Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Easily caught" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

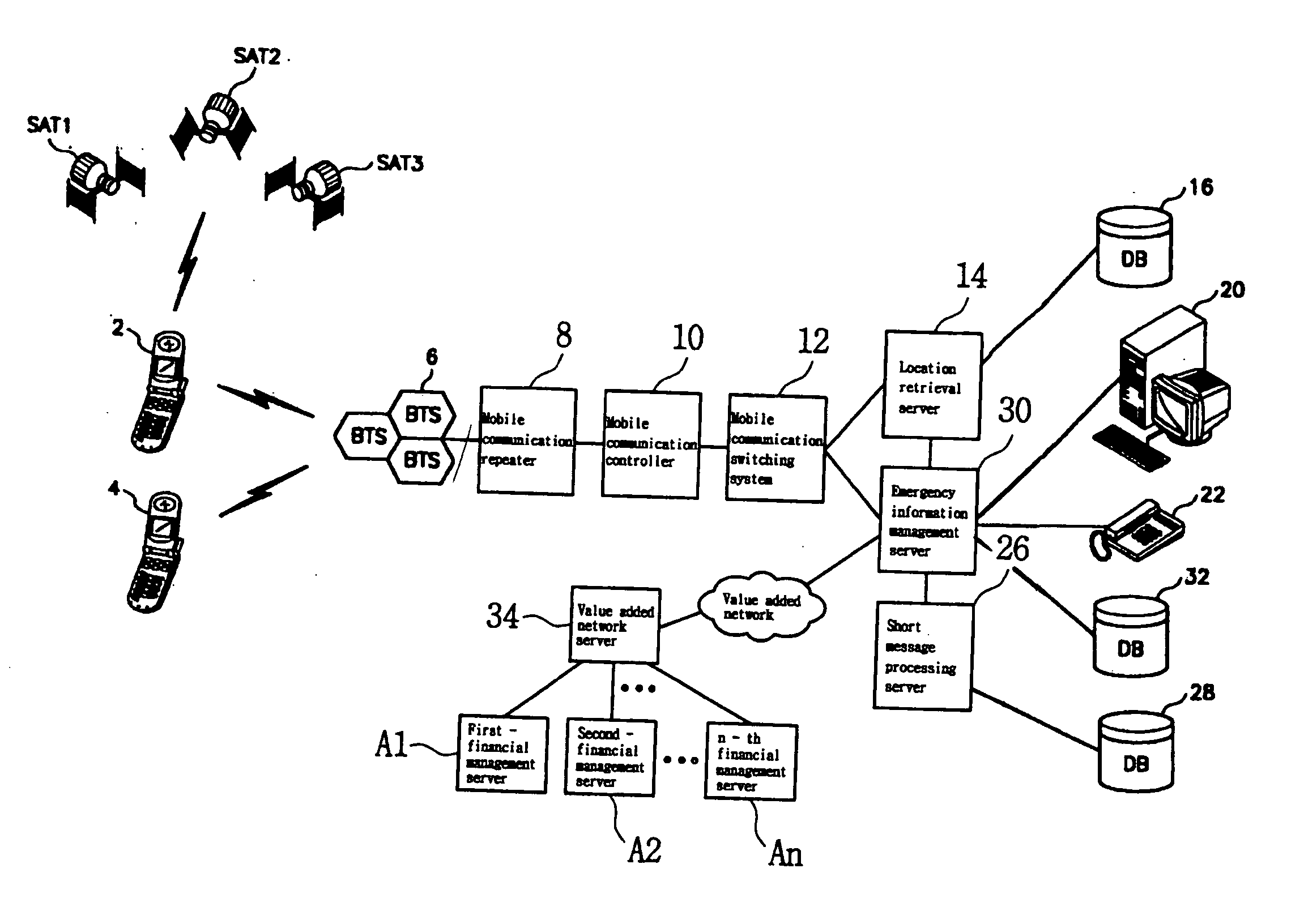

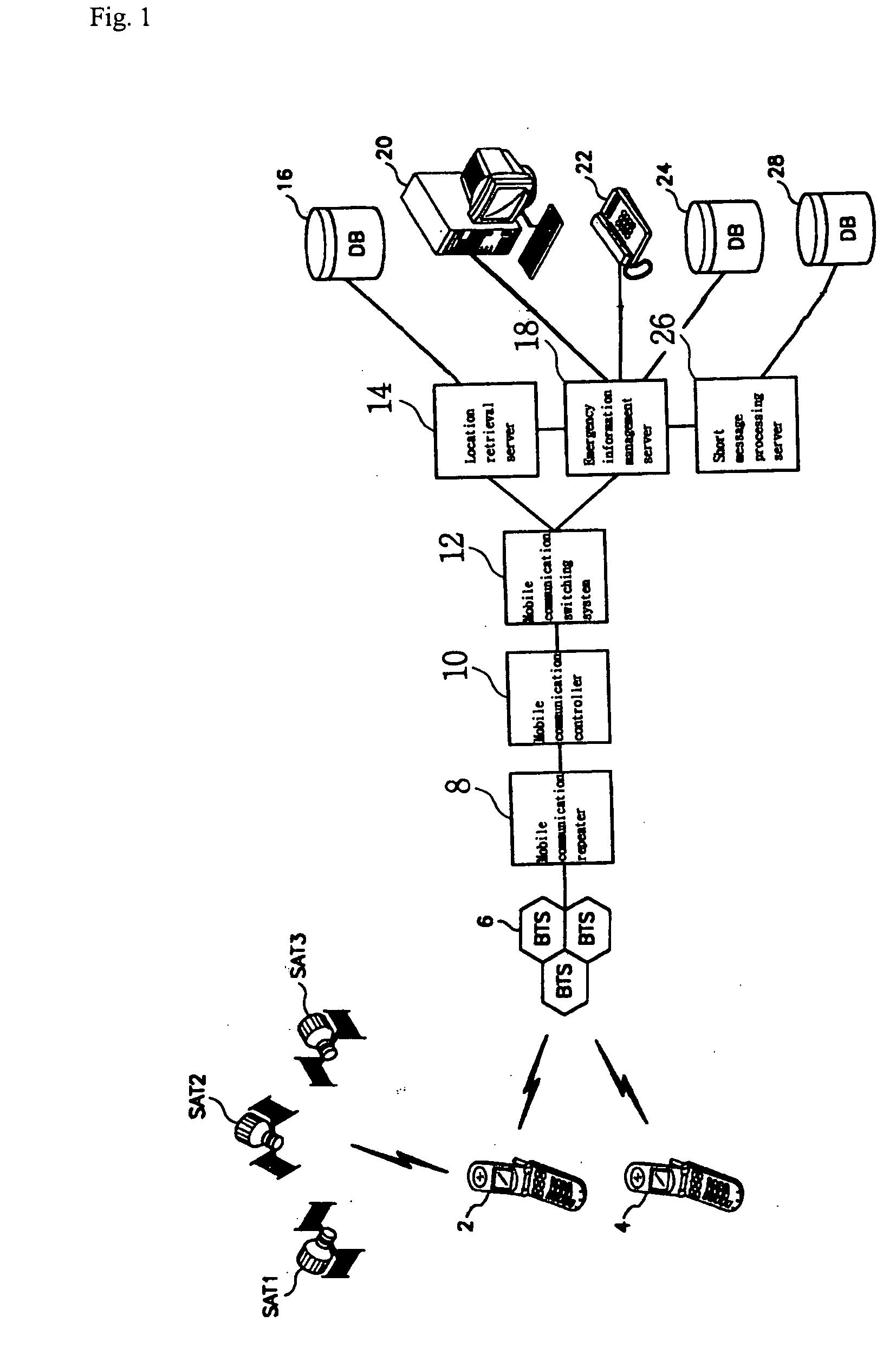

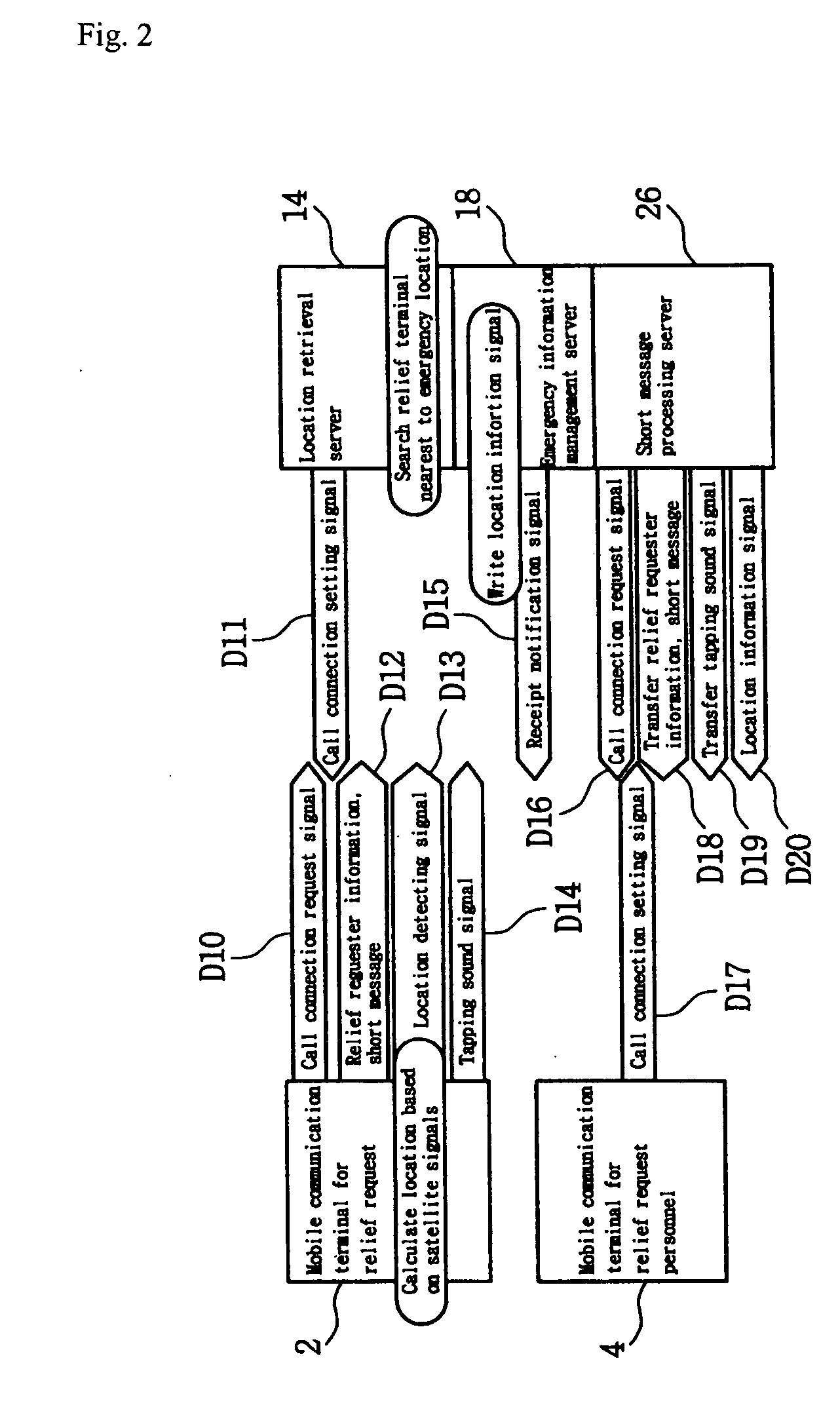

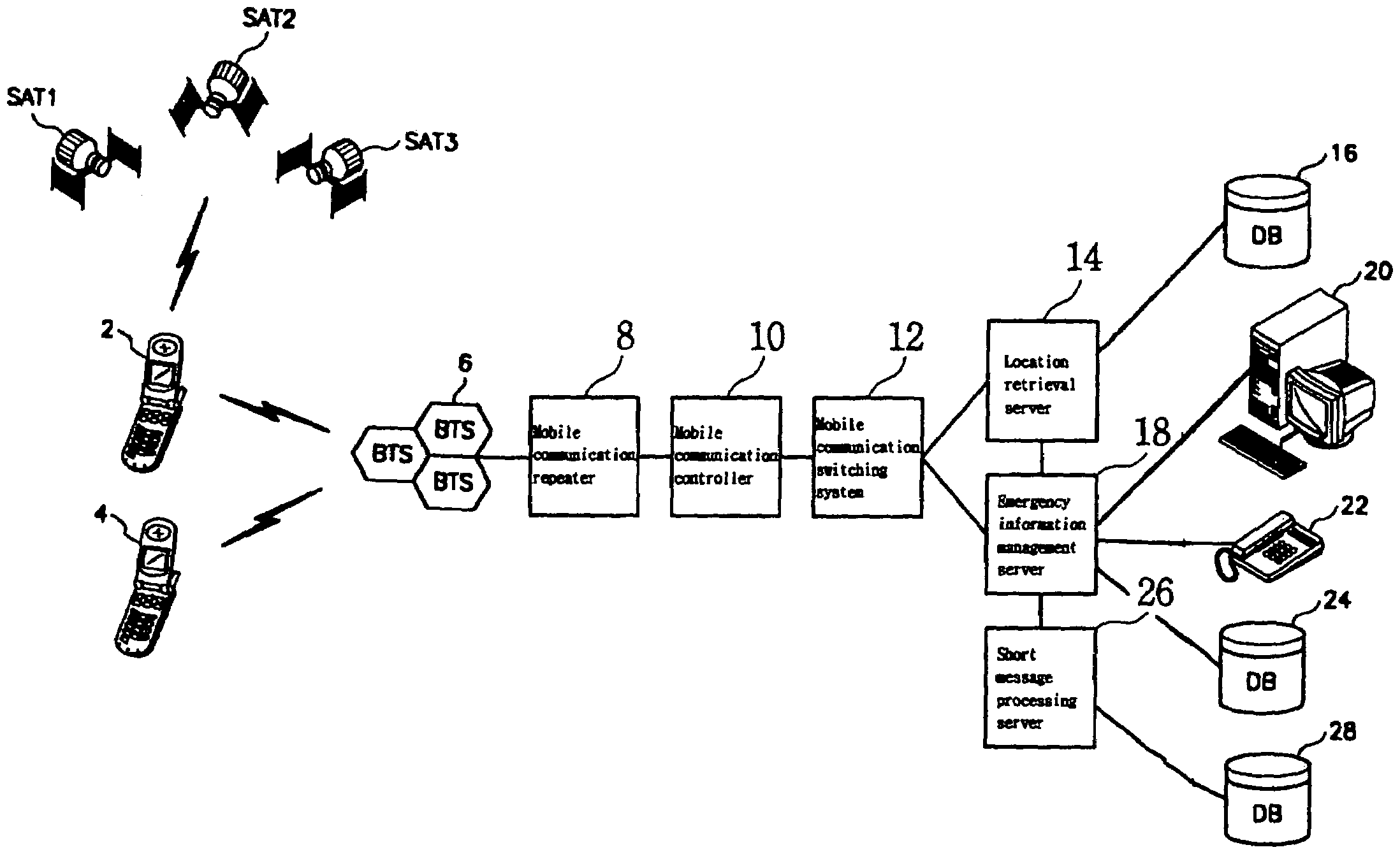

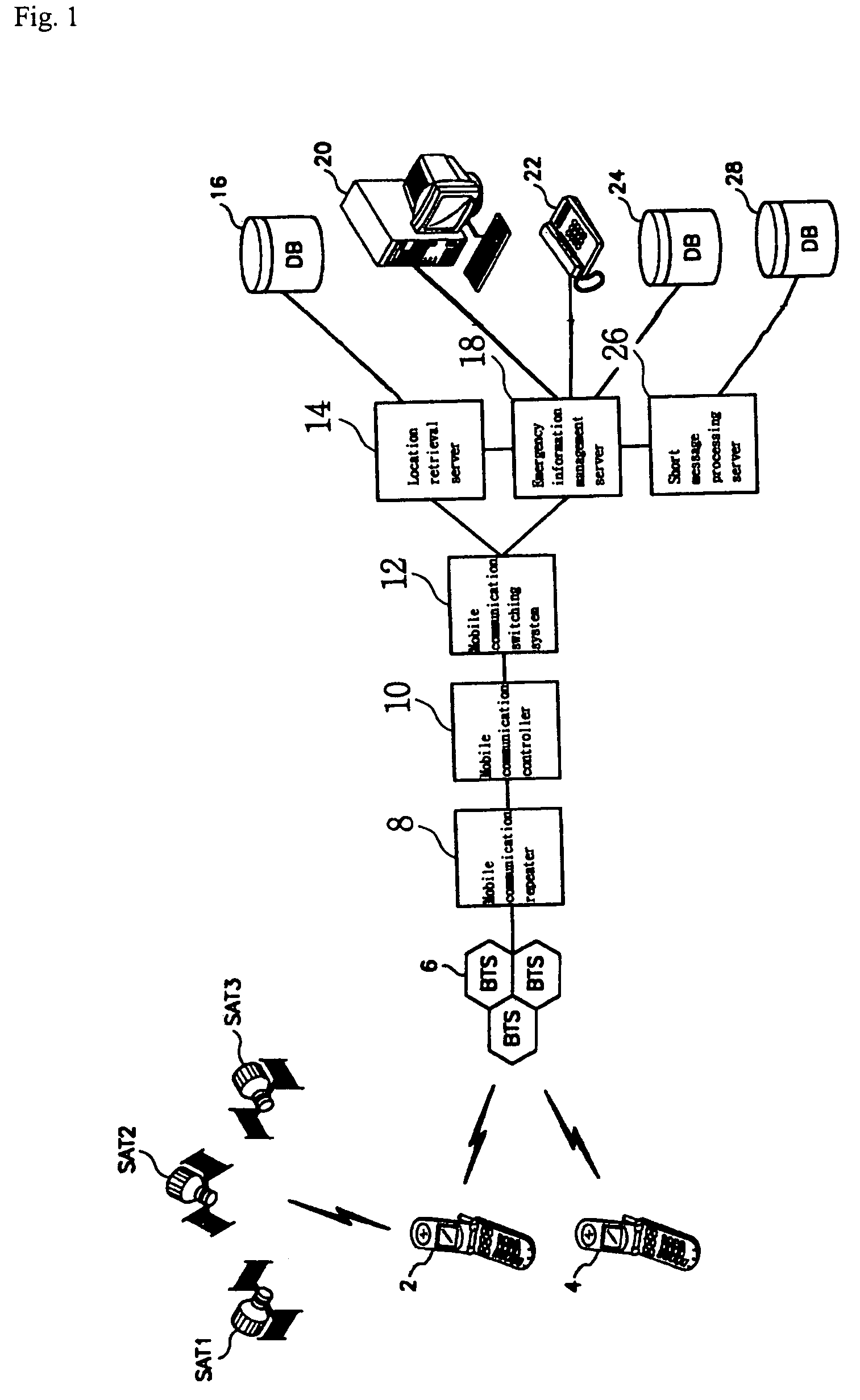

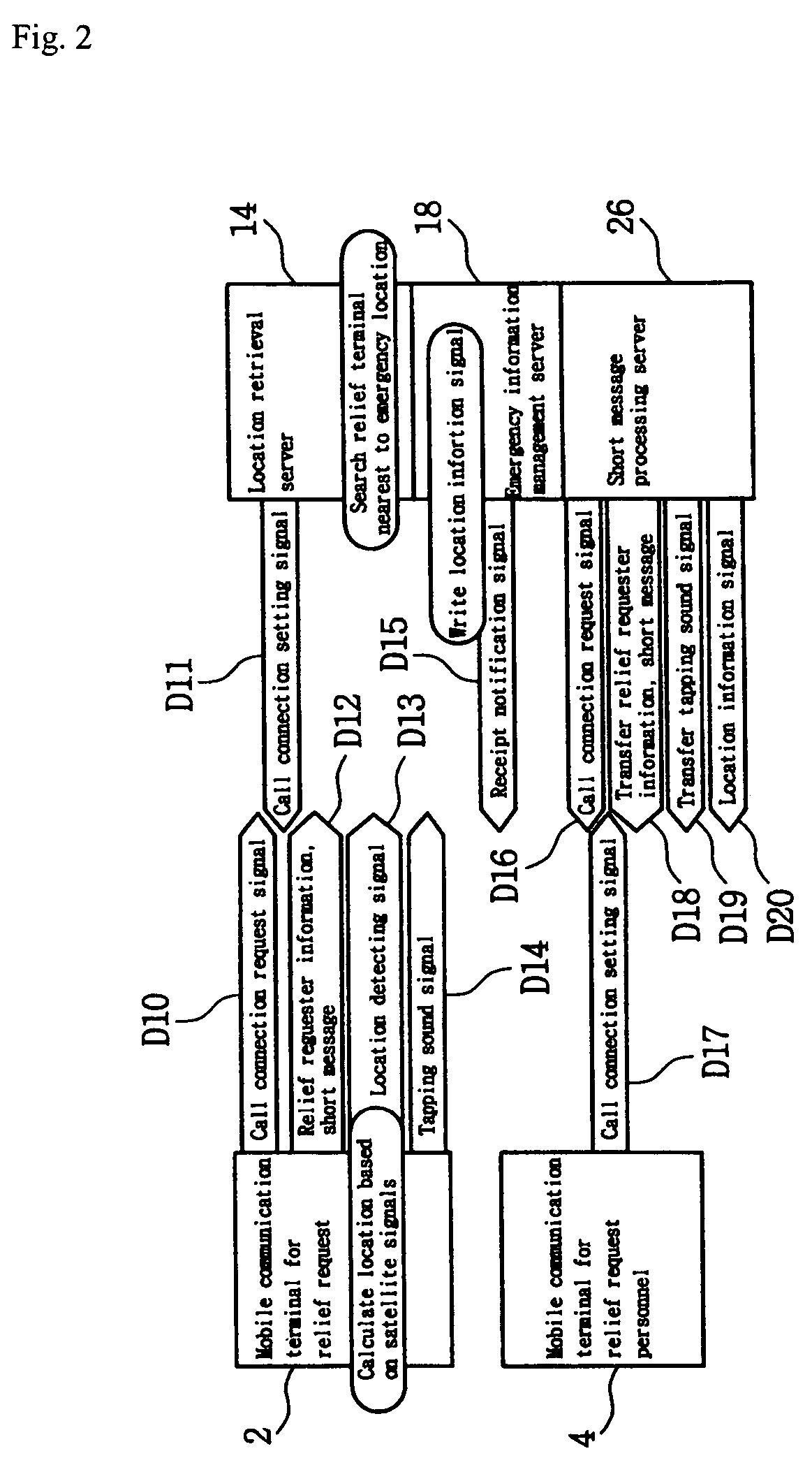

Location information of emergency call providing system using mobile network

InactiveUS20050239477A1Easily caughtQuick stopEmergency connection handlingUnauthorised/fraudulent call preventionTelecommunicationsSTI Outpatient

The present invention relates to a system for providing location information using a mobile communication network, and more particularly, to a system for providing emergency relief location information using a mobile communication network, by which location and situation information of a mobile communication subscriber can be easily known through the mobile communication network using the mobile communication terminal. An object of the present invention is to provide a system for providing emergency relief location information using a mobile communication network, capable of notifying location and situation information of a given mobile communication subscriber who is placed in an emergency situation through a mobile communication terminal of a given relief personnel adjacent to the place where the emergency situation has occurred. Another object of the present invention is to provide a system for providing emergency relief location information using a mobile communication network, which can prevent in advance illegal deposit withdrawal by stopping a transaction of financial accounts owned by a given mobile communication subscriber in case of emergency. Still another object of the present invention is to provide a system for providing location information using a mobile communication network, which can provide location information that allows the location among the mobile communication subscribers to be easily found through the satellite communications and the mobile communication network.

Owner:KIM SEONGSOO +1

Location information of emergency call providing system using mobile network

InactiveUS7349706B2Easily caughtEmergency connection handlingUnauthorised/fraudulent call preventionTelecommunicationsSTI Outpatient

The present invention relates to a system for providing location information using a mobile communication network, and more particularly, to a system for providing emergency relief location information using a mobile communication network, by which location and situation information of a mobile communication subscriber can be easily known through the mobile communication network using the mobile communication terminal. An object of the present invention is to provide a system for providing emergency relief location information using a mobile communication network, capable of notifying location and situation information of a given mobile communication subscriber who is placed in an emergency situation through a mobile communication terminal of a given relief personnel adjacent to the place where the emergency situation has occurred. Another object of the present invention is to provide a system for providing emergency relief location information using a mobile communication network, which can prevent in advance illegal deposit withdrawal by stopping a transaction of financial accounts owned by a given mobile communication subscriber in case of emergency. Still another object of the present invention is to provide a system for providing location information using a mobile communication network, which can provide location information that allows the location among the mobile communication subscribers to be easily found through the satellite communications and the mobile communication network.

Owner:KIM SEONGSOO +1

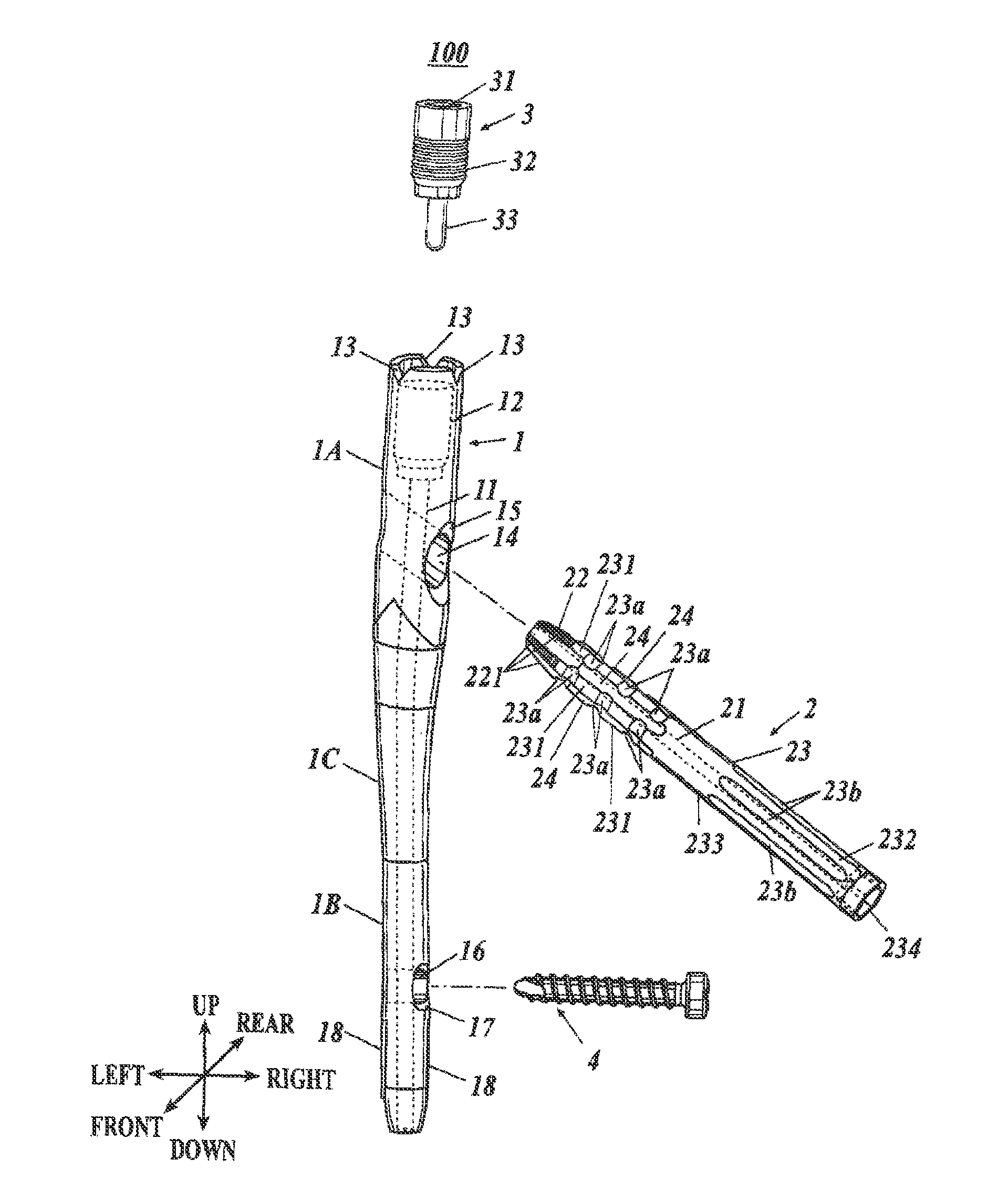

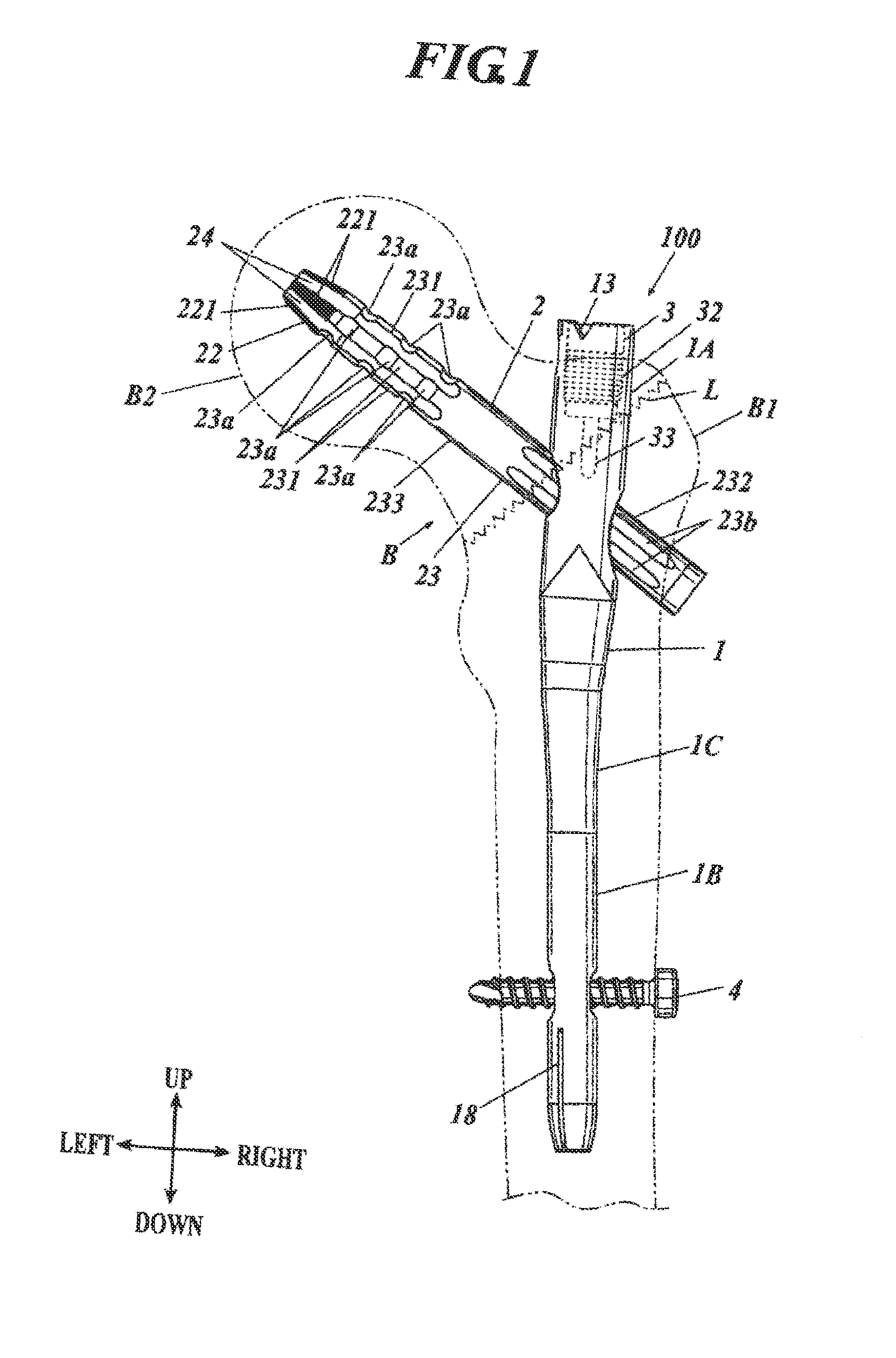

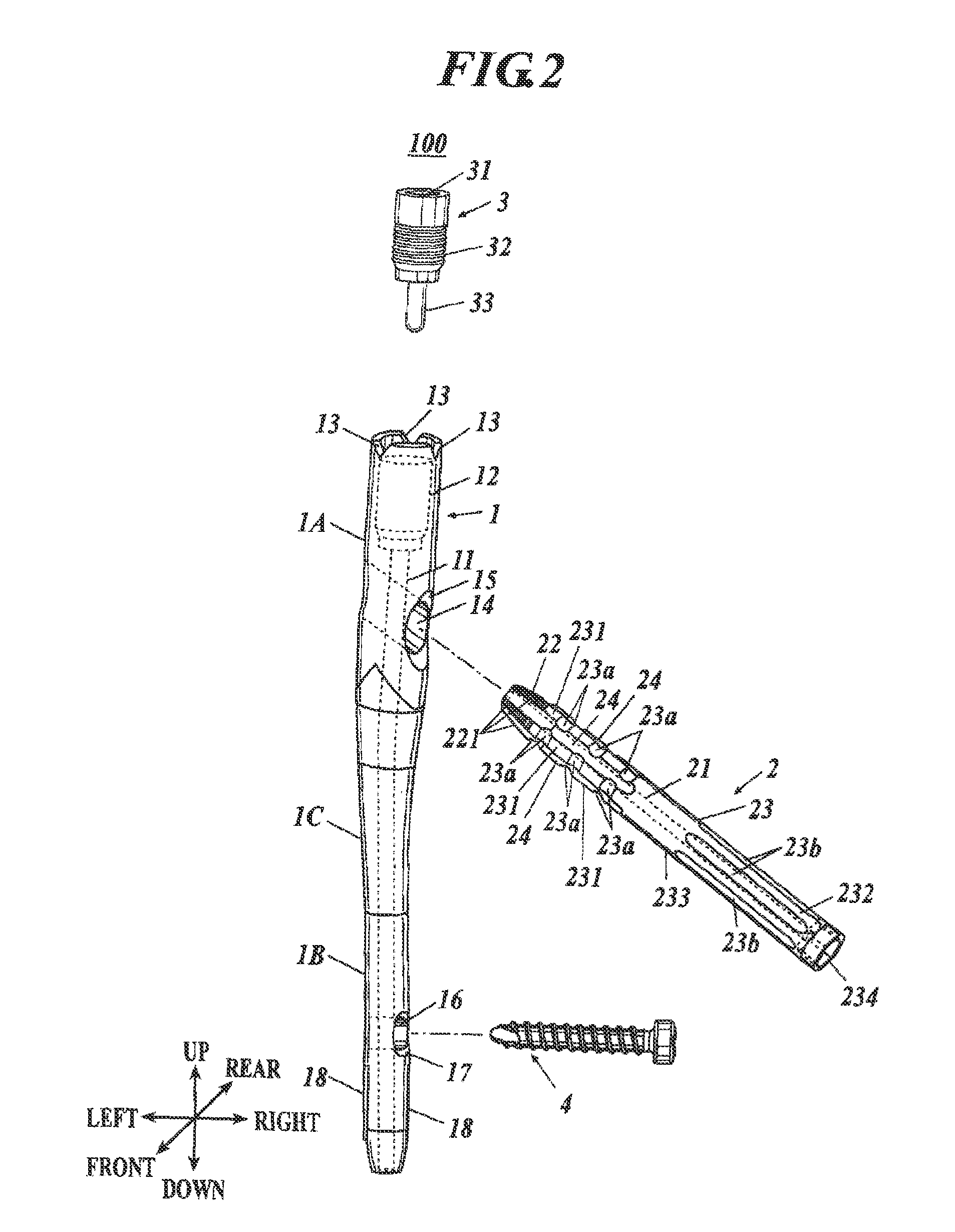

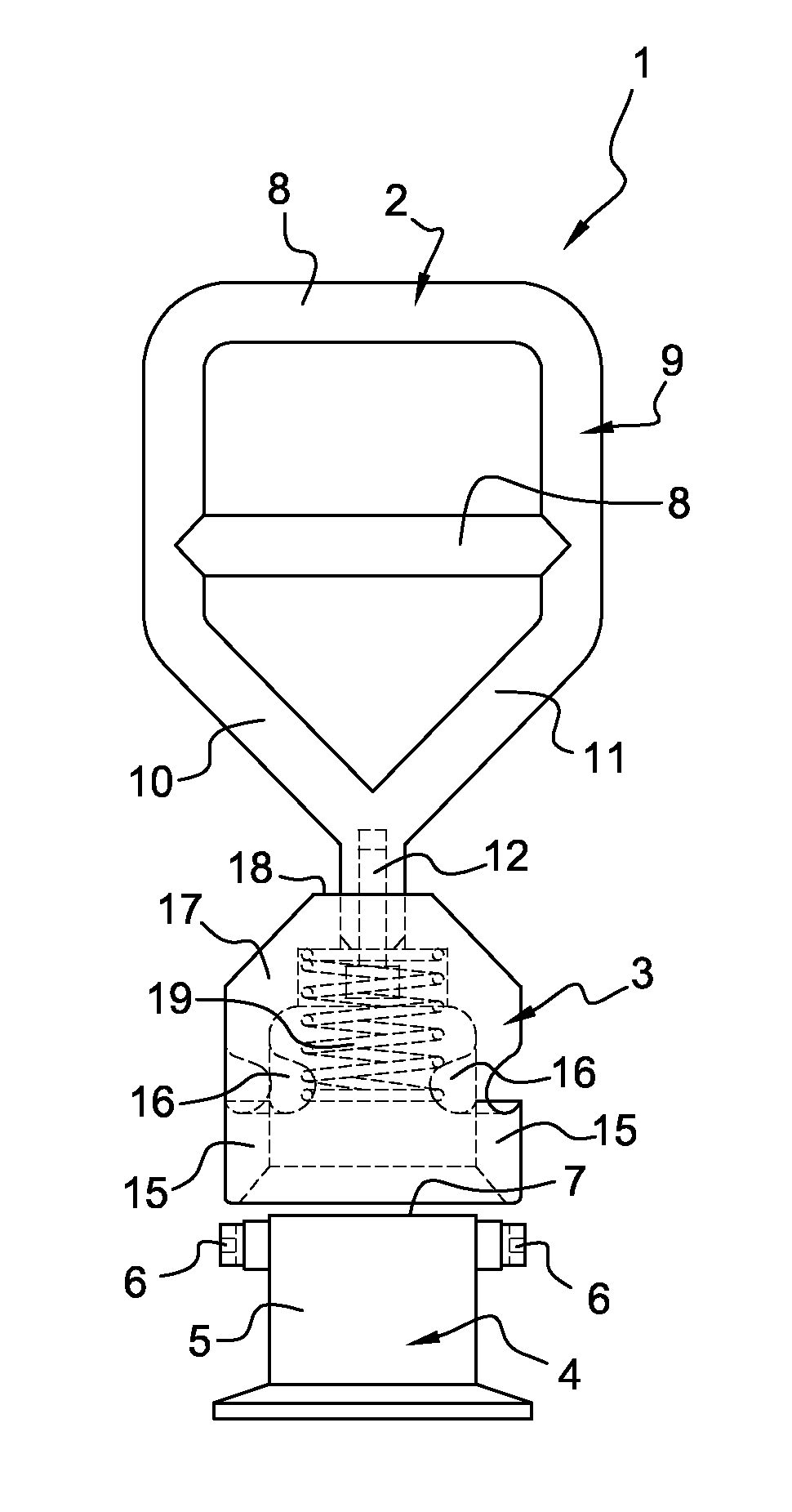

Bone Fixing Material and Thighbone Fixing System

InactiveUS20110196372A1Easily caughtIncrease surface areaInternal osteosythesisJoint implantsThighMedullary cavity

A bone fixing blade (2), which is fixed at a intermedullary nail main body (1) to be inserted into a medullary space of a fractured thighbone and which fixes a big bone piece portion (B1) and a small bone piece portion (B2) composing the thighbone, is provided with a cut-out portion forming unit (231) formed in a stick-like shape along a circumferential direction of the bone fixing blade comprised of three cut-out portions (23a) cut out from the surface toward the inside, wherein the cut-out portion forming unit (231) is pressed into the inside of each of the big bone piece portion and the small bone piece portion to be in a position on a recess side that is deeper than a bone fracture line (L).

