Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Good deoxidizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing welding wire made of nickel base alloy

ActiveCN103949805AEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

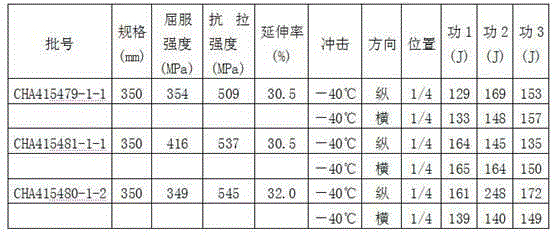

Extremely-thick low alloy steel plate for E-level high purity ocean platform and production method thereof

The invention discloses an extremely-thick low alloy steel plate for an E-level high purity ocean platform and further relates to a production method of the steel plate. The steel plate comprises, by weight, 0.10%-0.18% of C, 0.15%-0.35% of Si, 0.90%-1.60% of Mn, 0-0.02% of P, 0-0.005% of S, 0.020%-0.030% of Nb, 0.010%-0.080% of Al, 0.035%-0.065% of V, 0-0.025% of Ti, and the balance Fe and inevitable impurities. The production method of the steel plate includes the following steps of electric furnace smelting, LF / VD refining, continuous casting, electroslag remelting, steel ingot heating, rolling, water cooling after rolling, heat stacking, heat treatment and finished product obtaining. The maximum thickness of the steel plate obtained through the method can reach 350 mm, and the characteristics of being good in welding property, excellent in low temperature impact toughness and good in thickness directional property are achieved. Meanwhile, steel is clean, performance evenness is good, high flaw detection and performance requirements can be met, and a wide application prospect is achieved.

Owner:WUYANG IRON & STEEL

Method for preparing nickel base alloy welding wire with diameter smaller than 3 mm

ActiveCN103962755AEasy to processHigh strengthWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a nickel base alloy welding wire. Alloy of the nickel base alloy welding wire comprises, by mass, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0.025% or less of P, 0.02% or less of S, 28%-30% of Cr, 49%-51% of Ni, 0.1% or less of Co, 0.1% or less of Mo, 0.1% or less of Ti, 0.1% or less of Al, 4.0%- 5% of W and the balance being Fe. The method for preparing the nickel base alloy welding wire includes the steps of alloy smelting, electroslag remelting, hot forging and blooming, hot rolling and annealing, acid pickling and coping, cold drawing and hydrogen withdrawing. A CaF2 slag system, an Al2O3 slag system and a CaO slag system are adopted in electroslag remelting. Through the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting requirements can be prepared, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

Nickel alloy welding wire for welding cast iron pipe

InactiveCN105108377AImprove performanceImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaNickel alloyUltimate tensile strength

The invention belongs to the technical field of welding, relates to a welding wire, discloses an alloy welding wire and particularly relates to a nickel alloy welding wire for welding a cast iron pipe. Chemical components of the welding wire comprise, by mass, 0%-0.30% of C, 0%-0.03% of Mn, 0%-0.60% of Si, 0%-0.020% of P, 0%-0.02% of S, 55.00%-85.00% of Ni and the balance iron. A method includes the steps of alloy smelting, electroslag remelting and the like. According to the mechanical properties of the welding wire, the yield strength is 300-600 Mpa, the tensile strength is 500-700 Mpa, the ductility is 10-40%, and impact strength is 56J. The mechanical properties of the welding wire are better than those of similar foreign products, and the welding wire can completely take the place of imported welding wires.

Owner:DANYANG XINHANG SPECIAL ALLOY

Nickel base alloy welding wire with diameter smaller than 3 mm

ActiveCN103962747AEasy to processHigh strengthWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a nickel base alloy welding wire. Alloy of the nickel base alloy welding wire comprises, by mass, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0.025% or less of P, 0.02% or less of S, 28%-30% of Cr, 49%-51% of Ni, 0.1% or less of Co, 0.1% or less of Mo, 0.1% or less of Ti, 0.1% or less of Al, 4.0%- 5% of W and the balance being Fe. A method for preparing the nickel base alloy welding wire includes the steps of alloy smelting, electroslag remelting, hot forging and blooming, hot rolling and annealing, acid pickling and coping, cold drawing and hydrogen withdrawing. A CaF2 slag system, an Al2O3 slag system and a CaO slag system are adopted in electroslag remelting. Through the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting requirements can be prepared, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

Manufacturing method of stainless steel welding wire

InactiveCN108526768AImprove antioxidant capacityImprove liquidityWelding/cutting media/materialsSoldering mediaSlagHeating furnace

The invention relates to a manufacturing method of a stainless steel welding wire. The method comprises the following steps: smelting through a vacuum electric furnace; heating an alloy ingot in a heating furnace under the initial temperature which is not greater than 600 DEG C; cooling a horizontal continuously-casted steel blank; and then rolling. With the adoption of the method, the oxidation resistance of a welding seam at high temperature can be improved; and meanwhile, Si is a good deoxidizing agent; in addition, the flowability of slags and molten metal can be improved, and meanwhile, the surface of the welding seam is prevented from slag bonding, so that the welding efficiency is improved, and the performance of welding cladding metal as well as the use performance can be achieved.

