Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Enables indirect measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

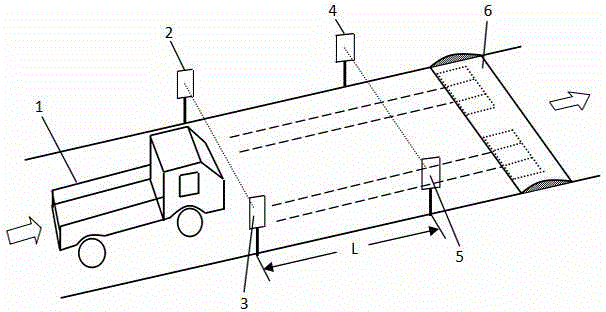

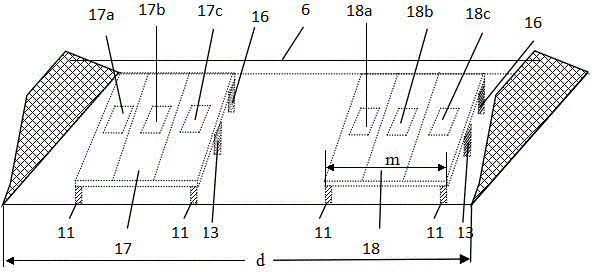

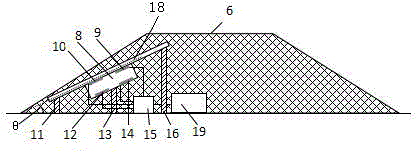

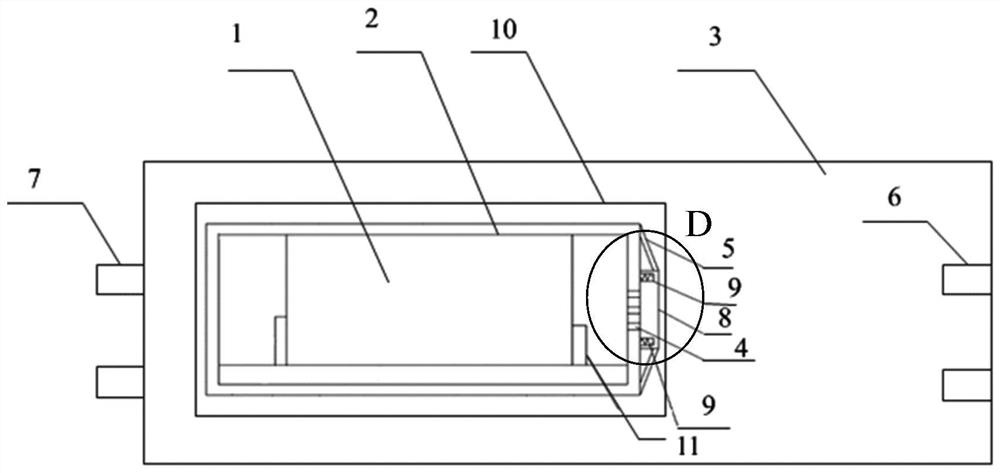

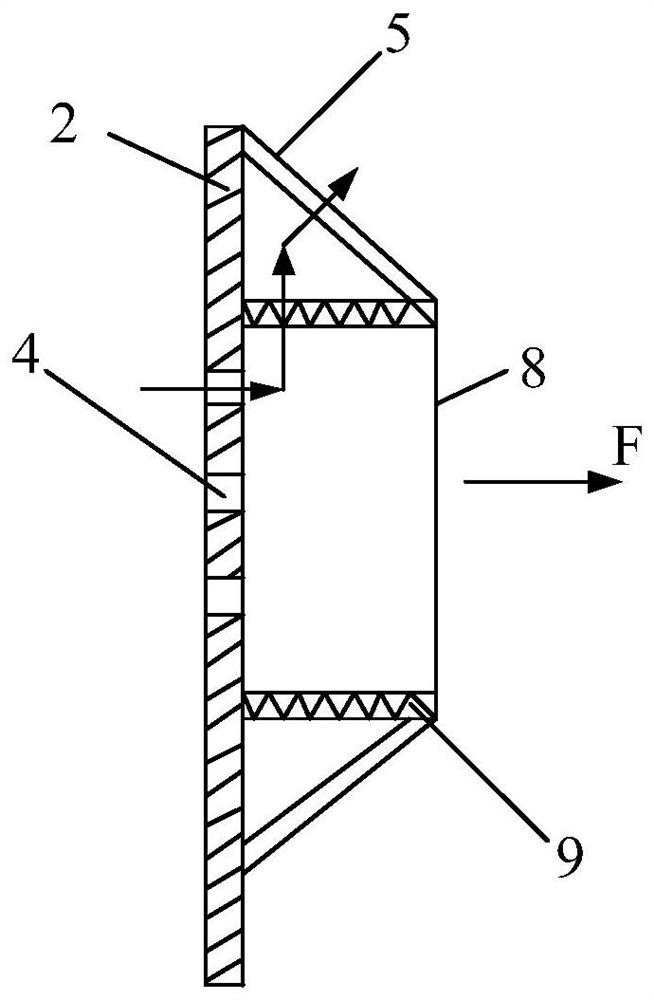

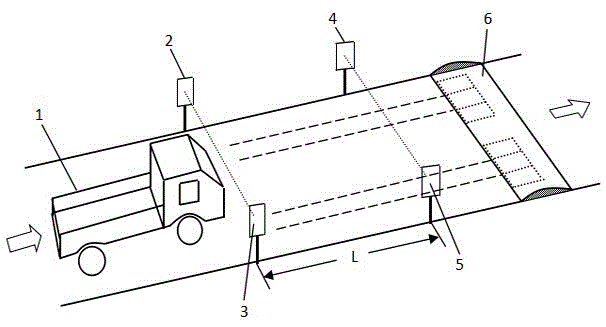

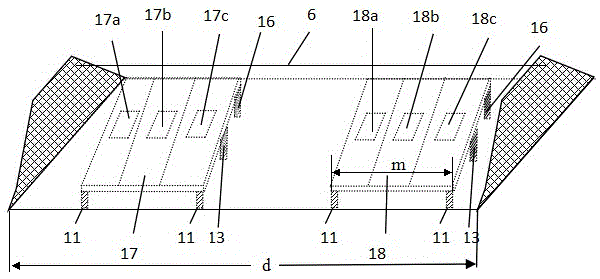

Toll station vehicle dynamic weighing estimation method and device

ActiveCN104089690AImprove traffic efficiencyShorten the timeSpecial purpose weighing apparatusMeasurement deviceVehicle dynamics

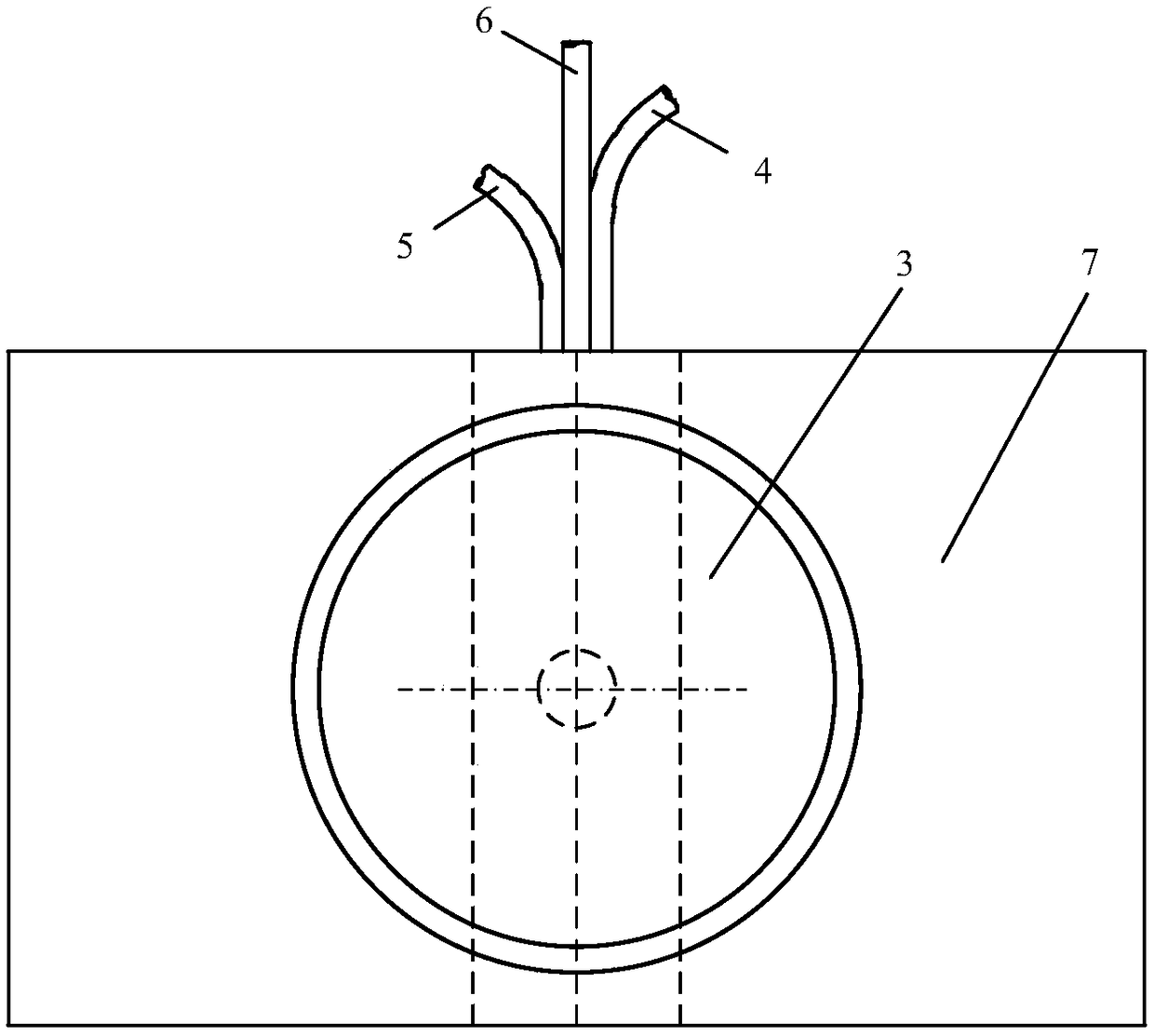

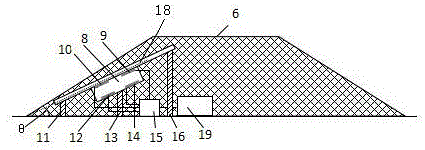

The invention discloses a toll station vehicle dynamic weighing estimation method and device. The method comprises the steps that a laser emitter set and a photoelectric receiver set are arranged on the left side and the right side of a toll station road respectively; a vehicle to be measured blocks laser emitted by the first laser emitter at first and then blocks laser emitted by the second laser emitter, an MCU control system calculates the speed of the vehicle to be measured when the vehicle passes through an impact force measurement device, and a left pressure sensor set and a right pressure sensor set input signals of impact force of a left wheel and a right wheel into the MCU control system; the speed and impact force of the vehicle to be measured serve as input of BP artificial neural network model, mass of the vehicle to be measured serves as output, and the mass of the vehicle is estimated. According to the toll station vehicle dynamic weighing estimation method and device, the relation between the kinetic energy of the moving vehicle and the impact force generated when the vehicle collides with a force measurement device is comprehensively considered, a road speed bump is utilized, the vehicle is allowed to keep a certain speed when passing through the speed bump, and meanwhile the artificial neural network technology is utilized, so that indirect measurement of the vehicle mass is achieved, and toll station going-through efficiency is improved.

Owner:佛山市衡王电子衡器有限公司

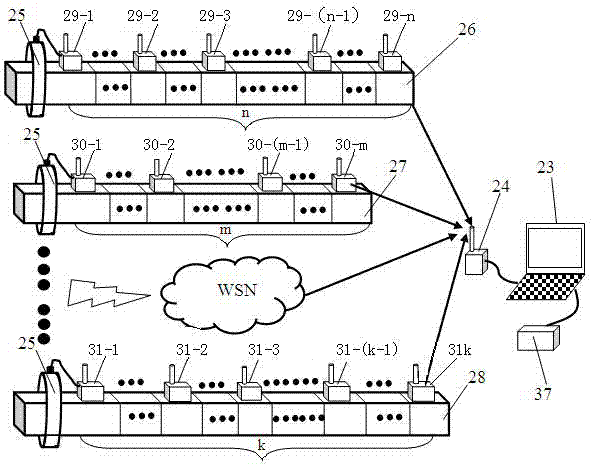

Busbar voltage detecting system and fault diagnosis method based on wireless sensor network (WSN)

InactiveCN104849528AReduce in quantityLow costCurrent/voltage measurementDiagnosis methodsIntegrated circuit

The present invention discloses a busbar voltage detecting system and a fault diagnosis method based on a wireless sensor network (WSN). A plurality of busbar voltage detecting points are arranged in turn on each busbar trunk line; each MCU control circuit box is internally provided with a busbar A phase power picking device, a busbar zero phase power picking device and an MCU integrated circuit; each busbar voltage detecting point sends data to the least busbar voltage detecting point on the corresponding busbar trunk line through a corresponding node wireless module, and the last busbar voltage detecting points send all the data to an upper computer for processing through a terminal node device; and the upper computer calculates a voltage difference and a resistance changing value between two adjacent busbar voltage detecting points, compares the resistance changing value with a preset resistance changing value, and determines if faults exist within a busbar region between the two adjacent busbar voltage detecting points. The number of busbar voltage detecting devices can be effectively reduced, diagnosis of busbar fault regions is realized combining the WSN technology.

Owner:JIANGSU YINONE ELECTRIC

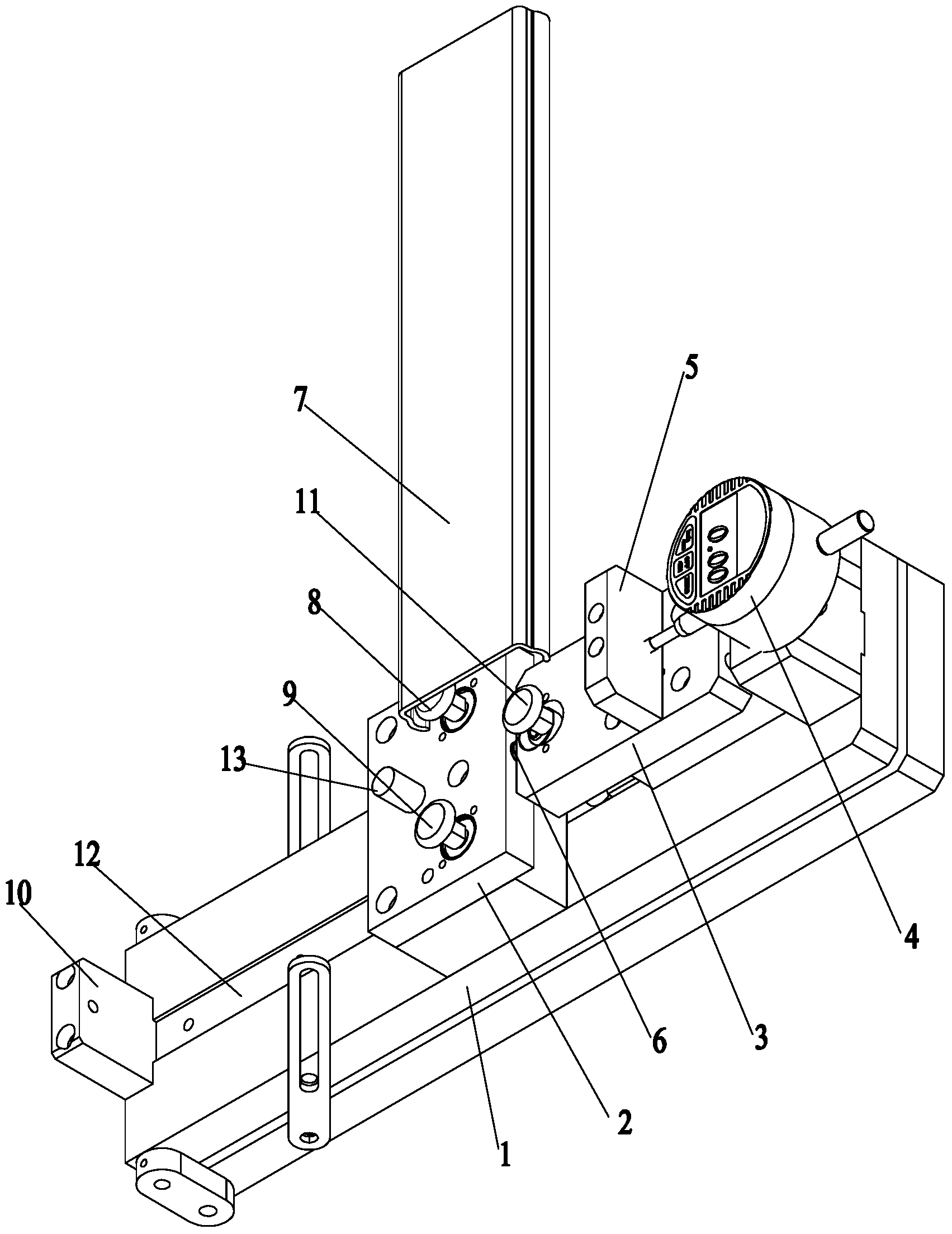

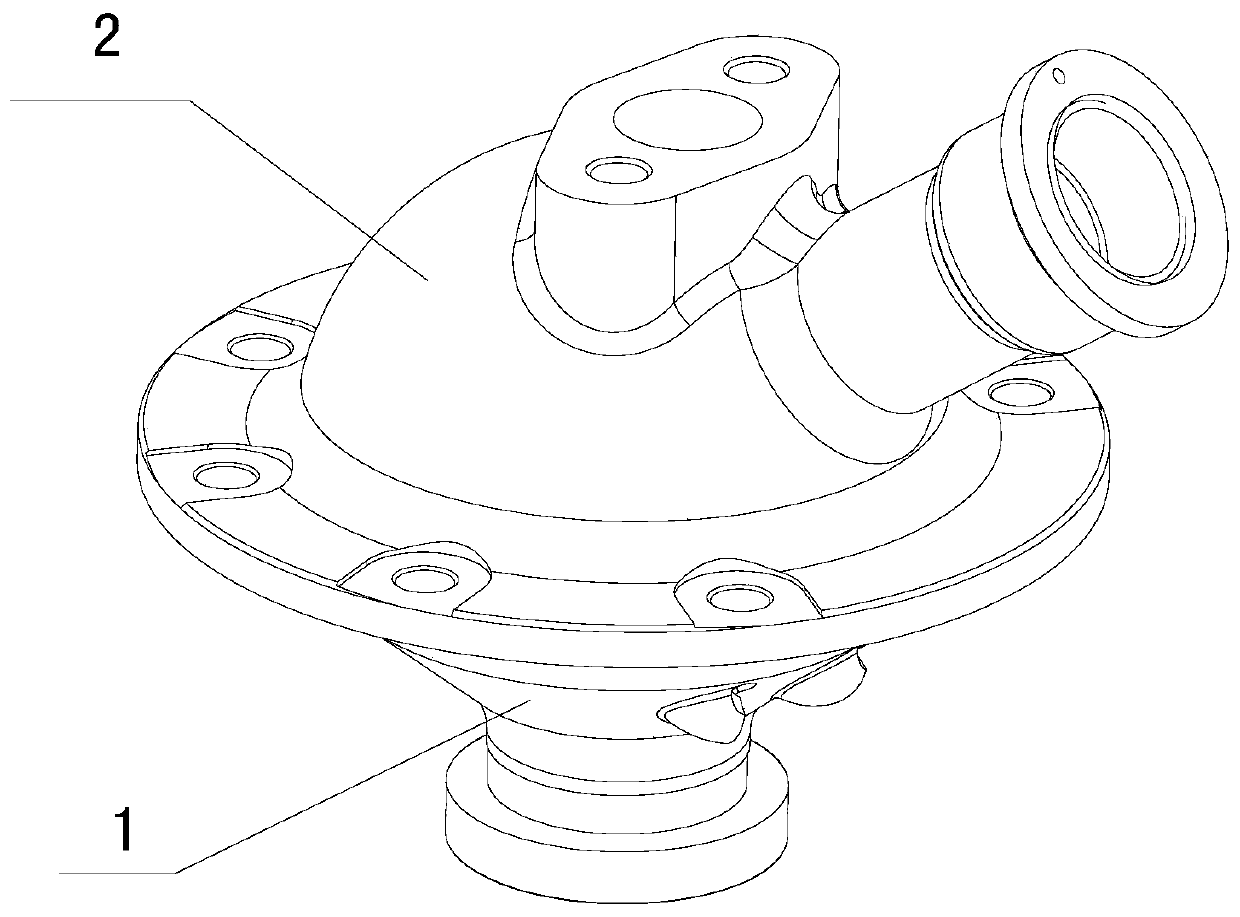

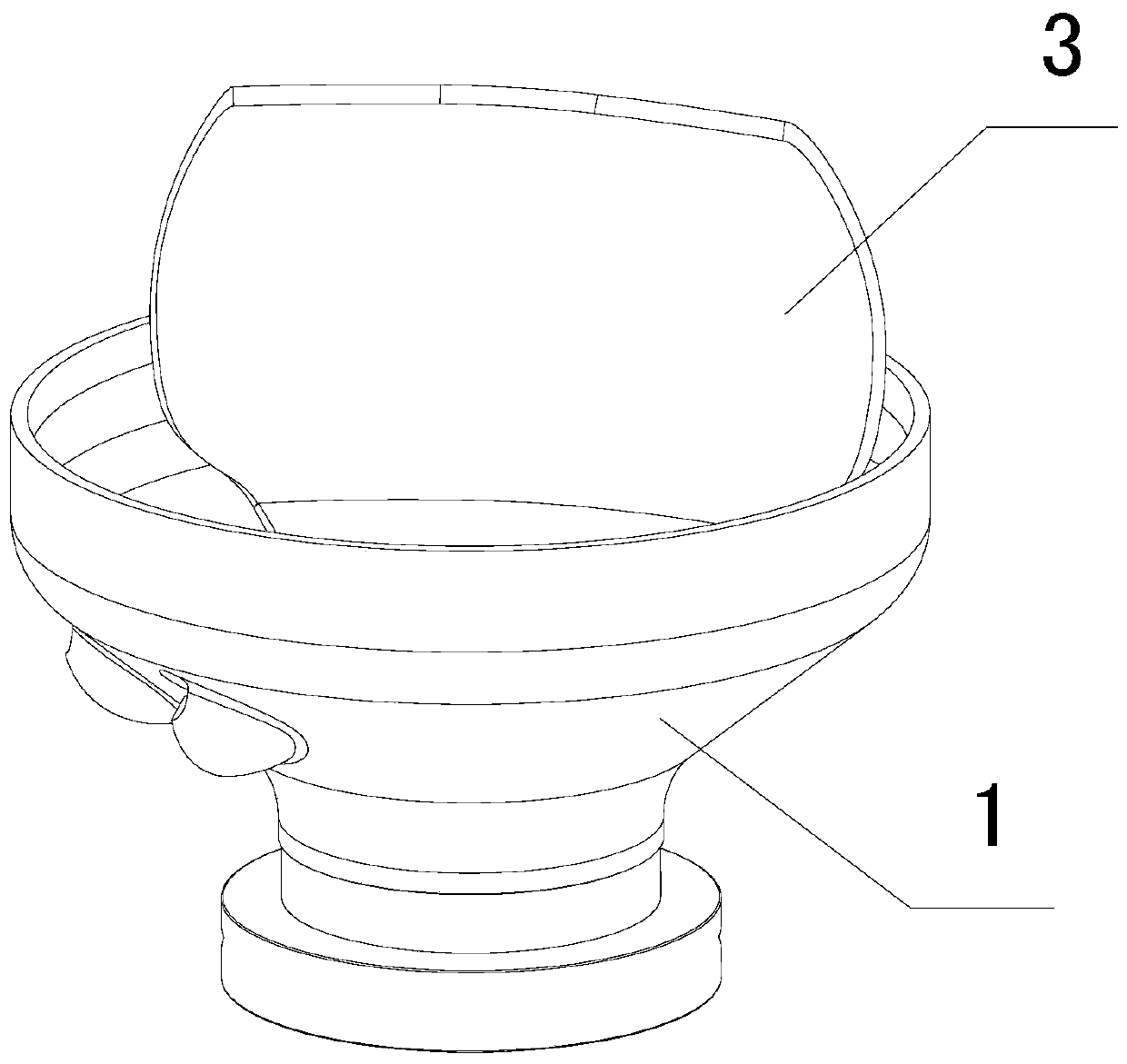

Measuring technology of gear clearance between water pump gear and crankshaft gear

ActiveCN105841586ARealize coaxial rotationEnables indirect measurementsMechanical clearance measurementsGear wheelEngineering

The invention discloses a measuring technology of a gear clearance between a water pump gear and a crankshaft gear. The measuring technology includes the following steps that: the water pump gear is assembled on the rotation shaft of a water pump, a water pump turbine is installed on the rotation shaft through a fastening nut on the water pump turbine, and the water pump is assembled to an engine, and the water pump gear and the crankshaft gear are engaged with each other; the crankshaft of the crankshaft gear is fixedly installed; a first sealing flange at the inlet of the water pump is disassembled, a measurement fixture is concentrically connected onto the fastening nut, the measurement fixture is provided with two scribed lines, and the distance between the two scribed lines is the reference circle diameter of the water pump gear; a second sealing flange at the outlet of the water pump is provided with a supporting mechanism provided with a dial indicator, and the pushing pin of the dial indicator abuts against one of the scribed lines; the dial indicator is zeroed; and the water pump gear is rotated towards the direction of the dial indicator. The measuring technology is simple in measuring process and easy in operation, and can assist in shortening measuring time and improving working efficiency. The measurement of the gear clearance between the water pump gear and the crankshaft gear can be realized through the dial indicator, and measuring accuracy is high.