Owner:ROBERT REID INC

Method for suppressing nonspecific hybridization in primer extension method

InactiveUS6033851ASuppress hybridizationEasily caughtSugar derivativesMicrobiological testing/measurementNon specificNucleic acid

PCT No. PCT / JP95 / 02535 Sec. 371 Date May 30, 1997 Sec. 102(e) Date May 30, 1997 PCT Filed Dec. 11, 1995 PCT Pub. No. WO96 / 17932 PCT Pub. Date Jun. 13, 1996An object of the present invention is to suppress nonspecific extension reaction of the primer in the primer extension method. The primer extension reaction to form a nucleic acid strand complementary to a nucleic acid template strand with the use of a primer according to the present invention is characterized in that the reaction between the primer and the template strand is carried out in the presence of a nucleic acid or a derivative thereof which is complementary to said primer and has an affinity for said primer is equivalent to or less than that of said primer for the nucleic acid template strand.

Owner:WAKUNAGA SEIYAKU KK

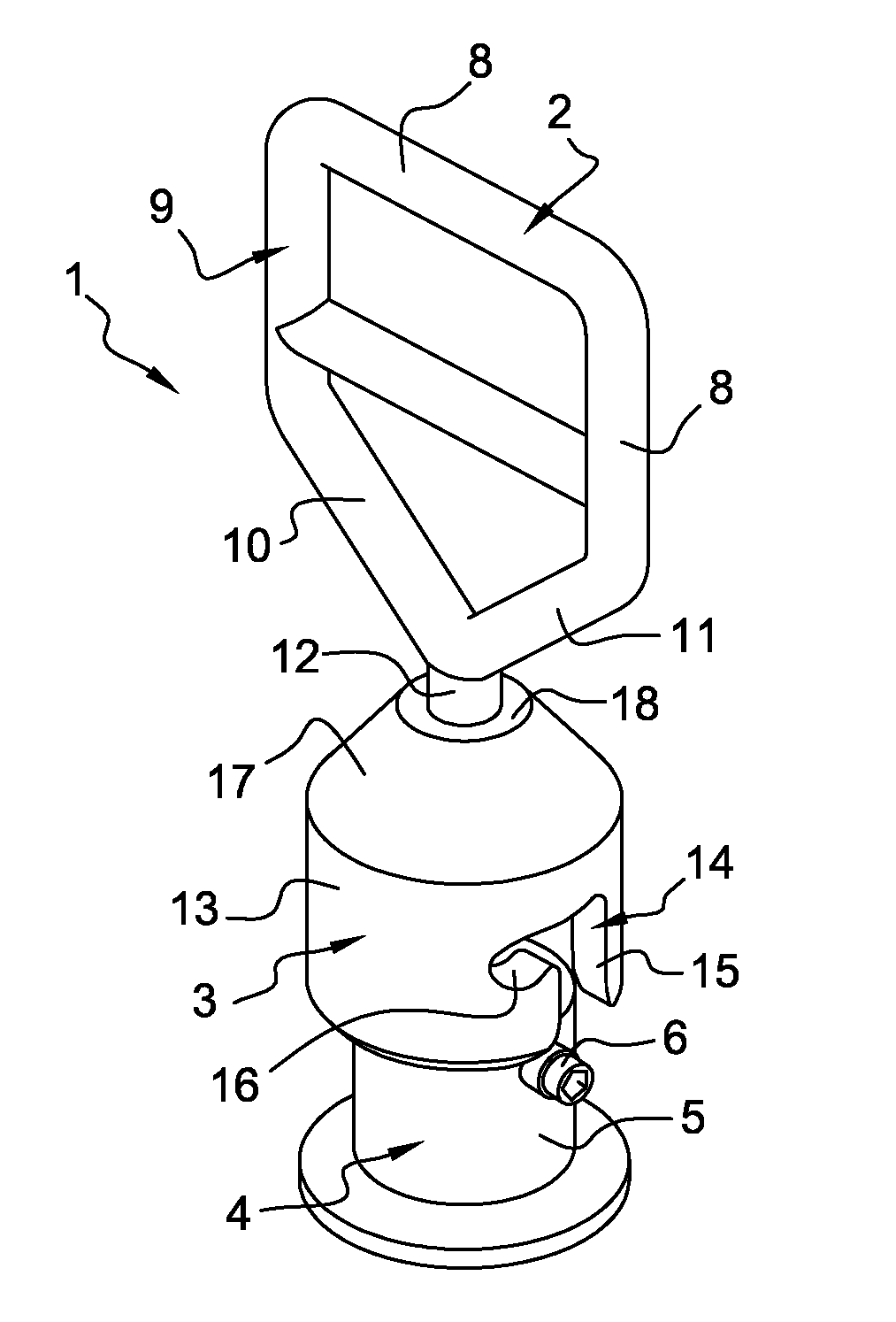

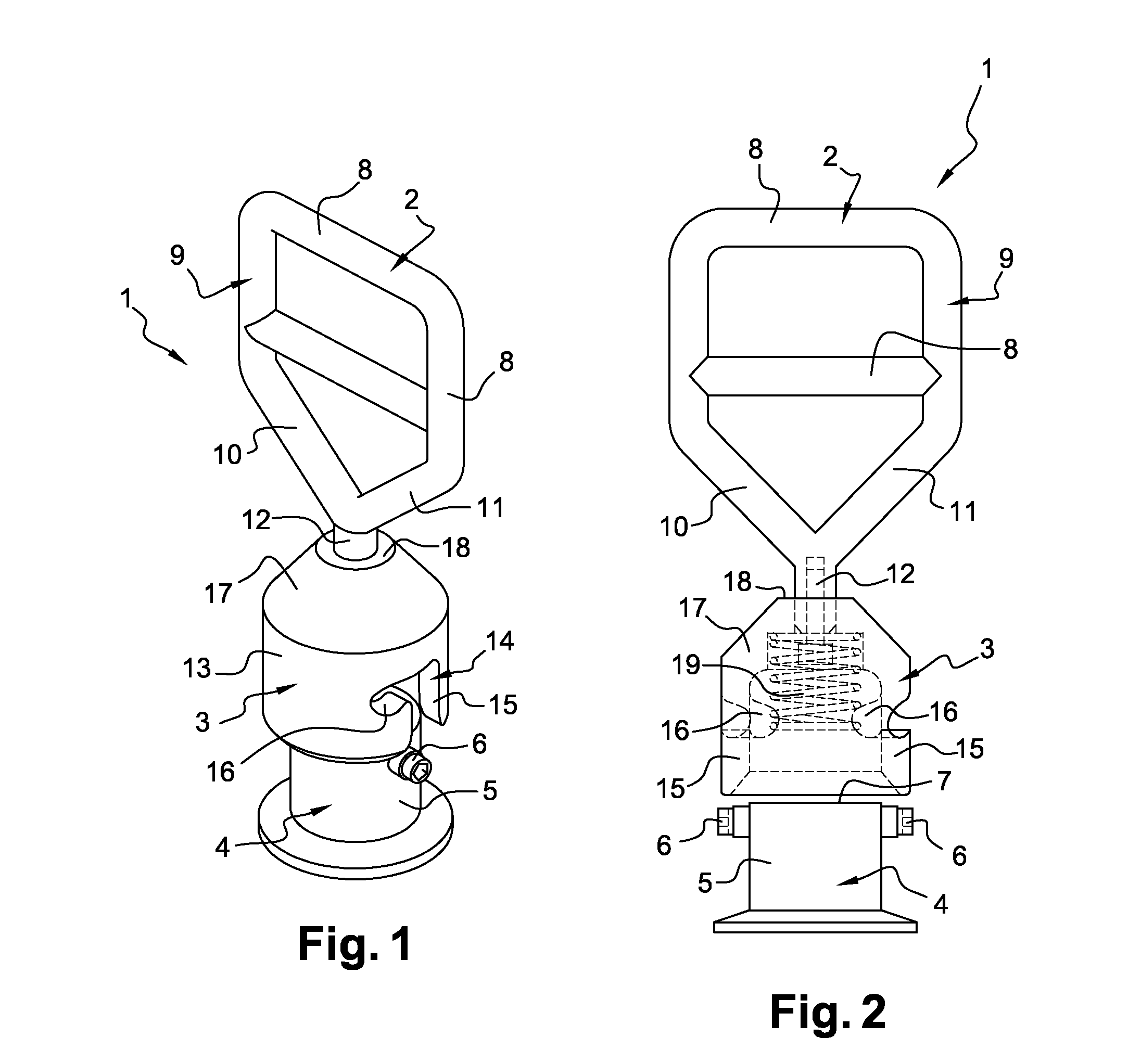

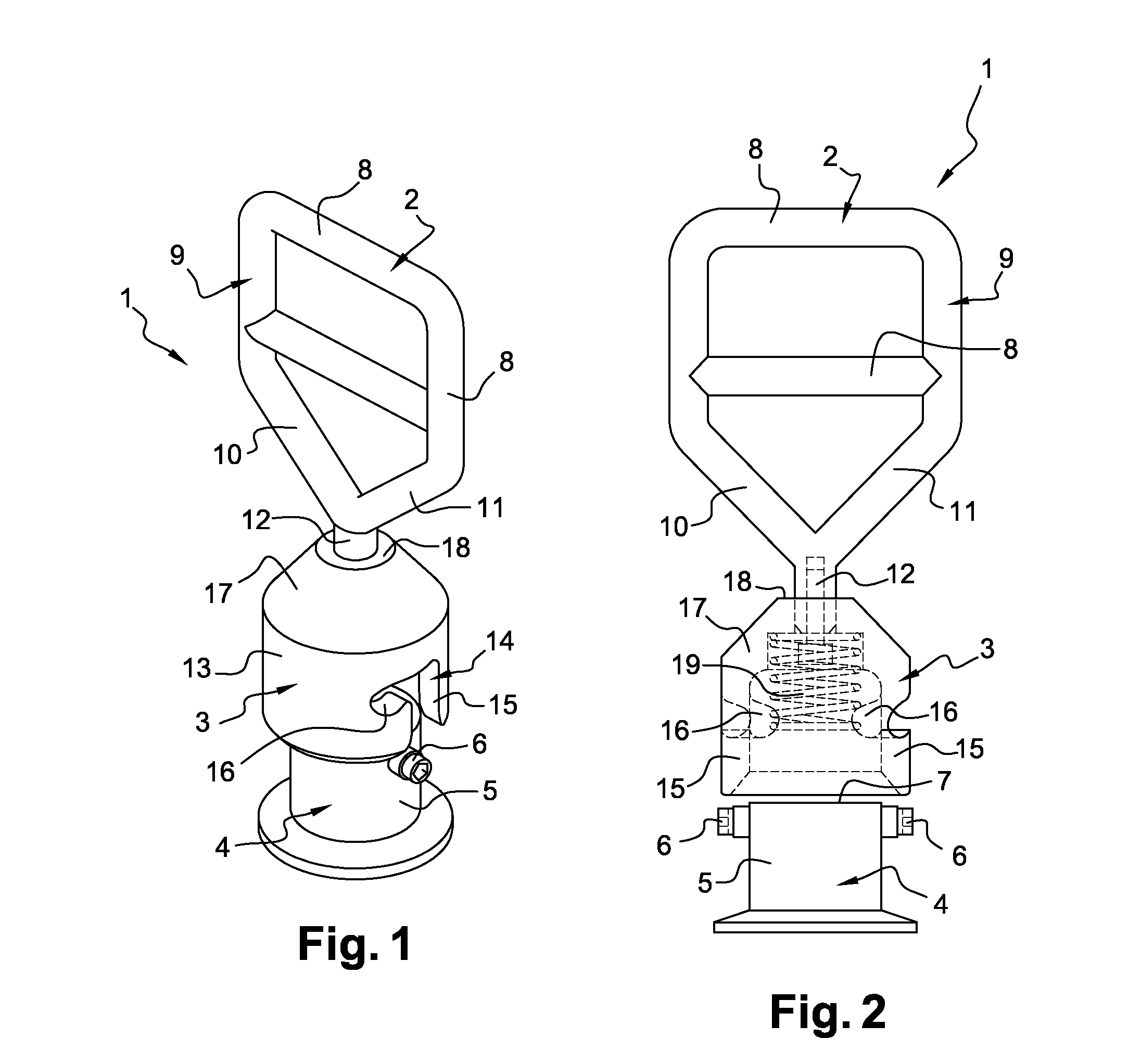

Tool for the handling of a protection device for subsea electrical or fiber optical connectors

InactiveUS8869661B2Easy to handleEasily and rapidly handledCoupling device engaging/disengagingSpannersFiberEngineering

A tool (1) for the handling by a Remotely Operated Vehicle (ROV) of a protection device (4) provided to protect a subsea electrical or optical fiber connector. The main feature of a tool is that said tool (1) is attached to the ROV and comprises a ROV friendly handle (2).

Owner:NEXANS

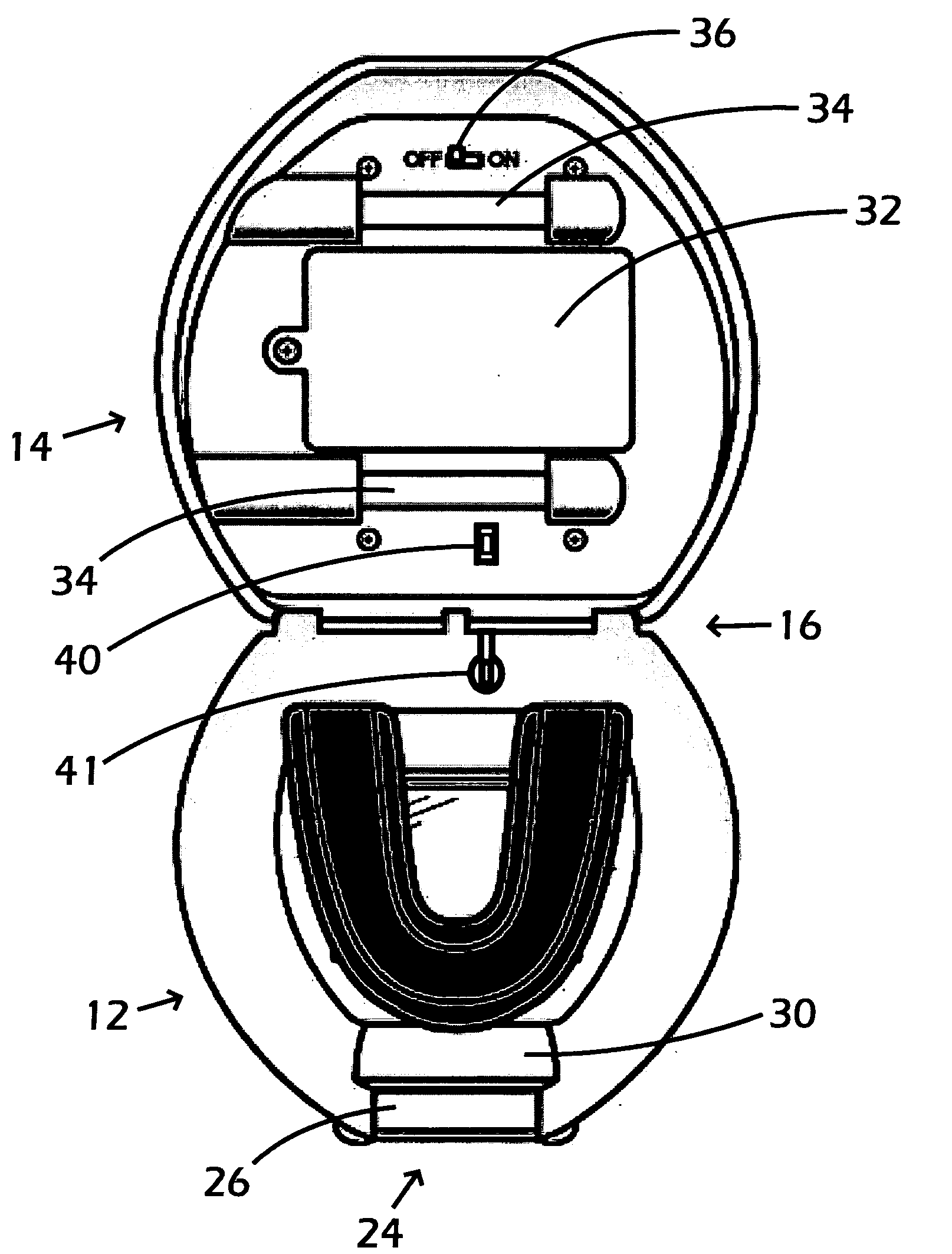

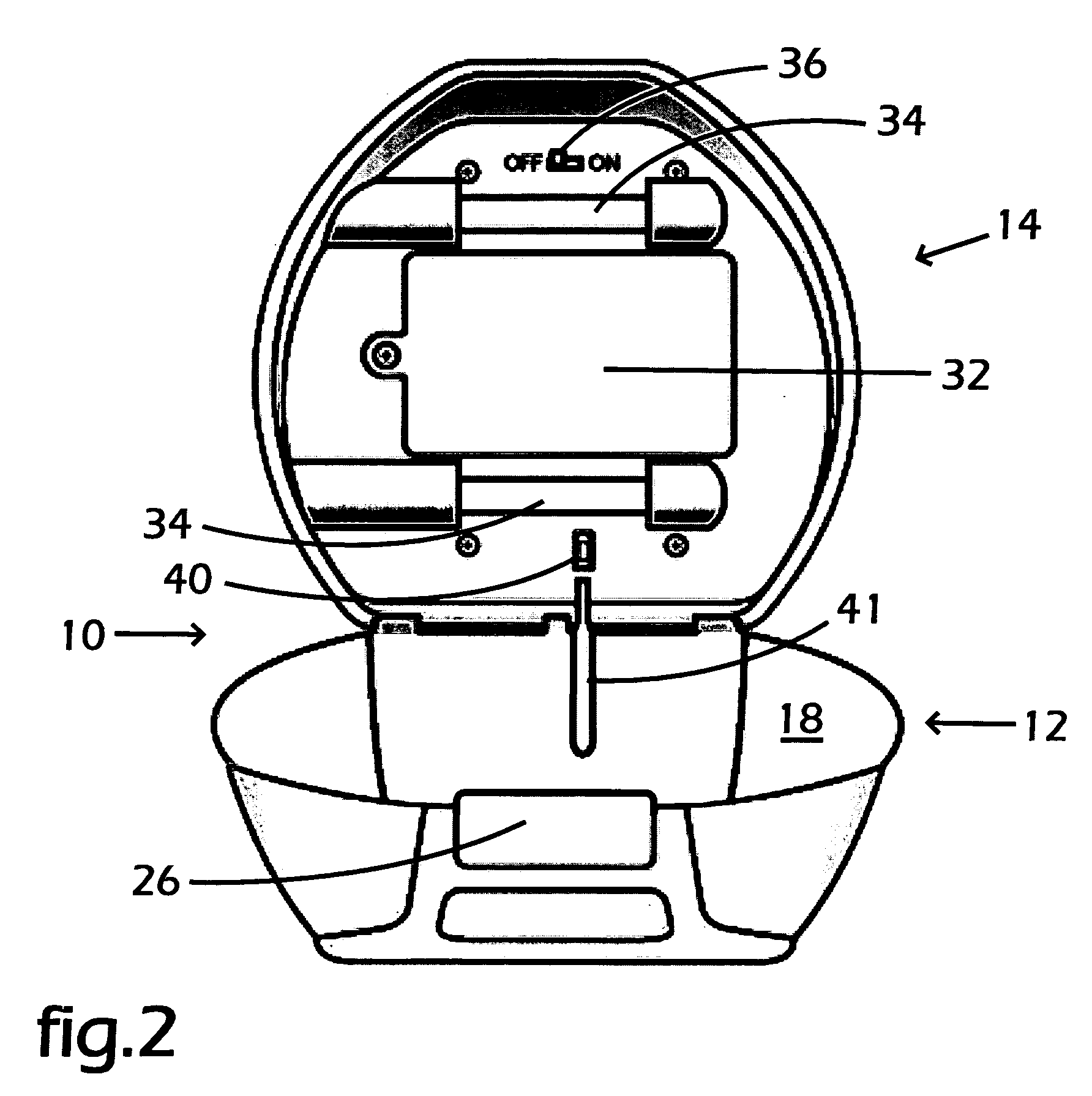

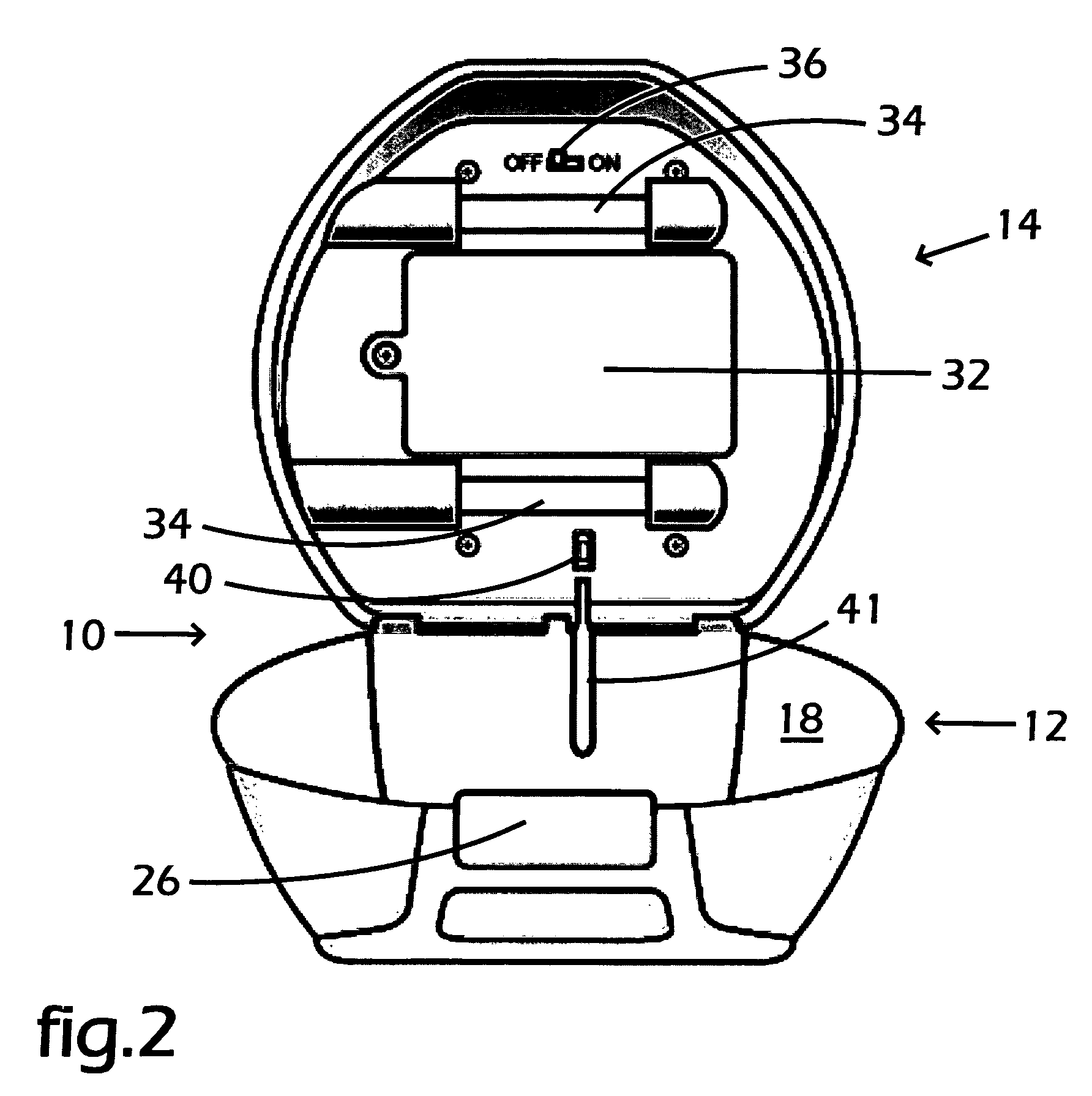

UV Sanitizer for Tethered and Untethered Mouthguards

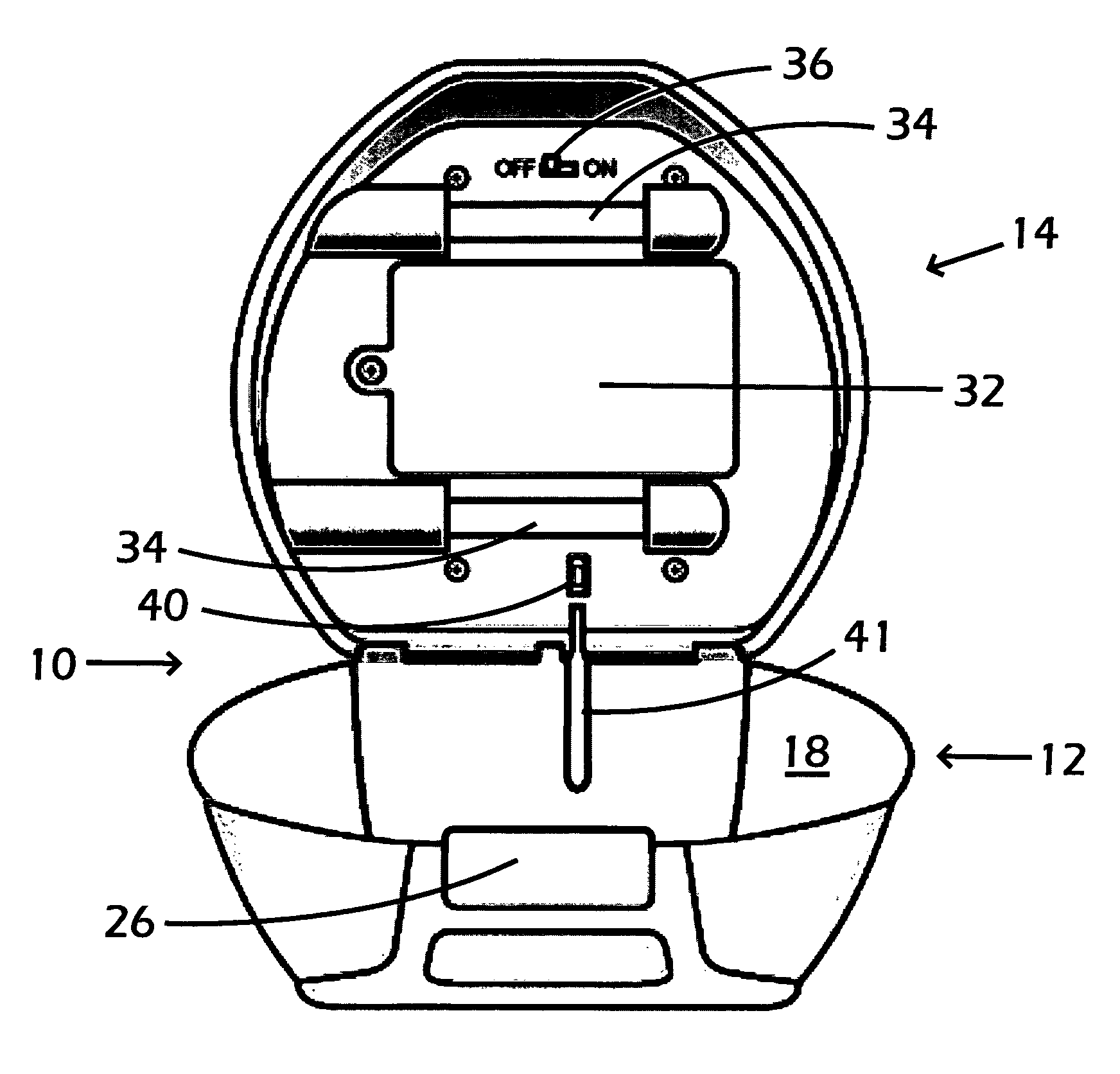

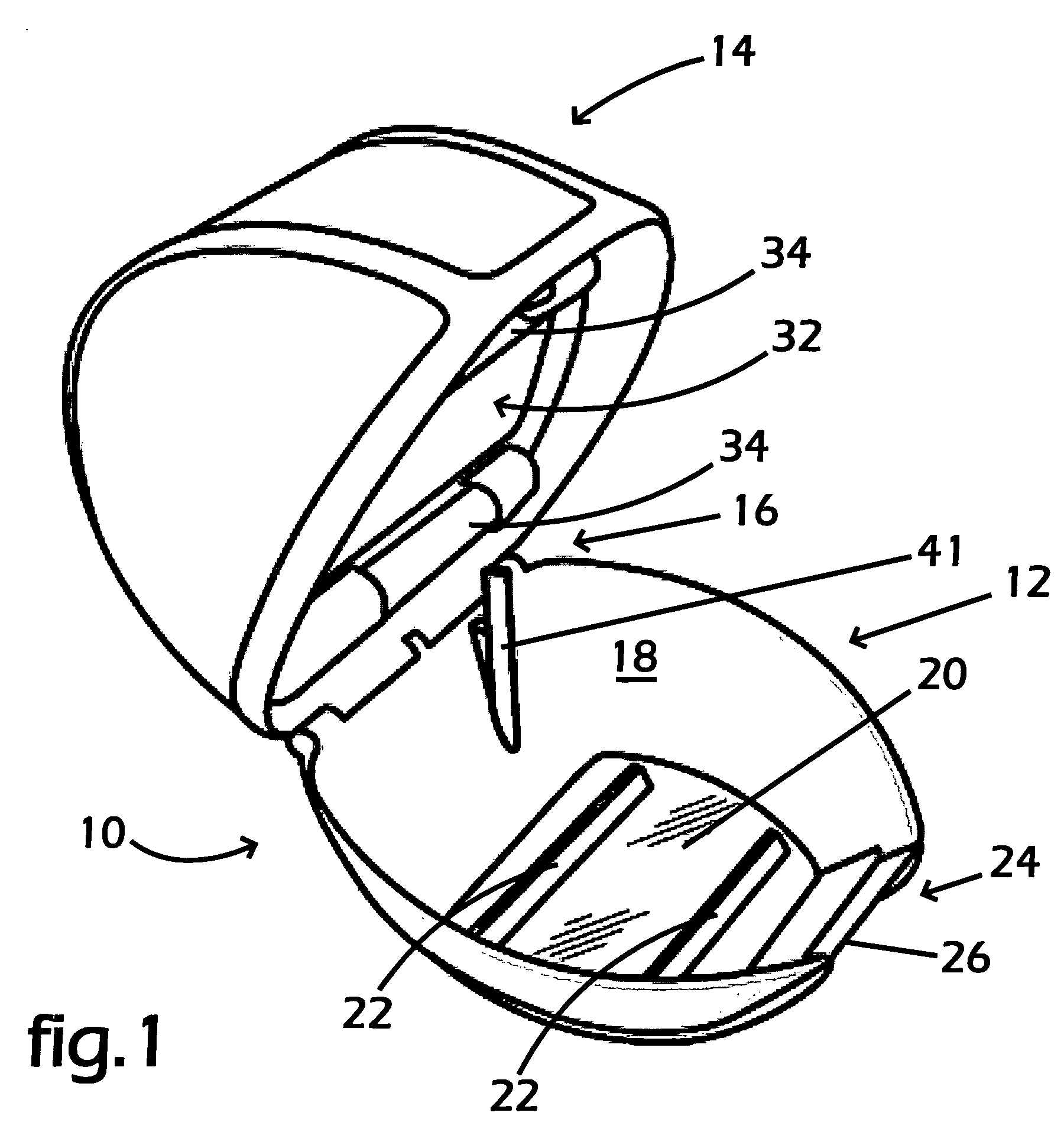

InactiveUS20090311149A1Readily tossed and safely caughtEasily caughtMaterial analysis using wave/particle radiationElectric discharge tubesMouthguardRespirator

A portable, battery-powered UV sanitizer kills germs and bacteria on the mouthpieces of tethered mouthguards of a wide variety of tether sizes and configurations and on the mouthpieces of untethered mouthguards. It doubles as a protective case when not in antimicrobial use. It includes a dishwasher safe detachable tray. It may be used with other dental appliances.

