Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Contact surface stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

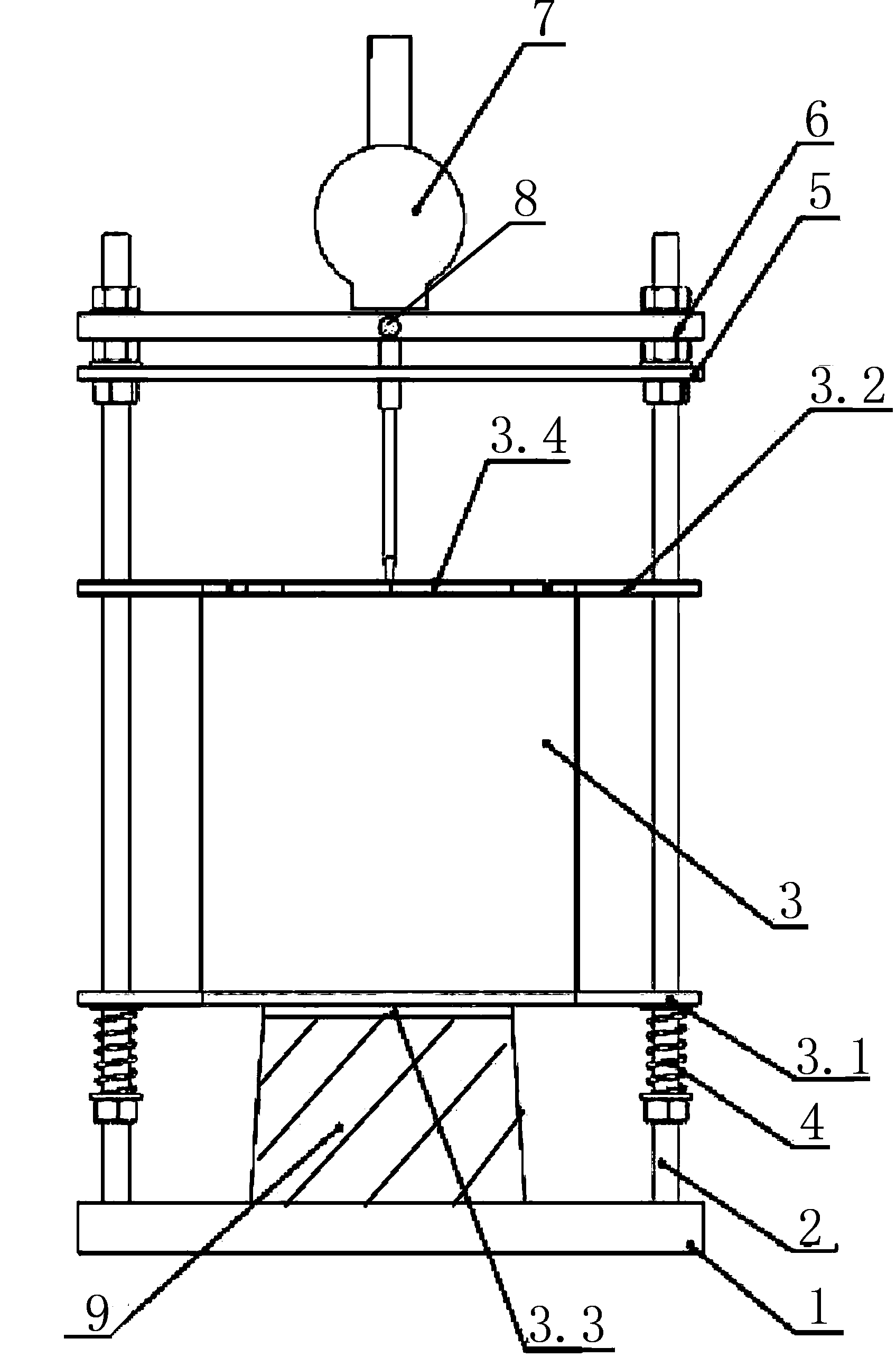

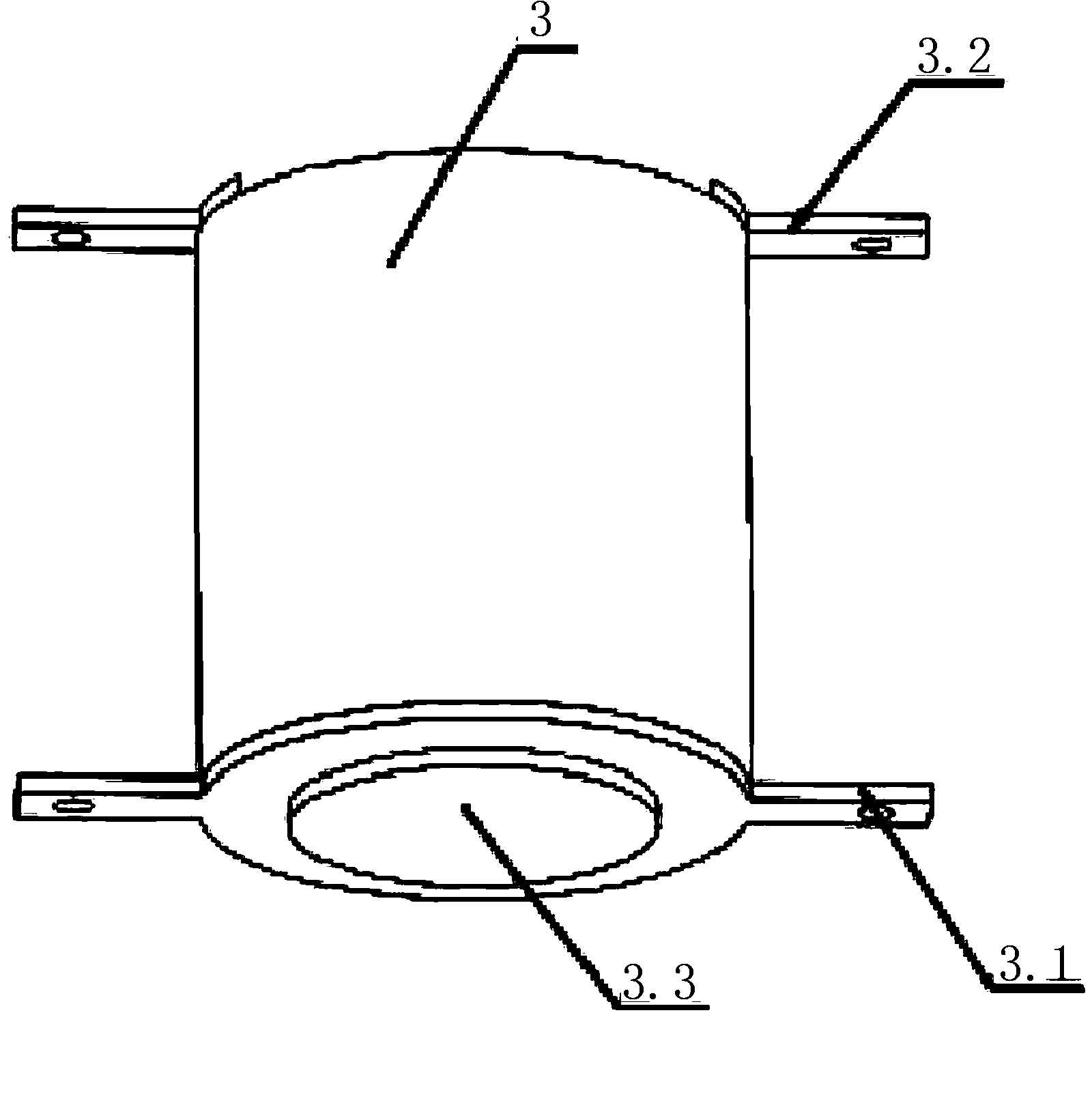