Owner:淮北百壹领域建筑科技有限公司

Method for manufacturing Cr28Ni48W5 nickel base alloy into welding wire

ActiveCN103962756AEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a nickel base alloy welding wire. The nickel base alloy comprises, by weight, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0%-0.025% of P, 0%-0.02% of S, 28%-30% of Cr, 49%-51% of Ni, 0%-0.1% of Co, 0%-0.1% of Mo, 0%-0.1% of Ti, 0%-0.1% of Al and 4.0%-5.0% of W, and the balance iron. The preparing method comprises the step of alloy smelting, electroslag remelting, hot forging cogging, hot rolling annealing, acid pickling, coping, cold drawing and hydrogen retreating, and a CaF2, Al2O3 and CaO slag system is adopted in the electroslag remelting. According to the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting the requirement can be obtained, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

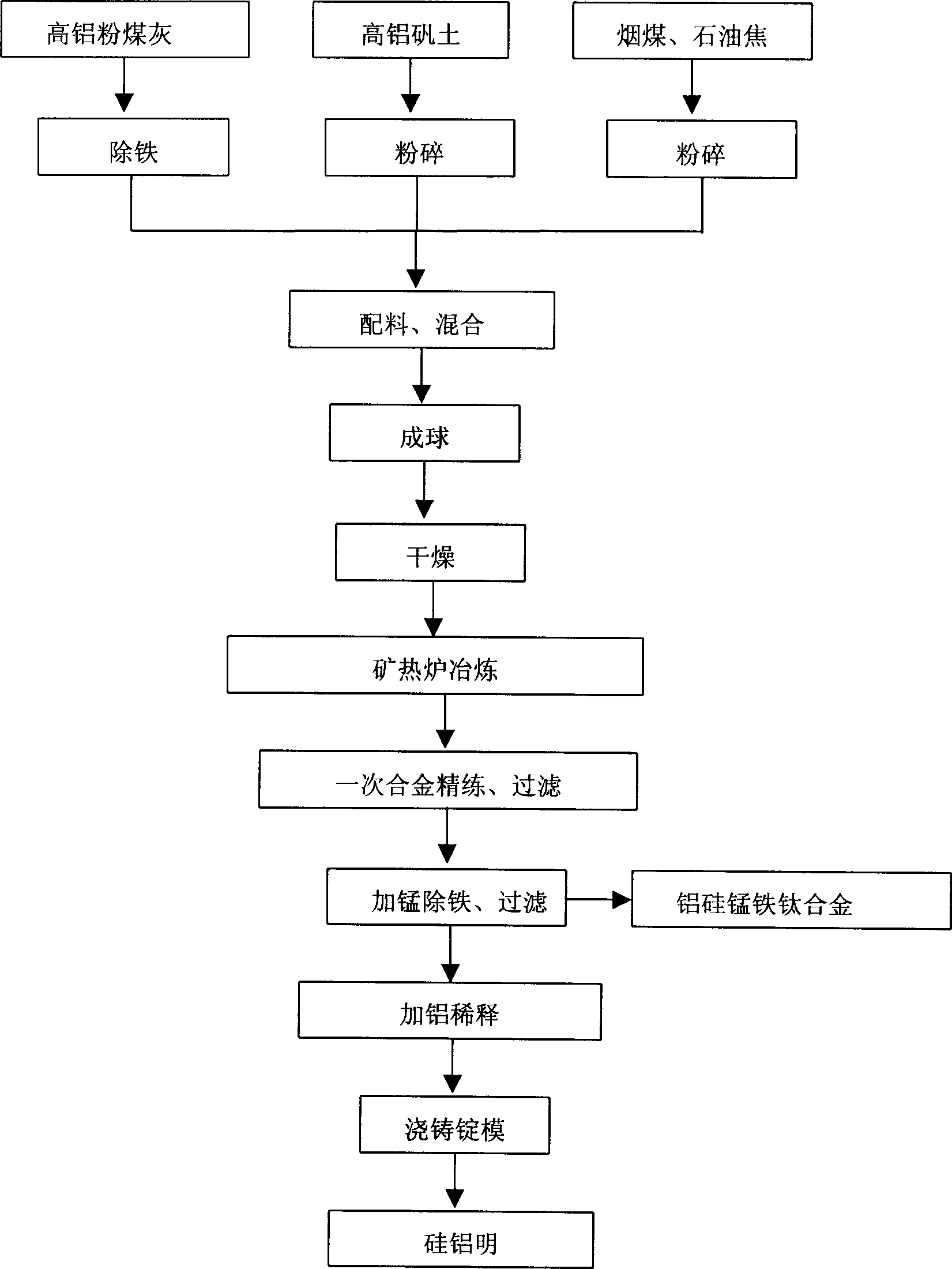

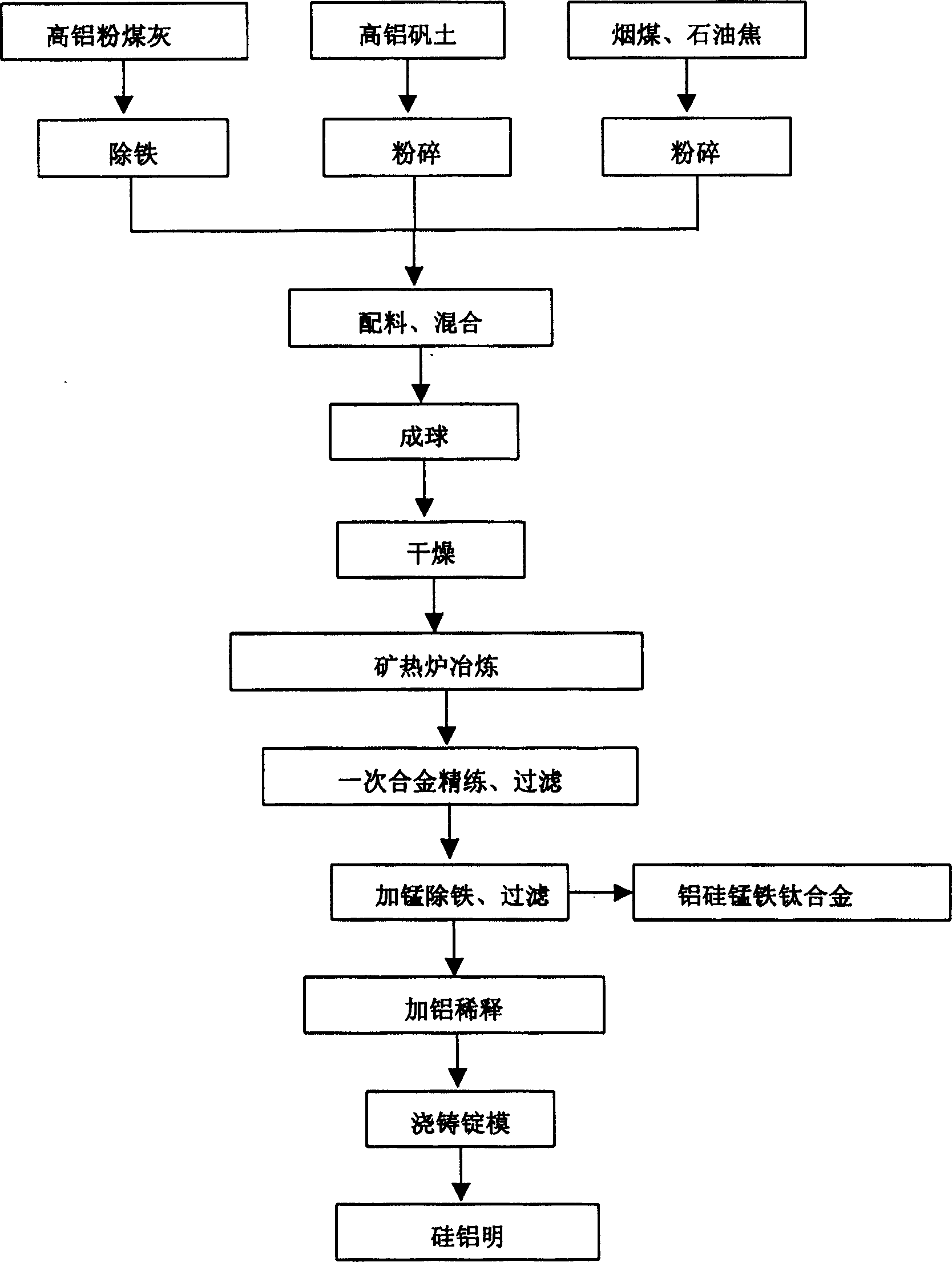

Method for preparing silumin and Al-Si-Mn-Fe-Ti alloy by using high-aluminum fly ash

ActiveCN1690235ARealize resource utilizationReduce manufacturing costProcess efficiency improvementSiluminAdhesive

Preparing silumin and Al-Si-Mn-Fe-Ti alloy with coal ash of high-alumina powder, relates to the technical sphere of non-ferro metals smelting. The steps of the invented process are: 1) deironing from coal ash of high-alumina powder, and breaking separately the bauxite chamotte and reducer boghead coal and oil coke; 2) batching and mixing them; 3) adding adhesive and water to the mixture, globularzing and drying; 4) sending the dried pellet to the stove and smelting in a high temperature to prepare primary alloy; 5) cleaning up of inclusion and gas in the primary alloy by refining and filtering it; 6) adding manganese to the refined alloy and deironing and filtering to prepare the Al-Si-Mn-Fe-Ti allay; 7) adding Al to the deironed and filtered alloy, diluting and casting ingot, to prepare silumin. The invention is characterized in that the investment is a little, the productive cycle is short, the energy consumption is low, and the quality of the alloy is nice.

