

The invention belongs to the field of machining, and provides a method for machining a positioning welding clamp. The machining method includes the steps that firstly, a bottom plate used for connecting three brackets and two positioning pin mechanisms is machined, and position lines of the brackets and the positioning pin mechanisms are drawn through a numerically-controlled needle; secondly, after single-piece machining and welding are conducted on the brackets and the positioning pin mechanisms, internal force is removed through annealing, the bottom faces of the brackets and the positioning pin mechanisms are milled to be flat through a milling machine, and it is ensured that the brackets and the positioning pin mechanisms are attached to the bottom plate; and thirdly, the whole bottom plate, the whole brackets and the whole positioning pin mechanisms are machined, the bottom plate, the brackets and the positioning pin mechanisms are measured to be qualified after numerically-controlled machining, and inspection is conducted after bench workers polish numerically-controlled machining moulding faces. The machining method has the beneficial effects that due to the adoption of the machining method, the relative position relationship of the three brackets and the positioning pin mechanisms can be ensured, and the tolerance requirement of the positioning and welding clamp can be ensured.

Owner:SHENYANG AIRCRAFT CORP

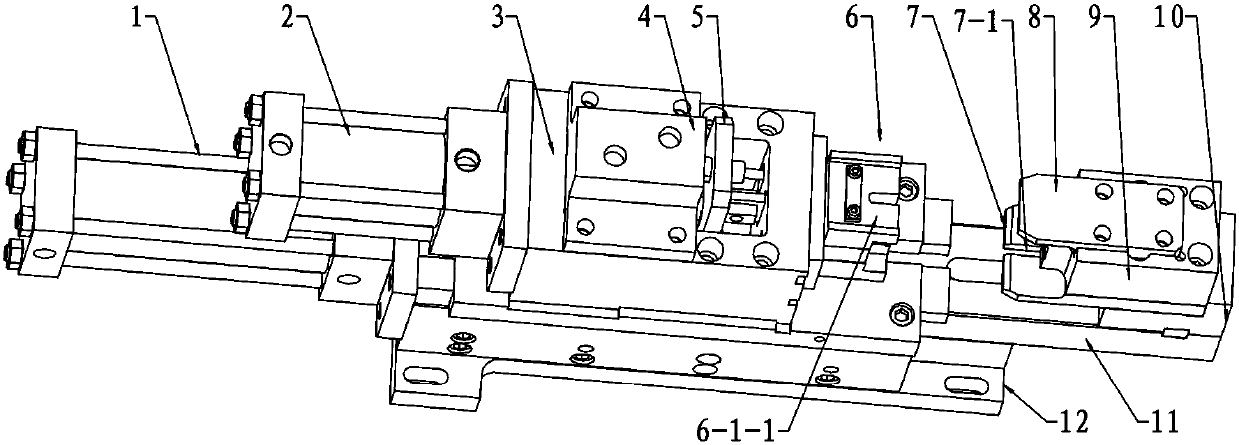

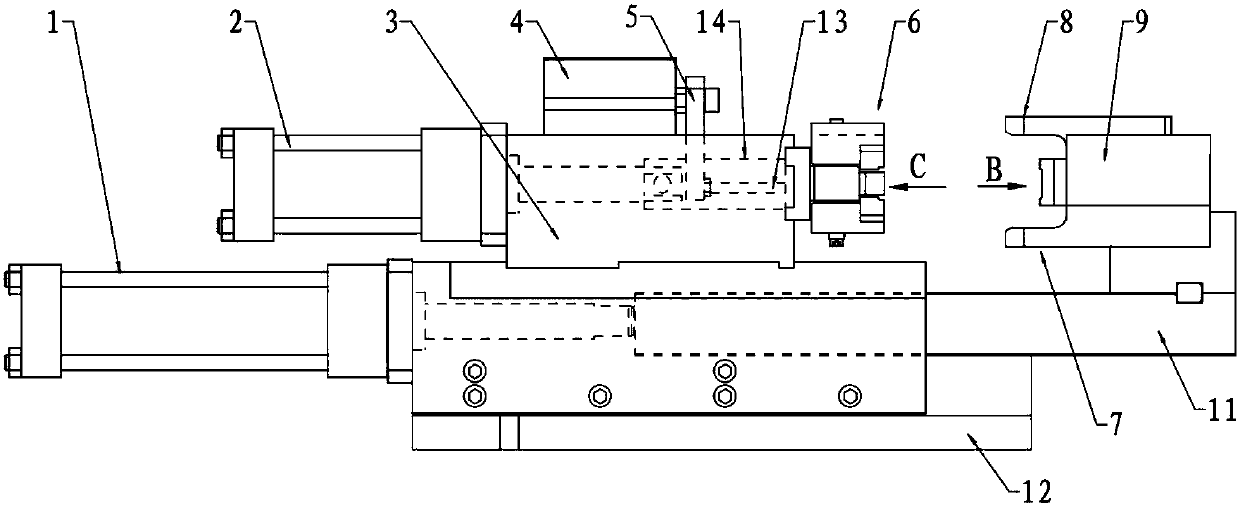

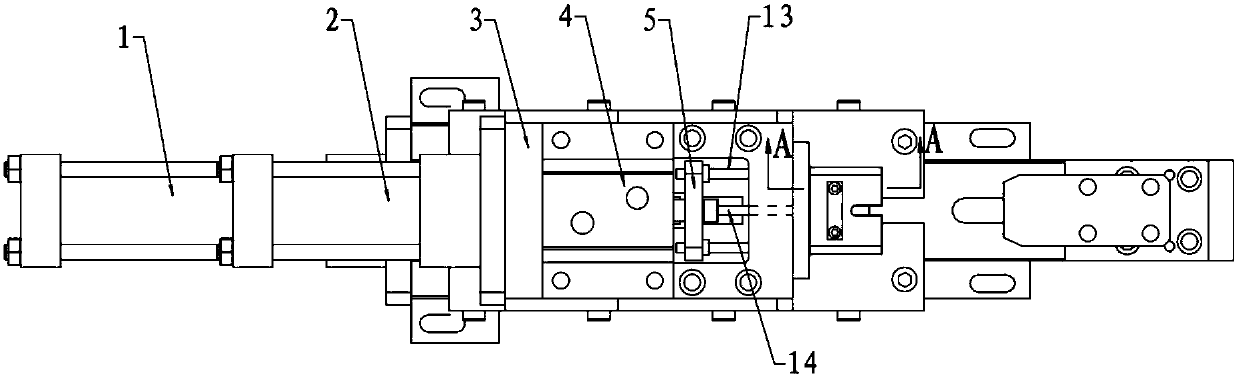

Cutting-off and material returning device for cutting off automobile door glass guide rails

ActiveCN105772838AIncrease productivityNo deformationMetal-working feeding devicesNibbling shearing machinesReturn functionEngineering

A cutting-off and material returning device for cutting off automobile door glass guide rails comprises a base, a clamping mechanism, a cutting-off mechanism and a material returning mechanism. The clamping mechanism comprises a clamping oil cylinder, a sliding block, a movable clamping block and a clamping assembly. A clamping oil cylinder piston rod is fixedly connected with one end of the sliding block, and the other end of the sliding block is fixedly connected with the movable clamping block through a movable clamping block mounting seat. An upper wedge and a lower wedge are fixed to the upper portion and the lower portion of the movable clamping block correspondingly. The clamping assembly comprises an upper knife, a middle shaping plate and a lower knife. The middle shaping plate is fixed to a mounting frame. The upper knife and the lower knife are connected to the upper portion and the lower portion of the middle shaping plate in a floating mode correspondingly. The front end of the movable clamping block corresponds to the middle shaping plate. The upper wedge and the lower wedge correspond to the upper portion of the upper knife and the lower portion of the lower knife respectively. The cutting-off mechanism comprises a cutting-off oil cylinder and a cutting-off knife. The material returning mechanism comprises a material returning oil cylinder and a material returning rod. According to the cutting-off and material returning device for cutting off the automobile door glass guide rails, structure setting is ingenious, feeding is convenient, material returning is smooth, non-deformation of cut-off products can be guaranteed, and an automatic material returning function can be completed after cutting-off.

Owner:凌云工业股份(芜湖)有限公司

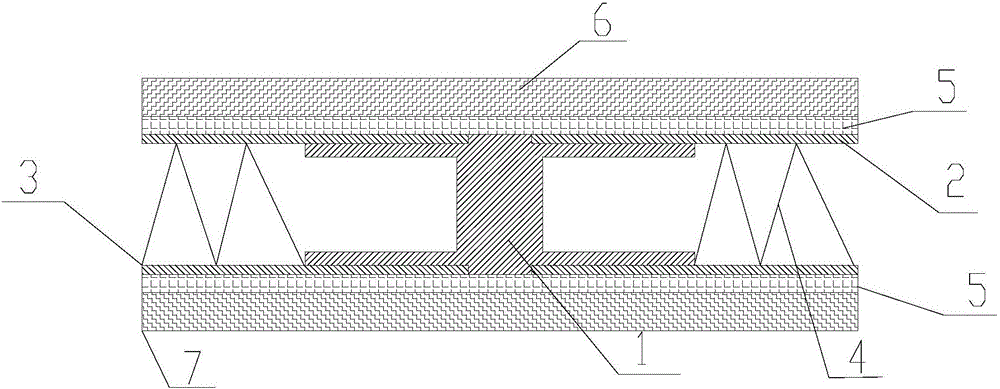

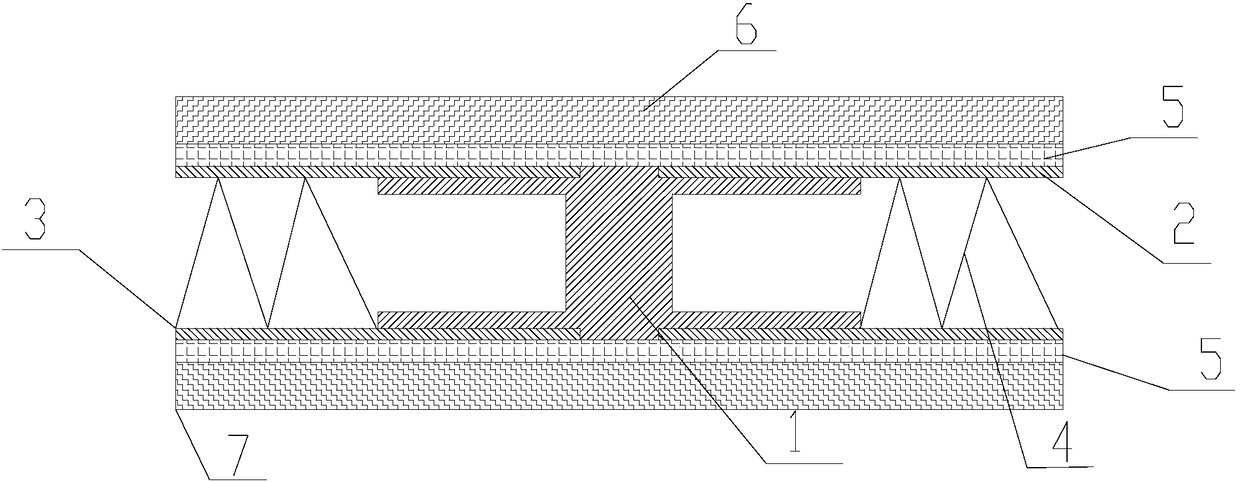

Two-dimensional high-precision worktable with grating ruler

InactiveCN108127803AGuaranteed precise arcGuaranteed Tolerance RequirementsUsing optical meansWorking accessoriesGratingMachine parts

A two-dimensional high-precision worktable with a grating ruler comprises a motor I, a fixed seat, a grating ruler reading head, a sliding seat I, a grating head mounting support, a grating ruler seat, a motor II, the grating ruler, a grating support and a sliding seat II; the motor I is connected with the sliding seat I through a transmission mechanism I, and the grating head mounting support ismounted on the sliding seat I; the grating ruler reading head is mounted on the grating head mounting support; the grating ruler seat is mounted on the fixed seat; when the sliding seat I moves up anddown, the grating ruler reading head and the grating ruler seat make mutual movement, and the grating ruler reading head records the moving trajectory; the sliding seat II is connected with the sliding seat I through a sliding block; the motor II drives the sliding seat II through a transmission mechanism II to move relative to the sliding seat I; the grating ruler is fixed to the sliding seat I;the grating support is fixed to the sliding seat II; and when the sliding seat II moves forwards and backwards, the grating ruler records the moving trajectory. Through the two-dimensional high-precision worktable, the accurate radian feeding mode of a tile-shaped wire cutting machine can be guaranteed, and the tolerance requirement of a machined part R1 is guaranteed.