Owner:WEICHAI HEAVY MACHINERY

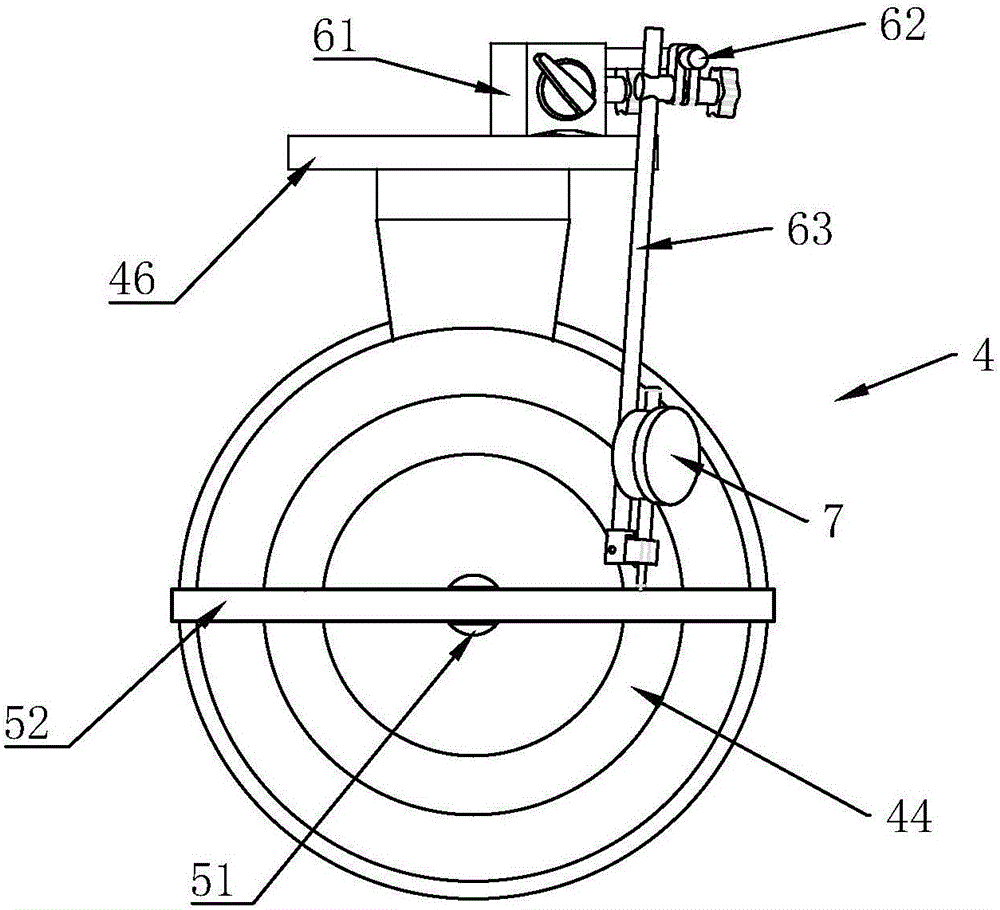

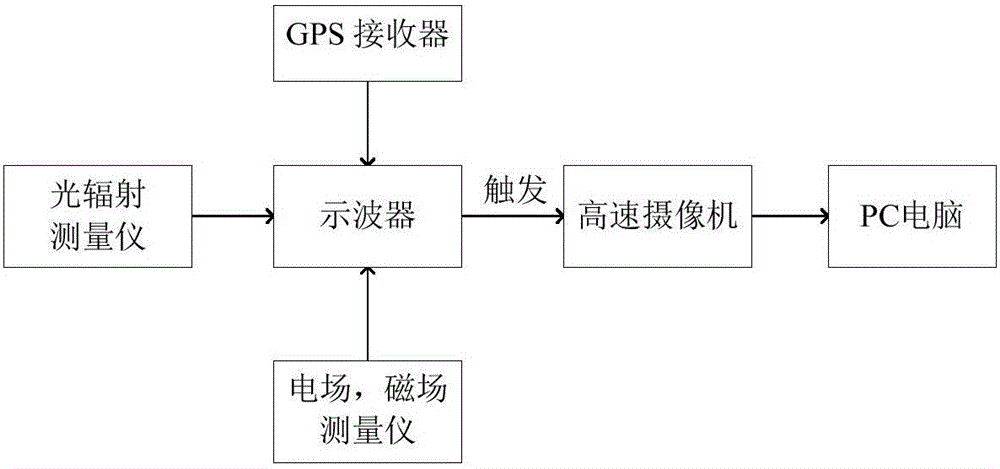

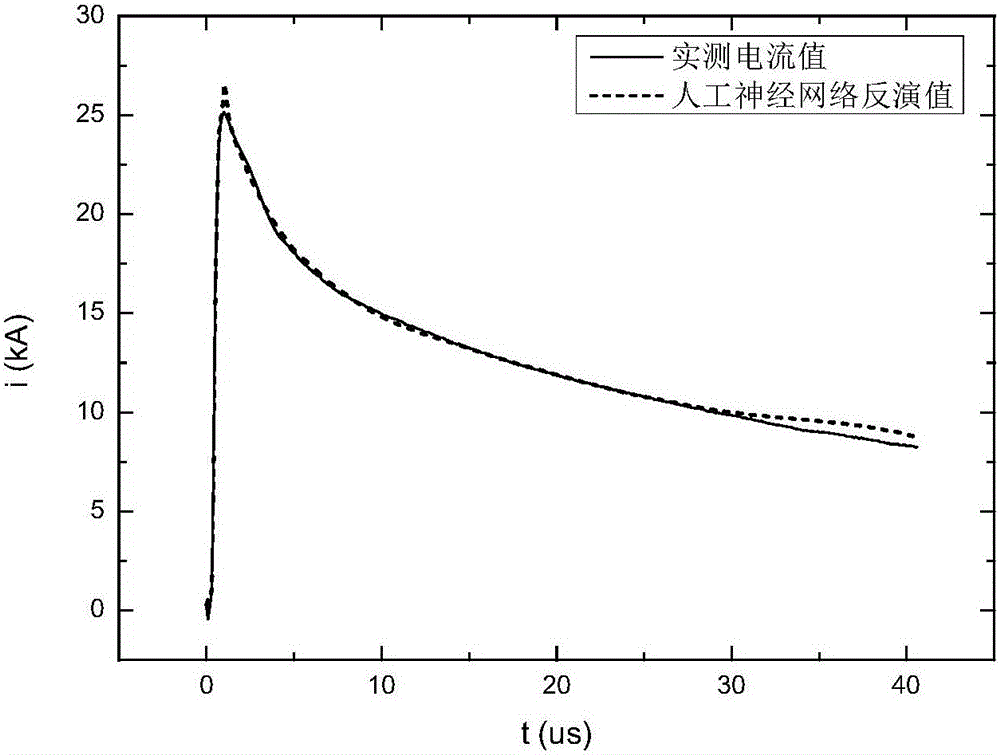

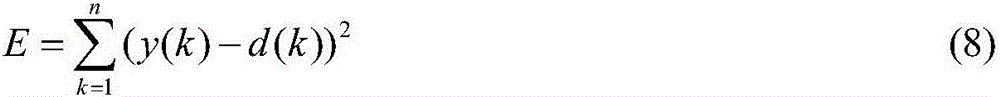

Method for obtaining lightning current based on artificial neural network

InactiveCN106124830AEnables indirect measurementsIndirect measurement method is convenientCurrent measurements onlyWavelet denoisingElectromagnetic field

The invention relates to a method for obtaining lightning current based on an artificial neural network, which belongs to the lightning monitoring technology in the field of electric engineering. The method includes: using electric field and magnetic field sensors at different distances from the observation point in a lightning optical and electromagnetic synchronous observation system to obtain data of the electric field and magnetic field The training sample set and the test sample set are composed, and then preprocessing measures such as wavelet noise reduction and smoothing are performed on the data in the training sample set, and the artificial neural network is trained through the training sample set to obtain the network parameters of the artificial neural network: connection weights, Finally, use the test sample set to test the trained artificial neural network. The present invention is based on the Elman artificial neural network, and uses the electromagnetic field generated by the measured lightning discharge to calculate the lightning current data, thereby obtaining characteristic parameters such as the amplitude of the lightning current, providing basic parameters for lightning protection, and making lightning protection targeted.

Owner:TSINGHUA UNIV

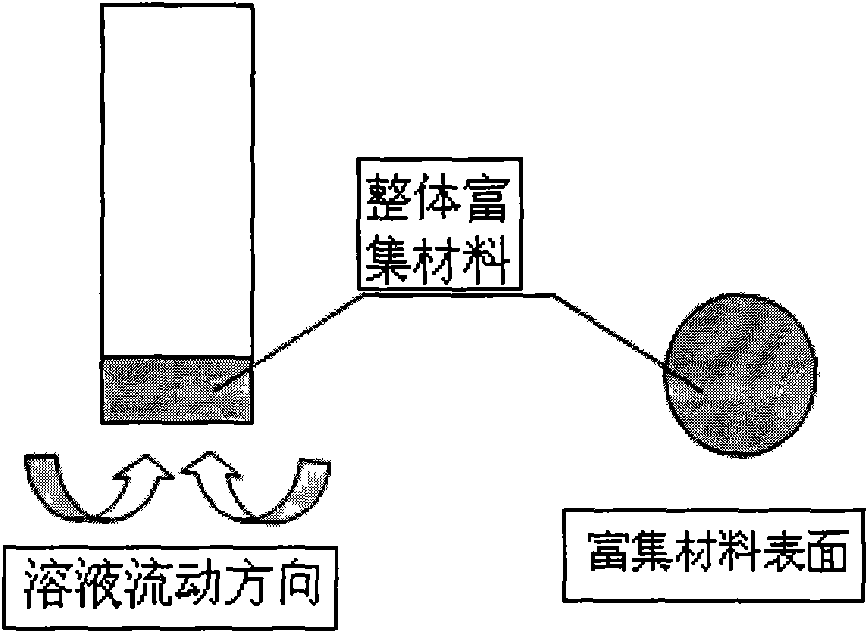

Micro near-infrared spectral analytical method based on enrichment of integrated material

InactiveCN101660999AEliminate distractionsHigh measurement sensitivityPreparing sample for investigationScattering properties measurementsIn situ polymerizationAdhesive

The invention relates to a micro near-infrared spectral analytical method based on enrichment of an integrated material, which comprises the following steps: the in-situ polymerization is carried outon the integrated material for enrichment in an enrichment device or a fixed mould; the material is modified according to needs; the thickness of the in-situ polymerization material is 5-10 mm; as forthe material previously synthesized in the mould, the integrated material is cut into round slices with the thickness of 5-10 mm; the integrated material round slice is fixed on one end of the deviceby adhesive or a physical cutting ferrule and aligned with the edge; and after the enrichment, the near-infrared spectrum of the material surface with concentrated analytical components is measured in a scattered reflection mode. The method enhances the effects of purification and enrichment, realizes the near-infrared spectral direction measurement of the material surface after the enrichment, enhances the analytical sensitivity, achieves the goal of the near-infrared spectral analysis on the micro substances and realizes the indirect measurement of metallic elements by using a near-infraredspectrum. The material can be repetitively used with basically unchanged effects of absorption and enrichment.

