Low-carbon high-strength steel with resistance to seawater corrosion, and manufacturing method thereof

A low-alloy, high-strength, seawater-resistant technology, applied in the field of steel materials, can solve the problems of high preparation cost, poor practicability, and inability to truly achieve corrosion resistance, and achieve the effects of improving mechanical properties, preventing corrosion, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a kind of seawater corrosion-resistant low-alloy high-strength steel, comprising the following components by weight percentage:

[0030] C: 0.02~0.04%;

[0031] Si: 0.10~0.20%;

[0032] Mn: 0.12~0.15%;

[0033] Al: 0.02~0.03%;

[0034] Cr: 1.20~1.50%;

[0035] Ni: 0.20~0.30%;

[0036] Cu: 0.30~0.40%;

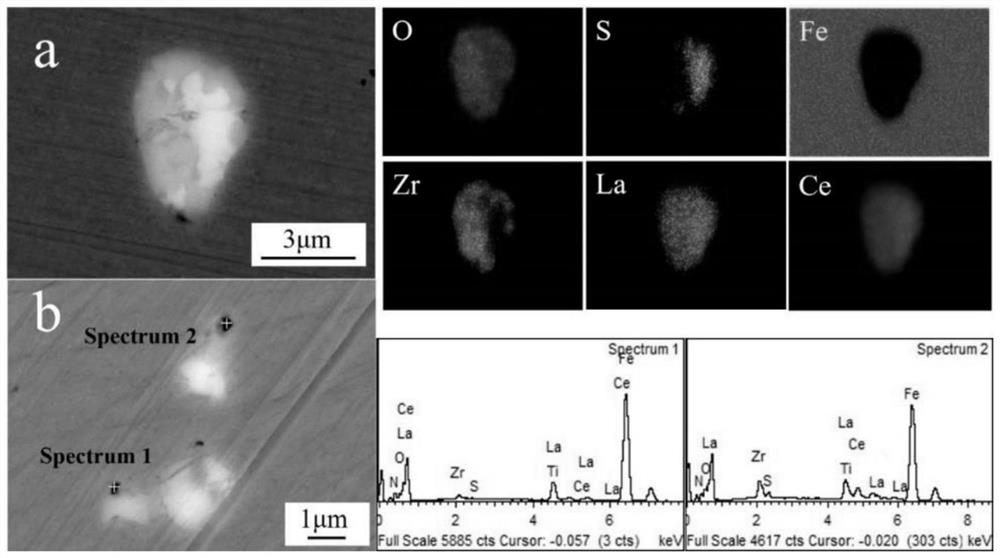

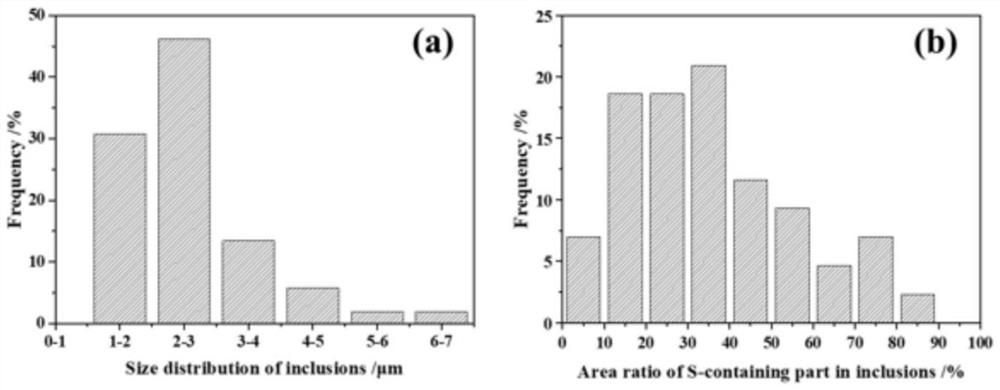

[0037] Zr+Ti: 0.02~0.03%;

[0038] Re: 0.05~0.06%;

[0039] P: ≤0.015%, S: ≤0.008%, and the rest are Fe and unavoidable impurities.

