Machining method of umbrella-shaped valve disc

A processing method and technology for an umbrella valve, which are applied in the field of valve disc processing, can solve the problems that the valve disc is not easy to clamp, and it is difficult to ensure the coaxial accuracy of the upper and lower ends of the workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

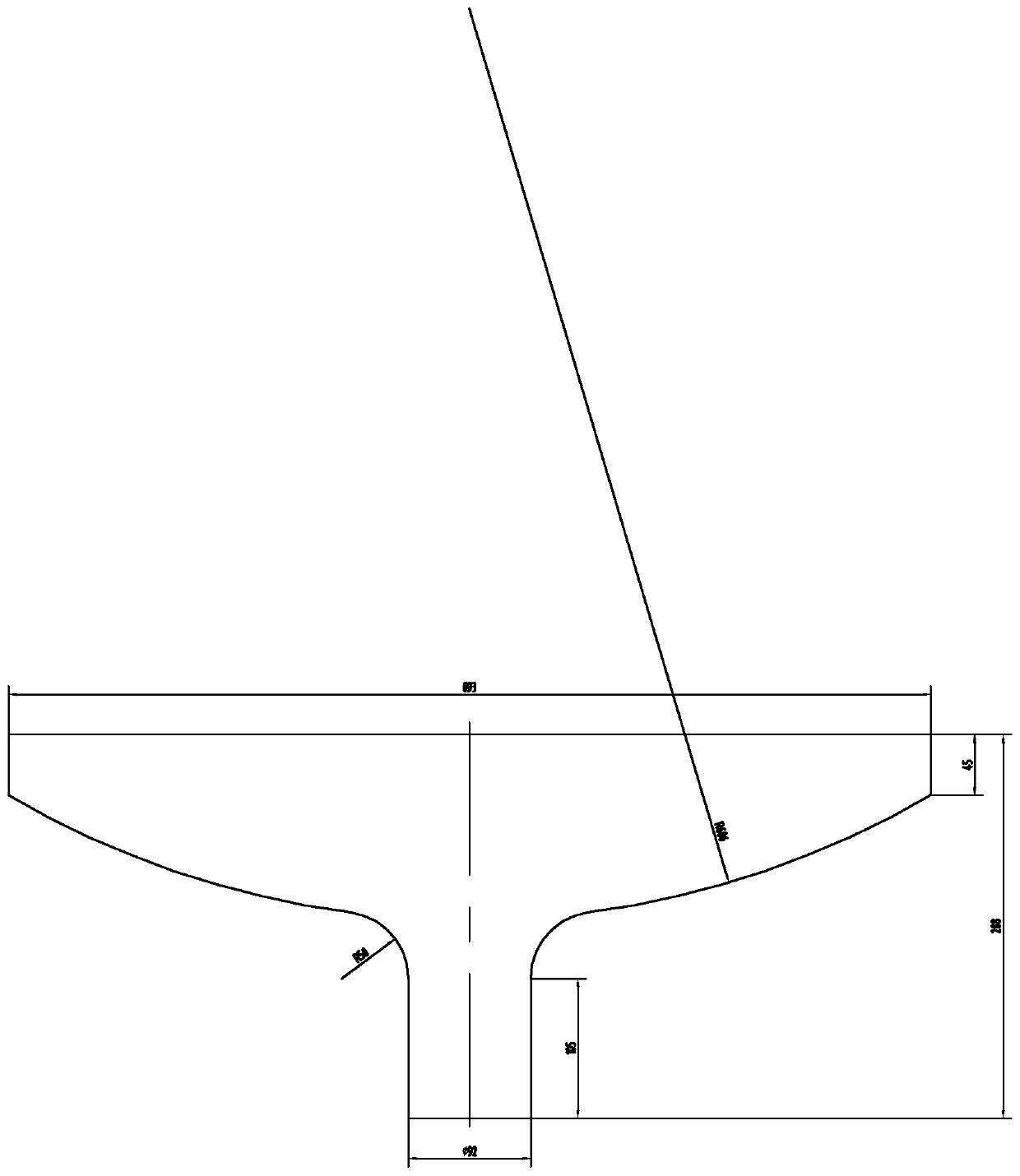

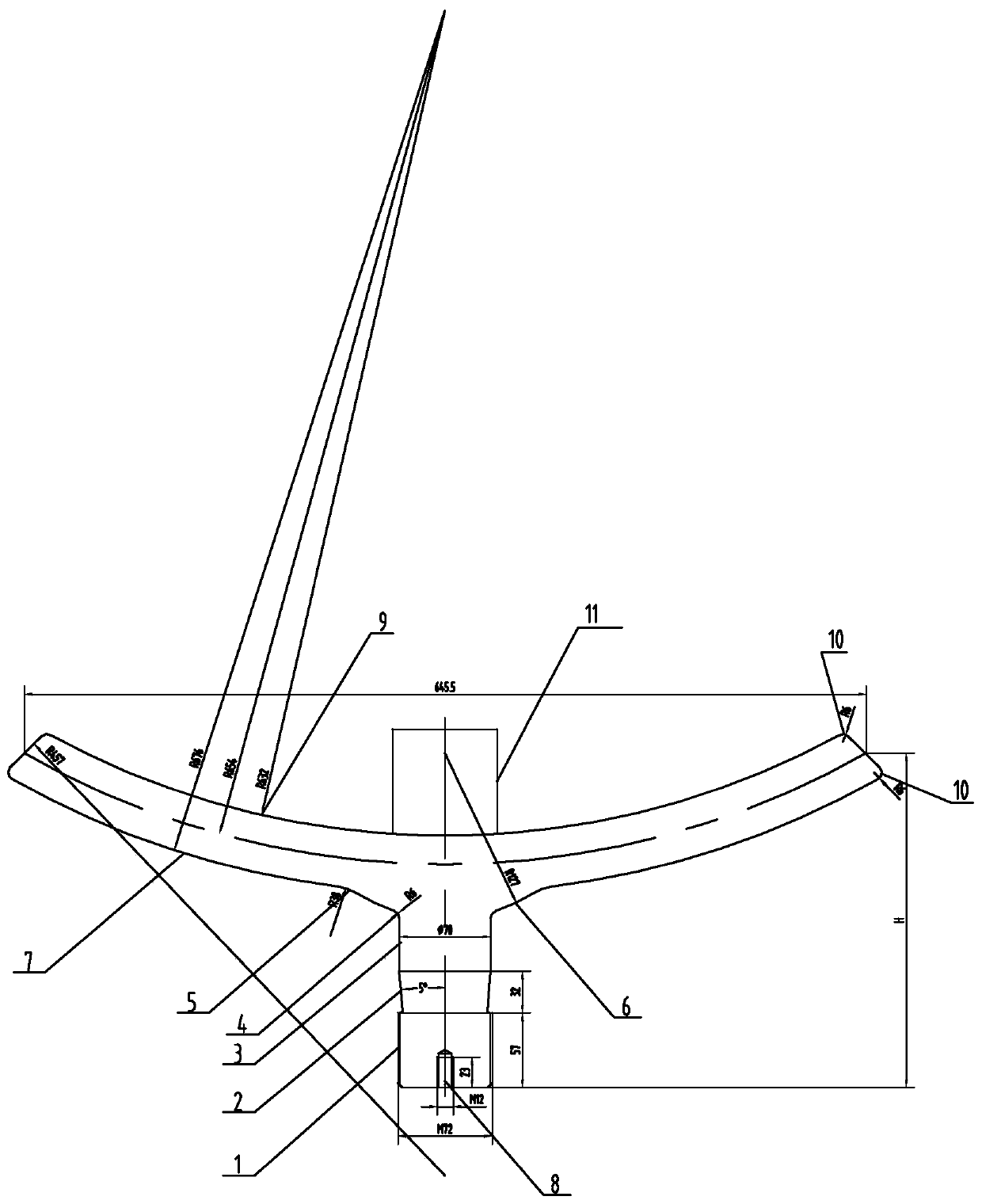

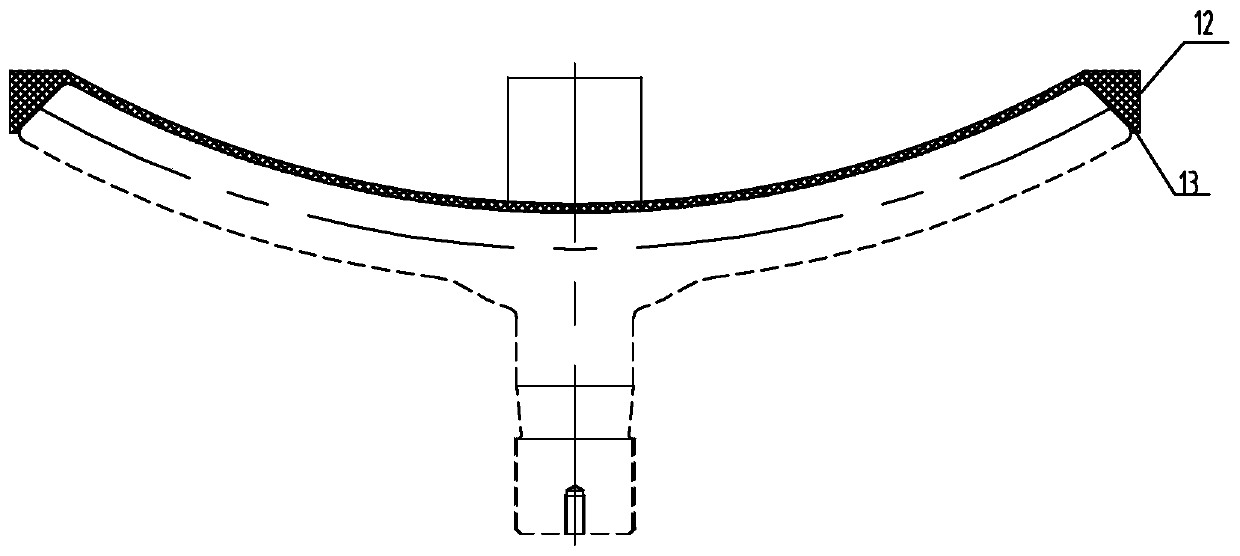

[0032] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, the processing method of the umbrella-shaped valve disc described in this embodiment is carried out in the following steps:

[0033] Step 1: preparing a blank and forging the blank;

[0034] Step 2: select a horizontal lathe to rough turn the blank obtained in step 1, rough turn the outer circle and end face of the blank, and leave a clamping auxiliary head 11 at the center of the upper end of the workpiece;

[0035] Step 3: Tempering and stress-relieving the workpiece obtained after rough turning in Step 2;

[0036] Step 4: Select a horizontal lathe to turn each part of the lower end of the workpiece obtained in step 3;

[0037] Turning steps are as follows:

[0038] 1. Use the four-jaw chuck configured on the lathe to clamp the clamping auxiliary head reserved in the center of the upper end of the workpiece;

[0039] 2. Turn the threaded section 1 at the lower end of the...

specific Embodiment approach 2

[0050] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, the forging process described in Step 1 of this embodiment is: heating the forging to be processed to 1150°C, forging according to the external dimensions of the forging, annealing the part after forging, heating at 860°C, and keeping warm 3 hours, followed by furnace cooling for 8 hours to obtain a blank. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0051] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, in step 2 of this embodiment, the machining allowance on one side of the outer circle and the end face is 3mm, the rotation speed is 80r / min, the feed rate is 0.2mm / r, and the cutting depth is 2mm. Other components are the same as those in Embodiment 1 in terms of connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com