Owner:HUNAN YUJING MACHINE

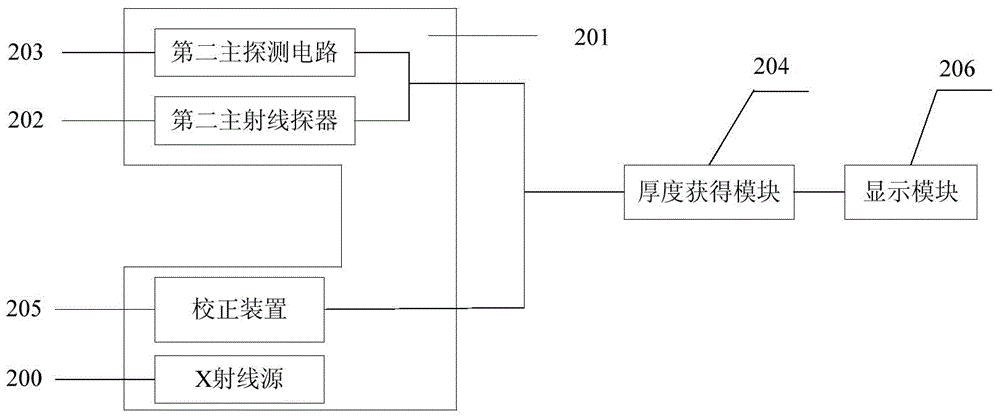

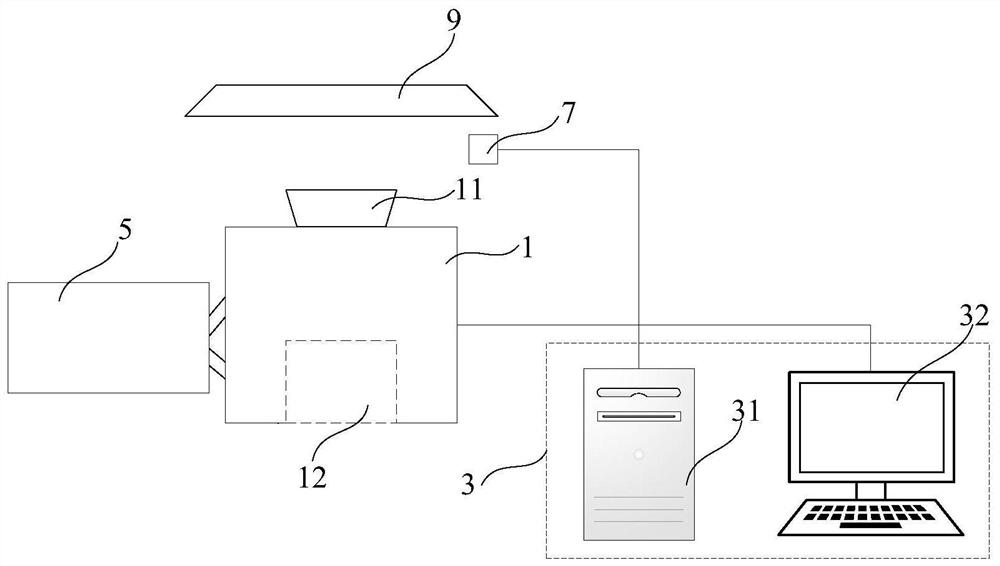

An online calibration device and method for an X-ray thickness gauge

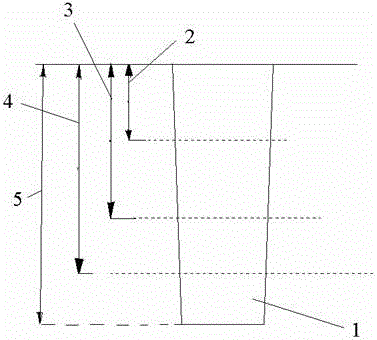

ActiveCN104475462BGuaranteed Tolerance RequirementsEliminate the effects of measurement accuracyMeasuring devicesMetal rolling arrangementsSoft x rayControl system

The invention provides an on-line correction device and method of an X-ray thickness gauge. The method includes that during measurement of the X-ray thickness gauge, X ray is divided into working ray and non-working ray, the working ray is used for measuring thickness of a measured object, and the non-working ray is used for obtaining strength of the X ray; the strength of the X ray is monitored according to the non-working ray; when the strength change of the X ray exceeds a threshold value, a calibration curve is corrected, and the calibration curve is a relation curve between the working ray and the thickness of the measured object. The on-line correction device and method of the X-ray thickness gauge has the advantages that the influence of the strength changes of the X ray on the measuring accuracy can be eliminated, accurate thickness measured values can be provided for a rolling mill thickness controlling system, increasing of the controlling accuracy of a rolling mill can be facilitated, and the requirement of tolerance of rolled strip materials can be guaranteed.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

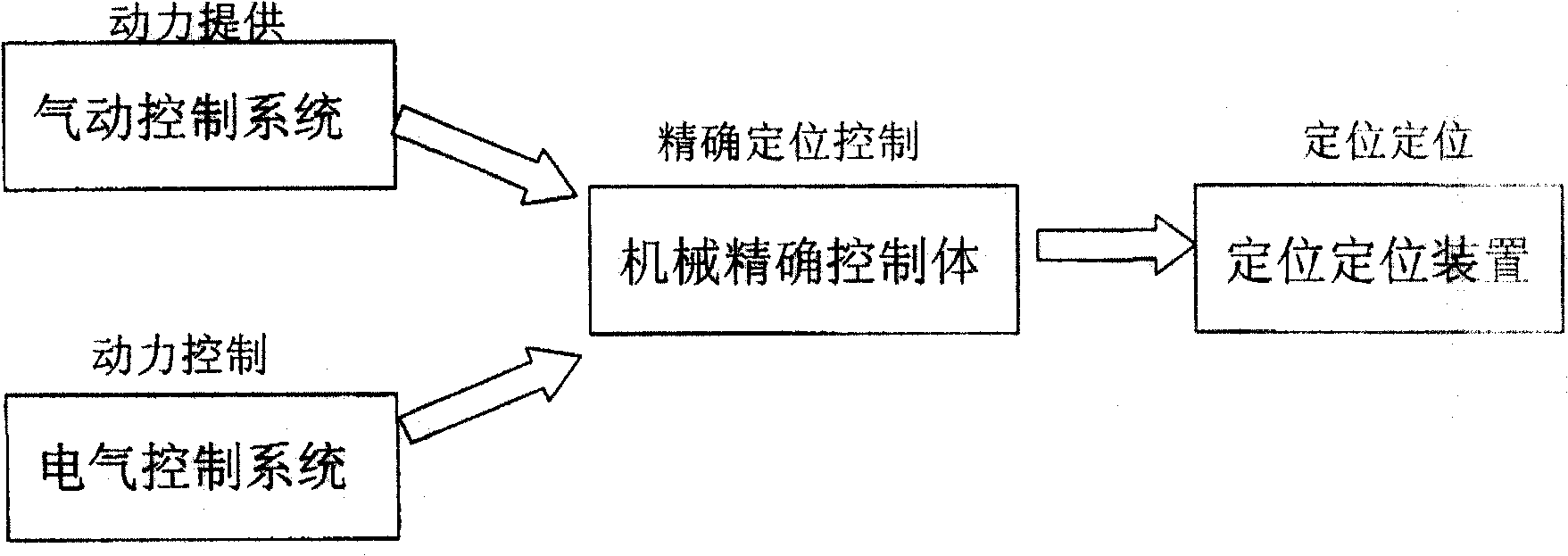

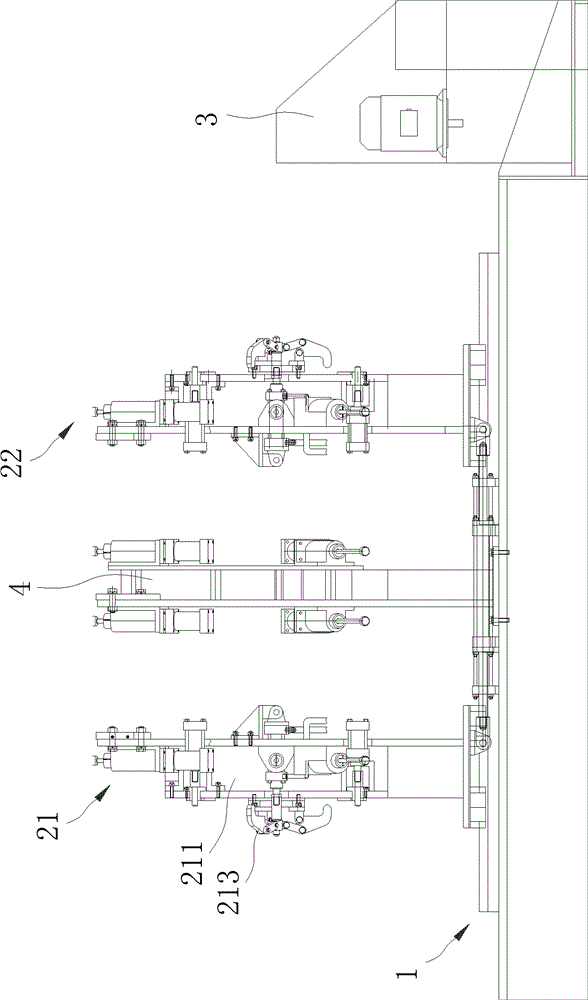

Pneumatic control localizer

ActiveCN100453267CReduce training timeReduce demandAutomatic control devicesFeeding apparatusControl theoryProduction cycle

The present invention discloses an aerodynamic control localizer comprising a mechanical locating controller, a locating rod moving through the mechanical locating controller and electric and aerodynamic parts. The present invention is characterized in that the lower end of the locating rod which is equipped and can slide in the mechanical locating controller is connected with a floating head connected with a cylinder link lever and an initiative locating shim which makes the locating rod end reach the initiative locating position; the cylinder link lever drives the locating rod move axially by the connected axial cylinder; with a connected bullet pin, tangential cylinders equipped on both sides of the locating rod implement hole-to-hole location of the locating rod and the mechanical locating controller base to realize tangential location to make the locating device reach the final coordinate position. The localizer is characterized by simple flexible accurate structure, stable locating coordinates and conveniently controlled automatic operation. The present invention will thoroughly change and overcome the defect of the traditional screw type localizer that the locating accuracy is not high, location is not stable and the production cycle is long. Moreover, the volume is decreased by about one third compared with the tradition al screw type localizer.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

