Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Detailed steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

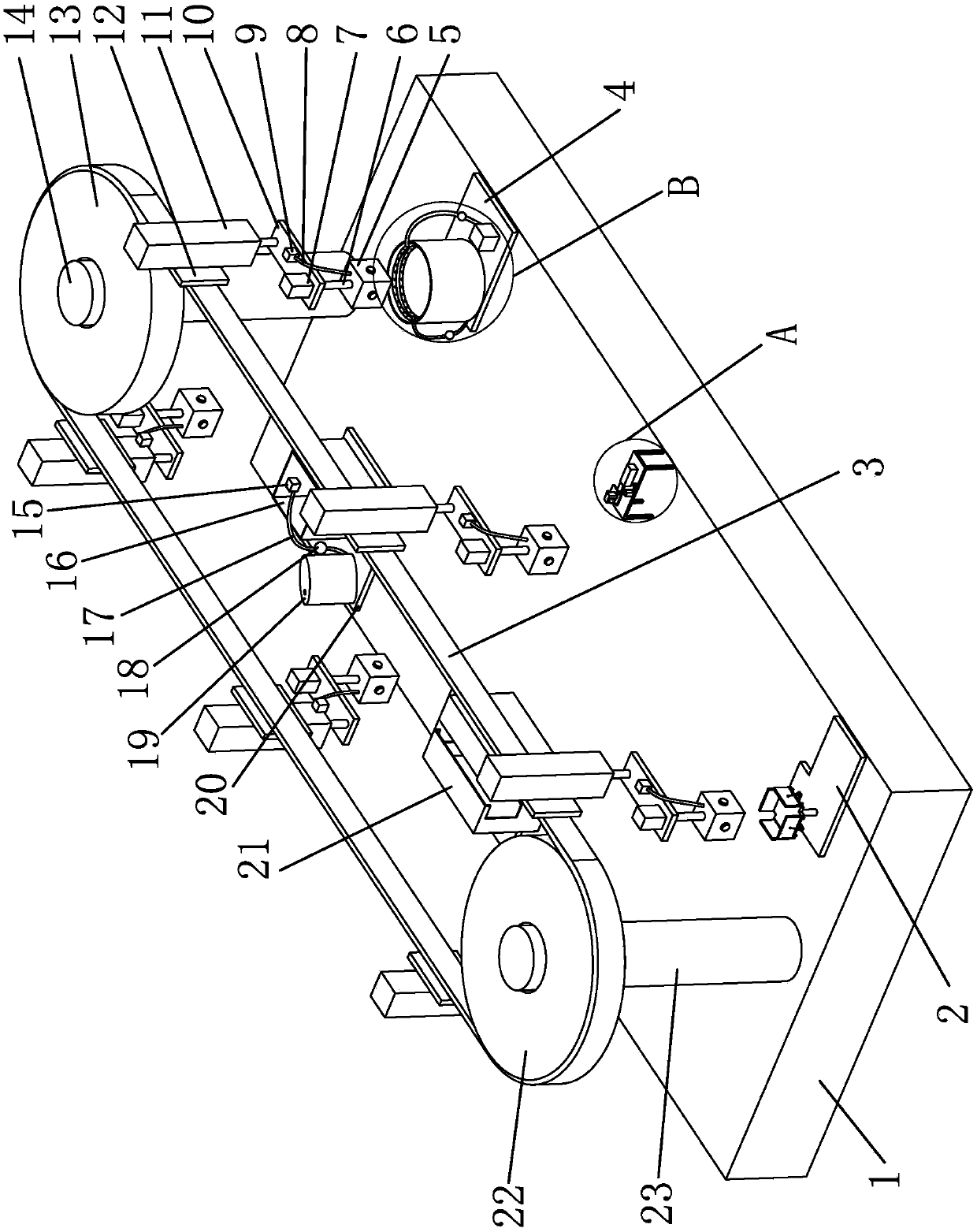

Machining method of dual-power-source transmitter

ActiveCN108296791ADetailed stepsReduce difficultyWelding/cutting auxillary devicesManufacture of electrical instrumentsEngineeringMachining

The invention provides a machining method of a dual-power-source transmitter. The technical problems that an existing transmitter is provided with no corresponding machining method, batch machining cannot be rapidly carried out, and the machining speed is low are solved. The machining method of the dual-power-source transmitter comprises the following steps that a, plate materials are machined into a shell through a production system, an anti-rust coating is arranged on the outer side of the shell, and the thickness of the anti-rust coating is 0.4-0.8 mm; b, a first circuit board and a secondcircuit board are assembled to the shell; c, a nixie tube is assembled to a panel; d, an adjusting button is assembled to the panel; e, a fence type terminal is assembled to the panel; f, the panel isassembled to the shell, and the dual-power-source transmitter is obtained; and g, the dual-power-source transmitter is detected through detection equipment. The machining method has the advantage ofbeing high in machining speed.

Owner:HAIYAN PYAN POWER TECH CO LTD

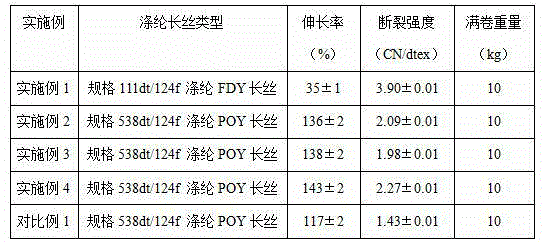

Method for industrial production of polyester filament yarn by using polyester waste yarn

InactiveCN104911748AIncrease profitAchieve recyclingFilament forming substance formingArtificial filament recoveryPolymer scienceSpinning

The invention belongs to the technical field of producing and processing of polyester filament yarns and particularly relates to a method for industrial production of polyester filament yarn by using polyester waste yarn. The method comprises the following specific operation steps: preparing a bubble material, crystallizing, drying and extruding; and preparing melt, filtering, homogenizing and spinning; and finally obtaining the polyester filament yarns. With the waste yarns generated in the process of recovering polyester bottle flakes to produce the polyester filament yarn as the raw material, the bubble material is produced from the waste yarns; the polyester filament yarns are industrially produced from the bubble material; cyclic utilization of the waste yarns is realized; the process disclosed by the invention is stable; the utilization rate of the recovered polyester bottle flakes is effectively improved; and the method can be popularized and applied.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

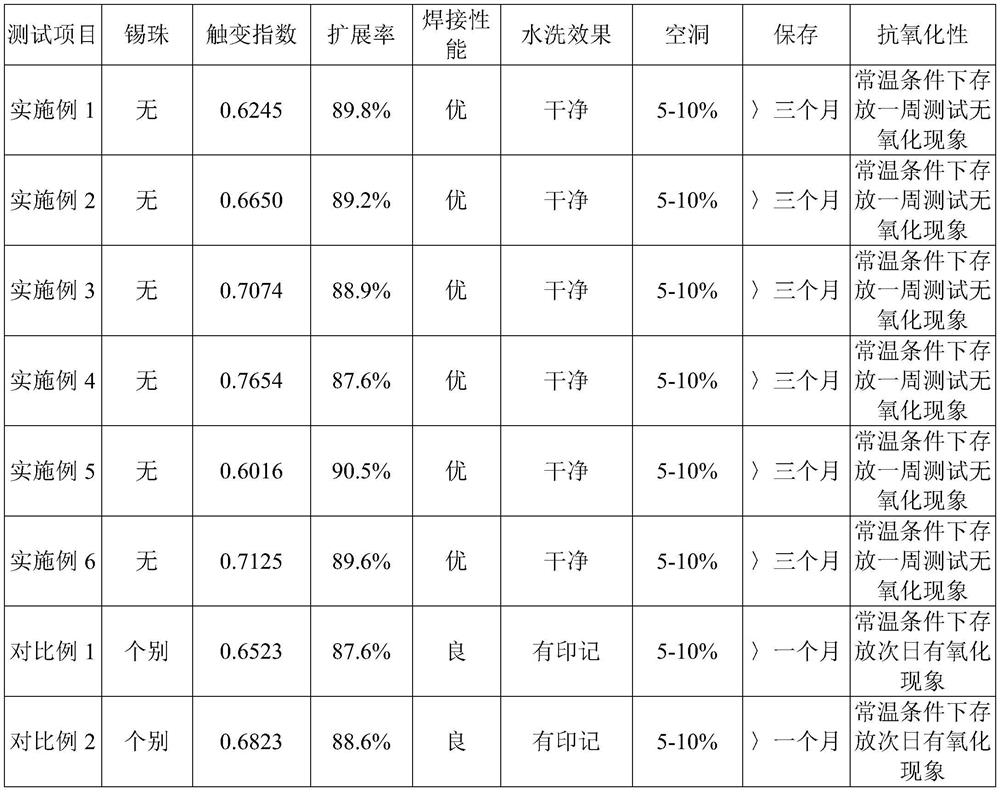

Water-soluble lead-free flux paste, washing solder paste and preparation method of washing solder paste

ActiveCN112589318AHigh viscosityHigh thixotropic indexWelding/cutting media/materialsSoldering mediaMetallurgyActive agent

The invention discloses washing superfine tin powder water-soluble lead-free high-temperature flux paste and a preparation method thereof. The washing superfine tin powder water-soluble lead-free high-temperature flux paste is prepared from the following raw materials in parts by weight: 30-55 parts of an antioxidant, 10-26 parts of an organic solvent, 4-8 parts of a thixotropic agent, 8-16 partsof an active agent, 6-10 parts of a corrosion inhibitor and 6-10 parts of a surfactant. The water-washing solder paste prepared from the flux paste is good in stability, and effectively meets the practical requirements for oxidation resistance, tin point plumpness, low void content, no splashing of residues, good cleaning performance and the like.