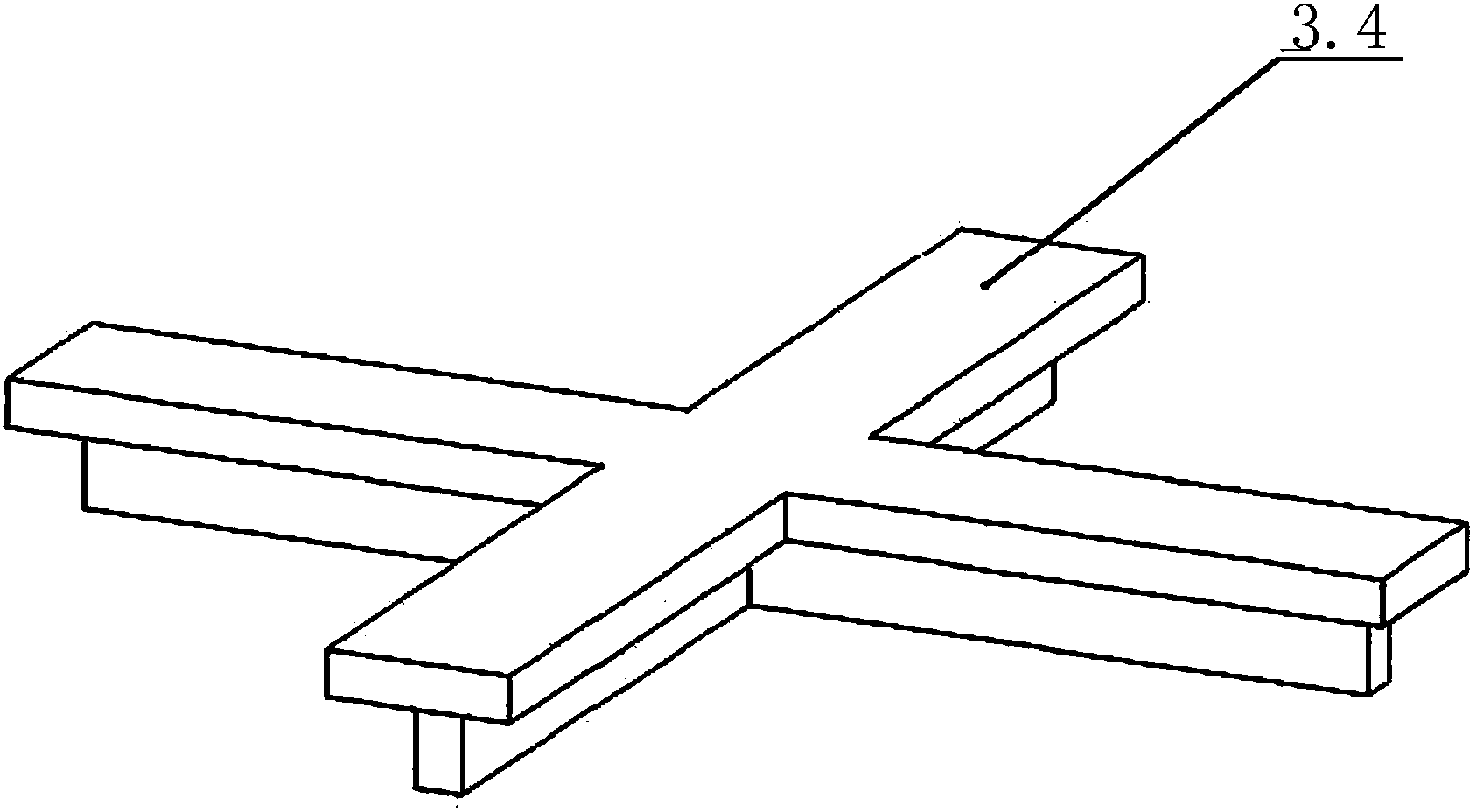

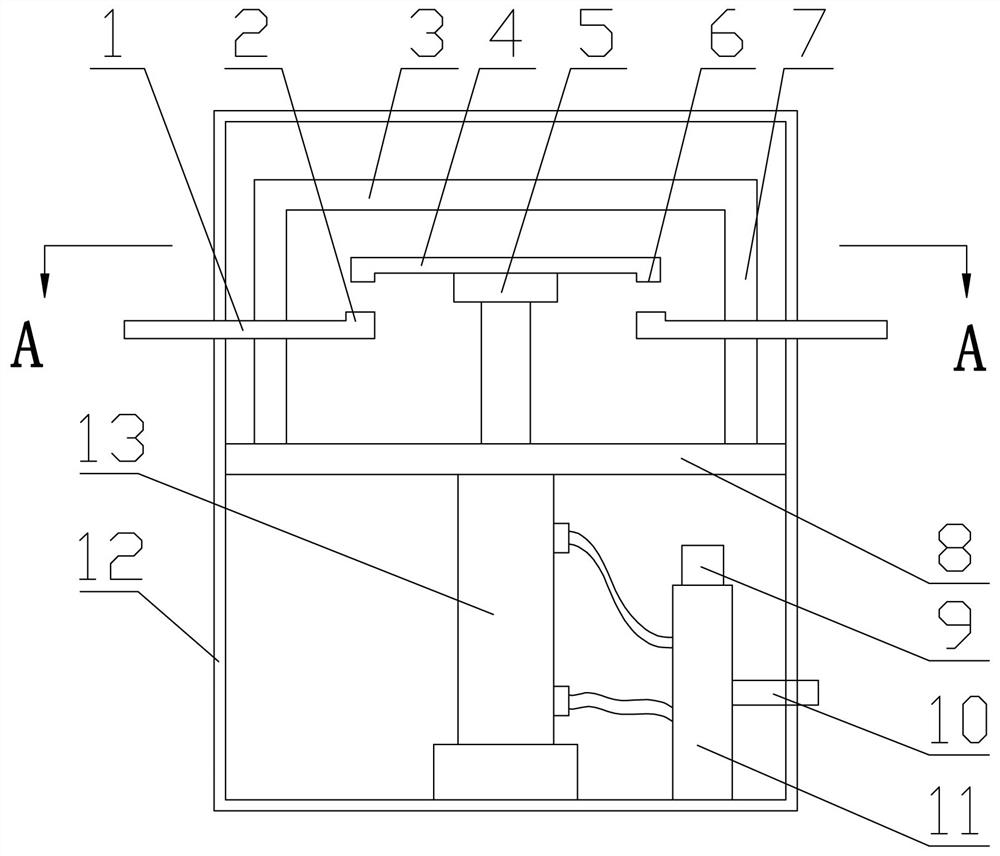

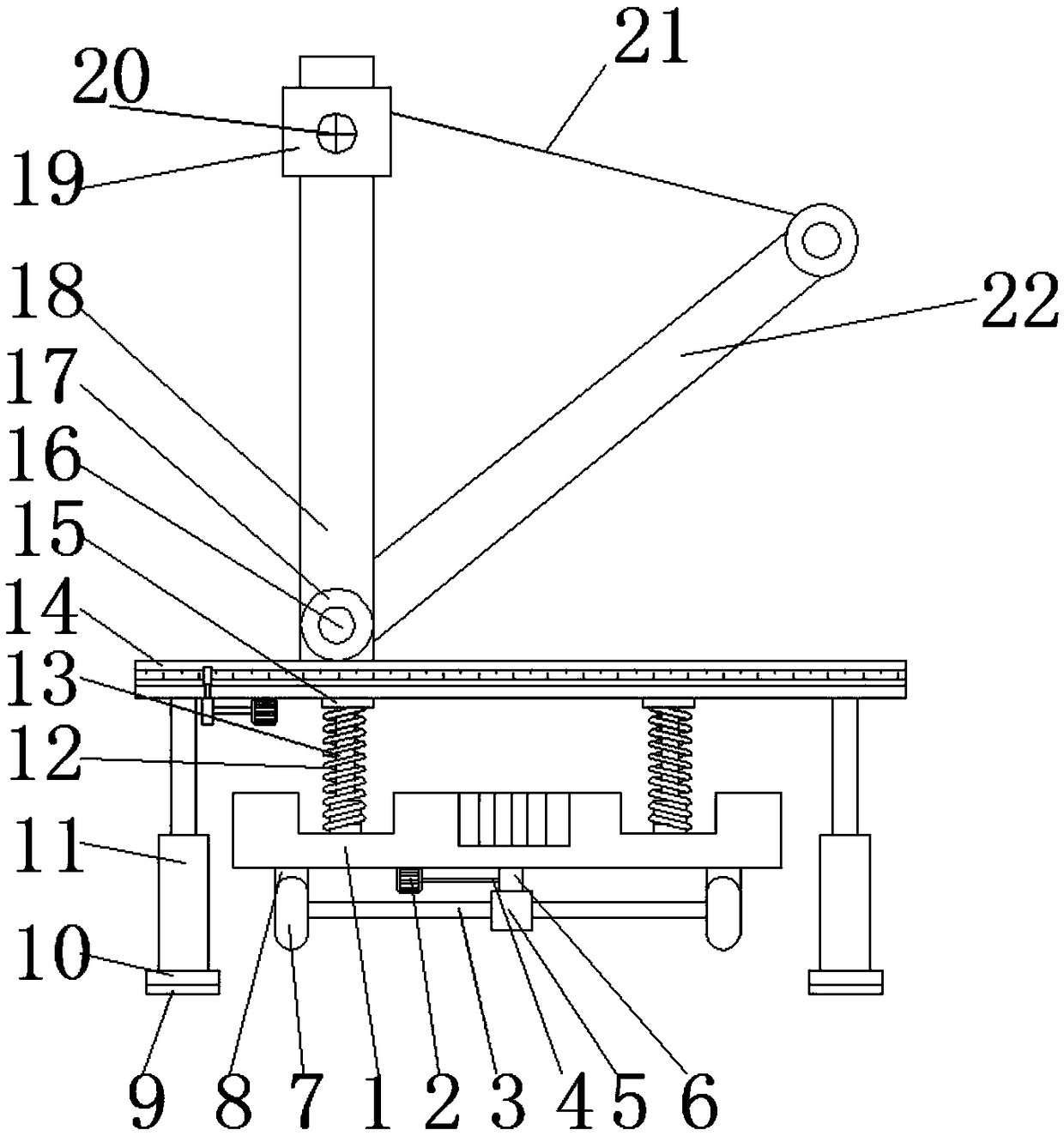

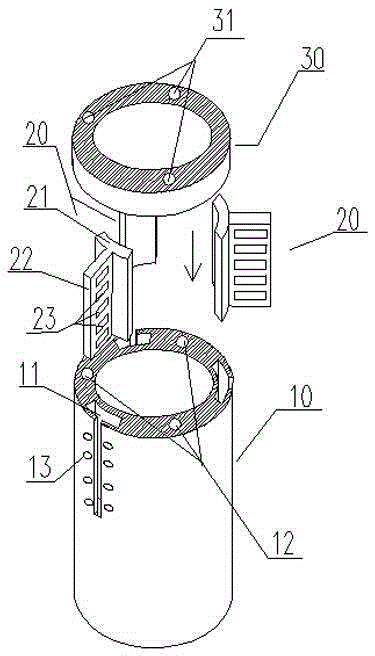

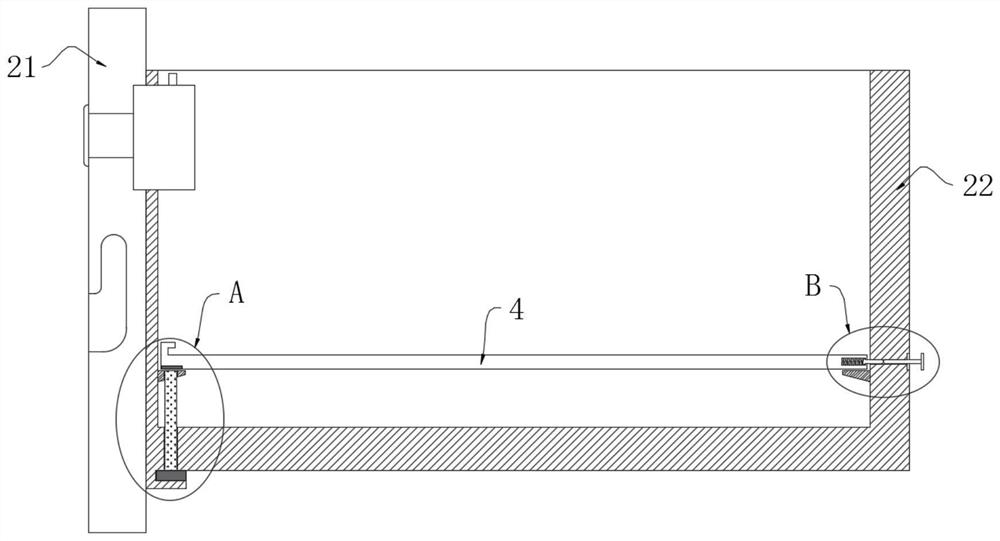

Measurement device and measurement method for fresh mortar non-lateral-confinement bearing capacity

InactiveCN104034595AEasy detectionEliminate the problem of uneven loadMaterial strength using tensile/compressive forcesMeasurement deviceTest sample