Owner:BREAKAWAY PRODS

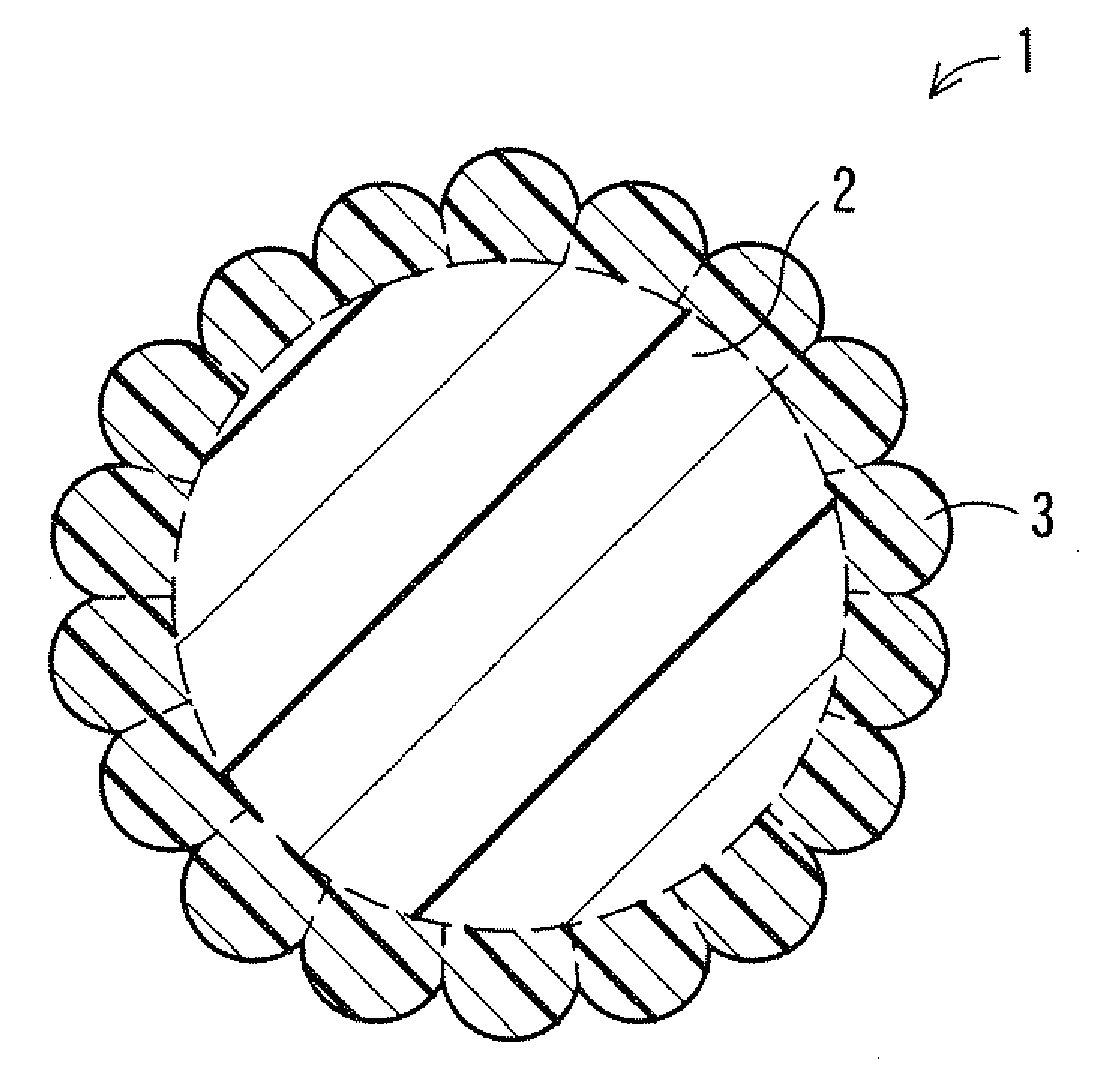

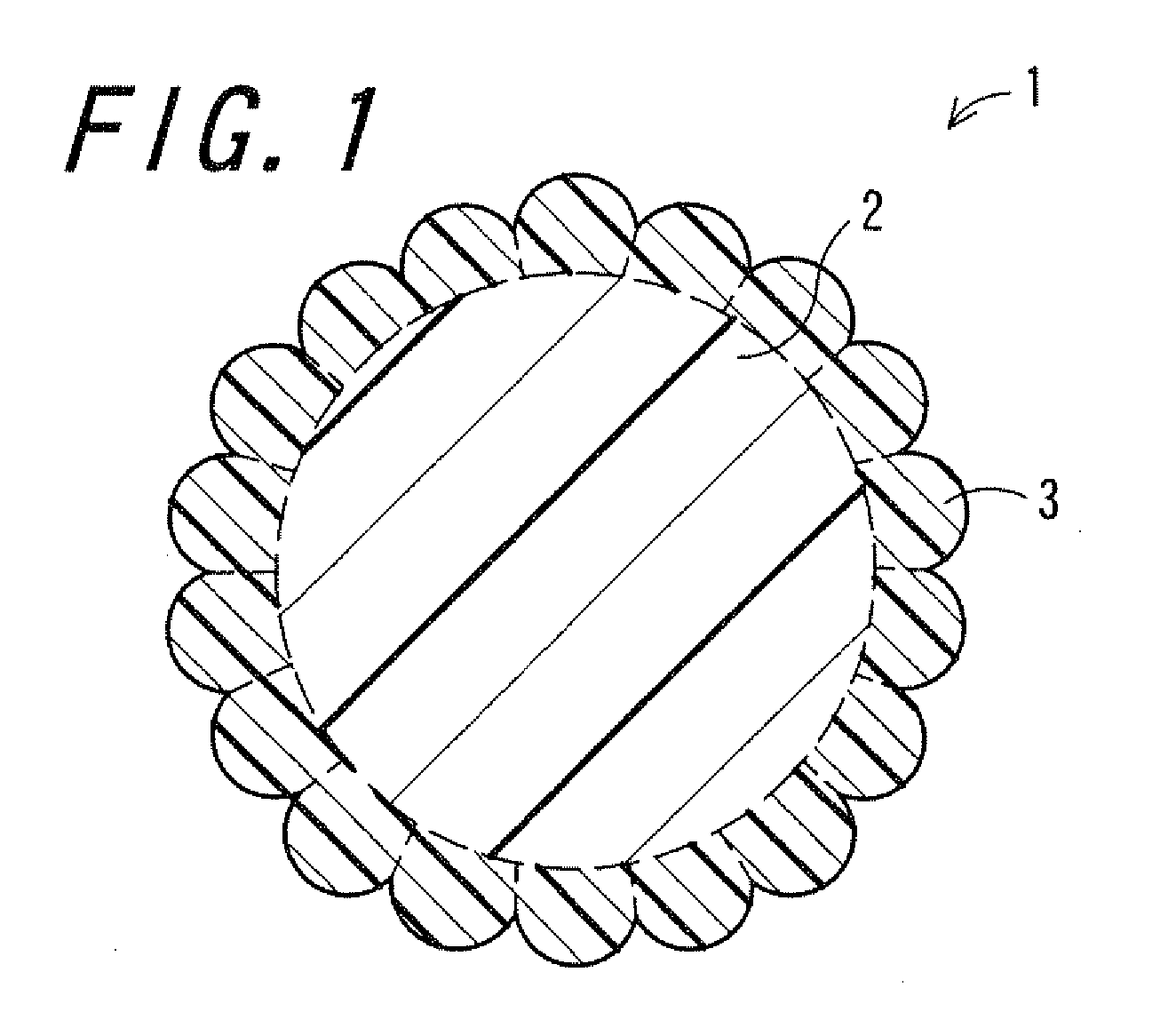

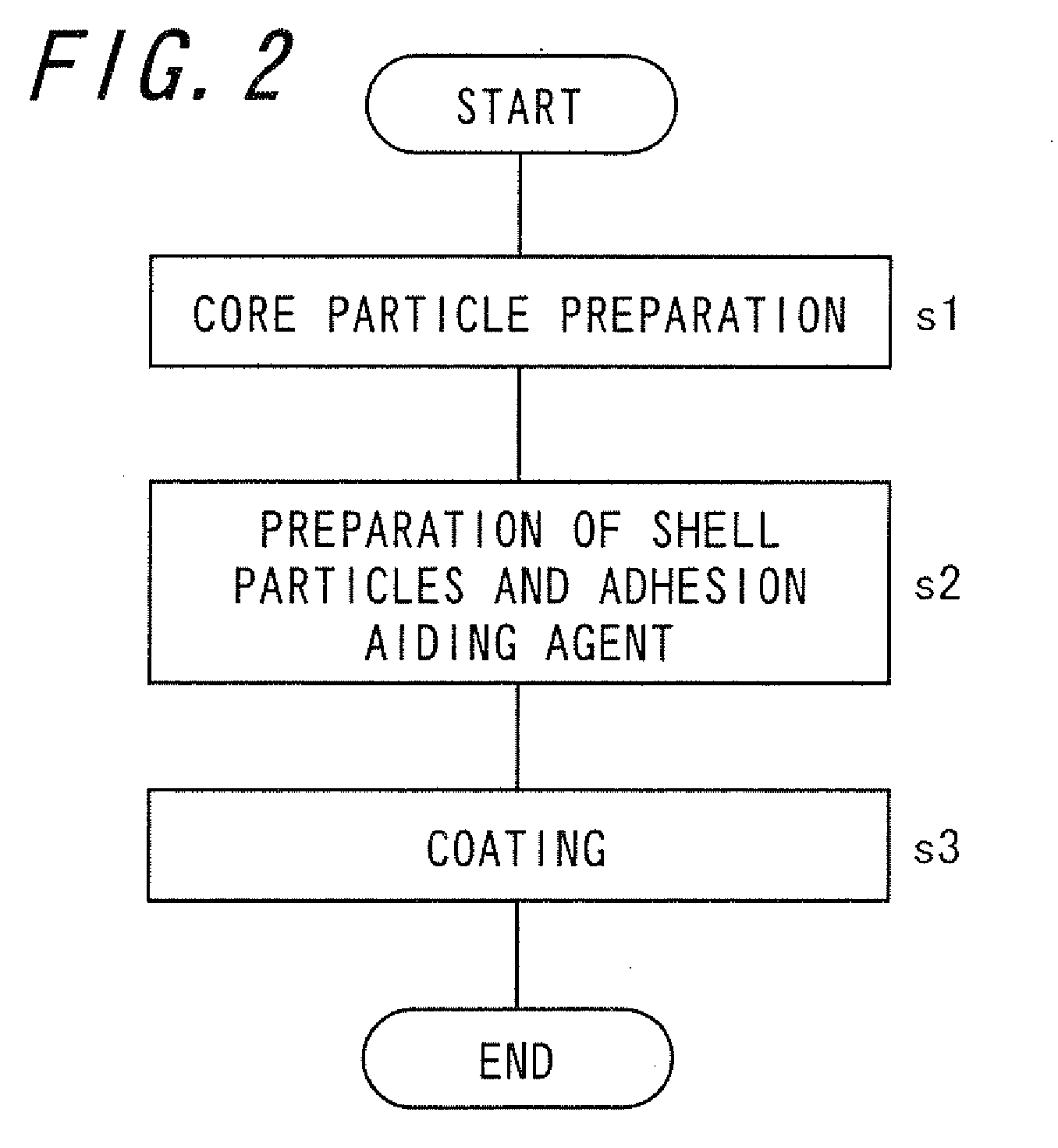

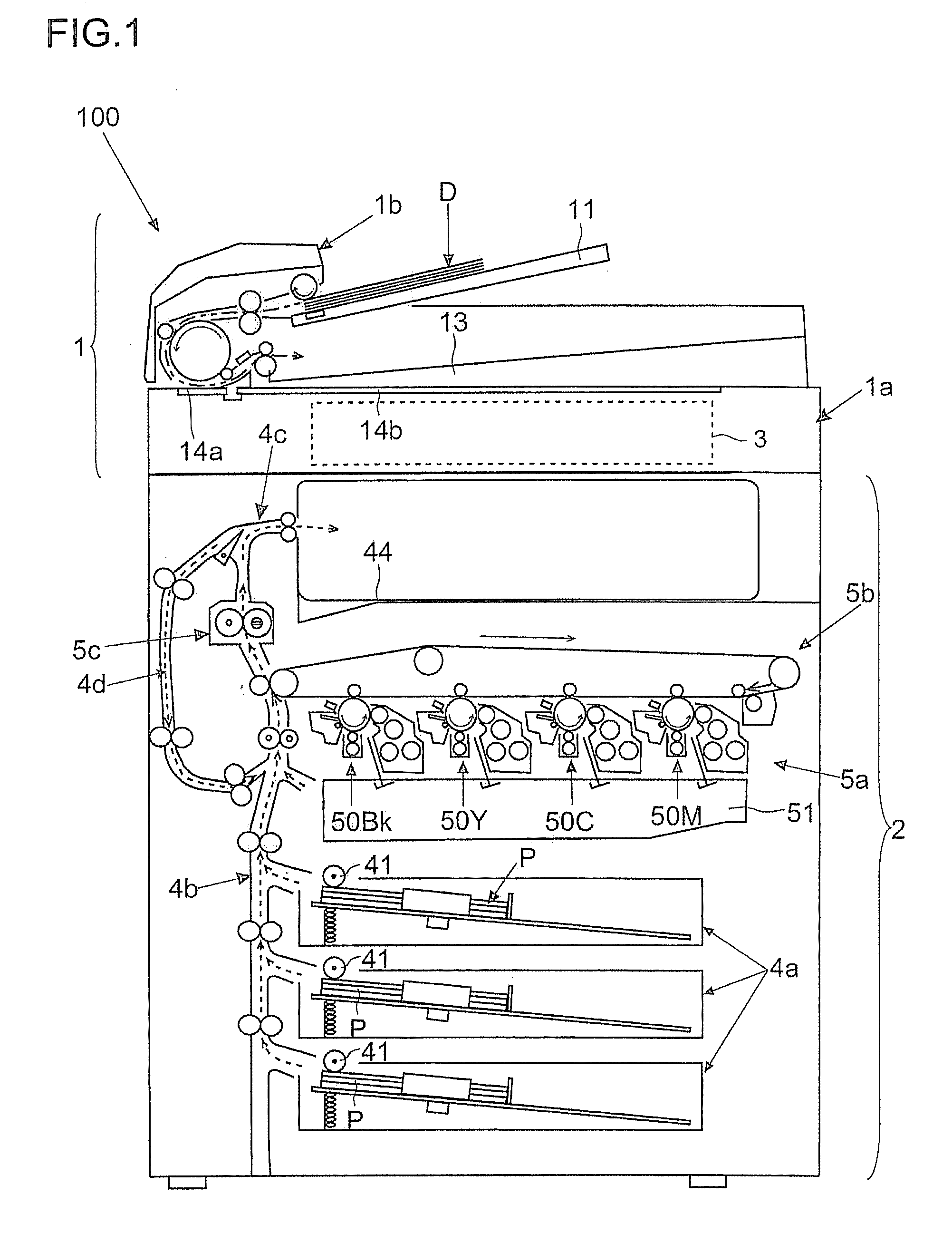

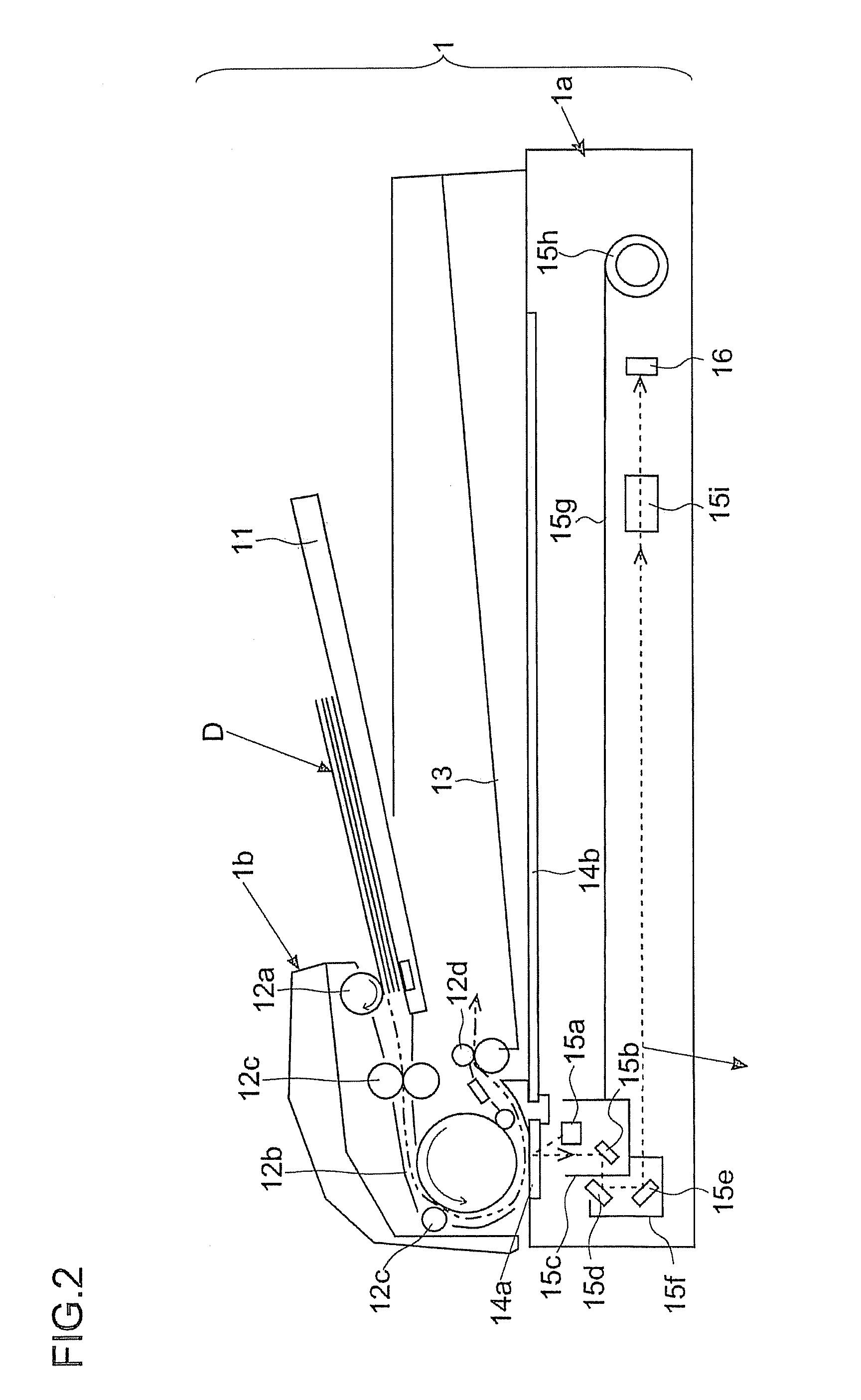

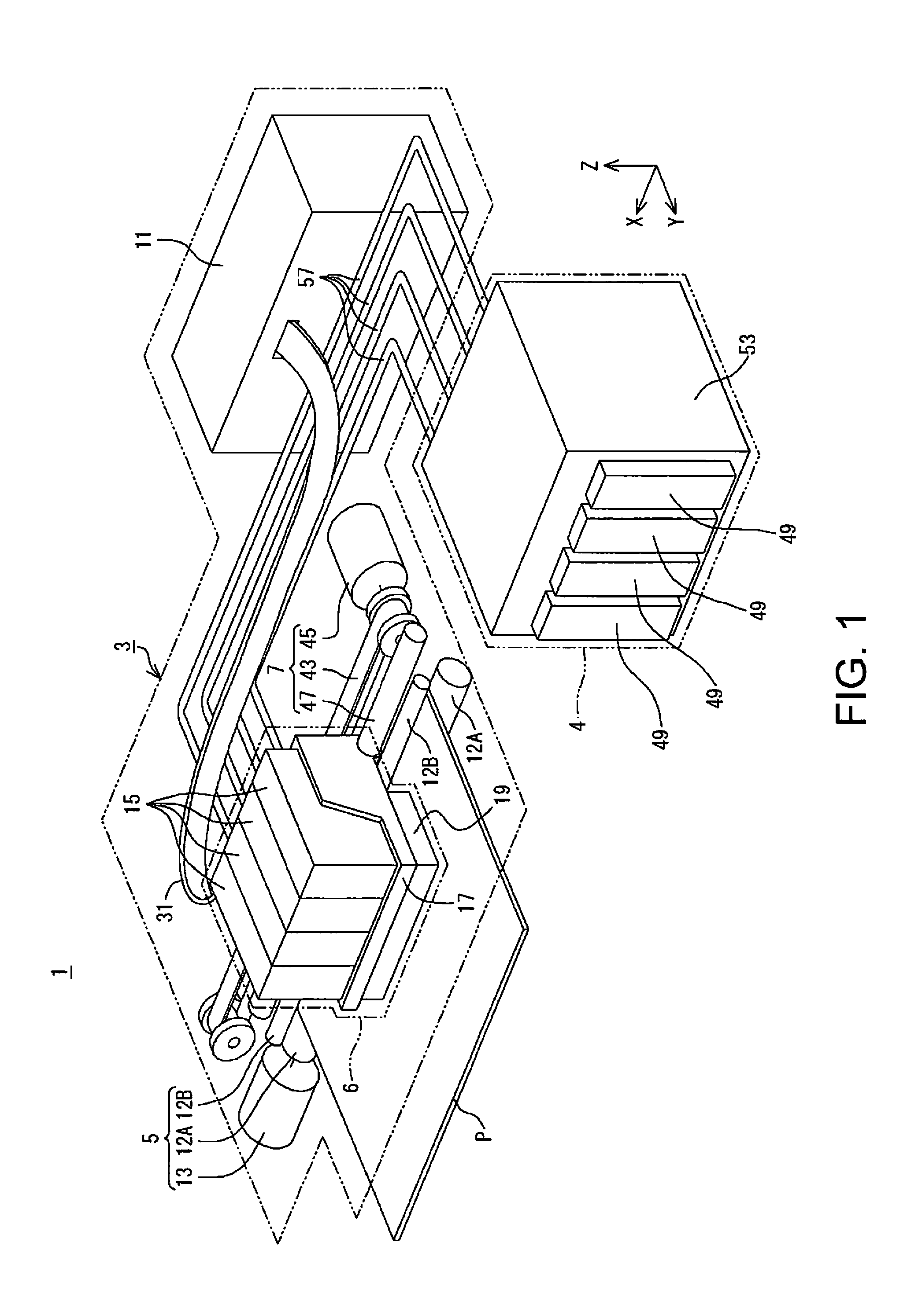

Toner, method of manufacturing the same, two-component developer using the same, developing device, and image forming apparatus

InactiveUS20090011357A1Appropriate thicknessDeterioration of handleabilityDevelopersVolume averageEngineering

A toner is a capsule particle including a toner particle composed of a core particle that is a resin particle and shell particles covering the surface of the core particle. The toner is manufactured by controlling the particle size so that the toner particles have a volume average particle size of 4.0 or more and 8.0 μm or less, and a ratio of a toner particle having a number average particle size of 3.0 μm or less of 8% by number or more and 25% by number or less to the entirety of the toner particles. The shell particles are melt-bonded to the core particle to be integrated therewith.

