Non-contact testing system and method for rfid tag antenna

An RFID tag, non-contact technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of easy eye fatigue, inability to measure electrical properties, and increased chip loss rate, to avoid unreliable contact and achieve Effects of automated inspections, reduced accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

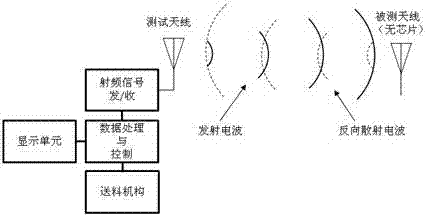

Problems solved by technology

Method used

Image

Examples

Embodiment 1

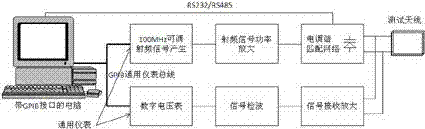

[0041] The antenna under test is an RFID high-frequency (HF) antenna, and a computer with a GPIB general instrument interface bus is used as a control and display unit. The computer communicates with the RF signal generator and digital voltmeter that also have a GPIB interface through the GPIB bus.

[0042] The RF signal generator and the digital voltmeter are connected to the computer via the GPIB cable to receive program-controlled commands and send data to the computer. The computer sends instructions to the RF signal generator through the GPIB bus to generate RF signals of specified frequency and amplitude.

[0043] The broadband radio frequency signal power amplifier amplifies the power of the signal generated by the radio frequency signal generator. The computer controls the tuning and matching circuit through the serial communication port to make the antenna resonant frequency the same as the frequency of the radio frequency signal generator. The tuning and matching circ...

Embodiment 2

[0049] The antenna under test is an RFID ultra-high frequency (UHF) antenna, and a computer with a GPIB universal instrument interface bus is used as a control and display unit. The computer communicates with a microwave radio frequency signal generator and a digital voltmeter that also have a GPIB interface through the GPIB bus.

[0050] The microwave radio frequency signal generator and the digital voltmeter are connected to the computer through the GPIB cable to receive program-controlled commands and send the data to the computer. The computer sends instructions to the microwave radio frequency signal generator through the GPIB bus to generate high-frequency signals of specified frequency and amplitude. Broadband microwave radio frequency The signal power amplifier amplifies the power of the signal generated by the microwave radio frequency signal generator. The computer controls the tuning matching circuit through the serial communication port to make the antenna resonant f...

Embodiment 3

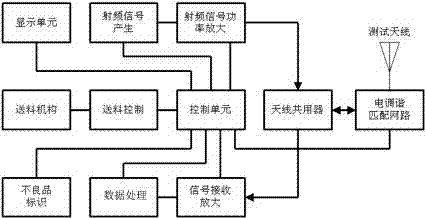

[0056] The antenna under test is an RFID high-frequency (HF) antenna, and the microprocessor (MCU) is used as the central control unit to control the work of each module. The TTF liquid crystal display is connected to the microprocessor (MCU) to display data through the SPI, I2C or RS232 communication port. , Test results, SD memory card connected to the microprocessor for storing test data and configuration data.

[0057] Microprocessor (MCU) through SPI, I 2 C or parallel port controls the direct digital synthesis (DDS) radio frequency signal generator module to generate a specified frequency signal, the broadband radio frequency signal power amplifier amplifies the power of the radio frequency signal generated by direct digital synthesis (DDS), and the microprocessor (MCU) controls the digital-analog ( The D / A) conversion module outputs a precise voltage used as a bias for the varactor diode to tune the antenna at the frequency of the Direct Digital Synthesis (DDS) RF signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com