Owner:EAST CHINA UNIV OF SCI & TECH

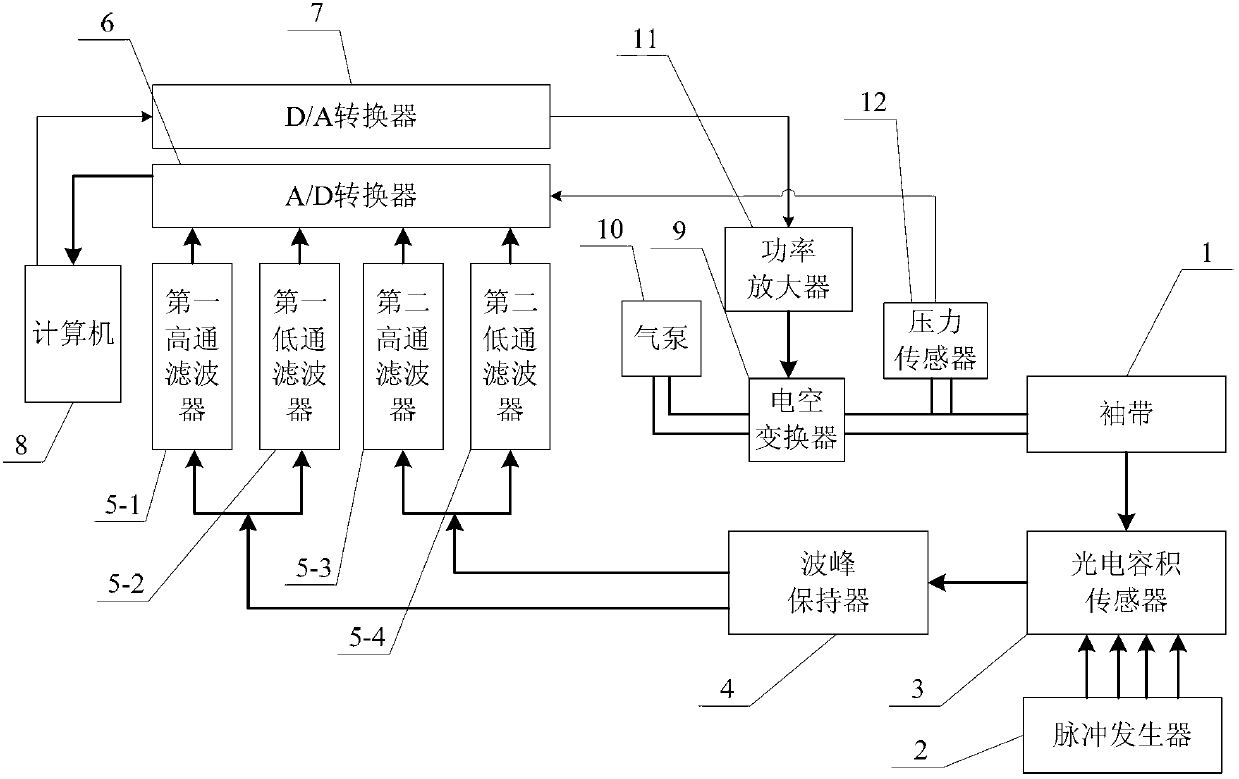

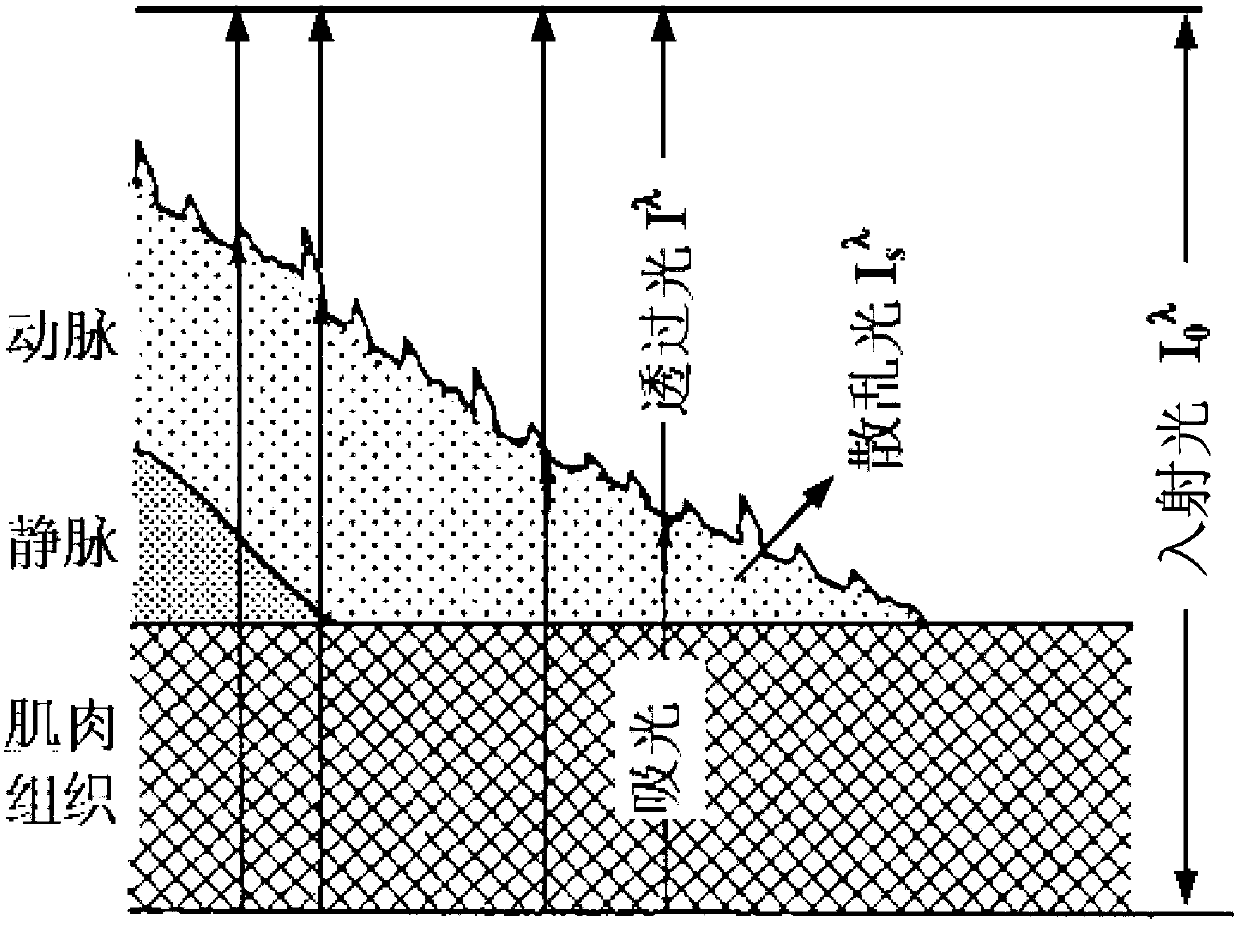

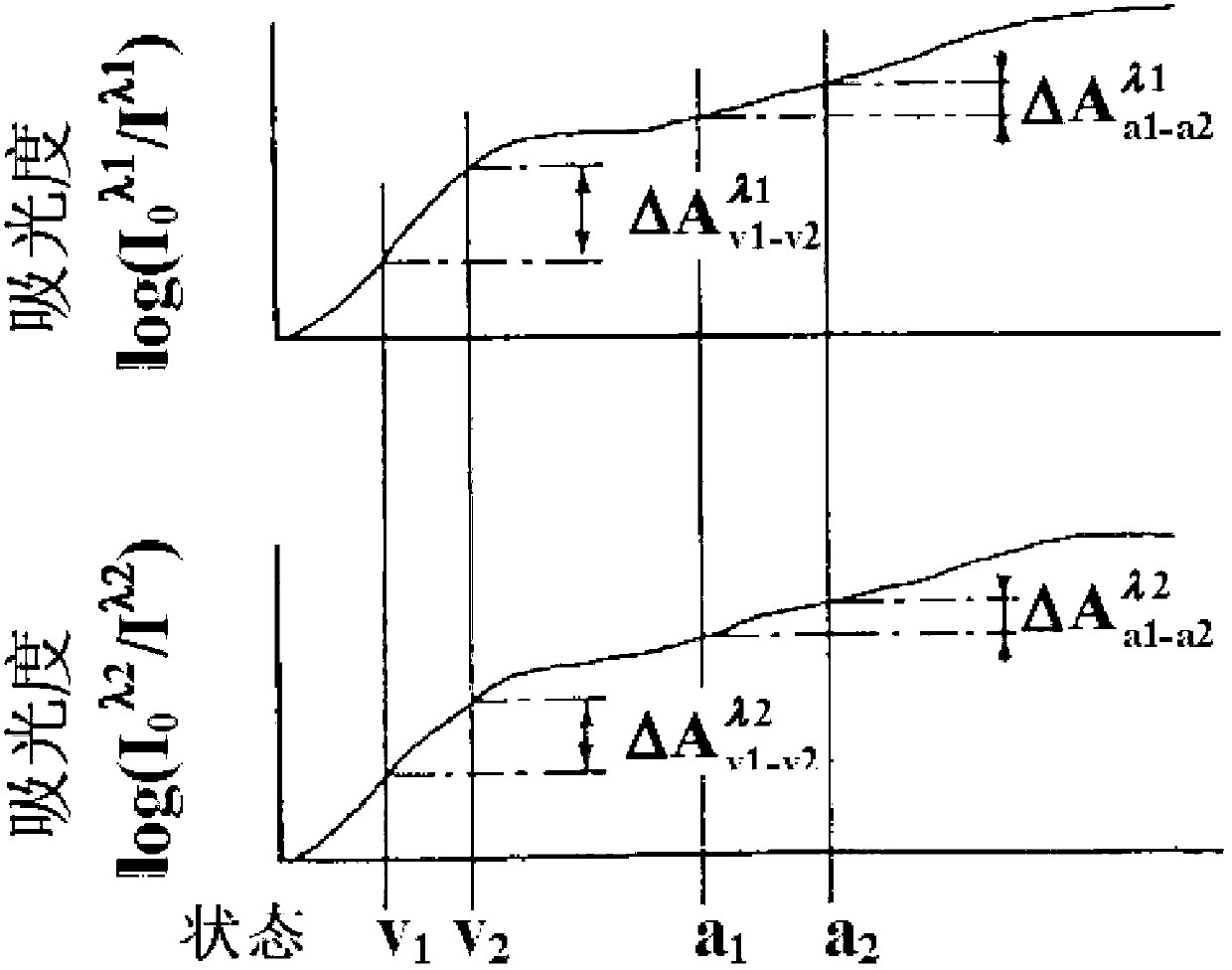

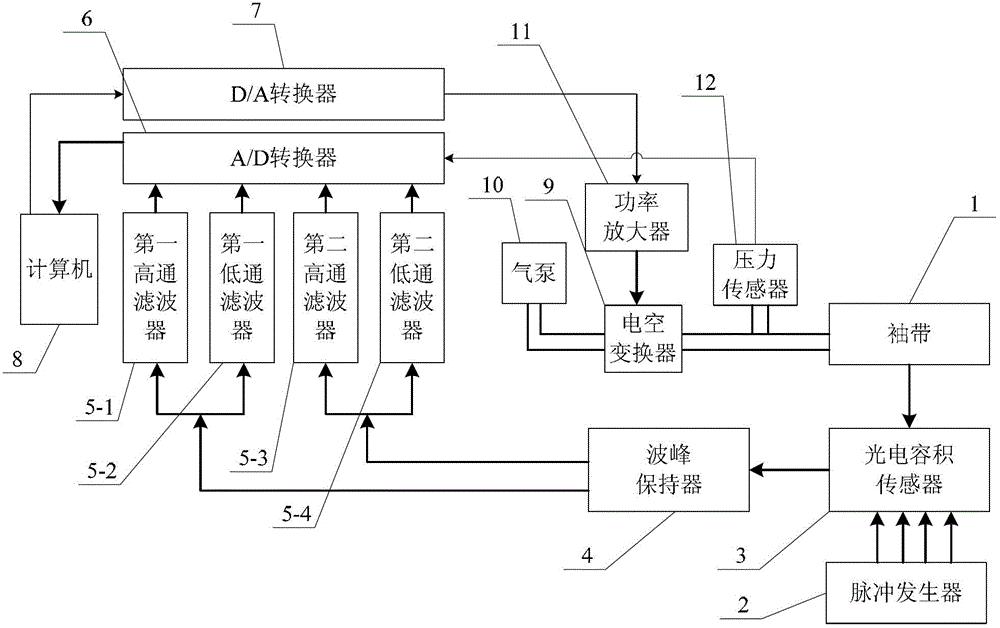

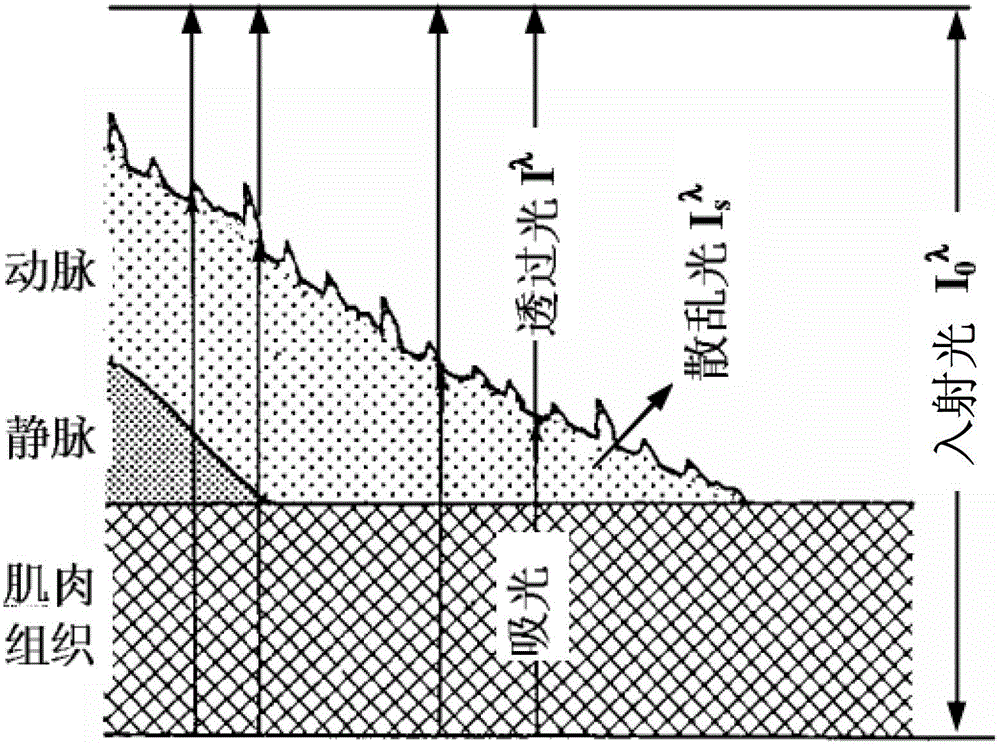

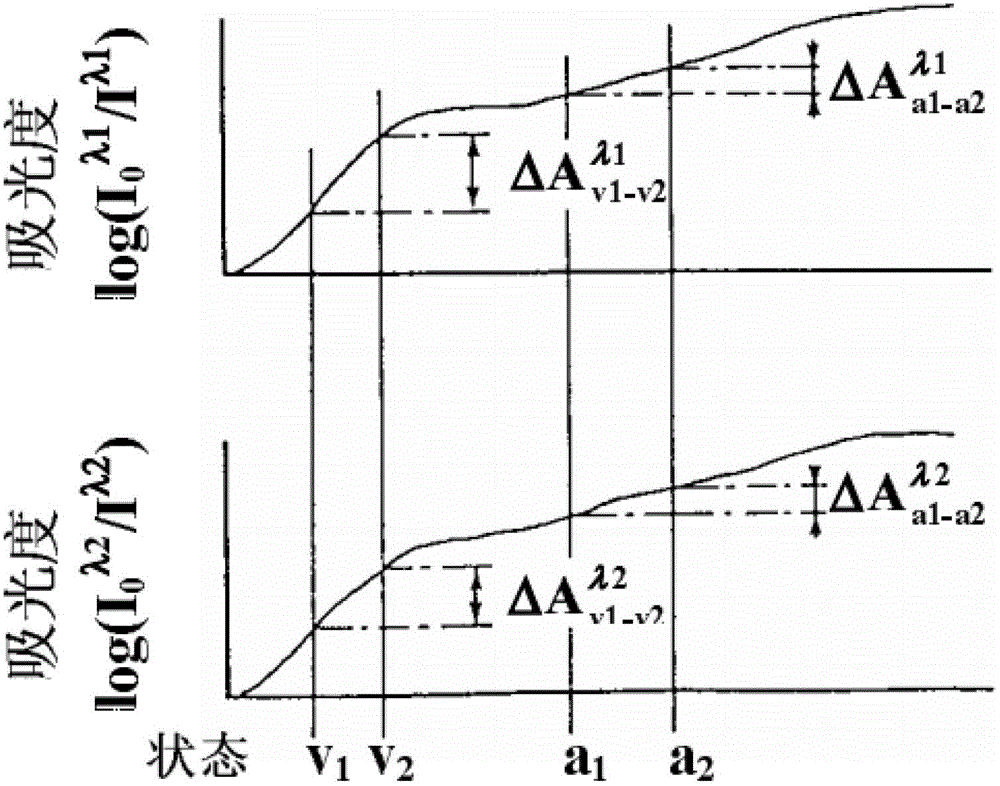

Device and method for detecting blood pressure and oxyhemoglobin saturation simultaneously

ActiveCN102715893AEnables indirect measurementsEnable non-invasive testingSensorsBlood characterising devicesVenous bloodAir pump

The invention discloses a device and a method for detecting blood pressure and oxyhemoglobin saturation simultaneously, and belongs to the technical field of radial artery detection. By the device and the method, the problems that the blood pressure and the oxyhemoglobin saturation are needed to be detected by using separate sensors at present, so more electronic components of a detection device are needed, and the detection device is complex in structure are solved. The device comprises a cuff, a pulse generator, a photoelectric plethysm sensor, a wave crest retainer, a first high-pass filter, a first low-pass filter, a second high-pass filter, a second low-pass filter, an analog to digital (A / D) converter, a digital to analog (D / A) converter, a computer, an electro-pneumatic converter, an air pump, a power amplifier, and a pressure sensor; and according to the method, the radial artery is used as a detected target, the blood pressure, and the oxyhemoglobin saturation of arterial and venous blood can be detected simultaneously, and the oxyhemoglobin saturation of the venous blood is measured indirectly. The device and the method are suitable for detecting the blood pressure and the oxyhemoglobin saturation simultaneously.

Owner:HEILONGJIANG UNIV

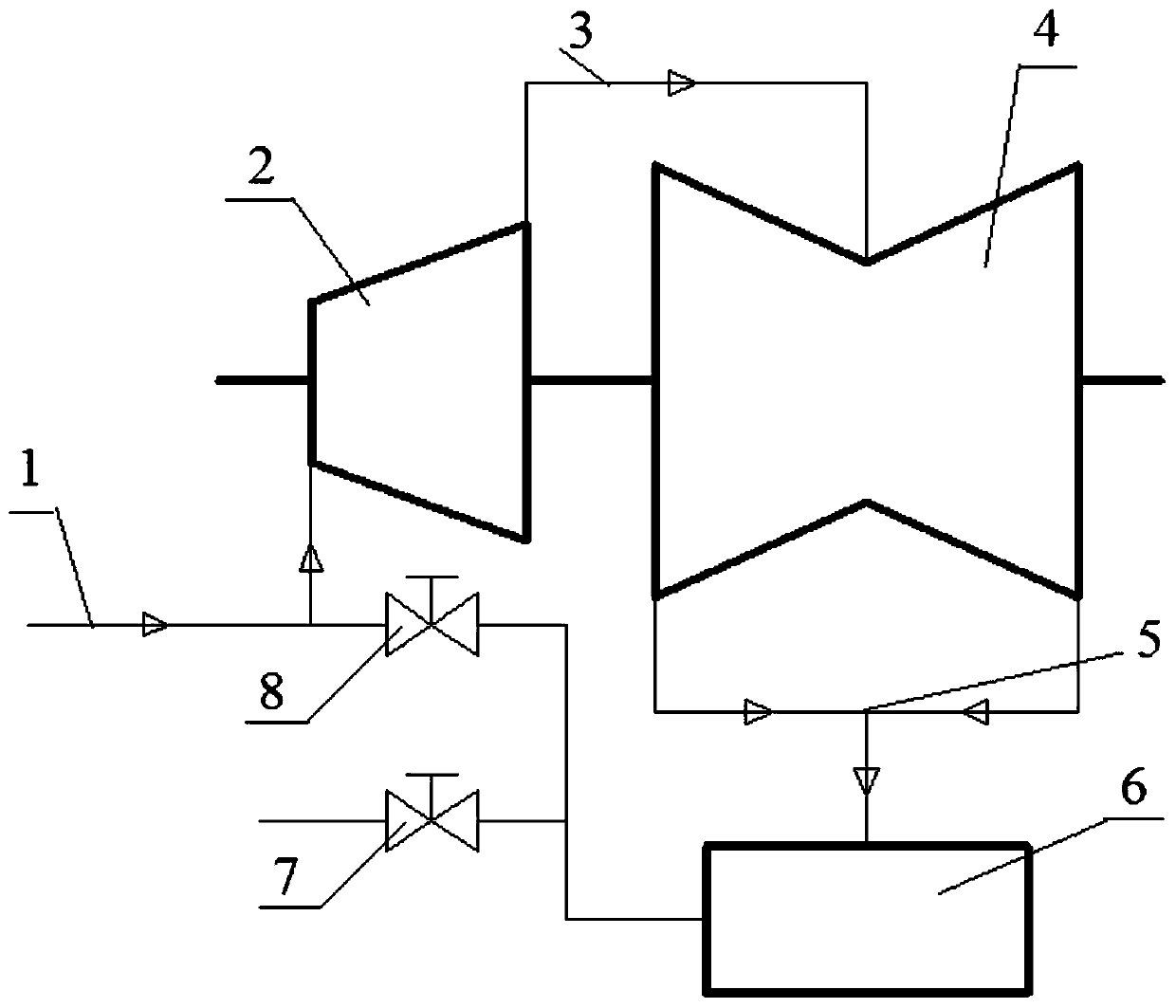

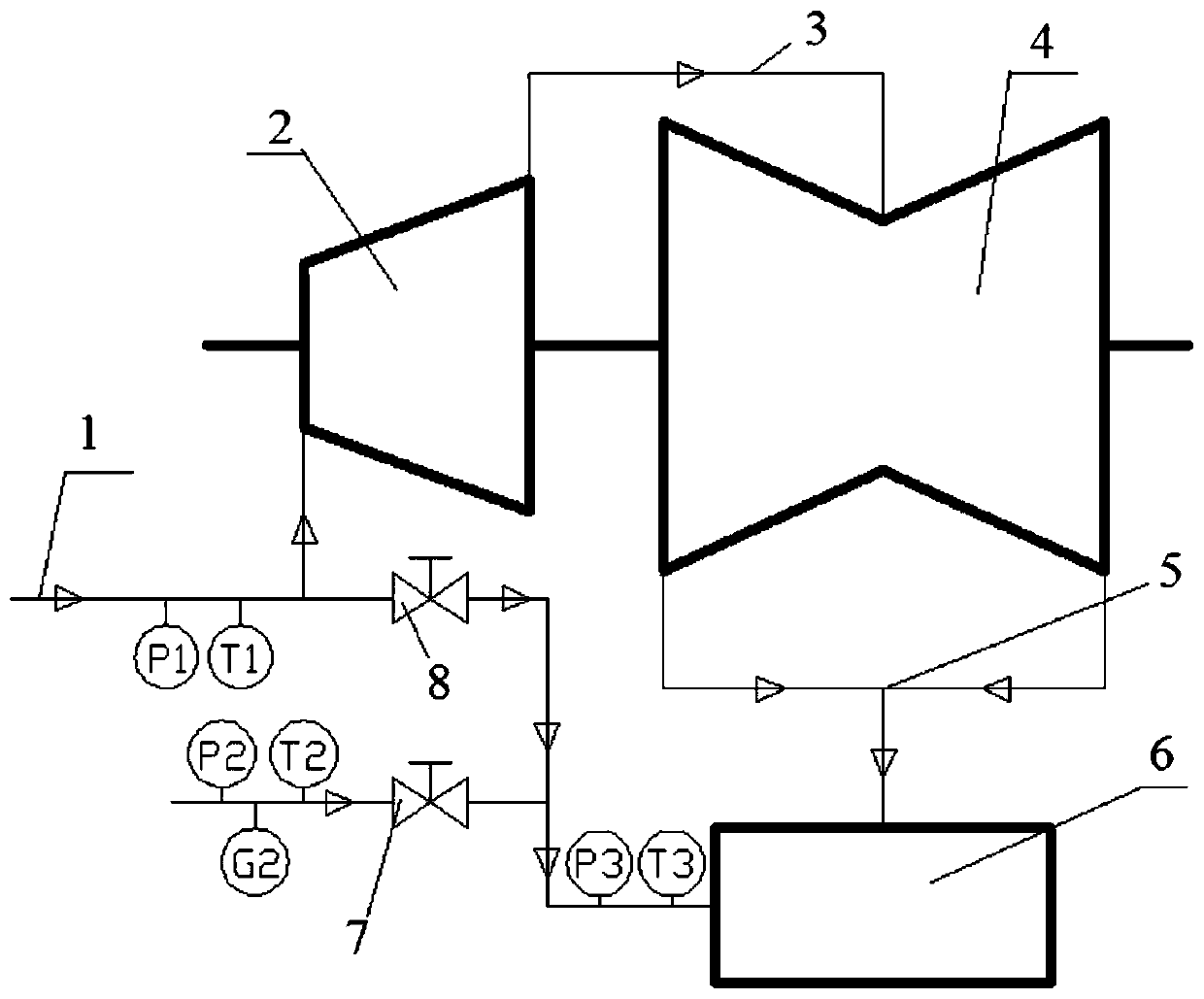

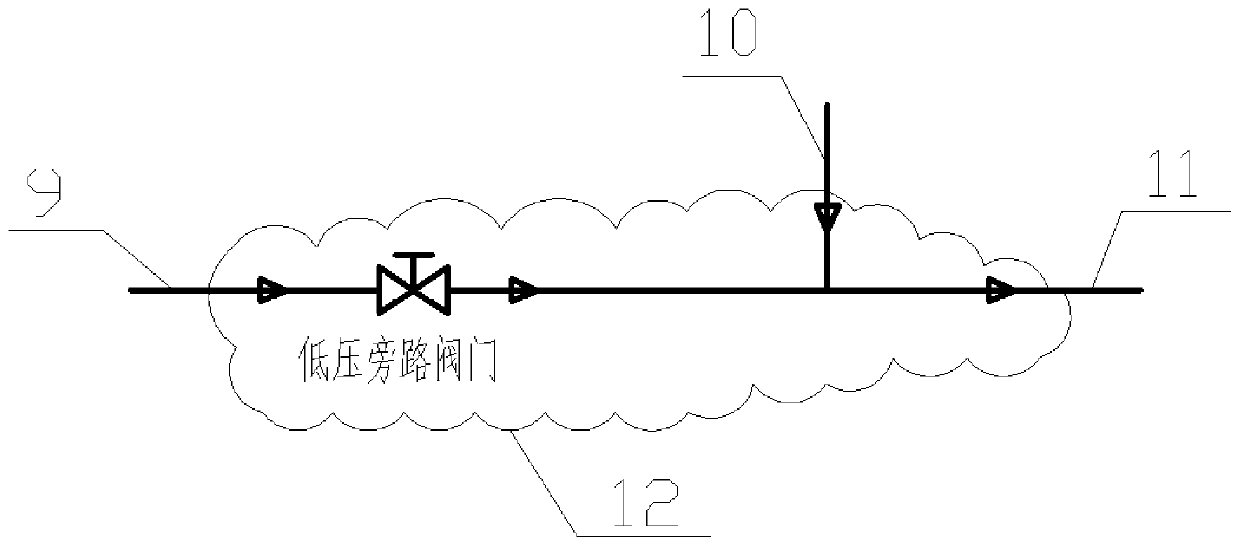

Test method for steam internal leakage quantity of low-pressure bypass valve of thermal generator set

ActiveCN110608858AEnables indirect measurementsMeasurement of fluid loss/gain rateMachine valve testingRunning economyEnergy balanced

A test method for steam internal leakage quantity of a low-pressure bypass valve of a thermal generator set comprises the following steps of (1) selecting a set load for performing internal leakage test on a bypass voltage of a low-pressure cylinder; (2) determining a boundary condition of experiment; (3) obtaining steam parameter change conditions of a low-pressure bypass system before and afterdesuperheating water flow change by changing bypass desuperheating water flow of the low-pressure cylinder; (4) recording an experiment parameter of each working condition point, and forming originalexperiment data; and obtaining internal leakage steam flow of the low-pressure bypass valve by calculation. An energy balance, mass balance and same boundary loss item offset method is employed, the internal leakage steam flow of the low-pressure bypass valve of the thermal generator set is obtained by accurate and quantitative calculation of experiment, quantitative analysis and calculation is performed for the low-pressure bypass valve of the thermal generator set when internal leakage occurs, and the most direct data support is provided for power plant running economy and maintenance operation of the low-pressure bypass valve of a power plant.

Owner:魏丽蓉

Metering self-adaptation method for flow meter

InactiveCN103900654AHigh degree of intelligenceSolving Manual Calibration IssuesTesting/calibration apparatusVolume meteringControl engineeringPulse number

The invention discloses a metering self-adaptation method for a flow meter. The method comprises the steps that A. a one-to-one-corresponding relation table of the standard pulse count c and the pulse frequency f of a pipeline is established; B. the needed dose V is recorded; C. calibration is carried out, and flow in a single-time timing period is computed; and D. flow in single-time timing periods in the step C is added. The shortcomings in the prior art can be overcome, automatic calibration is achieved, influence from external factors is removed, metering accuracy is improved, cost is saved, and production efficiency is improved.

