Ray-type thickness gauge and calibration method thereof

A calibration method and technology of thickness gauges, applied in instruments, measuring devices, utilizing wave/particle radiation, etc., can solve the problems that the production environment and the stability of the equipment itself affect the measurement accuracy of the thickness gauges, and save the required time, Eliminate errors and ensure the effectiveness of tolerance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

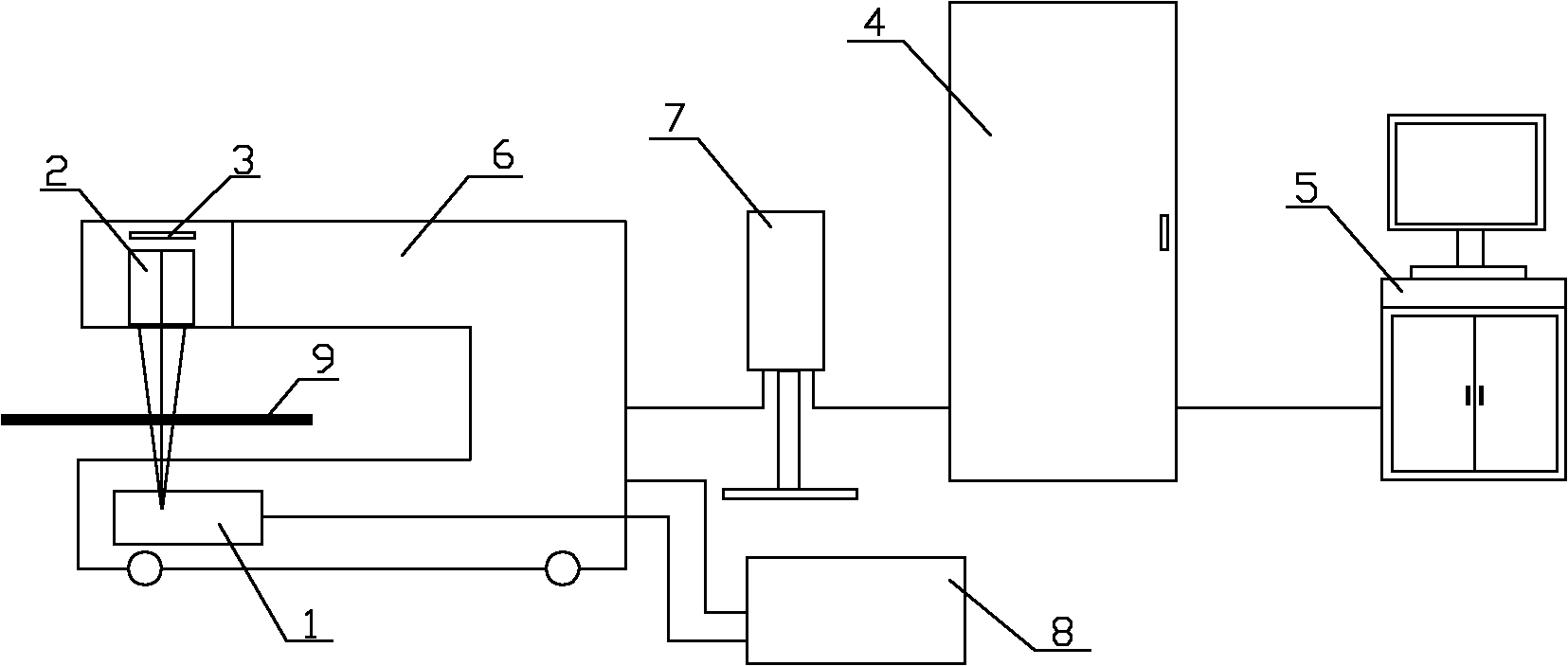

[0030] The present invention is a kind of ray type thickness gauge, such as figure 1 As shown, it includes a radiation source 1 , a radiation detector 2 , a preamplifier circuit board 3 , a control cabinet 4 , a terminal display and operation device 5 , a C-frame 6 , a water cooling box 8 and a junction box 7 .

[0031] The ray source 1 is set at the lower part of the throat gap of the C-frame 6 , the radiation detector 2 is set at the upper part of the throat gap of the C-frame 6 , the metal strip 9 to be tested is located in the middle of the throat gap of the C-frame 6 , and the preamplifier circuit board 3 The control cabinet 4 is connected through the junction box 7, the radiation source 1 and the C-frame 6 are connected to the water cooling box 8, and the control cabinet 4 is connected to the terminal display and operation device 5, which is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com