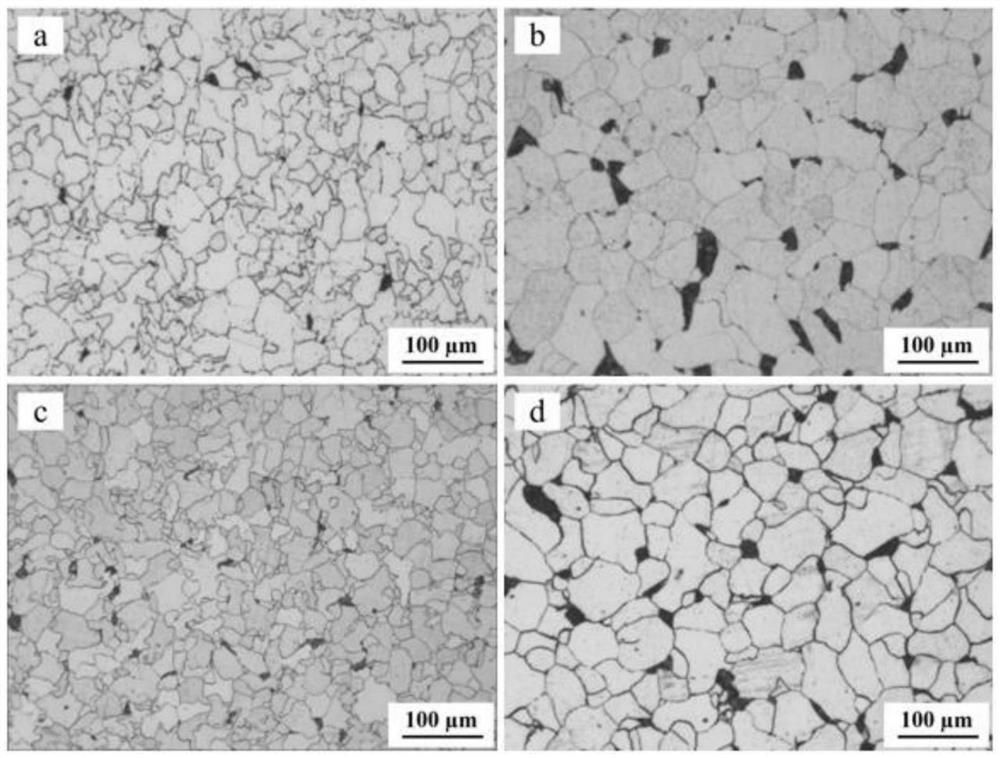

[0040] The production method of corrosion-resistant low-carbon high-strength steel is: TMCP+normalizing.

[0041] The seawater corrosion-resistant low-alloy high-strength steel prepared in Example 1 is denoted as Zr-Ti-Re.

Embodiment 2

[0043] This embodiment provides a kind of seawater corrosion-resistant low-alloy high-strength steel, comprising the following components by weight percentage:

[0044] C: 0.024%;

[0045] Si: 0.10%;

[0046] Mn: 0.12%;

[0047] Al: 0.02%;

[0048] Cr: 1.20%;

[0049] Ni: 0.20%;

[0050] Cu: 0.30%;

[0051] Zr+Ti: 0.02%;

[0052] Re: 0.05%;

[0053] P: ≤0.015%, S: ≤0.008%, and the rest are Fe and unavoidable impurities.

[0054] The production method of corrosion-resistant low-carbon high-strength steel is: TMCP+normalizing.

Embodiment 3

[0056] This embodiment provides a kind of seawater corrosion-resistant low-alloy high-strength steel, comprising the following components by weight percentage:

[0057] C: 0.03%;

[0058] Si: 0.15%;

[0059] Mn: 0.13%;

[0060] Al: 0.024%;

[0061] Cr: 1.30%;

[0062] Ni: 0.25%;

[0063] Cu: 0.34%;

[0064] Zr+Ti: 0.025%;

[0065] Re: 0.055%;

[0066]P: ≤0.015%, S: ≤0.008%, the rest is Fe and unavoidable impurities;

[0067] The production method of corrosion-resistant low-carbon high-strength steel is: TMCP+normalizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com