Owner:江苏中聚检测服务有限公司

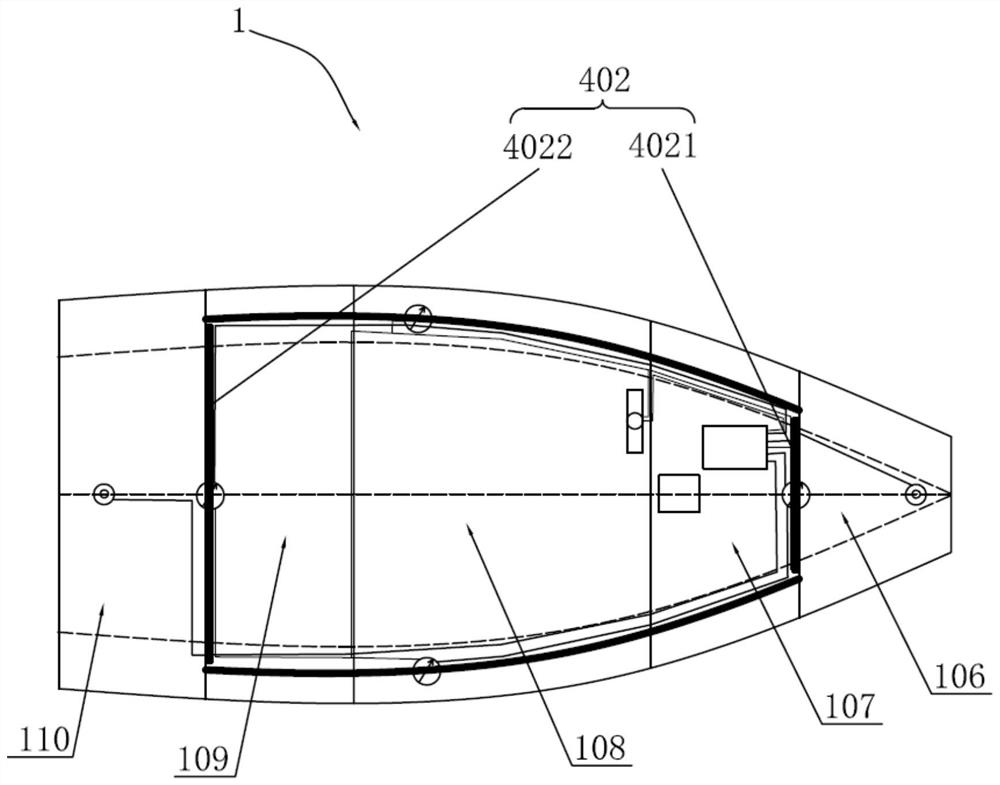

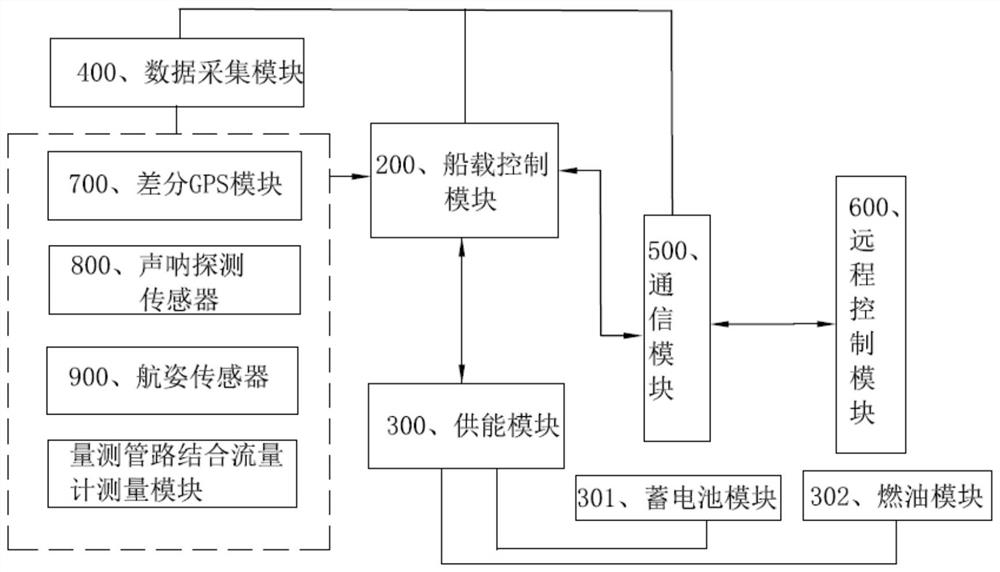

Unmanned ship flow velocity and flow measurement system

ActiveCN112113611ARealize Estimation MeasurementsEnables indirect measurementsWaterborne vesselsMeasurement devicesHydrometryStream flow

The invention relates to the technical field of unmanned ship monitoring, and provides an unmanned ship flow velocity and flow measurement system, which realizes direct measurement of the flow velocity and flow of a ship body relative to a river and lake water body within the immersion depth by arranging a measurement pipeline for providing water body overflowing channels in the longitudinal and transverse directions on the ship body and arranging a flow meter on the measurement pipeline. A differential GPS module used for obtaining real-time position information of the ship body is arranged on the ship body, so that indirect measurement of the surface flow velocity of the river and lake water body is achieved, and a sonar detection sensor used for detecting and sensing the section water depth is arranged on the ship body, so that estimation and measurement of the river section flow are achieved. According to the scheme, accurate measurement of the flow velocity and flow of a surface blind area can be achieved based on the measurement pipeline, a quantitative basis can be provided for adjusting the energy output of a ship body energy supply module and the direction of a steering engine in real time, and therefore the action response precision of the unmanned ship control system can be effectively improved; and the system can be directly used for hydrological business work withcorresponding precision requirements.

Owner:深圳市国艺园林建设有限公司

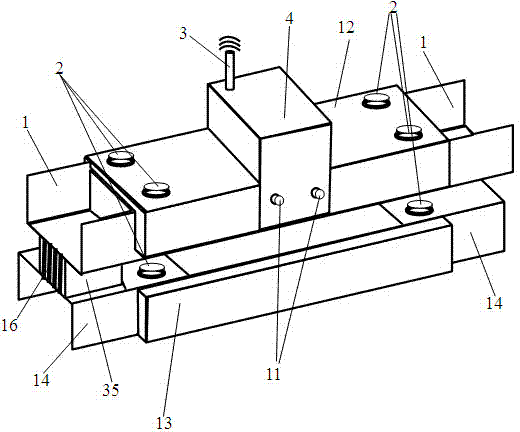

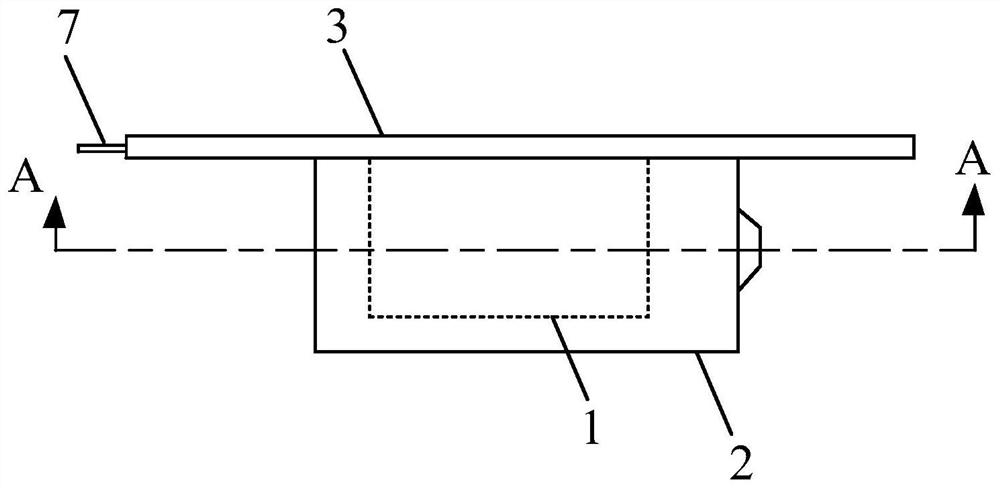

Sliding rail outer rail measuring device

ActiveCN103940400AEasy to measureEnables indirect measurementsMeasurement devicesEngineeringMechanical engineering

Owner:WUXI JINGMEI PRECISION SLIDE

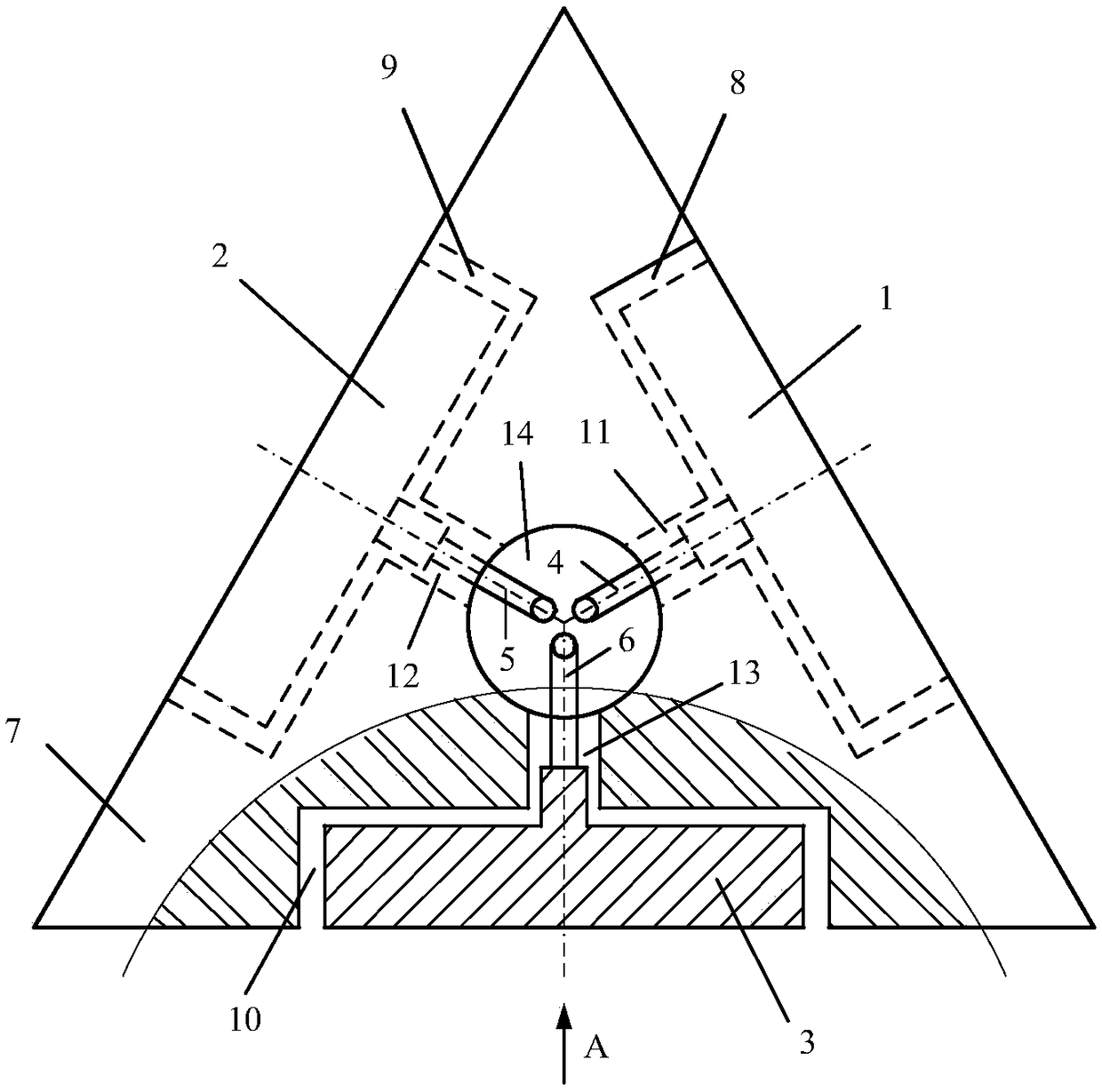

Plane point stress state detector and detection method

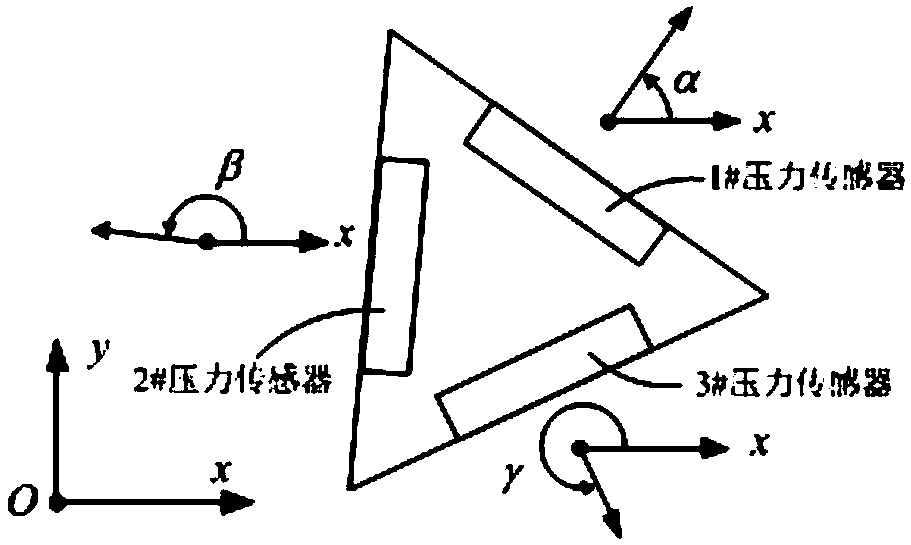

InactiveCN108801525AEnables indirect measurementsEasy to determineApparatus for force/torque/work measurementEngineeringStressed state

The invention provides a plane point stress state detector and a detection method. The detector comprises a pedestal, a pressure sensor and a cable corresponding to the pressure sensor, wherein the pedestal is a triangular prism; the first side surface, the second side surface and the third side surface are respectively provided with an embedding groove for containing the pressure sensor, and a cable through hole extending inwards is formed in the center of each embedding groove; and an axial cable through hole is formed in the center of the triangular prism. The plane point stress state detector is simple in structure and easy to install, and the pedestal is of a triangular prism shape, so that the deflection angle is conveniently determined. Indirect measurement of the stress state of apoint on the inner plane of a material is achieved.

Owner:CHINA ELECTRIC POWER RES INST +2

Slide rail outer rail measuring device

ActiveCN103940400BEasy to measureEnables indirect measurementsMeasurement devicesMechanical engineeringEngineering

Owner:WUXI JINGMEI PRECISION SLIDE

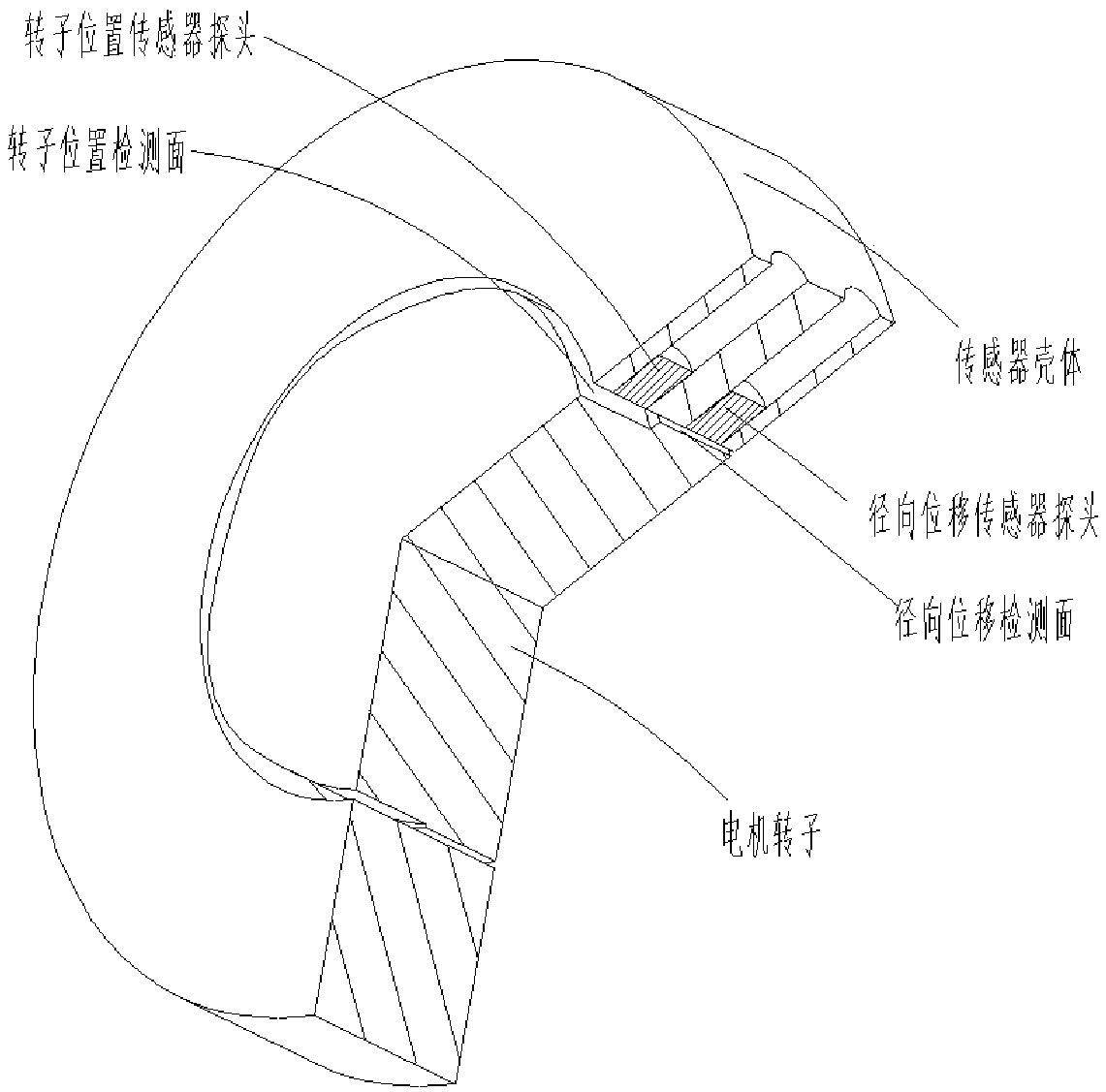

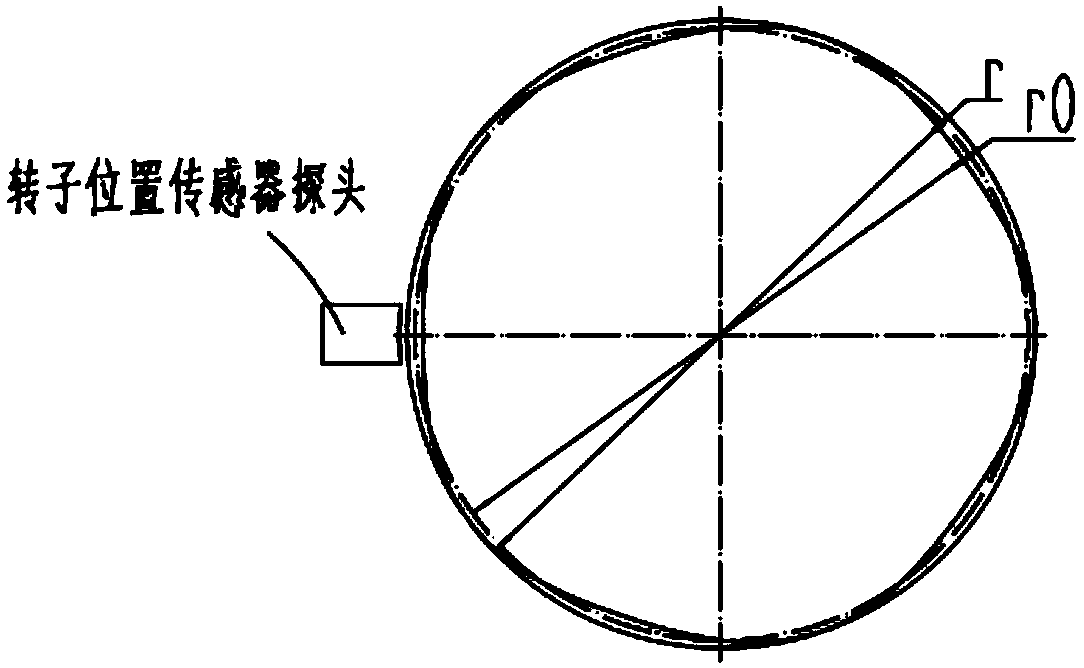

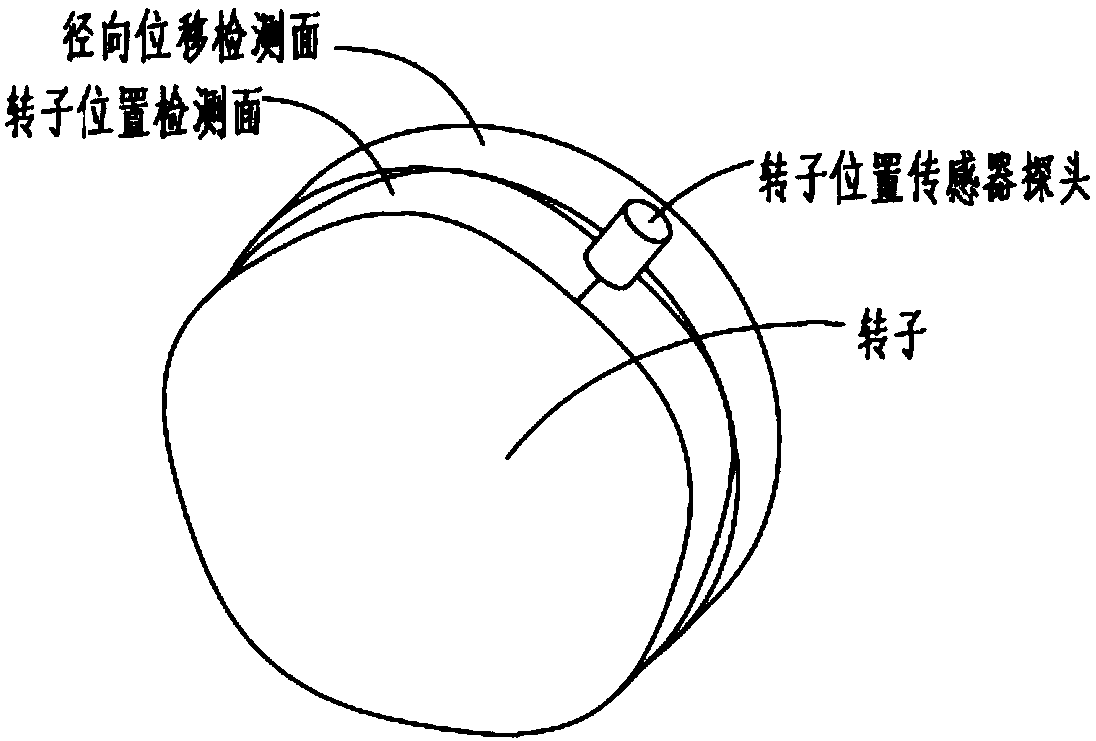

Novel high-speed magnetic levitation motor and method for detecting rotor position of motor

PendingCN108809154AEnables indirect measurementsStructural associationMagnetic holding devicesEngineeringControl theory

The invention relates to a novel high-speed magnetic levitation motor and a method for detecting a rotor position of the motor. The motor comprises a rotor and a stator, wherein the rotor comprises aradial displacement detection cylinder and a position detection cylinder; the radial displacement detection cylinder and the position detection cylinder are coaxially arranged; the radial displacementdetection cylinder is a cylinder of which the radius is R; the position detection cylinder is a cylinder of which the edge is in a regular arc form; and the maximum radius of the position detection cylinder is R. According to the novel high-speed magnetic levitation motor, the rotor is designed into the structure of which the upper part and the lower part are different in shape, and the distancesbetween the outer surfaces of the upper part and the lower part and a detection sensor are detected through the detection sensor to obtain a space position of the rotor, thereby achieving indirect measurement of a space angle of the rotor.