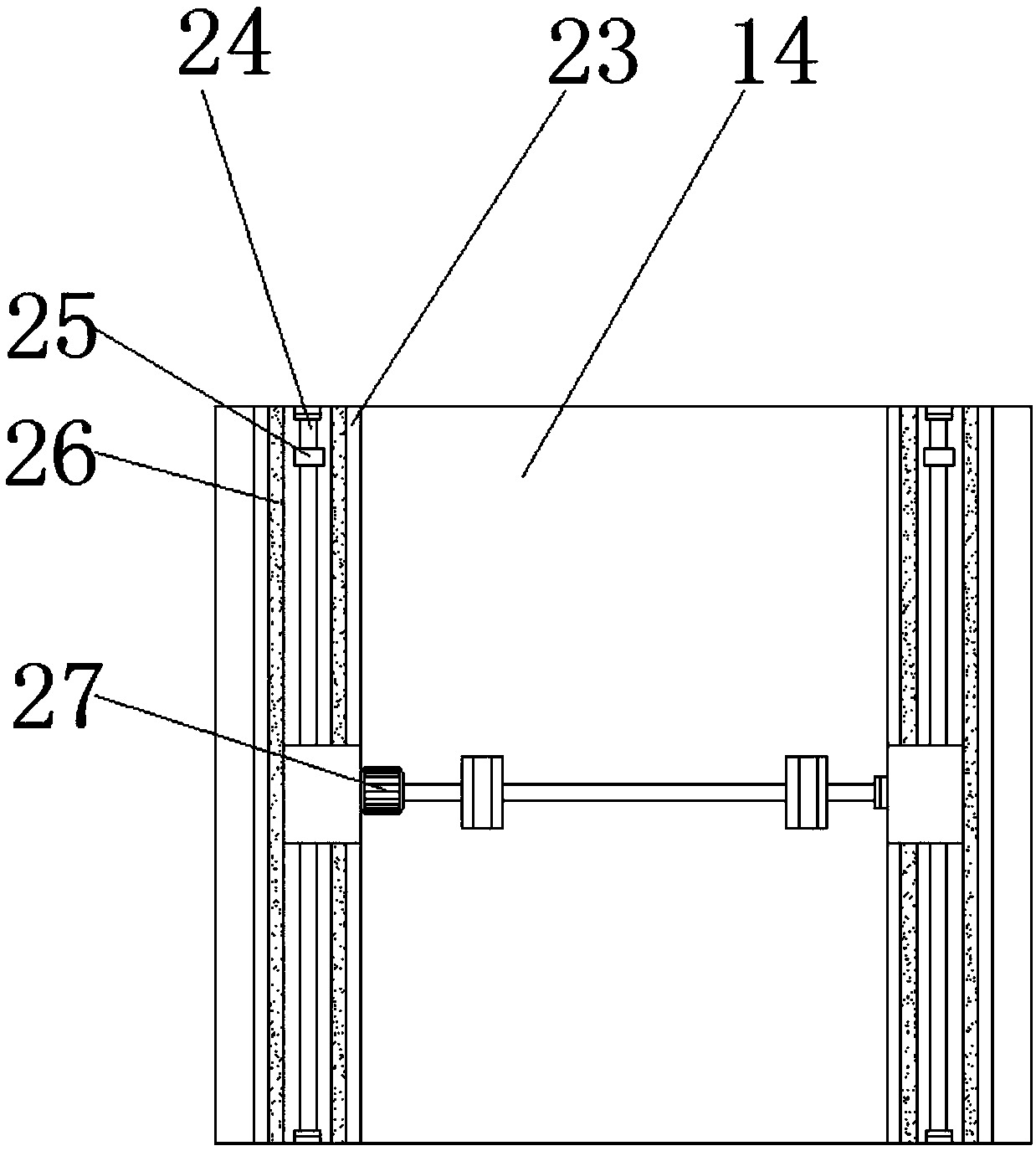

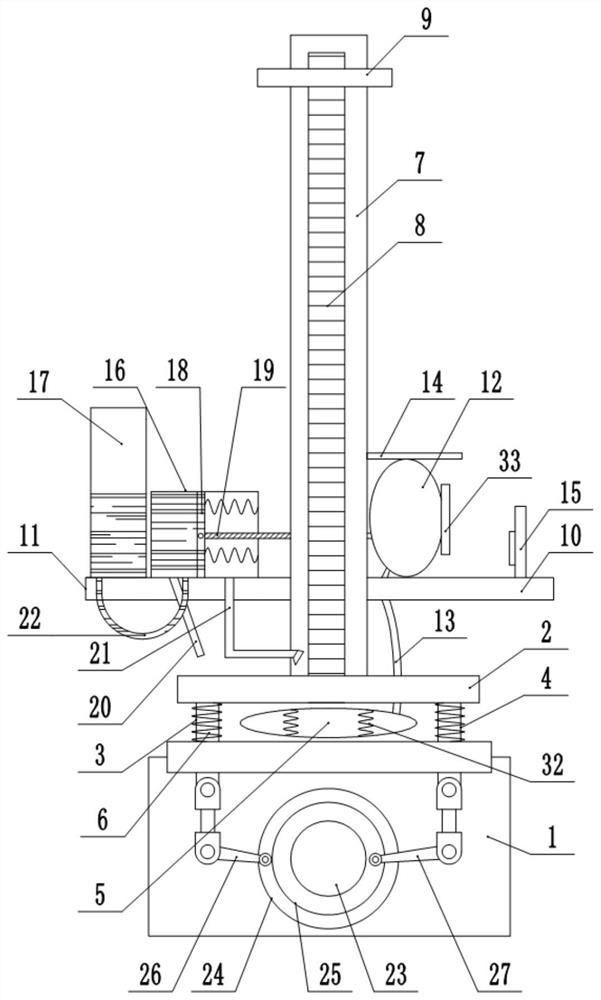

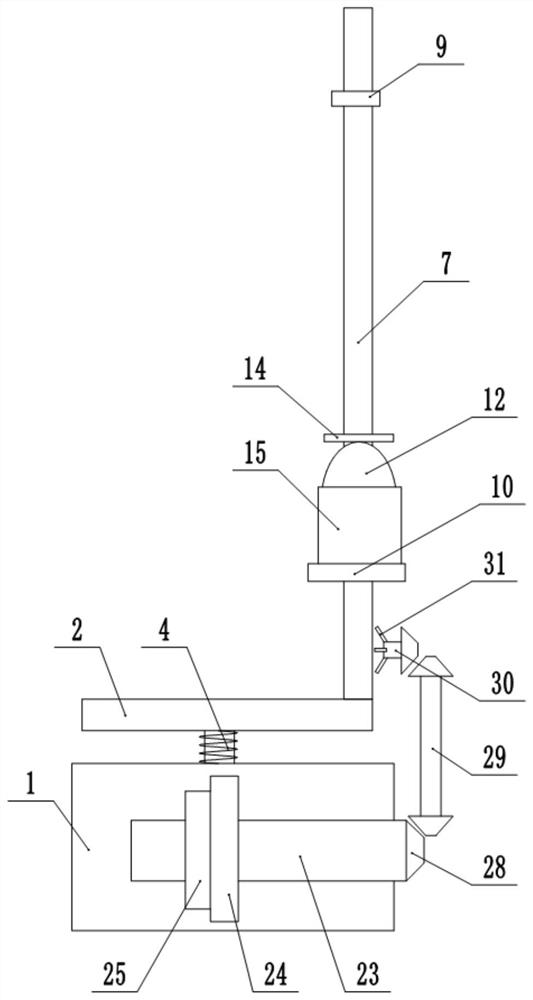

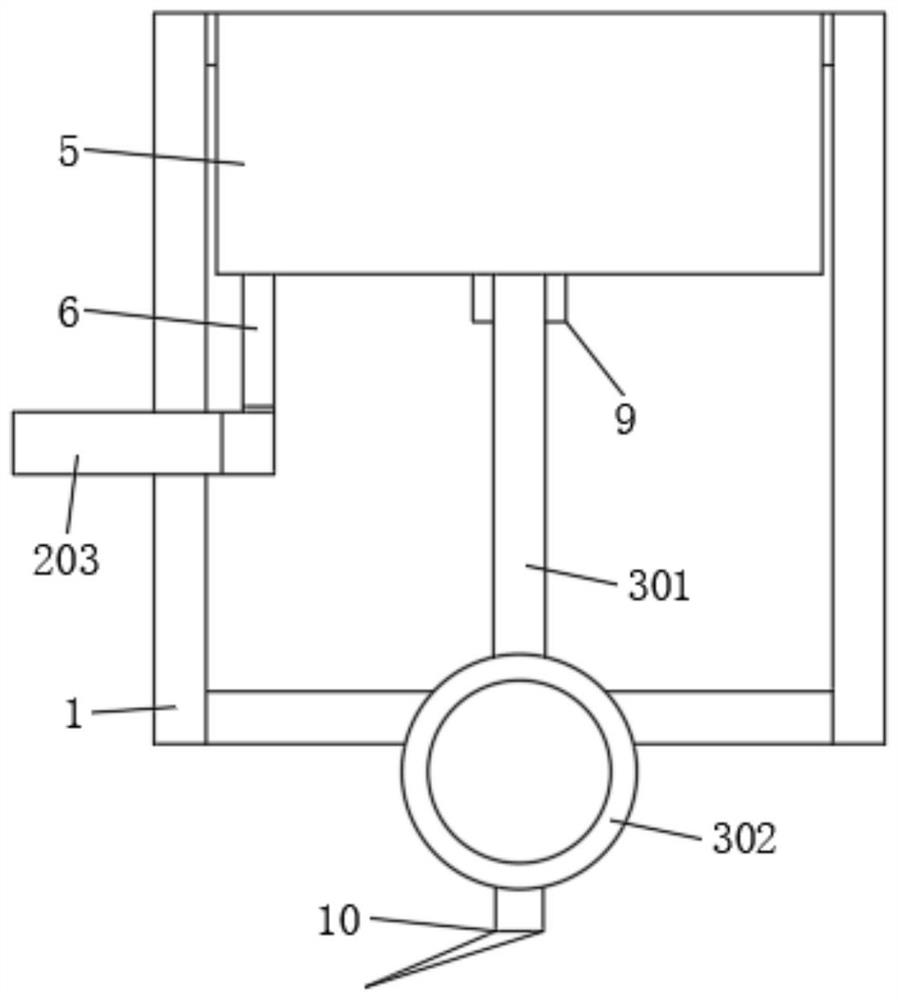

The invention relates to a measurement device for fresh mortar non-lateral-confinement bearing capacity. The measurement device comprises a frame body, a loading device and a vertical displacement measurement device which are arranged from bottom to top respectively, wherein the frame body comprises a base, as well as a screw rod and a plurality of nuts for mounting the loading device and the vertical displacement measurement device, the loading device comprises a loading barrel, a loading plate is arranged on the bottom surface of the loading barrel, a loading barrel upper cover is arranged at the top of the loading barrel, a test sample is arranged between the loading plate and the base, and the vertical displacement measurement device comprises a screw rod fixing cross beam, a dial gauge mounting beam and a dial gauge. The device can be used for utilizing the dead load of liquid to load, and can load continuously and eliminate load unevenness, and the measurement device is simple in structure and convenient in use, and can easily measure the bearing capacity and displacement change of fresh mortar in a corresponding loading direction.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

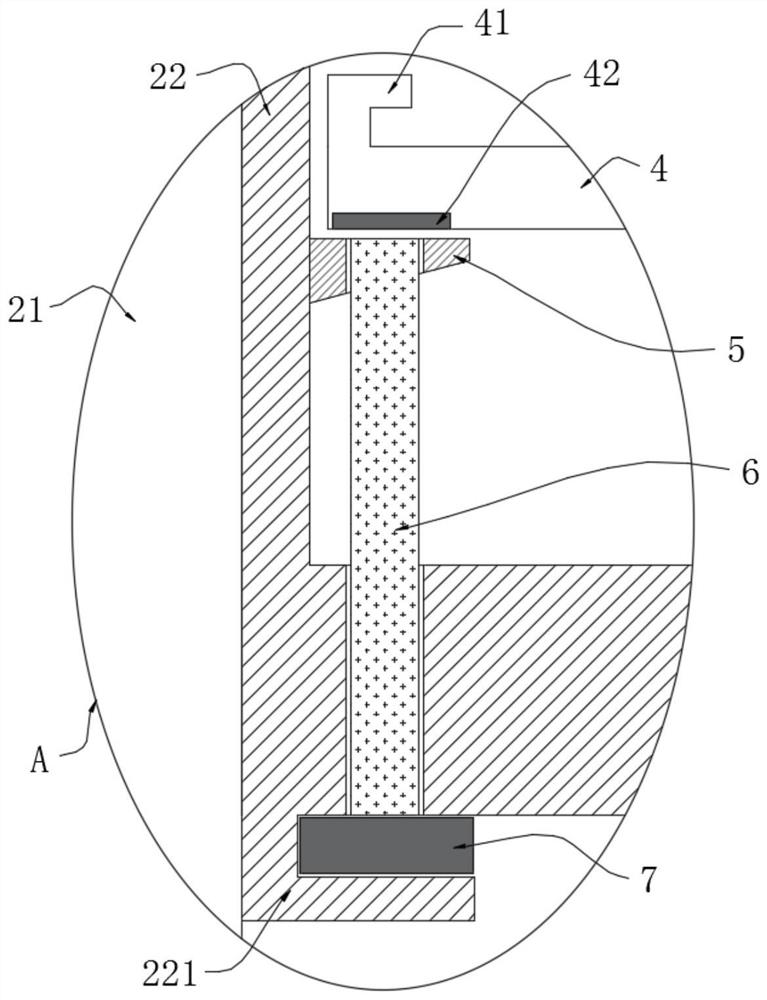

Automatic cleaning device of measuring instrument

ActiveCN108814612AFast dryingAutomate the disinfection processDiagnostic recording/measuringSensorsMeasuring instrumentLiquid storage tank

The invention relates to an automatic cleaning device of a measuring instrument. The device comprises a base and a measuring plate, a first support column and a second support column are fixedly connected to the bottom of the measuring plate, a first air bag is arranged between the first support column and the second support column which are sleeved with support springs, and the support springs are located between the base and the measuring plate; a stand column is fixedly connected to the side of the measuring plate, a first support platform and a second support platform are fixedly connectedto the two sides of the stand column respectively, a second air bag is fixedly connected to the first support platform, a gas-guide tube is communicated between the second air bag and the first air bag, the second support platform is provided with a disinfection tank and a liquid storage tank, a piston is slidably connected into the disinfection box, the piston divides the interior of the liquidstorage tank into a liquid chamber and a gas chamber, a piston rod is fixedly connected to the piston, the free end of the piston rod is movably connected to the second air bag, a sprinkler pipe is arranged at the bottom of the liquid chamber, a gas ejector pipe is communicated with the bottom of the gas chamber, and a U-shaped pipe is communicated between the liquid chamber and the liquid storagetank. By means of the device, the measuring instrument can be cleaned.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