Owner:TSINGHUA UNIV +1

Welding wire made of Cr28 Ni48 W5 nickel base alloy

ActiveCN103949800AImprove antioxidant capacityImprove liquidityWelding/cutting media/materialsSoldering mediaSlagForging

The invention relates to a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. A method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

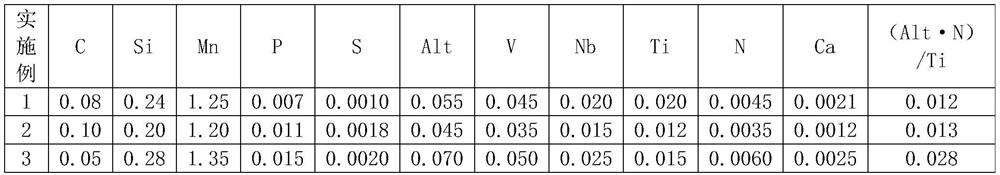

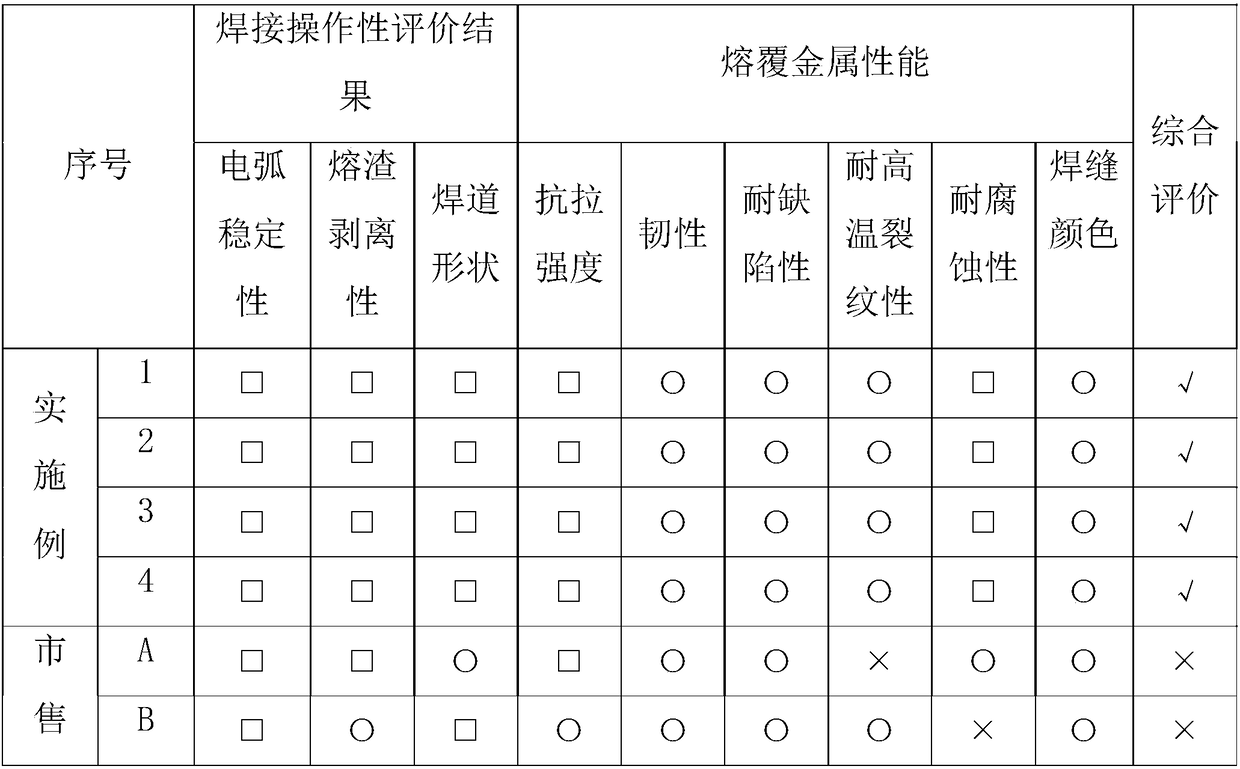

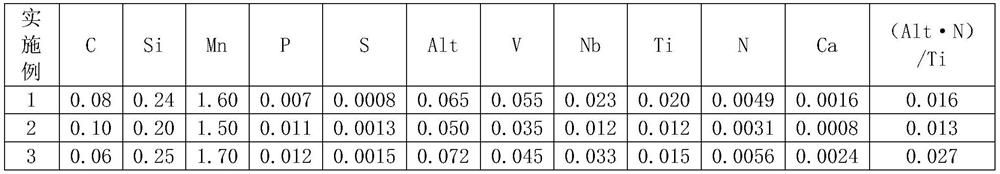

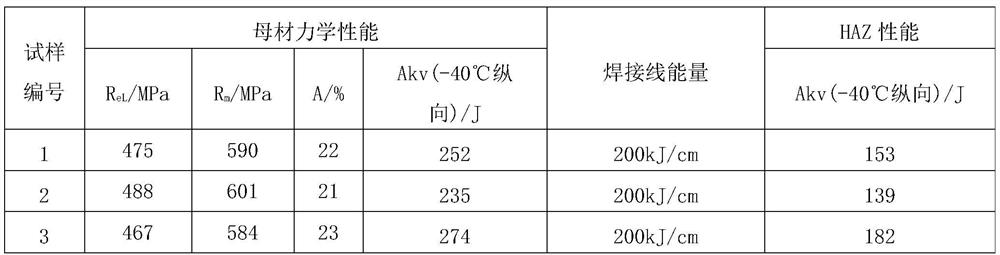

E420-W300 ultrahigh-strength ship plate steel and manufacturing method therefor

The invention discloses E420-W300 ultrahigh-strength ship plate steel, comprising the following chemical components in percentage by mass: 0.04-0.12% of C, 0.15-0.35% of Si, 1.20-1.40% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030-0.060% of V, 0.010-0.030% of Nb, 0.030-0.080% of Ant, 0.005-0.030% of Ti, 0.0005-0.0040% of Ca, less than or equal to 0.0060% of N.(Alt N) / Ti is controlled within 0.010-0.030; the yield strength is larger than or equal to 420 MPa; the tensile strength is larger than or equal to 530 MPa; the steel plate is suitable for high-strength ship plate steel with the welding linear energy within the range of 300 kJ / cm; and the average impact energy of HAZ of the steel plate at the temperature of -40 DEG C is 42 J or above.