Owner:GREE ELECTRIC APPLIANCES INC

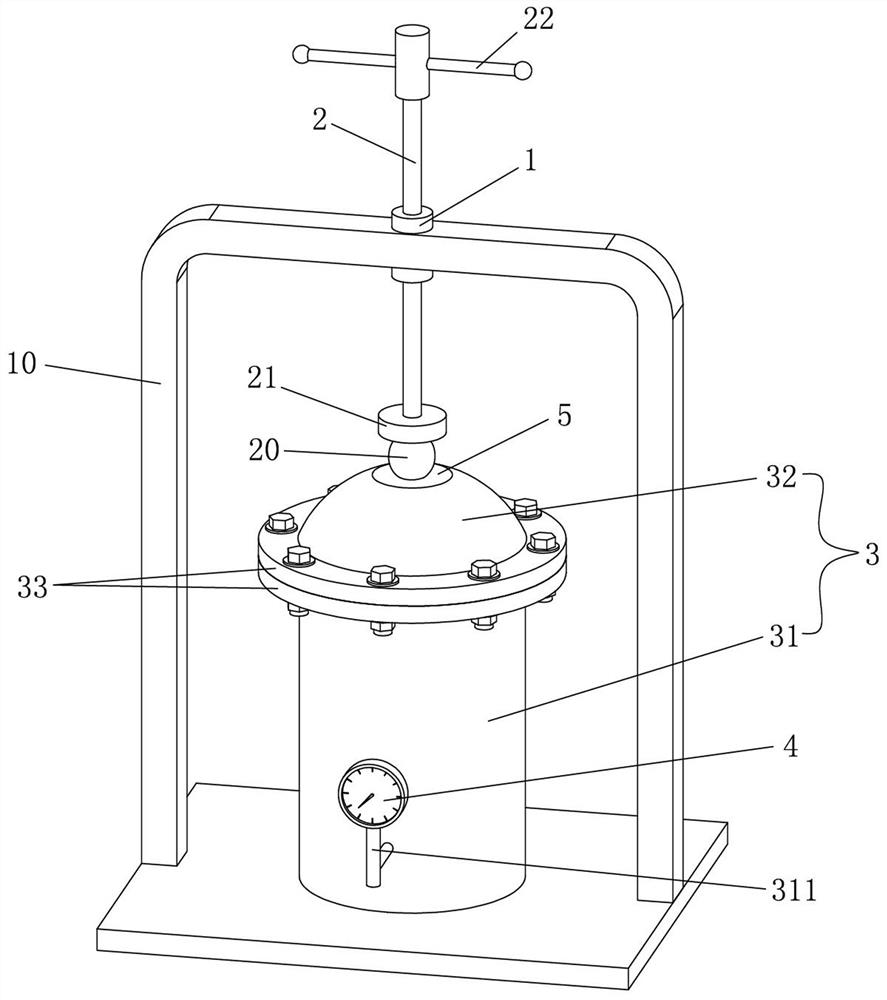

Simple tool for detecting strength of coal briquettes

InactiveCN112414856AEnables indirect measurementsSimple structureMaterial strength using tensile/compressive forcesWater pipeProcess engineering

The invention provides a simple tool for detecting the strength of coal briquettes. The simple tool comprises a support and a full-sealed water tank, a threaded sleeve is vertically installed on the support, a lead screw installed in the threaded sleeve in a threaded fit mode penetrates through the threaded sleeve, and the full-sealed water tank comprises a tank body with an opening in the upper portion and a leather cover buckled on the opening in the upper portion of the tank body; the tank body is communicated with a water pipe, a pressure gauge is installed at the end, exposed out of the tank body, of the water pipe, a horizontal base plate is arranged on the leather cover, the full-sealed water tank and the water pipe are filled with water, and coal briquettes are placed on the horizontal base plate during work. According to the invention, the coal briquettes are pressed on the full-sealed water tank, the pressure borne by the coal briquettes is converted into the water pressure in the full-sealed water tank in real time, and then the pressure gauge is used for monitoring the change of the water pressure in the full-sealed water tank, so that the indirect measurement of the compressive strength of the coal briquettes is realized, and the maximum value of the pressure gauge (the value monitored by the pressure gauge when the coal briquettes are about to break) can be used for representing the compressive strength of the coal briquettes.

Owner:雷静桃

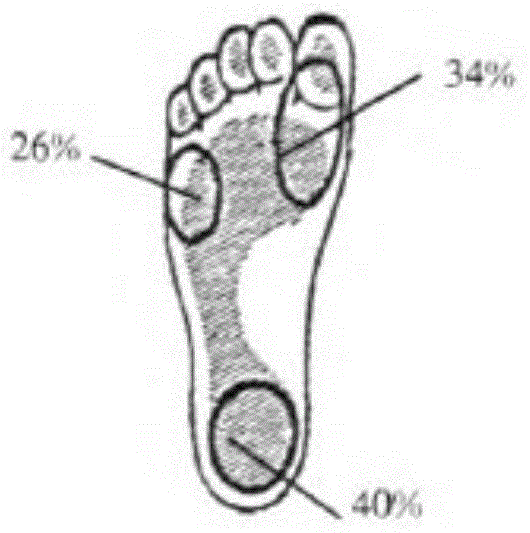

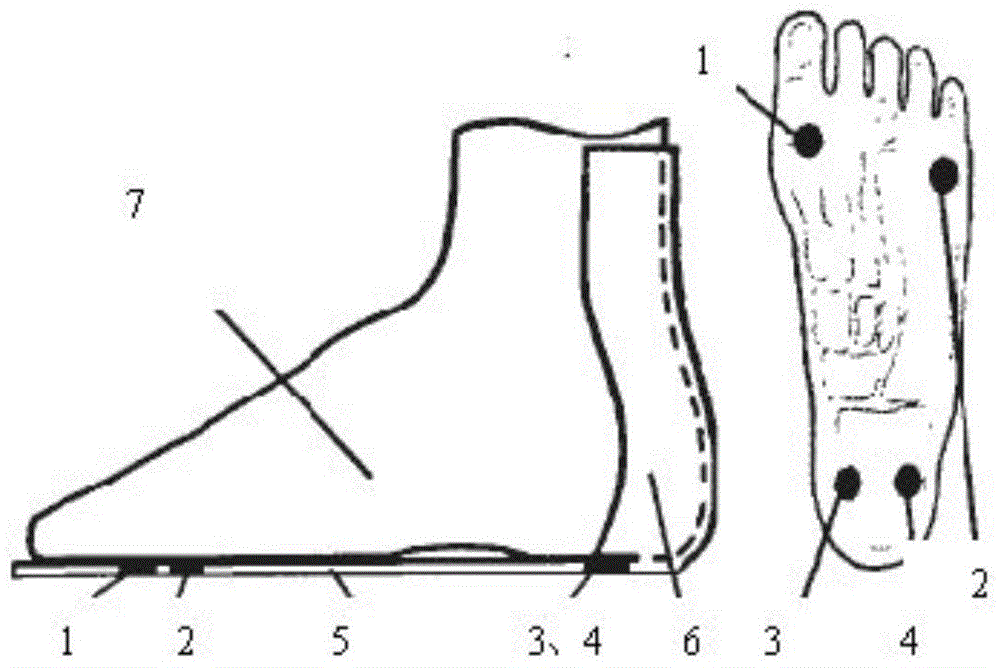

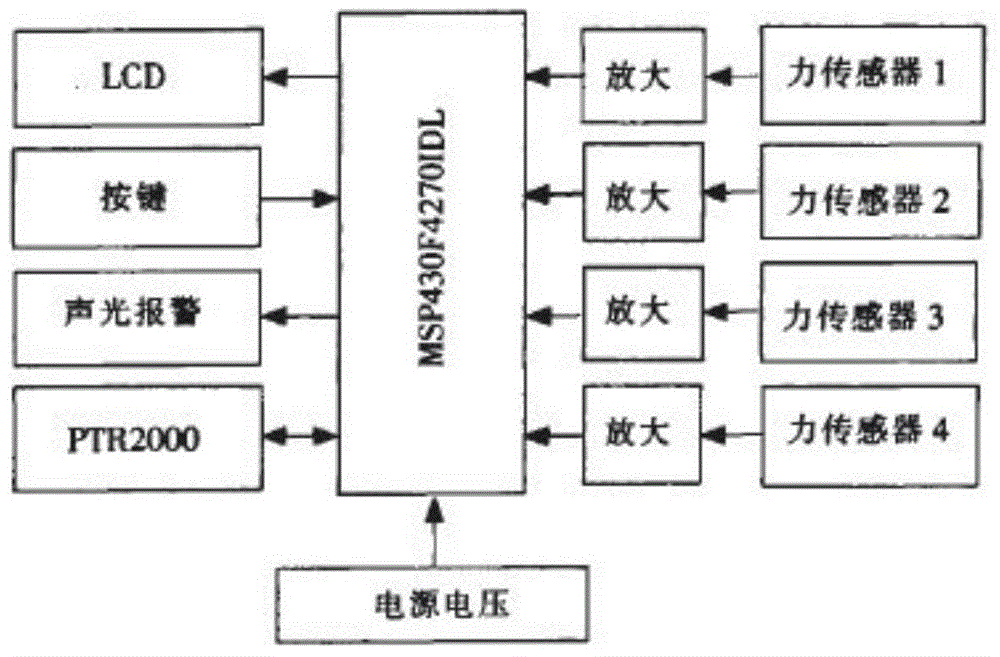

Ankle joint recovery stressed-force measuring device

InactiveCN104644190AEnables indirect measurementsEasy to control autonomouslyDiagnostic recording/measuringSensorsStrain sensorEngineering

The invention provides an ankle joint recovery stressed-force measuring device. The ankle joint recovery stressed-force measuring device comprises a bracket; a measuring plate is fixedly mounted at the bottom of the bracket; a first force sensor, a second force sensor, a third force sensor and a fourth force sensor are arranged on the measuring plate; the force sensor is a resistance strain sensor; two resistance strain sensors are symmetrically mounted under heel node landing positions, and two resistance strain sensors are mounted at the landing positions of the first head of phalanx and the fifth head of phalanx, respectively; the device further comprises a measuring device controller which is glued to the shank portion of the bracket by use of an adhesive tape; the first force sensor, the second force sensor, the third force sensor and the fourth force sensor are connected to an amplifier for inputting into a single chip MSP430F4270IDL, respectively; the single chip is connected with an LCD, a key and an audible and visual alarm, respectively; the measuring device communicates with an upper computer by use of a wireless module PTR2000. The ankle joint recovery stressed-force measuring device realizes indirect measurement of ankle joint recovery stressed force and torque and is convenient for patients to control the recovery strength under the guidance of a doctor.

Owner:SICHUAN DISCOVERY DREAM ELECTRONICS SCI & TECH

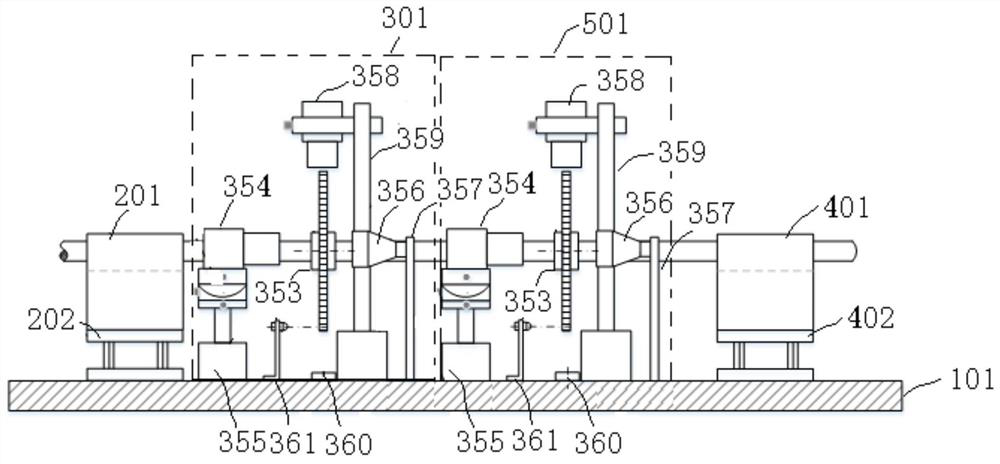

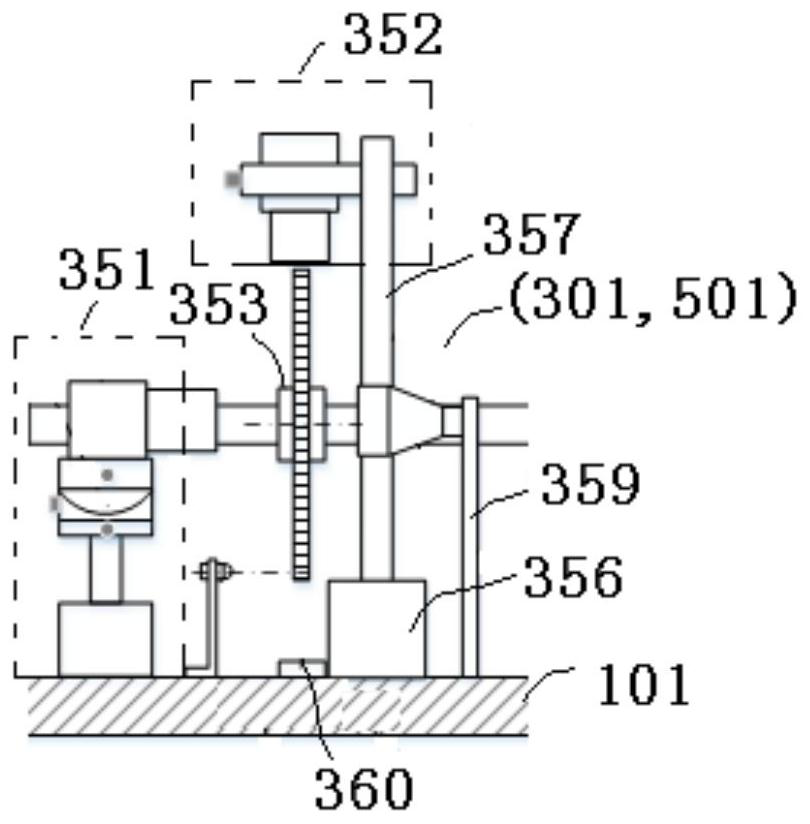

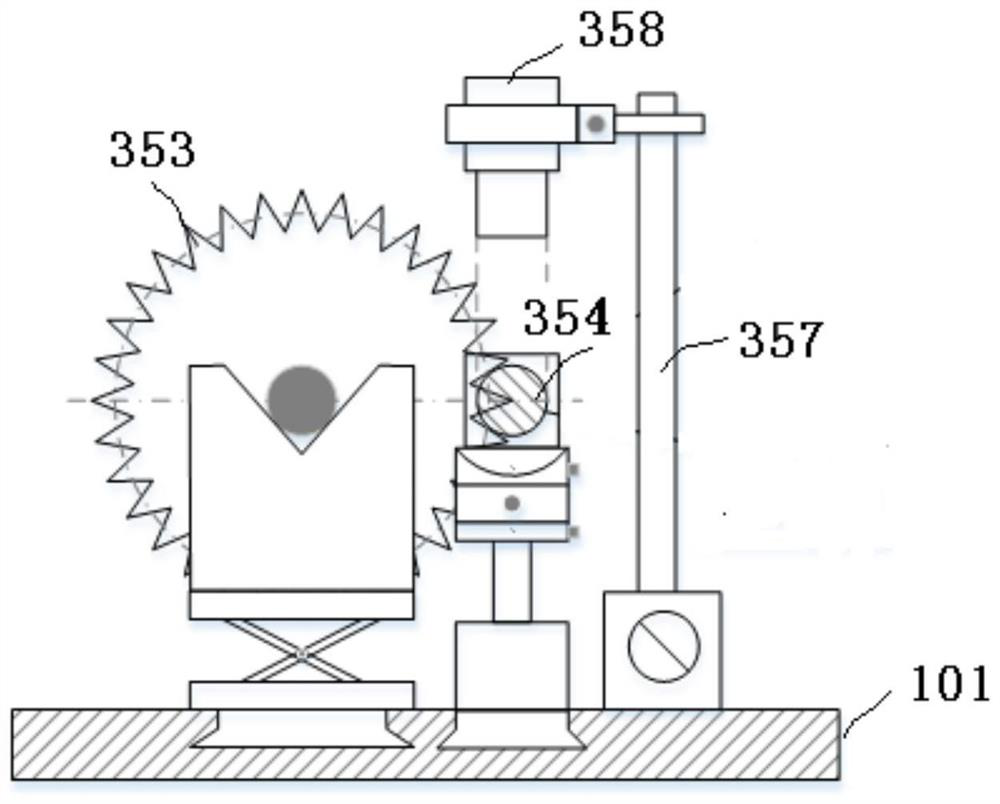

Visual precision detection device for measuring special-shaped workpiece

PendingCN114111571AEnables indirect measurementsLow costUsing optical meansVisual inspectionEngineering

The invention discloses a visual inspection device for special-shaped workpieces. The visual inspection device is composed of a visual inspection device body. The visual inspection device body comprises an optical carrying table, a first precise slewing bearing, a first multidirectional visual measurement system, a second precise slewing bearing and a second multidirectional visual measurement system; a first precise slewing bearing and a second precise slewing bearing are arranged at the two ends of the optical carrying table respectively, and a first multi-direction vision measurement system and a second multi-direction vision measurement system are sequentially connected between the first precise slewing bearing and the second precise slewing bearing in the axial direction; each of the first multi-direction vision measurement system and the second multi-direction vision measurement system comprises a radial dimension measurement vision mechanism, an axial dimension measurement vision mechanism and a rotary workpiece to be measured; the method is suitable for application occasions with high requirements for on-site rapid and precise measurement, and solves the problem of on-line rapid and precise measurement of the type of workpieces at present.

Owner:TIANJIN UNIV

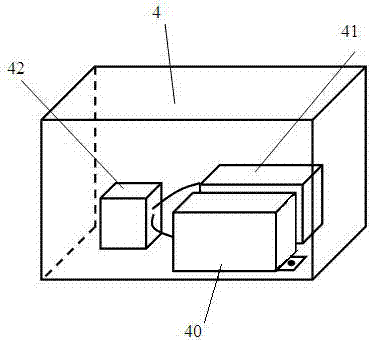

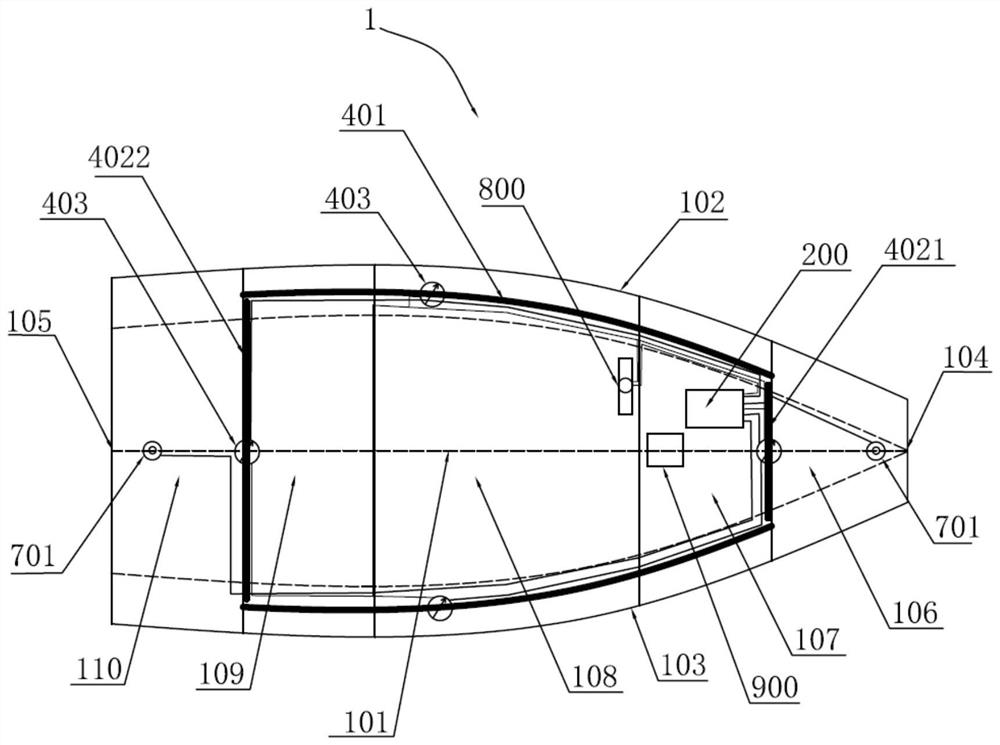

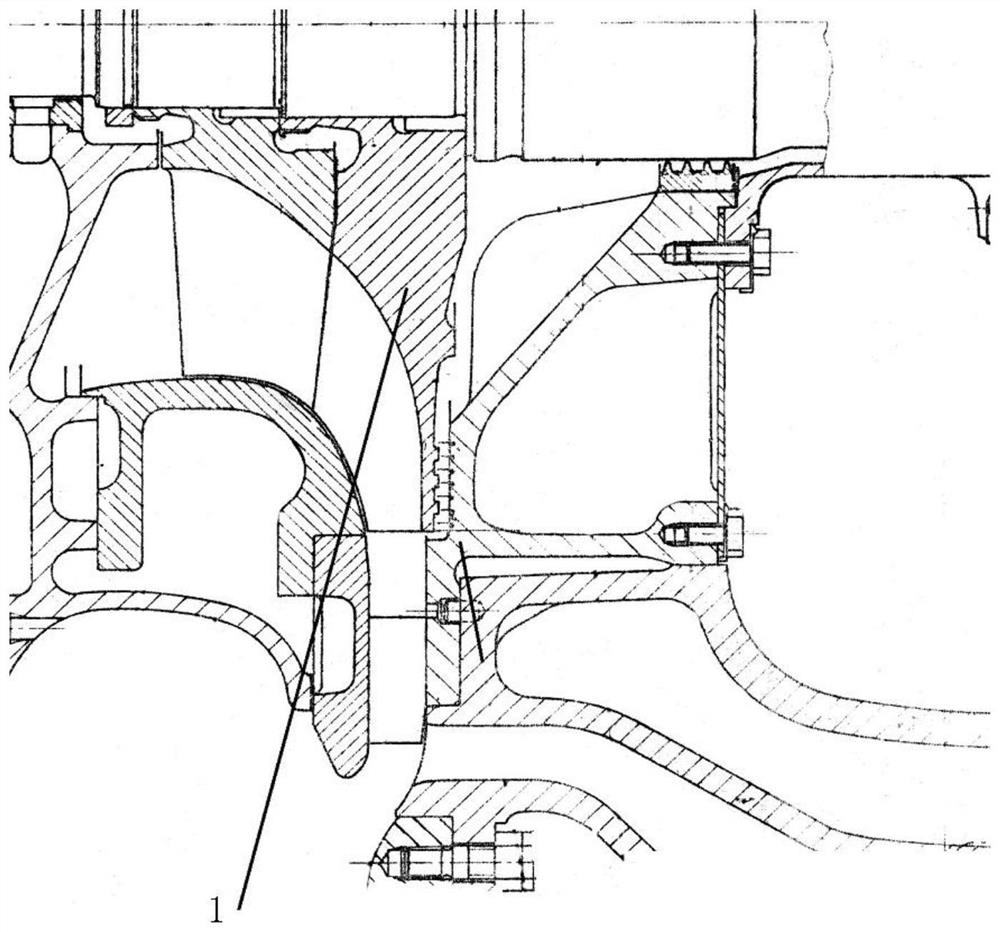

A processing method for compressor impeller of VTR series supercharger

ActiveCN110102989BGuaranteed flatnessGuaranteed parallelWork clamping meansChucksImpellerEngineering