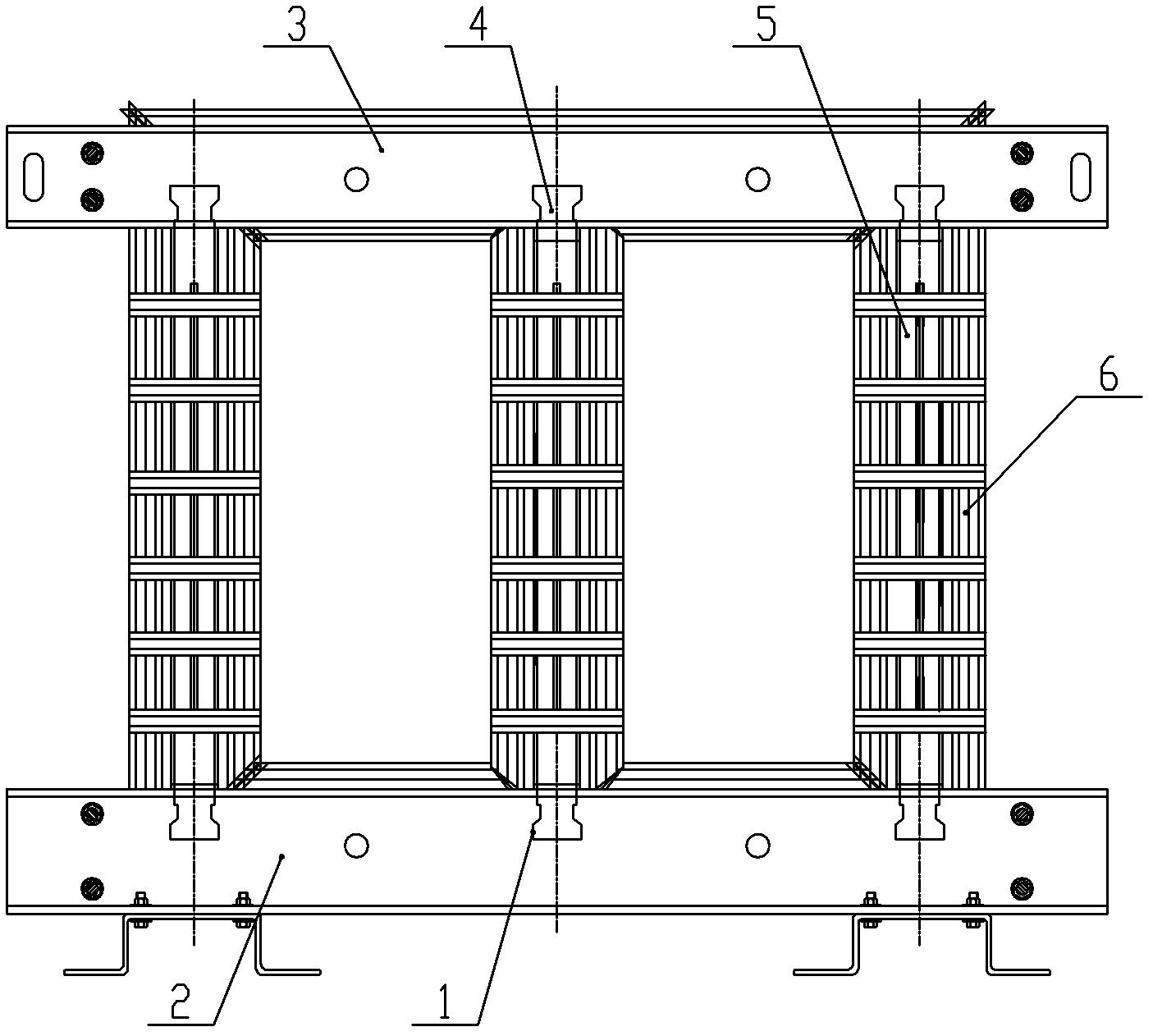

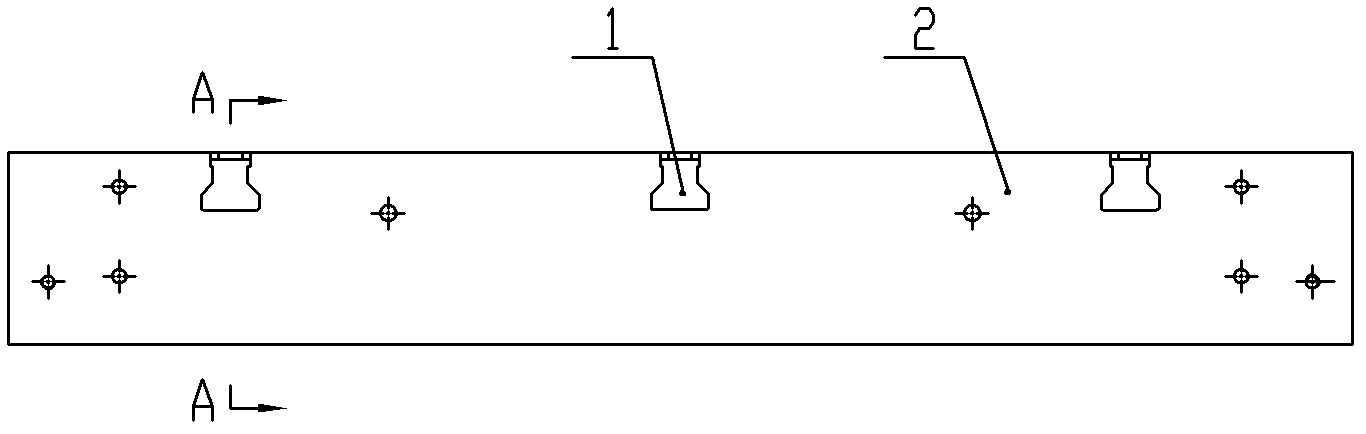

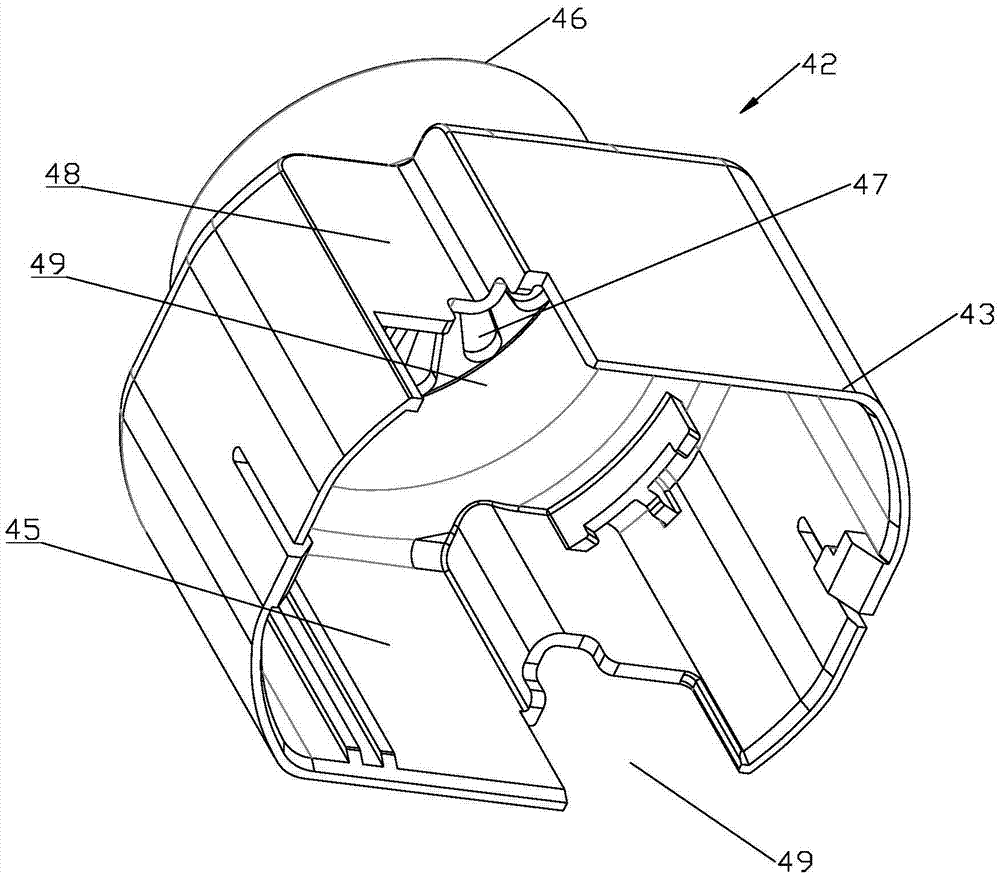

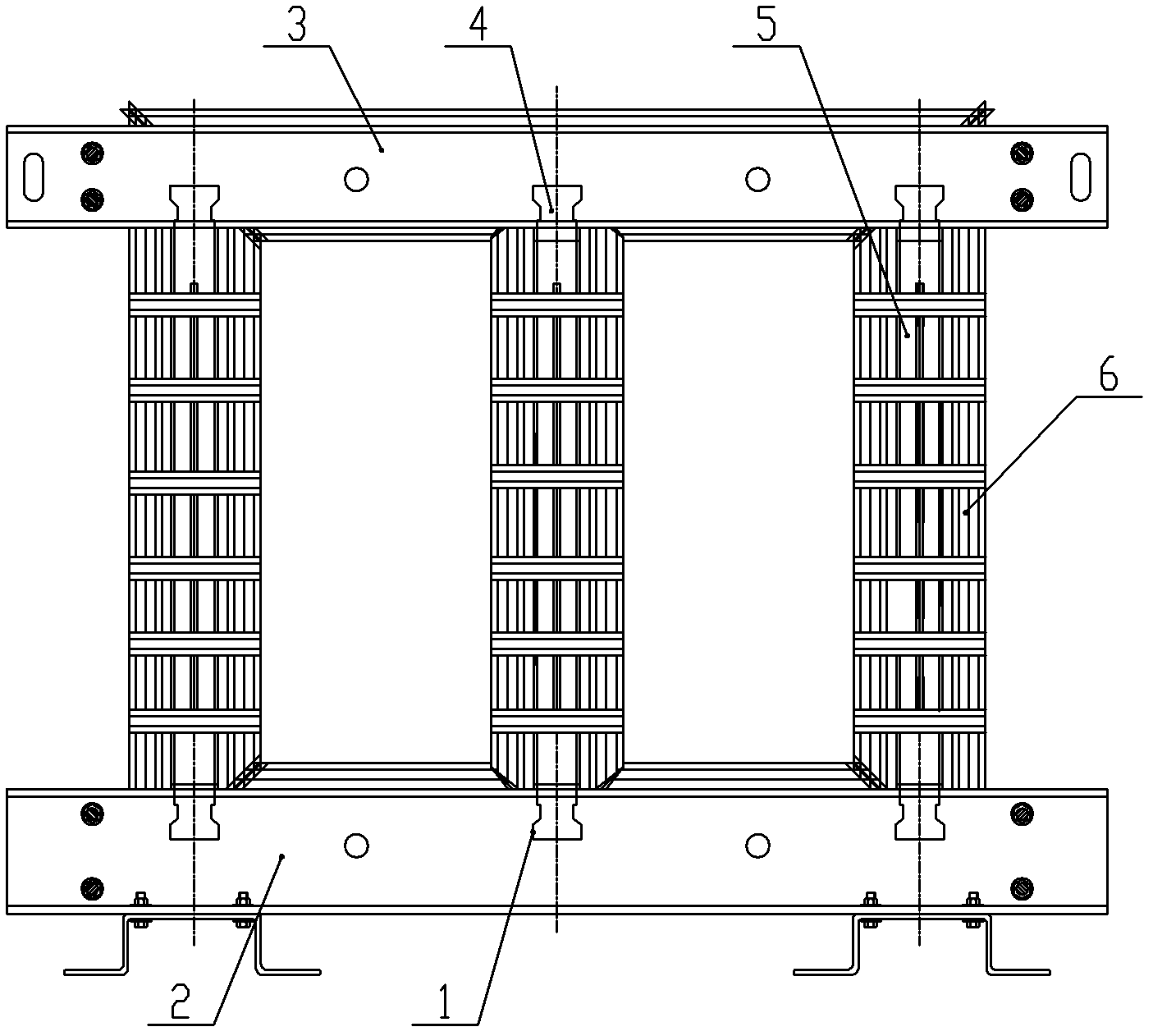

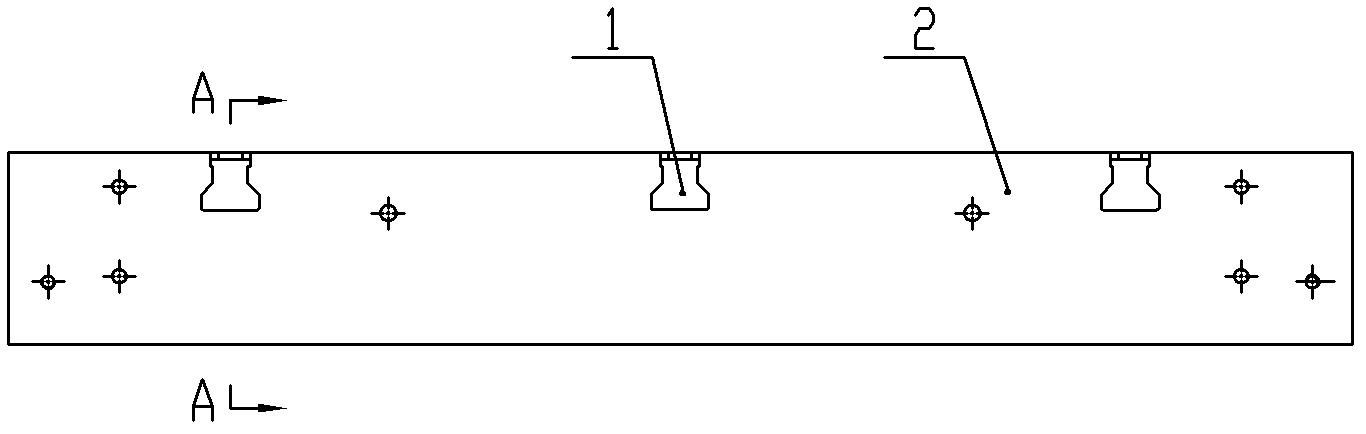

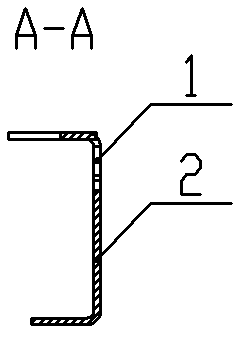

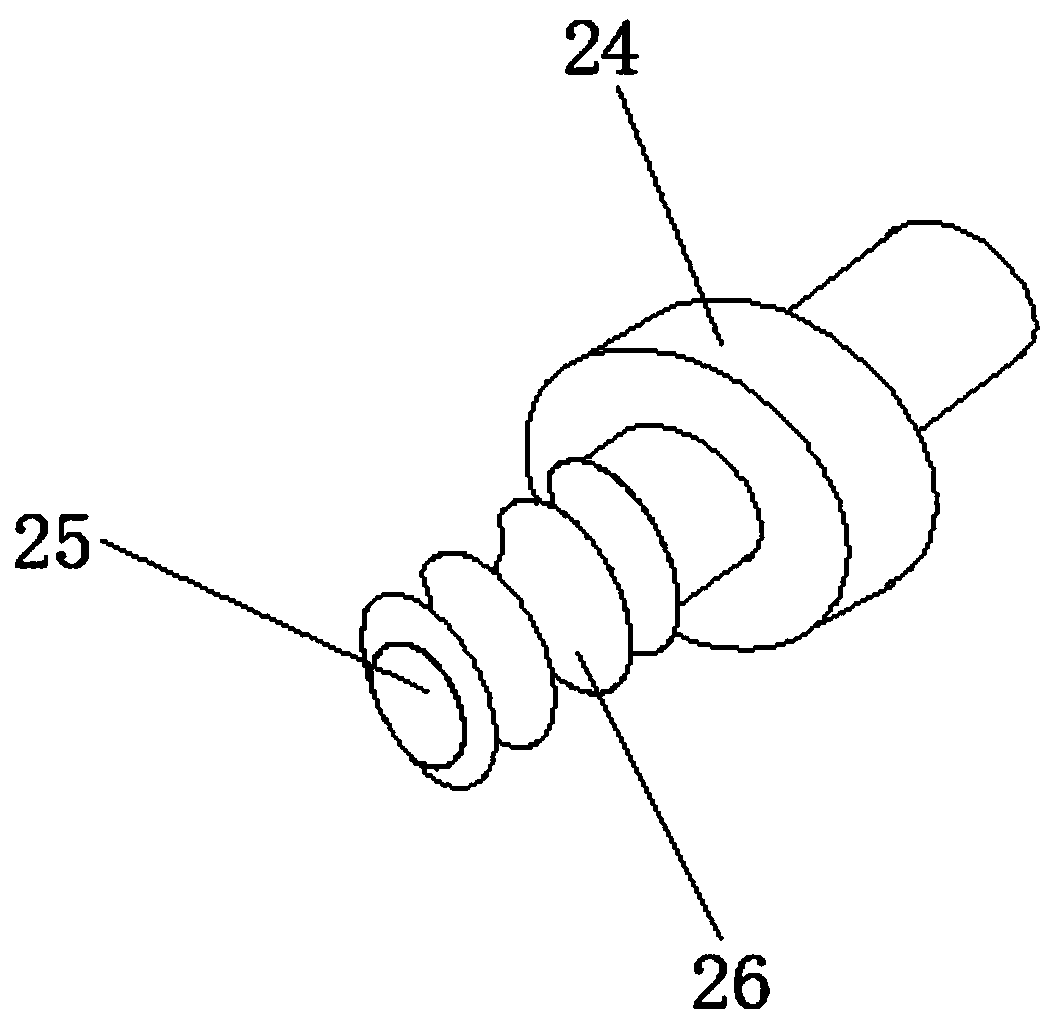

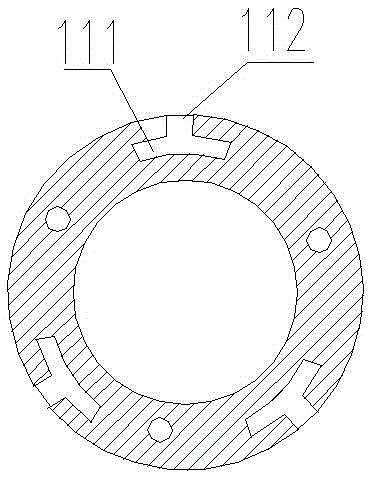

Full face type pulling plate and clamping piece structure

ActiveCN102360793AContact surface stabilityEnhanced binding effectTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The invention relates to a full face type pulling plate and clamping piece structure for a transformer iron core. The full face type pulling plate and clamping piece structure comprises an upper clamping piece, a lower clamping piece and a pulling plate, wherein cross sections of the upper clamping piece and the lower clamping piece have a groove shape; both ends of the pulling plate are providedwith chucks; the webs of the upper clamping piece and the lower clamping piece are provided with troughs of which the shapes are matched with those of the chucks; the chucks are clamped on the rear side of the troughs; and the pulling plate, the upper clamping piece and the lower clamping piece are stuck on the same plane of the iron core. In