A copper alloy welding wire, preparation method and application

A copper alloy and welding wire technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor melt fluidity, cold working performance, complex formula of manganese aluminum bronze alloy, and difficult operation, etc., so as to improve cold working performance , better melt fluidity, and the effect of improving flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

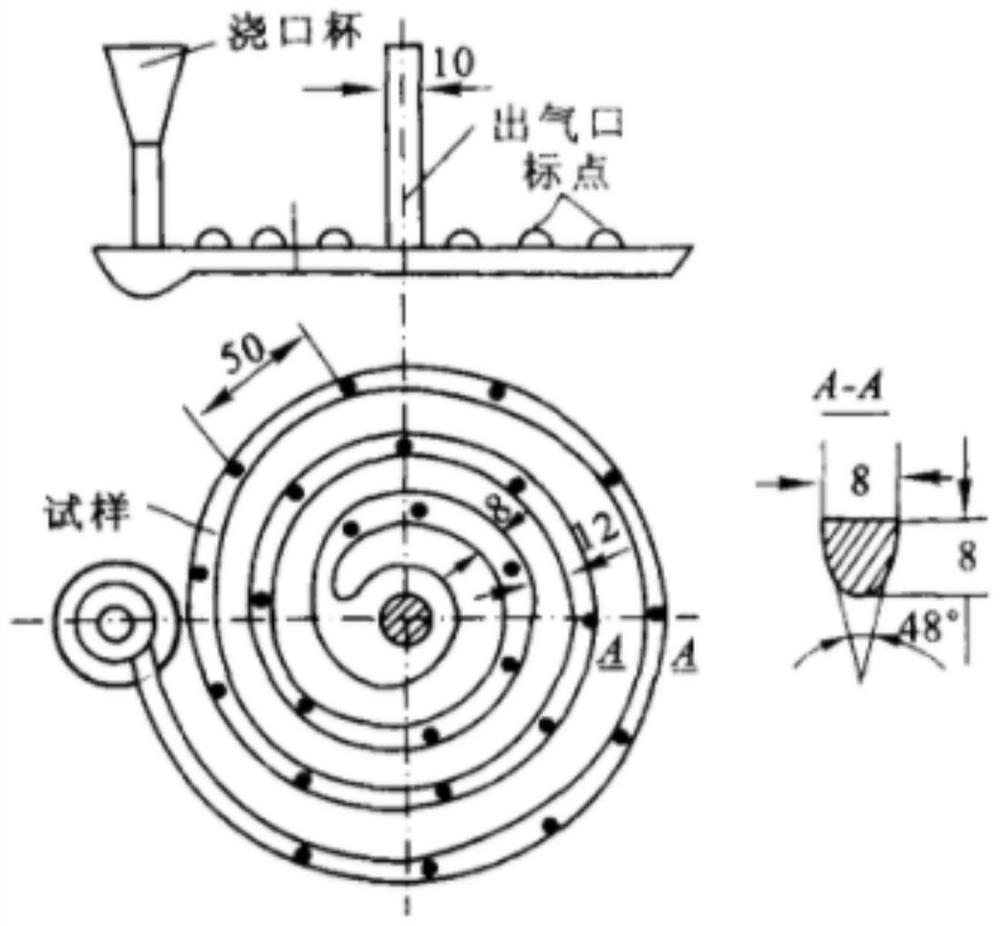

Image

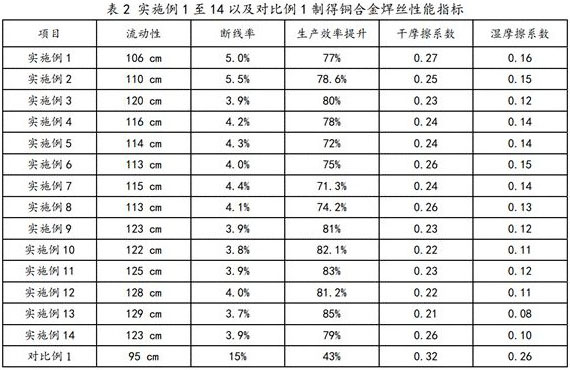

Examples

Embodiment 1

[0054] This embodiment discloses a copper alloy. The specific amount of substances is shown in Table 1. The specific preparation method includes the following steps:

[0055] Casting → hot rolling → annealing → swaging → drawing → peeling → sizing forming;

[0056] Among them, the continuous casting temperature is 1045°C and the casting speed is 0.5 m / min;

[0057] The rolling temperature is 570°C and the speed is 0.15 m / s;

[0058] Annealing temperature 580°C, holding time 1 h, reducing gas and inert gas protection;

[0059] Swivel speed 2.5 m / min;

[0060] Drawing speed 3.6 m / s;

Embodiment 2

[0062] The main difference between this embodiment and embodiment 1 is shown in Table 1;

[0063] The specific preparation method of this embodiment comprises the following steps:

[0064] Casting → hot rolling → annealing → swaging → drawing → peeling → sizing forming;

[0065] Among them, the continuous casting temperature is 1070°C and the casting speed is 0.6 m / min;

[0066] Rolling temperature 550℃, speed 0.2 m / s;

[0067] Annealing temperature 550°C, holding time 1.5 h, reducing gas and inert gas protection;

[0068] Swivel speed 2.5 m / min;

[0069] Drawing speed 3.6 m / s;

Embodiment 3

[0071] The main difference between this embodiment and embodiment 1 is shown in Table 1;

[0072] Concrete preparation method comprises the following steps:

[0073] Casting → hot rolling → annealing → swaging → drawing → peeling → sizing forming;

[0074] Among them, the continuous casting temperature is 1055°C and the casting speed is 0.55 m / min;

[0075] The rolling temperature is 520°C, and the speed is 0.15 m / s;

[0076] Annealing temperature 600°C, holding time 1.3 h, reducing gas and inert gas protection;

[0077] Swivel speed 2.5 m / min;

[0078] Drawing speed 3.6 m / s;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com