Owner:SHARP KK

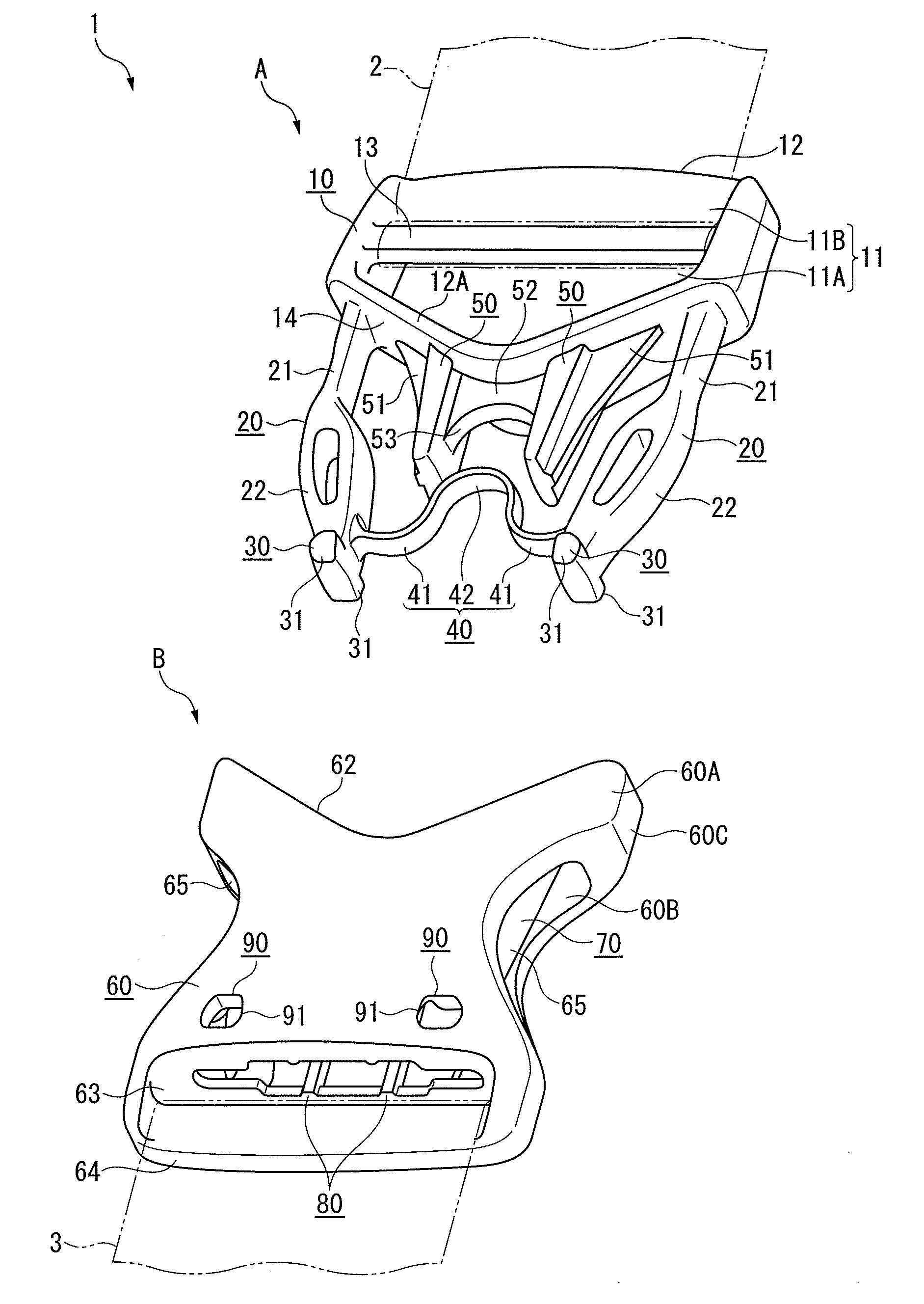

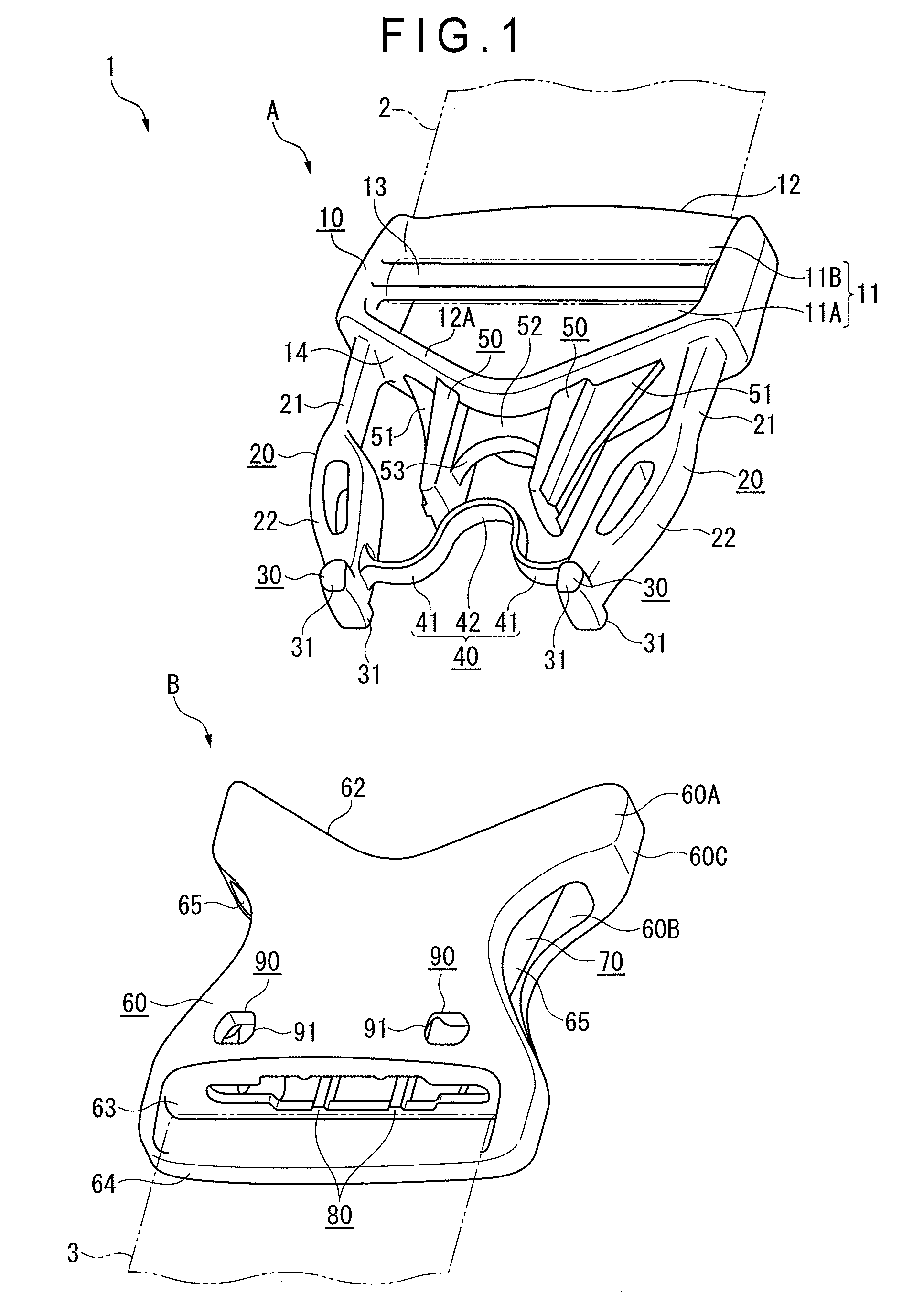

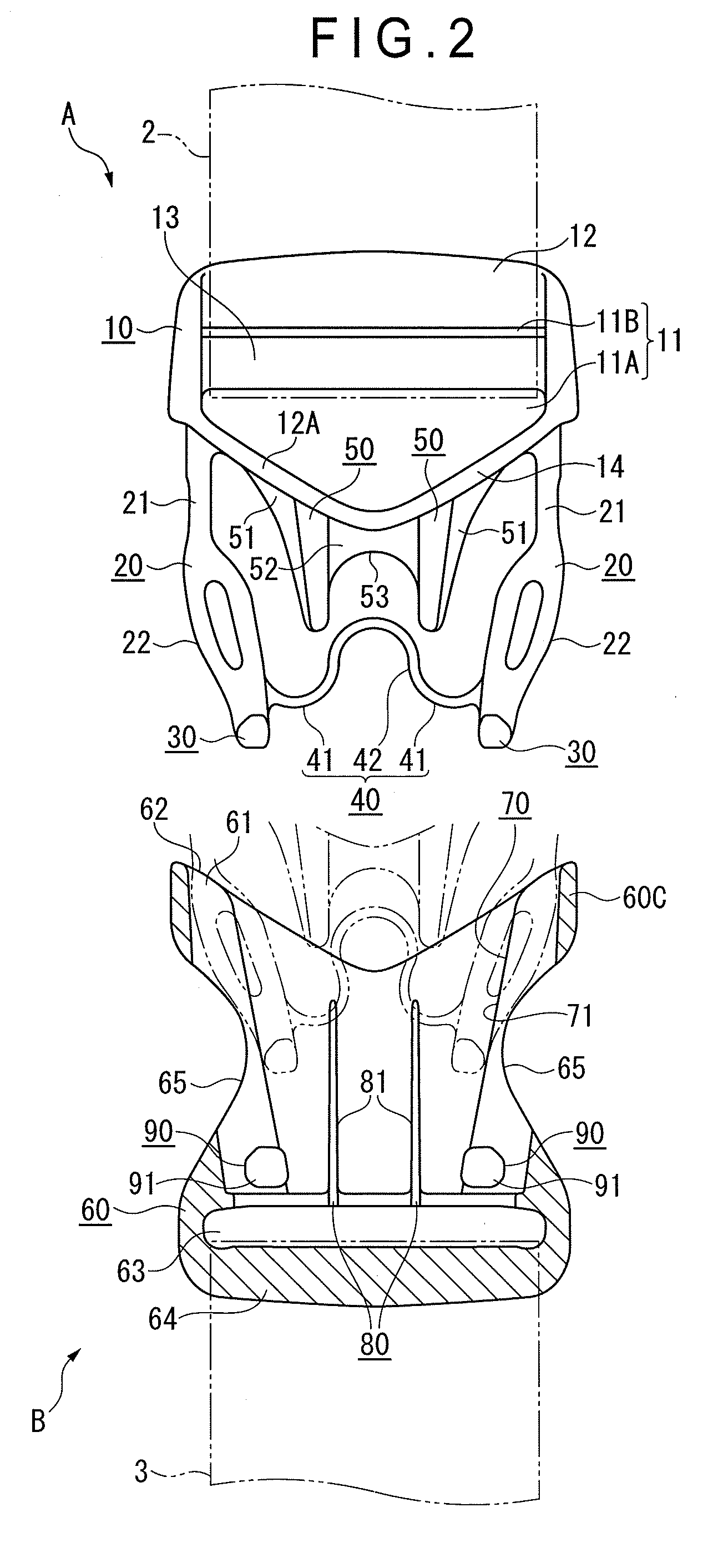

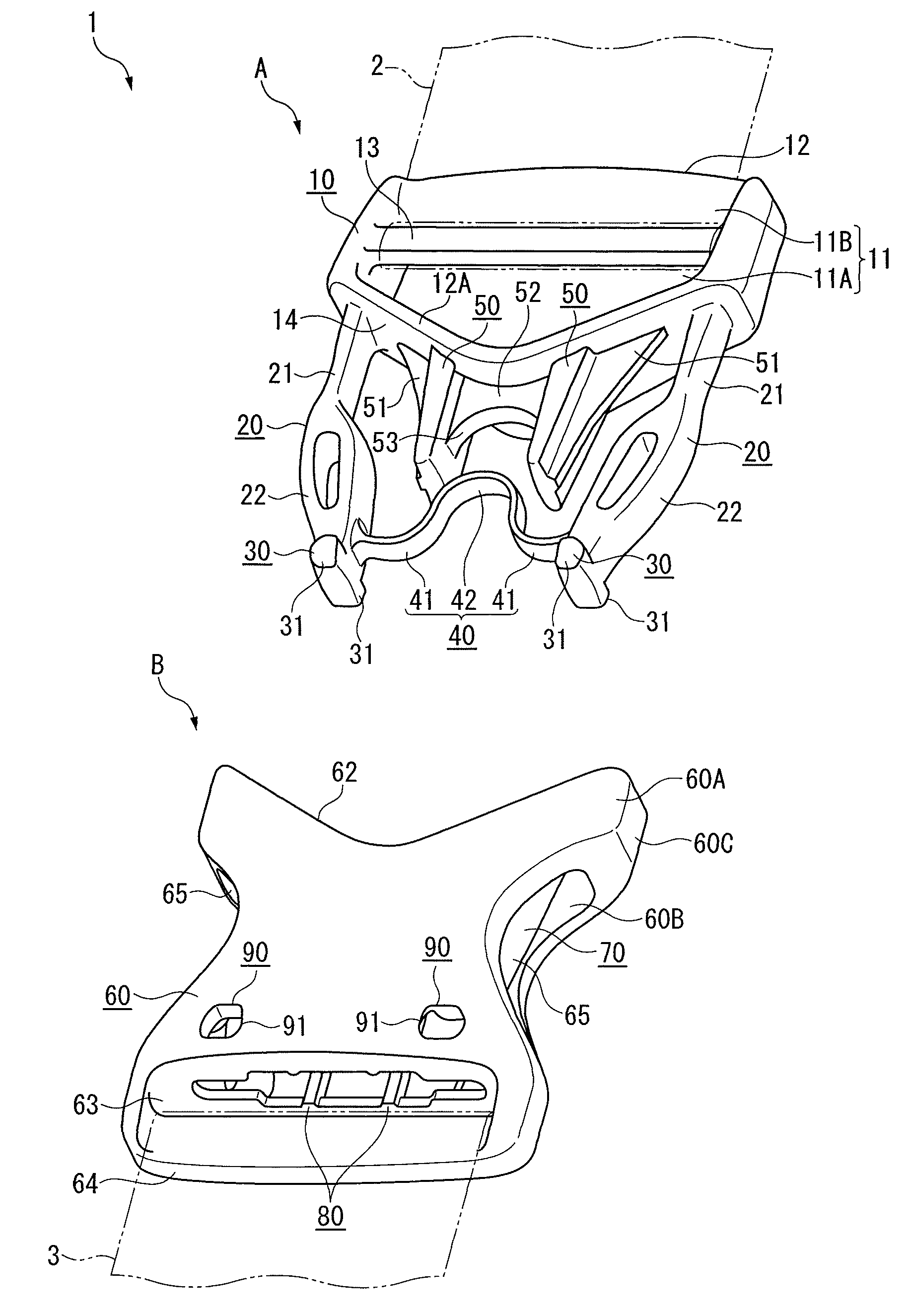

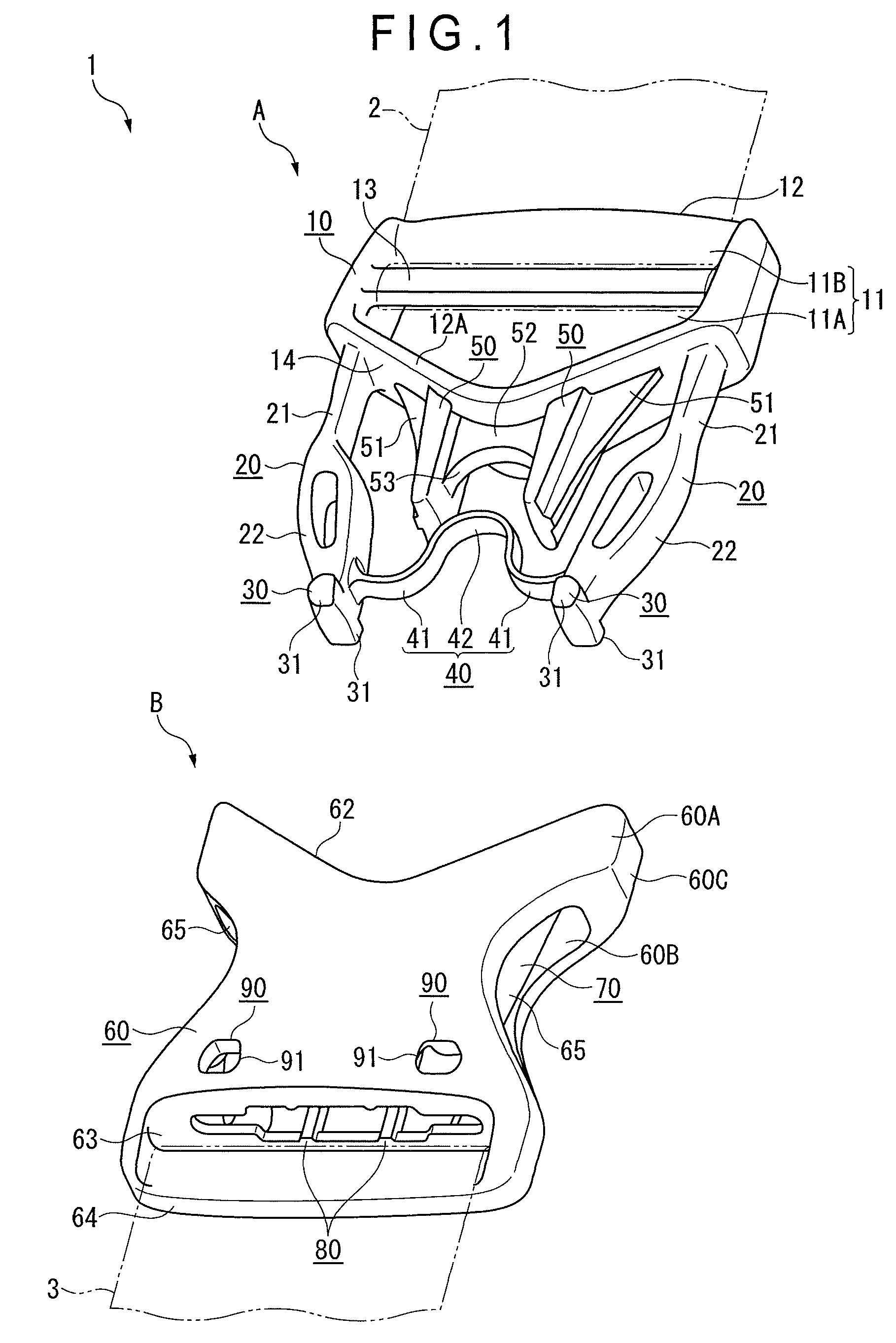

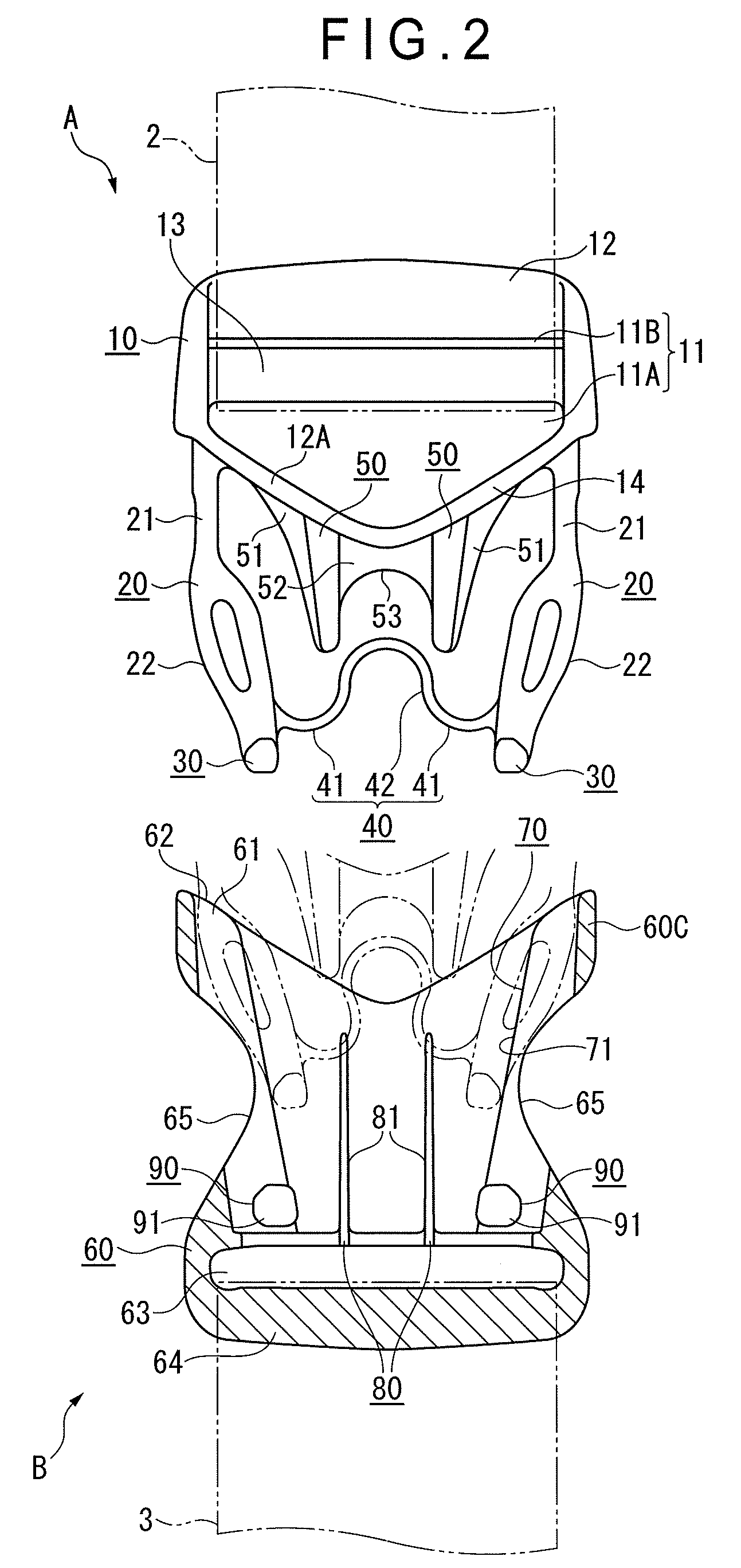

Buckle

ActiveUS20100306976A1Reduce external forceEasily caughtSnap fastenersClothes buttonsEngineeringMechanical engineering

A buckle includes a male member and a female member. The male member includes: a base; a pair of legs that project from the base; engaging portions that are provided on the legs to be engageable with the female member; and a linking body that links the pair of legs. The linking body includes a curved portion that is curved such that the middle thereof is closest to the base. A pair of projecting portions that are substantially parallel with an insertion direction of the male member extend from the base to be disposed outside the curved portion such that the curved portion is interposed therebetween. With this arrangement, the linking body for linking the pair of legs can be disposed with less possibility that other objects are caught in a space in the male member and without increasing a length dimension in the insertion direction more than necessary. The male member can be stably held relative to the female member against a torsion force.

Owner:YKK CORP

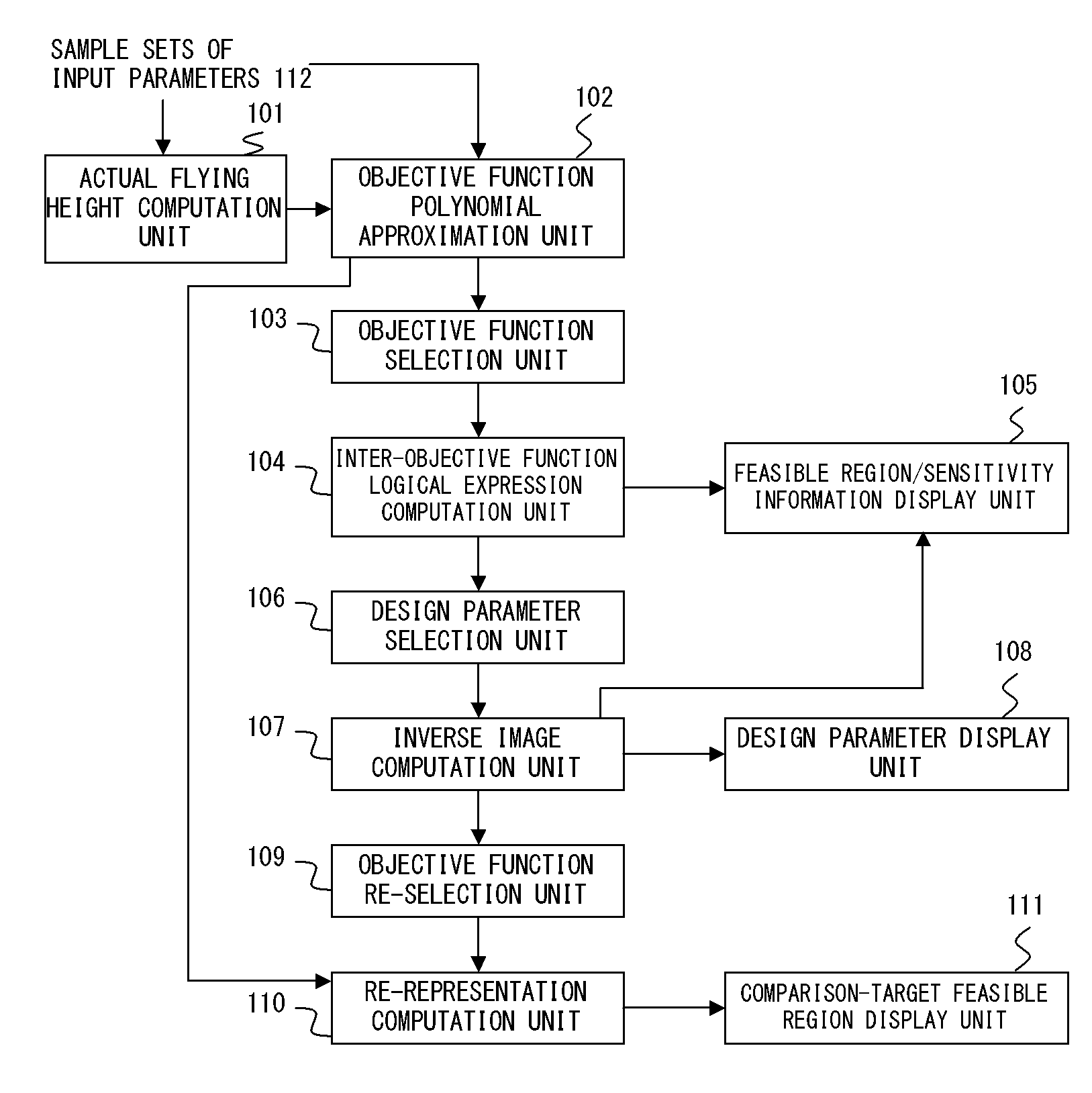

Multi-objective optimal design support device and method taking manufacturing variations into consideration

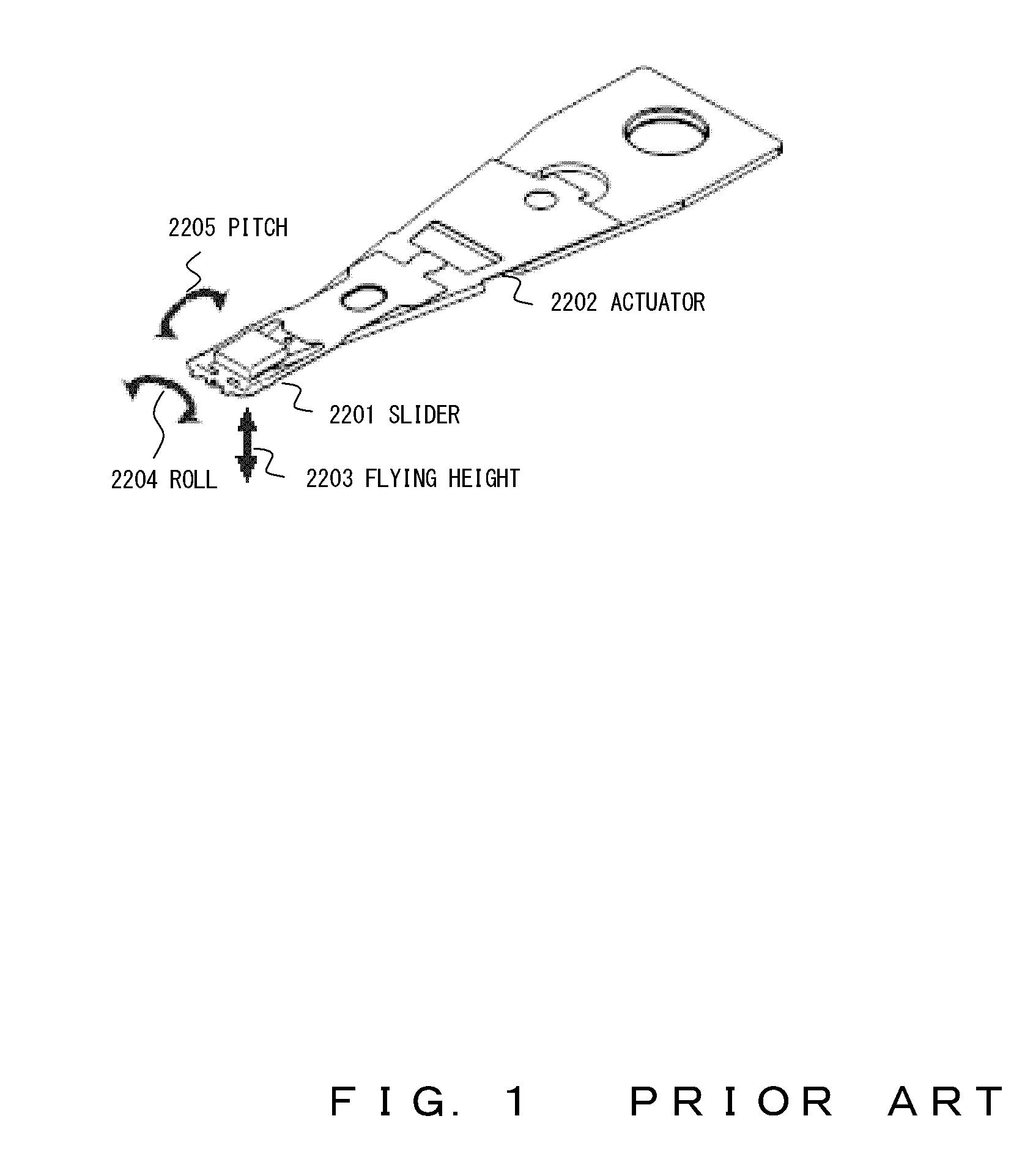

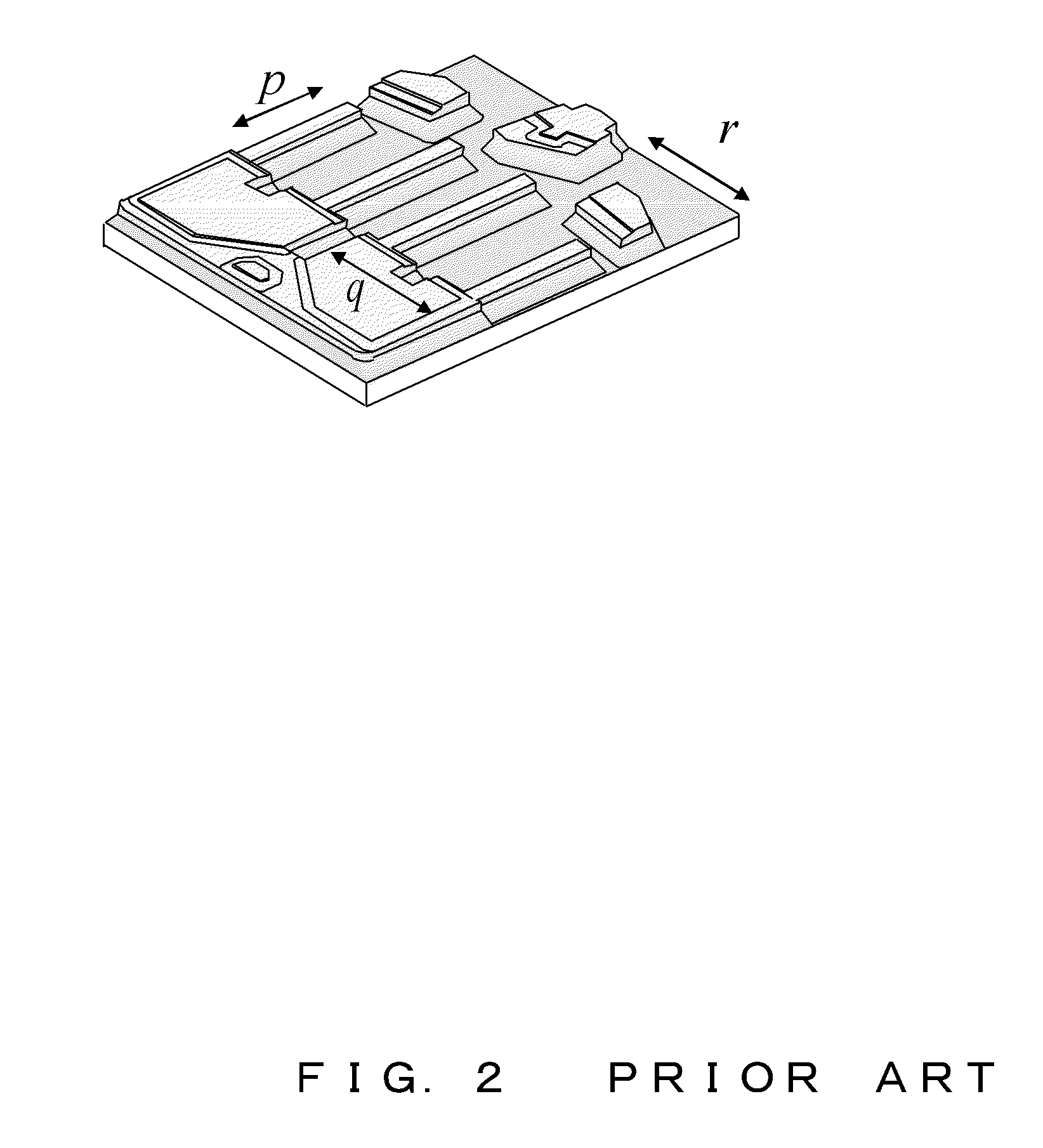

InactiveUS20090182695A1Strong robustnessEasily caughtDriving/moving recording headsDigital computer detailsOptimal designMulti-objective optimization

A logical expression indicating a logical relation between arbitrary two or three objective functions, of a plurality of mathematically approximated objective functions is computed. A feasible region / sensitivity information display unit displays the feasible region in arbitrary objective space according to it. An inverse image computation unit computes a point or area in design space corresponding to arbitrary design parameters in relation to a point or area specified by a user in the feasible region of the objective space. A feasible region / sensitivity information display unit displays the distribution state of the corresponding point or area as sensitivity information in relation to the specified point or area in the feasible region.

Owner:FUJITSU LTD

UV sanitizer for tethered and untethered mouthguards

InactiveUS7888656B2Readily tossed and safely caughtEasily caughtRadiation pyrometryMaterial analysis using wave/particle radiationMouthguardUv disinfection

A portable, battery-powered UV sanitizer kills germs and bacteria on the mouthpieces of tethered mouthguards of a wide variety of tether sizes and configurations and on the mouthpieces of untethered mouthguards. It doubles as a protective case when not in antimicrobial use. It includes a dishwasher safe detachable tray. It may be used with other dental appliances.

Owner:BREAKAWAY PRODS

Image forming apparatus and control method of an image forming apparatus

InactiveUS20140320876A1Saving and unpleasant noiseHigh speed readPictoral communicationDigital output to print unitsImage formationDocumentation

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Tool for the handling of a protection device for subsea electrical or fiber optical connectors

InactiveUS20130025419A1Fast and safe recoverySimple designCoupling device engaging/disengagingCoupling device detailsFiberEngineering

A tool (1) for the handling by a Remotely Operated Vehicle (ROV) of a protection device (4) provided to protect a subsea electrical or optical fiber connector. The main feature of a tool is that said tool (1) is attached to the ROV and comprises a ROV friendly handle (2).

Owner:NEXANS

Buckle

A buckle includes a male member and a female member. The male member includes: a base; a pair of legs that project from the base; engaging portions that are provided on the legs to be engageable with the female member; and a linking body that links the pair of legs. The linking body includes a curved portion that is curved such that the middle thereof is closest to the base. A pair of projecting portions that are substantially parallel with an insertion direction of the male member extend from the base to be disposed outside the curved portion such that the curved portion is interposed therebetween. With this arrangement, the linking body for linking the pair of legs can be disposed with less possibility that other objects are caught in a space in the male member and without increasing a length dimension in the insertion direction more than necessary. The male member can be stably held relative to the female member against a torsion force.

Owner:YKK CORP

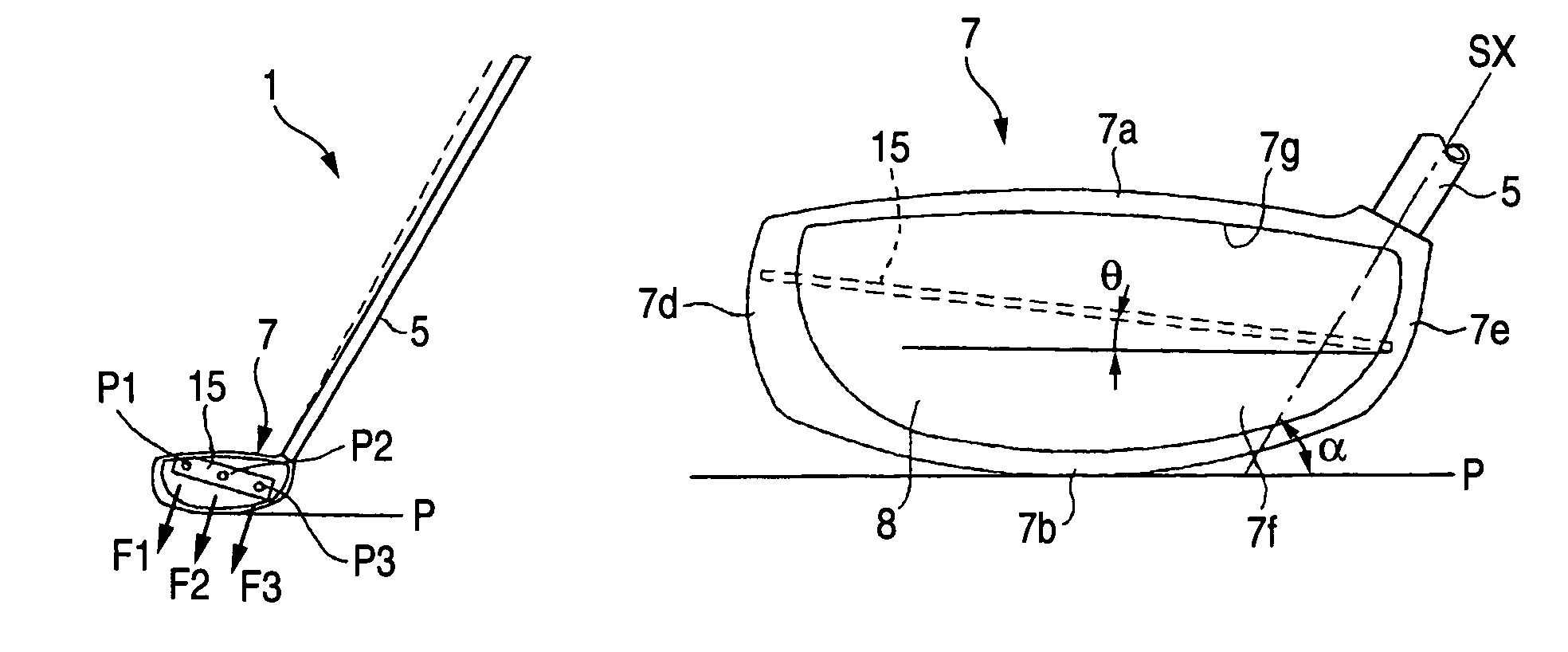

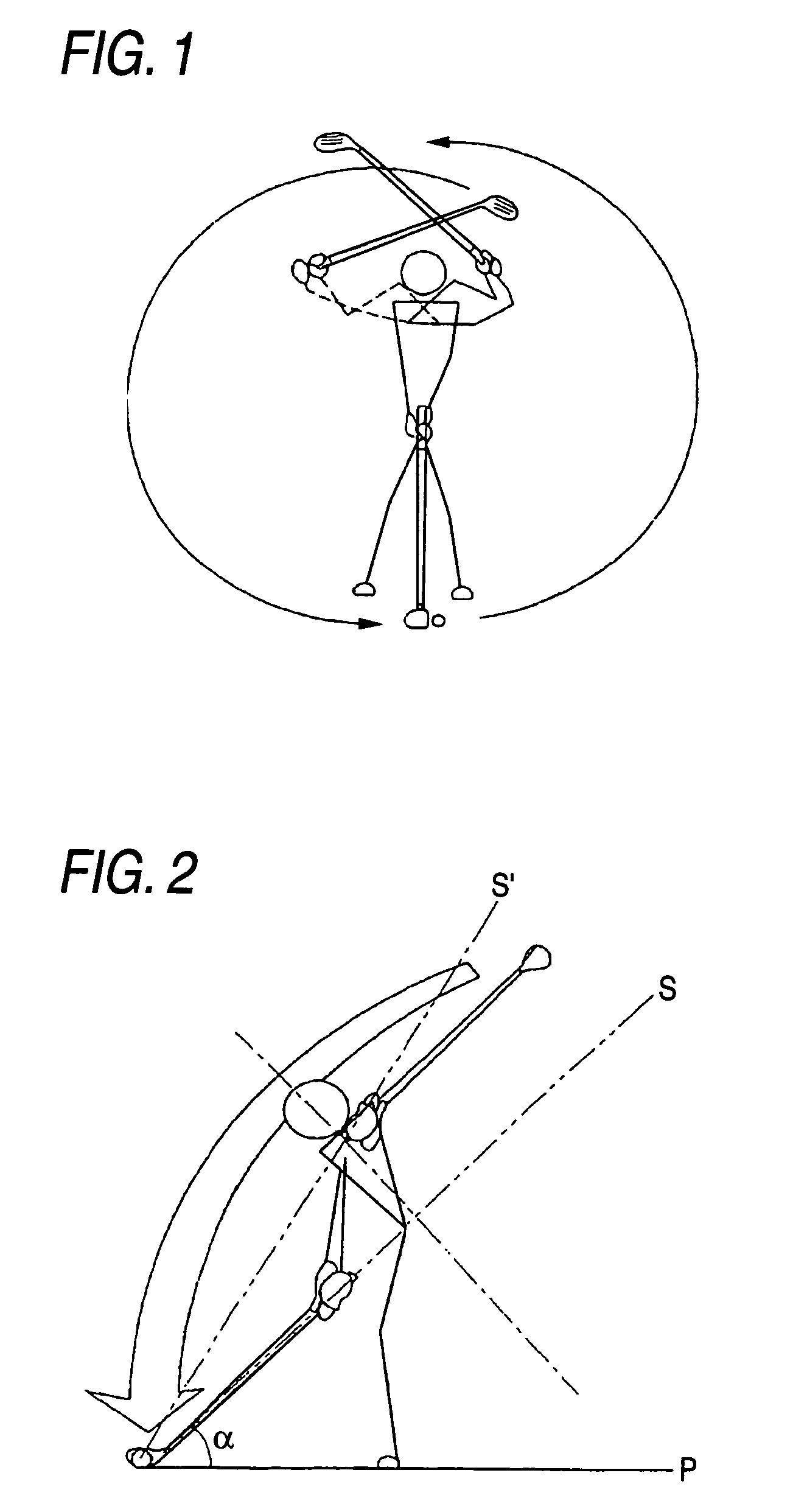

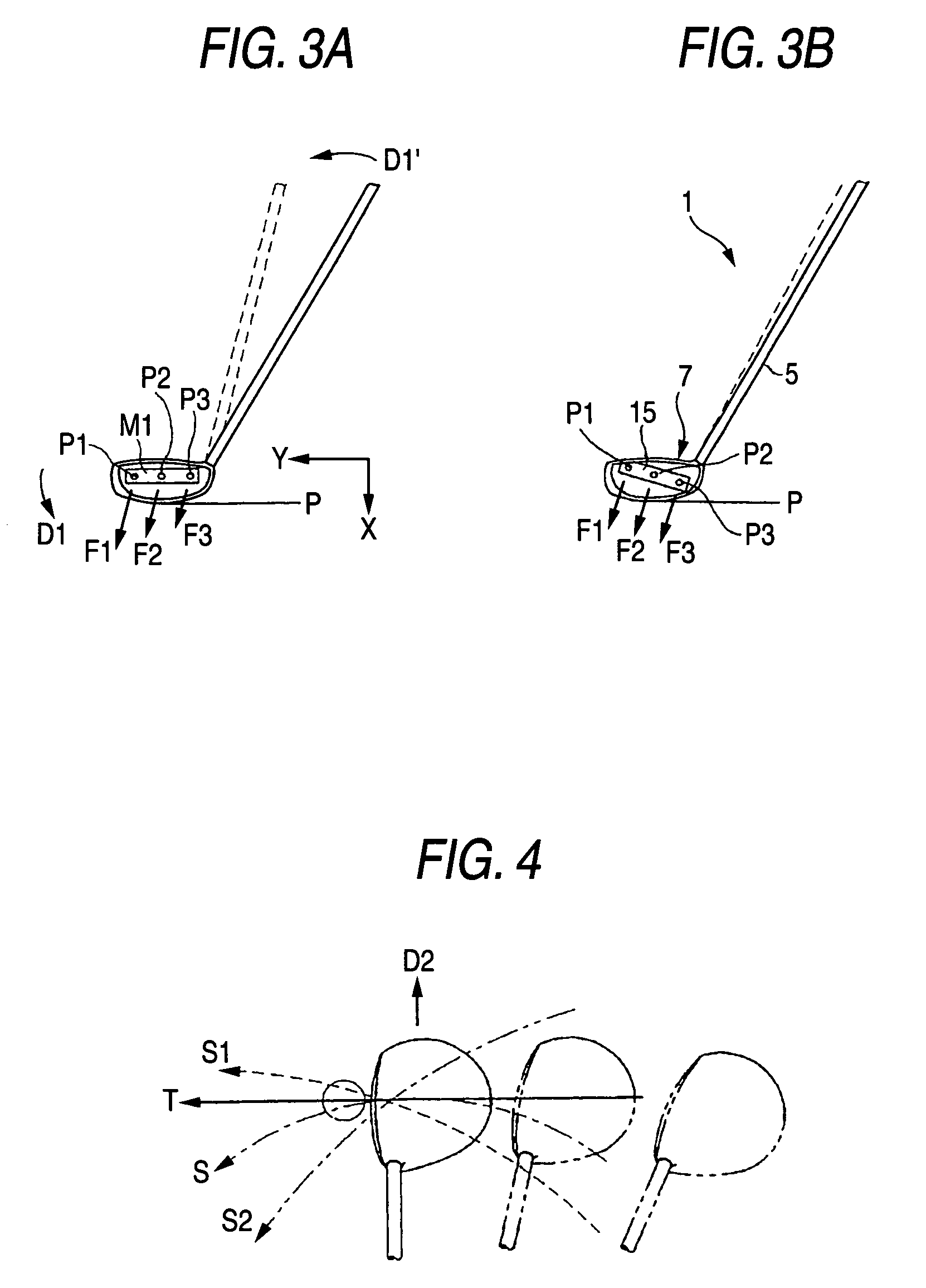

Golf club

A golf club of the invention has a head with a hollow outer shell construction which includes a crown portion, a sole portion, a back portion, a toe portion, a heel portion and a face portion which hits a ball and a shaft that is to be mounted on the head at a predetermined lie angle, wherein a weight concentrated portion is provided closer to a back portion side than to an axis of the shaft in the interior of the head in such a manner as to rise from a heel side to a toe side of the head with respect to a reference horizontal plane which regulates the lie angle.