the full face type pulling plate and clamping piece structure, both ends of the pulling plate are provided with the chucks, both ends of the pulling plate are clamped in the troughs of the upper clamping piece and the lower clamping piece in an inlaying way, and the pulling plate, the upper clamping piece and the lower clamping piece are stuck on the same plane of the iron core, so that the contact surface of the clamping pieces and the iron core is more smooth, and a bundling effect on the iron core is relatively good, and the difficulty in processing an insulating material filled in the center of the iron core is reduced. The full face type pulling plate and clamping piece structure is easy to assemble and has high iron core assembly efficiency.

Owner:WUXI PUTIAN IRON CORE CO LTD

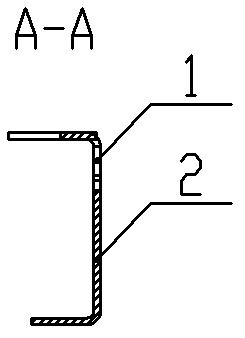

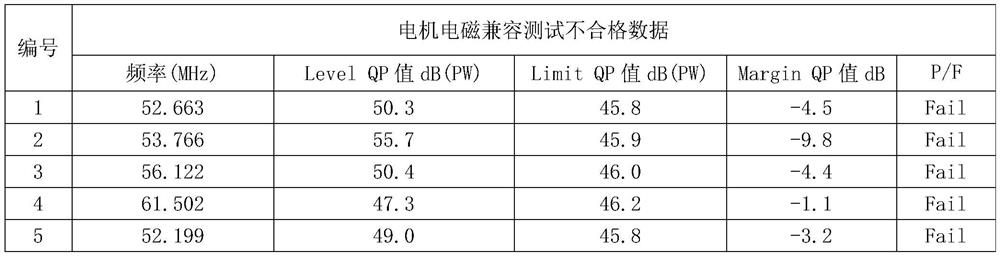

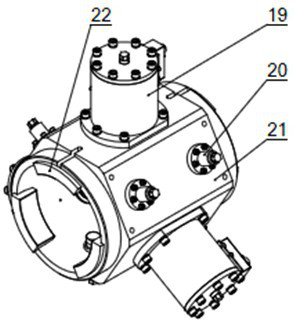

Dust collector motor and motor

PendingCN107231065ASmall sizeReduce volumeWindingsCooling/ventillation arrangementSuction forceElectric machine

The invention discloses a dust collector motor and a motor. The dust collector motor comprises a stator core, a stator core winding, a rotor core and a cooling fan, wherein the stator core