Two-dimensional high-precision worktable with grating ruler

A grating ruler, high-precision technology, applied to fine working devices, working accessories, manufacturing tools, etc., can solve the problems of lack of compensation movement and difficulty in ensuring the accuracy of arc surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

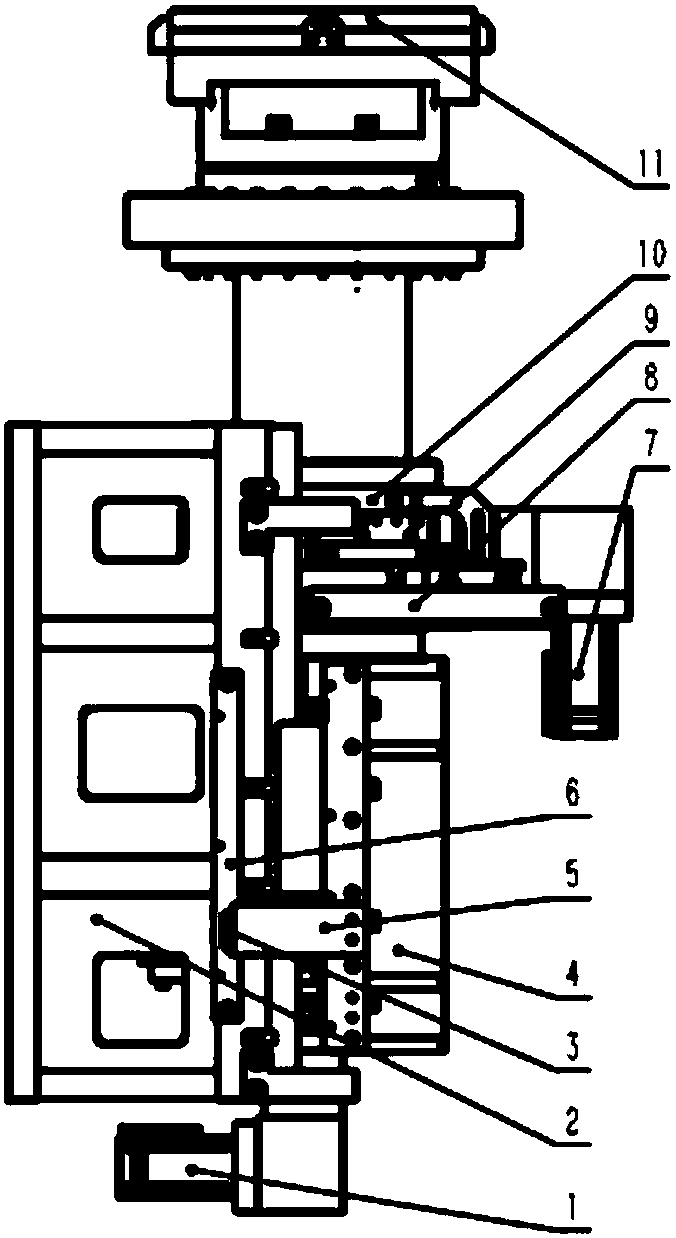

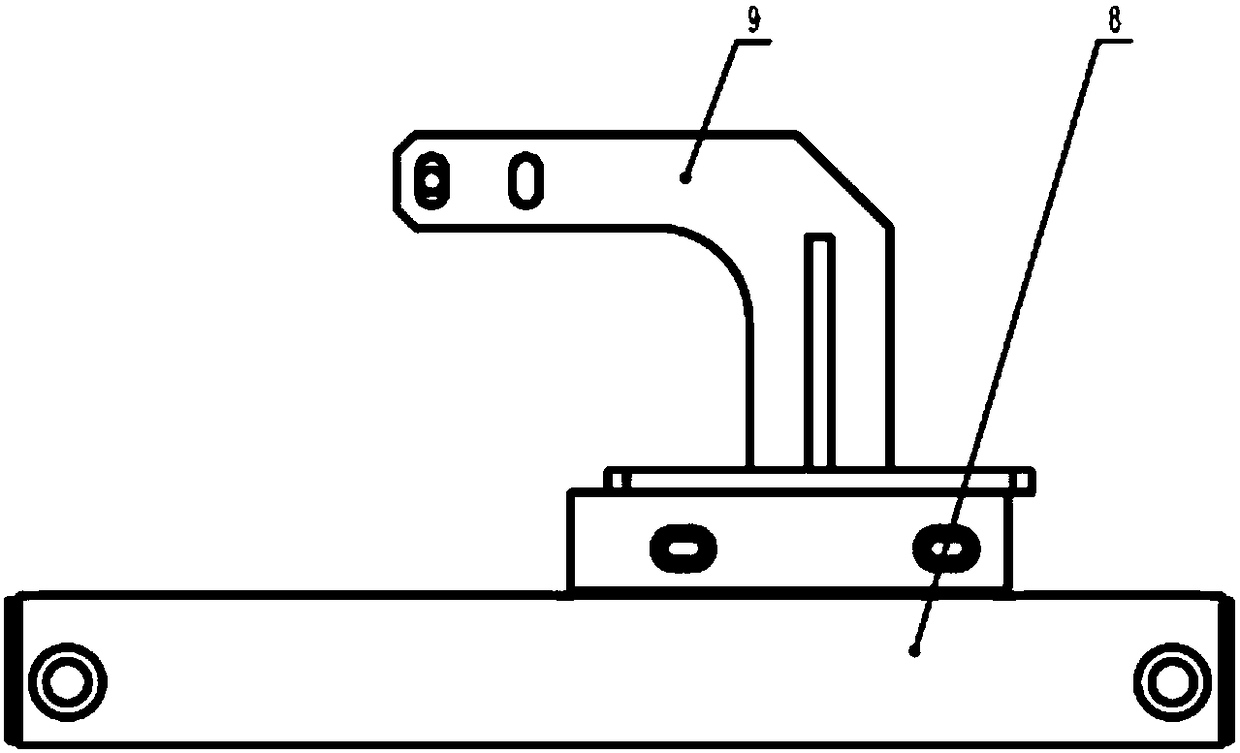

[0016] Referring to the accompanying drawings, this embodiment includes servo motor I1, fixed seat 2, grating ruler reading head 3, sliding seat I4, grating head mounting bracket 5, grating ruler base 6, servo motor II7, grating ruler 8, grating support 9, slide Seat II10; the fixed seat 2 is fixed on the structural parts of the cutting machine, the servo motor I1 is connected to the fixed seat 2 through a reducer, the servo motor I1 is connected to the reducer to drive the ball screw to rotate, and drives the slide seat I4 to move up and down , the grating head mounting bracket 5 is mounted on the sliding seat I4, the grating ruler reading head 3 is mounted on the grating head mounting bracket 5, the grating ruler base 6 is mounted on the fixing seat 2, and moves up and down on the sliding seat I4 , the grating ruler reading head 3 and the grating rule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com