Owner:NANJING IRON & STEEL CO LTD

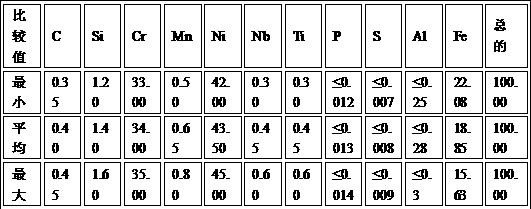

Low-phosphorus and low-sulfur high-strength heat-resistant Cr35Ni45 nichrome welding wire and preparation technology thereof

InactiveCN107138873AEfficient processHigh strengthWelding/cutting media/materialsSoldering mediaChromium nickelNichrome

The invention relates to a low-phosphorus and low-sulfur high-strength heat-resistant Cr35Ni45 nichrome welding wire and a preparation technology of the welding wire. The welding wire comprises, by mass, 0.35-0.45% of C, 1.20-1.60% of Si, 33.00-36.00% of Cr, 0.50-0.80% of Mn, 42.00-45.00% of Ni, 0.30-0.60% of Nb, 0.30-0.60% of Ti, 0.012%-0.014% of P, 0.007-0.009% of S, 0.25-0.30% of Al, 15.63-22.08% of Fe, and other unavoidable impurity elements. The preparation technology of the welding wire comprises the processes of vacuum smelting, homogenizing annealing, hot-forging cogging, multi-pass hot rolling, multi-pass cold drawing and finished product annealing. The welding wire has the good comprehensive mechanical property and well thermostable performance, the room temperature tensile strength of the welding wire is 1150-1250 MPa, and the room temperature percentage of elongation of the welding wire is 10-15%; and when the welding wire is tested at 1000 DEG C, the tensile strength is 600-700 MPa, and the elongation is greater than 25%.

Owner:JIANGSU YULI NEW MATERIAL TECH

A kind of method for preparing nickel-based alloy welding wire

ActiveCN103949805BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

Welding seam halogen-free ferrite stainless steel flux-cored wire and preparation method thereof

ActiveCN108994477AInhibit bindingImprove antioxidant capacityArc welding apparatusWelding/cutting media/materialsAdhesiveWeld seam

The invention belongs to the field of welding materials, and particularly relates to a welding wire, in particular to a welding seam halogen-free ferrite stainless steel flux-cored wire and a preparation method thereof. The welding wire is composed of a welding core and a coating, the coating wraps the welding wire, and an adhesive is used for bonding the coating around the welding core; and the preparation method specifically comprises the following steps: (1) preparing the adhesive; (2) mixing and granulating; (3) mixing the coating; (4) preparing the welding core, and (5) painting the coating and the periphery of the welding wire and baking to obtain the welding wire. According to the welding seam halogen-free ferrite stainless steel flux-cored wire, the welding wire can form a compactprotective layer after stainless steel is clad, and the combination of oxygen and metal components in the alloy is prevented, so that the surface of a welding seam is still silver white, the oxidationresistance is excellent, and the surface of the welding seam does not need to be subjected to subsequent de-oxidation treatment; and the production process is simple, the cost is low, the efficiencyis high, and continuous and large-scale production can be realized.

Owner:山东金泰隆焊材有限公司

A kind of preparation method of nickel base alloy welding wire with diameter less than 3mm

ActiveCN103962755BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a nickel base alloy welding wire. Alloy of the nickel base alloy welding wire comprises, by mass, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0.025% or less of P, 0.02% or less of S, 28%-30% of Cr, 49%-51% of Ni, 0.1% or less of Co, 0.1% or less of Mo, 0.1% or less of Ti, 0.1% or less of Al, 4.0%- 5% of W and the balance being Fe. The method for preparing the nickel base alloy welding wire includes the steps of alloy smelting, electroslag remelting, hot forging and blooming, hot rolling and annealing, acid pickling and coping, cold drawing and hydrogen withdrawing. A CaF2 slag system, an Al2O3 slag system and a CaO slag system are adopted in electroslag remelting. Through the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting requirements can be prepared, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

A kind of non-oxidation color ferritic stainless steel coated welding wire and its preparation method

ActiveCN108994477BInhibit bindingImprove antioxidant capacityArc welding apparatusWelding/cutting media/materialsAdhesiveAlloy

The invention belongs to the field of welding materials, and particularly relates to a welding wire, in particular to a welding seam halogen-free ferrite stainless steel flux-cored wire and a preparation method thereof. The welding wire is composed of a welding core and a coating, the coating wraps the welding wire, and an adhesive is used for bonding the coating around the welding core; and the preparation method specifically comprises the following steps: (1) preparing the adhesive; (2) mixing and granulating; (3) mixing the coating; (4) preparing the welding core, and (5) painting the coating and the periphery of the welding wire and baking to obtain the welding wire. According to the welding seam halogen-free ferrite stainless steel flux-cored wire, the welding wire can form a compactprotective layer after stainless steel is clad, and the combination of oxygen and metal components in the alloy is prevented, so that the surface of a welding seam is still silver white, the oxidationresistance is excellent, and the surface of the welding seam does not need to be subjected to subsequent de-oxidation treatment; and the production process is simple, the cost is low, the efficiencyis high, and continuous and large-scale production can be realized.