Owner:DAIWA SEIKO CORPORATION

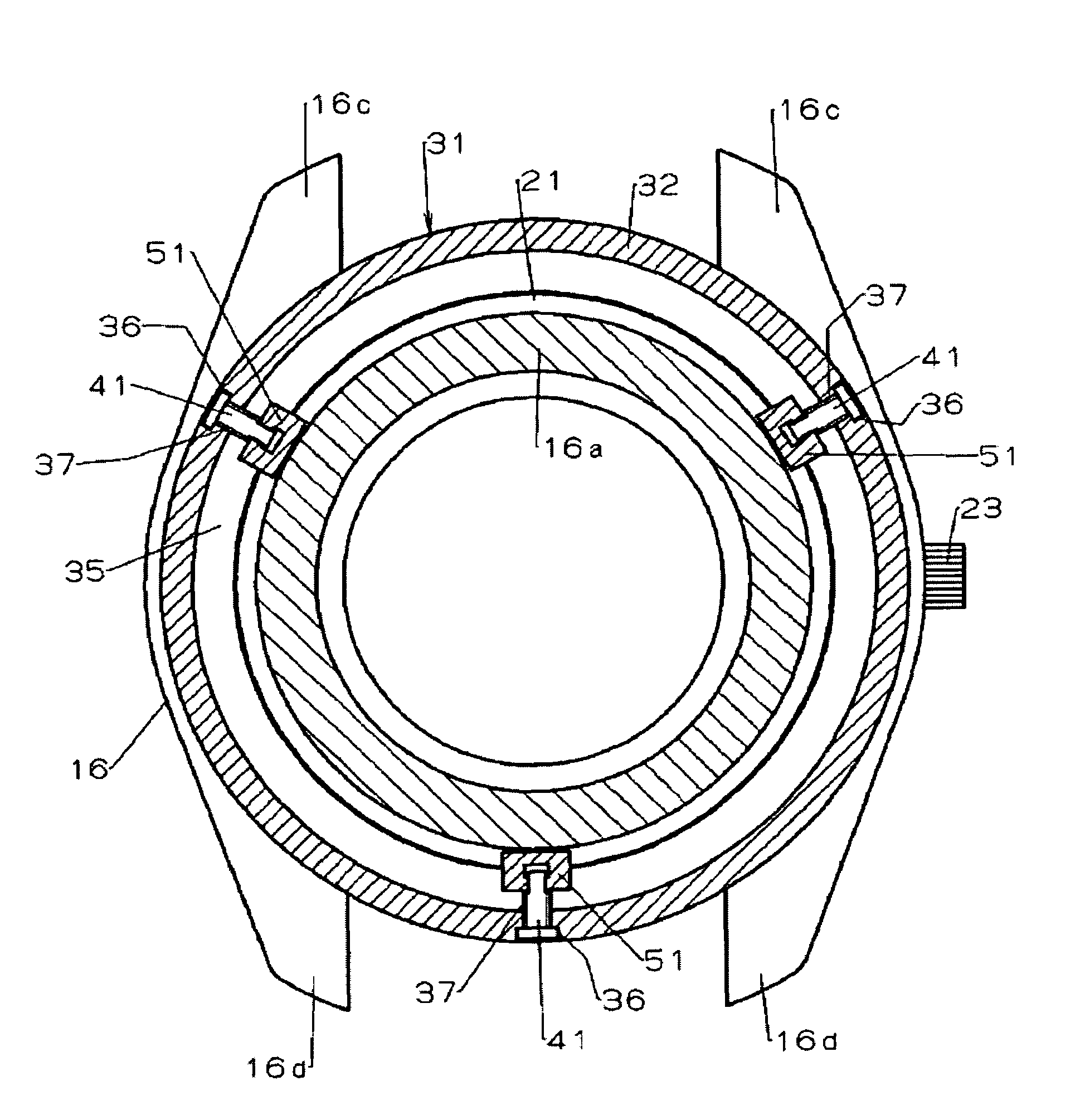

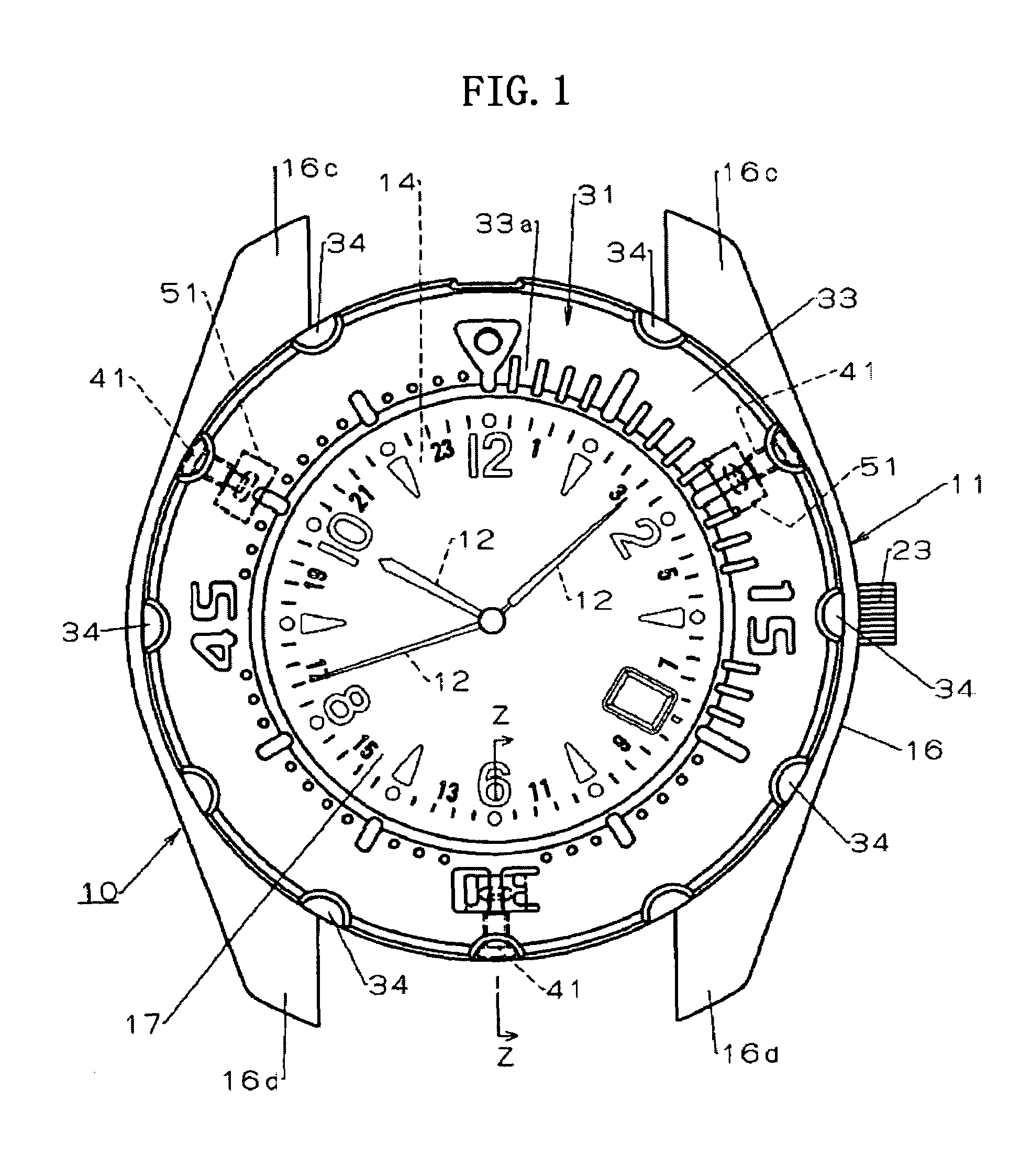

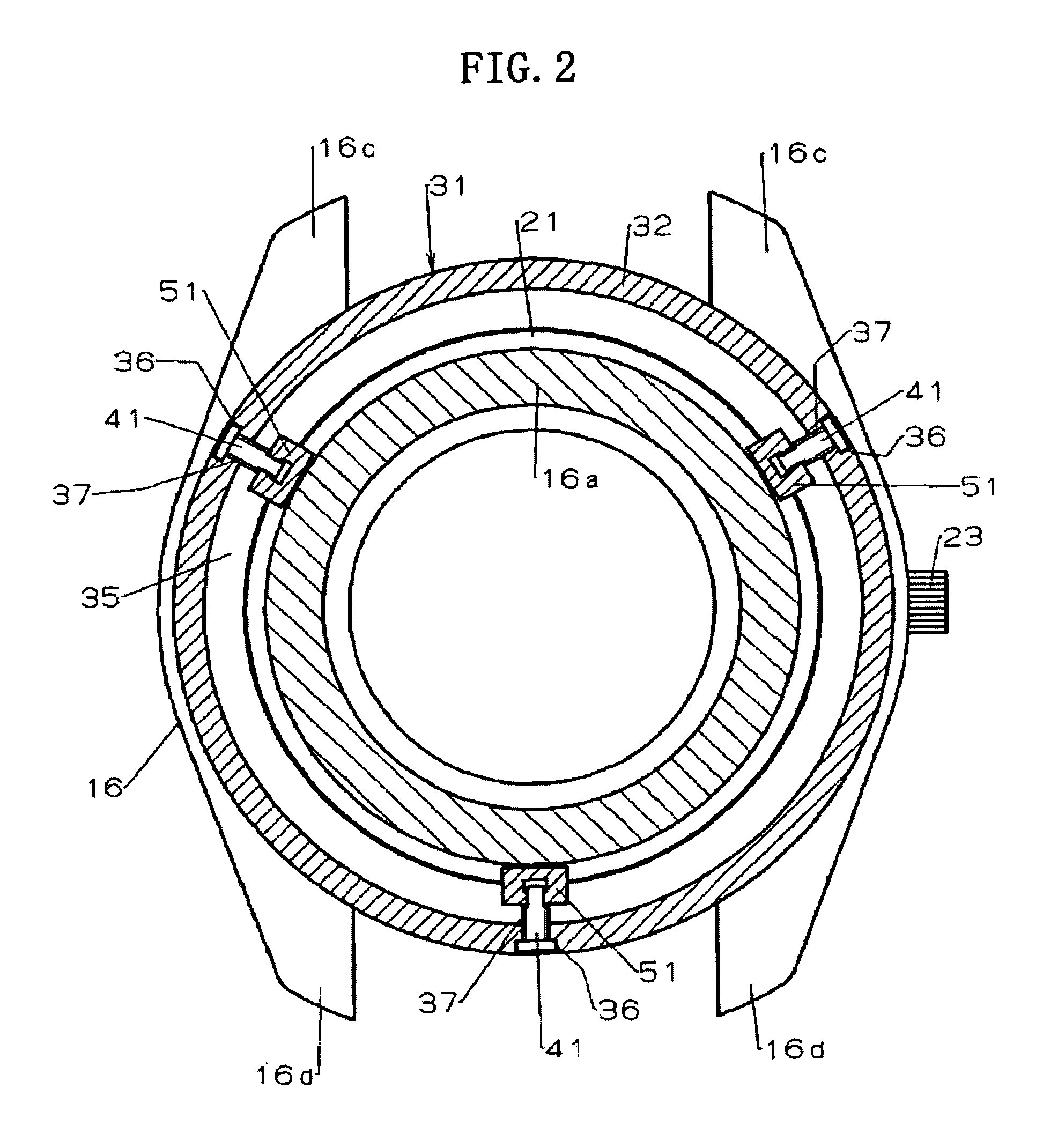

Timepiece having rotatable and detachable bezel

ActiveUS7614785B2Inhibit wearEasily caughtVisual indicationClockwork casesEngineeringMechanical engineering

Owner:SEIKO INSTR INC

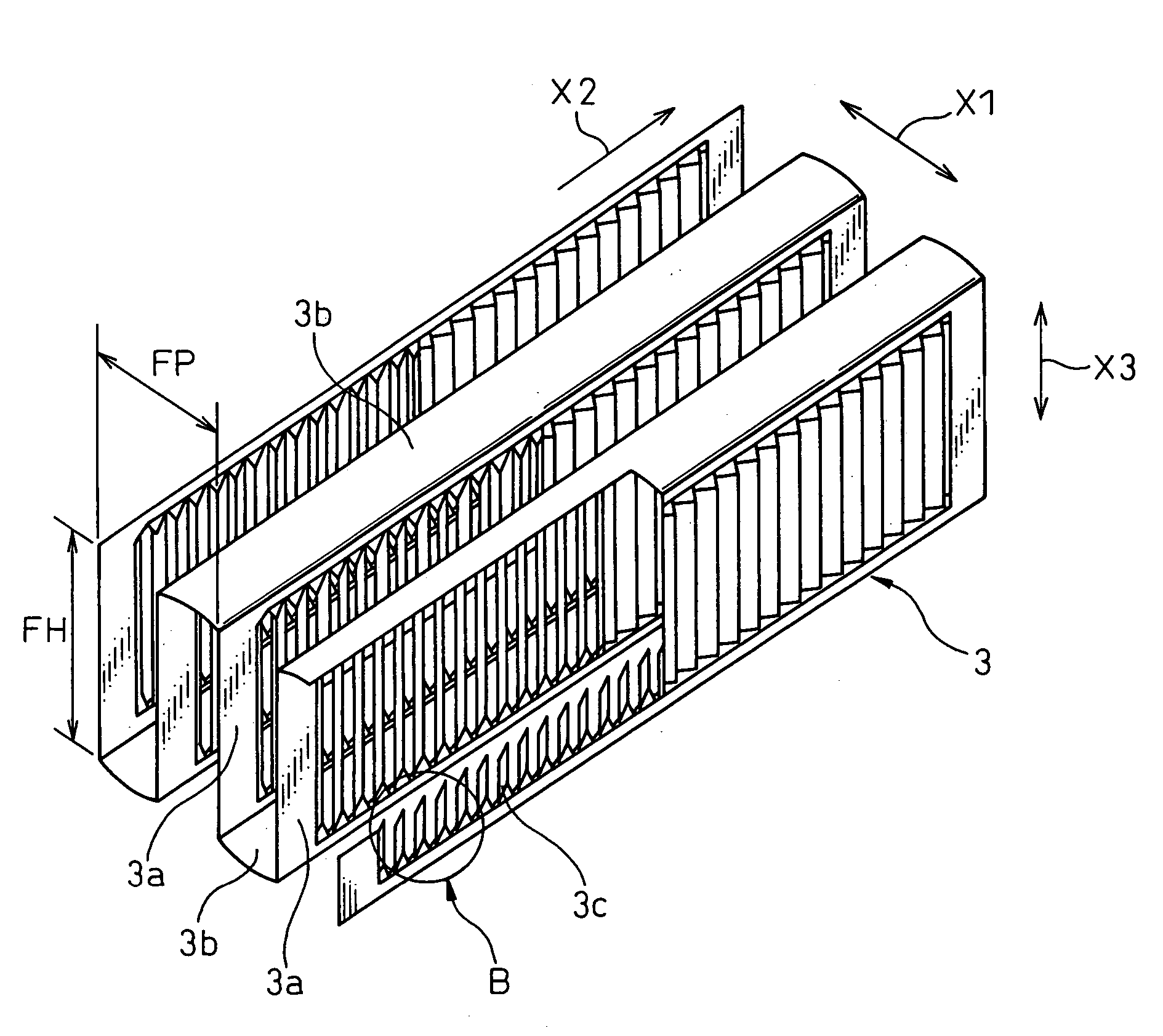

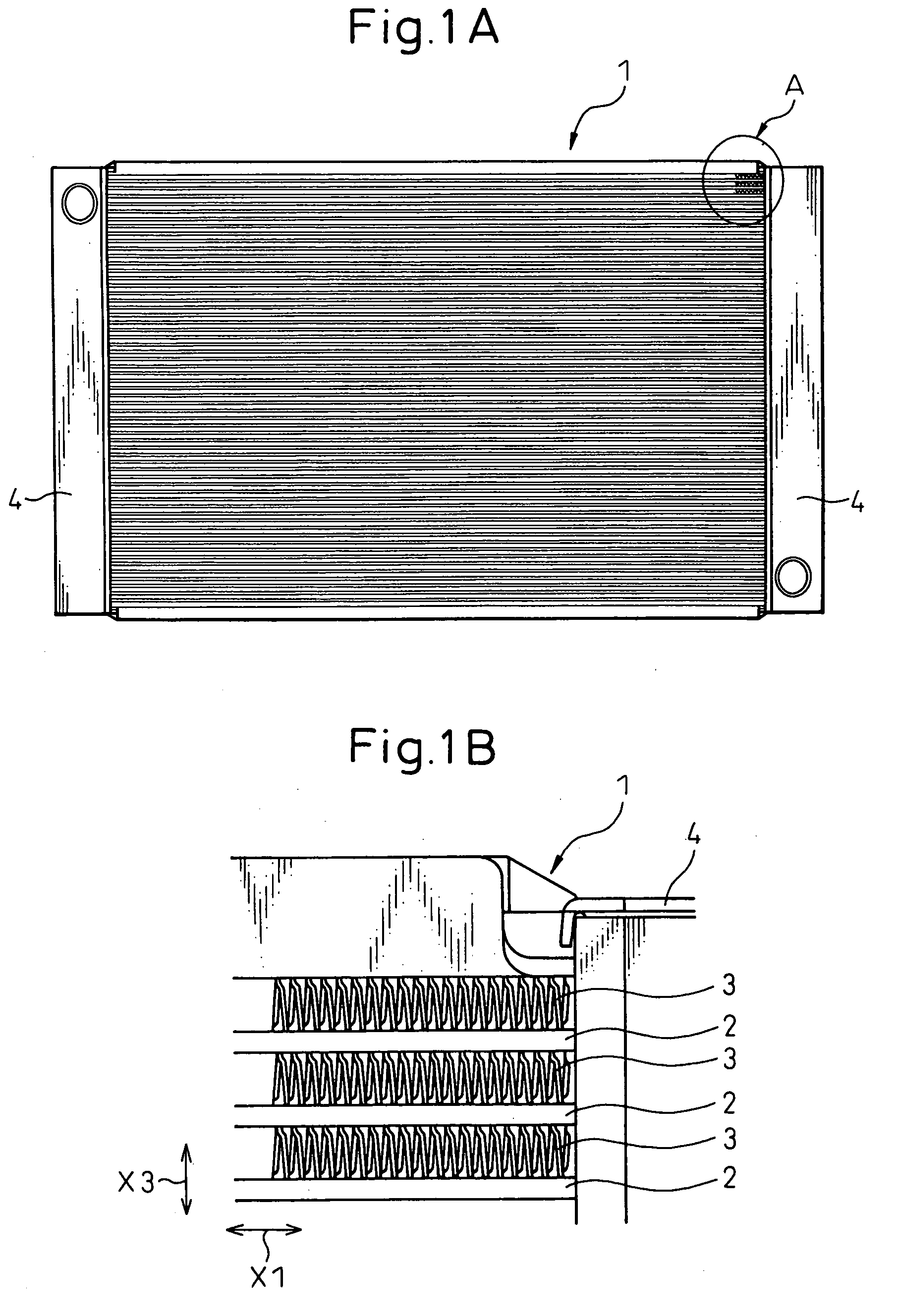

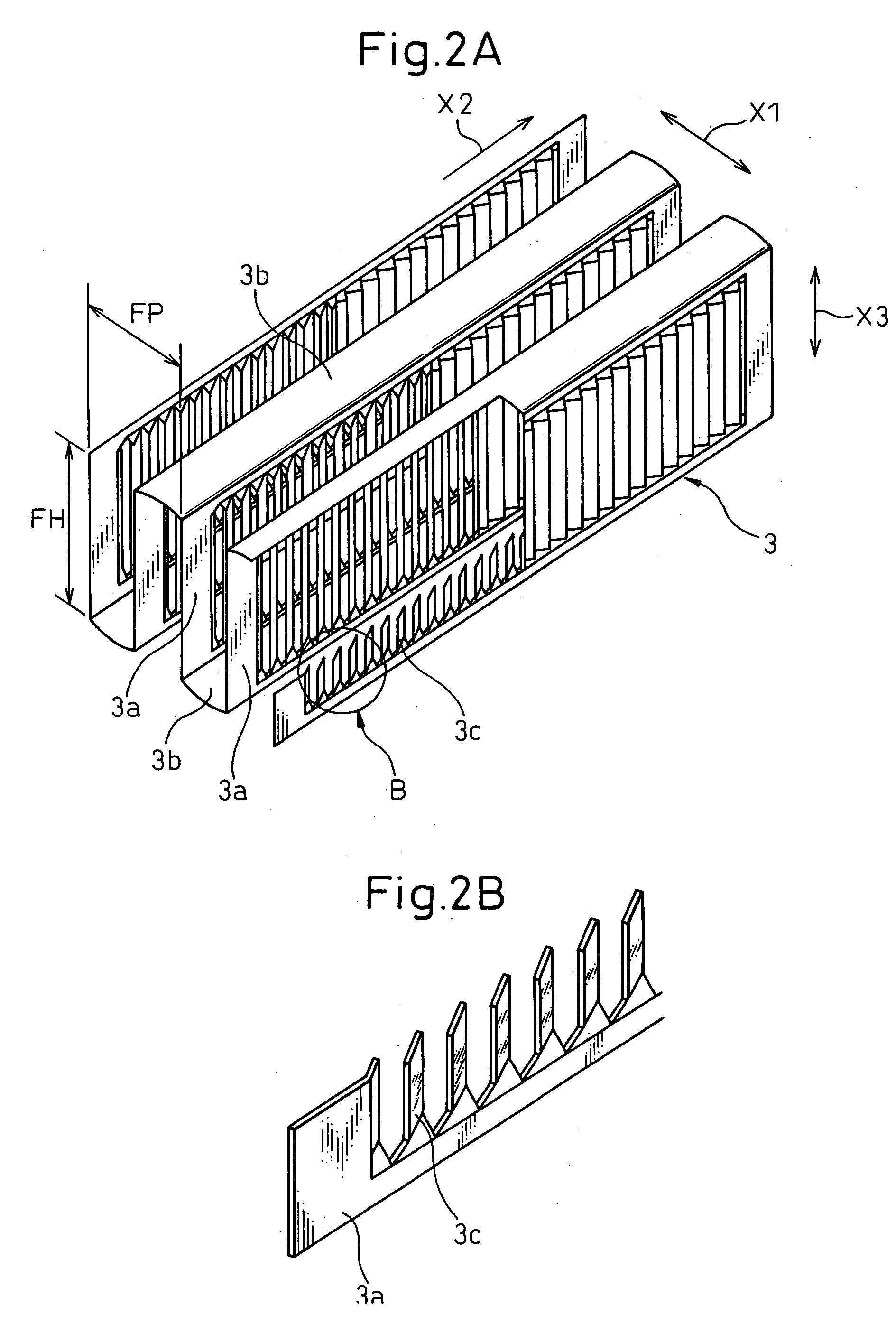

Heat exchanger

InactiveUS20060169443A1Easily caughtIncrease heightStationary conduit assembliesTubular elementsWater flowEngineering

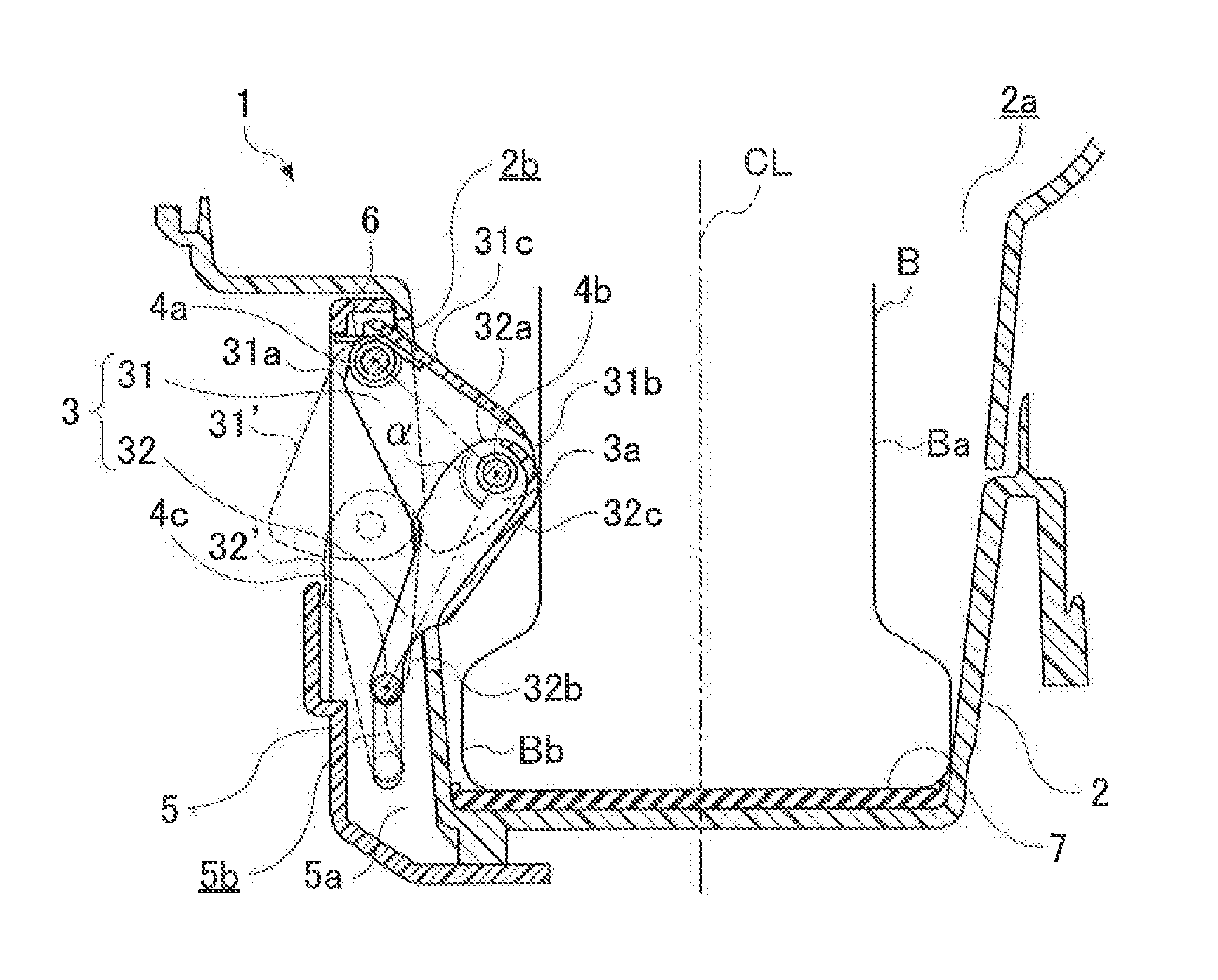

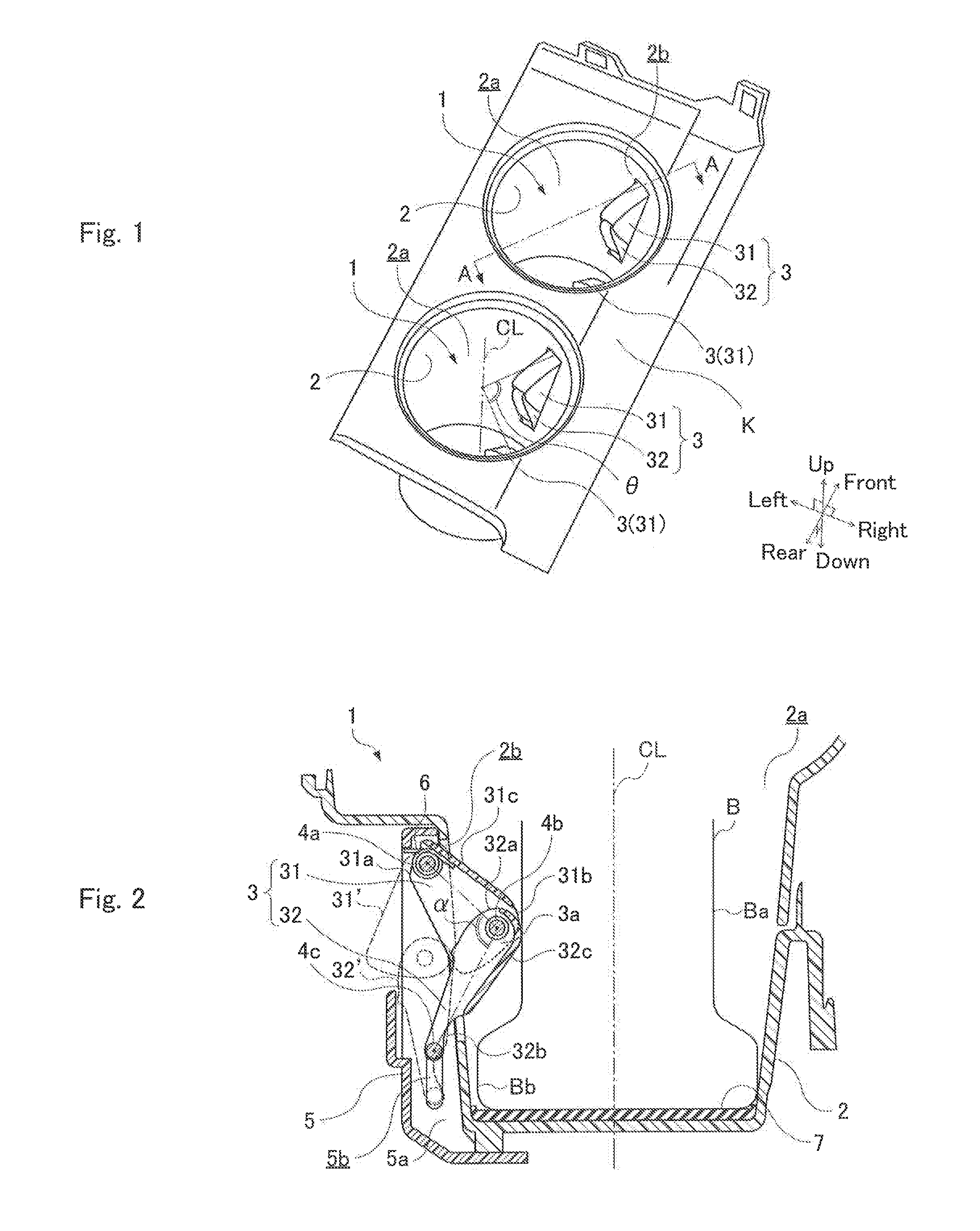

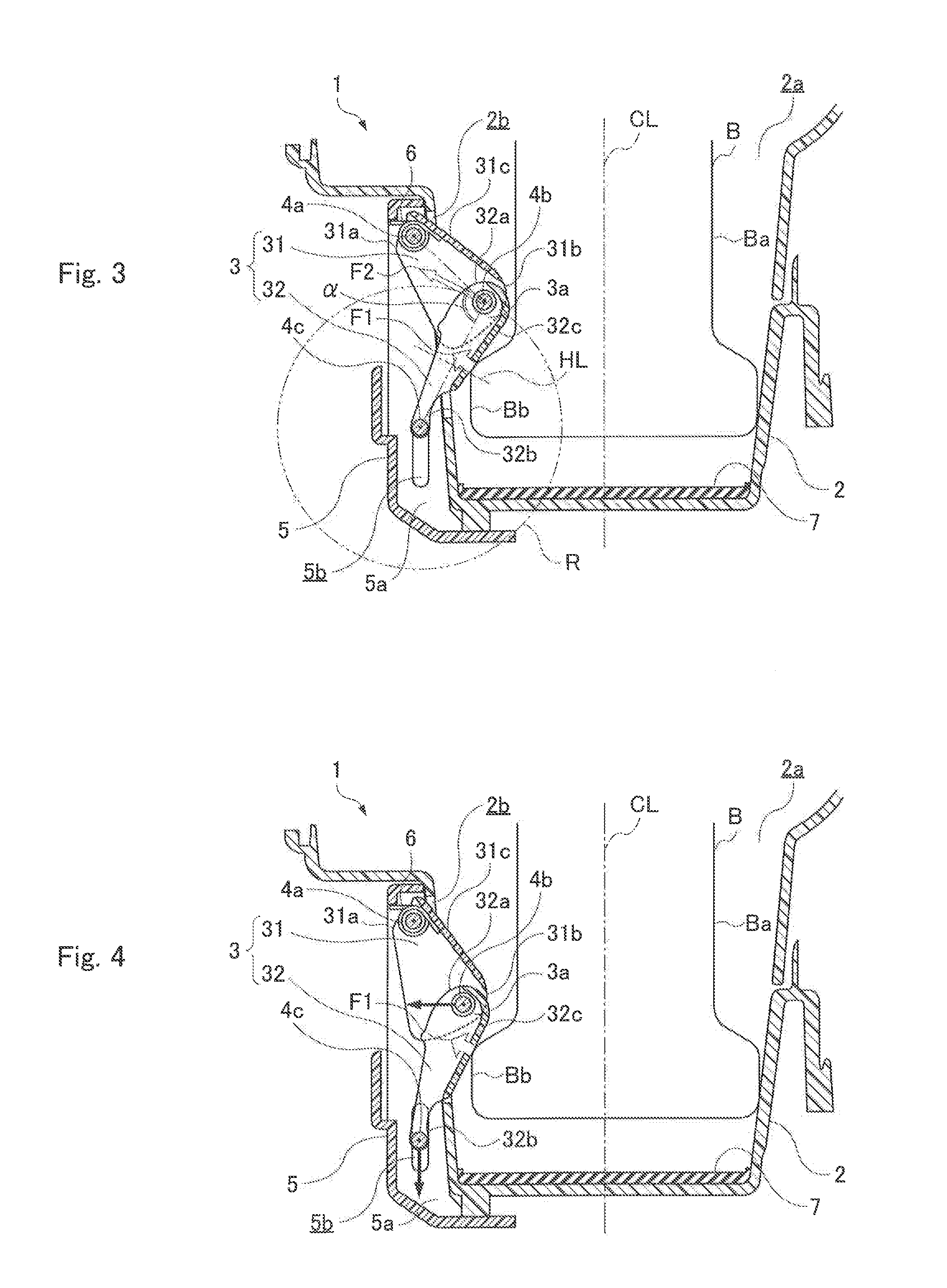

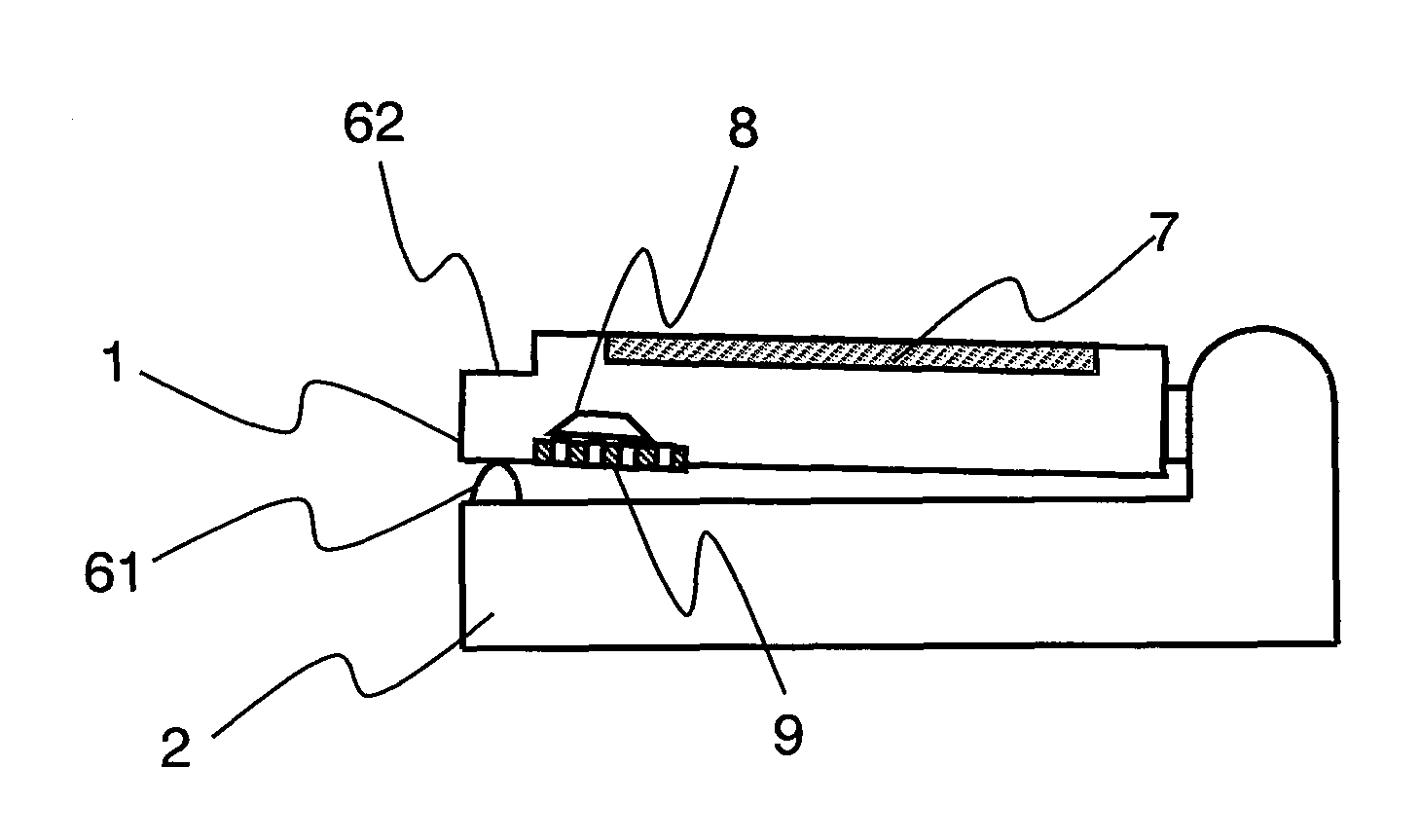

A heat exchanger, in which louver wall surfaces (3c) are twisted at a predetermined angle (θ1) with respect to a plurality of flat portions (3a) of fins (3) and an inter-louver path (5) is formed between the adjacent louver wall surfaces (3c), is disclosed. The center points (3d) of some louver wall surfaces (31c) are displaced from the center points (3d) of the other louver wall surfaces (32c) along the cooling water flow direction (X1). As a result, the real louver pitch height (HLP) is increased beyond the louver pitch heights (HLP1, HLP2) of the louver wall surfaces (31c, 32c), respectively. Even in the case where the louver width (L) is reduced, therefore, the cooling air can be caught by the louver wall surfaces (3c).