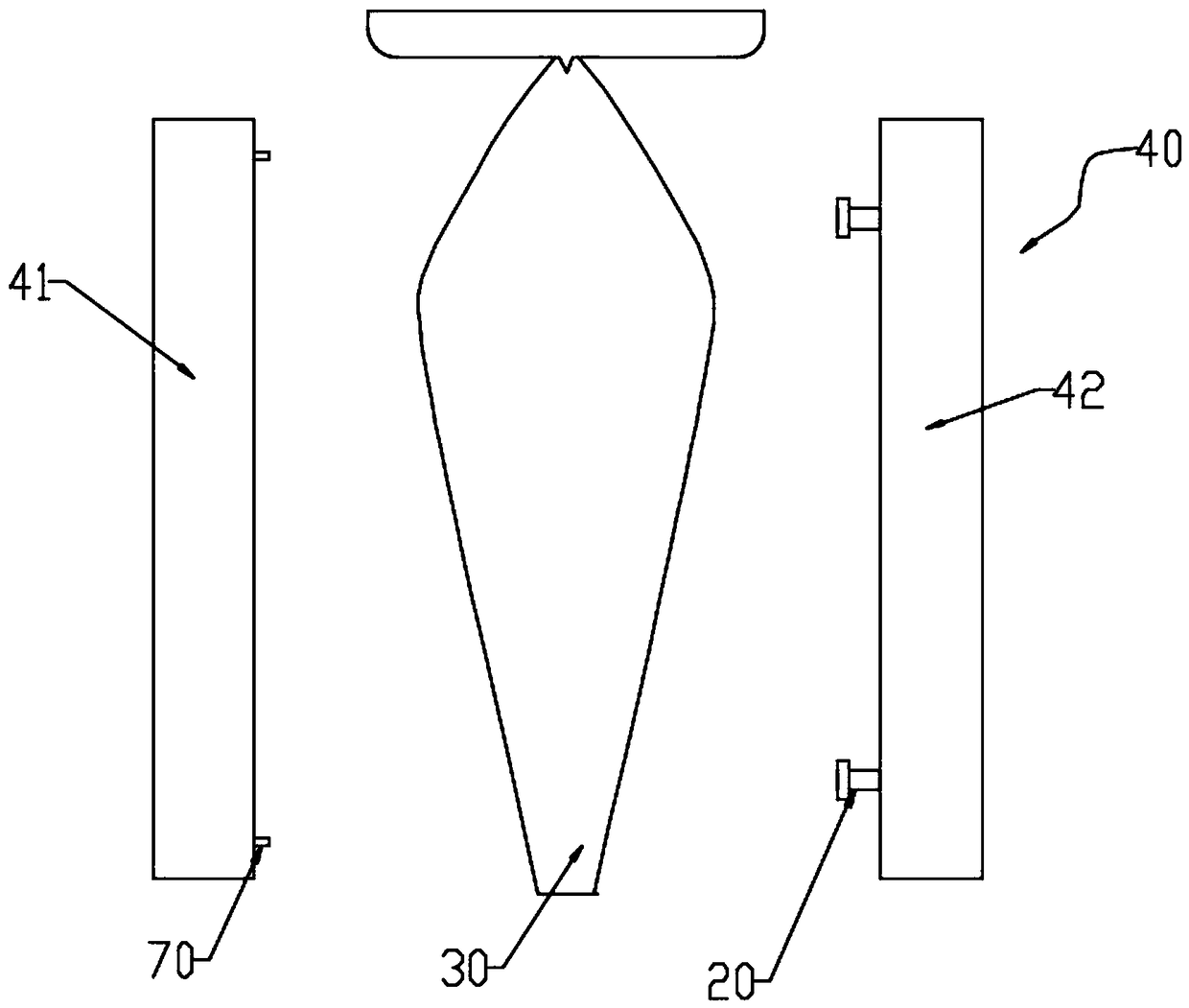

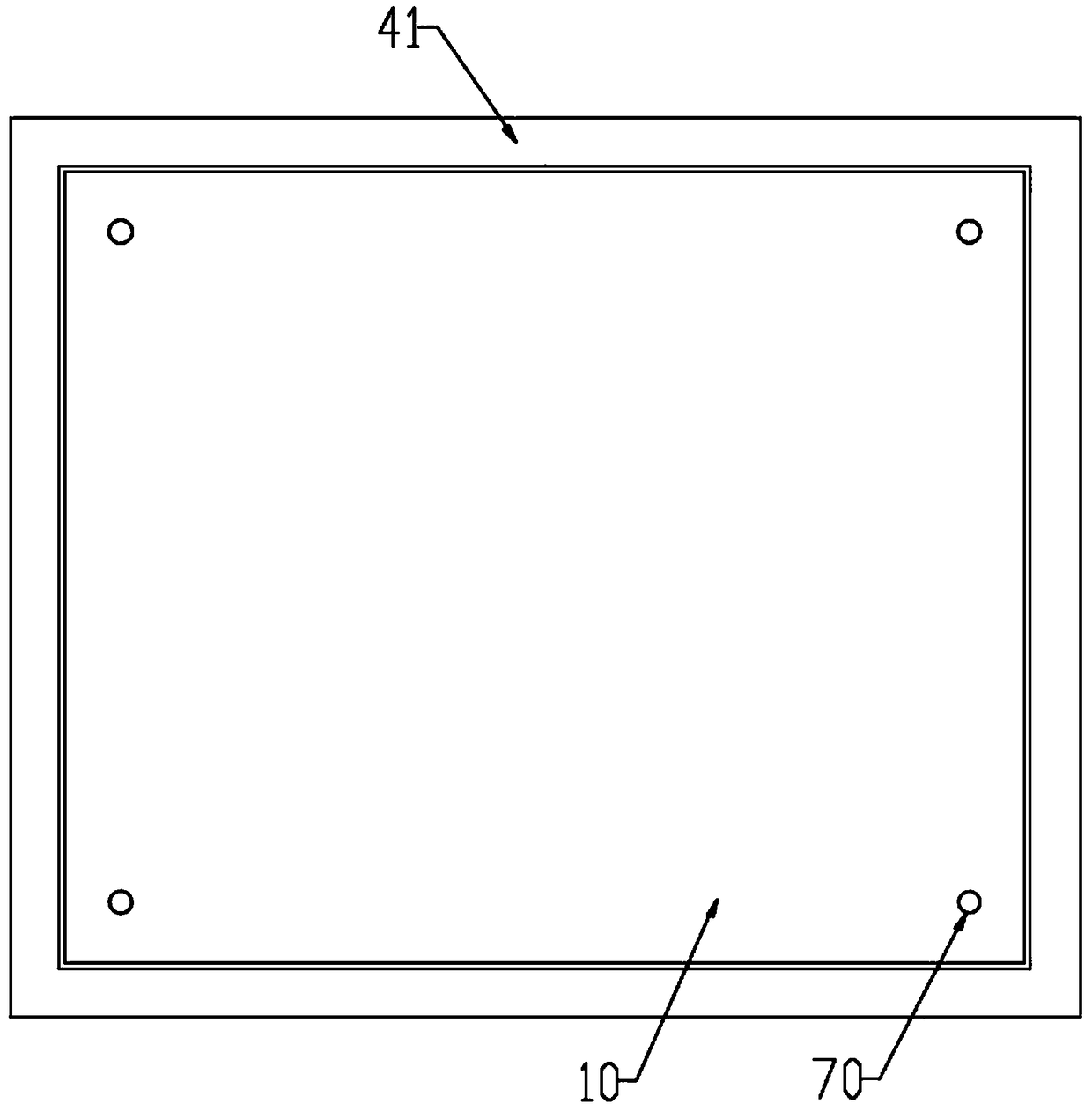

Tool for assembling and welding cylinder body

ActiveCN102500978BImprove general performancePrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention discloses a cylinder assembly welding tool, which comprises: a reference platform; a first mobile support and a second mobile support, which are movably arranged on the reference platform, so that the first mobile support and the second mobile support can be close to each other or Far away from each other, the first mobile bracket and the second mobile bracket are used to position and fasten the end plate and side plate of the cylinder body; the control part is used to control the first mobile bracket and the second mobile bracket to position and fasten the end plate and side plate , and control the movement of the first mobile bracket and the second mobile bracket on the reference platform, the cylinder assembly welding tool of the present invention has strong versatility, simple structure, convenient assembly of cylinder parts, high precision, and high degree of automation.

Owner:SANY HEAVY IND CO LTD (CN)

Spare tire cover plate production technology and mold for spare tire cover plate production technology and spare tire cover plate

InactiveCN108638481AIncrease productivityGuaranteed verticalityDomestic articlesSpare tireManufacturing engineering

The invention discloses a spare tire cover plate production technology, a mold for the spare tire cover plate production technology and a spare tire cover plate. The spare tire cover plate productiontechnology comprises the following steps of: preparing the mold, to be specific, hanging a drapery fabric on a front mold of the mold, and inserting a buckle into a back mold of the mold, wherein theconnecting end of the buckle protrudes out of the back mold; carrying out preposition manufacturing, to be specific, manufacturing a plastic rubber parison being at a soft state; and carrying out postposition manufacturing, to be specific, putting the plastic rubber parison between the front mold and back mold of the mold subjected to mold preparation, then causing the drapery fabric to be adheredto the plastic rubber parison and the connecting end of the buckle to be inserted and adhered to the plastic rubber parison through the mold closing of the mold, molding and solidifying the plastic rubber parison to form the spare tire cover plate. The spare tire cover plate production technology can save time and improve production efficiency, and can also overcome the technical problems that the manual fabric adhering causes unstable fabric hanging, and further bulges and creases are easily caused; the spare tire cover plate production technology enables the drapery fabric to be firmly hungand have good appearance effect and can ensure the perpendicularity of the buckle so as to meet the requirement on tolerances for products.