Owner:深圳市晨日科技股份有限公司

Plantation method of camellia in the north

Provided is a plantation method of northern camellia, pertaining to the agriculture field. The invention concretely relates to a systematic plantation method of camellia capable of robustly growing camellia in the north. The plantation method of camellia in the north is characterized in that one to three water drainage holes are perforated in pots or box bottoms of flowerpots, wood boxes or plastic boxes sued for cutting; each hole is 2 to 3 centimeters in size and in need of good drainage; holes are covered by crock; a layer of small stones is laid on a bottom layer; a layer of coarse sand is laid on a middle layer; cultivation soil of 5 to 10 centimeters is laid on an upper layer and generally uses acid red-yellow soil with 6 to 6.5 PH value; if viscosity is high, fine sand or sawdust scraps can be mixed; as a condition permits, a proper amount of humus soil, vermiculite, decomposed organic fertilizers or phosphate fertilizers and bone meals are mixed into cultivation soil; if cultivation soil is slightly alkaline, a ferrous sulfate solution is added for regulation such that a subacid reaction is made; cultivation soil can be exposed for several days under sunlight or disinfected by utilizing a formaldehyde solution; and a plastic thin film is utilized for smothering several days so that the sterilization effect is obtained.

Owner:赵宝瀛

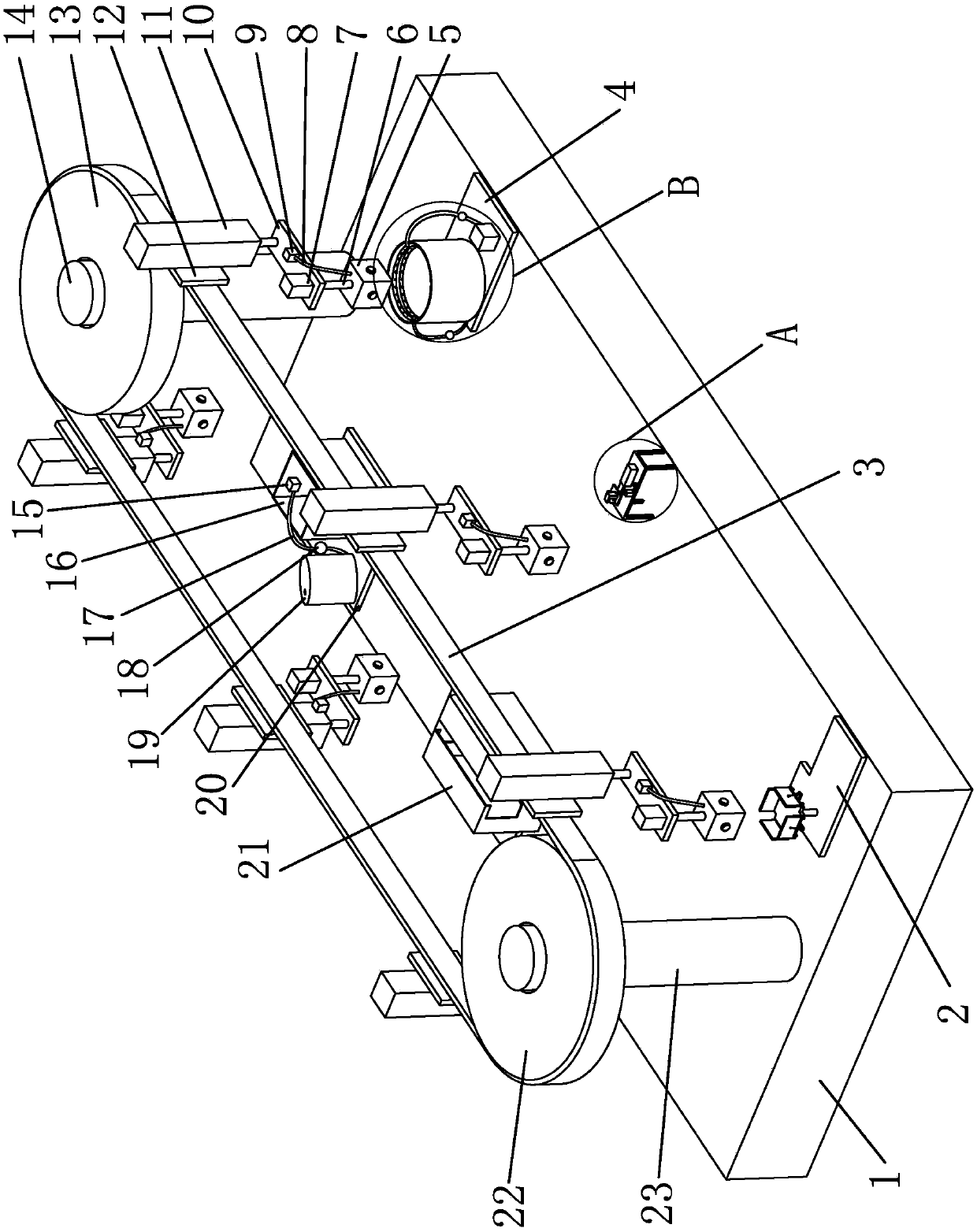

Production method for intelligent transmitting device

ActiveCN107627077ADetailed stepsRealize mass productionWelding/cutting auxillary devicesManufacture of electrical instrumentsLiquid-crystal displayHigh volume manufacturing

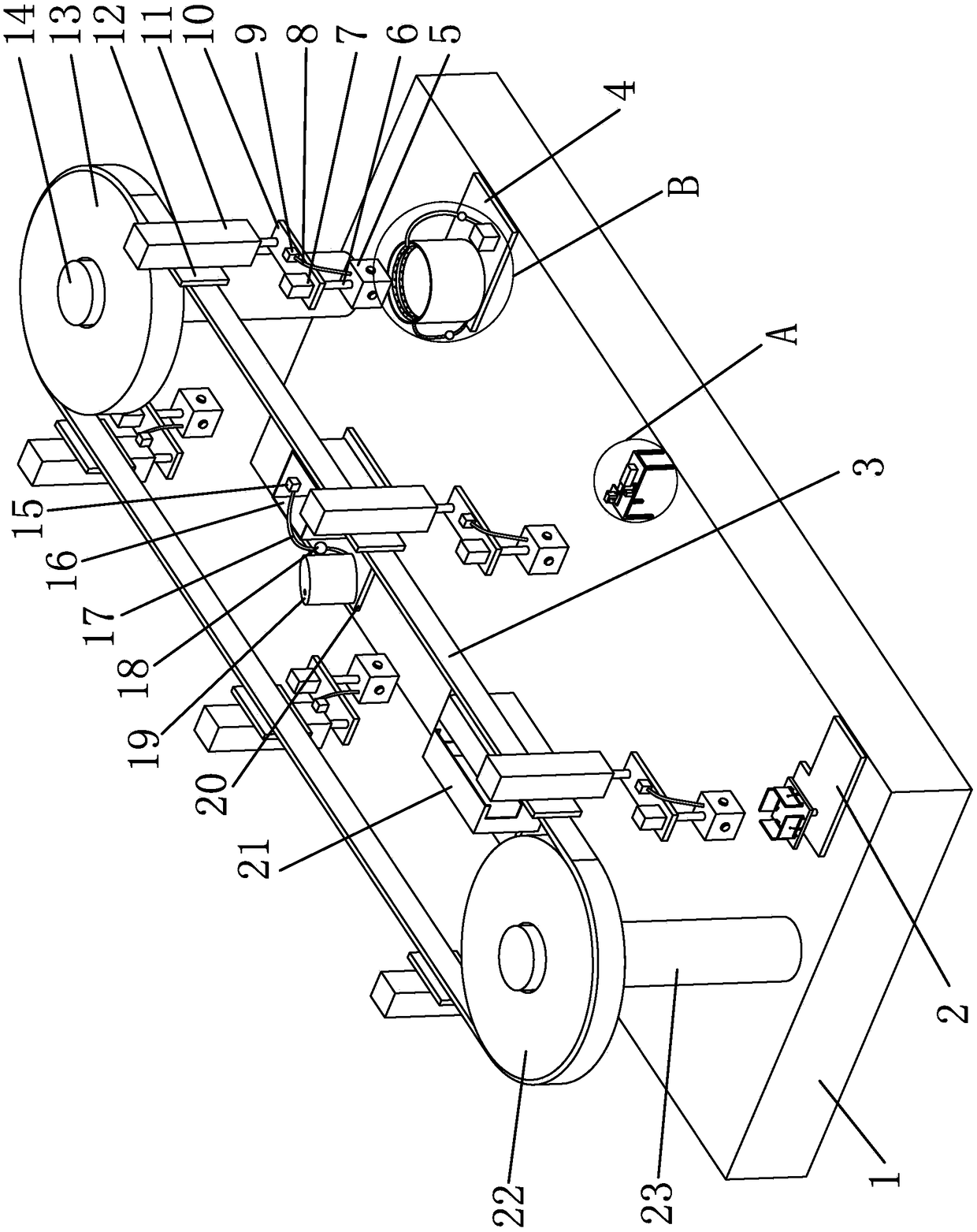

The invention provides a production method for an intelligent transmitting device, and solves the technical problems that an existing electrical quantity transmitter does not have the corresponding production method, cannot be produced on a large scale, and the like. The production method for the intelligent transmitting device comprises the following steps: a, processing plates into a box by a production system, wherein a protecting layer is arranged on the outside of the box, and the thickness of the protecting layer is 0.6-1.8 mm; b, gluing an auxiliary power supply circuit board, an inputting signal circuit board, a communication board and an analog quantity outputting and pulse outputting board by a gluing system; c, assembling a plastic guide track in the box; d, assembling the auxiliary power supply circuit board, the inputting signal circuit board, the communication board and the analog quantity outputting and pulse outputting board on a clamping board; e, assembling the clamping board on the plastic guide track; f, assembling a liquid crystal display screen on a front cover plate; and g, assembling a front cover plate and a rear cover plate to two ends of the box correspondingly to obtain the intelligent transmitting device. The production method for the intelligent transmitting device has the advantage of high production efficiency.

