Four-axis linkage machining mechanism of numerical-control machining center and operating method of four-axis linkage machining mechanism

A technology of four-axis linkage and processing mechanism, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult clamping, easy deformation, and large shape and position tolerance errors, and achieve simplified processing procedures , Improve the stability, the effect of high-precision machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

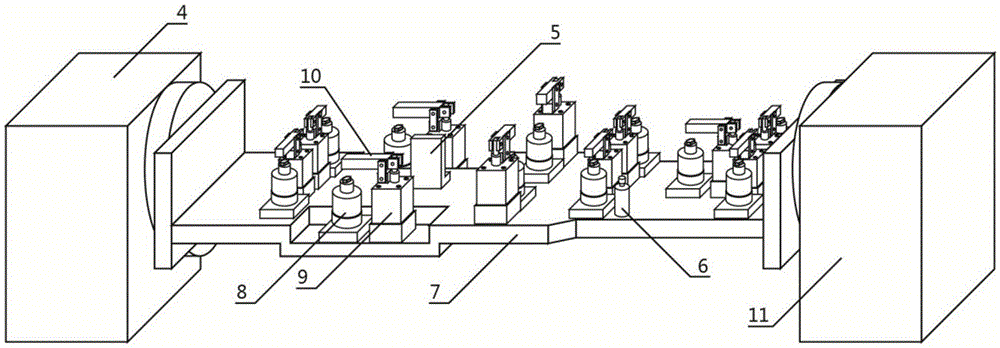

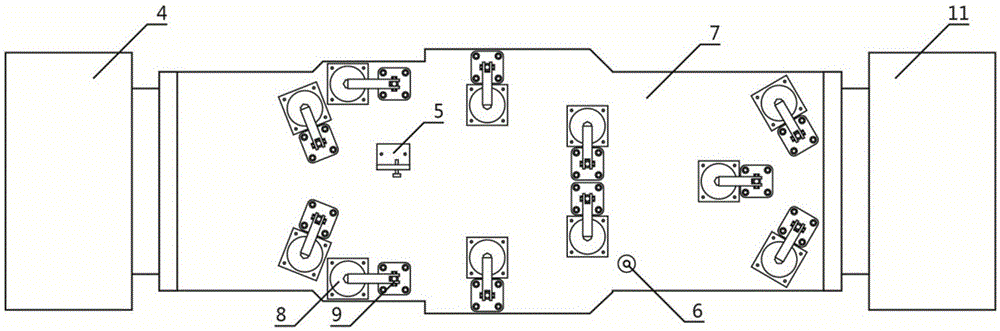

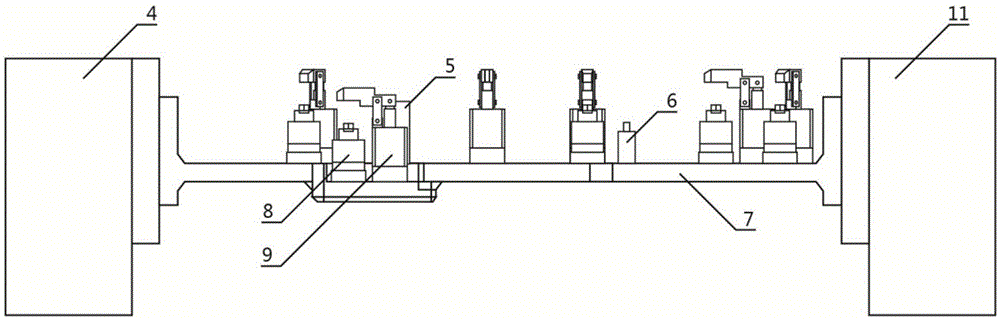

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 A four-axis linkage machining mechanism of a numerical control machining center and its working method are shown, which is characterized in that it includes an operation room 1, a processing spindle 2, and a processing table 3, the processing spindle 2 is located on one side of the operation room 1, and the processing The main shaft 2 is fixedly connected to the operating room 1, and the processing table 3 is located inside the operating room 1. The processing table 3 is fixedly connected to the operating room 1. The working table 3 is composed of a turntable tailstock 4 and a main positioning device for parts. 5. Part auxiliary positioning device 6, fixture main body 7 and turntable main body 11, said fixture main body 7 is located between turntable tailstock 4 and turntable main body 11, said fixture main body 7 is fixed to turntable tailstock 4 and turntable main body 11 connected, the part main positioning devic...

Embodiment 2

[0040] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 A four-axis linkage machining mechanism of a numerical control machining center and its working method are shown, which is characterized in that it includes an operation room 1, a processing spindle 2, and a processing table 3, the processing spindle 2 is located on one side of the operation room 1, and the processing The main shaft 2 is fixedly connected to the operating room 1, and the processing table 3 is located inside the operating room 1. The processing table 3 is fixedly connected to the operating room 1. The working table 3 is composed of a turntable tailstock 4 and a main positioning device for parts. 5. Part auxiliary positioning device 6, fixture main body 7 and turntable main body 11, said fixture main body 7 is located between turntable tailstock 4 and turntable main body 11, said fixture main body 7 is fixed to turntable tailstock 4 and turntable main body 11 connected, the part main positioning devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com