Owner:山东金泰隆焊材有限公司

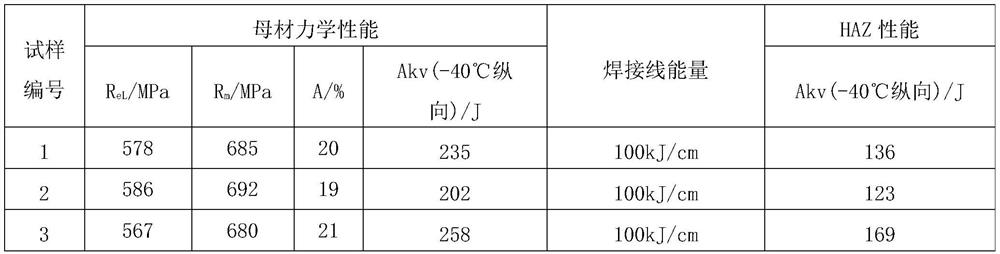

E550-W100 ultrahigh-strength ship plate steel and manufacturing method thereof

InactiveCN112322966AReduce plasticityReduce toughnessFurnace typesMetal rolling arrangementsUltimate tensile strengthWeld line

The invention discloses E550-W100 ultrahigh-strength ship plate steel. The E550-W100 ultrahigh-strength ship plate steel comprises the following chemical components in percentage by mass: 0.04%-0.12%of C, 0.15%-0.35% of Si, 1.50%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030%-0.060% of V, 0.010%-0.030% of Nb, 0.030%-0.080% of Alt, 0.005%-0.030% of Ti, 0.0005%-0.0040% of Ca and less than or equal to 0.0060% of N, wherein (Alt.N) / Ti is controlled to be 0.010 to 0.030. The yield strength of an obtained steel plate is larger than or equal to 550 MPa, the tensile strength of the steel plate is larger than or equal to 670 MPa, the steel plate is suitable for high-strength ship plate steel with the welding line energy within the range of 100 kJ / cm, andthe average impact energy of the HAZ of the steel plate at the temperature of -40 DEG C is 55 J or above.

Owner:NANJING IRON & STEEL CO LTD

Method of preparing magnesium-iron alloy welding wire with magnesium-iron alloy

InactiveCN109773374AEasy to processHigh strengthWelding/cutting media/materialsSoldering mediaMagnesiumForging

The invention relates to a method of preparing a magnesium-iron alloy welding wire with a magnesium-iron alloy. The alloy is prepared from the following components in percentage by mass: 0.4-0.45 percent of C, 1.0-1.5 percent of Ce, 0.15-1.2 percent of Sr, less than or equal to 0.025 percent of S, less than or equal to 0.02 percent of S, 28-30 percent of C1, 49-51 percent of Mg, less than or equalto 0.1 percent of Ne, less than or equal to 0.1 percent of Mo, less than or equal to 0.1 percent of Al, 4.0-5.0 percent of W and the balance of iron. The preparation method comprises the following steps of alloy smelting, electroslag remelting, hot forging cogging, hot roll annealing, acid pickling, repair grinding, cold drawing and hydrogen retreating, wherein in electroslag remelting, CaF2, Al2O3 and CaO slag systems are adopted. By adopting the preparation method of the magnesium-iron alloy welding wire, a thinner welding wire with the performance meeting the requirements can be prepared,and the yield is high.

Owner:马仲起

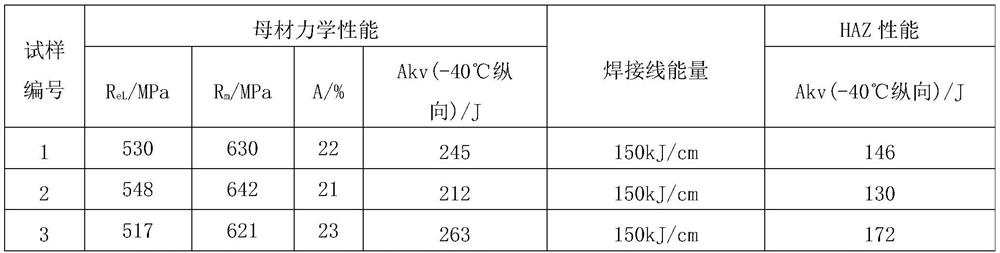

E500-W150 ultrahigh-strength ship plate steel and manufacturing method thereof

InactiveCN112322967AHigh strengthImprove toughnessTemperature control deviceFurnace typesChemical compositionUltimate tensile strength