Owner:HAIYAN PYAN POWER TECH CO LTD

Manufacturing method of intelligent electric quantity transmitter

ActiveCN107703338ADetailed stepsReduce difficultyWelding/cutting auxillary devicesManufacture of electrical instrumentsTransmitterCoating

The present invention provides a manufacturing method of an intelligent electric quantity transmitter which solves the technical problems that a conventional electric quantity transmitter does not have a corresponding manufacturing method, needs to depend on the experiences to manufacture, is tedious to manufacture, etc. The manufacturing method of the intelligent electric quantity transmitter comprises the following steps of a, processing a sheet matal into a shell via a production system, wherein the shell has an outer coating, and the thickness of the coating is between 0.5 mm and 1.5 mm; b, assembling a palisade terminal block on the outer end face of an upper cover; c, assembling a fixing rack on the inner end face of the upper cover; d, separately assembling a circuit board 1 and a circuit board 2 on the fixing rack; e, putting a spongy cushion at the bottom of the shell, and putting an insulating paper at the side part of the shell; f, assembling the upper cover on the shell toobtain a finished intelligent electric quantity transmitter; g, detecting the intelligent electric quantity transmitter via a detection device; h, packaging and warehousing the detected and qualifiedintelligent electric quantity transmitter. The manufacturing method of the present invention has the advantage of being convenient to manufacture.

Owner:HAIYAN PYAN POWER TECH CO LTD

Road asphalt and making technology thereof

The invention provides road asphalt and a making technology thereof, aiming at solving the technical problems that the existing road asphalt is simpler in components, cannot adapt to high and low temperature environment, is poor in functionality, and the like. The road asphalt is prepared from the following components in parts by weight: 20-35 parts of petroleum asphalt, 40-55 parts of coal tar asphalt, 0.2-0.5 part of zinc oxide, 3-5 parts of straw fibers and 1-2 parts of resin. The road asphalt has the advantage of being good in service performance.