Owner:广州中樱汽车零部件有限公司

Distribution type heat collection board molding method

ActiveCN106312487ASolve the heat collection problemTo achieve the purpose of purifying the fixture boardEngineeringSatellite

The invention discloses a distribution type heat collection board molding method. The method comprises the steps that a stainless steel clamp plate which is integrally molded is firstly designed, and the whole flatness of the clamp plate meets the use requirement; according to the appearance requirement for machining a distribution type heat collection board, fins and wheel type embedded blocks are machined, and the heat collection board is assembled; through the integrally-molded stainless steel clamp plate, the novel distribution type heat collection plate is subjected to whole brazing, and in the brazing process, the welding temperature condition is strictly ensured; a process hole is formed in the heat collection plate obtained after brazing. According to the method, the problem that the technical requirement caused by increasing of the appearance size, increasing of number of mechanical connectors, irregular distribution of hot connectors and the like of a novel returning satellite single-phase fluid loop heat collection board needs to be improved, and consequently, the heat collection problem to manufacturing and molding of the heat collection board is caused is solved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

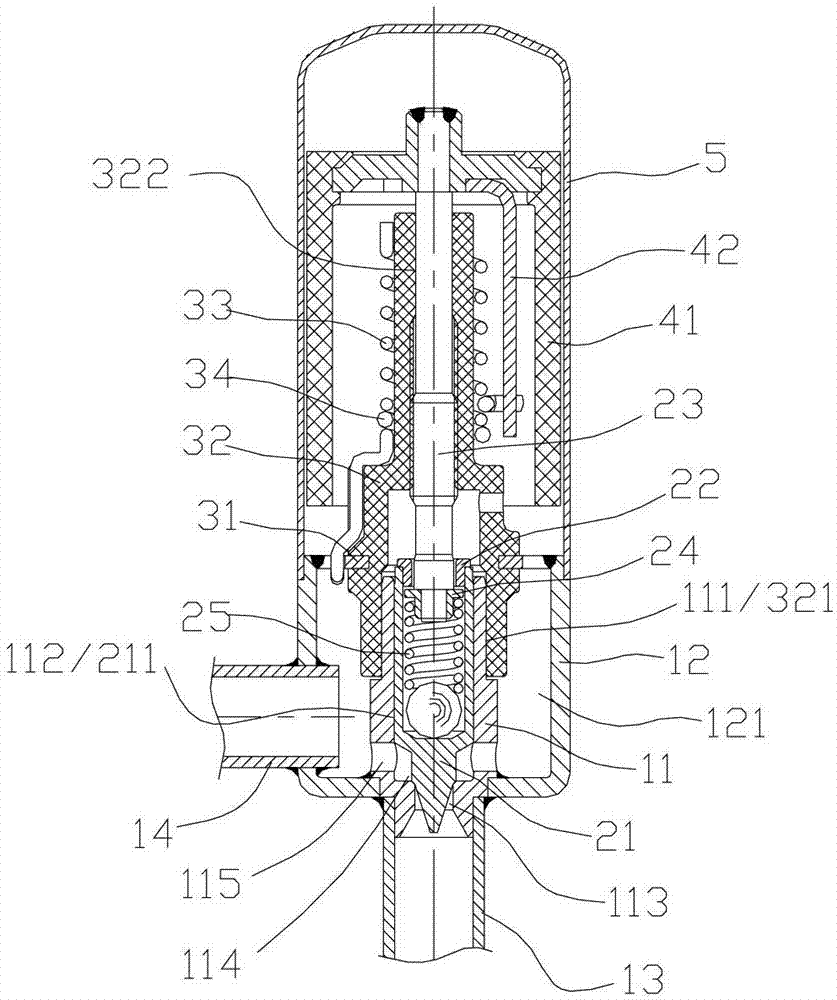

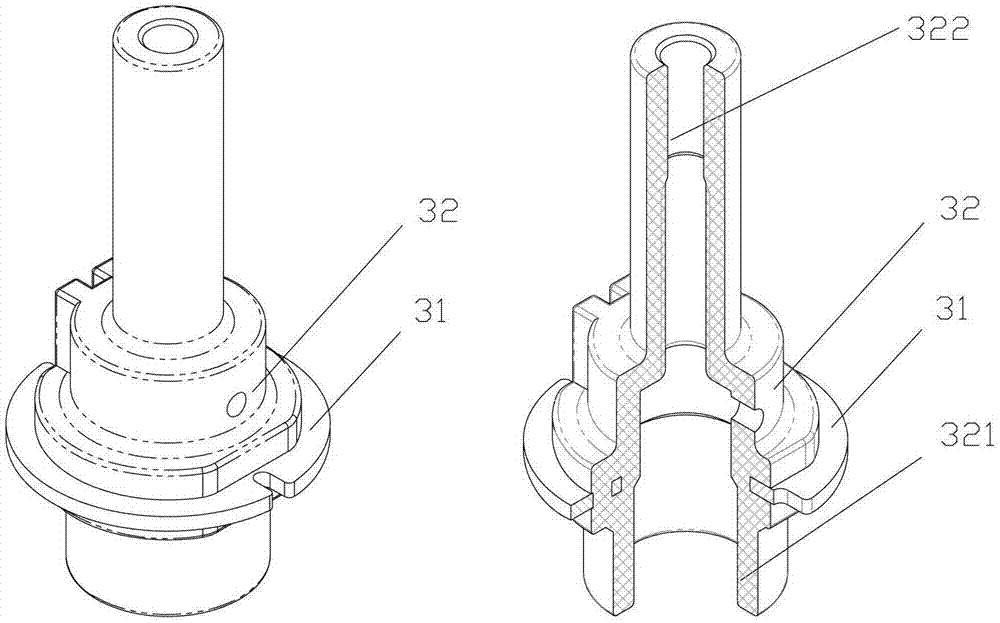

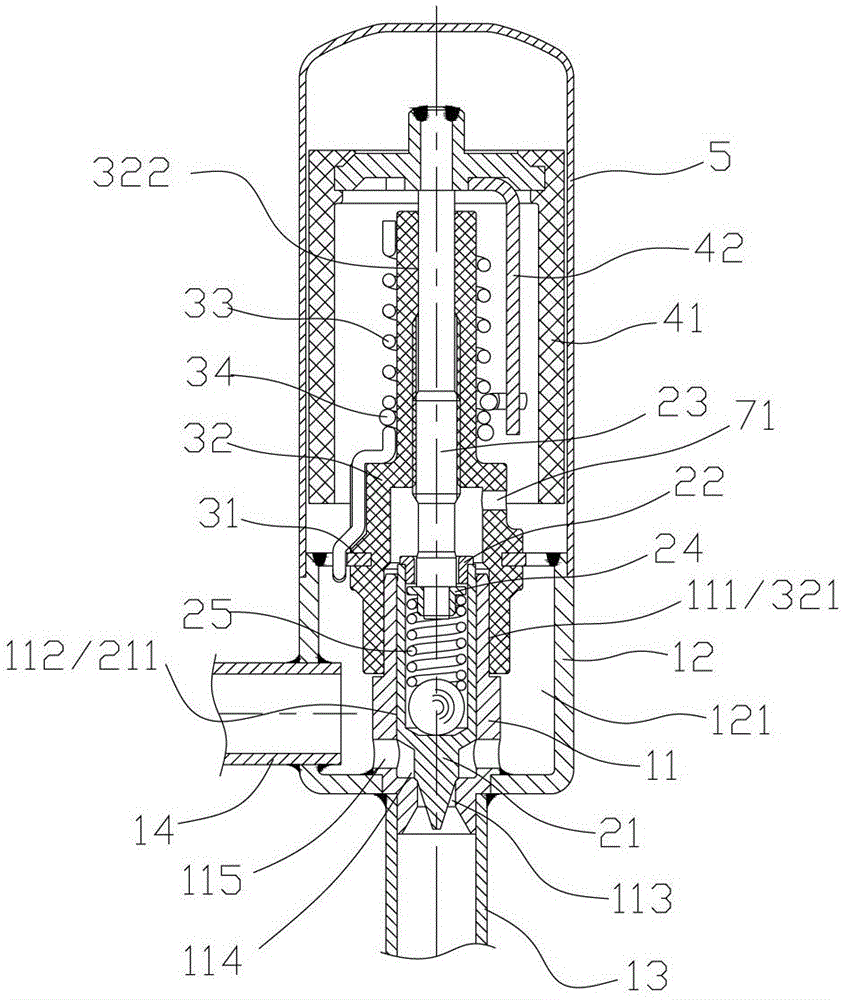

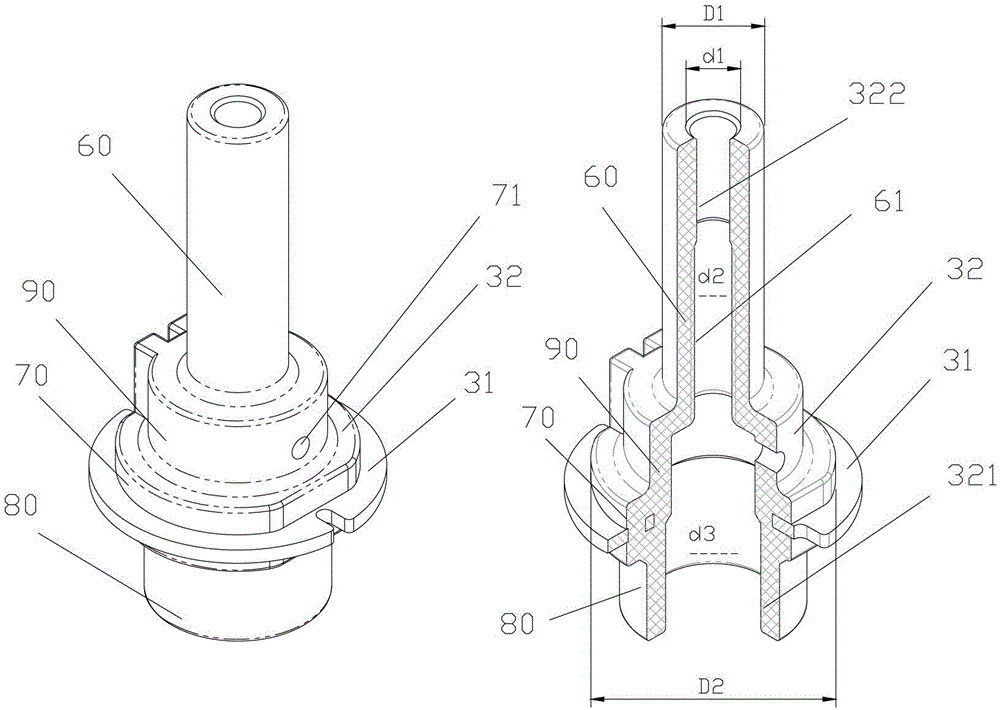

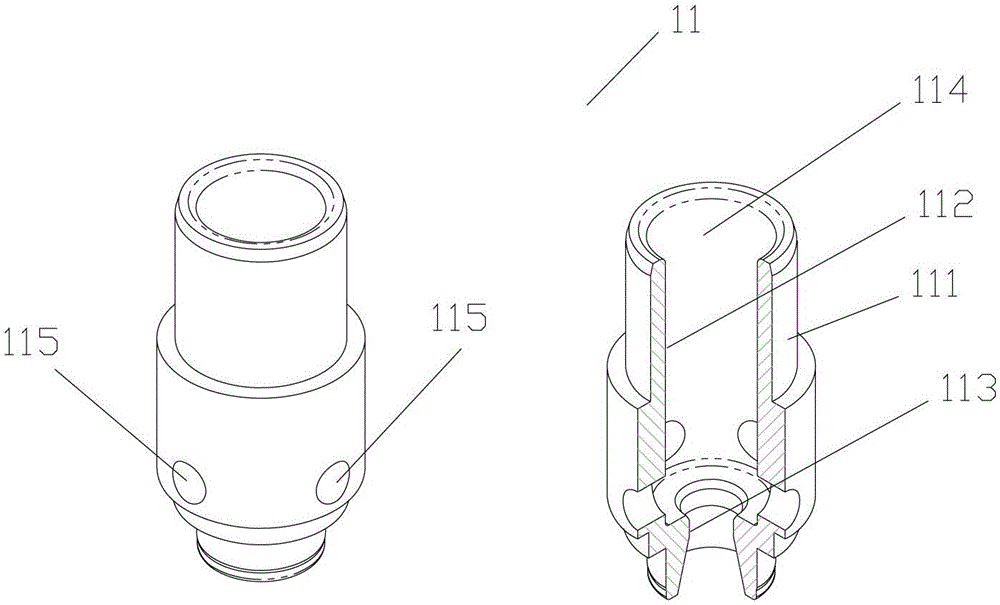

Electrical valve

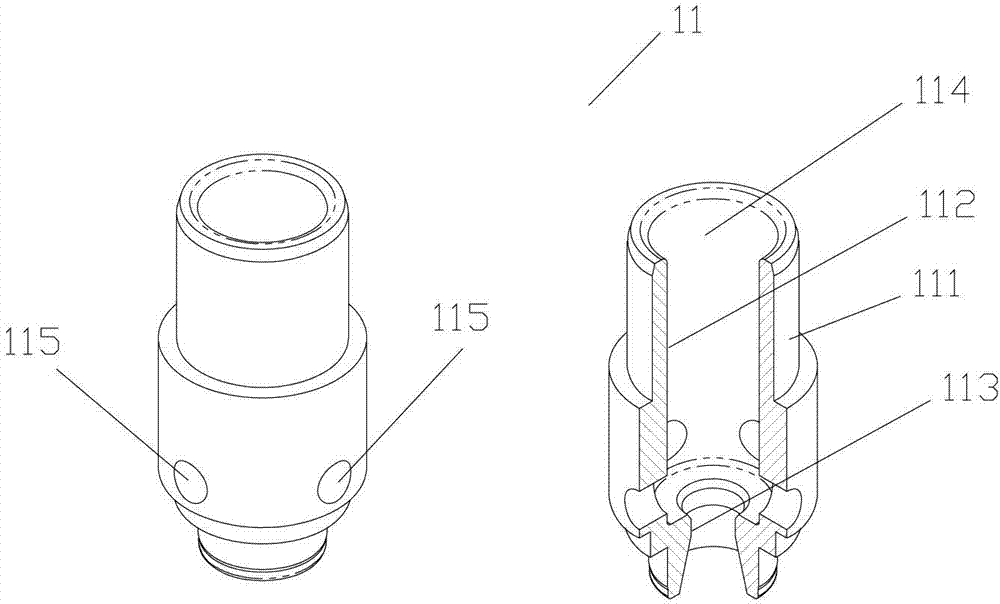

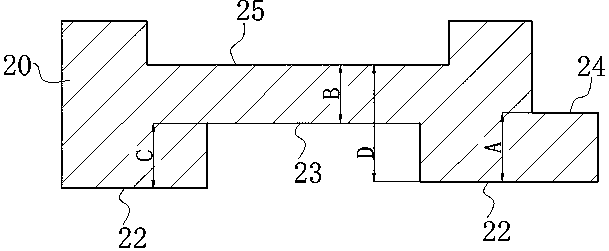

ActiveCN103261766BHigh operational reliabilityAvoid eccentric wearOperating means/releasing devices for valvesLift valveEngineeringValve seat

An electrical valve for adjusting fluid flow comprises a valve seat (12) provided with a valve chamber (121) and a valve plug seat (11) with a valve port (113) fixed on the valve seat; a valve needle-screw stem assembly comprises a screw stem (23) and a valve needle (21) drivable by the screw stem (23); a nut assembly comprises a nut (32) and a connecting plate (31), wherein the connecting plate is fixedly connected to the valve seat, the nut thread fits the screw stem, the nut is provided with a lower pilot segment (321) thereof, the valve needle is provided with a lower pilot segment (211), and the valve plug seat is provided with a first pilot segment (111) fitting the lower pilot segment of the nut and a second pilot segment (112) fitting the lower pilot of the valve needle. The electrical valve enables concentricity between the nut and the valve needle-screw stem assembly, and concentricity between the nut and the valve port of the valve plug seat to be easily ensured, so as to prevent the problems of the valve port not being sealed tightly or the valve port being worn eccentrically, such that the operational reliability of the electrical valve is increased.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

A method of processing the middle frame of mobile phone based on floating datum

ActiveCN109746761BGuaranteed processing size requirementsImprove efficiencyAutomatic control devicesFeeding apparatusEngineeringMobile phone