The invention discloses E500-W150 ultrahigh-strength ship plate steel. The E500-W150 ultrahigh-strength ship plate steel is prepared from the following chemical components in percentage by mass: 0.04%-0.12% of C, 0.15%-0.35% of Si, 1.40%-1.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030%-0.060% of V, 0.010%-0.030% of Nb, 0.030%-0.080% of Alt, 0.005%-0.030% of Ti, 0.0005%-0.0040% of Ca and less than or equal to 0.0060% of N, wherein (Alt.N) / Ti is controlled to be 0.010 to 0.030. The yield strength of the E500-W150 ultrahigh-strength ship plate steel is larger than or equal to 500 MPa, the tensile strength of the E500-W150 ultrahigh-strength ship plate steel is larger than or equal to 610 MPa, the E500-W150 ultrahigh-strength ship plate steel is suitable for high-strength ship plate steel with the welding linear energy within the range of 150 kJ / cm, and the average impact energy of the HAZ of a steel plate at the temperature of 40 DEG C below zerois 50 J or above.

Owner:NANJING IRON & STEEL CO LTD

A kind of preparation method of welding wire

ActiveCN103949806BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaSlagManganese

The invention relates to a preparing method of a nickel base alloy welding wire. The components of the welding wire comprise, by weight, 0.4%-0.45% of calcium, 1.0%-1.5% of manganese, 0.15%-1.2% of silicon, equal to or less than 0.025% of phosphorus, equal to or less than 0.02% of sulfur, 28%-30% of chromium, 49%-51% of nickel, equal to or less than 0.1% of cobalt, equal to or less than 0.1% of molybdenum, equal to or less than 0.1% of titanium, equal to or less than 0.1% of aluminum, 4.0%-5.0% of wolfram, and the rest of iron. The preparing method is alloy smelting, electro-slag re-smelting, hot forging cogging, hot rolling annealing, acid pickling, coping, cold draw and hydrogen back, and the electro-slag re-smelting adopts a calcium fluoride, aluminum oxide and calcium oxide slag system. The preparing method of the nickel base alloy welding wire can produce the fine welding wire which can satisfy the requirement of the performance, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

A welding wire made of cr28ni48w5 nickel base alloy

ActiveCN103949800BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. A method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

A kind of nickel base alloy welding wire

ActiveCN103949799BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention relates to a nickel-based alloy welding wire, which comprises the following components in percentage by mass: 0.4% to 0.45% of C, 1.0% to 1.5% of Mn, 0.15% to 1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28% to 30% of Cr, 49% to 51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0% to 5.0% of W, and the balance of iron. The preparation method comprises the following steps of alloy melting - electro slag remelting - hot forging cogging - hot-rolled annealing- pickling and grinding - cold drawing - hydrogen annealing, and the electro slag remelting uses CaF2, Al2O3 and CaO slag systems. A thinner welding wire which meets the performance requirement can be prepared by the method for preparing the nickel-based alloy welding wire, with a high yield.

Owner:JIANGSU TOLAND ALLOY

Machining method for high-wear-resistance alloy welding wire

InactiveCN109807496AEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention relates to a machining method for a high-wear-resistance alloy welding wire. The high-wear-resistance alloy welding wire is prepared from the following alloy components in percentage bymass: 0.4-0.45% of C, 1.0-1.5% of Ce, 0.15-1.2% of Sr, less than or equal to 0.025% of S, less than or equal to 0.02% of S, 28-30% of Cl, 49-51% of Mg, less than or equal to 0.1% of Ne, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The preparation method comprises the following steps of carrying out alloysmelting, carrying out electroslag remelting, carrying out hot forging cogging, carrying out hot rolling annealing, carrying out acid pickling and grinding, carrying out cold-drawing and carrying outhydrogen annealing, wherein electroslag remelting adopts a CaF2, Al2O3 and CaO slag system. According to the preparation method for the magnesium-iron alloy welding wire, the relatively fine welding wire with the performance meeting requirement can be prepared, and the yield is high.

Owner:薛红剑

Method for preparing silumin and Al-Si-Mn-Fe-Ti alloy by using high-aluminum fly ash

ActiveCN1288258CRealize resource utilizationReduce manufacturing costProcess efficiency improvementAdhesiveManganese

Owner:TSINGHUA UNIV +1

Low-carbon high-strength steel with resistance to seawater corrosion, and manufacturing method thereof

The invention provides low-carbon high-strength steel with resistance to seawater corrosion, and a manufacturing method thereof. The low-carbon high-strength steel is composed of, by weight, 0.02%-0.05% of C, 0.10%-0.30% of Si, 0.10%-0.15% of Mn, 0.02%-0.04% of Al, 1.00%-1.50% of Cr, 0.20%-0.40% of Ni, 0.30%-0.50% of Cu, 0.02%-0.03% of Zr + Ti, 0.05%-0.08% of Re, no more than 0.015% of P, no more than 0.008% of S and the balance Fe and inevitable impurities. A TMCP process and a normalizing treatment mode are adopted. The tensile strength of the low-alloy high-strength steel with resistance to seawater corrosion is 400-600 MPa; The percentage elongation after fracture is greater than or equal to 30%. and the -40 DEG C low-temperature toughness is greater than or equal to 300, and the steel plate is excellent in mechanical comprehensive performance and high in seawater corrosion resistance.