Owner:海宁永欣科技咨询有限公司

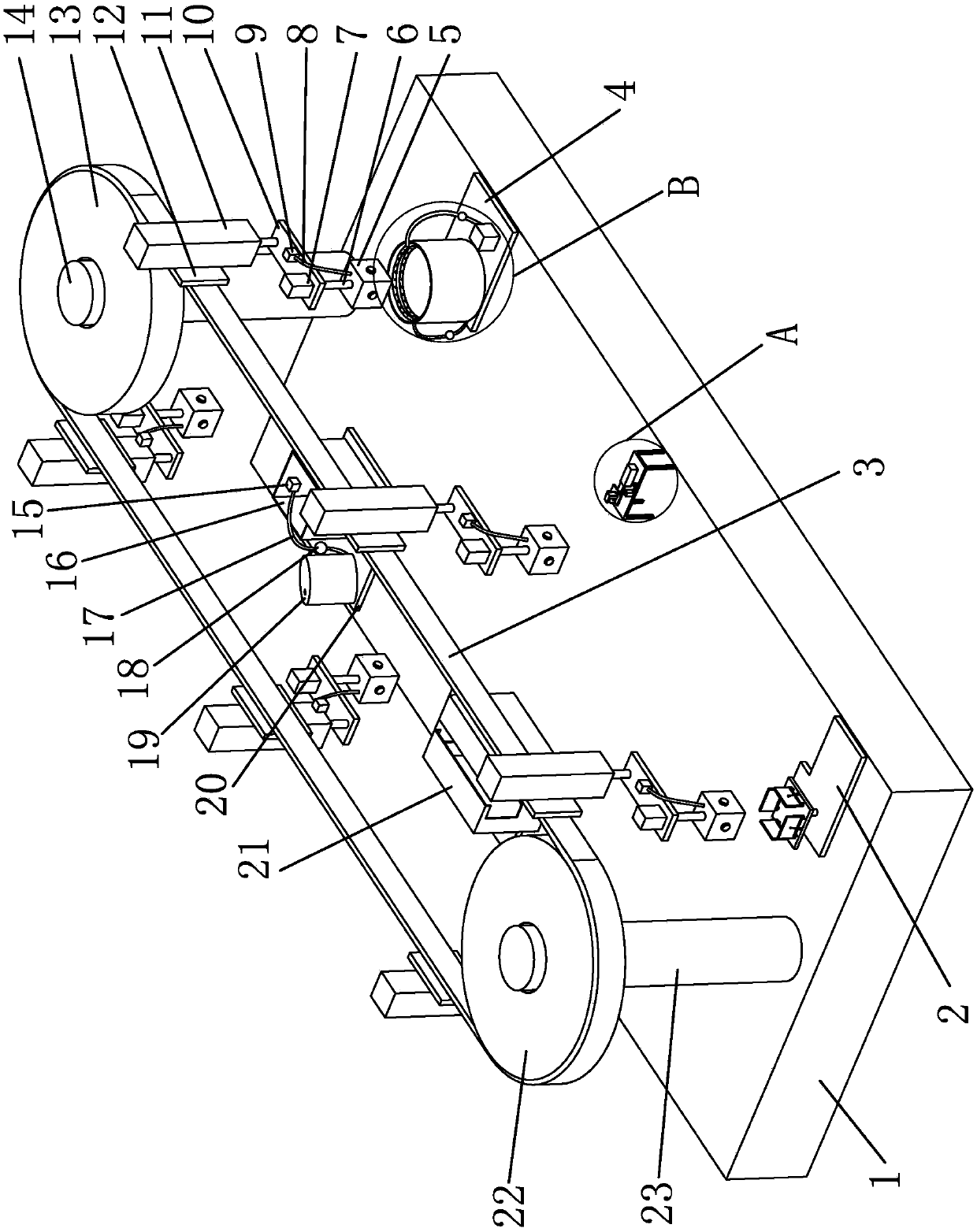

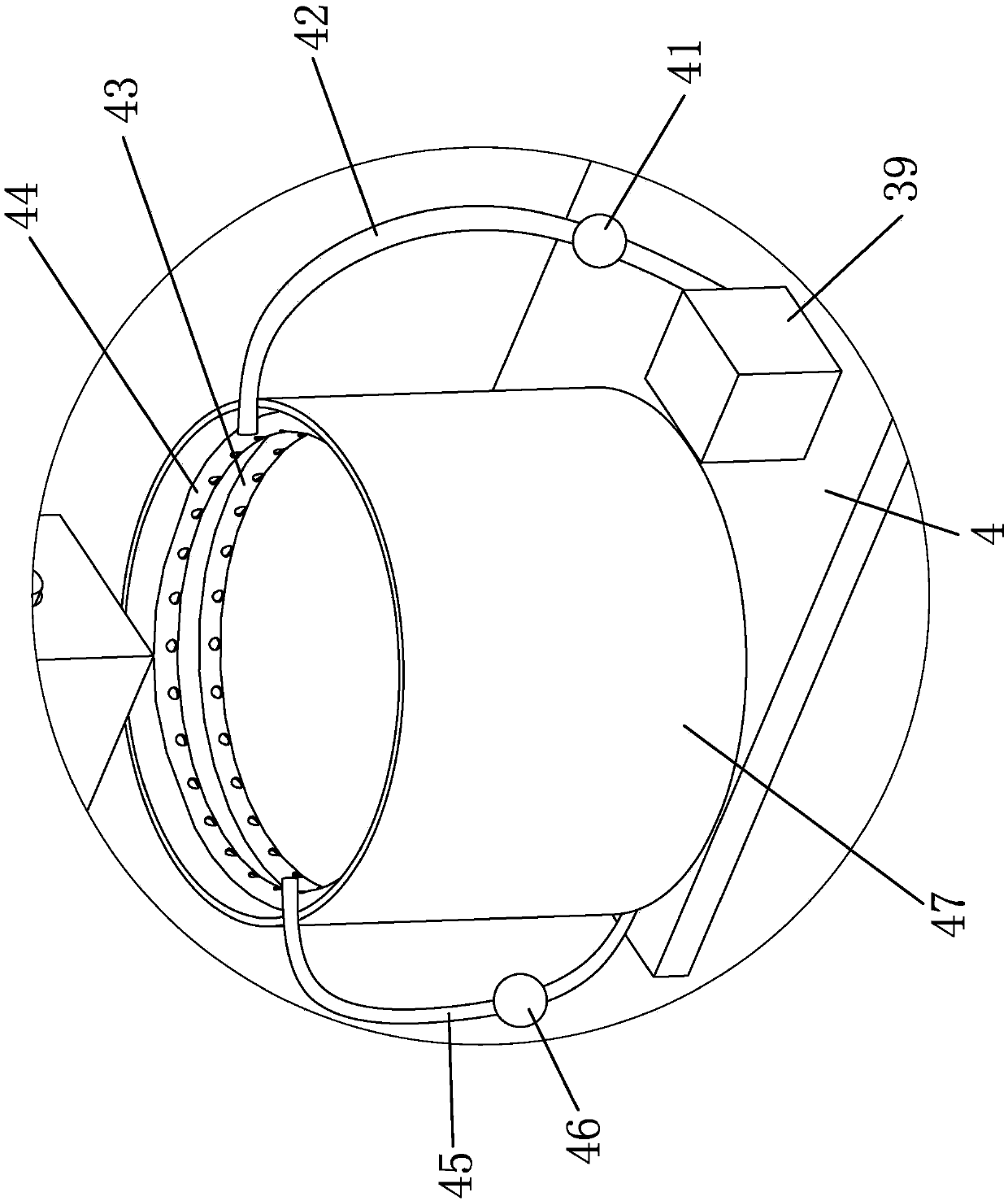

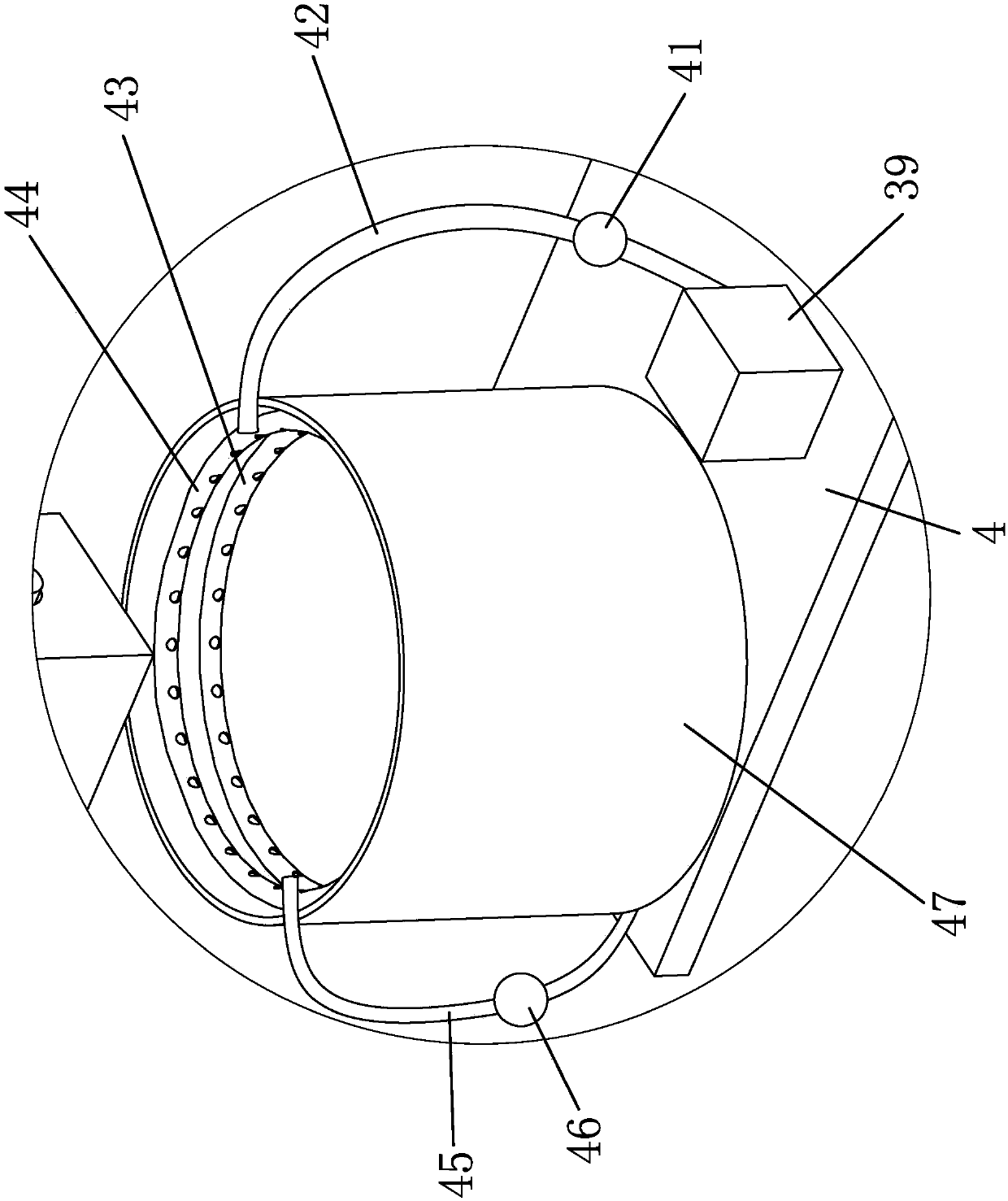

Non-contact intraocular pressure measuring device and method

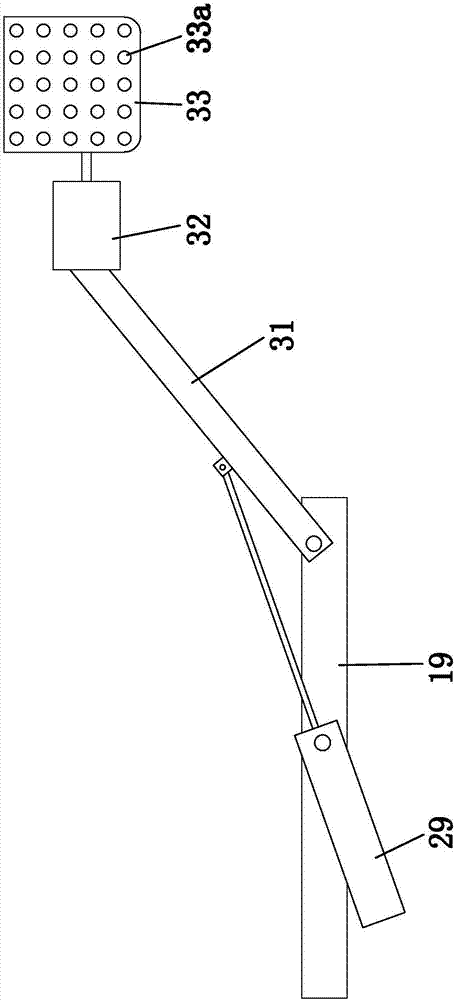

InactiveCN110338753AStable structureReduce waiting timeTonometersMedical equipmentMeasuring instrument

