Distribution type heat collection board molding method

A forming method and a heat collecting plate technology, which are applied in the field of spacecraft thermal control, can solve the problems that the new heat collecting plate cannot be guaranteed to meet the use requirements, and the heat collecting plate is difficult to manufacture and form, so as to ensure good appearance, reduce weight, reduce volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0037] The invention provides a method for forming a distributed heat collecting plate, the processing steps are as follows:

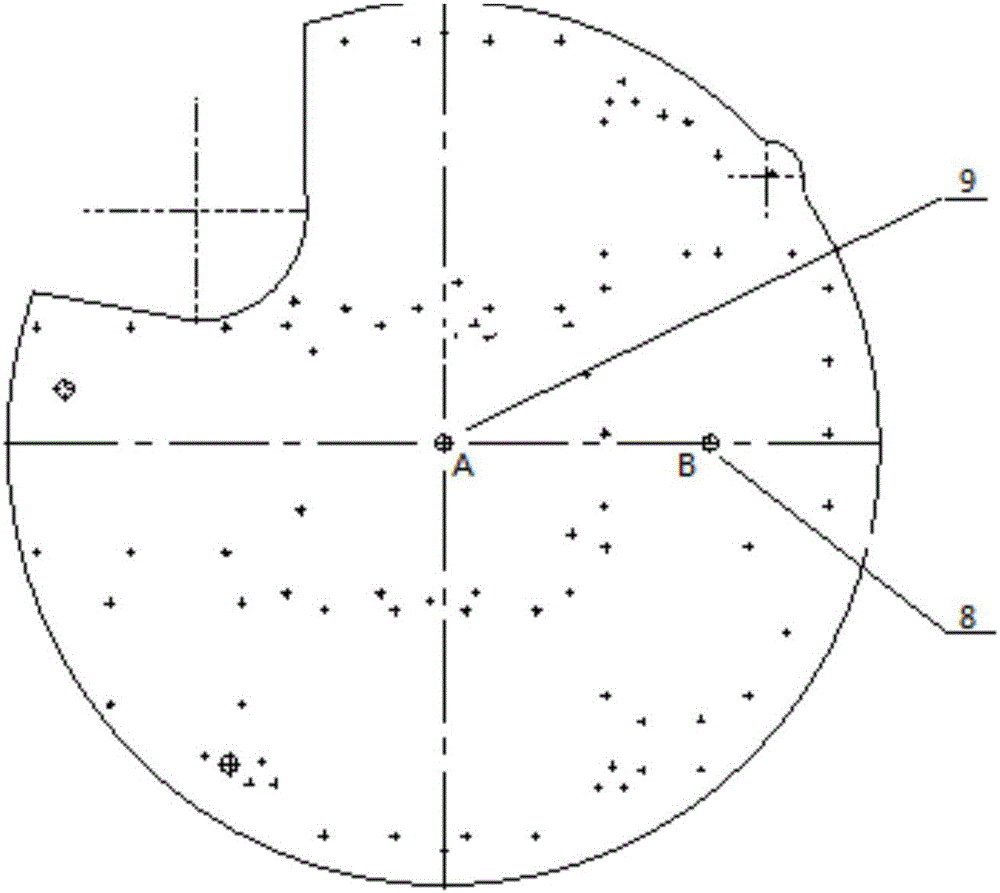

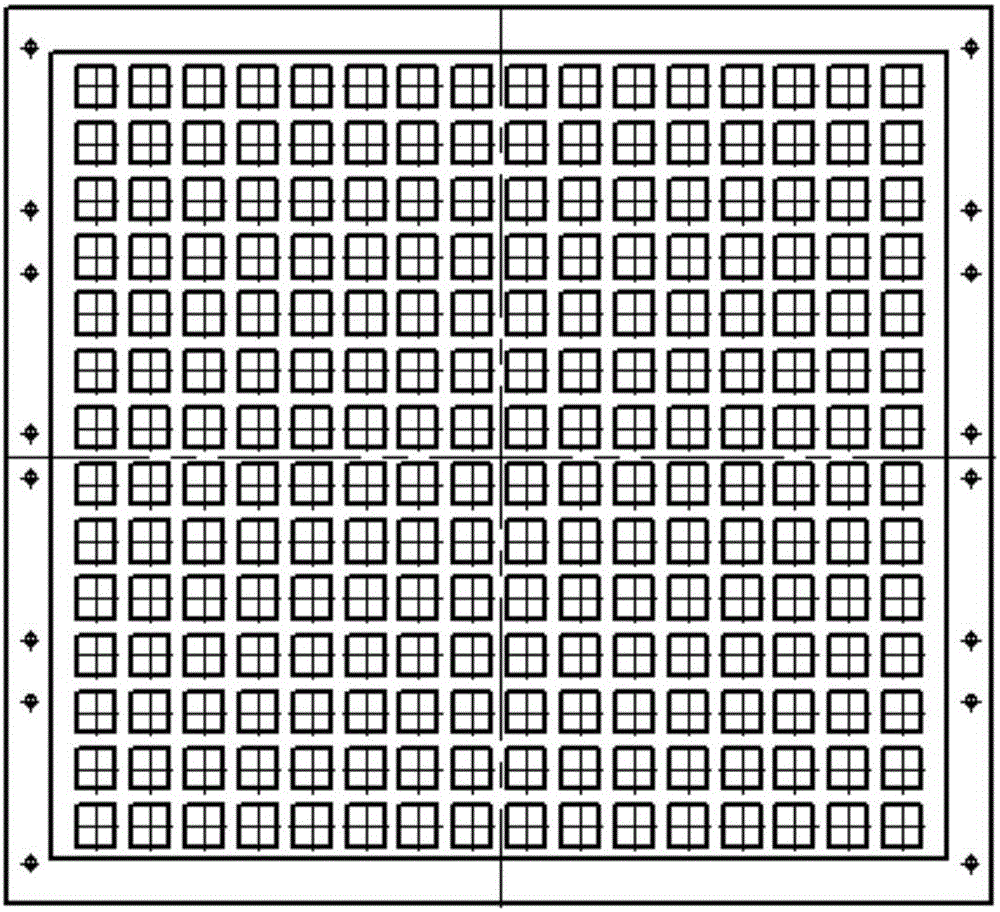