The invention provides a method for processing the compressor impeller of a VTR series supercharger, comprising the steps of: a. the inner hole of the shaft of the impeller center; b. heat treatment; c. turning the end surface and outer circle of the impeller; d. turning the small end of the impeller and the impeller shaft Facing the inner hole, take the sample ring on the impeller at the same time; e. Inspection; f. Rough turning the small end of the impeller; g. Blades and runners; i. The outer circle of the large end of the finishing impeller; j. The large end of the finishing impeller and the axial inner hole of the impeller; k. Clamping and positioning the impeller on the turning tool, the impeller positioning surface used in the next process of finishing turning ; l. The large end of the impeller and the axial inner hole of the impeller; m. The small end face of the impeller; n. The meridian surface of the impeller and the end face of the blade. This method improves the matching accuracy and sealing performance between the large end surface of the impeller and the air seal, and solves the problem that the original sample ring and the impeller are separated and then heat treated, and the sample ring cannot truly reflect the performance status of the part after heat treatment.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

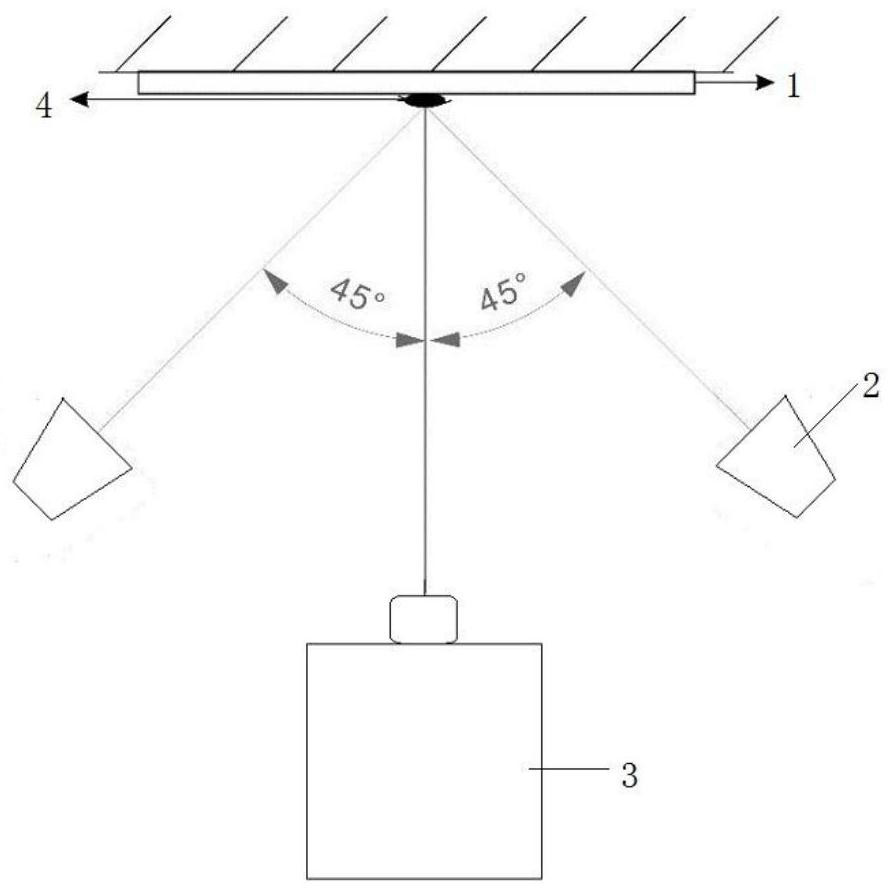

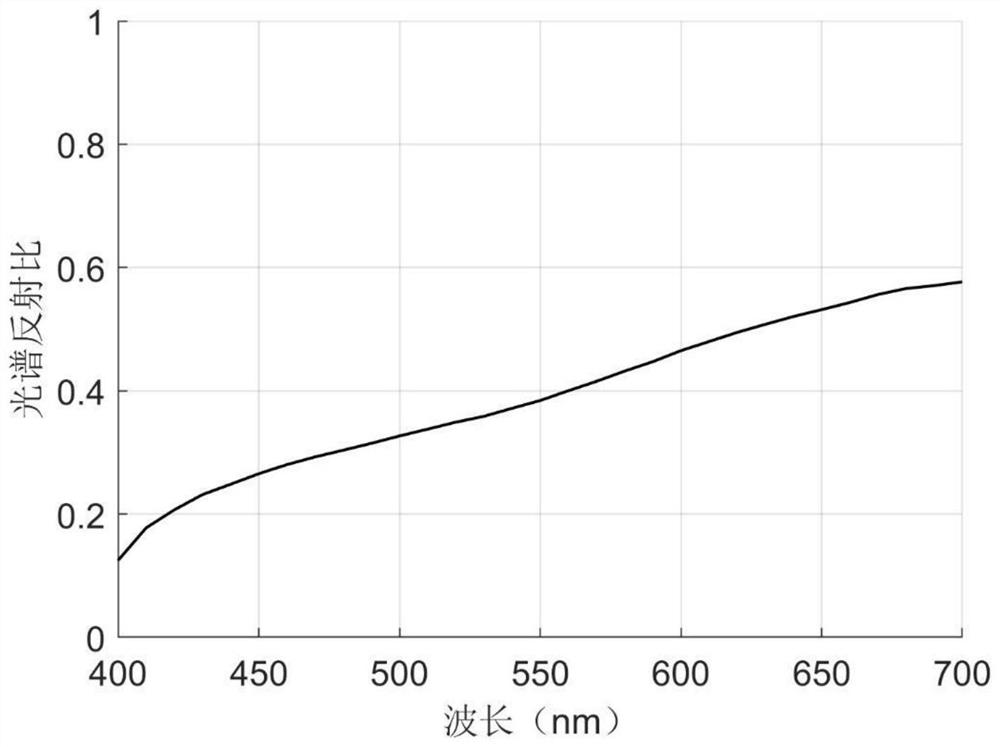

Method for Indirect Measurement of Spectral Reflectance of Insect Body Surface

ActiveCN109855734BAvoid damageEnables indirect measurementsScattering properties measurementsAbsorption/flicker/reflection spectroscopySpectroradiometerRadiance

The invention discloses a method for indirectly measuring the spectral reflectance of an insect body surface, which comprises the following steps: using a spectrophotometer to measure the spectral reflectance on the surface of a correction plate to obtain the spectral reflectance r on the surface of the correction plate; A light source is placed on the left and right sides of the plate, and the light from the two light sources is projected onto the surface of the correction plate. Directly in front of the calibration plate and on the same side as the two light sources, the measurement direction of the spectroradiometer is perpendicular to the surface of the calibration plate, forming a 45°x:0° illumination and measurement geometry with the light source; use the spectroradiometer to measure insect bodies Spectral radiance l reflected by the surface s and the spectral radiance l reflected by the correction plate surface c ; Calculate the spectral reflectance of the insect body surface. The invention has the characteristics of simple and convenient operation, easy implementation and guaranteed measurement accuracy.

Owner:诸暨市祥鹏针织有限公司

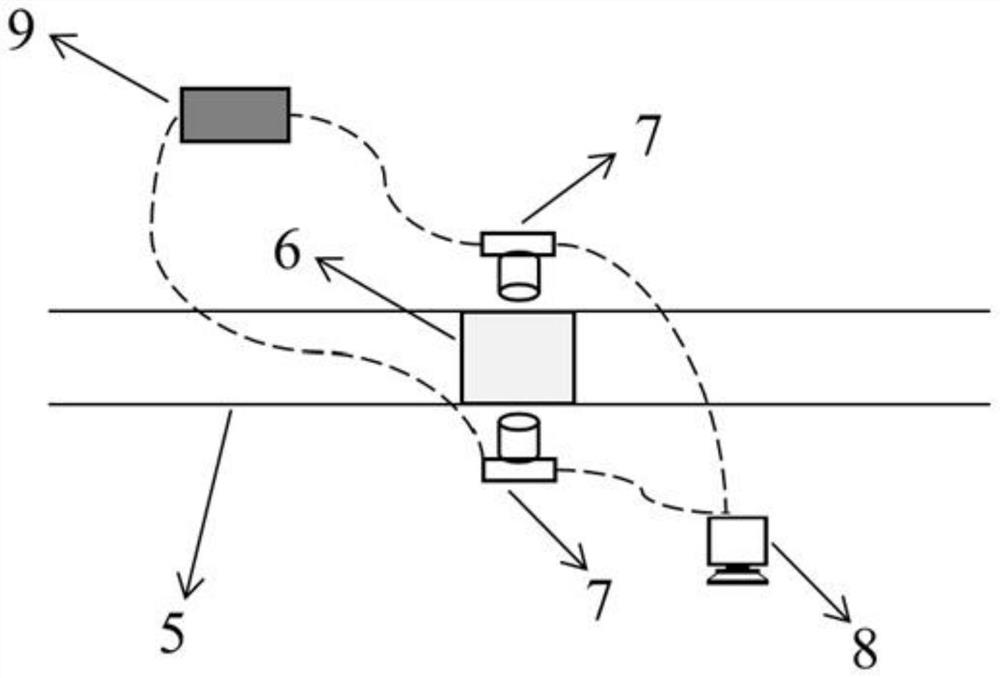

Non-contact testing system and method for rfid tag antenna

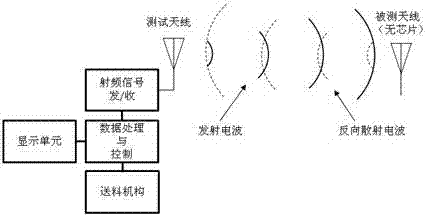

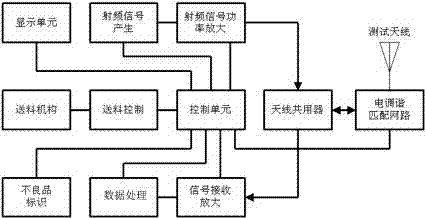

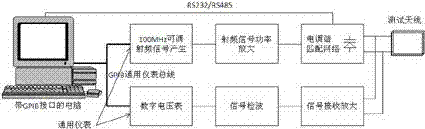

ActiveCN103267911BReduce work intensityReduced precision requirementsElectrical testingContact testTag antenna

The invention discloses a non-contact test system and method of an RFID label antenna. The non-contact test system of the RFID label antenna comprises a display unit, a data processing and controlling unit, a radio-frequency signal transmit / receive unit, a feed mechanism unit and a test antenna unit. The data processing and controlling unit is connected with the display unit, the radio-frequency signal transmit / receive unit and the feed mechanism unit in sequence, and the test antenna unit is connected with the radio-frequency signal transmit / receive unit. Due to the fact that non-contact test is adopted, test can be carried out free of requirement of binding a chip, dissipation of the chip is reduced, and working strength of testing personnel is reduced; the fault testing rate and the leak testing rate are low; automatic testing can be achieved, and testing efficiency is high; indirect measurement to electrical property can be achieved. The non-contact test system and method of the RFID label antenna can achieve automatic test and greatly reduces demands for mechanical mechanisms, and are very suitable for large-batch production testing.

Owner:SUZHOU ZUENS IOT TECH CO LTD

Distributed optical fiber sensor

InactiveCN113063449AGuaranteed to workExtended service lifeMeasurement apparatus housingsConverting sensor output opticallyEngineeringMaterials science

The embodiment of the invention discloses a distributed optical fiber sensor. The distributed optical fiber sensor comprises an optical fiber sensor body, a shell and a metal substrate; the optical fiber sensor body is fixed in the shell; heat dissipation holes and a filter screen are arranged on the side wall of the shell; a mounting groove and a welding groove are formed in the metal substrate; the mounting groove is used for mounting the shell; the welding groove is used for welding an object to be detected. According to the embodiment of the invention, the optical fiber sensor is fixed on the metal substrate through the shell, sensing optical fibers in the distributed optical fiber sensor are prevented from being broken in the use process, dust prevention and heat dissipation are realized through the heat dissipation holes and the filter screen, and the to-be-measured object is indirectly measured through the metal substrate, so that the sensing optical fibers are prevented from being broken, the measurement cost is reduced, heat dissipation and dust prevention can be achieved, the service life is prolonged, and the measurement precision of the distributed optical fiber sensor is improved.