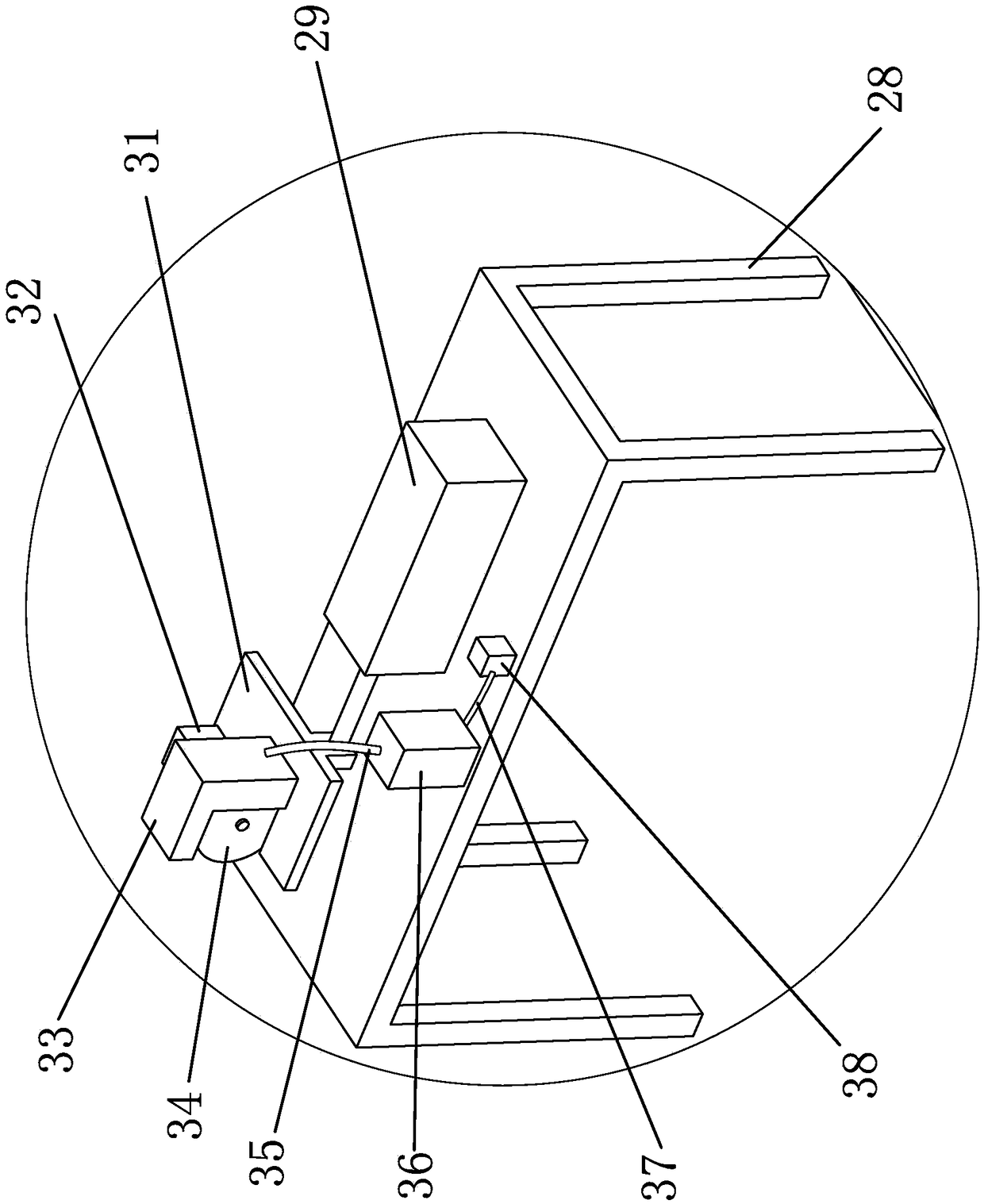

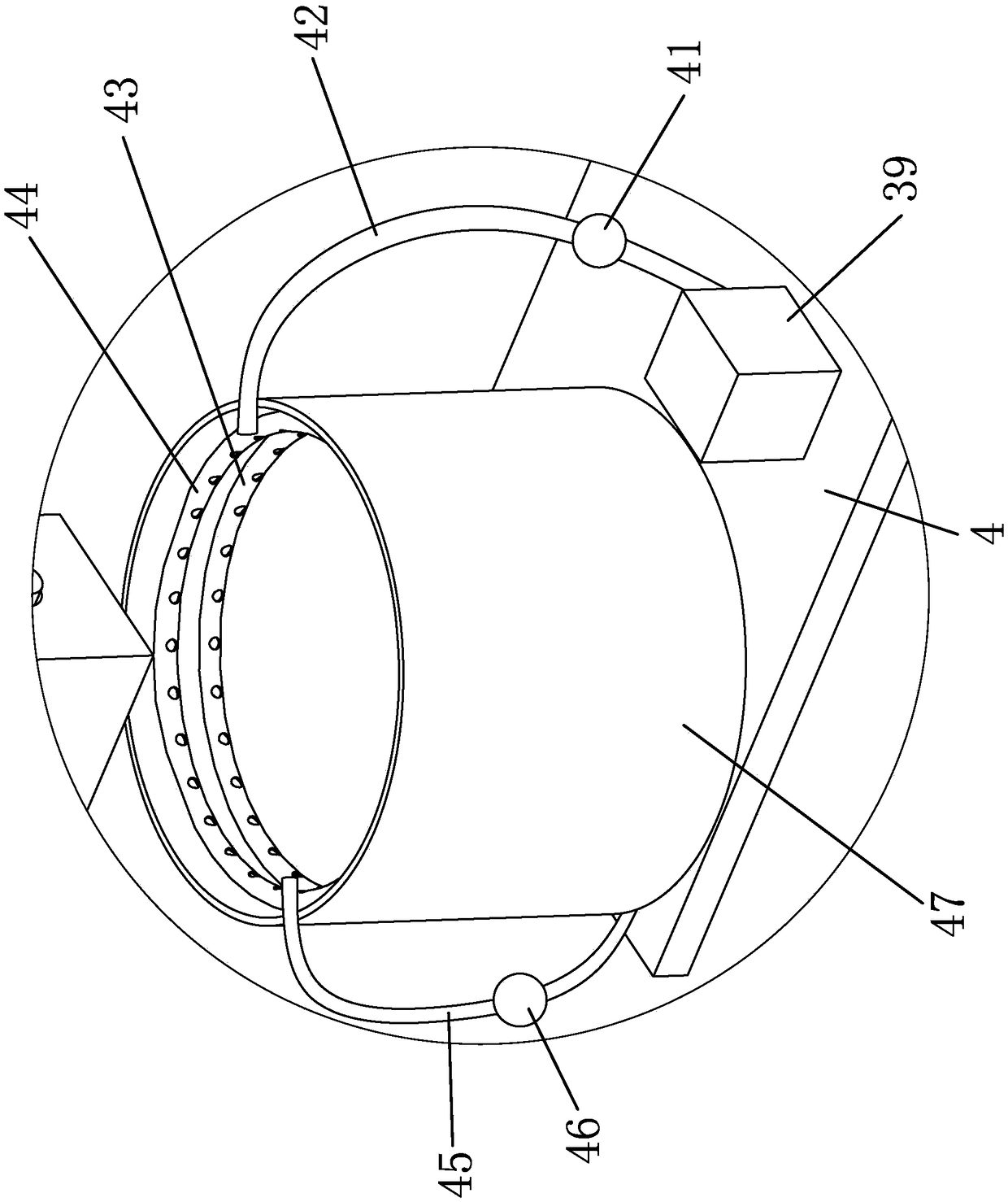

The invention relates to the technical field of medical equipment and discloses a non-contact intraocular pressure measuring device and method. The non-contact intraocular pressure measuring device comprises a main measuring instrument body, a straight plate, a connecting plate and a supporting plate, wherein an output shaft of a slow-speed motor and the lower end of the main measuring instrumentbody are provided with screw rods; two groups of moving mechanisms are arranged on the two sides of the lower end of the straight plate and the two sides of the upper end of the connecting plate; fourgroups of guide mechanisms are uniformly arranged on the outer side of the lower end of the connecting plate; three hydraulic lifting columns are arranged between the middle of the lower end of the connecting plate and the middle of the upper end of the straight plate; the middle of one side of the main measuring instrument body is fixedly provided with a jaw support; the upper end of the other side of the main measuring instrument body is fixedly provided with a control panel, and the lower end of one side of the main measuring instrument body is provided with two holding rods in parallel. The device is stable in structure, convenient to adjust and high in working efficiency; meanwhile, the measuring method is clear in step, small in operation difficulty and high in intraocular pressuredetection accuracy.

Owner:温州中壹技术研究院有限公司

Production process of road asphalt

The invention provides a production process of road asphalt, aiming at solving the technical problems that the existing road asphalt is simpler in composition, cannot adapt to high and low temperatureenvironments, is poor in functionality, and the like. The production process of the road asphalt comprises the following steps: a. cutting the straw by using a common cutting machine, wherein the cutting length is 7 mm; b. soaking the cut straw into a solution for 3 hours, and drying until the water content of the straw is 45%; c. adding the straw obtained in the step b into pulping equipment forscattering so as to obtain slurry, wherein the pulping time is 15 min; d. dehydrating, drying and opening the slurry by using processing equipment so as to obtain straw fibers; e. heating and meltingpetroleum asphalt at the temperature of 190 DEG C, then sequentially adding coal tar asphalt, zinc oxide, the straw fibers and resin, raising the heating temperature to 220 DEG C, and stirring by using an ordinary disperser for 14min at a speed of 1800 r / min. The production has the advantage of being simple and convenient to operate.

Owner:海宁永欣科技咨询有限公司

Bisphenol A epoxy resin preparation method and product prepared therethrough

The invention discloses a bisphenol A epoxy resin preparation method and a product prepared therethrough. The method comprises the following steps: carrying out a pre-reaction and a ring closing reaction on raw materials comprising bisphenol A and chloropropylene oxide to prepare a crude bisphenol A epoxy resin, removing water and excess chloropropylene oxide, refining, desalinating, neutralizing through water washing, removing a solvent, and concentrating to obtain a bisphenol A epoxy resin. The preparation method has the advantages of stable process, clear parameters, detailed steps and strong feasibility; and the bisphenol A epoxy resin prepared through the preparation method has high purity, has an organic chloride content of below 0.02wt%, and has high epoxy value, high softening point and extremely good quality, so the performances of the bisphenol A epoxy resin are improved.

Owner:建滔(广州)电子材料制造有限公司

Asparagus fern dwarfing method

InactiveCN105309146AEasy to controlAccurately grasp the growth cycleHorticulture methodsBiologyCladodes

The invention belongs to the field of agriculture, and particularly relates to an asparagus fern dwarfing method which is simple and capable of avoiding sudden and violent growing and overhigh and overlong phenomena of asparagus ferns. The asparagus fern dwarfing method is characterized in that fertilizer cannot be applied too much to young plants in strong growth seasons of spring and summer, and the fertilizer can be generally applied once a month; the fertilizer amount cannot be too large, and the mild principle needs to be mastered; the fertilizer should be applied less or not be applied to old plants, and fresh soil is filled into the bottoms of pots or a less amount of the fertilizer is applied when the old plants need to be repotted; in this way, stable growth vigor can be maintained whether for the young plants or for the old plants; frequent pruning needs to be paid attention to, growth of the asparagus ferns is faster, old branches and dry stems need to be pruned and thinned out to keep a low posture. Meanwhile, sprawling branches need to be pruned in time to keep the asparagus ferns tall and straight, beautiful, well-spaced and verdant.

Owner:赵宝瀛

Planting method of peonies

InactiveCN108401767AEasy to controlAccurately grasp the growth cycleCultivating equipmentsEconomic benefitsPest control

The invention discloses a planting method of peonies and belongs the technical field of planting of flowers. The planting method includes pretreatment of planting, peony seed treatment, planting, field treatment, pest and disease prevention and control and harvesting of peonies. The method is simple, and the procedures are specific; by means of the planting method of peonies, farmers can easily take control and accurately know about the growth period and growth habits of the peonies; after the method is adopted, the growth speed of the peonies can also be increased substantially, and the economic benefit is further increased.