Owner:DENSO CORP

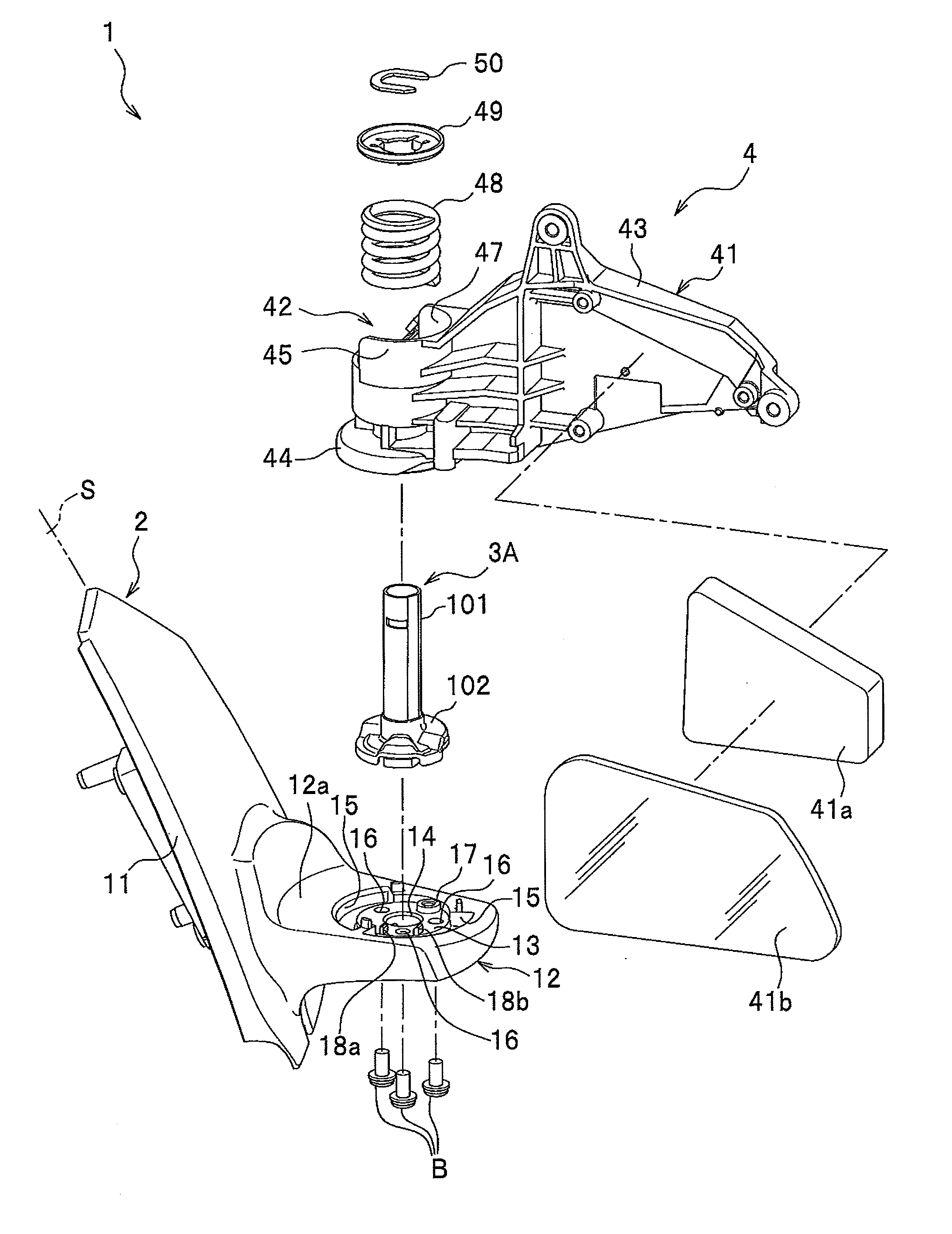

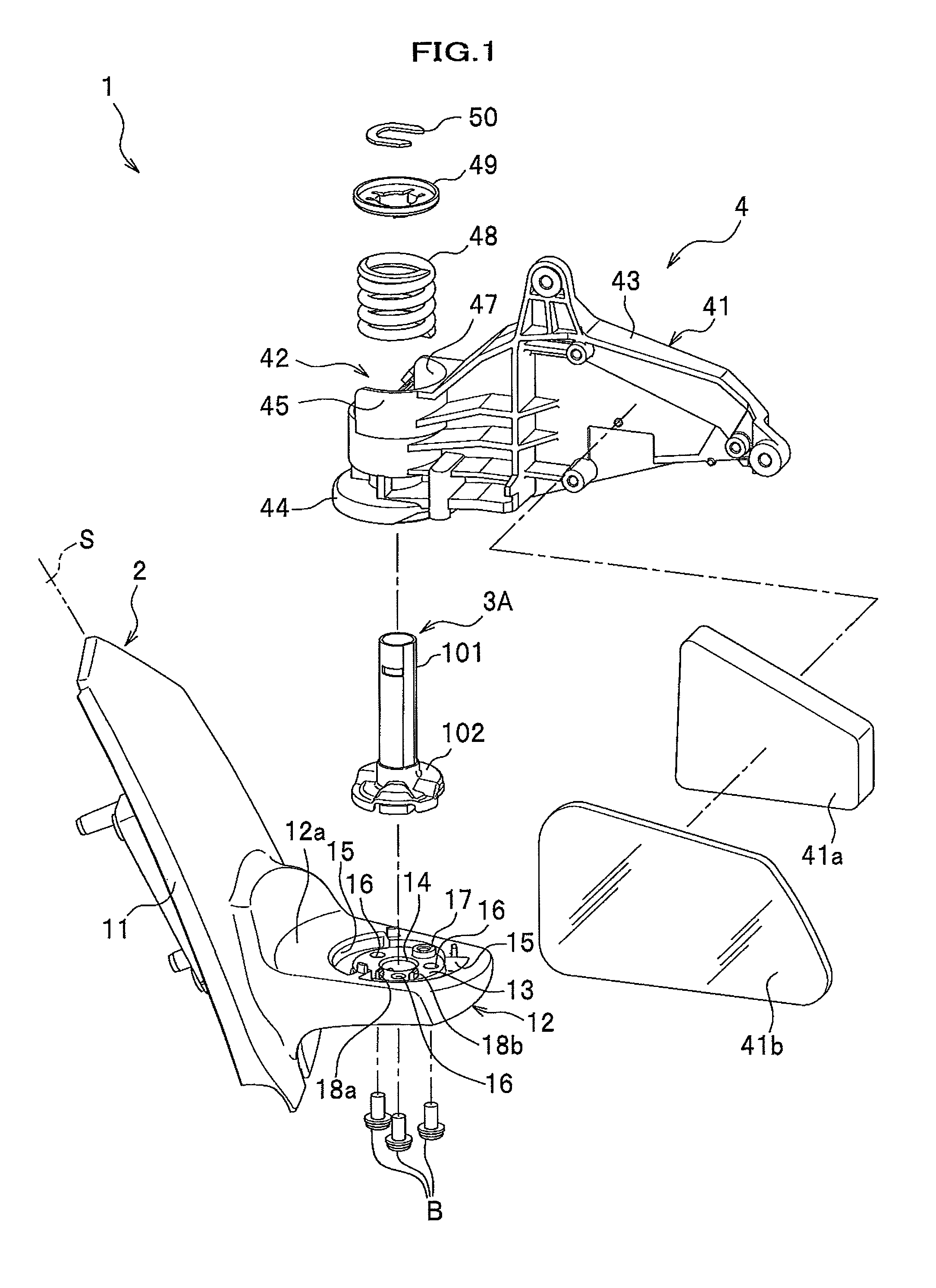

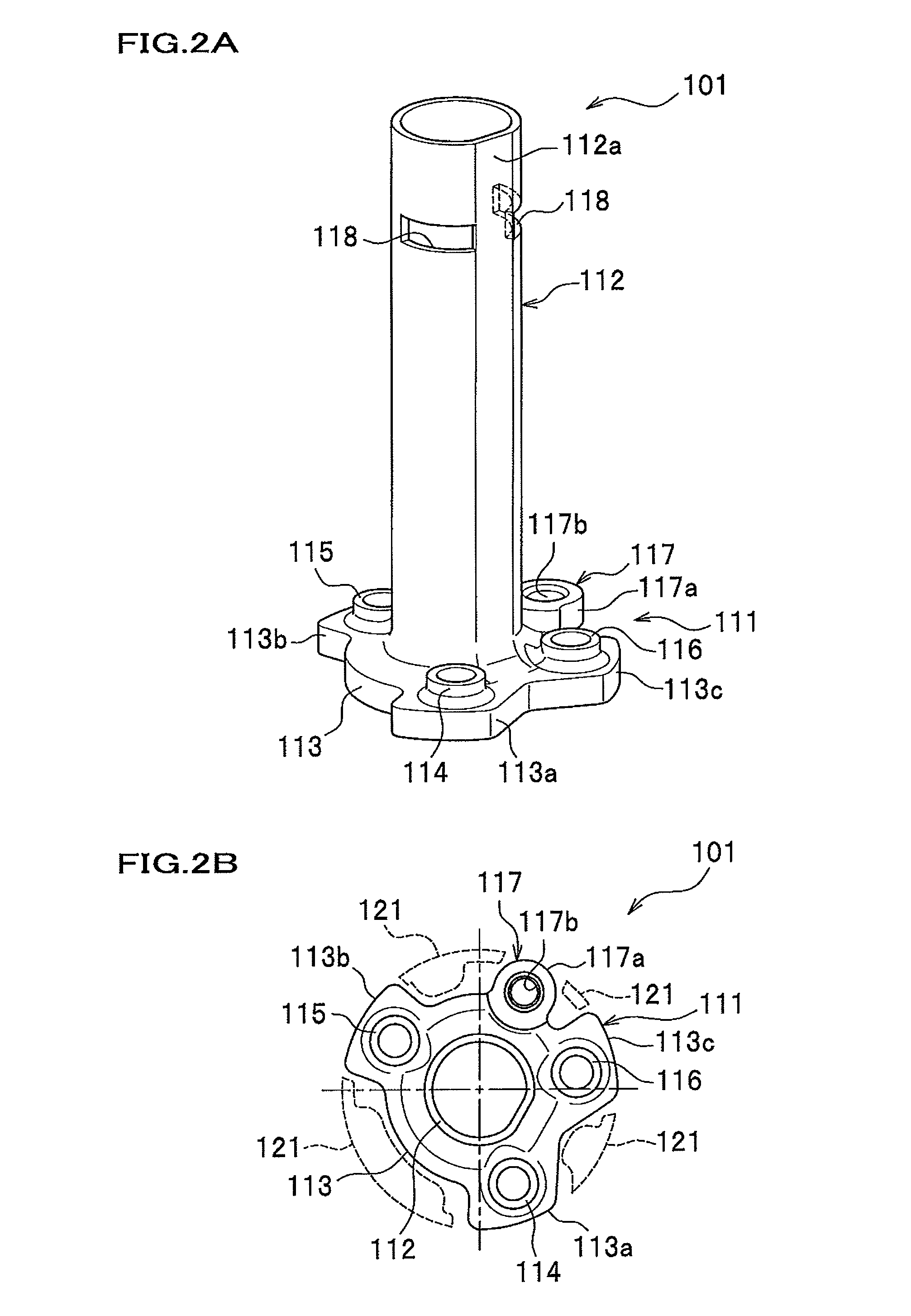

Shaft structure of retractable outer mirror

In a shaft structure of a retractable outer mirror, a shaft includes: a first member; and a second member. The first member includes: a base section having an attachment boss; a shaft section vertically arranged on the base section; and a catch part by which a catch member is caught. The second member includes: clutch parts that performs an engagement or a release of the engagement in response to rotation of a frame; and an insert portion inserted into a shaft section. The second member is fitted in with the shaft section from above a top end side of the shaft section.

Owner:MURAKAMI CORP

Spring feeder

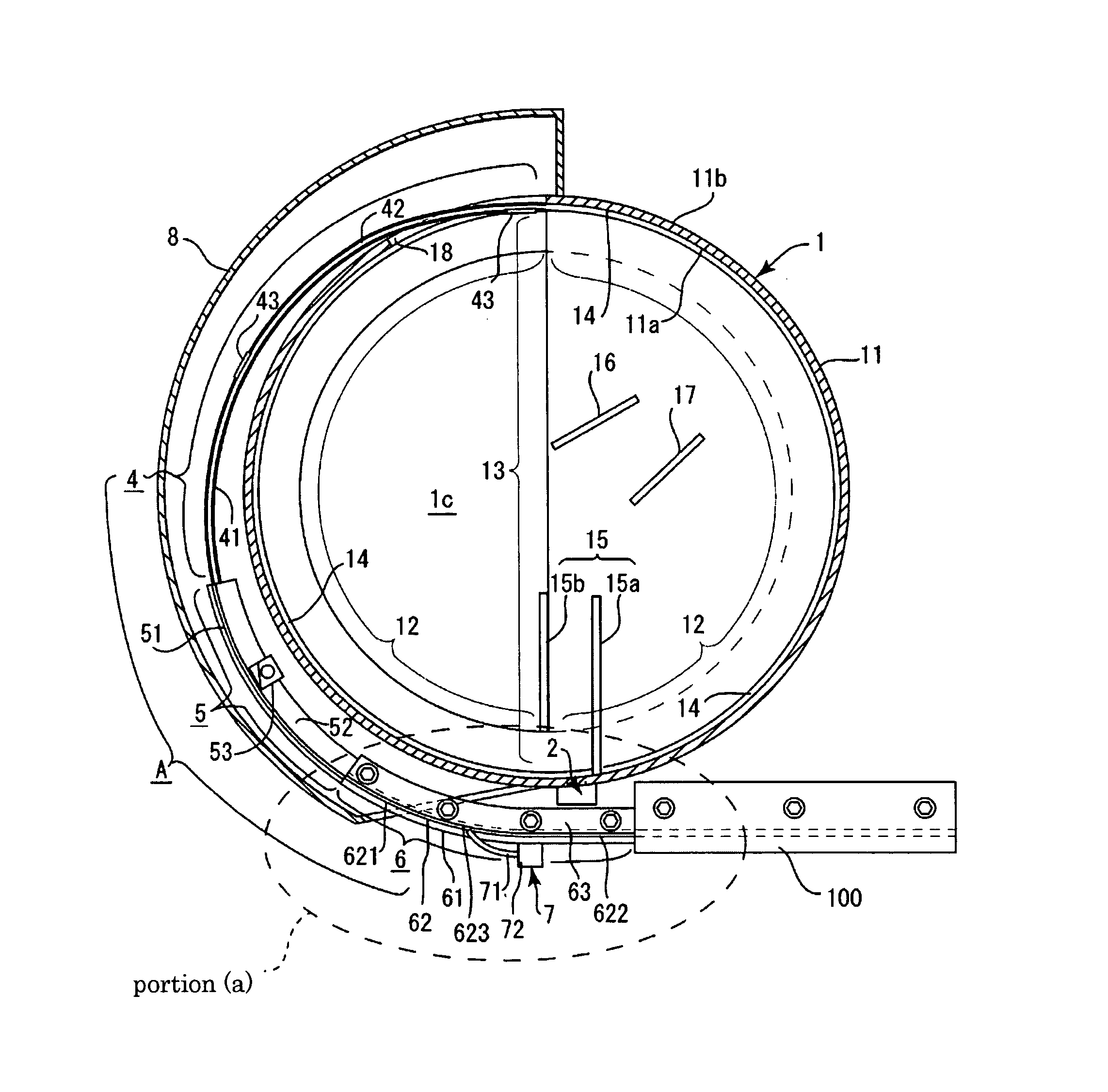

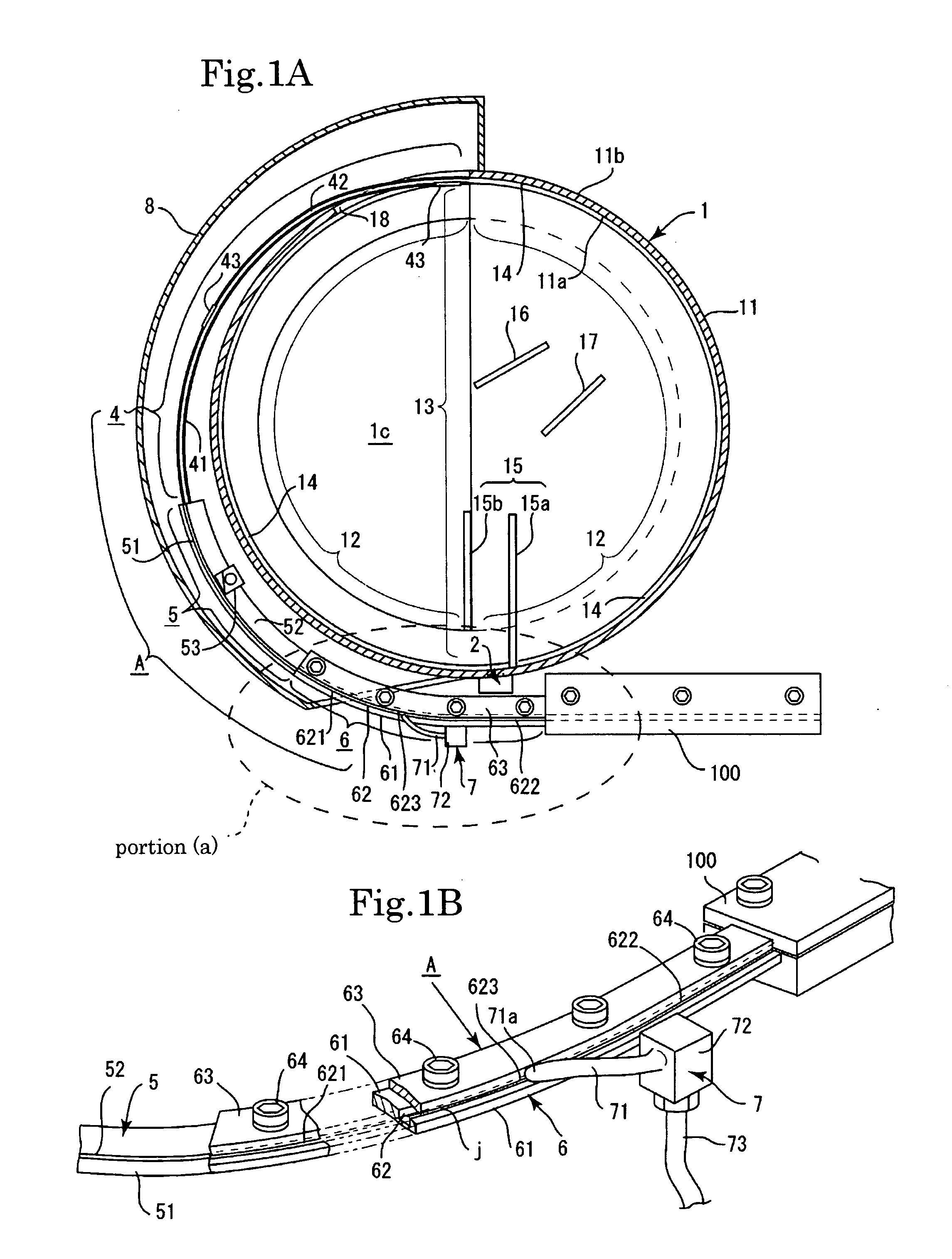

ActiveUS8640852B2Easily caughtLoss of air pressureSortingJigging conveyorsEngineeringMechanical engineering

Owner:KANTO ELECTRONICS

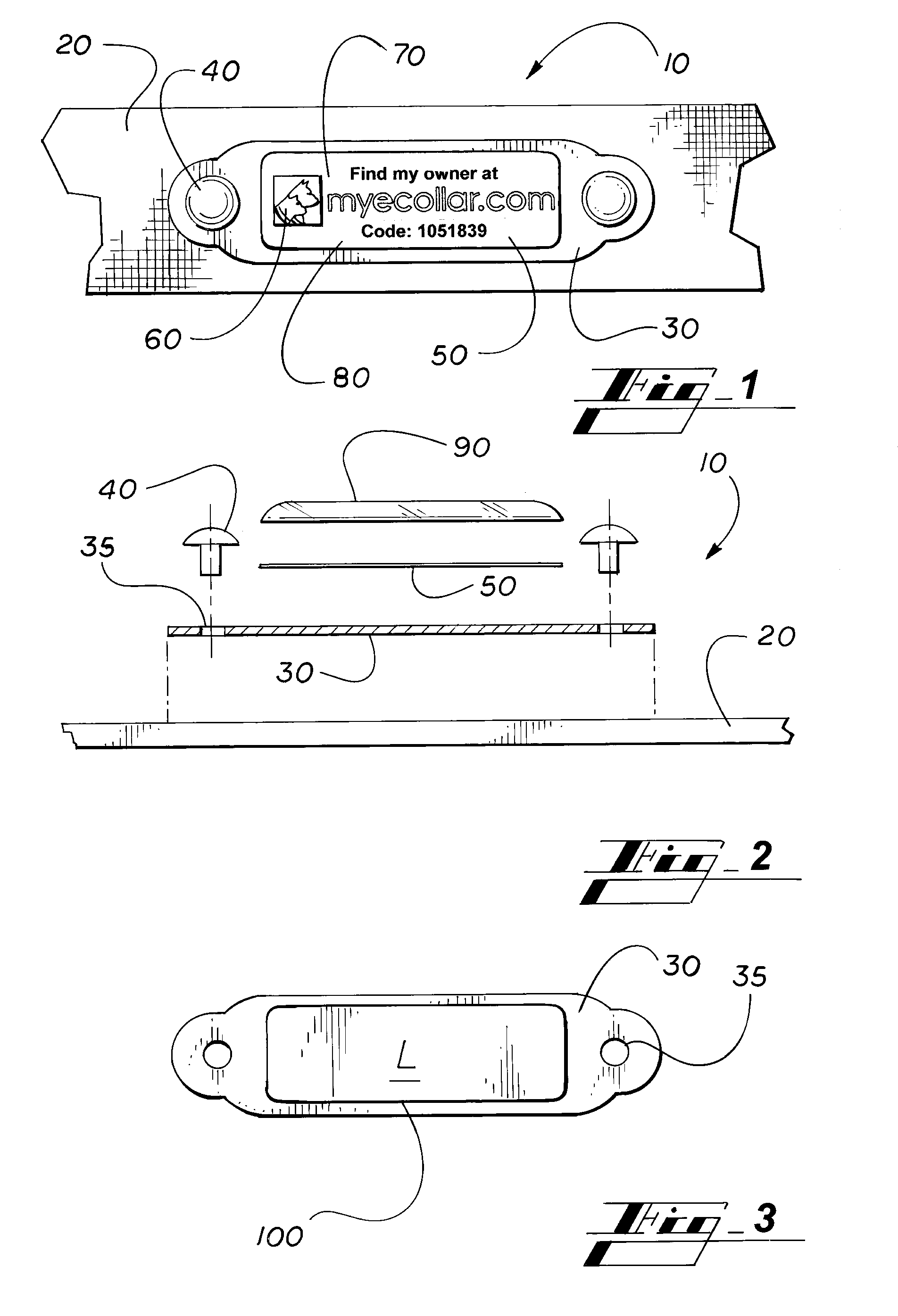

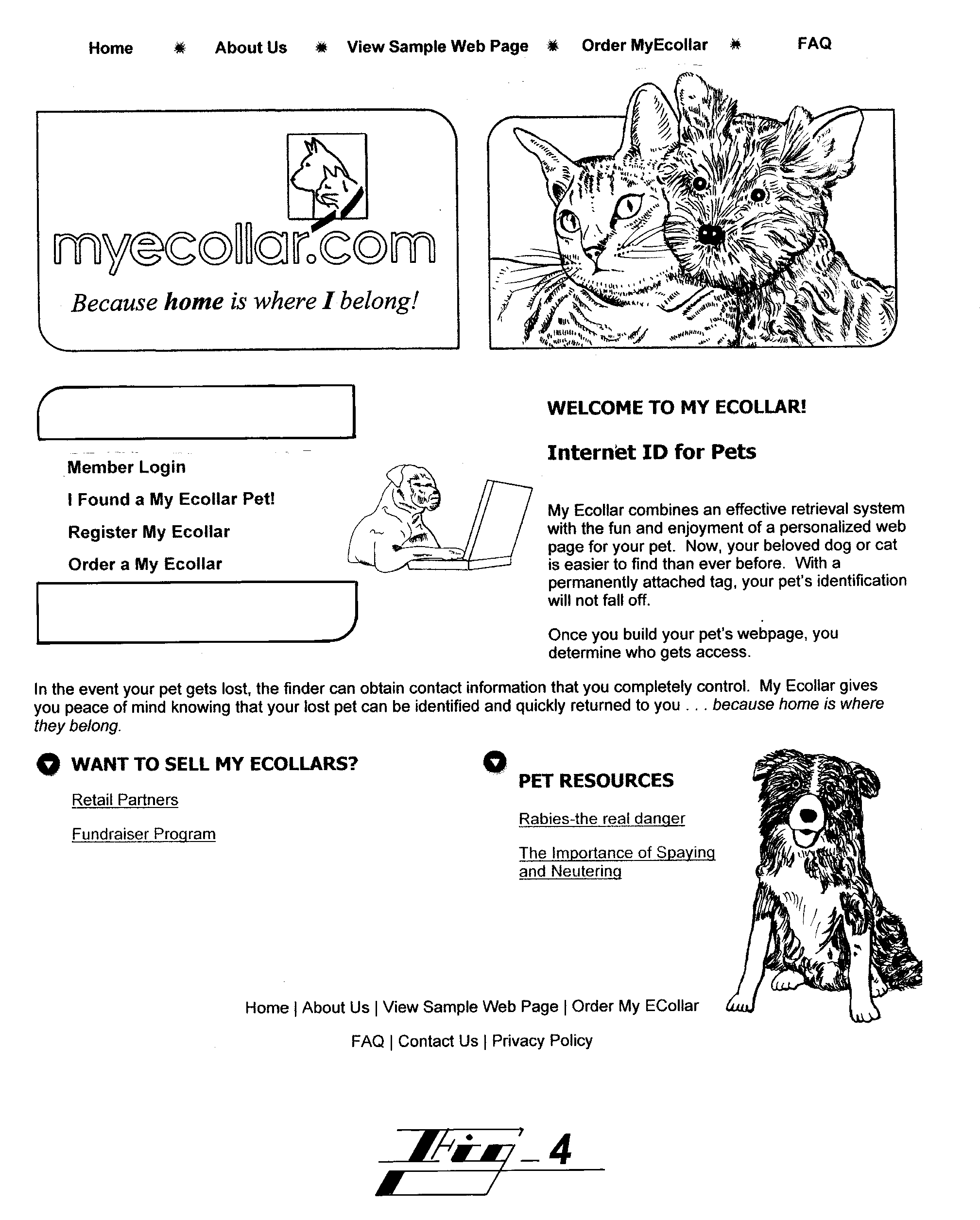

Pet Identification and Retrieval System

InactiveUS20090288616A1Assisted recoveryEasily dislodged from collarSafety beltsAlarmsInternet privacyCompanion animal

Disclosed is a pet collar comprising a firmly affixed identification tag system with encoded identifier, and a related system and method providing for association of said encoded identifier with one or more webpages providing owner-specified information about the pet, and for assisting an owner's recovery of said pet, if lost.

Owner:CSENAR BEVERLY ANN

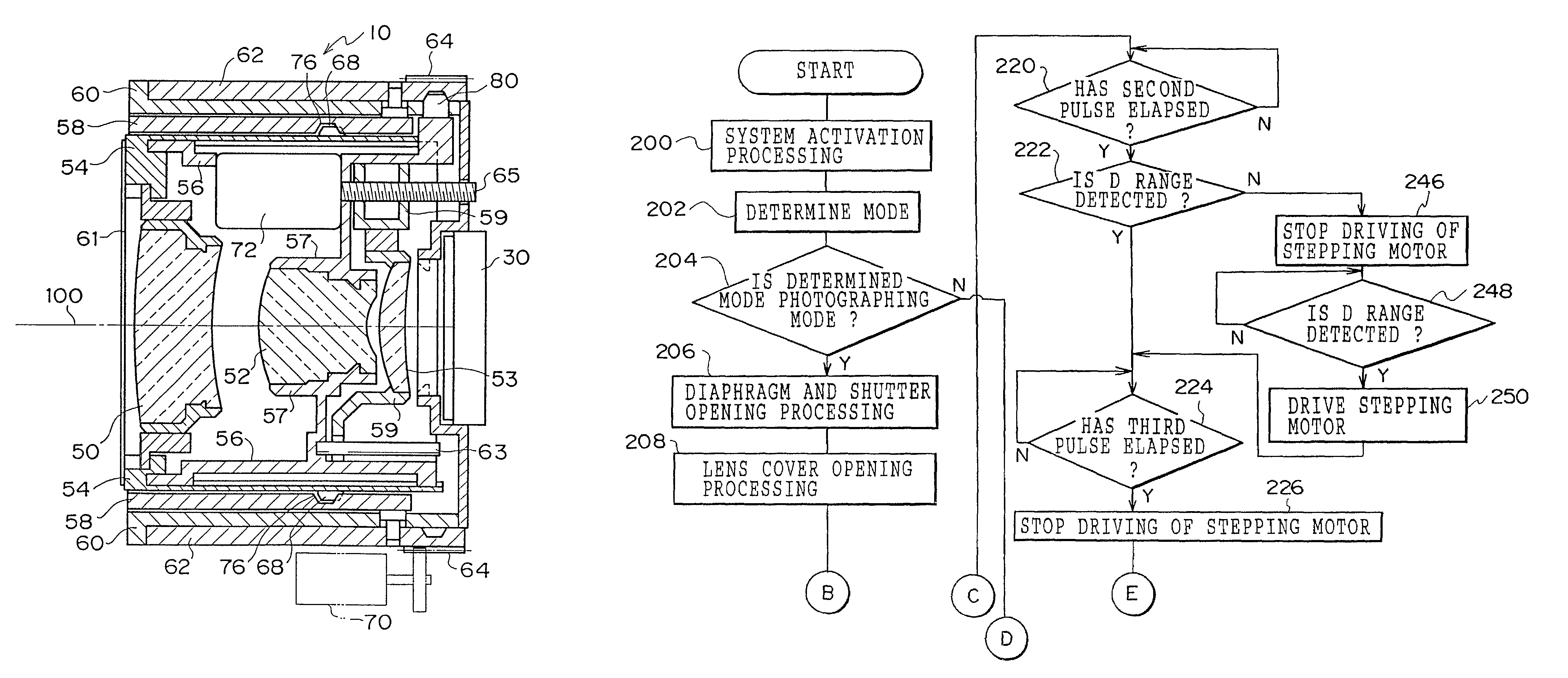

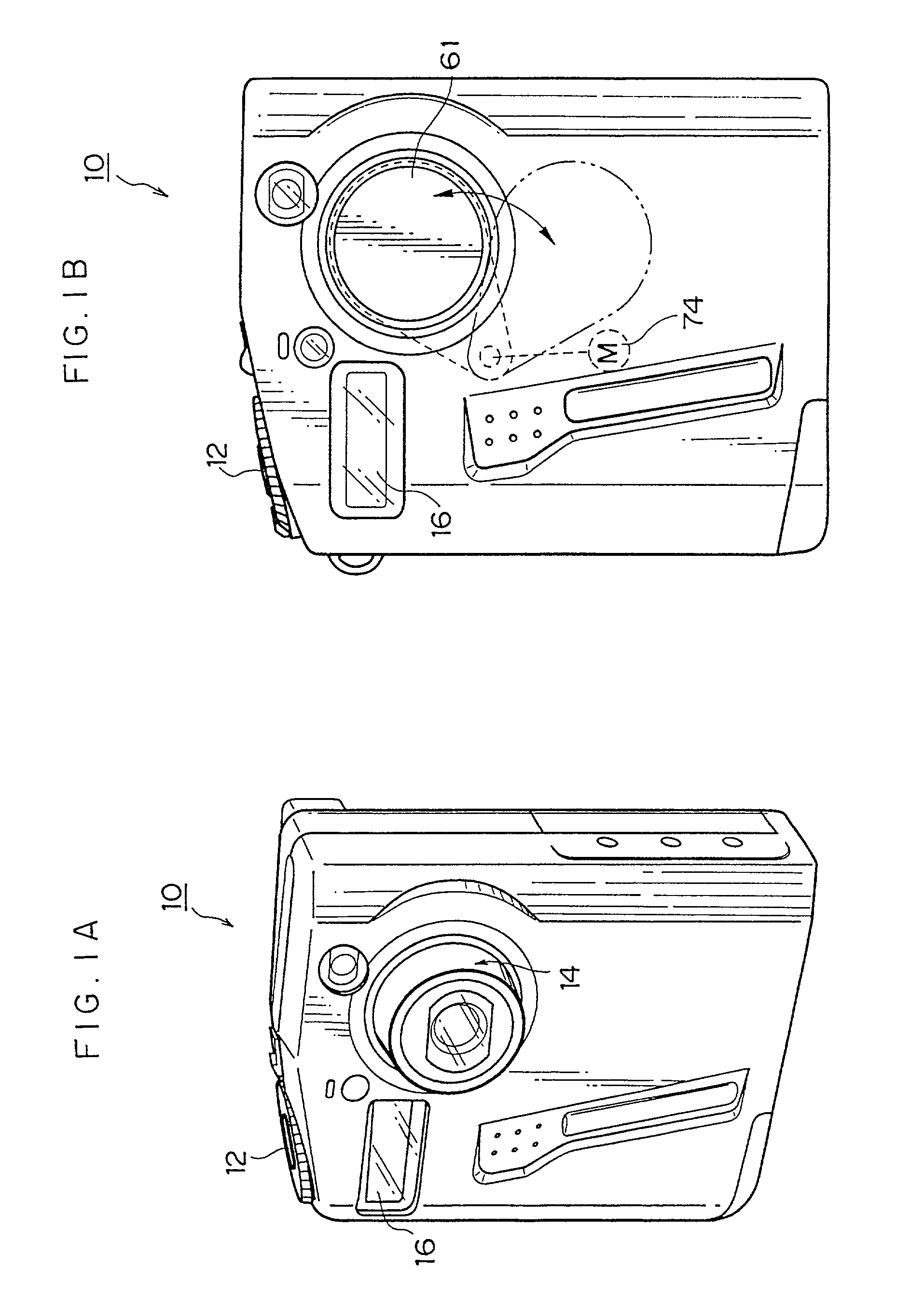

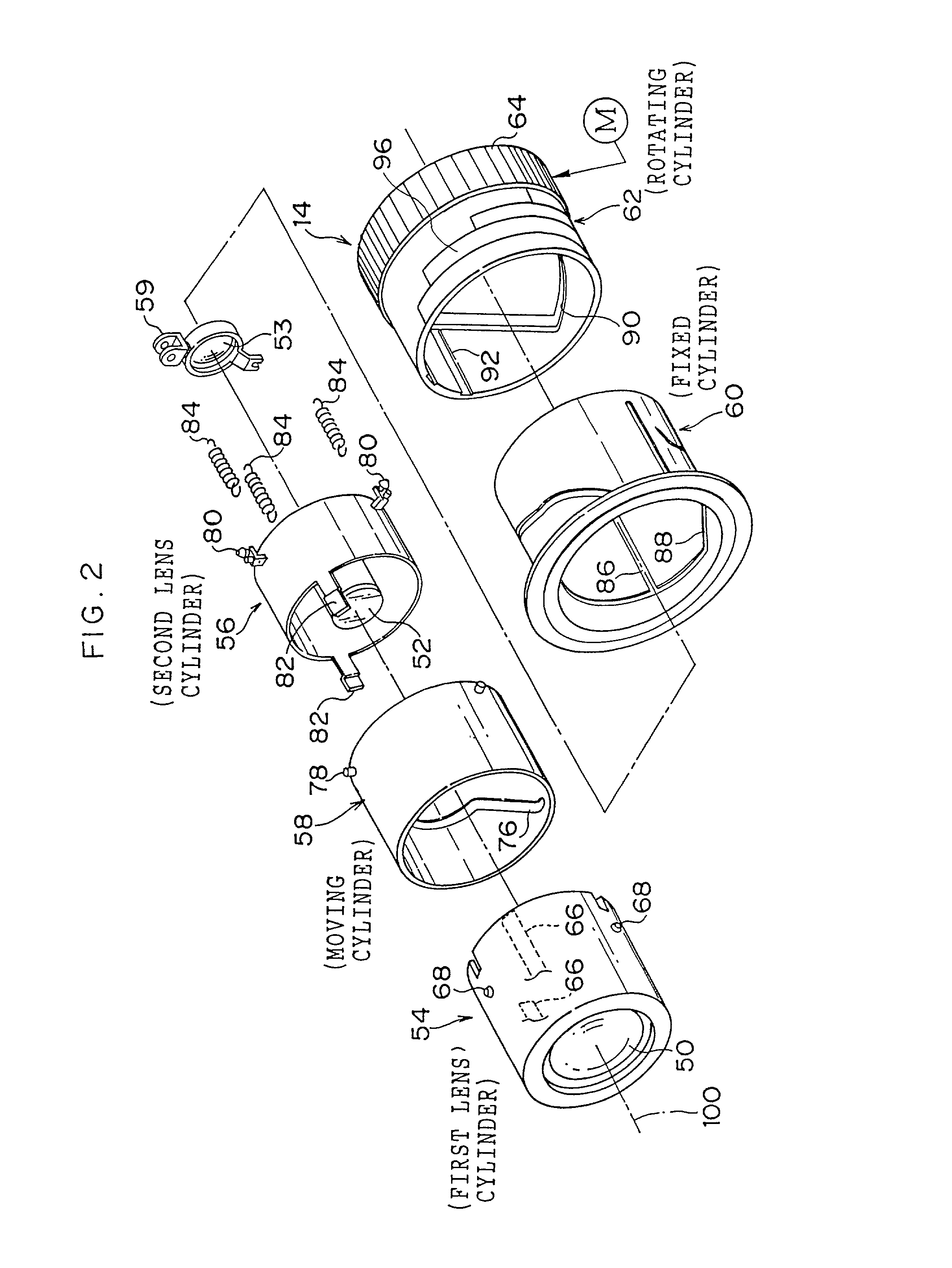

Digital camera for fast start up

InactiveUS7274401B2Reduce startup timeReduce the numberTelevision system detailsColor television detailsCamera lensStart up time

The present invention provides a digital camera in which the start-up time which is from when a power source is turned on until the digital camera is in a state in which photographing is possible is short. A DC motor and a stepping motor are driven simultaneously. A cord plate which is provided in advance at an outer circumferential surface of a rotating cylinder is detected. Then, the stepping motor is driven to move the focus lens by a movement amount corresponding to a detected range of the cord plate. When the setting of various types of components necessary for photographing other than the lens groups has finished, even if the zoom lens groups (forward lens group and backward lens group) are moving to their home positions, the digital camera is in a state in which photographing is possible.