[0038] Step 1: Design and process integrated stainless steel fixture plates, such as image 3 As shown, there is a weight-reducing hole on one side of the fixture plate, pre-baking the fixture plate before use, the pre-baking temperature is 650±3°C, and the holding time is 1.5±0.1h, so that the gas inside the fixture plate can be fully released;

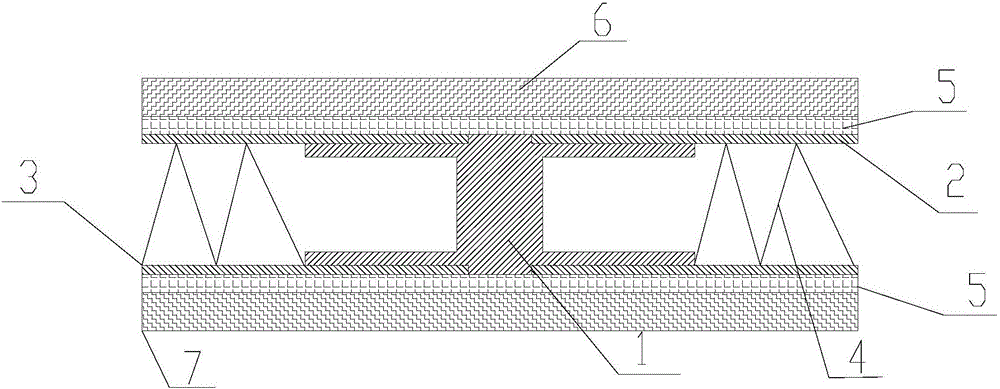

[0039] Step 2: In order to ensure the flatness of the welding wheel embedded block 1 and the fin deflector 4, the flatness of the clamping surface of the fixture plate must be higher than that of the heat collector wheel embedded block 1 and the fin deflector The design of 4 requires flatness, therefore, the clamping surface of the fixture plate is milled before use, so that the flatness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com