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

A heat treatment method for h13 die steel

ActiveCN109706297BHigh hardnessImprove wear resistanceSolid state diffusion coatingTemperingSurface cleaning

Owner:襄阳新东特锻造有限公司

Intelligence-protecting eye-glaring mother liquor and preparation method thereof

PendingCN114073662ABeauty is goodGood sun protectionCosmetic preparationsToilet preparationsOphthalmologySkin elasticity

The invention discloses an intelligent-protecting eye-glaring mother liquor and a preparation method thereof. The intelligent-protecting eye-glaring mother liquor is prepared from hexapeptide-9, palmitoyl tetrapeptide-7, tripeptide-1, palmitoyl pentapeptide-4, palmitoyl tripeptide-5, palmitoyl tripeptide-1, pearl extract, fullerene and glycyrrhiza glabra root extract.The intelligent-protecting eye-glaring mother liquor has very good beautifying, sunscreen, whitening and freckle-removing substances; according to the present invention, the pearl extract can effectively prevent eye aging and eye roughness, has certain anti-inflammatory and antibacterial effects on eye skin, can make the eye skin healthy, fine, moist, smooth and white, can improve the aging and eye skin roughness, can maximally recover the eye skin elasticity, can increase the gloss, can effectively prevent the eye aging and the eye roughness, can obviously reduce wrinkles and eliminate black spots, and has the effects of filling and leveling, healing, diminishing inflammation and promoting tissue regeneration on eye sores and furuncles, whelks, wounds and the like.

Owner:GUANGDONG CHANGHAO PHARMACY CO LTD

Planting method of chrysanthemums

InactiveCN108633678AEasy to controlAccurately grasp the growth cycleFlowers cultivationHorticulture methodsDiseaseEconomic benefits

The invention discloses a planting method of chrysanthemums, and belongs to the technical field of flower planting. The method comprises the steps of preparation before planting, pretreatment of seedlings, planting, field treatment, disease and pest prevention and control, and harvest of the chrysanthemums. The method disclosed by the invention is simple, and has the detailed steps; and when the planting method for the chrysanthemums is used, the planting can be easy to control, the growth cycle and growth habit of the chrysanthemums can be accurately grasped, and after the method is used, thegrowth speed of the chrysanthemums can be greatly improved, and the economic benefits can be further improved.

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

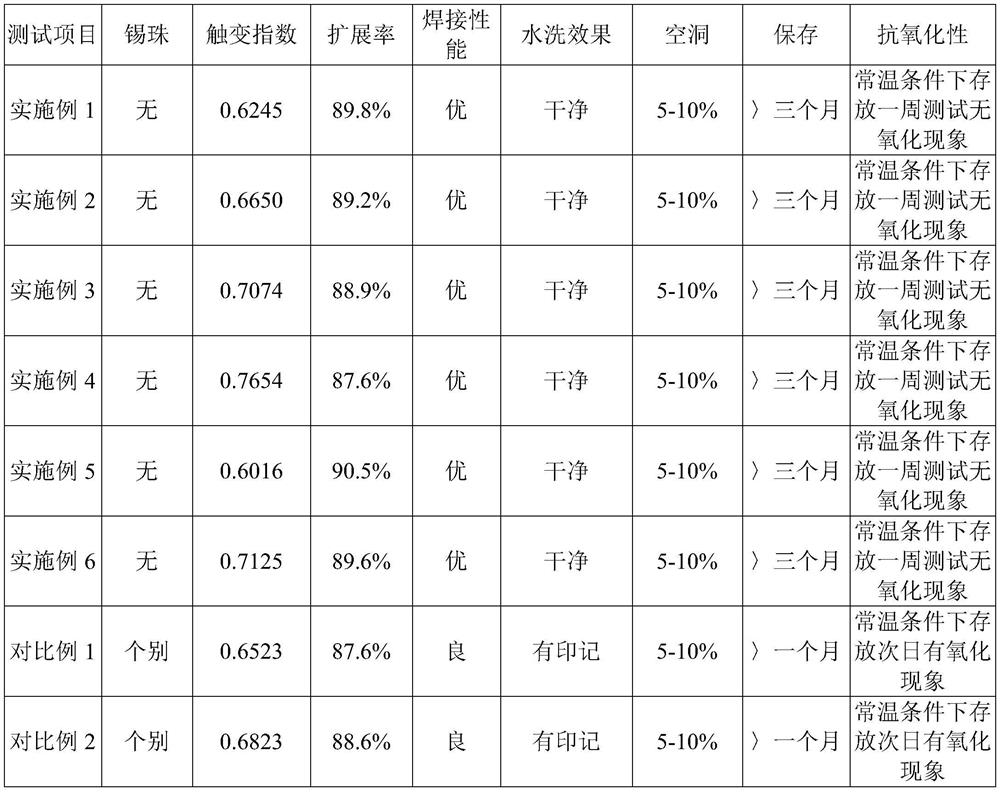

A kind of water-soluble lead-free solder paste, water-washing solder paste and preparation method thereof

ActiveCN112589318BHigh viscosityHigh thixotropic indexWelding/cutting media/materialsSoldering mediaMetallurgyActive agent

The invention discloses a water-washable superfine tin powder water-soluble lead-free high-temperature soldering paste and a preparation method thereof, comprising the following raw materials in parts by weight: 30-55 parts of antioxidant, 10-26 parts of organic solvent, and 4-4 thixotropic agent 8 parts, 8-16 parts of active agent, 6-10 parts of corrosion inhibitor and 6-10 parts of surfactant. The water-washed solder paste prepared by using the solder flux paste of the invention has good stability and effectively meets practical requirements such as oxidation resistance, fullness of tin dots, low voids, no residue splashing, and good cleaning performance.

Owner:深圳市晨日科技股份有限公司

Injection molding method for middle sundries box

InactiveCN107322864AReduce operating errorsQuality assuranceDomestic articlesInjection mouldingInjection molding machine

The invention discloses an injection molding method for a middle sundries box. The method is characterized by comprising the following specific steps that (1) injection molding equipment is checked firstly; (2) mold mounting is conducted, and after mold mounting is finished, the two-time adjustment process is further conducted to enable the injection molding equipment to enter an automatic mold adjusting state; (3) injection is conducted; (4) injection is finished, cooling molding is conducted, a product is made to be in a pressure maintaining stage, the pressure is maintained to be 60-80 bar, the time is 1-3 S, then the product is cooled, and the cooling time is 1-4 S; and (5) a mold is opened, and after cooling, only the mold needs to be opened to take out the product. The invention provides the complete plastic injection using method. The method is detailed in step and comprehensive in consideration; meanwhile after molding mounting is finished, the two-time adjustment process is further conducted to enable the injection molding equipment to enter the automatic mold adjusting state; and specific steps are given, operation errors are reduced, the product quality is indirectly ensured, and the product qualification rate is increased.

Owner:ANHUI JIANGSHAN MACHINERY

Planting method of roses

InactiveCN108651120AEasy to controlAccurately grasp the growth cycleSeed and root treatmentFertilising methodsEconomic benefitsHabit

The invention discloses a planting method of roses. The planting method comprises preparation before planting, rose seed treatment, planting, field treatment, pest control and prevention and rose harvesting. The planting method of roses belongs to the technical field of flower planting. The method disclosed by the invention is simple and detailed in steps; due to the use of the planting method ofroses, disclosed by the invention, the planting is easy to control, and the growth cycle and growth habit of the roses can be accurately mastered; and after the method disclosed by the invention is used, the growth speed of the roses can also be greatly increased, and the economic benefit can be further increased.

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

Asparagus fern maintenance method

InactiveCN105309144AEasy to controlAccurately grasp the growth cycleHorticultureRoom temperatureEngineering

The invention belongs to the field of agriculture, and particularly relates to an asparagus fern maintenance method which is simple and capable of avoiding the phenomena of yellowing leaves and fallen leaves. The asparagus fern maintenance method is characterized by comprising the steps that 1, fertilize water is regulated, fertilizer does not need to be applied too often during growth of asparagus ferns, topdressing is generally conducted only in spring and in autumn, diluted rotten manure or a low-concentration compound fertilizer solution or washing water of rice or bean juice is applied once every other 10-15 days, the fertilizer is not suitable for being applied in summer which is high in temperature or in winter which is low in temperature, and the fertilizer needs to be applied according to the principles of being not overdosed and not out of date; watering needs to be conducted when soil is dry, the soil needs to be drenched when the soil is dry, and steep water is not left on pot surfaces; water is regularly sprayed on leaf surfaces to remove dust on the leaf surfaces; 2, the asparagus ferns need to be placed appropriately, the asparagus ferns can grow well in the environment which is semi-shade, semi-light and slightly wet, solarization needs to be avoided, a place which has sunlight is appropriate, ventilation is needed, the asparagus ferns need to keep far away from a furnace and a television, heat preservation is needed, the lowest room temperature cannot be lower than five DEG C, and a plastic housing is needed for keeping the asparagus ferns from the cold if the room temperature ranges from zero DEG C to four DEG C.