The invention discloses a method for machining a mobile phone middle frame based on a floating datum. The method includes the steps that the mobile phone middle frame is positioned by a jig, so that afirst positioning face on the jig and a first datum face, used for guaranteeing the first machining size, on the mobile phone middle frame are attached flatly; the position of the mobile phone middleframe is adjusted, a floating datum face on the floating datum and a second datum face, used for guaranteeing the second machining size, on the mobile phone middle frame are attached flatly, and halfof the floating datum face is exposed out of the second datum face; a to-be-machined product is clamped by a clamp; a Z direction coordinate value of the floating datum face is detected; the Z direction coordinate value of the floating datum face is compensated into a machining program of a corresponding machining face; and the machining program controls a cutter to machine to the surface of themobile phone middle frame. During batch production, due to one-time clamping, the tolerance requirement of different machining sizes of different datum faces existing in the machined product is stablyguaranteed, the yield is guaranteed, and the efficiency of batch production is improved.

Owner:CHITWING DONGGUAN TECH

Method for processing vertical pin holes in workpiece taper faces

The invention relates to a method for processing vertical pin holes in workpiece taper faces. The method includes the following steps: (1) designing a second workpiece matching with the taper face of a workpiece according to the shape of the taper face of the workpiece, wherein the second workpiece comprises a horizontal surface and a surface matching with the taper face of the workpiece; (2) welding the workpiece with the second workpiece; (3) aligning a drill bit with the central portion of the horizontal surface of the second workpiece to drill downwards vertically till reaching the needed depth of the pin hole; (4) using a cutting tool to cut open the workpiece with the taper face and the second workpiece; (5) grinding the workpiece with the taper face to smooth. The method solves the problem that direct processing cannot be carried out without work aids; combination is facilitated, operation is simple, performance is high, timesaving and laborsaving effect is achieved, and quality and tolerance requirements of the processed pin hole are assured; cutting precision is improved, harm to workpieces is small, and the method is an efficient taper-face workpiece perforating method.

Owner:SINOHYDRO BUREAU 14 CO LTD

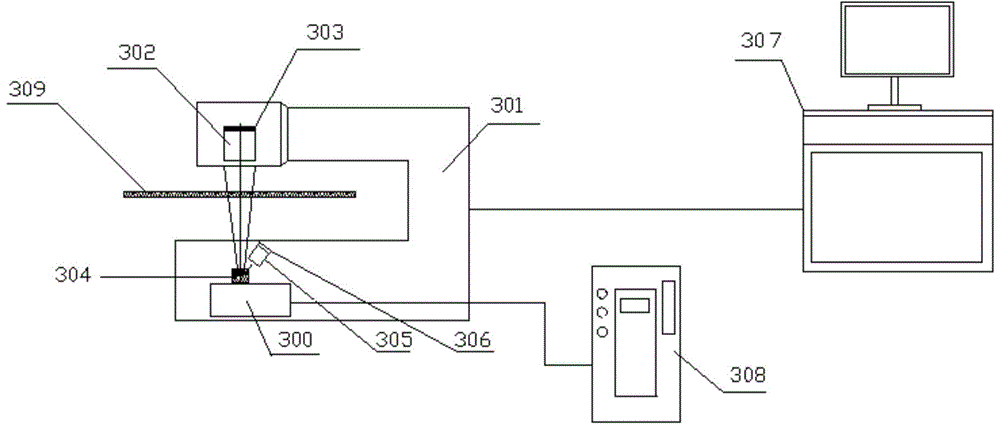

Ray-type thickness gauge and calibration method thereof

InactiveCN102564361BEliminate errorsIncrease productivityUsing wave/particle radiation meansControl systemCorrection method

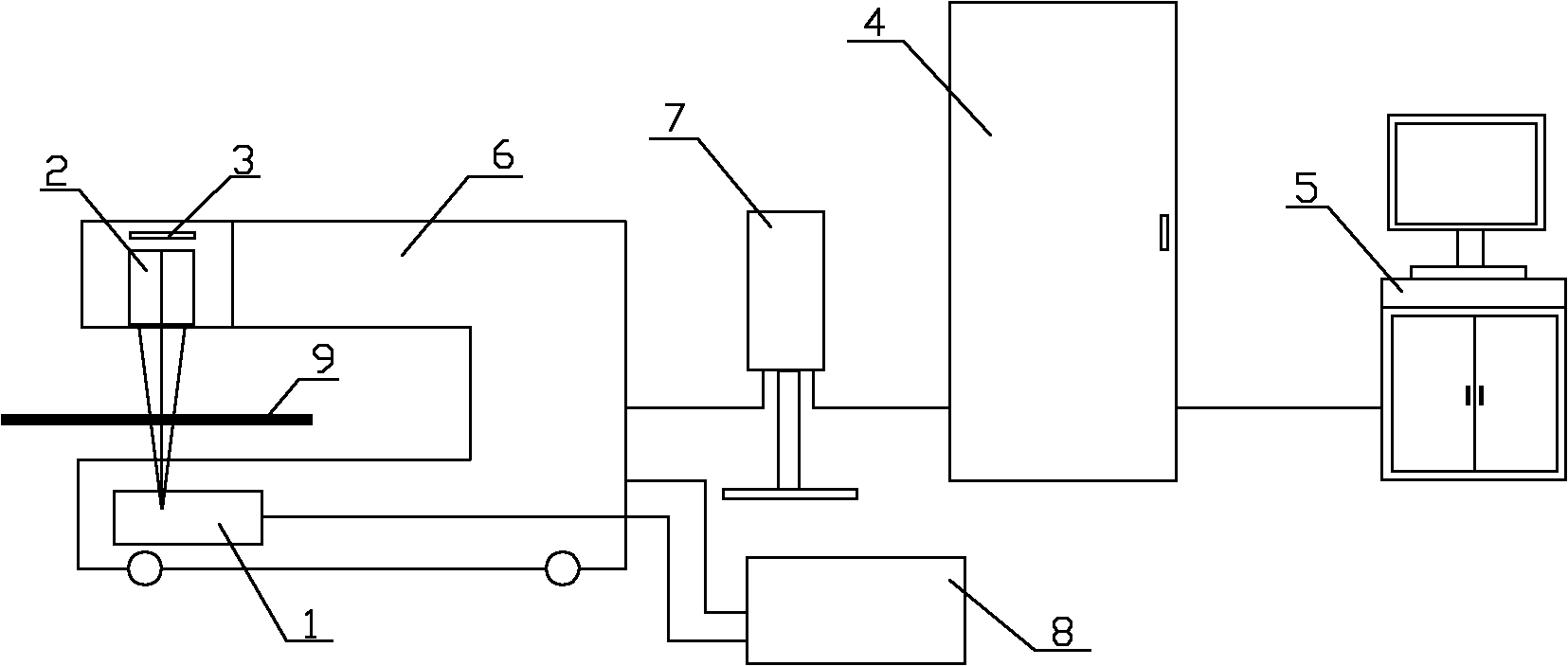

The invention discloses a ray-type thickness gauge and a calibration method thereof. The thickness gauge comprises a ray source, a ray detector, a pre-amplification circuit board, a control cabinet, a terminal display and operation device, and a C-shaped rack, wherein the ray source is arranged at the lower part of the throat gap of the C-shaped rack; the ray detector is arranged at the upper part of the throat gap of the C-shaped rack; a to-be-measured metal belt penetrates through the throat gap of the C-shaped rack; the pre-amplification circuit board is connected with the control cabinet; and the control cabinet is connected with the terminal display and operation device, and is used for calculating and displaying a thickness and receiving the instruction of an operator. According to the calibration method of the thickness gauge, the measuring accuracy after fast calibration can reach the precision level of a just calibrated thickness gauge, so as to save time spent in re-calibration, eliminate an error caused by anthropic factors during calibration carried out by the operator, and provide a high-precision thickness measure value for the thickness control system of a rolling mill. Therefore, the production efficiency of the rolling mill can be improved; and the tolerance requirement of the metal belt rolled by the rolling mill can be guaranteed.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