Owner:QINGYUAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID CO LTD

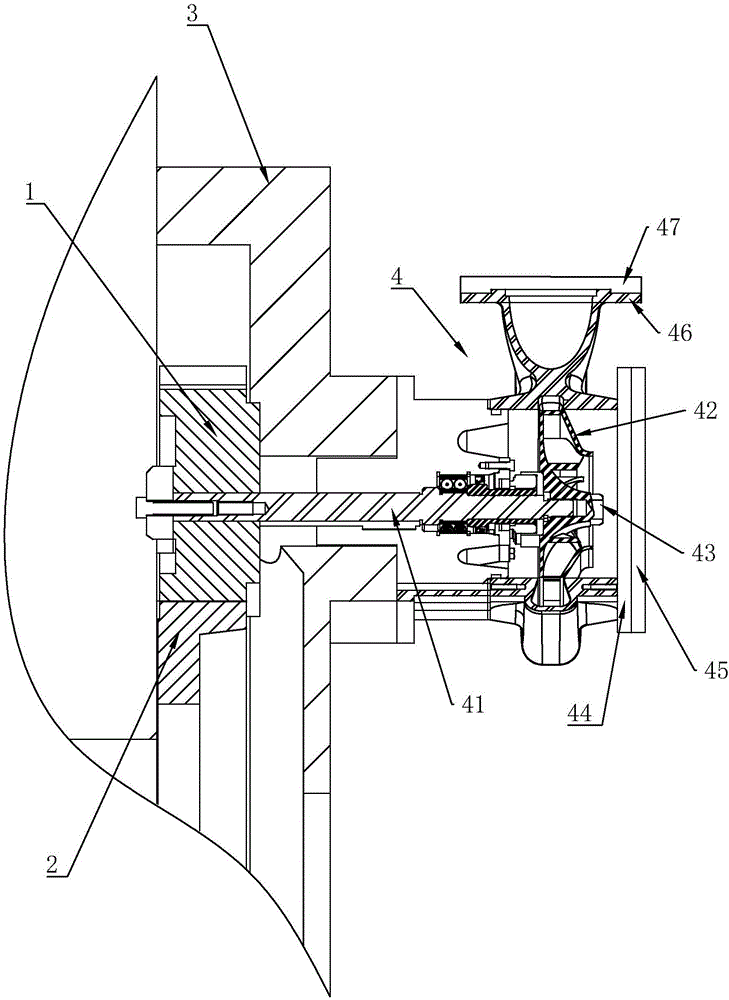

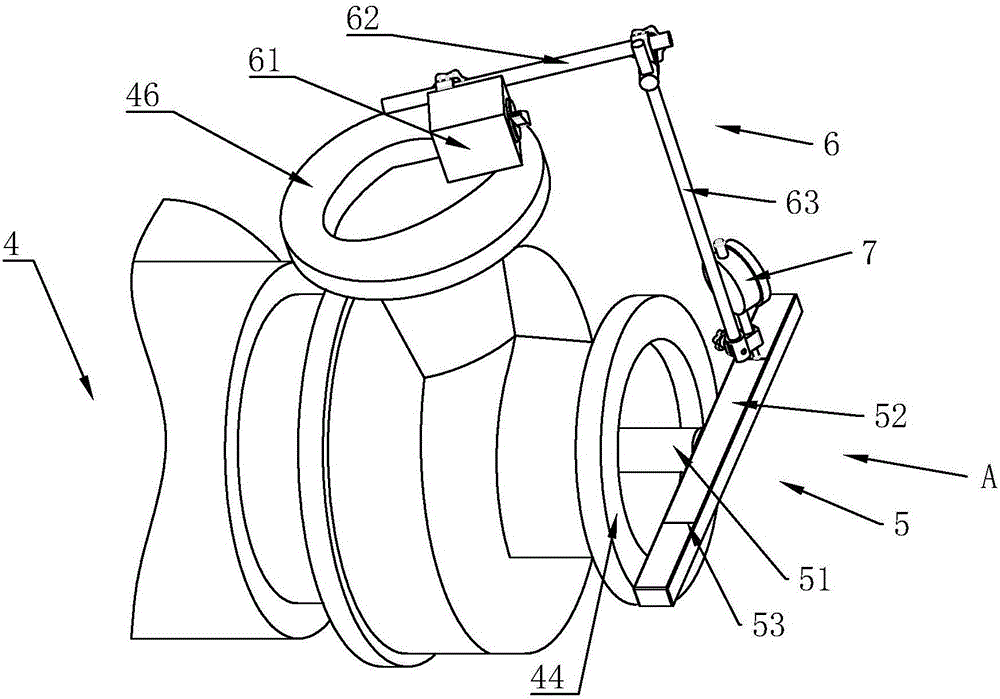

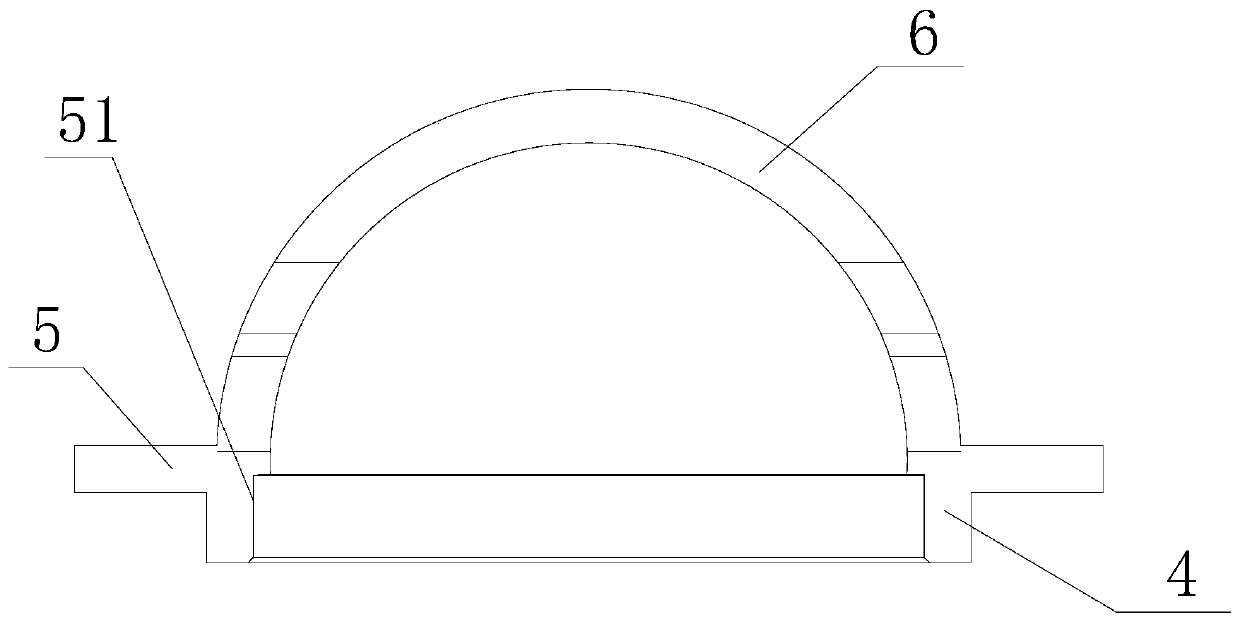

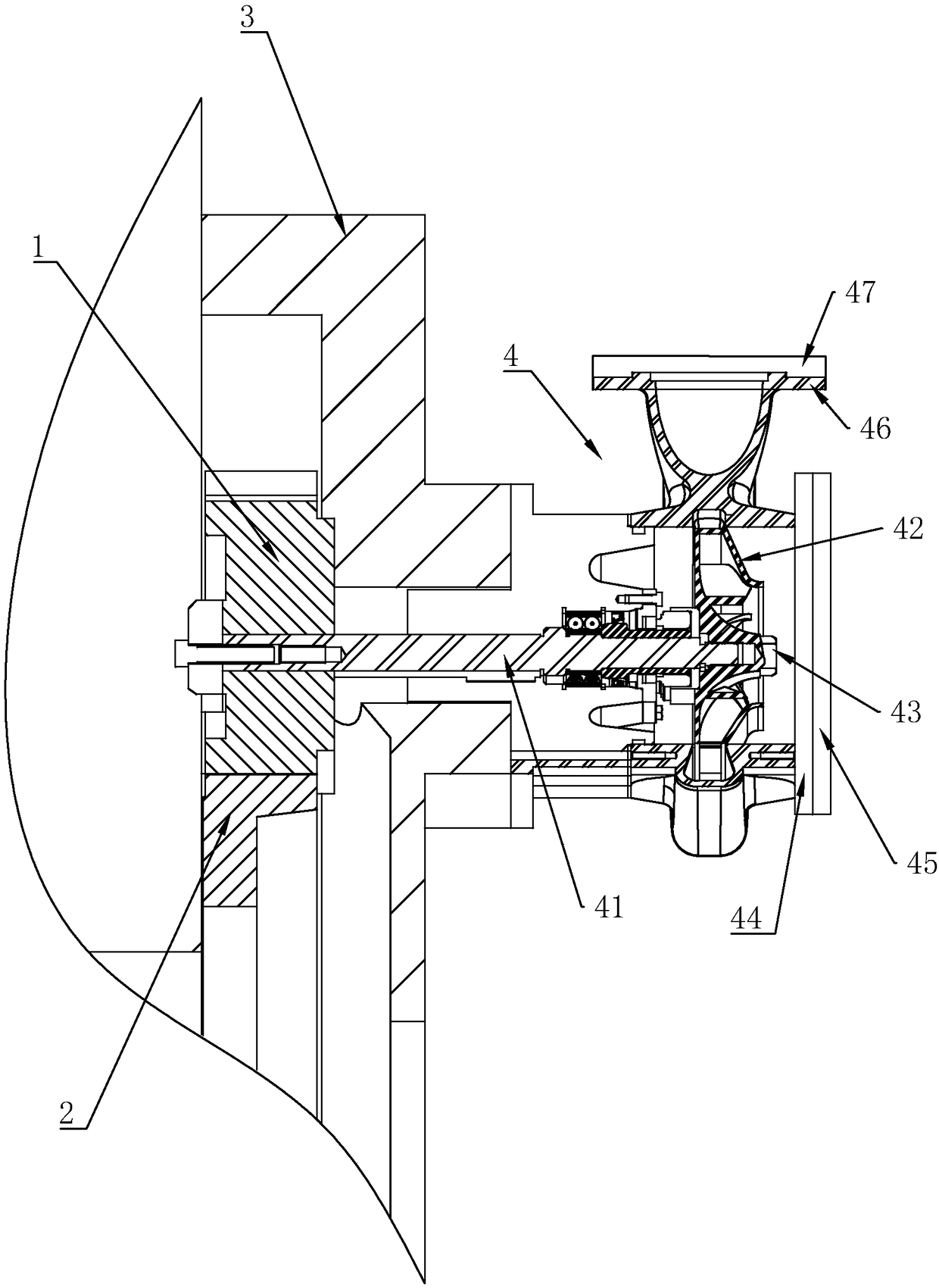

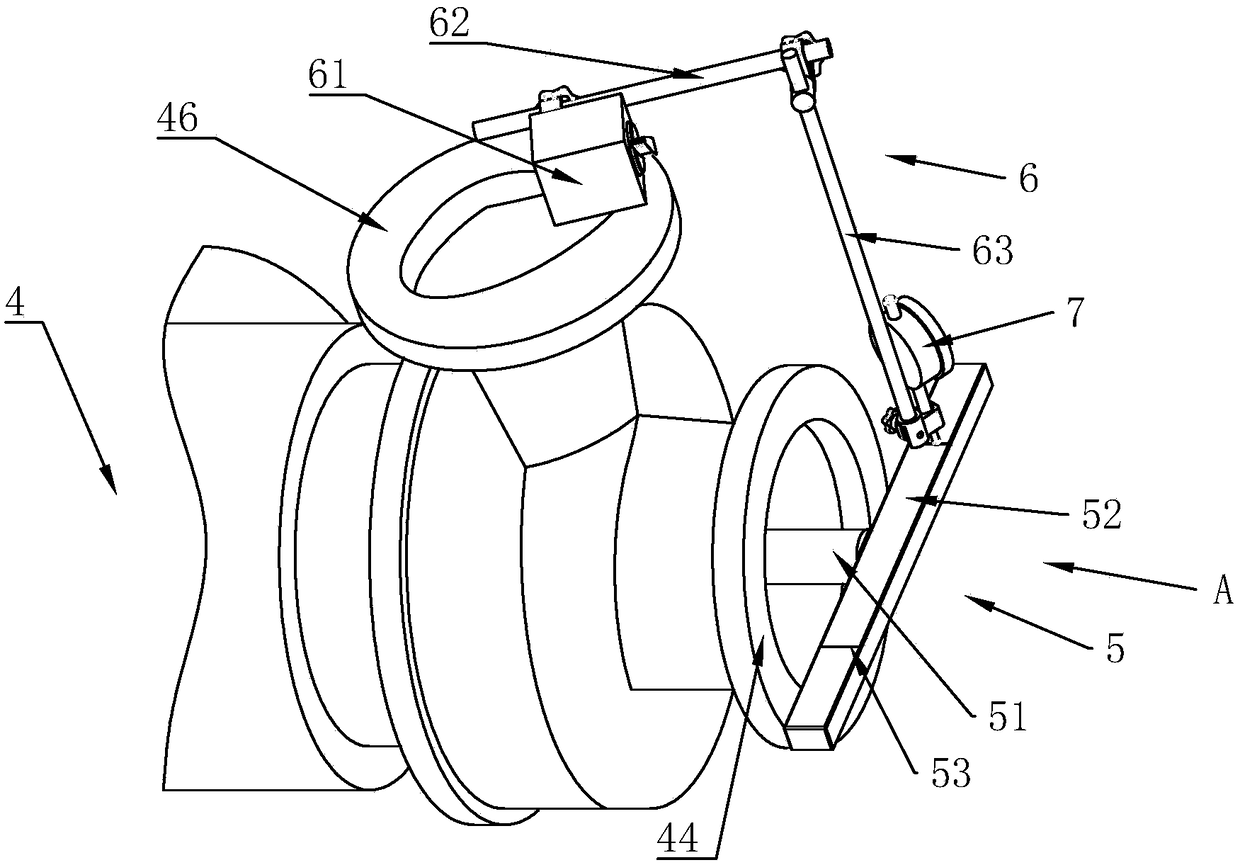

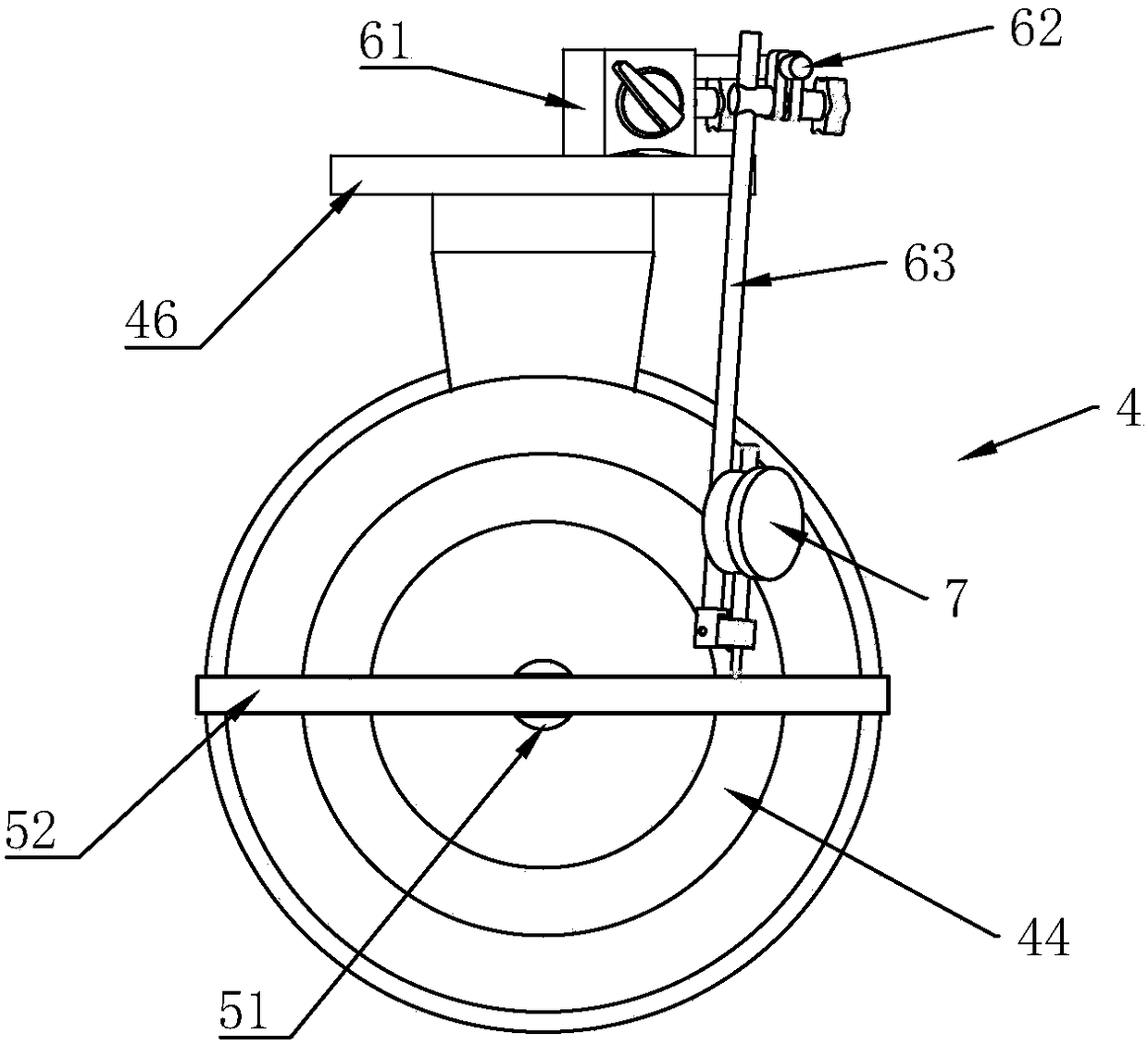

Measuring device and method for igniter

ActiveCN107063694BSatisfy the use effectImprove stabilityEngine testingMeasurement deviceEngineering

The present invention discloses a measurement device for an igniter and a measurement method for an igniter. The method is configured to measure the fit clearance between the flow baffle of the igniter and an upper housing. The measurement device comprises a pedestal configured to play a support and location effect and a fixing ring arranged on the pedestal, the fixing ring is provided with an arc plate configured to locate and measure a datum plane, the inner side surface of the arc plate is completely matched with the inner side surface of the upper housing, and the inner side wall of the fixing ring is provided with a neck configured to clamp the upper end opening of the igniter skirt of an igniter. The measurement device for the igniter and the measurement method for the igniter are simple in structure and convenient to control, can rapidly realize the indirect measurement the fit clearance between the flow baffle of the igniter and the upper housing, ensure the assembling quality of combination pieces, satisfy the usage performance of the igniter, improve the processing precision of the igniter parts, play an important effect on the improvement of the stability of the igniter, and have great popularization and application values.

Owner:CHINA HANGFA SOUTH IND CO LTD

A measuring technology of gear gap between water pump gear and crankshaft gear

ActiveCN105841586BRealize coaxial rotationEnables indirect measurementsMechanical clearance measurementsGear wheelTurbine

The invention discloses a measuring technology of a gear clearance between a water pump gear and a crankshaft gear. The measuring technology includes the following steps that: the water pump gear is assembled on the rotation shaft of a water pump, a water pump turbine is installed on the rotation shaft through a fastening nut on the water pump turbine, and the water pump is assembled to an engine, and the water pump gear and the crankshaft gear are engaged with each other; the crankshaft of the crankshaft gear is fixedly installed; a first sealing flange at the inlet of the water pump is disassembled, a measurement fixture is concentrically connected onto the fastening nut, the measurement fixture is provided with two scribed lines, and the distance between the two scribed lines is the reference circle diameter of the water pump gear; a second sealing flange at the outlet of the water pump is provided with a supporting mechanism provided with a dial indicator, and the pushing pin of the dial indicator abuts against one of the scribed lines; the dial indicator is zeroed; and the water pump gear is rotated towards the direction of the dial indicator. The measuring technology is simple in measuring process and easy in operation, and can assist in shortening measuring time and improving working efficiency. The measurement of the gear clearance between the water pump gear and the crankshaft gear can be realized through the dial indicator, and measuring accuracy is high.

Owner:WEICHAI HEAVY MACHINERY CO LTD

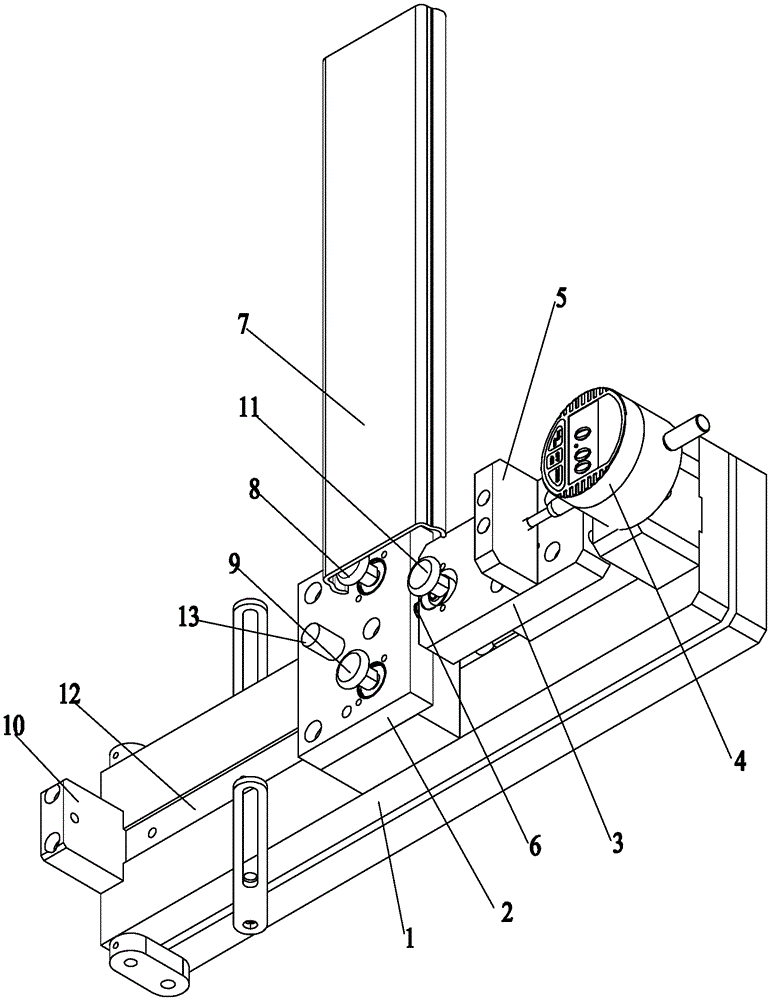

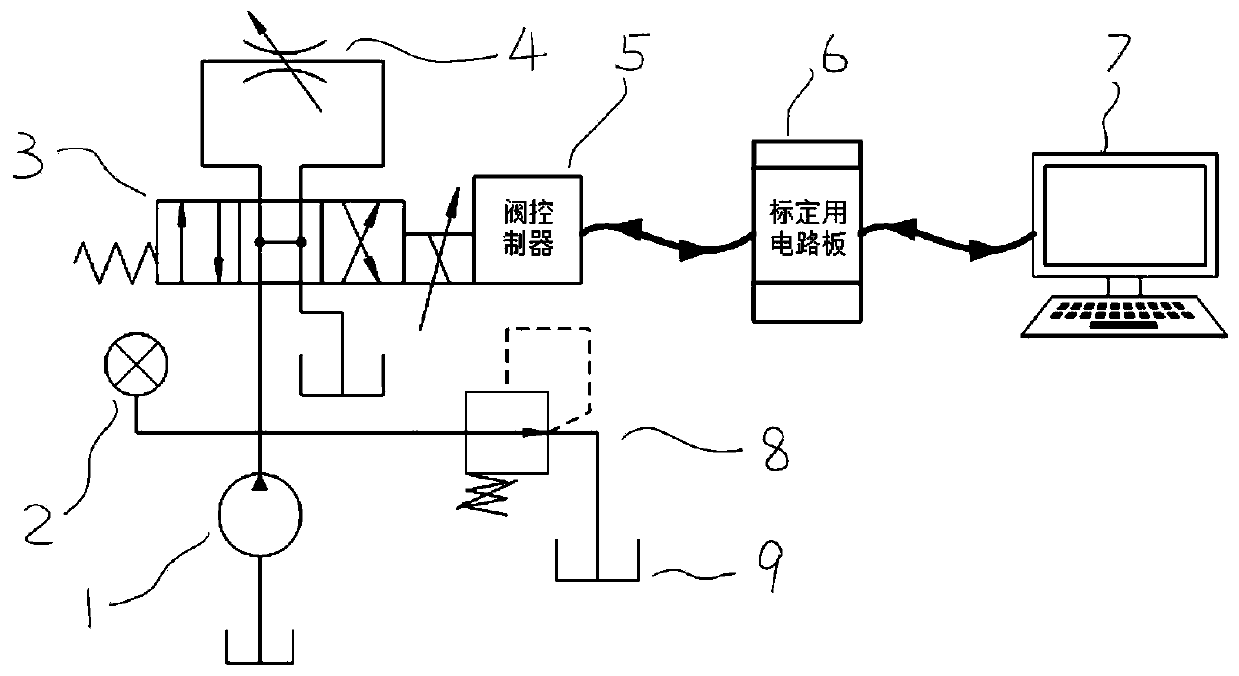

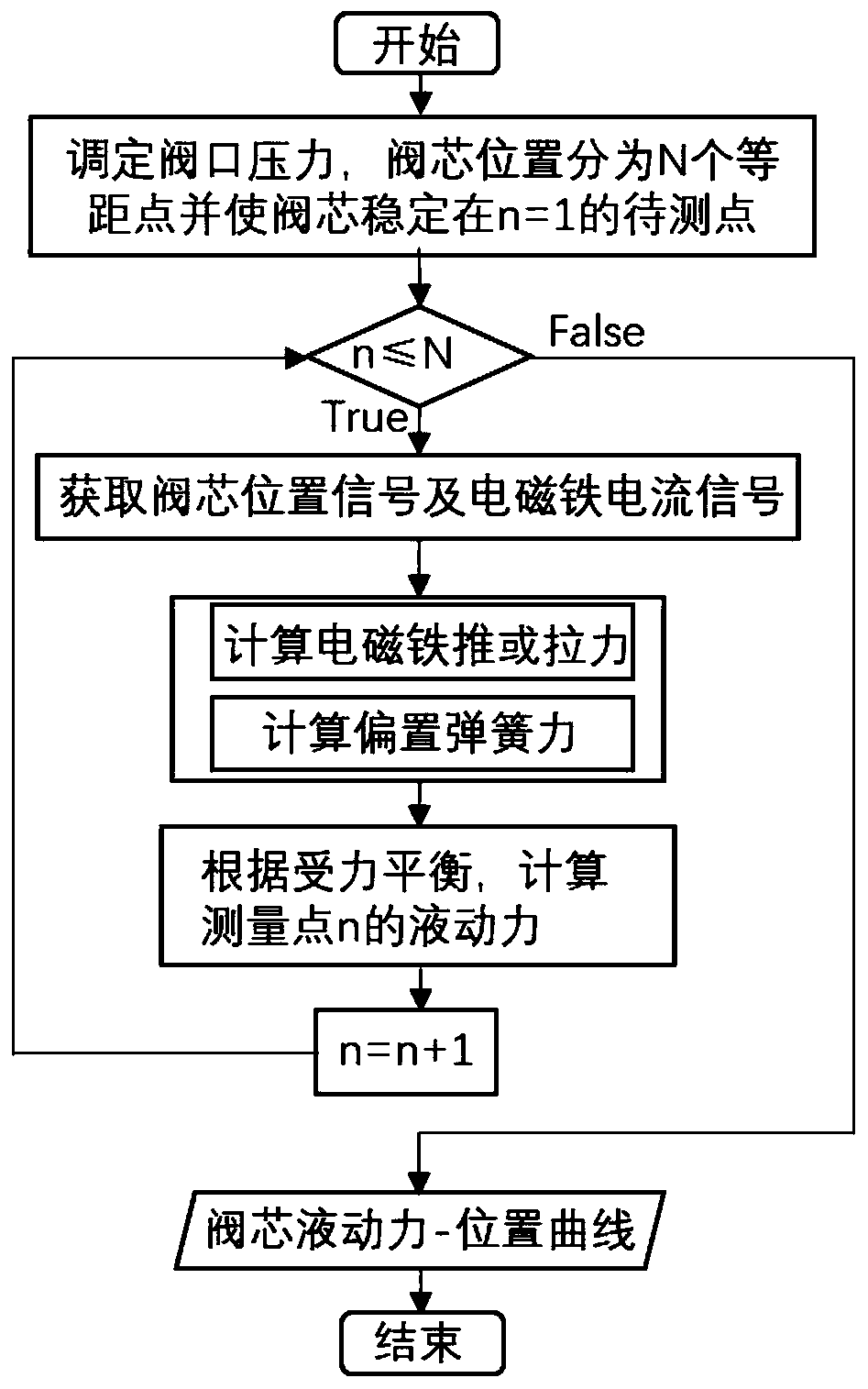

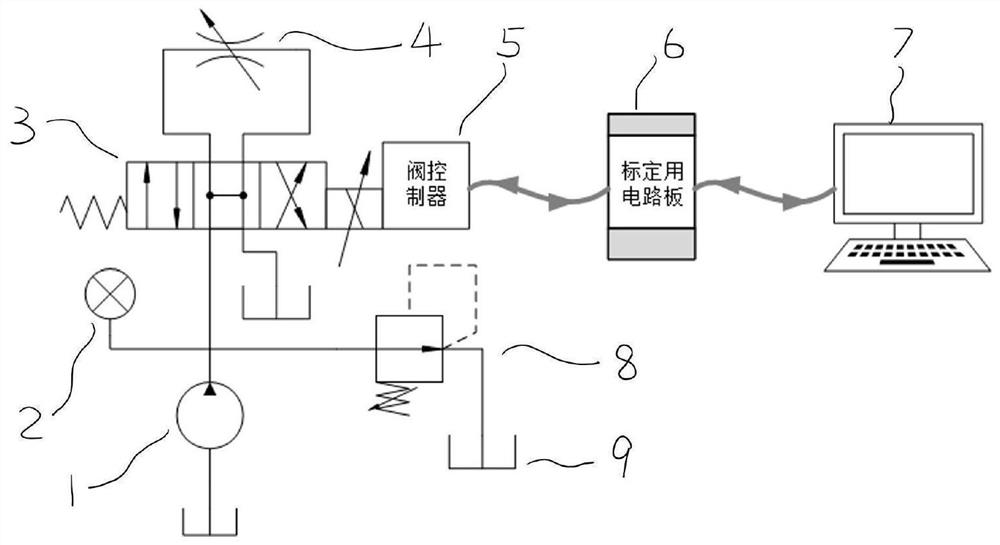

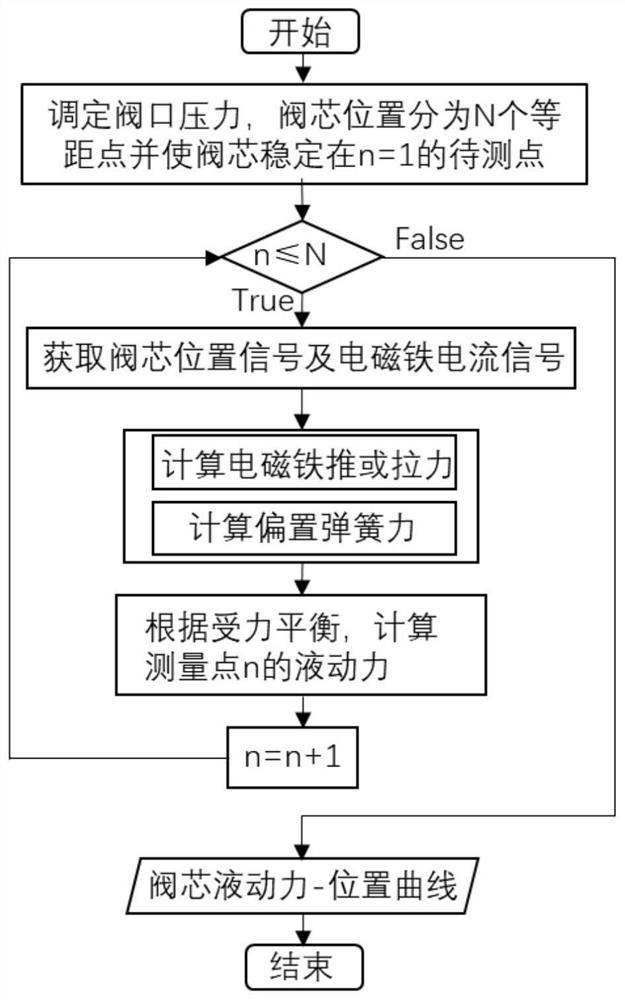

Intelligent calibration device and method for steady-state fluid force of valve element of proportional valve

ActiveCN111306143AEffective measurementEnables indirect measurementsFluid-pressure actuator testingPhysicsEngineering

The invention relates to a proportional valve, in particular to an intelligent calibration device and method for a steady-state fluid force of a valve element of a proportional valve. The proportionalvalve with a valve controller is mounted in a mounting table of a pressure adjustable hydraulic system valve; a circuit board for calibration is connected to the valve controller, and a D / A module onthe circuit board sends out a position command to the valve controller, so that the circuit board is controlled in a target position, and the A / D module receives a valve element position fed back bythe valve controller and a current signal of the proportional valve; the circuit board is programmed by using a singlechip microcomputer or other microprocessors, a signal collected by a program is processed to obtain a fluid force of a measuring point and a position command signal of a next measuring point is sent out till the fluid forces of all measuring points are measured, and at the moment,the circuit board for calibration sends measured data to a computer by way of serial communication or bus communication. According to the intelligent calibration device and method, the amplitude of the fluid force can be calibrated automatically without detaching a proportional valve body.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

Method and device for dynamic weighing estimation of toll booth vehicles

ActiveCN104089690BEnables indirect measurementsImprove traffic efficiencySpecial purpose weighing apparatusSpeed bumpLaser transmitter

The invention discloses a method and device for dynamic weighing and estimation of vehicles at a toll station. The left and right sides of the toll station road are respectively equipped with a laser transmitter group and a photoelectric receiver group; the vehicle to be tested first blocks the laser light emitted by the first laser transmitter, and then Block the laser emitted by the second laser transmitter, the MCU control system calculates the speed of the vehicle to be measured before passing the impact force measuring device, and the left and right pressure sensor groups input the signals of the impact force of the left and right wheels into the MCU control system; The speed and impact force of the vehicle to be tested are used as the input of the BP artificial neural network model, and the mass is used as the output to estimate the vehicle mass; the present invention comprehensively considers the kinetic energy of the moving vehicle and the impact force generated during the collision with the force measuring device. Using road speed bumps to allow vehicles to maintain a certain speed passing through the speed bumps, combined with artificial neural network technology to achieve indirect measurement of vehicle quality and improve toll station traffic efficiency.