Owner:FUJIFILM CORP

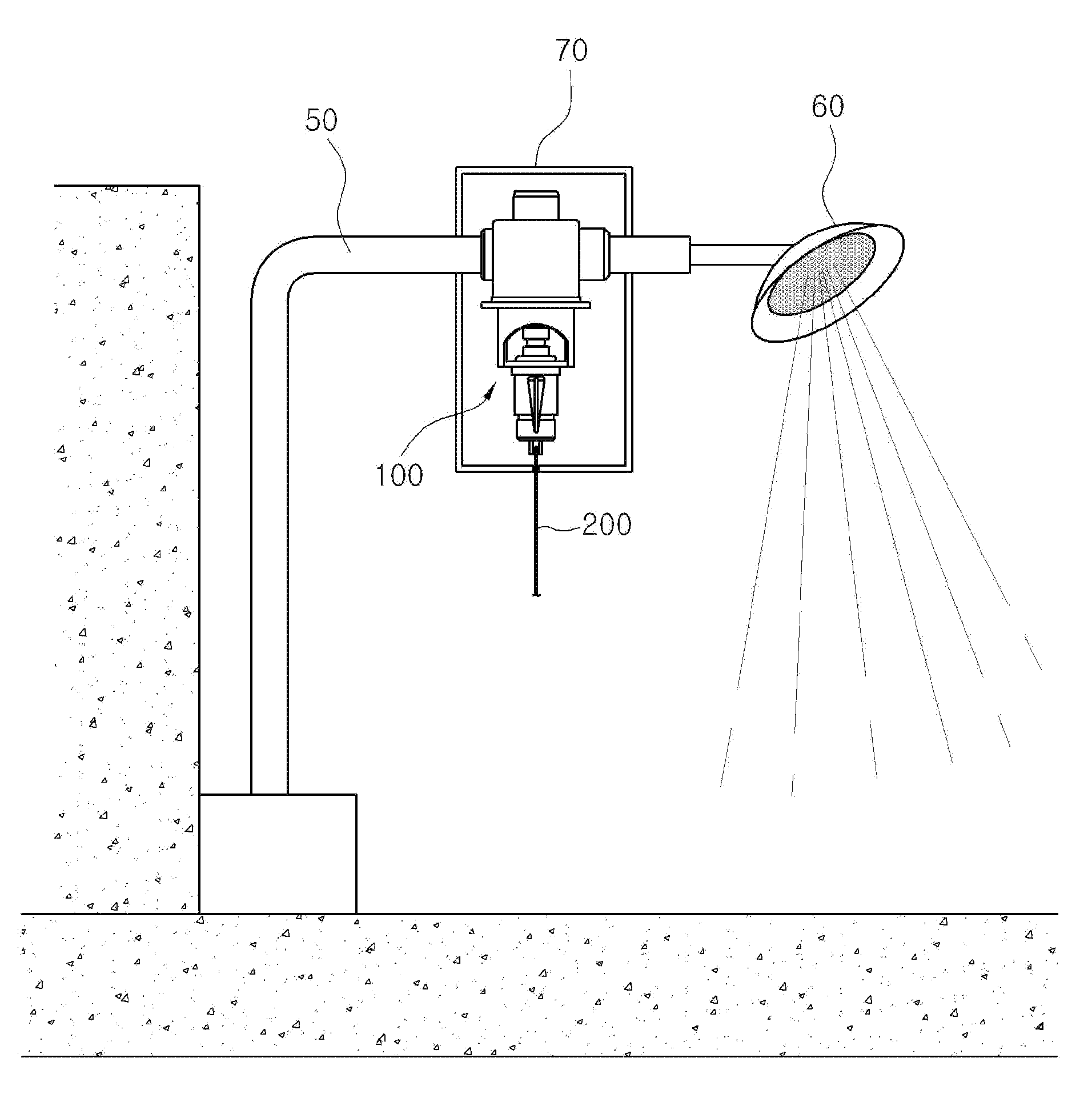

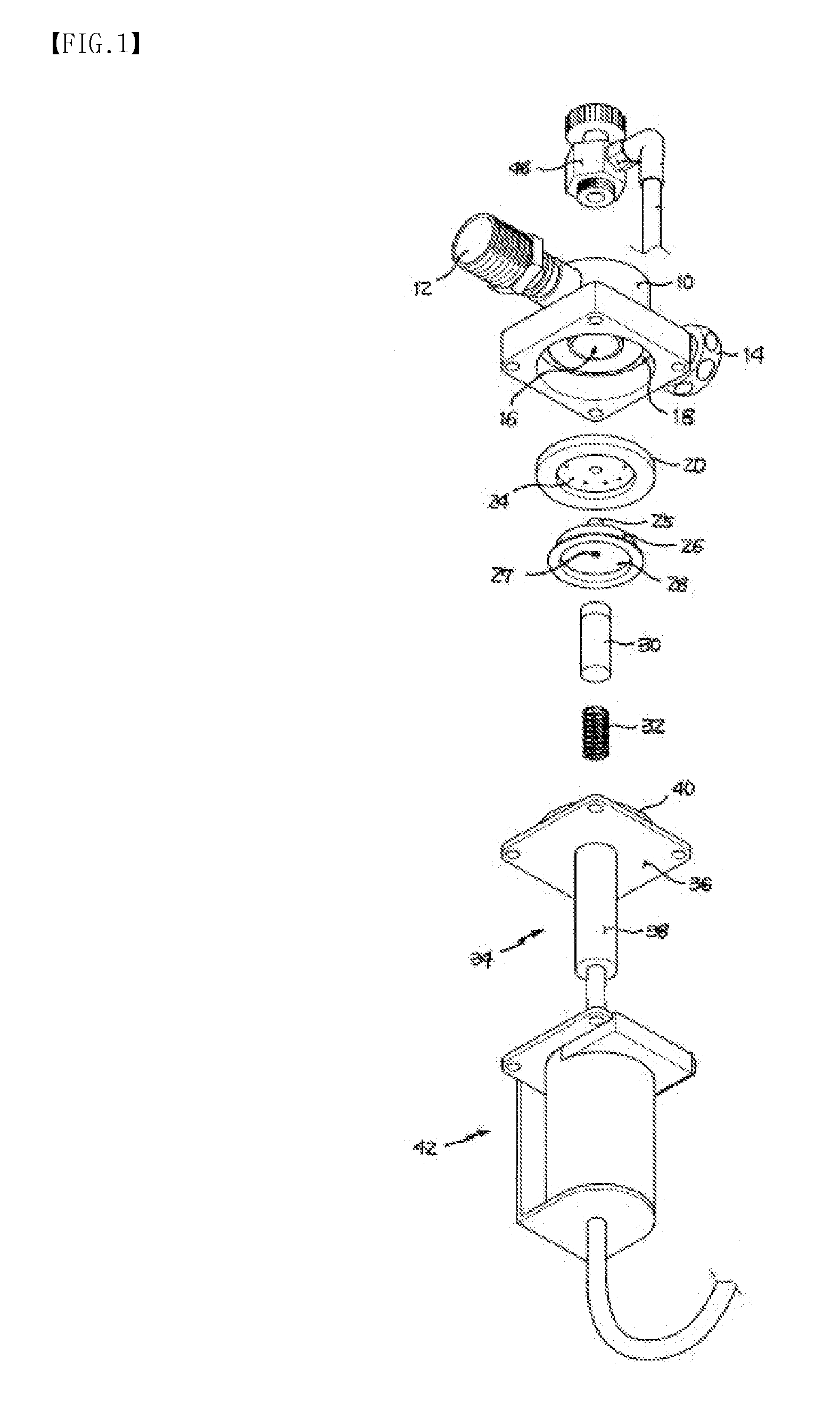

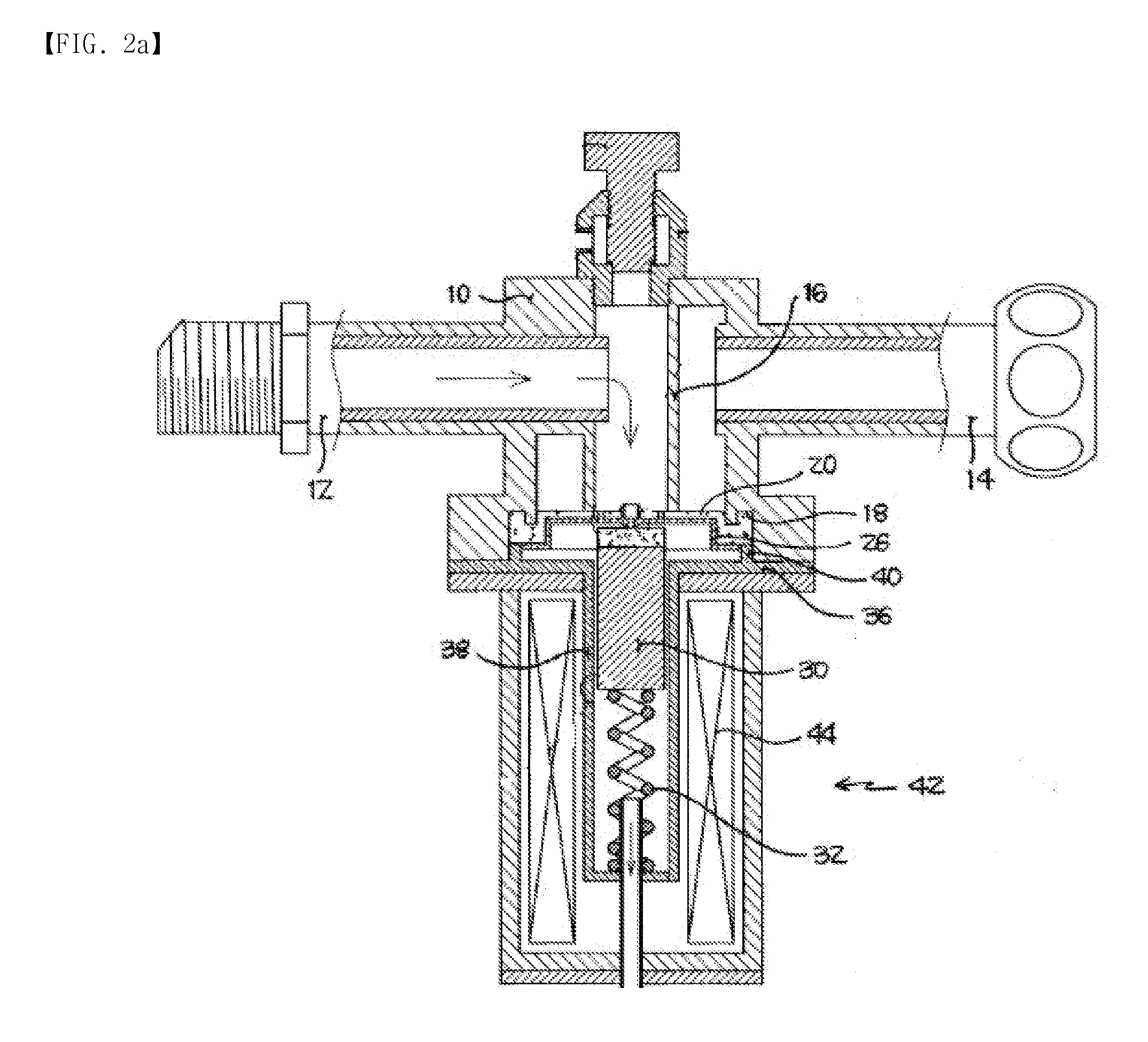

Water saving valve device

InactiveUS20100148104A1Reduce maintenance costsReduce manufacturing costPlug valvesBathsWater savingEngineering

Disclosed herein is a water saving valve device having a valve body, a coupling unit, a spring, an actuating rod, a push plate, and a packing. A manual manipulating unit is coupled to the coupling unit to manually move the actuating rod up and down, and includes a lower body, a slide bar, a spring, and a locking piece. The lower body is coupled to the coupling unit and has a vertical pipe on its lower portion. The slide bar has on its upper end a magnet, thus vertically moving the actuating rod by magnetic force. The spring is fitted over the lower portion of the slide bar. The upper end of the locking piece is alternately stopped by first and second locking holes when the slide bar moves up and down, and the lower end is supported by the outer circumference of the vertical pipe.

Owner:HO YEONG JEONG

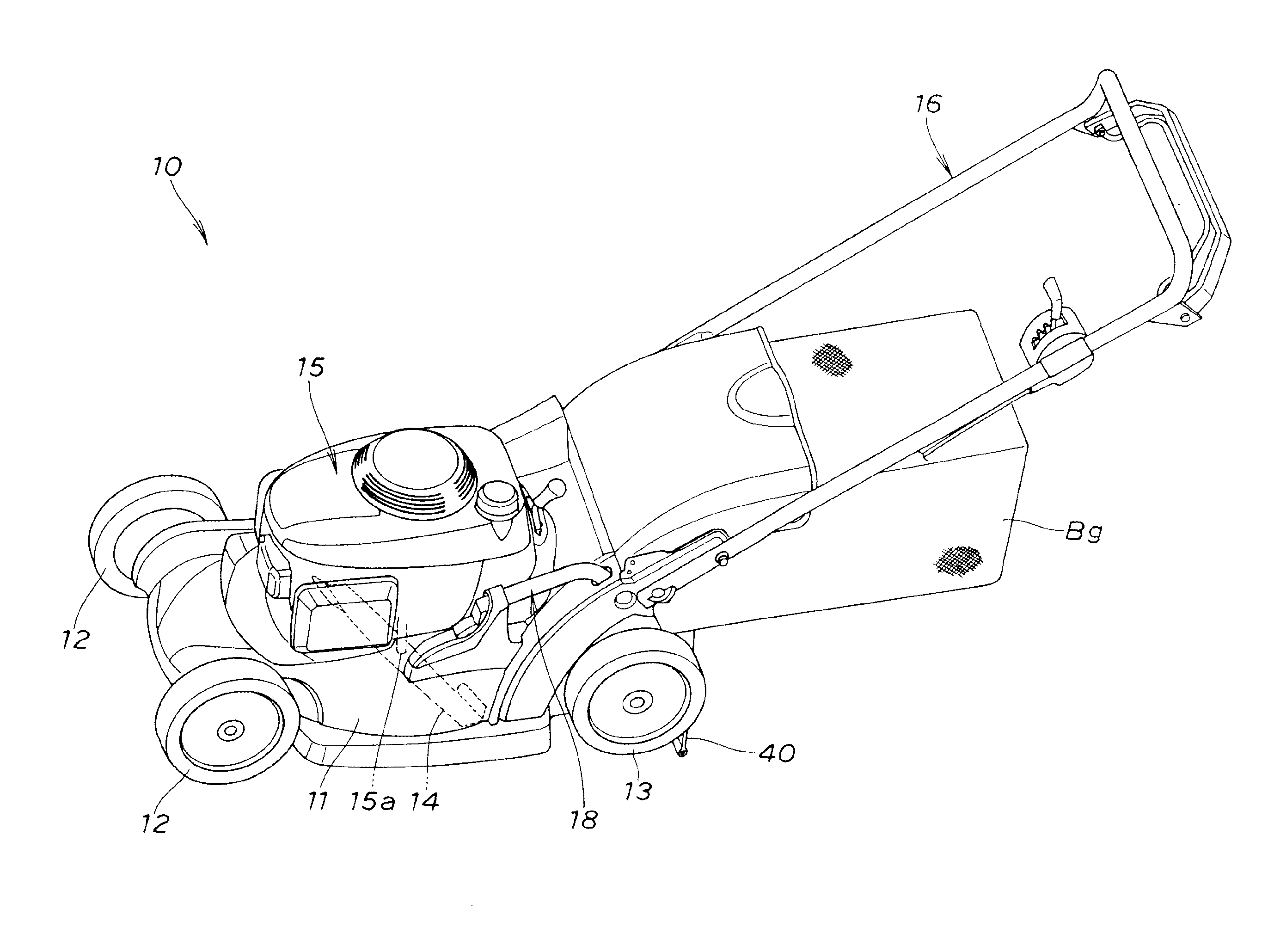

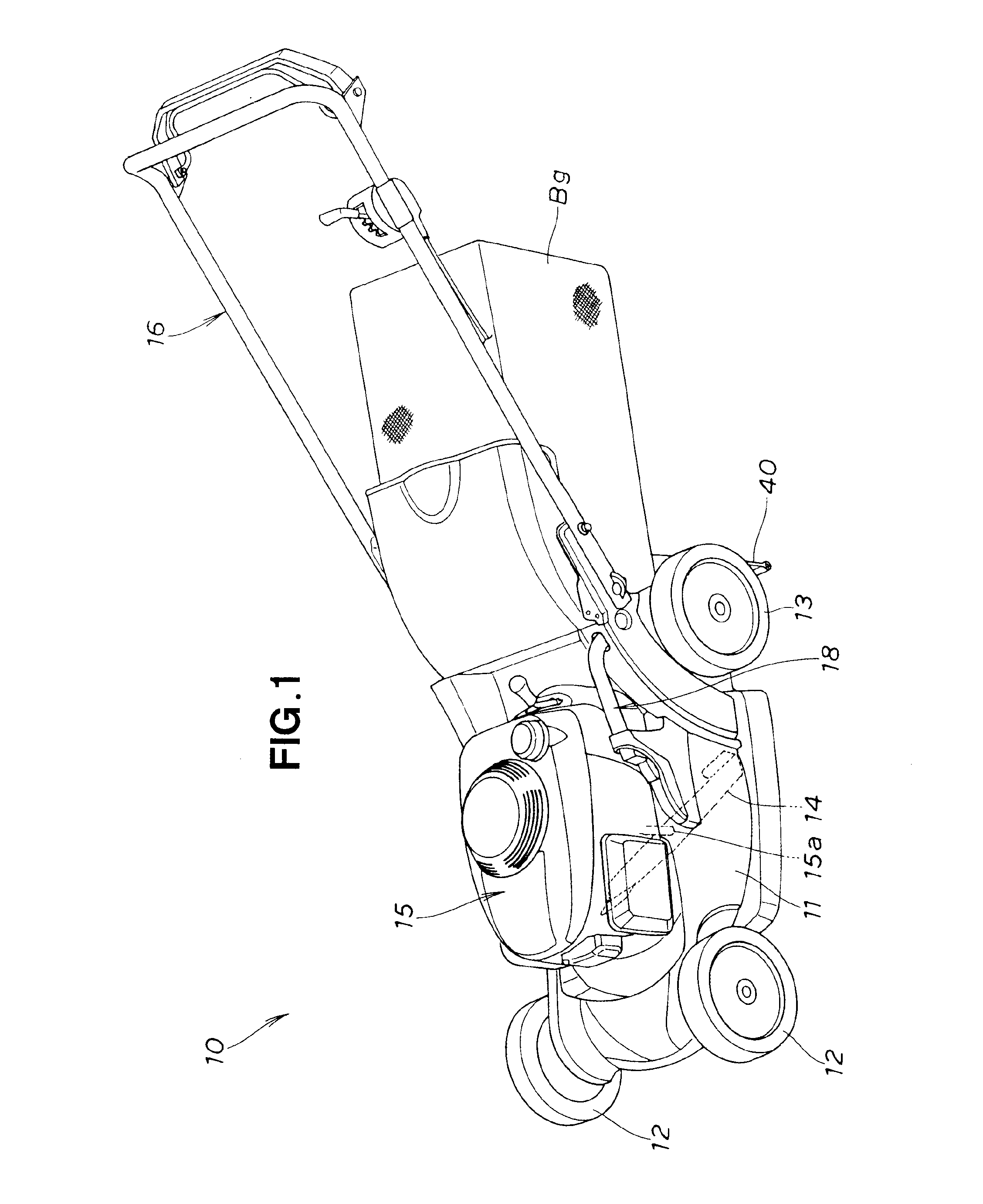

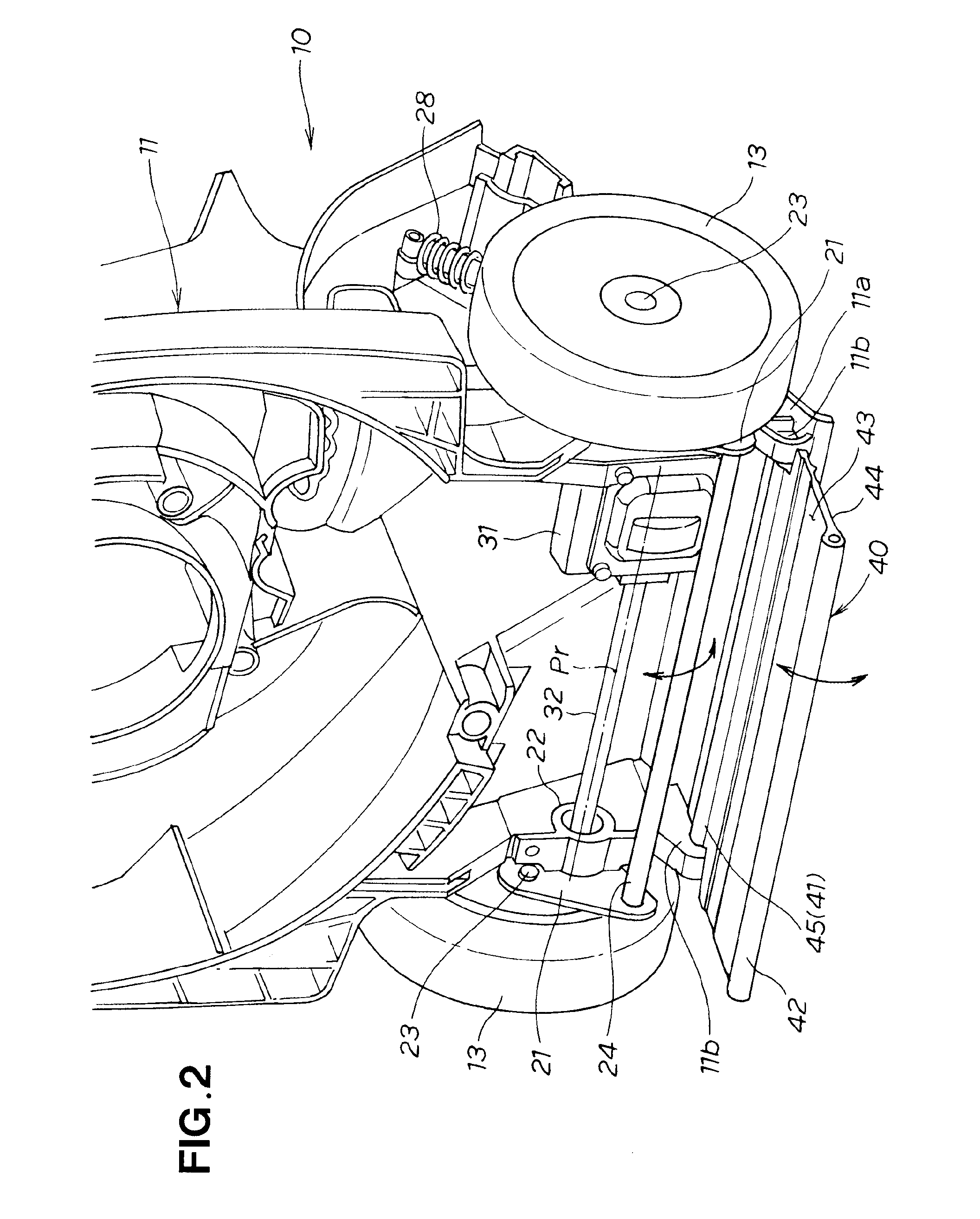

Walk-behind lawnmower having a rear shield

ActiveUS8522518B2Minimize bendingReduce rigidityLawn-mowersAgricultural undercarriagesEngineeringMower

The rear shield of a walk-behind lawnmower extends downward from a rear end part of a housing and is in the form of an elastic sheet. The sheet has a thin-walled part formed in a central site in a heightwise direction between an upper end part and a lower end part, the upper end part being attached to the rear end part of the housing. The thin-walled part has a thickness set to be smaller than a thickness of other parts.

Owner:HONDA MOTOR CO LTD

Cup holder

ActiveUS20130256351A1Easily caughtTravelling carriersVehicle arrangementsMechanical engineeringEngineering

Owner:TOYODA GOSEI CO LTD +1

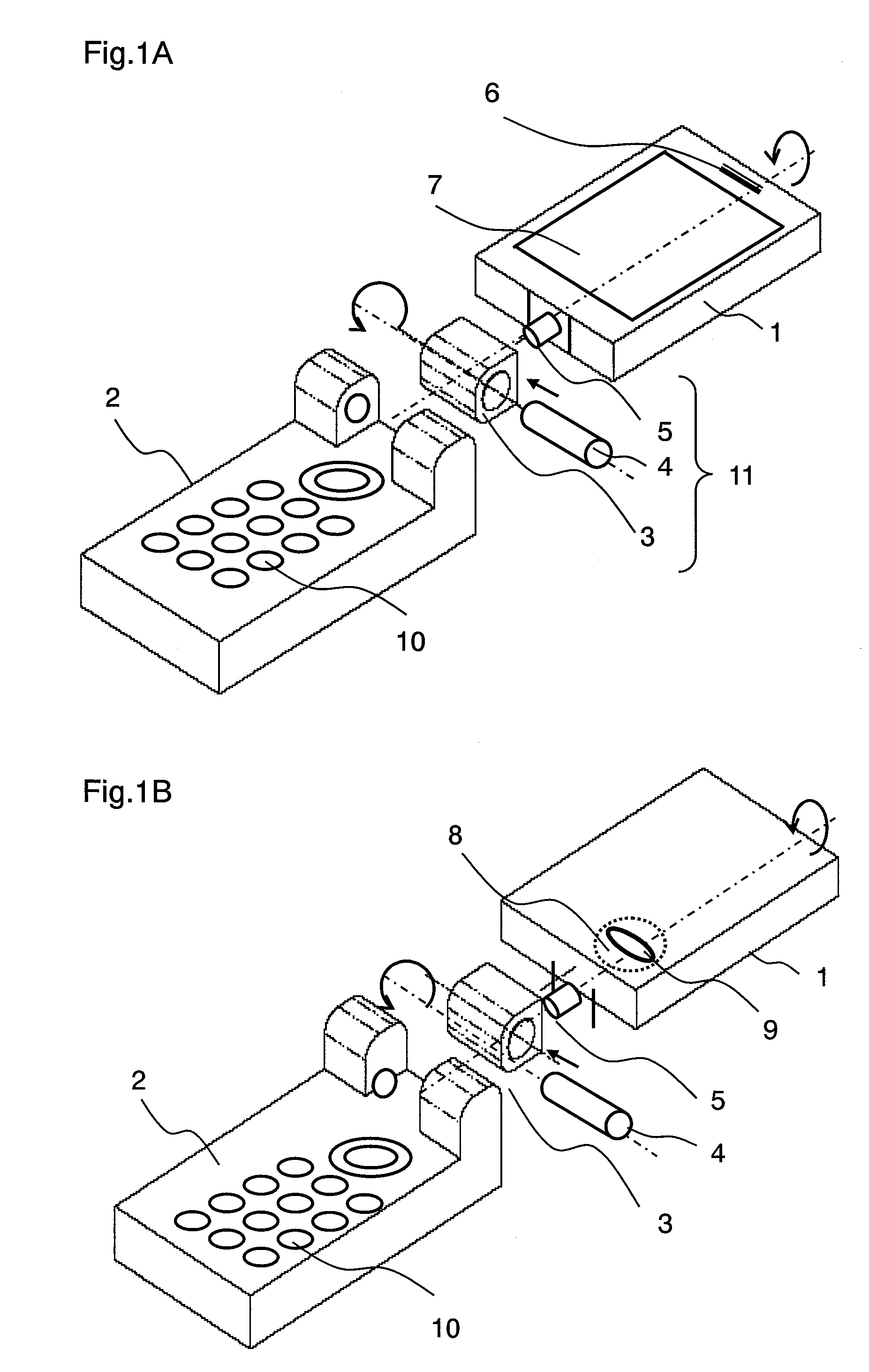

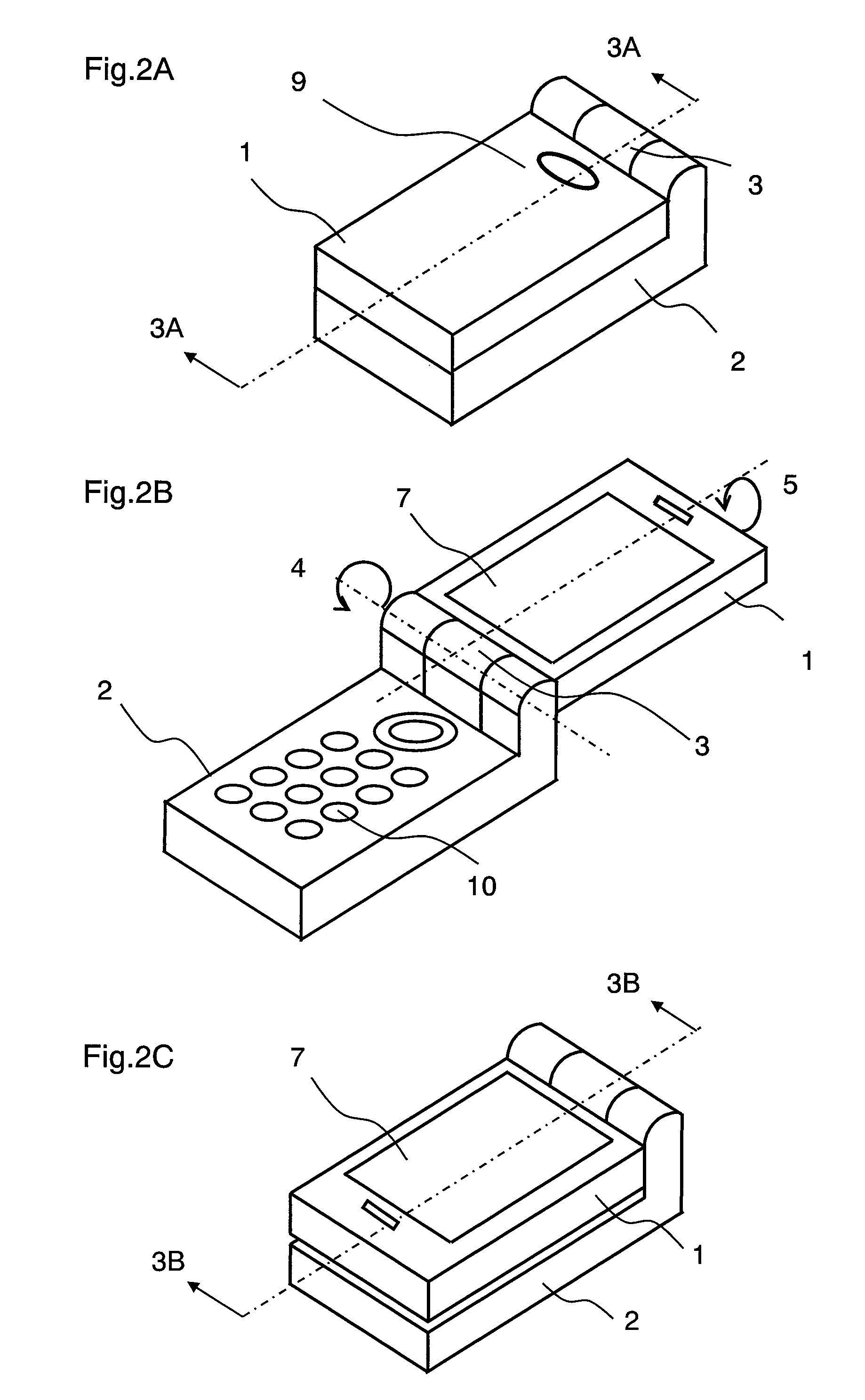

Foldable portable terminal device

InactiveUS7856256B2Easily caughtSecure spaceTransmissionTelephone set constructionsCouplingTerminal equipment

A foldable portable terminal device provided with a first housing includes a display unit, a speaker and a speaker sound hole, a second housing, and a hinge unit that couples the housings rotatably around two directions that perpendicularly intersect with each other. The device is configured such that coupling of the first housing and the hinge unit is coupled to a second rotary shaft of the hinge unit at a position closer to a surface having the speaker sound hole than a midpoint in a cross-section in a thickness direction of the first housing, and that a gap formed in a folded state in which the first housing is overlaid on the second housing with a surface having the speaker sound hole facing inside is greater than a gap formed in the folded state with the surface having the speaker sound hole facing outside.

Owner:PANASONIC CORP

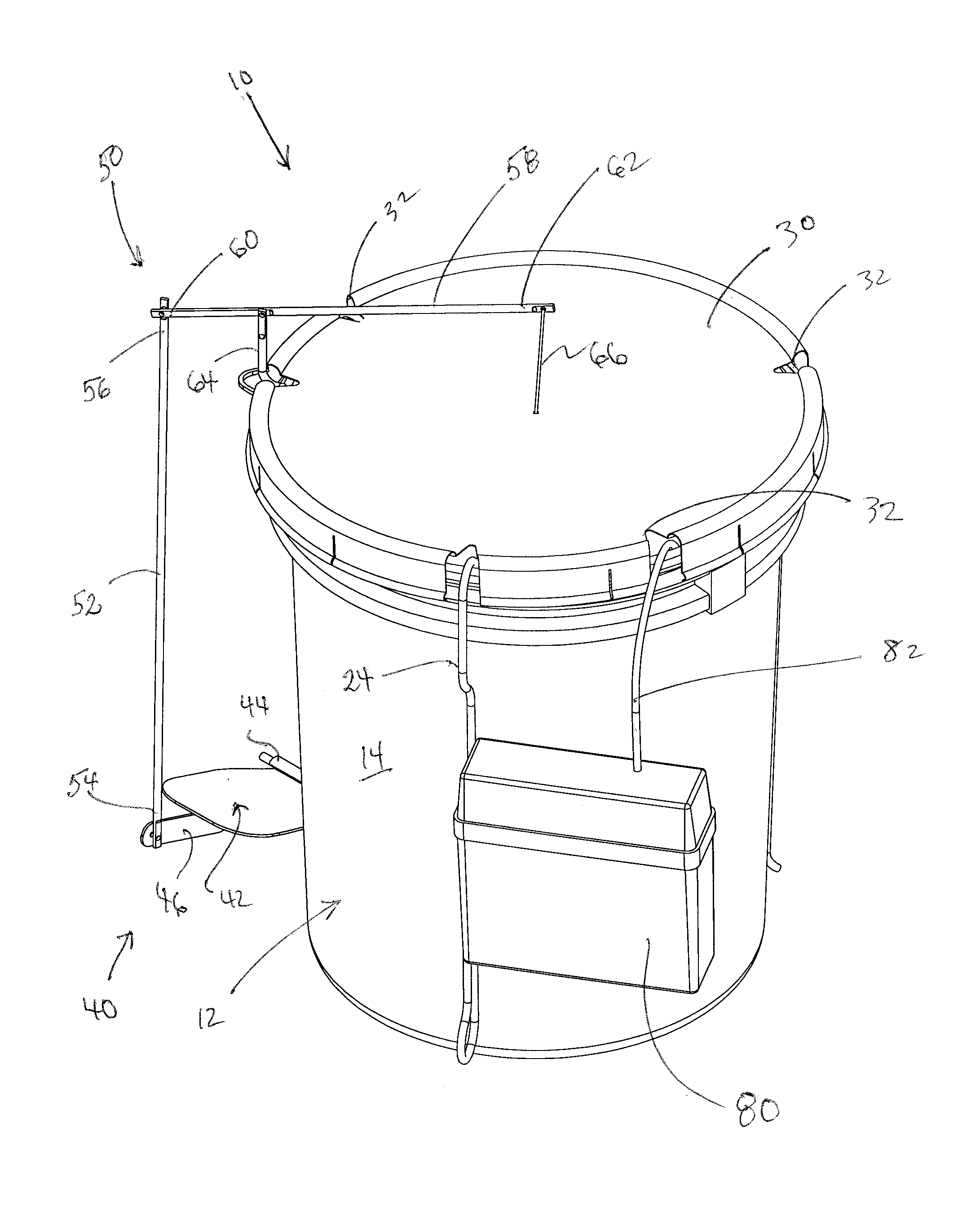

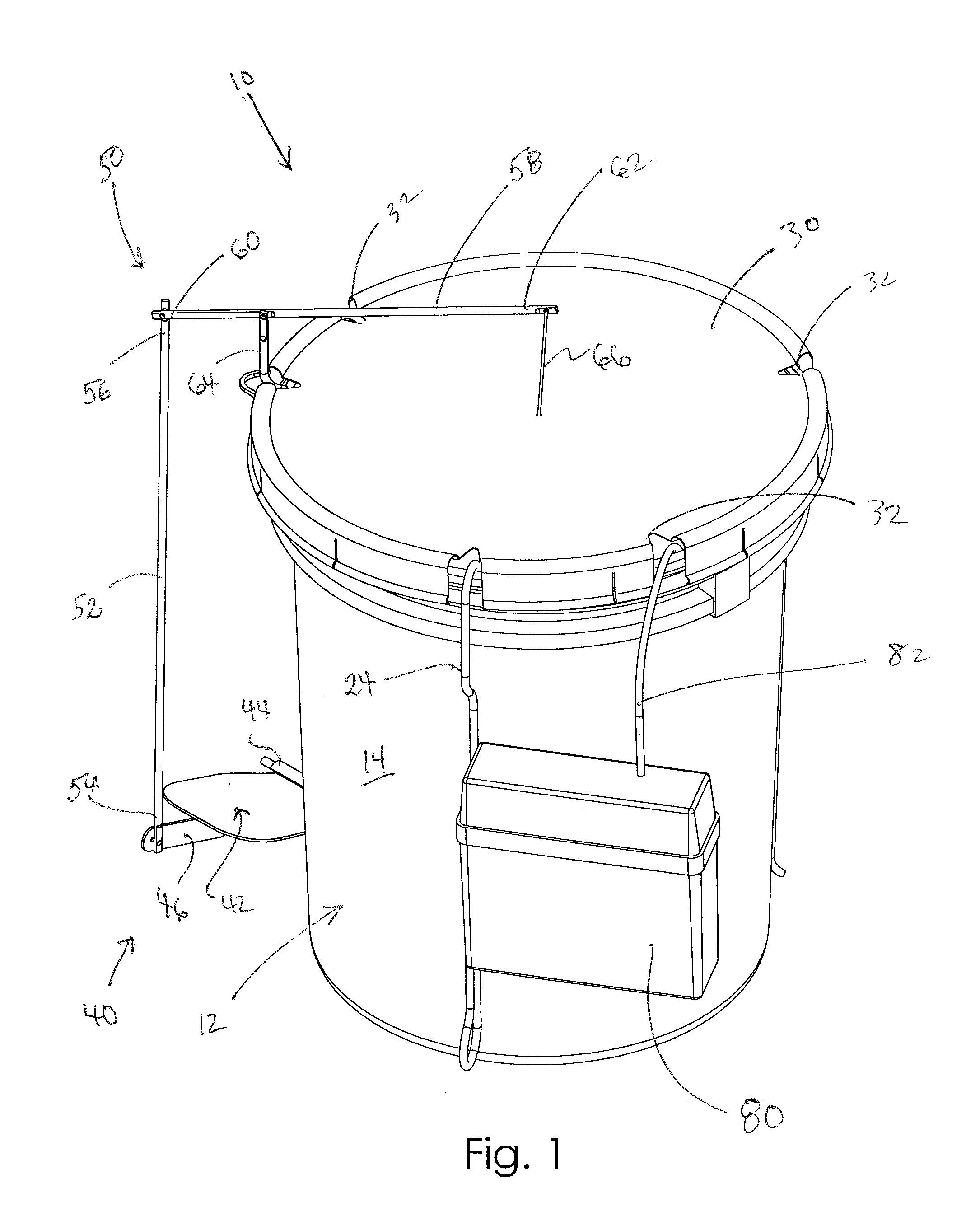

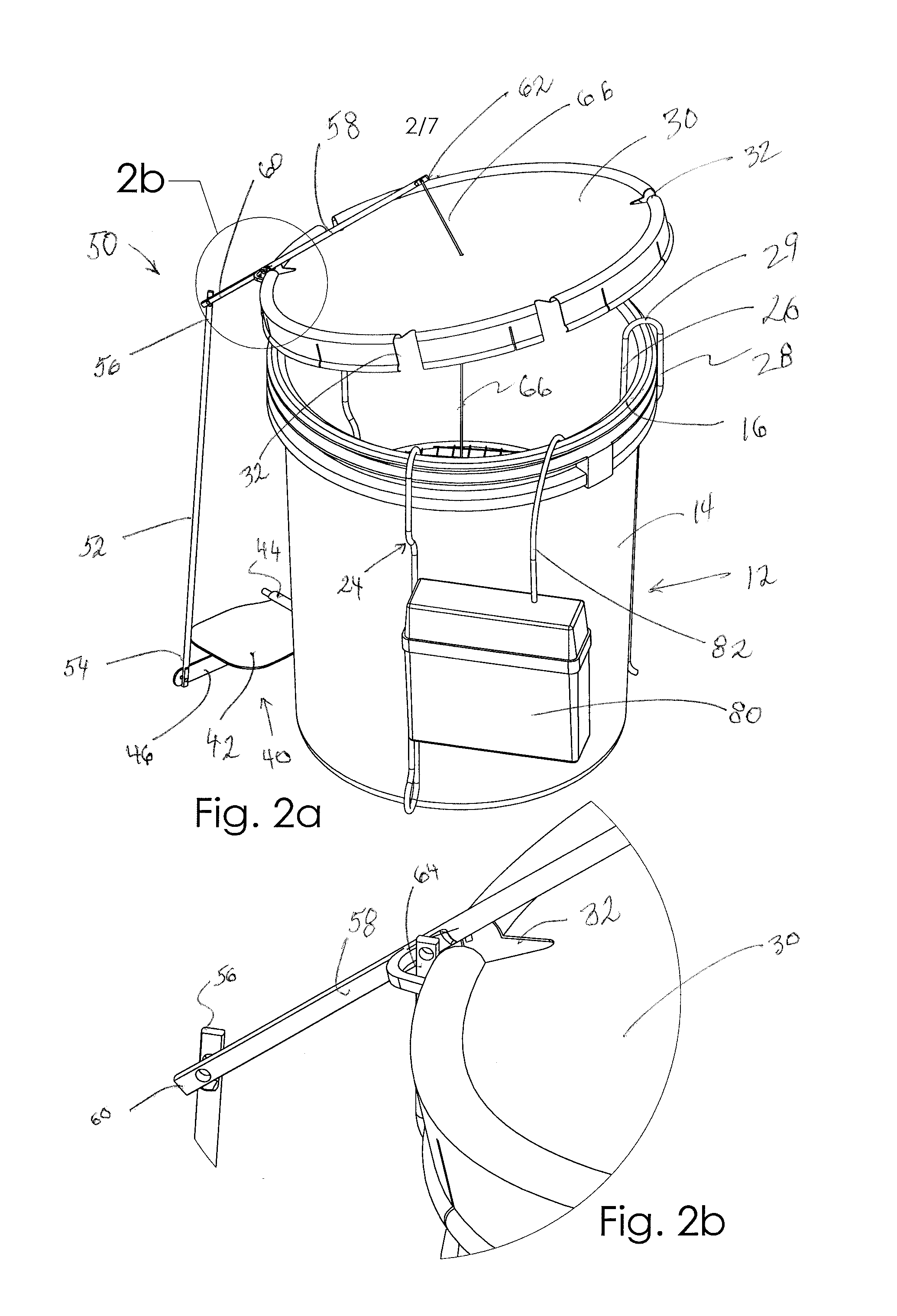

Hands-Free Bait Storage and Retrieval Apparatus

A hands-free bait storage and retrieval apparatus for use with a bucket having a continuous side wall defining an interior area and an open top includes a mounting frame having an upper ring and a plurality of mounting fasteners configured to selectively couple the upper ring to the bucket side wall such that the upper ring is situated in the bucket interior area and adjacent the open top thereof. A basket is selectively positioned in the bucket interior area. The apparatus includes a lifting assembly having a foot pedal and a linkage operatively coupling the foot pedal to the basket, the foot pedal being movable between a deployed configuration at which the basket is at a raised configuration within the bucket interior area and a released configuration at which the basket is at a lowered configuration within the bucket interior area.