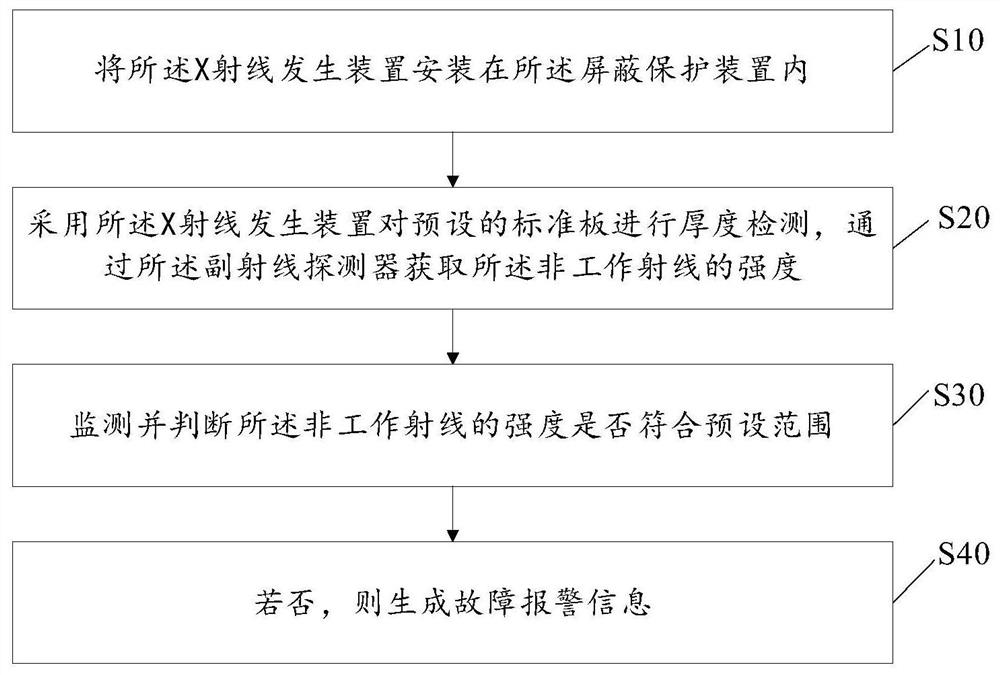

Fault detection method and system for X-ray generating device of thickness gauge

InactiveCN112325812AHigh control precisionGuaranteed Tolerance RequirementsUsing wave/particle radiation meansRadiation intensity measurementMechanical engineeringRay

The invention discloses a fault detection method and system for an X-ray generating device of a thickness gauge, wherein the method and system are used for a detection platform which comprises a shielding protection device, an analysis device, and an auxiliary ray detector. An opening is formed in the shielding protection device and is used for allowing working rays of the X-ray generation deviceto pass through; the analysis device is connected with the auxiliary ray detector, the auxiliary ray detector is used for detecting the intensity of the non-working rays, and the analysis device is used for monitoring the intensity of the non-working rays. The method comprises the steps: installing an X-ray generation device in a shielding protection device; detecting the thickness of a preset standard plate by adopting an X-ray generating device, and acquiring the intensity of non-working rays through an auxiliary ray detector; monitoring and judging whether the intensity of the non-working rays conforms to a preset range or not; and if not, generating fault alarm information. By means of the invention, whether the X-ray generating device breaks down or is stable or not can be accuratelyjudged in advance.

Owner:武汉钢铁有限公司

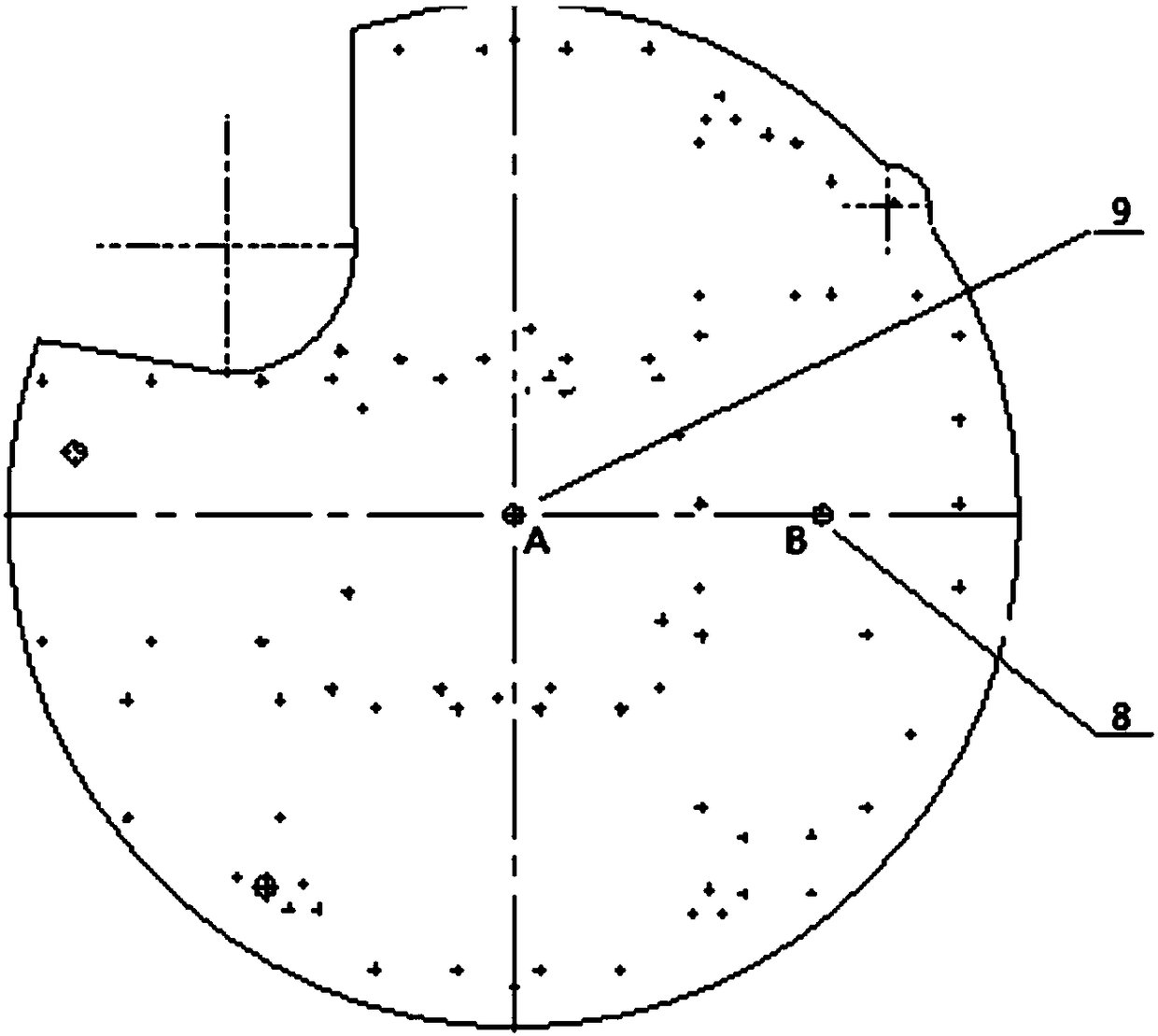

Upper end cover assembly of flexible strapdown gyroscope

InactiveCN102324798BHigh precisionIncrease in sizeManufacturing dynamo-electric machinesSupports/enclosures/casingsPower flowGyroscope

The invention belongs to the technical field of design and relates to an upper end cover assembly of a flexible strapdown gyroscope. In the invention, the strapdown gyroscope is divided into an upper body and a lower body, so that the influence of electromagnetic interference and heat emission of a gyro motor on an announciator and a torquer is reduced and the upper end cover assembly has an obvious effect of improving the accuracy of a small gyroscope; the processing on an announciator iron core is completed on an upper end cover of the gyroscope, so that the integration of the announciator iron core and the upper end cover is realized, the volume of the gyroscope is effectively shortened, and the number of parts and the assembly workload are reduced; and a torquer assembly is arranged on the upper end cover, so that the influence of heat emission of a large current on the performance of the gyroscope when the gyroscope works under a high angular speed is reduced.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