Owner:CAIGUJINDAI (FOSHAN) METAL COMPOSITE MATERIALS CO LTD +1

Method for making cr28ni48w5 nickel base alloy into welding wire

ActiveCN103962756BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a nickel base alloy welding wire. The nickel base alloy comprises, by weight, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0%-0.025% of P, 0%-0.02% of S, 28%-30% of Cr, 49%-51% of Ni, 0%-0.1% of Co, 0%-0.1% of Mo, 0%-0.1% of Ti, 0%-0.1% of Al and 4.0%-5.0% of W, and the balance iron. The preparing method comprises the step of alloy smelting, electroslag remelting, hot forging cogging, hot rolling annealing, acid pickling, coping, cold drawing and hydrogen retreating, and a CaF2, Al2O3 and CaO slag system is adopted in the electroslag remelting. According to the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting the requirement can be obtained, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

E460-W200 ultrahigh-strength ship plate steel and manufacturing method thereof

InactiveCN112195400AHigh strengthImprove toughnessTemperature control deviceTension/compression control deviceMetallurgyUltimate tensile strength

The invention discloses E460-W200 ultrahigh-strength ship plate steel which comprises the following chemical components in percent by mass: 0.04-0.12% of C, 0.15-0.35% of Si, 1.30-1.50% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030-0.060% of V, 0.010-0.030% of Nb, 0.030-0.080% of Alt, 0.005-0.030% of Ti, 0.0005-0.0040% of Ca and less than or equal to 0.0060% of N, wherein (Alt.N)Ti is controlled within 0.010-0.030. For the ship plate steel, the yield strength is greater than or equal to 460 MPa and the tensile strength is greater than or equal to 570 MPa.The manufacturing method is suitable for the high strength ship plate steel, the weld heat input of which is in a range of 200 kJ / cm. The average ballistic work of HAZ of the steel plate at 40 DEG C below zero is over 46 J.

Owner:NANJING IRON & STEEL CO LTD

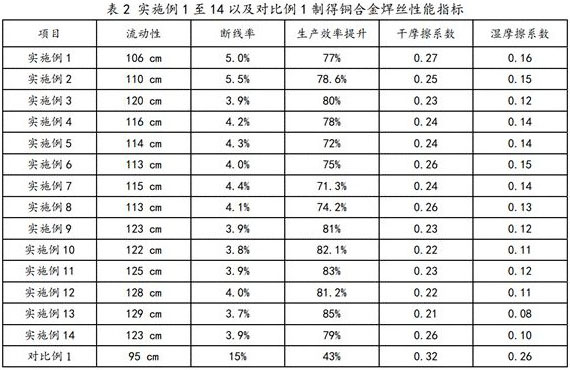

A copper alloy welding wire, preparation method and application

ActiveCN113234957BEasy to processNarrow single-phase areaWelding/cutting media/materialsSoldering mediaSwagingCopper alloy

The invention discloses a copper alloy welding wire, which comprises: 8.0 to 10.0% Al; 10.0 to 12.0% Mn; 2.0 to 4.0% Fe; 0.2 to 0.5% Sn; 0.1 to 0.3% Zn; 0.01 to 0.03% P; 0.01 to 0.35% Cr; 0.03 to 0.06% Si; the balance is Cu and unavoidable impurities; the invention also discloses a forming method of copper alloy welding wire, combining material properties, introducing hot rolling and swaging, specifically including: ingredients, Casting, hot rolling, annealing, swaging, wire drawing, peeling, and sizing forming; the invention also discloses the application of the copper alloy welding wire; the copper alloy welding wire casting performance and processing performance of the invention are greatly improved, and with the efficient forming method, The disconnection rate in the production process is reduced, the yield is increased, and the production efficiency is significantly improved.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

A nickel-based alloy welding wire with a diameter less than 3mm

ActiveCN103962747BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a nickel base alloy welding wire. Alloy of the nickel base alloy welding wire comprises, by mass, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0.025% or less of P, 0.02% or less of S, 28%-30% of Cr, 49%-51% of Ni, 0.1% or less of Co, 0.1% or less of Mo, 0.1% or less of Ti, 0.1% or less of Al, 4.0%- 5% of W and the balance being Fe. A method for preparing the nickel base alloy welding wire includes the steps of alloy smelting, electroslag remelting, hot forging and blooming, hot rolling and annealing, acid pickling and coping, cold drawing and hydrogen withdrawing. A CaF2 slag system, an Al2O3 slag system and a CaO slag system are adopted in electroslag remelting. Through the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting requirements can be prepared, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

a welding wire

ActiveCN103949801BEasy to processImprove antioxidant capacityFurnace typesWelding/cutting media/materialsSlagManganese

Owner:JIANGSU TOLAND ALLOY

A kind of preparation method of nickel base alloy welding wire

ActiveCN103949798BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaAdditive ingredientSlag

The invention relates to a preparation method for nickel base alloy welding wire with a relatively high yield. The alloy comprises the following ingredients in parts by weight: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The preparation method comprises the following steps of alloy smelting, electroslag remelting, hot forging cogging, hot rolling annealing, pickling, coping, cold drawing and hydrogen annealing, wherein electroslag remelting adopts CaF2, Al2O3 and CaO slag systems. According to the preparation method for the nickel base alloy welding wire, which is disclosed by the invention, the thin welding wire of which the performance can satisfy the requirement can be prepared, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com