A cutting and ejecting device for cutting off the glass guide rail of an automobile door

A technology for glass guide rails and car doors, which is applied to cutting devices with nibbling action, shearing devices, accessories of shearing machines, etc. Large and other problems, to achieve the effect of gap-free cutting quality, ingenious structure setting, and smooth material return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

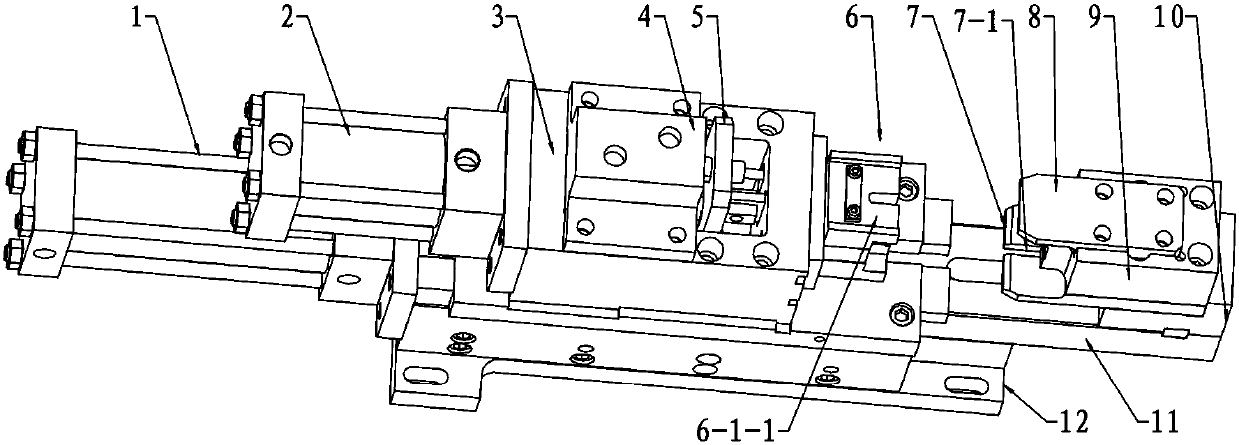

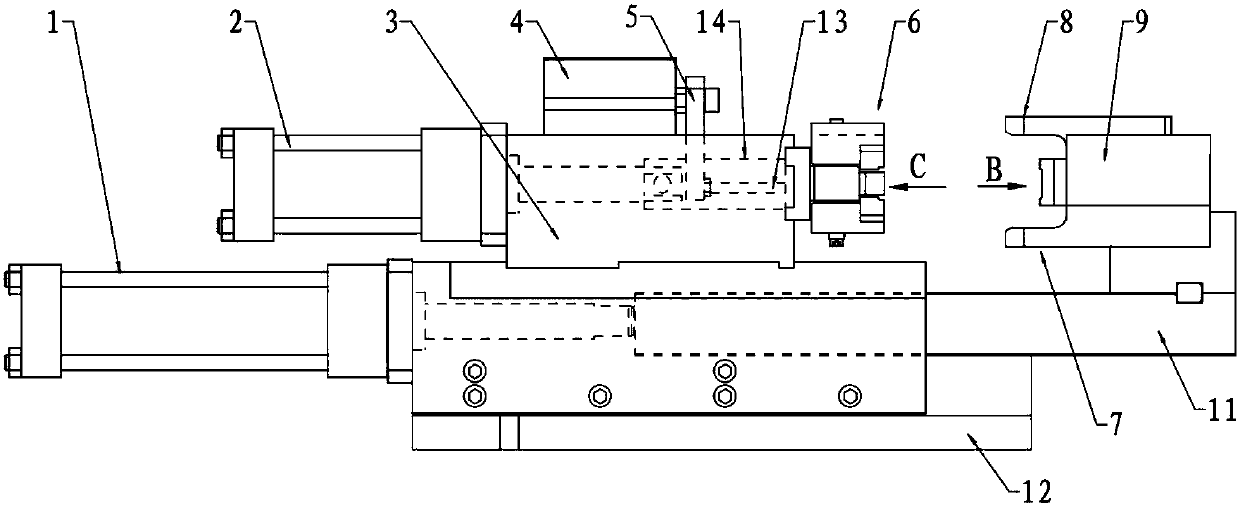

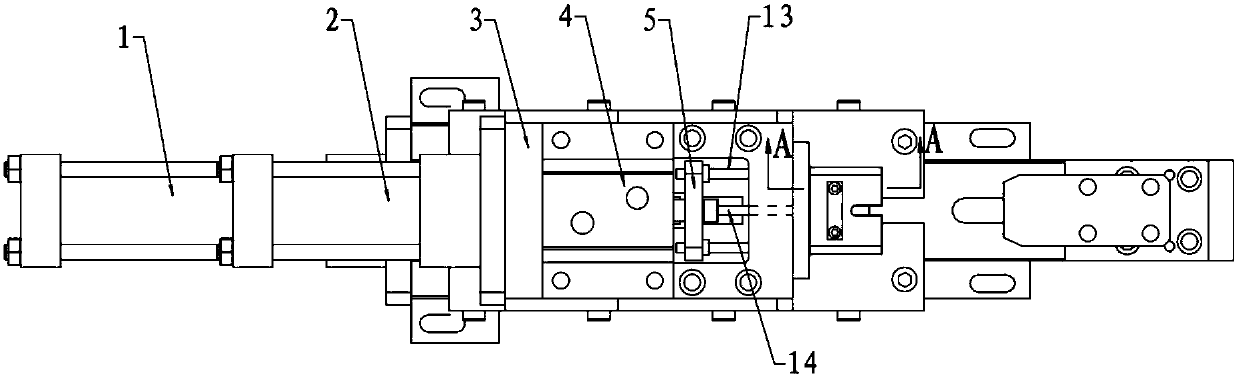

[0025] see Figure 1-Figure 3 , The cutting and ejecting device of the present invention includes a base 12, and an installation frame 3 is fixed on the upper part of the base. In order to realize the functions of cutting and returning the bent automobile door glass guide rail product parts, the present invention is provided with a clamping mechanism, a cutting mechanism and a material returning mechanism. The material return mechanism is used to push down the cut-off automobile door glass guide rail product parts. The material return mechanism includes a material return cylinder 4, a material return plate 5 and a material return rod 13. The material return cylinder is fixed on the top of the mounting frame, and the return material The piston rod of the oil cylinder is fixedly connected to the stripping plate, and the two stripping rods are symmetrically fixed on the lower part of the stripping plate. fall. The cutting mechanism includes a cutting oil cylinder 2 and a cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com