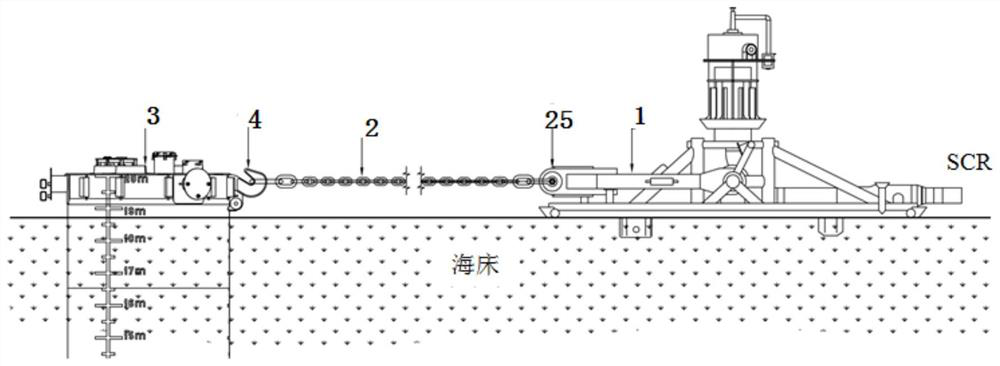

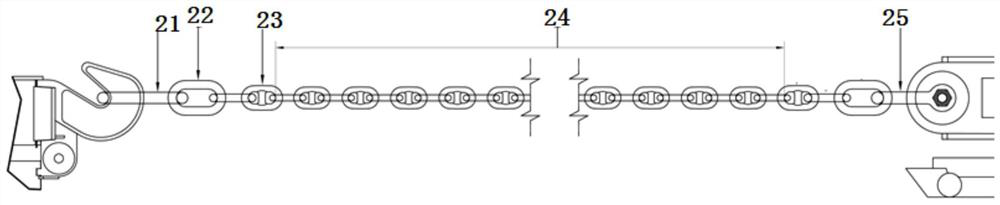

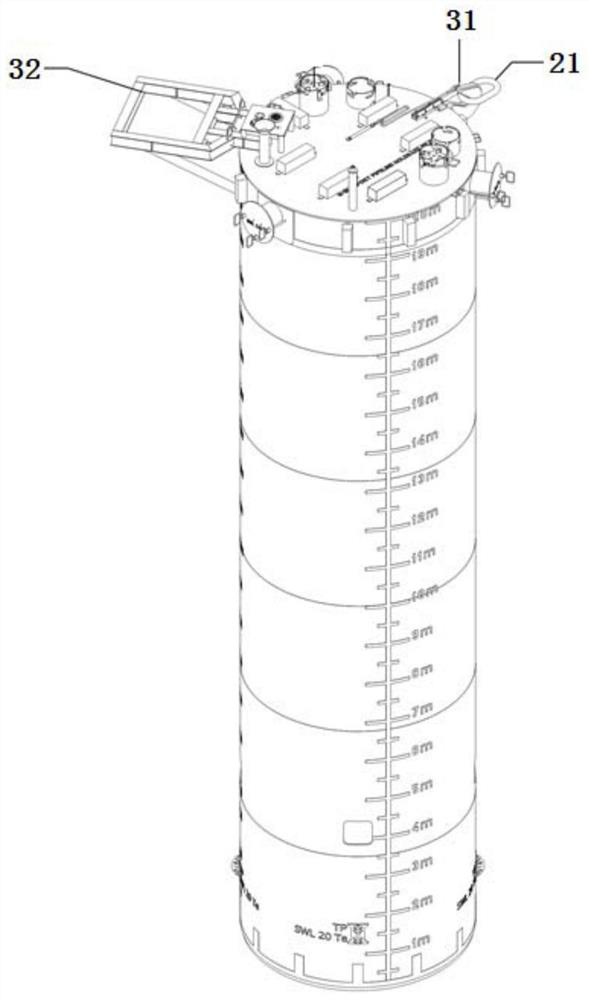

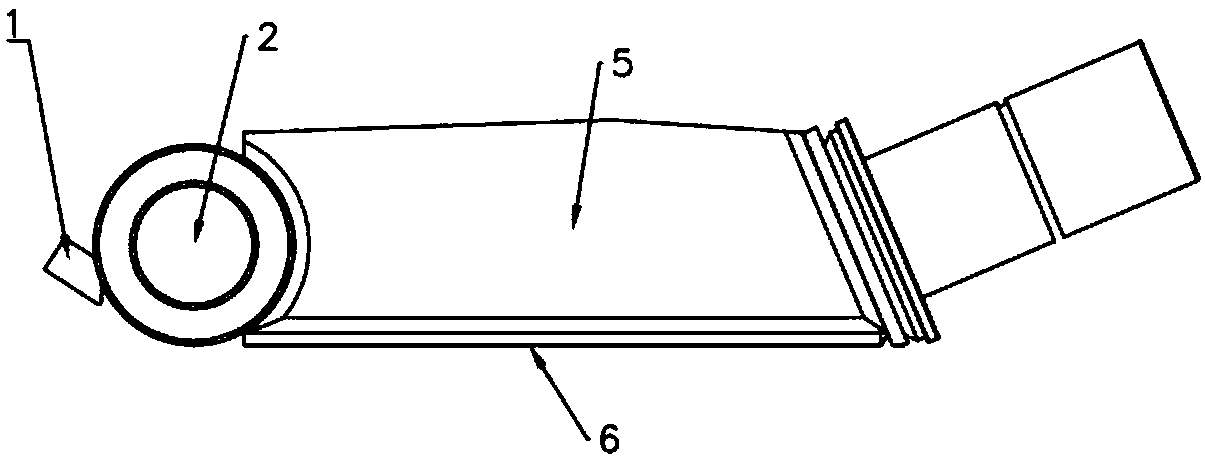

Tension balancing system arranged at bottom of stand pipe

PendingCN113718754AImprove integrityProtection securityPipe laying and repairBulkheads/pilesSuction forceUnderwater

The invention discloses a tension balancing system arranged at the bottom of a stand pipe. The tension balancing system comprises a stand pipeline terminal, a tension balancing anchor chain and a deepwater suction pile; one end of the tension balancing anchor chain is connected to a lifting lug at the pipeline terminal through a shackle, and the other end of the tension balancing anchor chain is connected to an underwater ROV lifting hook on the deepwater suction pile through a reinforcing ring; the tension balancing anchor chain is composed of a reinforcing ring, a special end ring, an end ring, a common chain ring and the shackle which are connected in sequence; and the deepwater suction pile comprises an ROV (remote operated vehicle) platform and an ROV lifting hook, and the ROV lifting hook is fixed on the ROV platform. According to the tension balancing system, a steel catenary riser is connected to a riser pipeline terminal, unbalanced tension is transmitted to the deepwater suction pile through the tension balancing anchor chain, passive balancing of tension is achieved due to the unidirectional stress characteristic of the anchor chain, and the purpose of protecting integrity and safety of deepwater subsea pipeline end facilities and underwater facilities connected to the deepwater subsea pipeline end facilities is achieved.

Owner:OFFSHORE OIL ENG

Welding and locating device of swing arm

InactiveCN109465580AConvenient welding workGuaranteed size requirementsWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineering

The invention discloses a welding and locating device of a swing arm. The welding and locating device comprises a base. A locating shaft used for locating a sleeve is vertically mounted on the base, and a pressing part used for pressing the sleeve is mounted at the end, away from the base, of the locating shaft. A locating seat used for locating a pin assembly and a press block used for pressing the pin assembly are further mounted on the base. Locating pins are further mounted on the base. A locating plate used for pressing a partition plate is arranged on the locating pins. A step plate usedfor locating the bottom plate is arranged beside the locating plate. A locating block used for locating a limiting block is arranged beside the locating shaft. According to the locating device, aftermain components of the swing arm are precisely located, welding work can be conveniently carried out on the swing arm later; the structure is simple, and locating is precise; and the position dimension and tolerance requirements for parts of a swing arm assembly can be guaranteed.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

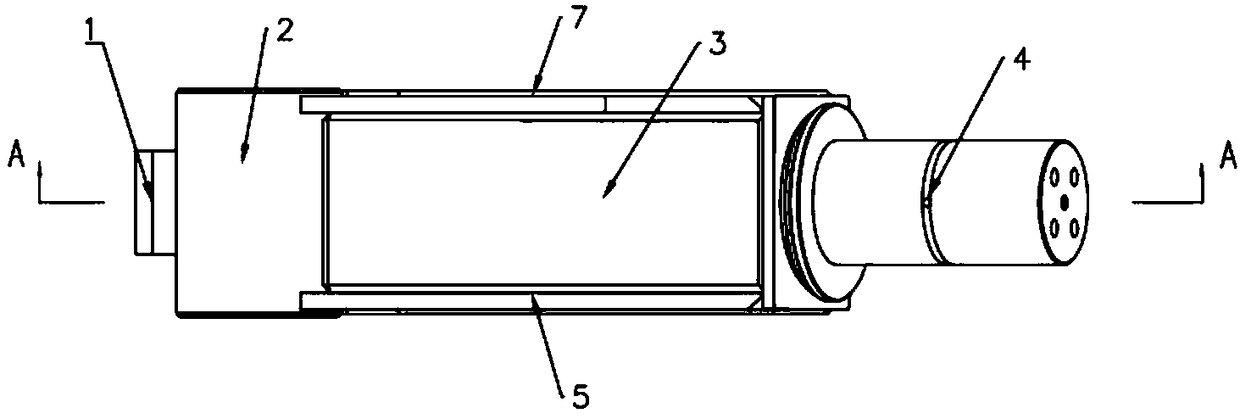

Electrically-operated valve

ActiveCN103261765BHigh operational reliabilityEasy to assembleOperating means/releasing devices for valvesLift valveEngineeringValve seat

An electrical valve for adjusting fluid flow comprises a valve seat (12) provided with a valve chamber (121) and a valve plug seat (11) with a valve port (113) fixed on the valve seat; a valve needle-screw stem assembly comprises a screw stem (23) and a valve needle (21) drivable by the screw stem (23); a nut assembly comprises a nut (32) and a connecting plate (31), wherein the connecting plate is fixedly connected to the valve seat, the nut thread fits the screw stem, the nut is provided with a lower pilot segment (321) thereof, the valve needle is provided with a lower pilot segment (211), and the valve plug seat is provided with a first pilot segment (111) fitting the lower pilot segment of the nut and a second pilot segment (112) fitting the lower pilot of the valve needle. The electrical valve enables concentricity between the nut and the valve needle-screw stem assembly, and concentricity between the nut and the valve port of the valve plug seat to be easily ensured, so as to prevent the problems of the valve port not being sealed tightly or the valve port being worn eccentrically, such that the operational reliability of the electrical valve is increased.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

A cutting and ejecting device for cutting off the glass guide rail of an automobile door

ActiveCN105772838BIncrease productivityNo deformationMetal-working feeding devicesNibbling shearing machinesReturn functionCutting glass

A cutting-off and material returning device for cutting off automobile door glass guide rails comprises a base, a clamping mechanism, a cutting-off mechanism and a material returning mechanism. The clamping mechanism comprises a clamping oil cylinder, a sliding block, a movable clamping block and a clamping assembly. A clamping oil cylinder piston rod is fixedly connected with one end of the sliding block, and the other end of the sliding block is fixedly connected with the movable clamping block through a movable clamping block mounting seat. An upper wedge and a lower wedge are fixed to the upper portion and the lower portion of the movable clamping block correspondingly. The clamping assembly comprises an upper knife, a middle shaping plate and a lower knife. The middle shaping plate is fixed to a mounting frame. The upper knife and the lower knife are connected to the upper portion and the lower portion of the middle shaping plate in a floating mode correspondingly. The front end of the movable clamping block corresponds to the middle shaping plate. The upper wedge and the lower wedge correspond to the upper portion of the upper knife and the lower portion of the lower knife respectively. The cutting-off mechanism comprises a cutting-off oil cylinder and a cutting-off knife. The material returning mechanism comprises a material returning oil cylinder and a material returning rod. According to the cutting-off and material returning device for cutting off the automobile door glass guide rails, structure setting is ingenious, feeding is convenient, material returning is smooth, non-deformation of cut-off products can be guaranteed, and an automatic material returning function can be completed after cutting-off.

Owner:凌云工业股份(芜湖)有限公司

Metallurgical slag pot trunnion casting method

The invention relates to a trunnion imbedding method of a metallurgical slag pot. A processed trunnion is cast on a slag pot body to complete casting of the trunnion and the slag pot body when the slag pot body is cast. The trunnion imbedding method comprises the following steps of (1) preparing an outer sand mould; namely transversely embedding the processed trunnion in the sand mould, and stretching an inside end of the trunnion into a cavity of the outer sand mould; and (2) enabling the outer sand mould to be sleeved on an inner sand mould, casting molten steel in a cavity between an outer sand mould model and an inner sand mould model, casting the trunnion on the slag pot body, removing the sand moulds after cooling, and completing the casting of the trunnion and the slag pot body. The trunnion imbedding method is simple in operation, high in work efficiency, short in production period and low in production cost.

