Tension balancing system arranged at bottom of stand pipe

A balancing system and tension technology, applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/fittings, etc., can solve problems affecting the integrity of pipeline end connectors and jumpers, system leakage, damage, etc. The effect of protecting integrity and security and avoiding system damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

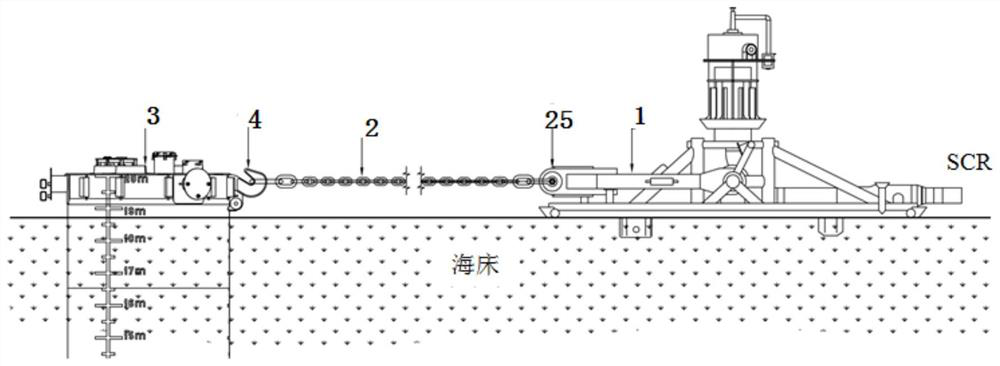

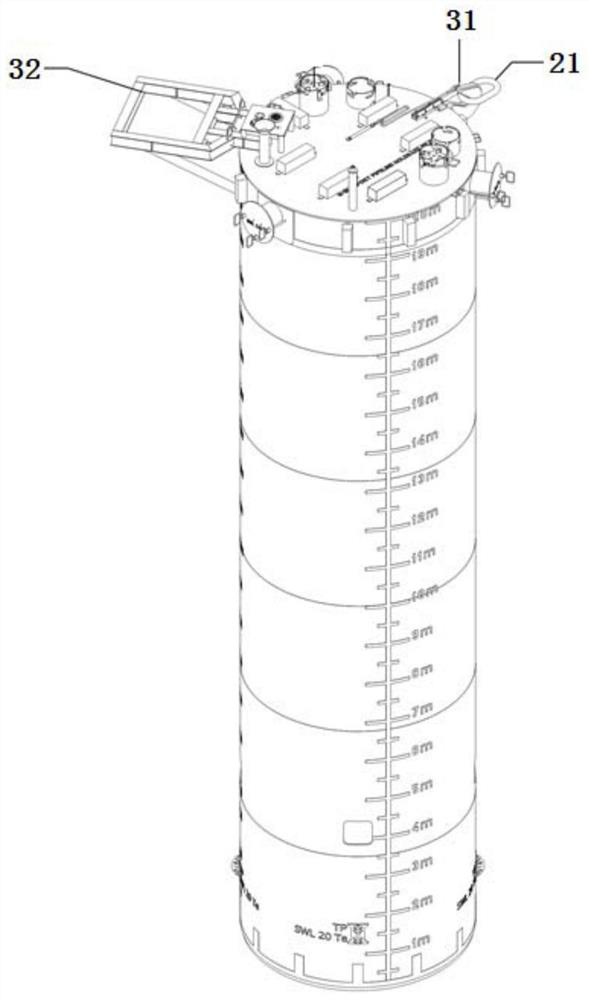

[0022] example, as Figure 1 to Figure 3 As shown, the present invention discloses a tension balance system arranged at the bottom of a riser, including a riser pipeline terminal 1, a tension balance anchor chain 2 and a deep water suction pile 3;

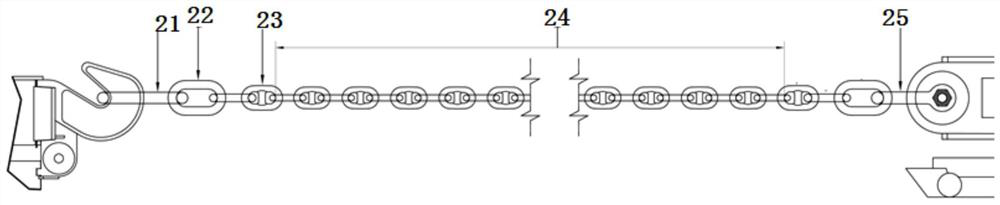

[0023] Tension balance anchor chain 2, one end of the tension balance anchor chain 2 is connected to the lifting ear of the pipeline terminal through the shackle 25, and the other end is connected to the underwater ROV hook 31 on the deep water suction pile 3 through the reinforcement ring 21; the tension balance anchor chain 2 It is composed of reinforcing ring 21, special end ring 22, end ring 23, common chain ring 24 and shackle 25 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com