Novel magnetic suspension energy storage flywheel rotor

A technology of energy storage flywheel and flywheel rotor, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit, and mechanical energy control, and can solve problems such as large tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

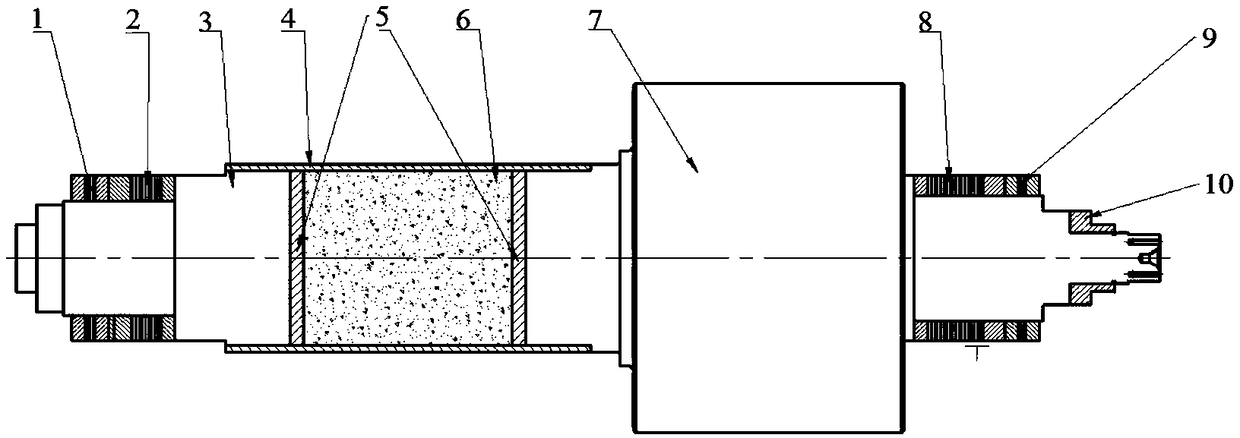

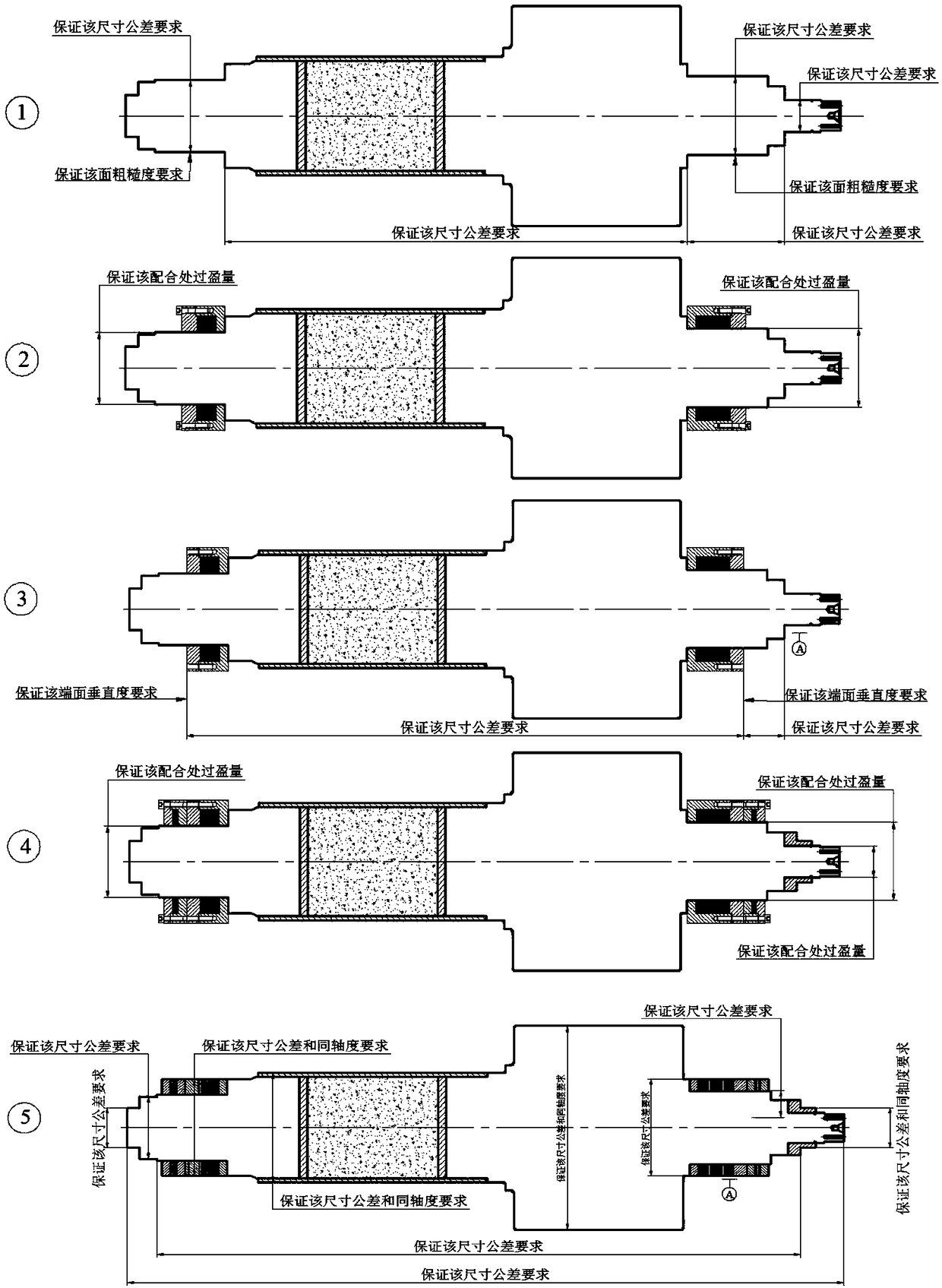

[0010] As shown in the figure, in the figure: upper speed sensor rotor 1; upper magnetic bearing rotor 2; flywheel upper shaft 3; motor rotor sheath 4; magnetic steel partition 5; rotor magnetic steel 6; flywheel lower shaft 7; lower magnetic bearing Rotor 8; Lower speed sensor rotor 9; Thrust disc seat 10. In general, the permanent magnet of the motor in the energy storage flywheel should not only have good magnetic properties, but also have a sufficiently high operating temperature and thermal stability. Due to the high-speed and high-frequency additional losses of the high-speed permanent magnet rotor, the heat dissipation conditions are poor. In order to prevent the irreversible demagnetization of the permanent magnet caused by the overheating of the rotor, the permanent magnet of the motor rotor in this example is made of integral cylindrical samarium cobalt material, which has the best magnetic stability, and its Curie temperature is higher than that of NdFeB, and its tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com