Owner:赵宝瀛

Method for planting paeonia lactiflora

InactiveCN108575650AEasy to controlAccurately grasp the growth cycleFlowers cultivationEconomic benefitsHabit

The invention discloses a method for planting paeonia lactiflora. The method comprises the following steps: carrying out preparation before planting, treating paeonia lactiflora seeds, carrying out planting, carrying out field treatment, preventing and controlling diseases and pests, and harvesting paeonia lactiflora. The invention belongs to the technical field of flower planting. The method provided by the invention is simple, and the steps are detailed. Through the utilization of the paeonia lactiflora planting method provided by the invention, the planting is easy to control, and the growth period and the growth habit of the paeonia lactiflora can be accurately mastered. With the utilization of the method, the growth speed of the paeonia lactifloracan be greatly improved, and the economic benefit is further improved.

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

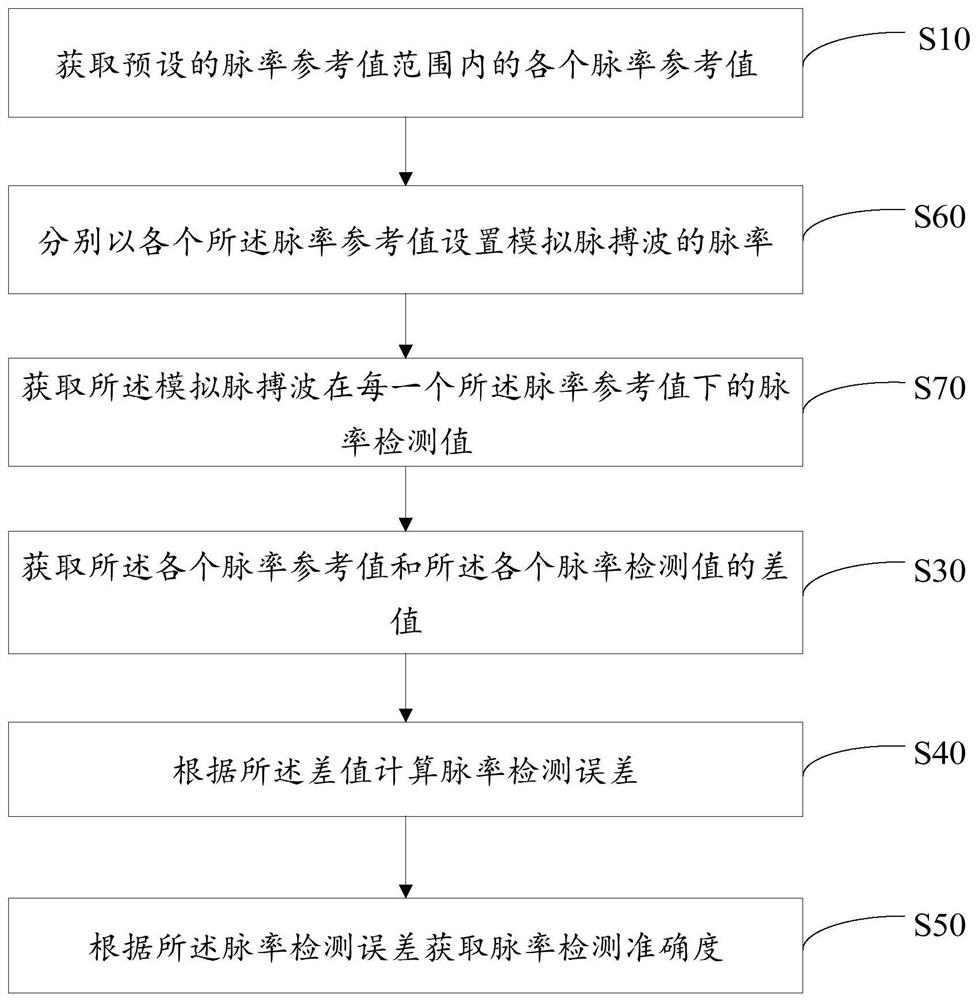

Pulse rate accuracy test method, device and computer-readable storage medium

ActiveCN108523871BDetailed stepsIncrease credibilityHealth-index calculationSensorsPulse rateAcoustics

The invention discloses a detecting method for pulse rate accuracy. The method comprises the steps that reference values of all pulse rates in a preset pulse rate reference value range are acquired, each pulse rate detecting value corresponding to each pulse rate reference value is acquired, difference values between all the pulse rate reference values and all the pulse rate detecting values are acquired, according to the difference values, the pulse rate detecting error is calculated, and according to the pulse rate detecting error, the pulse rate detecting accuracy is acquired. The inventionfurther discloses a detecting device for the pulse rate accuracy and a computer readable storage medium. According to the method, the difference values between all the pulse rate reference values andall the pulse rate detecting values are acquired, according to the difference values, the pulse rate detecting error is calculated, according to the pulse rate detecting error, the pulse rate detecting accuracy is acquired, the detecting method with detailed steps and a high-reliability detecting result for the pulse rate accuracy is provided and fills the gap in the detecting technology for thepulse rate accuracy detected by a wearable product with a photoplethysmography sensor.

Owner:RHEINLAND SHENZHEN

Processing method of dual power transmitter

ActiveCN108296791BDetailed stepsReduce difficultyWelding/cutting auxillary devicesManufacture of electrical instrumentsMachiningTransmitter

The invention provides a machining method of a dual-power-source transmitter. The technical problems that an existing transmitter is provided with no corresponding machining method, batch machining cannot be rapidly carried out, and the machining speed is low are solved. The machining method of the dual-power-source transmitter comprises the following steps that a, plate materials are machined into a shell through a production system, an anti-rust coating is arranged on the outer side of the shell, and the thickness of the anti-rust coating is 0.4-0.8 mm; b, a first circuit board and a secondcircuit board are assembled to the shell; c, a nixie tube is assembled to a panel; d, an adjusting button is assembled to the panel; e, a fence type terminal is assembled to the panel; f, the panel isassembled to the shell, and the dual-power-source transmitter is obtained; and g, the dual-power-source transmitter is detected through detection equipment. The machining method has the advantage ofbeing high in machining speed.

Owner:HAIYAN PYAN POWER TECH CO LTD

Preparation method of density gradient column

PendingCN114739866AFast preparationDetailed stepsMaterial analysis by observing immersed bodiesPhysical chemistryDrug product

The invention relates to a preparation method of a density gradient column. The preparation method comprises the following steps: determining the number and density of required floaters according to the volume density range of a to-be-detected product; selecting a first medicine and a second medicine according to the to-be-detected product; firstly, the density value of the highest liquid level and the density value of the lowest liquid level of mixed liquid in the density gradient tube are determined; wherein the mixed liquid is formed by mixing a first liquid and a second liquid, and the density of the first liquid is lower than that of the second liquid; further determining the density preparation value of the first liquid and the density preparation value of the second liquid in the mixed liquid at the target control temperature; preparing the first medicine and the second medicine into first liquid and second liquid according to the density preparation value; and filling the prepared floater, the first liquid and the second liquid into a density gradient tube to prepare the density gradient column. According to the preparation method of the density gradient column provided by the invention, the linear density gradient column within the target density gradient range can be rapidly prepared at one time.

Owner:山西钢科碳材料有限公司

Manufacturing method of smart power transmitter

ActiveCN107703338BDetailed stepsReduce difficultyWelding/cutting auxillary devicesManufacture of electrical instrumentsTransmitterCoating

The present invention provides a manufacturing method of an intelligent electric quantity transmitter which solves the technical problems that a conventional electric quantity transmitter does not have a corresponding manufacturing method, needs to depend on the experiences to manufacture, is tedious to manufacture, etc. The manufacturing method of the intelligent electric quantity transmitter comprises the following steps of a, processing a sheet matal into a shell via a production system, wherein the shell has an outer coating, and the thickness of the coating is between 0.5 mm and 1.5 mm; b, assembling a palisade terminal block on the outer end face of an upper cover; c, assembling a fixing rack on the inner end face of the upper cover; d, separately assembling a circuit board 1 and a circuit board 2 on the fixing rack; e, putting a spongy cushion at the bottom of the shell, and putting an insulating paper at the side part of the shell; f, assembling the upper cover on the shell toobtain a finished intelligent electric quantity transmitter; g, detecting the intelligent electric quantity transmitter via a detection device; h, packaging and warehousing the detected and qualifiedintelligent electric quantity transmitter. The manufacturing method of the present invention has the advantage of being convenient to manufacture.