Owner:武钢集团襄阳重型装备材料有限公司

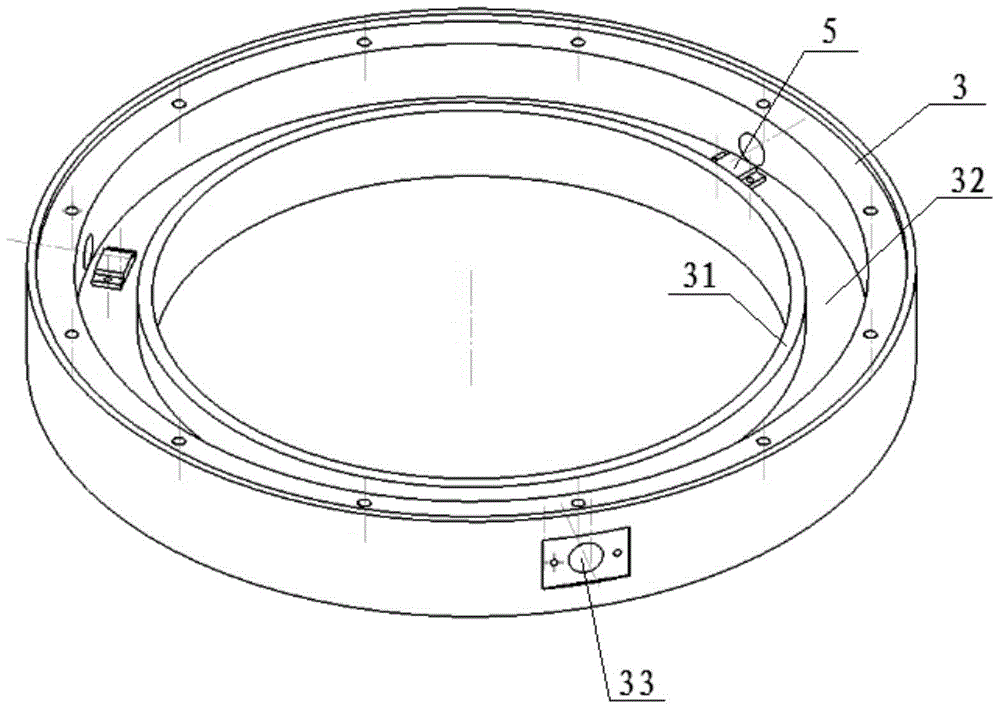

A Gravity Deformation Compensation Device for Optical Elements

InactiveCN105372949BReduce wearSave spacePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringSupport point

The invention discloses an optical element gravity deformation compensating device, which comprises an optical element, a deformable mirror frame, a pair of annular electromagnets, a capacitive sensor and an upper cover plate; the deformable mirror frame is composed of a mirror frame inner ring, a mirror frame outer ring and a supporting ring The integrated structure of the mirror frame, the inner ring of the frame is fixedly connected with the optical element through the glue injection hole on the side wall, the lower part of the supporting ring is in contact with the boss of the outer mirror frame to provide a support point, and a ring electromagnet is installed on the upper part of the outer ring of the mirror frame. The repulsion provides a vertical downward displacement. After loading, the outer frame of the deformable mirror frame drives the inner frame to move axially, which causes the optical element to deform, and finally realizes the compensation of rotationally symmetrical aberrations; it has the advantages of simple structure and reasonable design.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

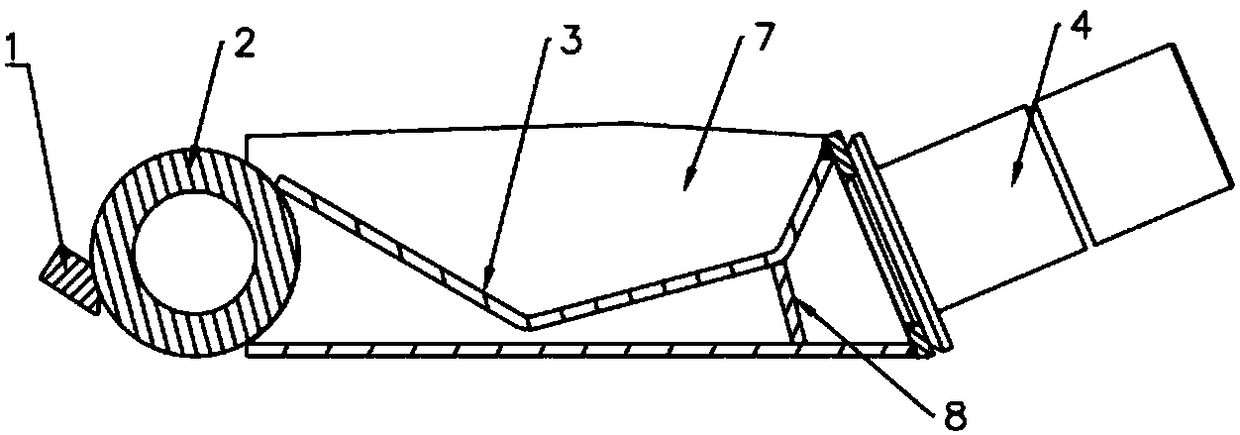

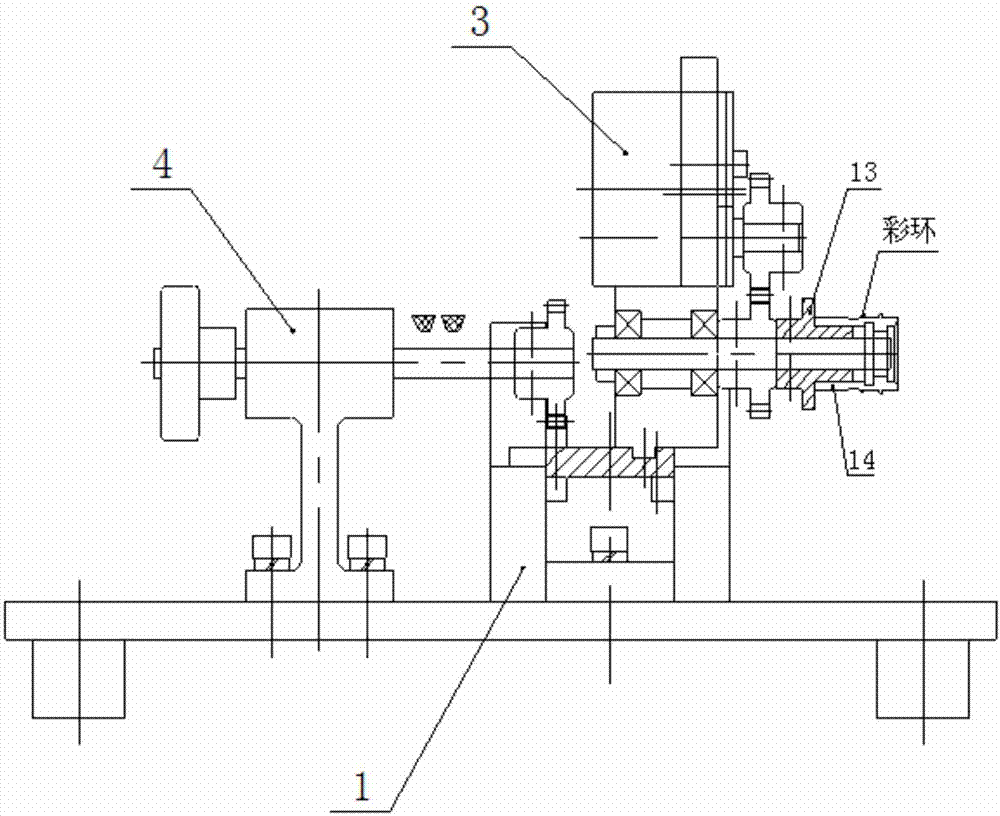

Device for automatically printing colored rings on shells

ActiveCN104723663AGuaranteed Tolerance RequirementsUniform color ringRotary pressesHigh volume manufacturingPrinting ink

The invention discloses a device for automatically printing colored rings on shells. The device is composed of a machine body (1), a main transmission system (2), a shell rotating system (3), a longitudinal movement system (4), a printing ink coating portion (5) and an electric portion (6), wherein the main transmission system (2), the shell rotating system (3), the longitudinal movement system (4) and the printing ink coating portion (5) are all located on the machine body (1), the electric portion (6) is electrically connected with the main transmission system (2) and the shell rotating system (3), the main transmission system (2) is connected with the printing ink coating portion (5), and the shell rotating system (3) is connected with the shells. The device is accurate in clamping and convenient to use, and precision requirements in terms of design and technology of color rings on the shells are met, bulk production is achieved, product quality is guaranteed, and qualified products can be delivered on schedule.

Owner:沈阳兴华航空电器有限责任公司

Method for processing crankshaft of multiaxial warp knitting machine

The embodiment of the invention discloses a method for processing a crankshaft of a multiaxial warp knitting machine. The crankshaft comprises a spindle diameter and a connecting rod diameter. The connecting rod diameter is connected with the spindle diameter. The method comprises the following steps of: step A: processing a raw material through the steps of drilling a first center hole, roughly turning, hardening and tempering, and fine turning an outer diameter to obtain a polished shaft; step B: respectively drilling a second center hole of the crankshaft and a third center hole of the connecting rod diameter at the opposite positions at both ends of the polished shaft, drilling a process positioning hole at the position at a distance of 20mm from the first center hole, carrying out fine turning on the spindle diameter and the connecting rod diameter according to the process positioning hole, the second center hole and the third center hole, and carrying out milling and rough grinding to obtain a semi-finished product; and step C: carrying out high-frequency quenching on the semi-finished product, drilling and reaming pin holes at both ends of the semi-finished product and carrying out fine grinding processing to obtain a finished product. In the embodiment of the invention, when the outer diameter, the spindle diameter and the connecting rod diameter are subjected to fine turning, positioning is carried out through the process positioning hole and the respective center holes, so that when the outer diameter, the spindle diameter and the connecting rod diameter are processed, the requirement on a tolerance of the eccentricity of the connecting rod diameter and the spindle diameter of the crankshaft can be guaranteed.

Owner:沈阳气体压缩机制造有限公司

A Method of Machining Vertical Pin Holes on Conical Surface of Workpiece

The invention relates to a method for processing vertical pin holes in workpiece taper faces. The method includes the following steps: (1) designing a second workpiece matching with the taper face of a workpiece according to the shape of the taper face of the workpiece, wherein the second workpiece comprises a horizontal surface and a surface matching with the taper face of the workpiece; (2) welding the workpiece with the second workpiece; (3) aligning a drill bit with the central portion of the horizontal surface of the second workpiece to drill downwards vertically till reaching the needed depth of the pin hole; (4) using a cutting tool to cut open the workpiece with the taper face and the second workpiece; (5) grinding the workpiece with the taper face to smooth. The method solves the problem that direct processing cannot be carried out without work aids; combination is facilitated, operation is simple, performance is high, timesaving and laborsaving effect is achieved, and quality and tolerance requirements of the processed pin hole are assured; cutting precision is improved, harm to workpieces is small, and the method is an efficient taper-face workpiece perforating method.

Owner:SINOHYDRO BUREAU 14 CO LTD

A method for forming a distributed heat collecting plate

ActiveCN106312487BSolve the heat collection problemTo achieve the purpose of purifying the fixture boardEngineeringSatellite

The invention discloses a distribution type heat collection board molding method. The method comprises the steps that a stainless steel clamp plate which is integrally molded is firstly designed, and the whole flatness of the clamp plate meets the use requirement; according to the appearance requirement for machining a distribution type heat collection board, fins and wheel type embedded blocks are machined, and the heat collection board is assembled; through the integrally-molded stainless steel clamp plate, the novel distribution type heat collection plate is subjected to whole brazing, and in the brazing process, the welding temperature condition is strictly ensured; a process hole is formed in the heat collection plate obtained after brazing. According to the method, the problem that the technical requirement caused by increasing of the appearance size, increasing of number of mechanical connectors, irregular distribution of hot connectors and the like of a novel returning satellite single-phase fluid loop heat collection board needs to be improved, and consequently, the heat collection problem to manufacturing and molding of the heat collection board is caused is solved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com