Owner:SCHEIBMEIR ARGIE

Pilfer-proof cash register

A cash register is provided with a pilfer prevention construction. Openings are formed in both the cash tray and the bottom panel of the sliding drawer as well as the bottom panel of the cash register. The opening of the sliding drawer is covered with a transfer door panel hingedly mounted at its front edge to the bottom panel of the drawer. A spring-biassed latch maintains the transfer door panel in a closed position when the drawer extends outside the cash register. A control means is provided which is operative to release the latch so that the transfer door panel will swung open downwards through the opening of the bottom of the cash register to dispense money from cash tray into a safety deposit box located below the cash register. The transfer door panel will be automatically closed whenever the sliding drawer moves outwards.

Owner:INTEL CORP

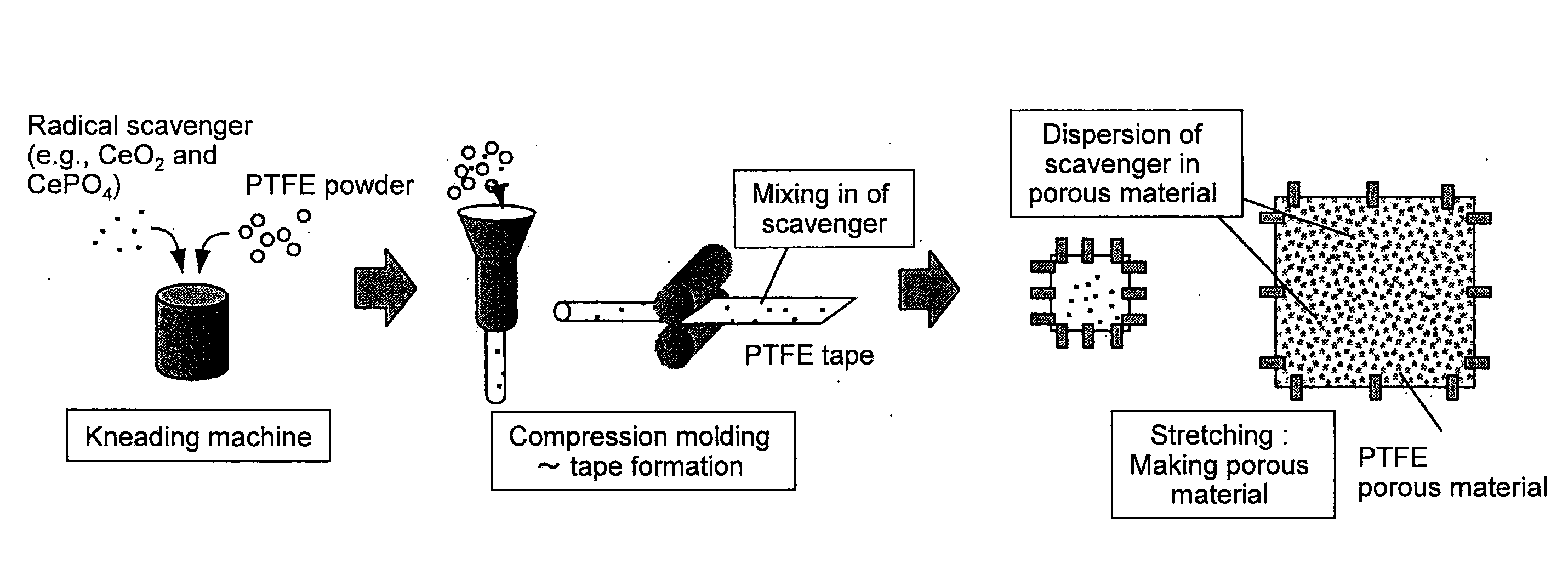

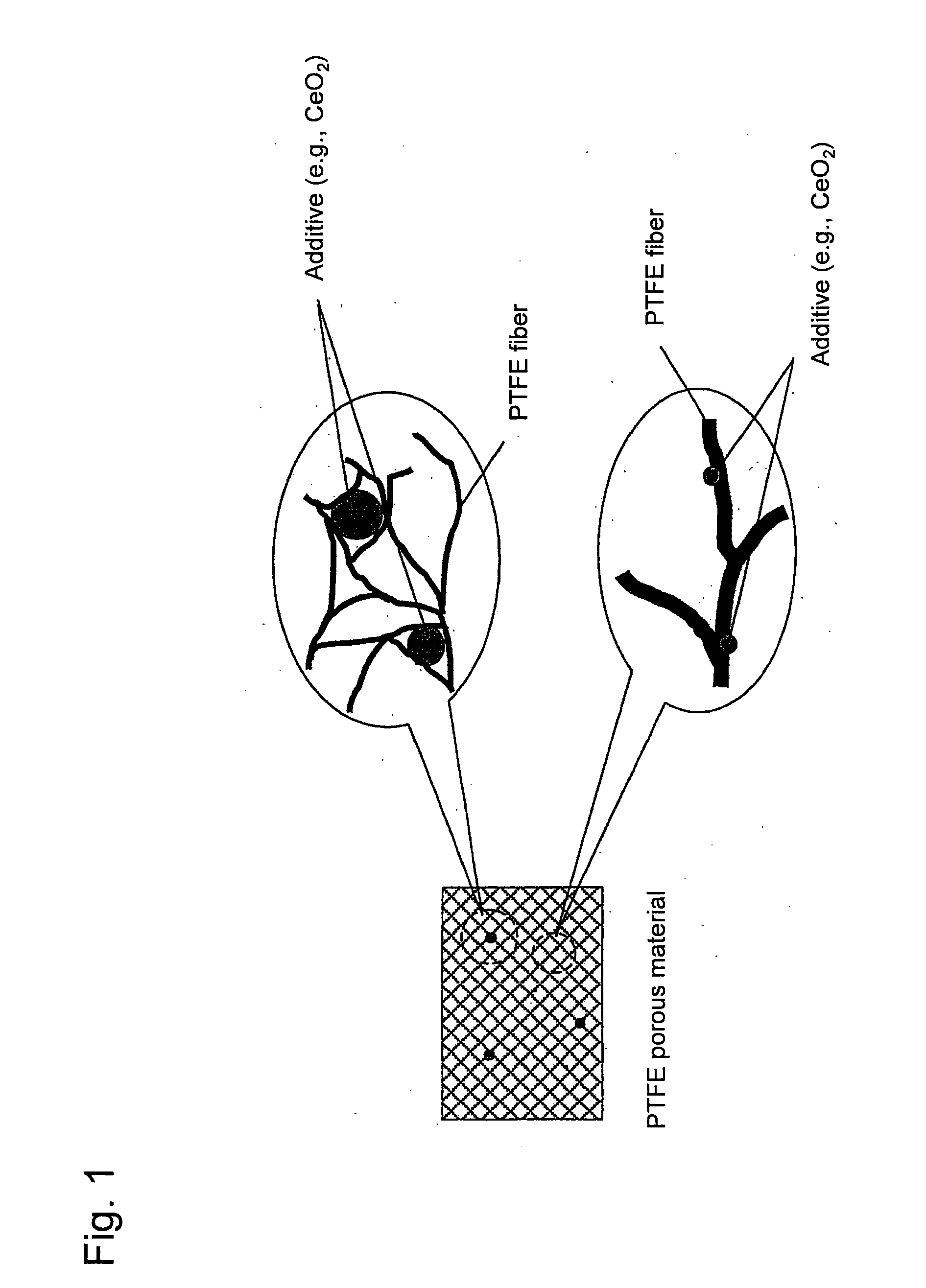

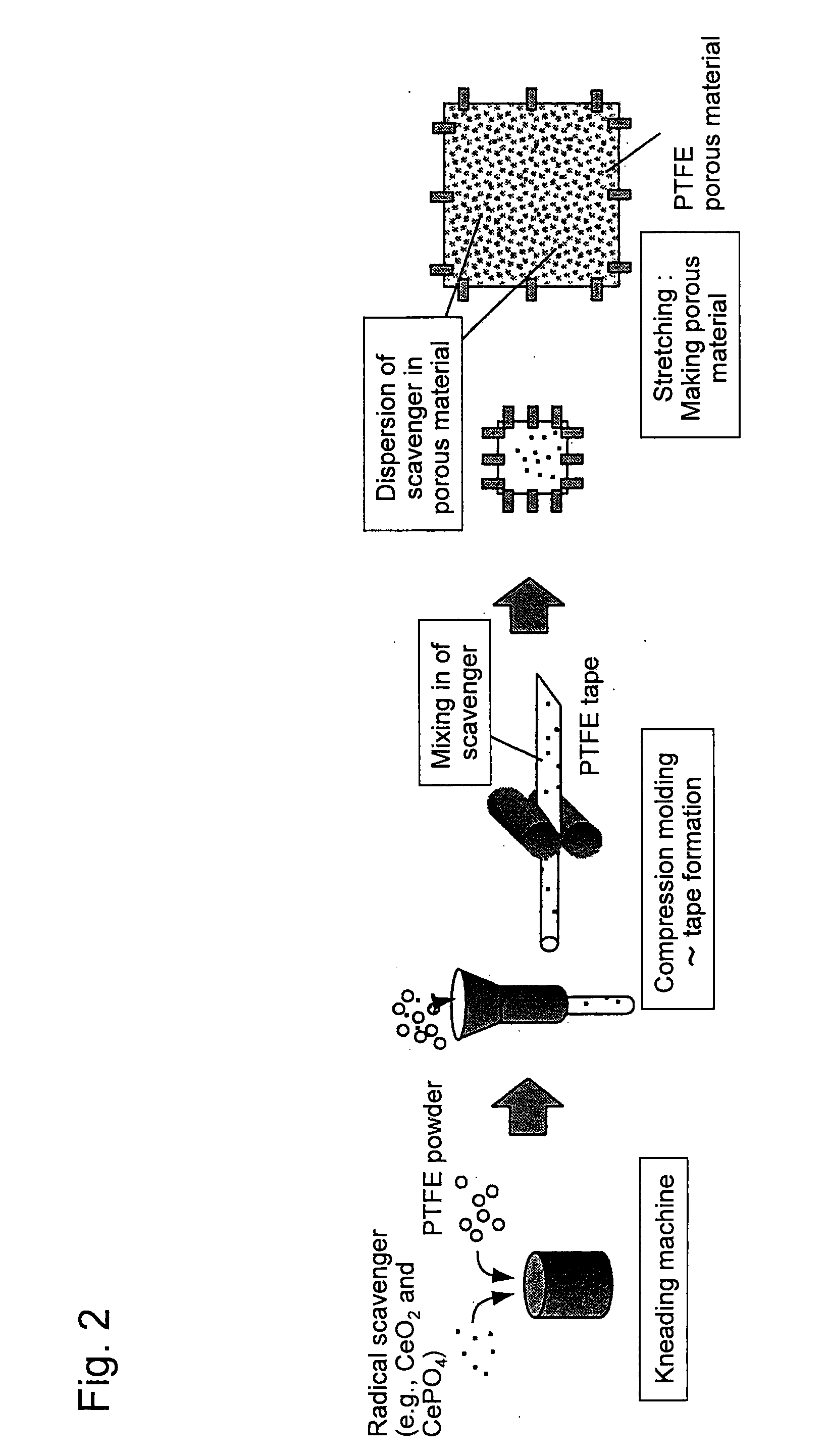

Reinforced electrolyte membrane for fuel cell, method for producing the membrane, membrane-electrode assembly for fuel cell, and polymer electrolyte fuel cell comprising the assembly

InactiveUS20100233571A1Excellent chemical durabilityIncrease power generation capacityElectrolyte holding meansFinal product manufacturePolymer electrolytesFuel cells

A reinforced electrolyte membrane for a fuel cell wherein the electrolyte membrane is reinforced with a porous membrane and a radical scavenger is immobilized in the porous membrane. The reinforced electrolyte membrane for a fuel cell is a solid polymer electrolyte membrane suppressing the radical scavenger from leaking outside of the system and having good chemical durability.

Owner:TOYOTA JIDOSHA KK

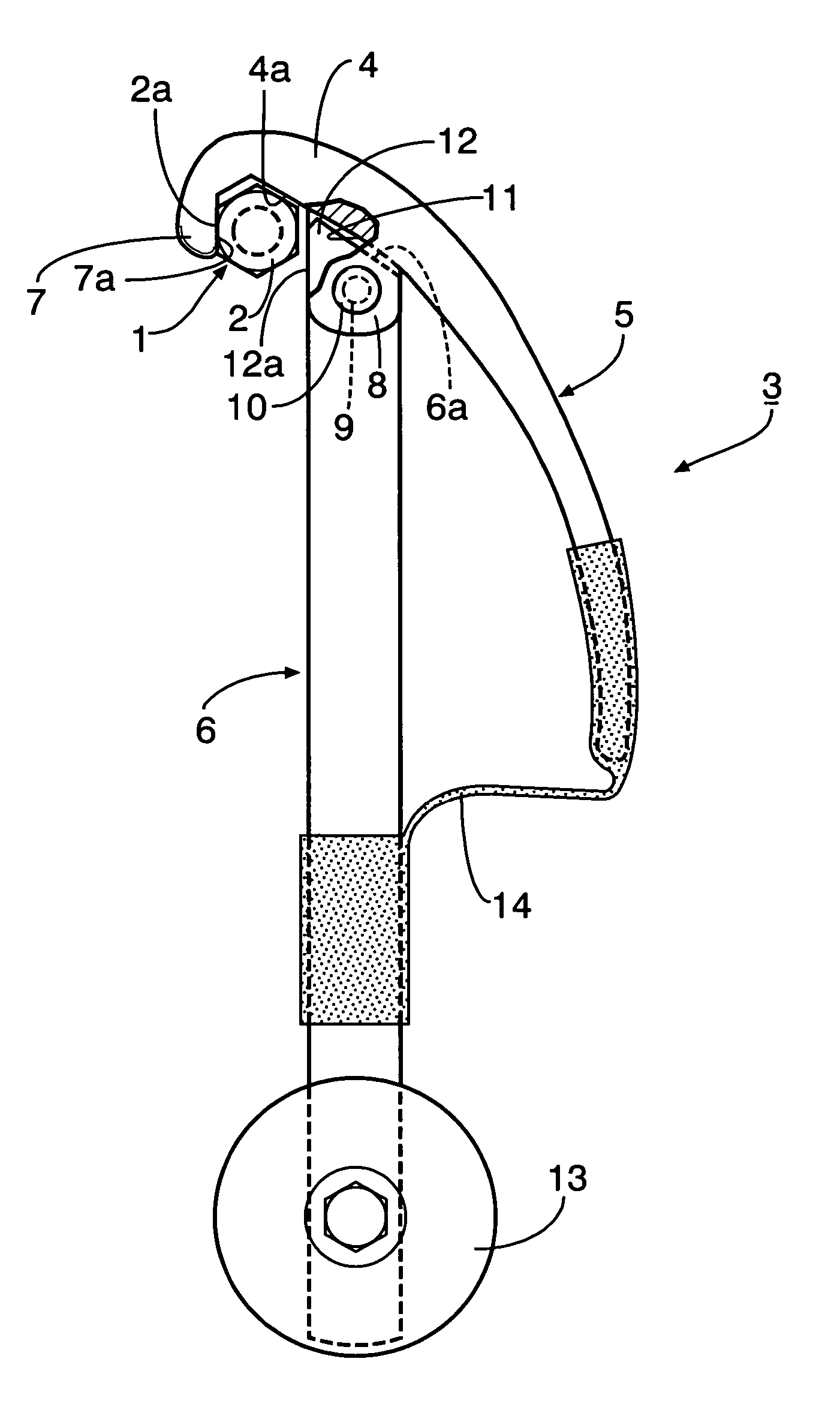

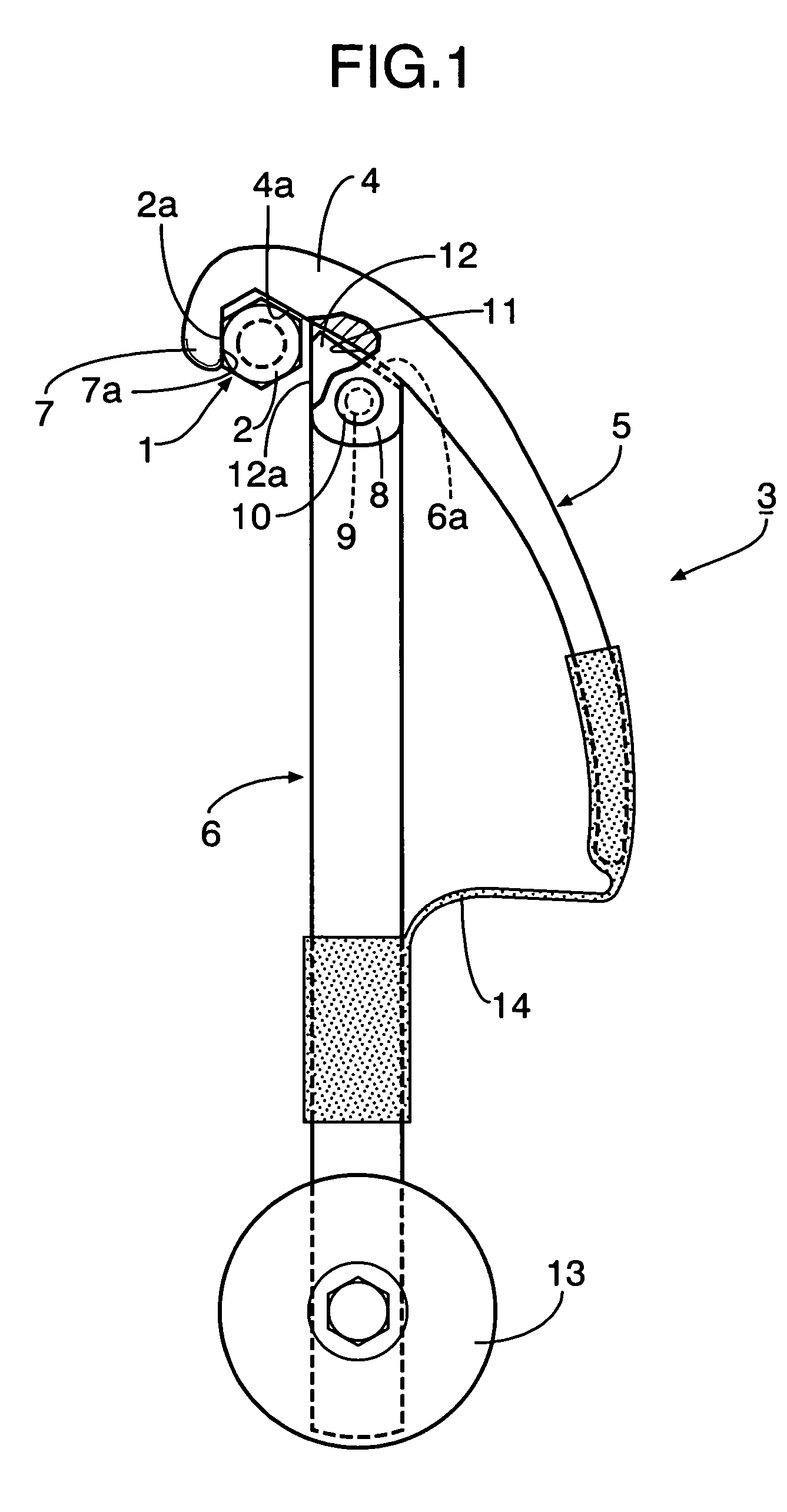

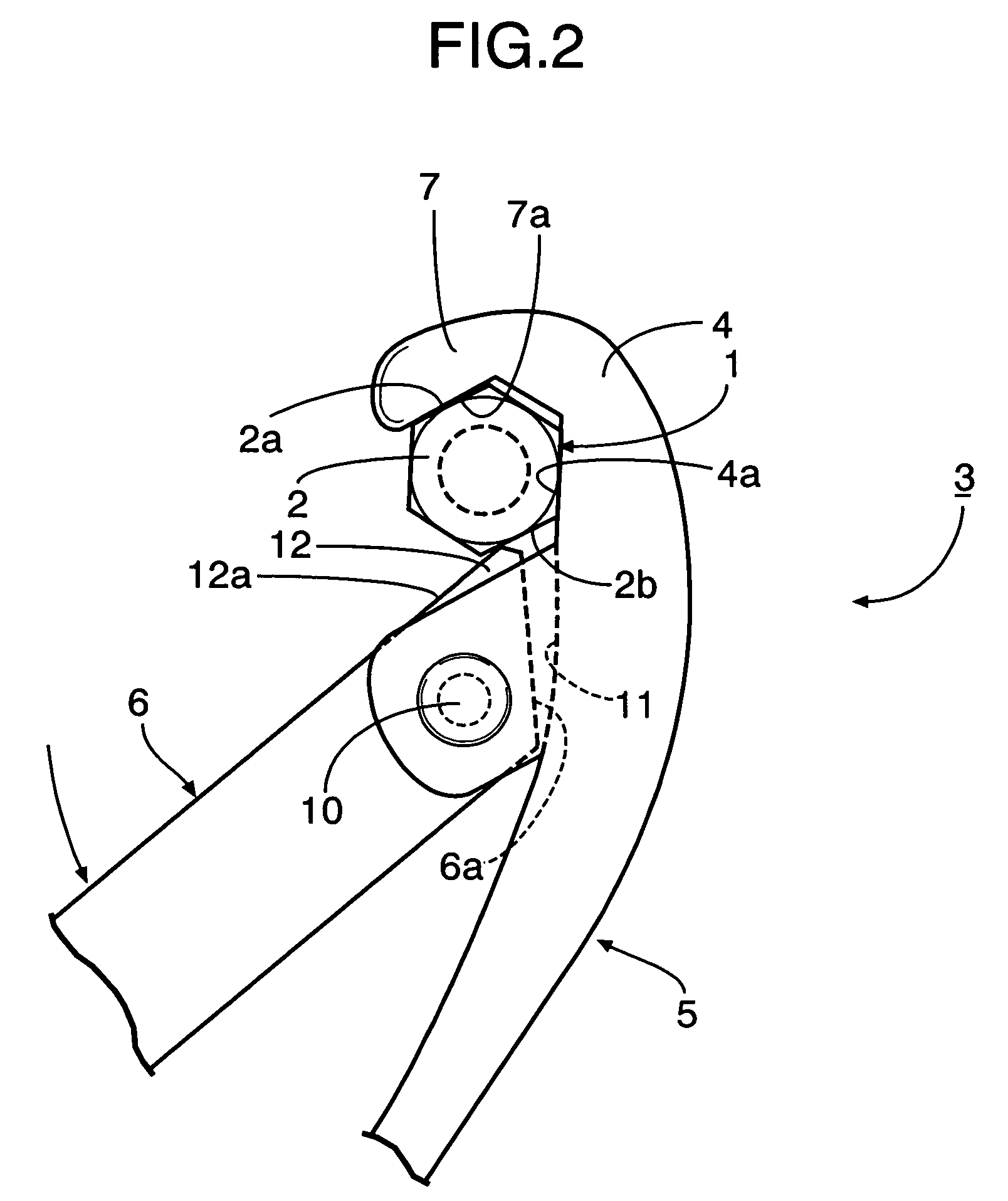

Rotatively operating tool for rotatively operated member having a pair of engaging surfaces

In a rotatively operating tool, a lever (5) having a head (4) at its tip end is turnably connected to a handle (6) provided at its tip end with a lower jaw (12). The head (4) is provided with an upper jaw (7) brought into engagement with an engaging surface (2a) of a bolt head (2). A spring (14) is mounted between the lever (5) and the handle (6) for biasing the lever (5) to turn it in a direction of abutment of a stopper face (11) of the lever (5) against the handle (6). When the handle (6) is turned in one direction, the lower jaw (12) at the tip end of the handle (6) is brought into abutment against an engaging surface (2b) of the bolt head (2), whereby the bolt head (2) is clamped between the lower jaw (12) and the upper jaw (7). When the handle (6) is turned in an opposite direction, it is brought into a state in which the clamping of the bolt head (2) is canceled. Even when the lever (5) is turned against a biasing force of the spring (14), the bolt head (2) is clamped between the upper jaw (7) and the lower jaw (12). Thus, it is possible to provide a rotatively operating tool having a simple structure, which is designed so that a rotatively operated member such as a bolt can be rotated in one direction and even in an opposite direction as required by the reciprocally turning operation of the tool.

Owner:HONDA MOTOR CO LTD

Walk-behind lawnmower

ActiveUS20110239615A1Minimize bendingReduce rigidityLawn-mowersAgricultural undercarriagesThin walledLawn mower

A walk-behind lawnmower having a rear shield is disclosed. The rear shield extends downward from a rear end part of a housing and is in the form of an elastic sheet. The sheet has a thin-walled part formed in a central site in a heightwise direction between an upper end part and a lower end part, the upper end part being attached to the rear end part of the housing. The thin-walled part has a thickness set to be smaller than a thickness of other parts.

Owner:HONDA MOTOR CO LTD

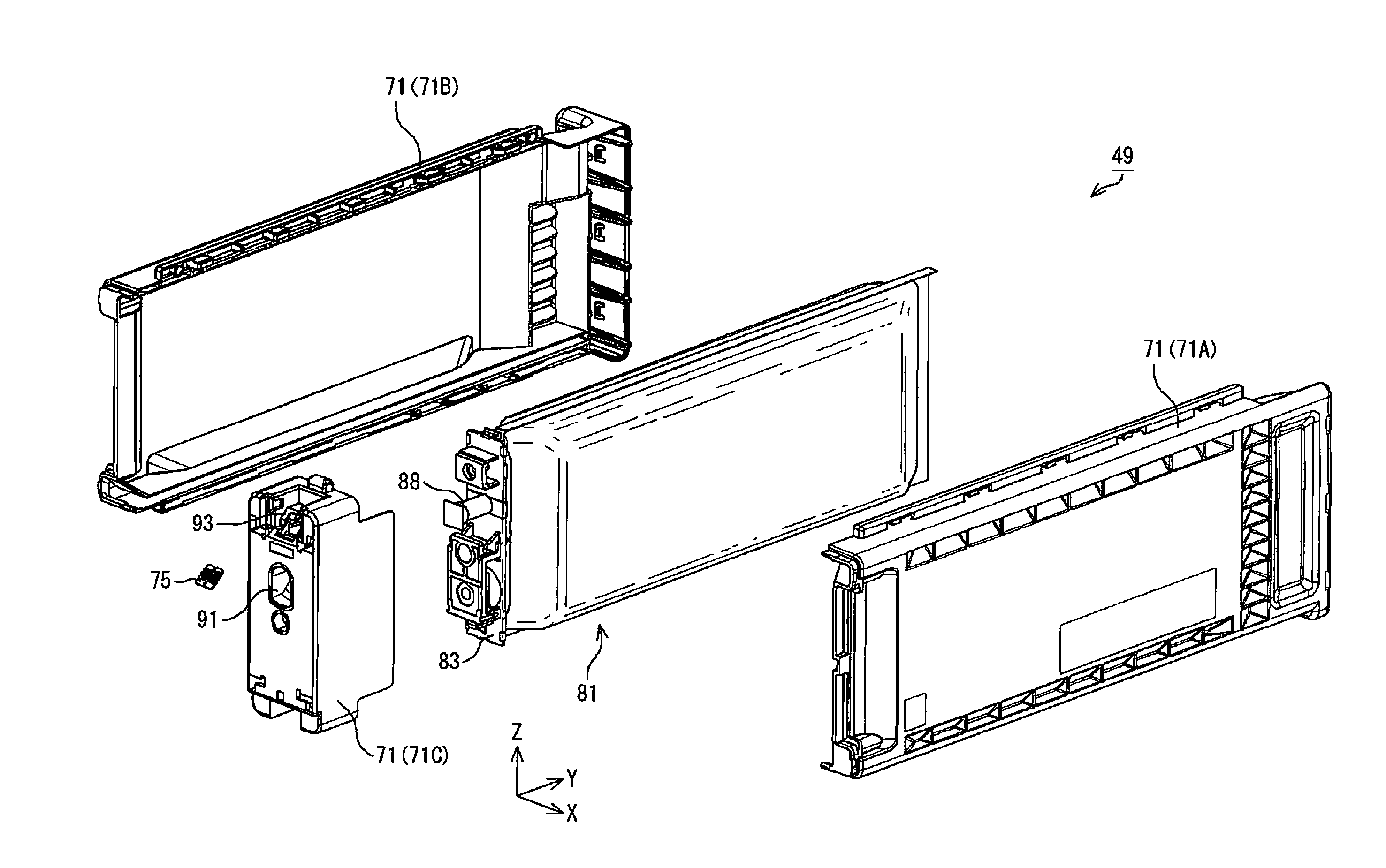

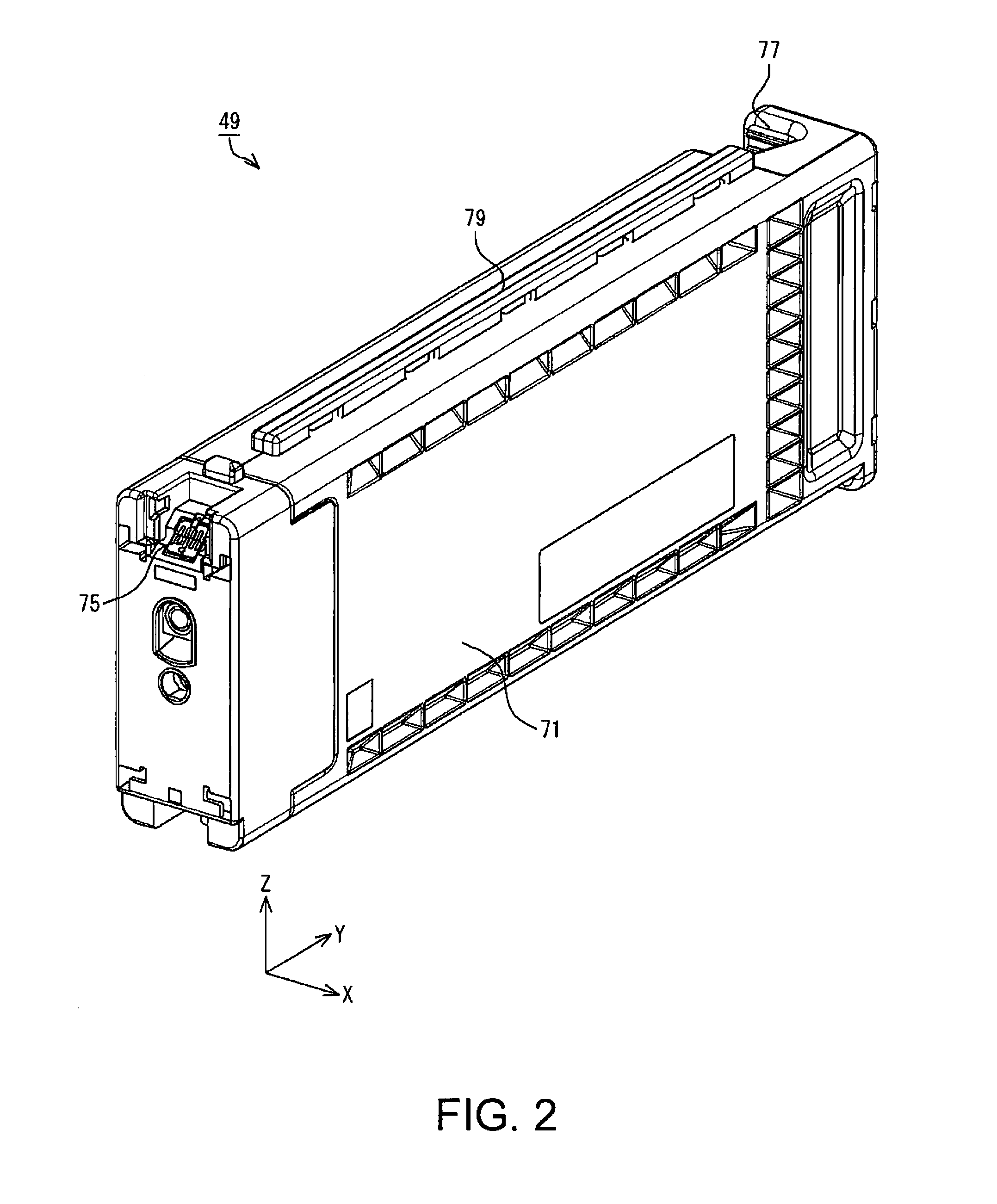

Liquid supply unit

ActiveUS20160311228A1Readily prevented from advancingOutflow of contaminants is readily reducedPrintingFiberLiquid jet

A liquid supply unit configured to supply a liquid to a liquid inlet of a liquid jet apparatus. The liquid supply unit includes a liquid housing part configured to house a liquid, a liquid outlet configured to draw the liquid from inside the liquid housing part to outside the liquid housing part, and a filter provided upstream of the liquid outlet in a channel of the liquid that is drawn from inside the liquid housing part to outside the liquid housing part via the liquid outlet. The filter includes a first filter and a second filter that are constituted by a plurality of fibers laminated in a flow direction of the liquid. The first filter is provided upstream of the second filter in the channel of the liquid, and the first filter and the second filter differ in coarseness.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com