Processing technology for thin annular parts

A technology of annular parts and processing technology, applied in the field of thin annular parts processing technology, can solve problems such as insufficient rigidity, elastic deformation shape error of parts, and excess flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

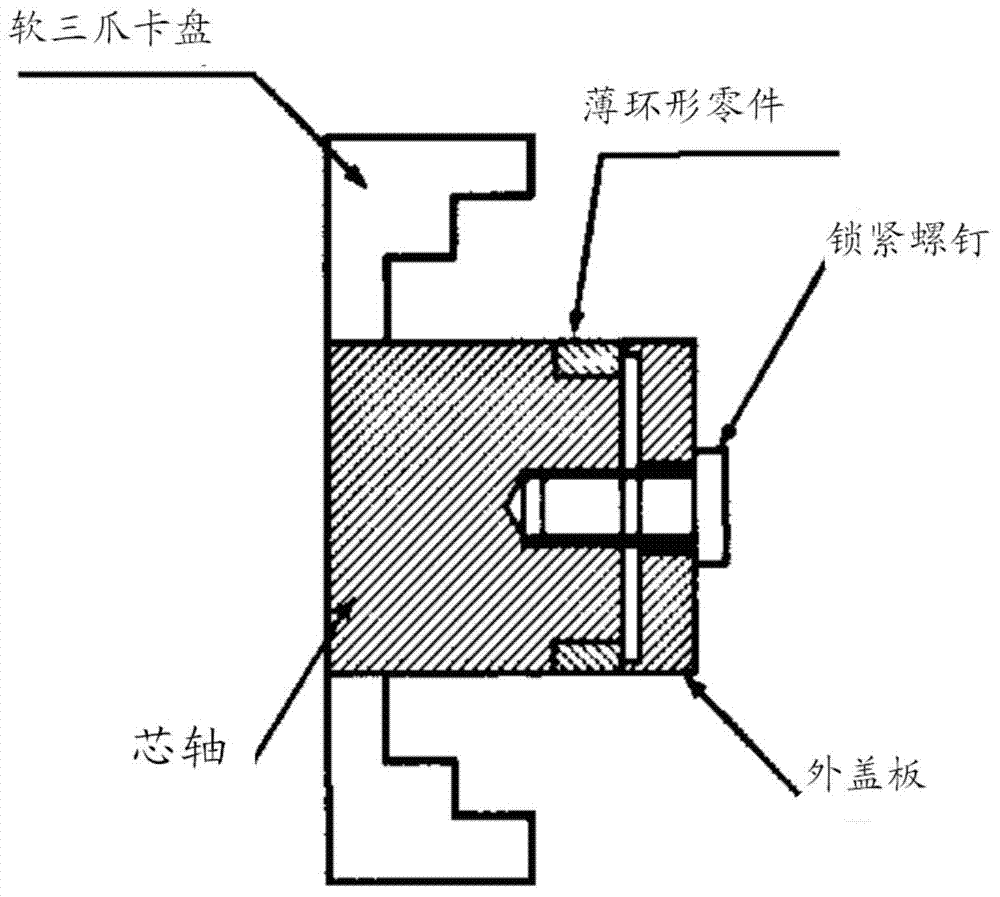

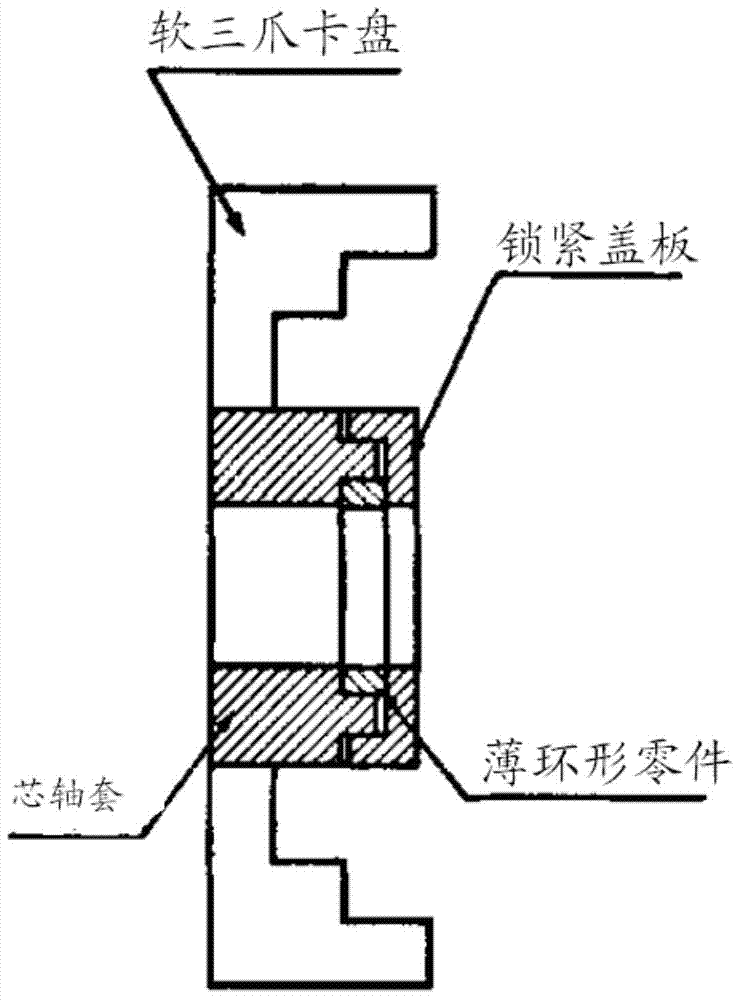

Method used

Image

Examples

Embodiment Construction

[0016] (1) Do not use force when locking the hexagon socket screw, just tighten it slightly, because the workpiece will be deformed by compression and the radial dimension after processing will be too small;

[0017] (2) The locking cover is screwed too tightly to prevent the workpiece from being deformed by force;

[0018] (3) The feed amount is controlled at 0.03-0.08mm according to the workpiece material;

[0019] (4) The rotating speed is controlled at 400~1200r / min according to different workpiece materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com