Owner:佛山市衡王电子衡器有限公司

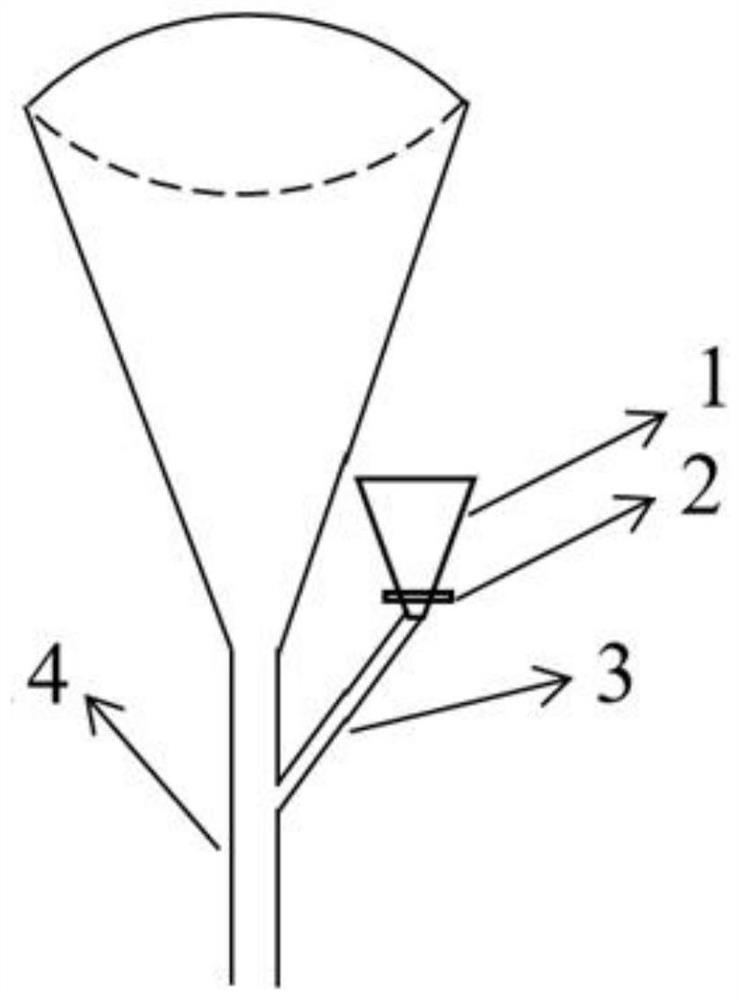

System and method for measuring pulverized coal concentration and speed deviation of boiler pulverized coal pipeline

PendingCN113739847ASafe and stable operationEnables indirect measurementsMeasurement devicesThermodynamicsImaging processing

The invention relates to a system and a method for measuring pulverized coal concentration and speed deviation of a boiler pulverized coal pipeline. The system comprises a mixing unit and a measuring unit. The mixing unit comprises a luminous powder falling pipe used for being connected with the coal falling pipe, the luminous powder falling pipe is connected with a luminous powder bin, the luminous powder bin is provided with an adjusting door used for adjusting the powder falling amount, and a lighting device used for light absorption of luminous powder is arranged in the luminous powder bin. The measuring unit comprises a section of transparent pipeline arranged on the primary powder pipe, high-speed cameras are arranged on the periphery of the outer side of the transparent pipeline, and the high-speed cameras are connected with the control module and the image processing unit. The flow and flow velocity of the pulverized coal airflow can be accurately measured by using one set of equipment under the condition that the pulverized coal airflow is not contacted, and the reliability is relatively high. And after the flow, namely the flow velocity, of the pulverized coal airflow is measured, an operator can adjust the flow and the flow velocity of each branch pulverized coal pipe according to a measurement result, so that safe and stable operation of the boiler is ensured.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST

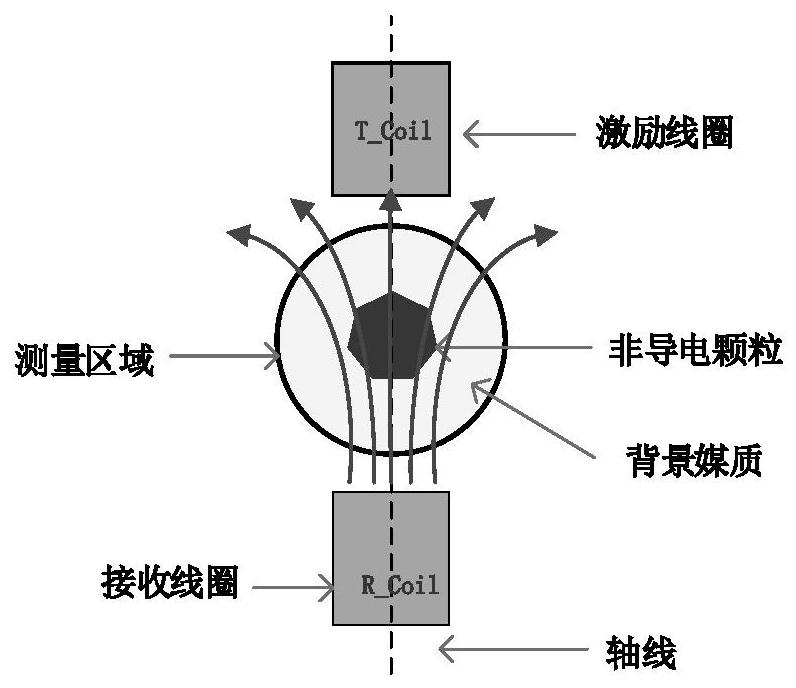

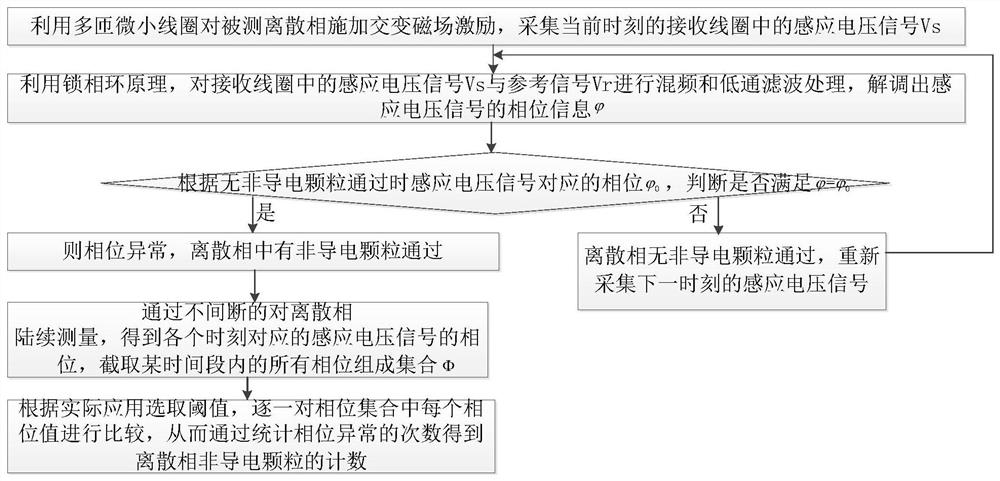

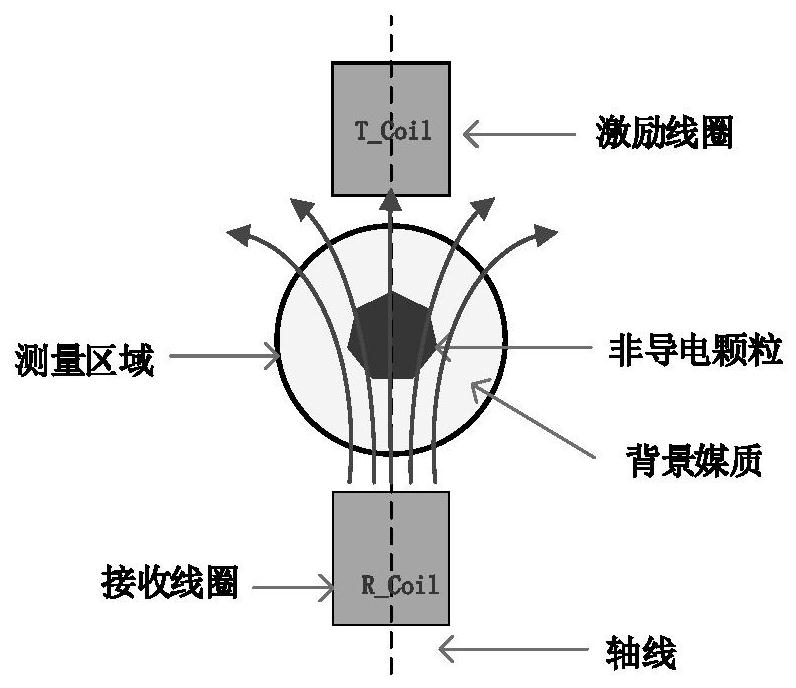

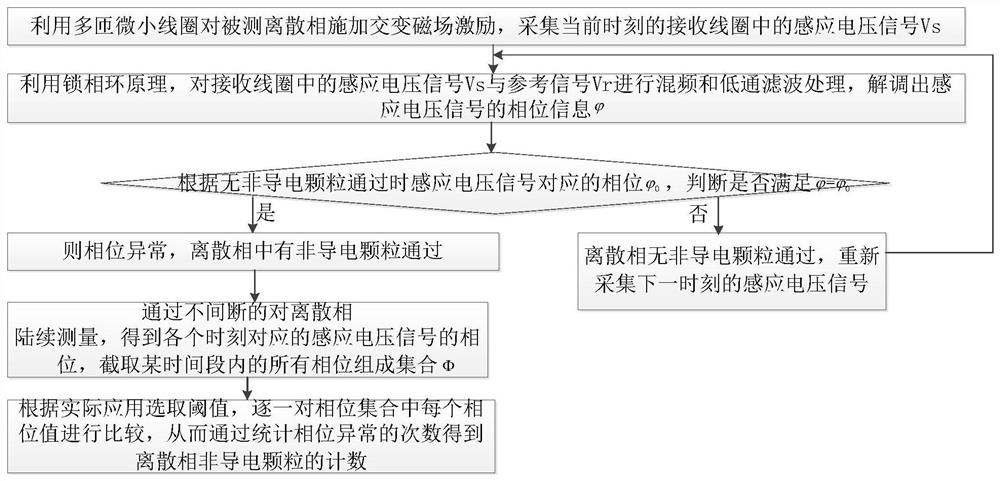

A non-contact electromagnetic detection method for discrete-phase non-conductive particles

ActiveCN112683754BEnables indirect measurementsRealize non-contact detectionIndividual particle analysisContinuous measurementCondensed matter physics

The invention discloses a non-contact electromagnetic detection method for discrete-phase non-conductive particles, which belongs to the field of electromagnetic measurement. The principle of the loop is to perform frequency mixing and low-pass filtering on the induced voltage signal and the reference signal, demodulate the phase, and then judge whether the phase corresponding to the induced voltage signal is equal to the phase when no non-conductive particles pass through. If so, the discrete phase is normal, and the next moment Otherwise, it means that the discrete phase has non-conductive particles passing through; through uninterrupted measurement, the phase corresponding to each moment is obtained, and finally, according to the selected threshold τ, each phase value is compared one by one, so as to pass the statistical phase The number of exceptions is obtained by counting the discrete phase non-conductive particles. The invention realizes high-efficiency and real-time detection of non-conductive particles in the flowing discrete phase.

Owner:BEIHANG UNIV

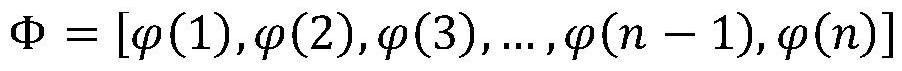

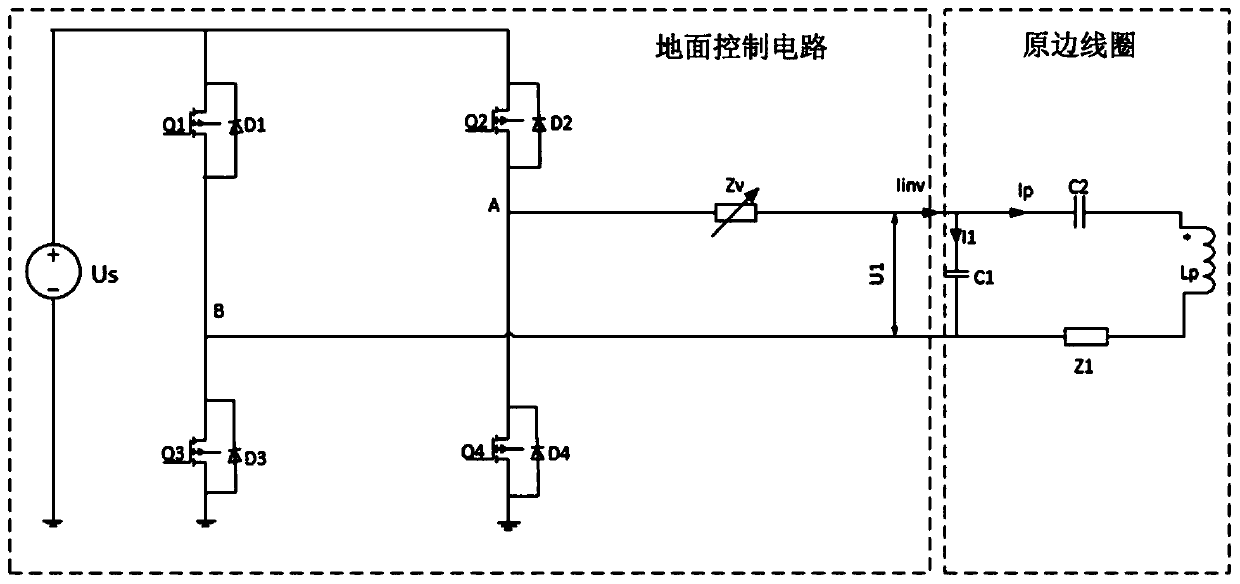

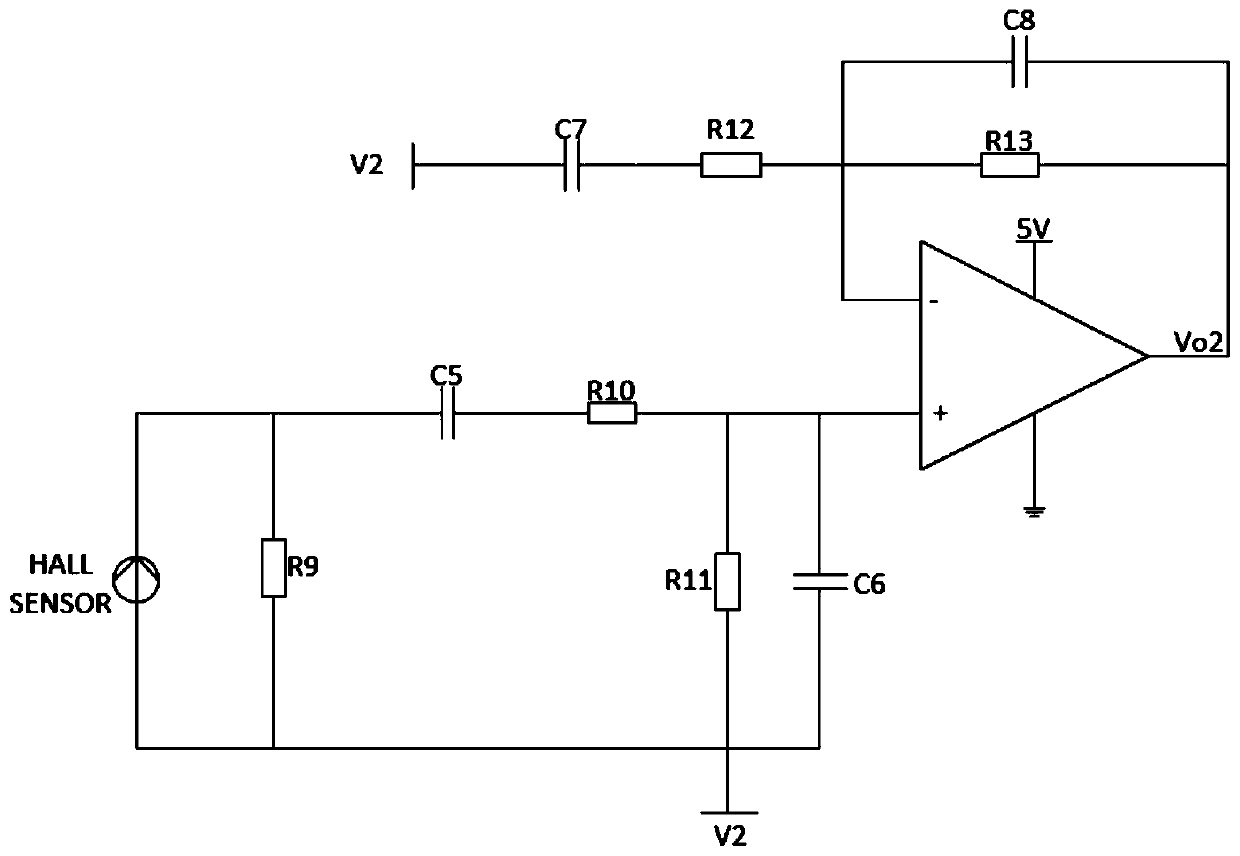

Primary side coil current measurement circuit of magnetic-induced radio energy transmission system

The invention discloses a primary side coil current measurement circuit of a magnetic-induced radio energy transmission system. The magnetic-induced radio energy transmission system comprises a groundcontrol circuit and a primary side coil arranged on the ground; the primary side coil current measurement circuit comprises an output voltage sampling circuit for processing output voltage of a ground control circuit and outputting the processed output voltage of the ground control circuit; and an output current sampling circuit for processing the output current of an inverter and outputting thevoltage corresponding to the processed output current of the inverter. The primary side coil current measurement circuit can realize indirect measurement on the primary side coil current, and then a system running state is judged by monitoring the primary side coil current in real time, and the reliability of the system running is guaranteed; and the primary side coil current measurement circuit is simple in structure, low in cost and capable of realizing remote measurement.

Owner:上海万暨电子科技有限公司

Device and method for detecting blood pressure and oxyhemoglobin saturation simultaneously

ActiveCN102715893BEnables indirect measurementsEnable non-invasive testingSensorsBlood characterising devicesVenous bloodAir pump

Owner:HEILONGJIANG UNIV

Intelligent Calibration Device and Method for Steady-state Hydraulic Power of Proportional Valve Spool

ActiveCN111306143BEnables indirect measurementsEfficient measurementFluid-pressure actuator testingControl engineeringControl theory

The present invention relates to proportional valves. The intelligent calibration device and method of the steady-state hydraulic power of the proportional valve spool of the present invention is to install the proportional valve with the valve controller on the installation table of the adjustable pressure hydraulic system valve; the calibration circuit board is connected with the valve controller , the D / A module on the circuit board sends a position command to the valve controller to make it control at the target position, and receives the valve core position and the current signal of the proportional valve through the A / D module; the circuit board adopts a single-chip microcomputer or other The microprocessor is programmed, and the program processes the collected signals to obtain the hydraulic force of the measuring point, and sends out the position command signal of the next measuring point until the hydraulic force of all measuring points is measured, at this time, the calibration circuit board communicates through the serial port Or bus communication and other methods to send the measured data to the computer. The solution of the invention can automatically calibrate the size of the hydraulic power without dismantling the proportional valve body.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

Non-contact electromagnetic detection method for discrete phase non-conductive particles

ActiveCN112683754AEnables indirect measurementsRealize non-contact detectionIndividual particle analysisElectrically conductivePhase-locked loop

The invention discloses a non-contact electromagnetic detection method for discrete phase non-conductive particles, which belongs to the field of electromagnetic measurement. The method specifically comprises the steps of firstly, applying alternating magnetic field excitation by using a multi-turn micro coil, and acquiring an induced voltage signal; utilizing a phase-locked loop principle to carry out frequency-mixing low-pass filtering processing on the induced voltage signal and a reference signal, demodulating a phase, judging whether the phase corresponding to the induced voltage signal is equal to the phase when no non-conductive particles pass through, if so, determining that a discrete phase is normal, and repeatedly executing the induced voltage signal at the next moment; otherwise, determining that the non-conductive particles pass through the discrete phase; obtaining the phase corresponding to each moment through uninterrupted measurement, and finally, comparing each phase value one by one according to a selected threshold tau, so that the count of the discrete phase non-conductive particles is obtained by counting the number of times of phase abnormality. According to the invention, efficient real-time detection of the flowing discrete phase non-conductive particles is realized.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com