Visual precision detection device for measuring special-shaped workpiece

A visual inspection device, a technology for special-shaped workpieces, applied in measuring devices, using optical devices, instruments, etc., can solve the problems of rapid measurement and inability to achieve assembly accuracy, achieve precise three-dimensional dimension measurement, meet the needs of rapid and precise measurement, and achieve rapid The effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

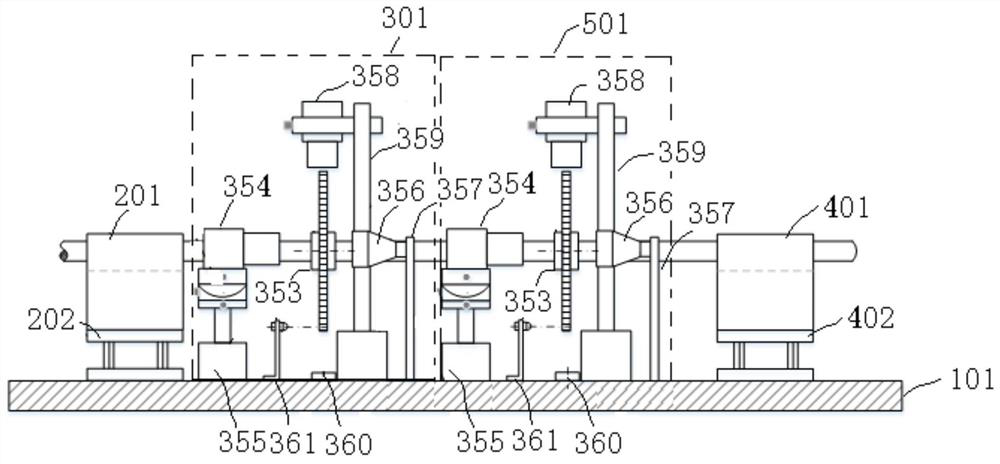

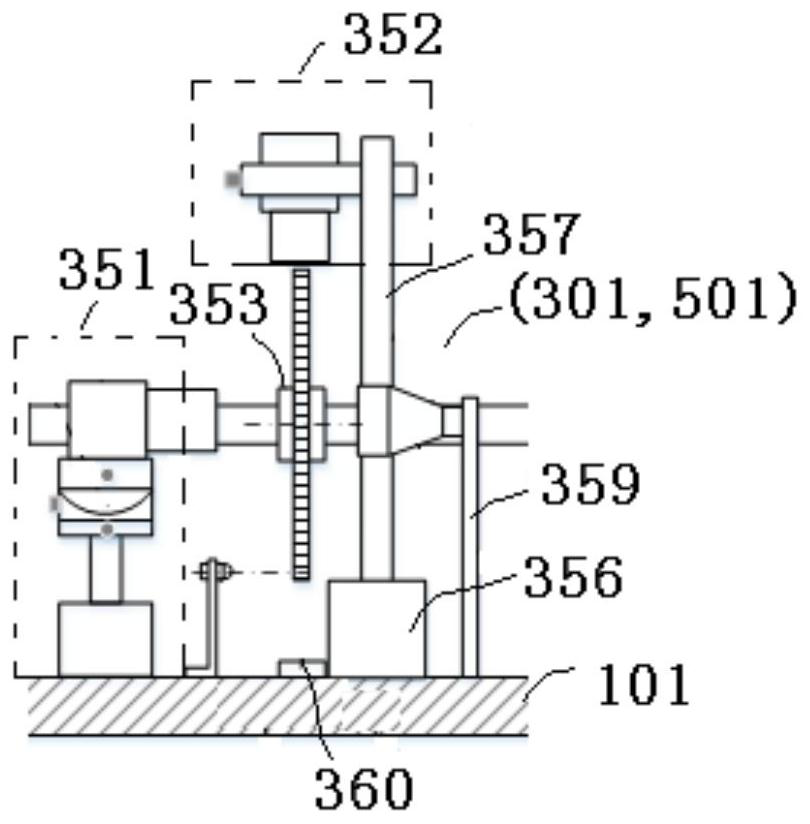

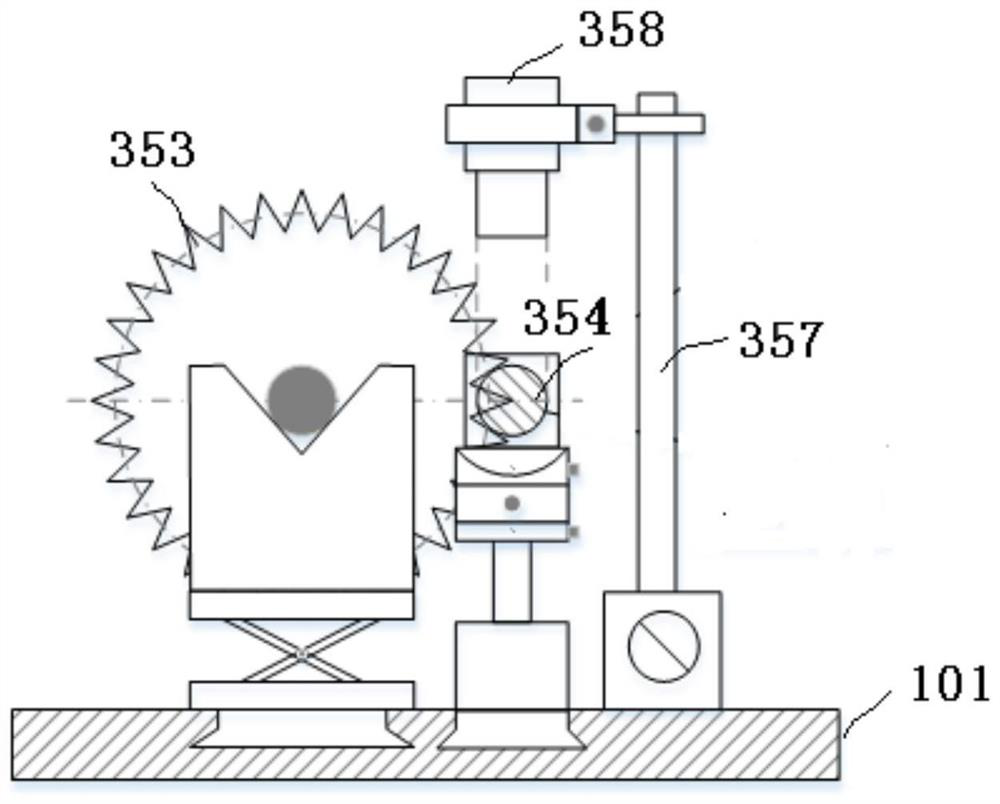

[0016] Such as figure 1 , figure 2 As shown, the present invention provides a visual precision inspection device for measuring special-shaped workpieces, which is composed of a visual inspection device body; the visual inspection device body includes an optical stage 101, a first precision slewing bearing 201, a first multi-directional System 301, the second precision slewing bearing 401 and the second multi-directional visual measurement system 501; the first precision slewing bearing 201 and the second precision slewing bearing 401 are respectively arranged at both ends of the optical carrier 101, and the first precision slewing bearing 201 and the second precision slewing bearing 401 connect the first multi-directional visual measurement system 301 and the second multi-directional visual measurement system 501 sequentially through the axial direction; the first multi-dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com