Test method for steam internal leakage quantity of low-pressure bypass valve of thermal generator set

A technology for thermal power generating units and bypass valves, which is used in mechanical valve testing, machine/structural component testing, fluid tightness testing, etc., and can solve problems such as thermal deformation of the door core, deviation of valve stroke control, and laxity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

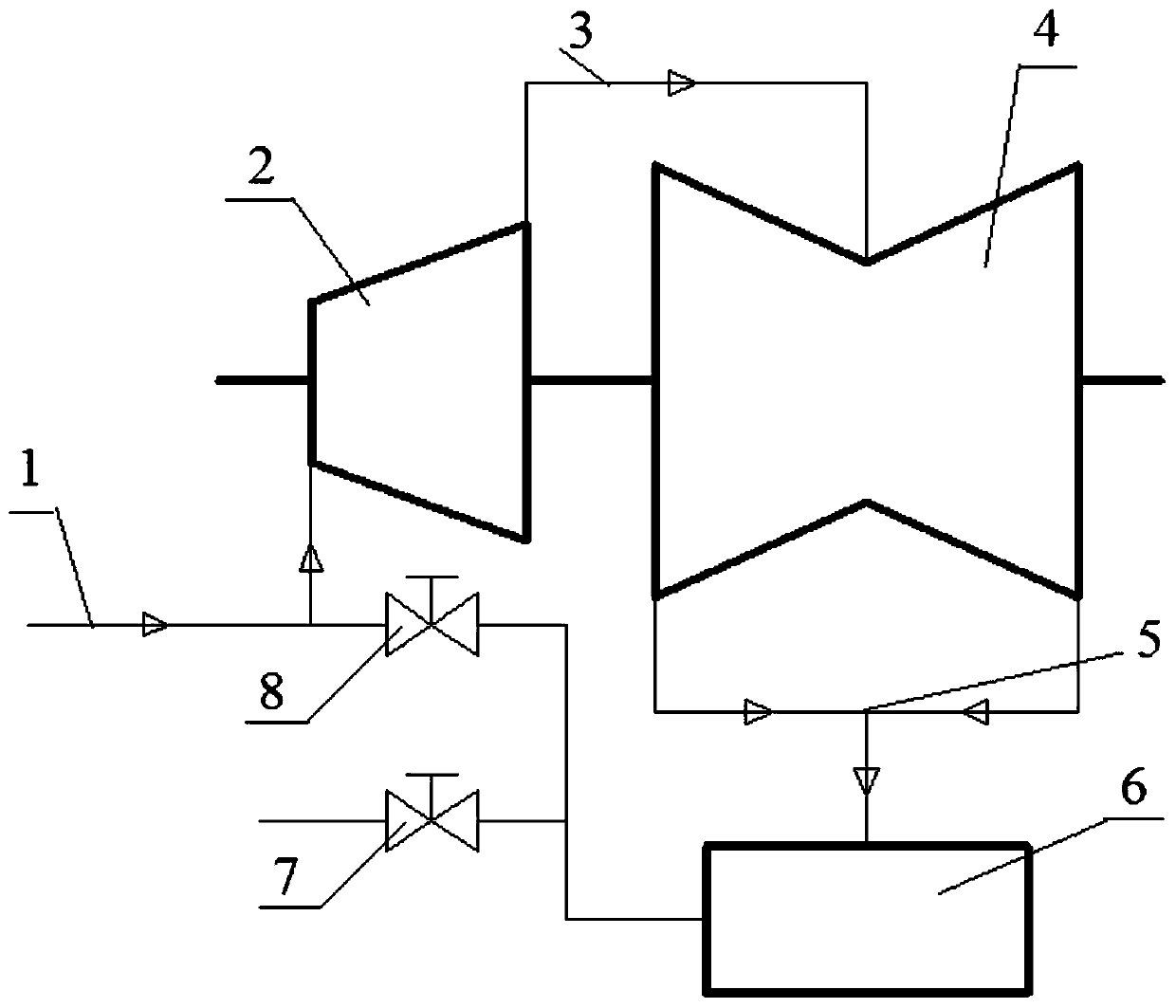

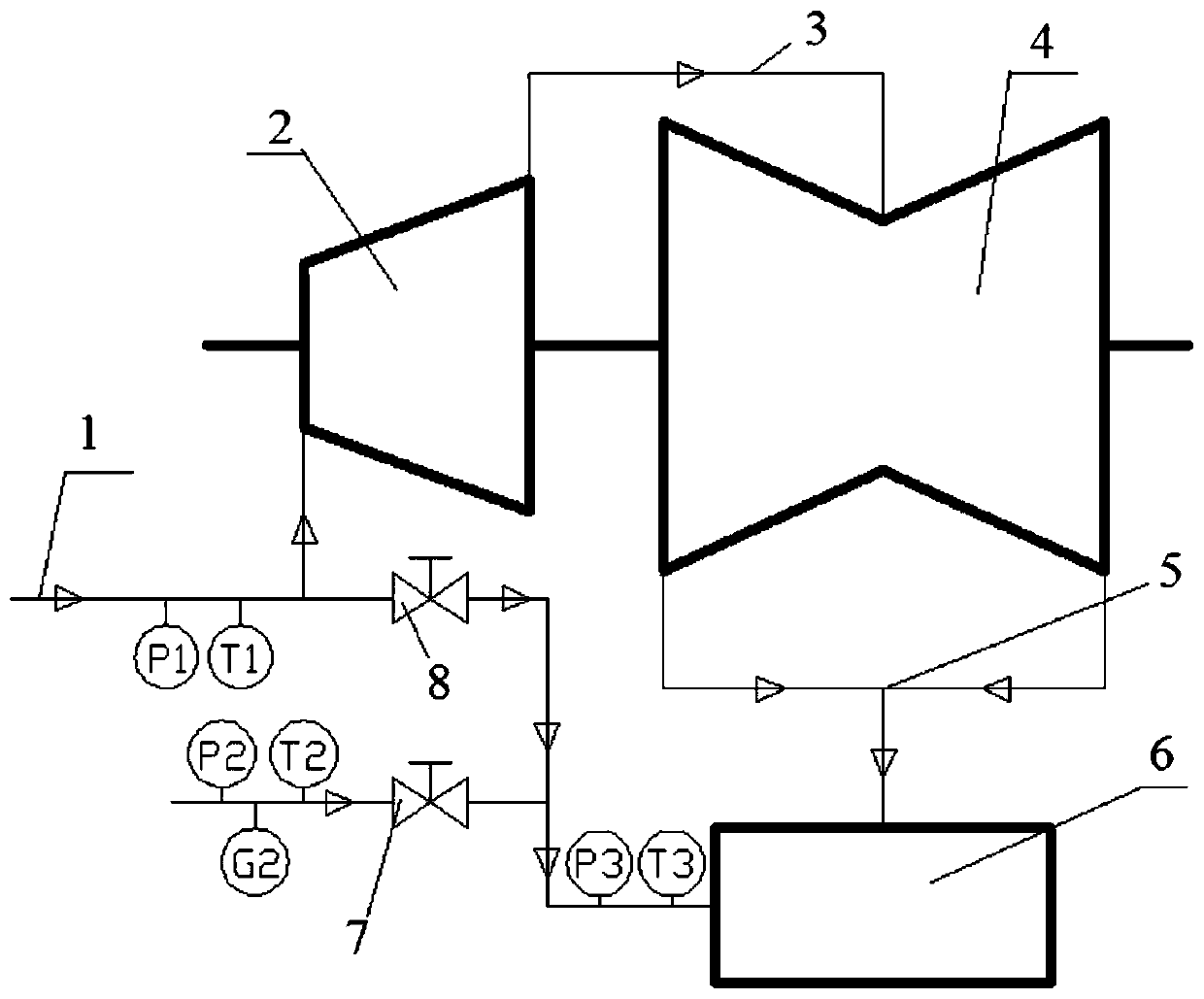

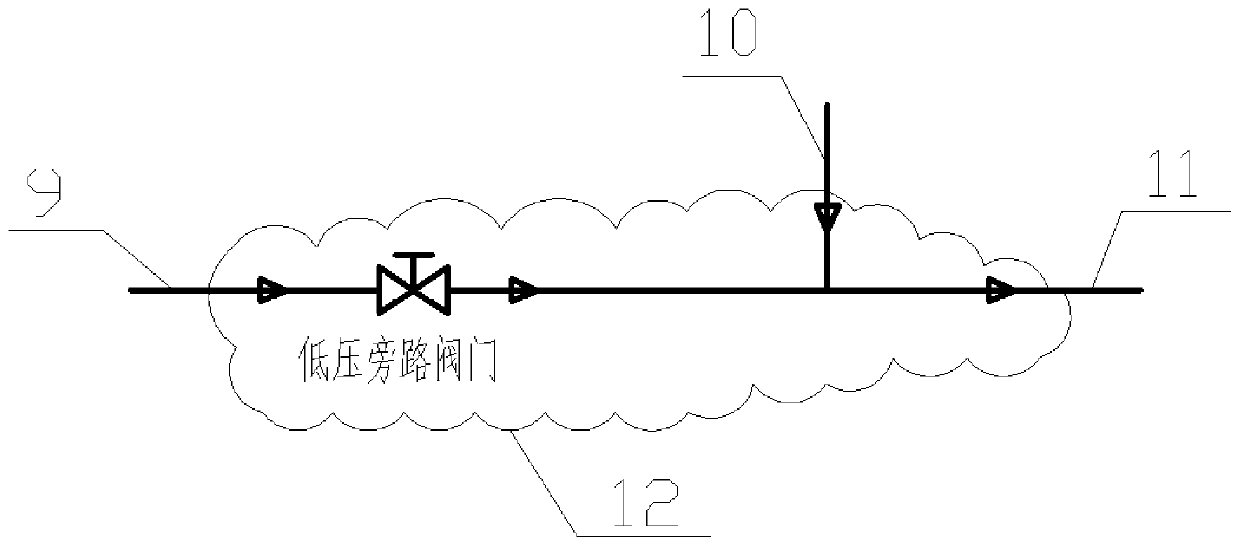

Method used

Image

Examples

specific example

[0065] A specific example of the test method of steam internal leakage of low-pressure bypass valve of thermal power generating set according to the present invention comprises the following steps:

[0066] 1) To determine the state of the unit, select three states of 100% rated load, 75% rated load and 50% rated load respectively. Make sure that the unit load, reheat steam pressure, reheat steam temperature and condenser vacuum are stable without large fluctuations in the selected state;

[0067] 2) Test procedure for working condition a: adjust the low-side desuperheating water valve in the selected state, and adjust the desuperheating water flow rate to G2a, so that the steam temperature value after low-side desuperheating is T3a. After 30 minutes of stabilization, record the unit load, Reheat steam pressure, reheat steam temperature, LP desuperheating water pressure, LP desuperheating water temperature, LP desuperheating water flow, LP desuperheating pressure, and LP desup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com