Owner:HAIYAN PYAN POWER TECH CO LTD

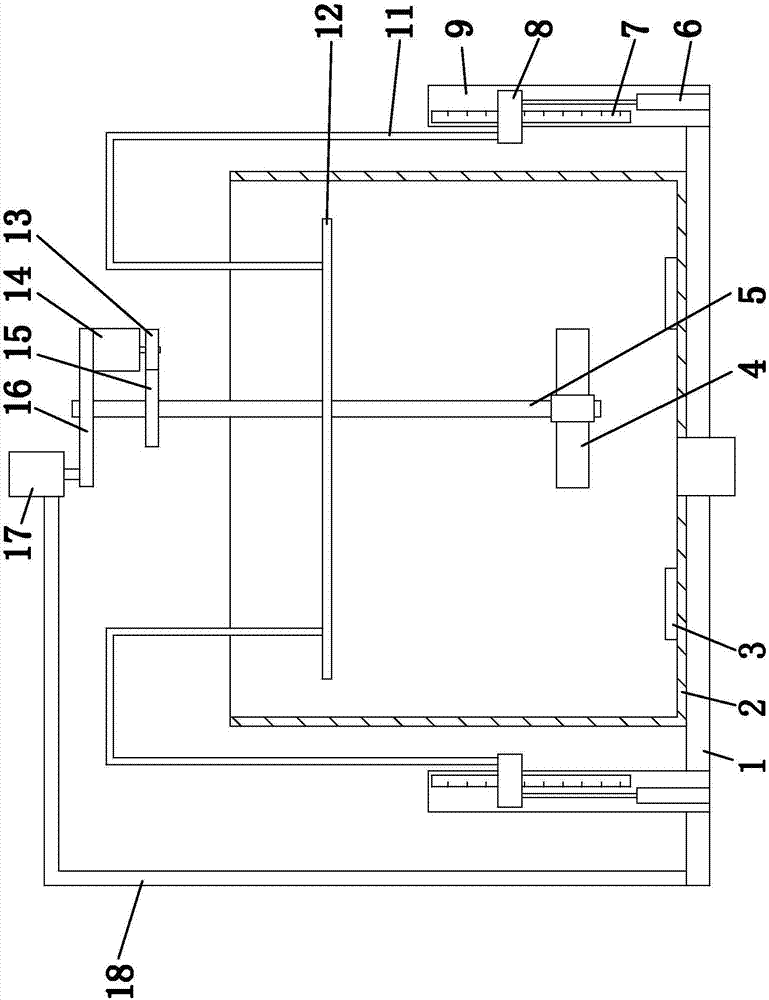

Production process of multi-function power transmitter

ActiveCN107486722BDetailed stepsReduce difficultyFireproof paintsWelding/cutting auxillary devicesTransformerTransducer

The invention provides a production process for a multifunctional electrical quantity transducer. According to the production process, the technical problems that an existing electrical quantity transducer does not have the corresponding production process and needs to be produced by relying on the experience, and production is complex are solved. The production process for the multifunctional electrical quantity transducer comprises the following steps that a, plates are machined into a shell through a production system, a coating layer is smeared on the shell, and the thickness of the coating layer is 0.4-1.2 mm; b, a fence-type terminal platform is assembled on the outer end face of a face plate; c, a base plate is assembled on the inner end face of the face plate; d, a main board, a transformer and a mutual inductor are assembled in sequence to the base plate; e, an insulating sponge cushion is placed into the shell; f, the face plate is assembled to the shell, and thus a finished product of the multifunctional electrical quantity transducer is obtained; g, the multifunctional electrical quantity transducer is detected through detecting equipment; and h, the multifunctional electrical quantity transducer which is detected to be qualified is packaged and put in storage. The production process has the advantages of fast production.

Owner:HAIYAN PYAN POWER TECH CO LTD

Experimental method for continuously compressing and tamping filling body test piece

PendingCN111638111AEasy to operateDetailed stepsPreparing sample for investigationMaterial strength using tensile/compressive forcesUniaxial compressionGeotechnical engineering

The invention relates to a filling body experiment method, and particularly discloses an experimental method for continuously compressing and tamping a filling body test piece. The method comprises five steps of experiment mold assembly, basic test piece preparation, multi-layer test piece preparation, uniaxial compression experiment and uniaxial creep experiment. The index of the strength characteristic of the filling body is mainly static uniaxial compressive strength; however, influence caused by tamping operation is rarely considered in an indoor experiment; especially, influence of multiple times of tamping is not consideredd; therefore, researchers need to restore the tamping influence on a goaf of an underground roadway and prepare corresponding tamped specimens to complete analysisand research in a laboratory; and the filling body strength conversion relation in an indoor stope and an in-situ stope are established; therefore, according to the experimental method for continuously compressing and tamping the filling body test piece, the preparation process of the test piece is attached to the tamping process of the underground goaf, the experimental operation method is suitable for most indoor experiments, and the test piece which is continuously tamped for multiple times can be prepared according to experimental requirements to carry out uniaxial compression and creep experiments.

Owner:ANHUI UNIV OF SCI & TECH

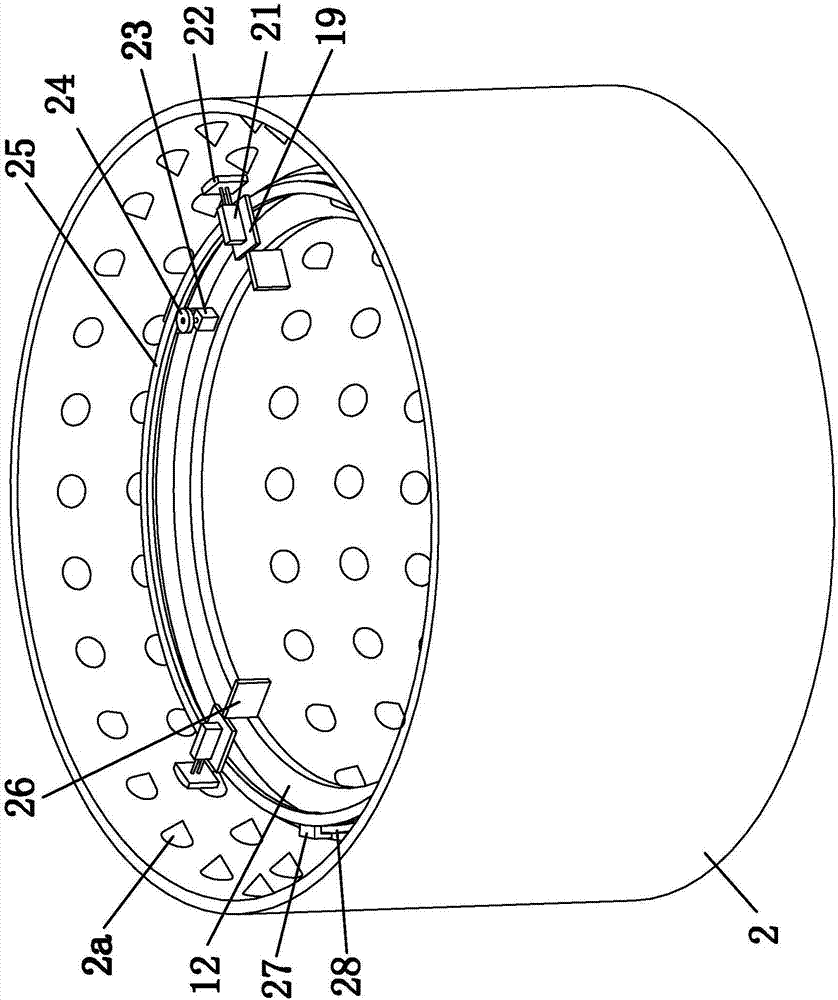

Technological process for producing silica gel wrist strap production die

The invention discloses a technological process for producing a silica gel wrist strap production die. The technological process comprises the following steps that S1, according to the specification of the produced die, a raw material plate is cut to be in needed size; S2, needed contents are engraved on the cut raw material plate, and therefore a semi-finished product of the die is obtained; S3, the semi-finished product is curved to form a round pipe-shaped structure; S4, a gap in the round pipe-shaped structure is subjected to welding closing operation; S5, the production die welded in the step S4 is corrected to form a regular round pipe-shaped structure; S6, a bottom cap is manufactured and is welded to the bottom of the regular round pipe-shaped structure, and therefore a crude product of the production die is obtained; and S7, the surface of the crude product is polished to obtain a finished product. The technological process for producing the silica gel wrist strap production die is detailed in step, simple in manufacturing process, short in manufacturing time, light, small and exquisite in produced die, fewer in consumed raw material and low in production cost.

Owner:刘华 +1

Planting method for gardenia jasminoides

InactiveCN108633679AEasy to controlAccurately grasp the growth cycleFlowers cultivationCultivating equipmentsEconomic benefitsPest control

The invention discloses a planting method for gardenia jasminoides, and belongs to the technical field of flower planting. The method comprises the steps of preparation before planting, treatment of the gardenia jasminoides before the planting, planting, field treatment, disease and pest prevention and control, and harvest of the gardenia jasminoides. The method disclosed by the invention is simple, and has the detailed steps; and when the planting method for the gardenia jasminoides is used, the planting can be easy to control, the growth cycle and growth habit of the gardenia jasminoides canbe accurately grasped, and after the method is used, the growth speed of the gardenia jasminoides can be greatly improved, and the economic benefits can be further improved.

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

Processing Technology of Digital Transmitting Device

ActiveCN107649829BDetailed stepsQuality assuranceAssembly machinesManufacture of electrical instrumentsEngineeringTransmitter

Owner:HAIYAN PYAN POWER TECH CO LTD

Product Life Extension Method Based on Material Ratio and Improvement of Key Process Parameters

ActiveCN104834794BConvenient guidanceAccurate lifespan growthSpecial data processing applicationsLife timeImproved method

An improved method for prolonging the product service life based on the material ratio and a key process parameter. The method comprises the following steps: 1, determining the key process parameter and a key performance parameter; 2, obtaining service life data of a product with the material ratio and the key process parameter controlled; 3, establishing a product service life prediction model based on the material ratio and the key process parameter; 4, optimizing the material ratio and the key process parameter to achieve prolonging of the product service life. According to the improved method for prolonging the product service life based on the material ratio and the key process parameter, the reliability and service life of the product are quantitatively adjusted in the view of optimizing the material ratio and the key process parameter, and the non-linear mapping relation model between the material ratio, the key process parameter and the product service life is established for the first time, so that the service life prolonging obtained according to the model is more accurate and more favorable for instructing the industrial production. The complete flow from parameter selection, data obtaining through experiment design and modeling to final prolonging of the service life is given. The method comprises the detailed steps and is easy to implement.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com