is provided with a first through hole; the stator core winding is arranged in the first through hole partially or totally; the rotor core penetrates through the first through hole and is rotatably arranged; the cooling fan comprises a fan blade and a fan housing; the fan housing is a cylinder whose first end is open, the fan housing is provided with a cylinder cavity and an air inlet is arranged in a second end of the fan housing; the fan blade is arranged in the cylinder cavity of the fan housing and sleeves the end of the rotor core, and the rotor core drives the fan blade to rotate; the second end of the fan hosing sleeves the outer surface of the stator core. Compared with the existing motor with the same vacuum suction and the same power, the cross sectional area of the stator core of the motor in the invention is reduced by 36% at most, and the volume is reduced by 8% at most.

Owner:AMETEK IND TECH SHANGHAI CO LTD

Full face type pulling plate and clamping piece structure

ActiveCN102360793BContact surface stabilityEnhanced binding effectTransformers/inductances magnetic coresInductances/transformers/magnets manufactureEngineeringMechanical engineering

Owner:WUXI PUTIAN IRON CORE CO LTD

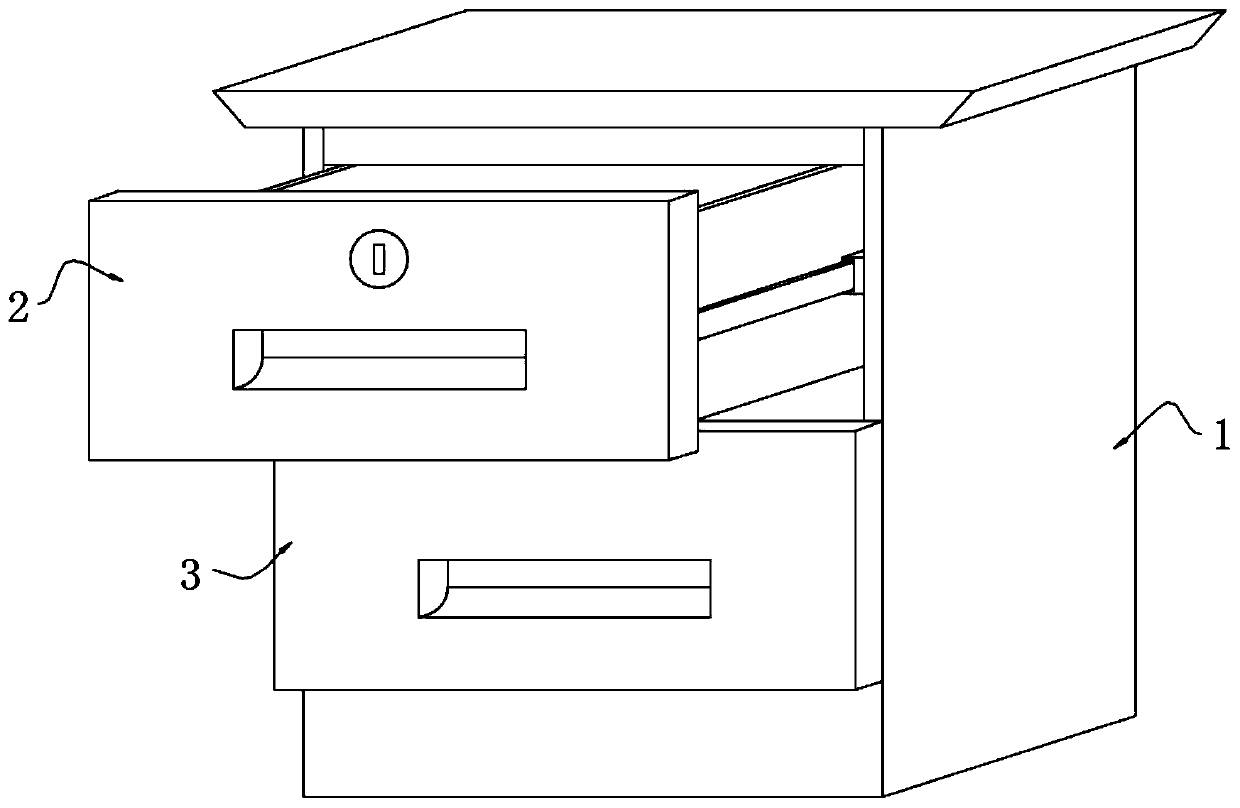

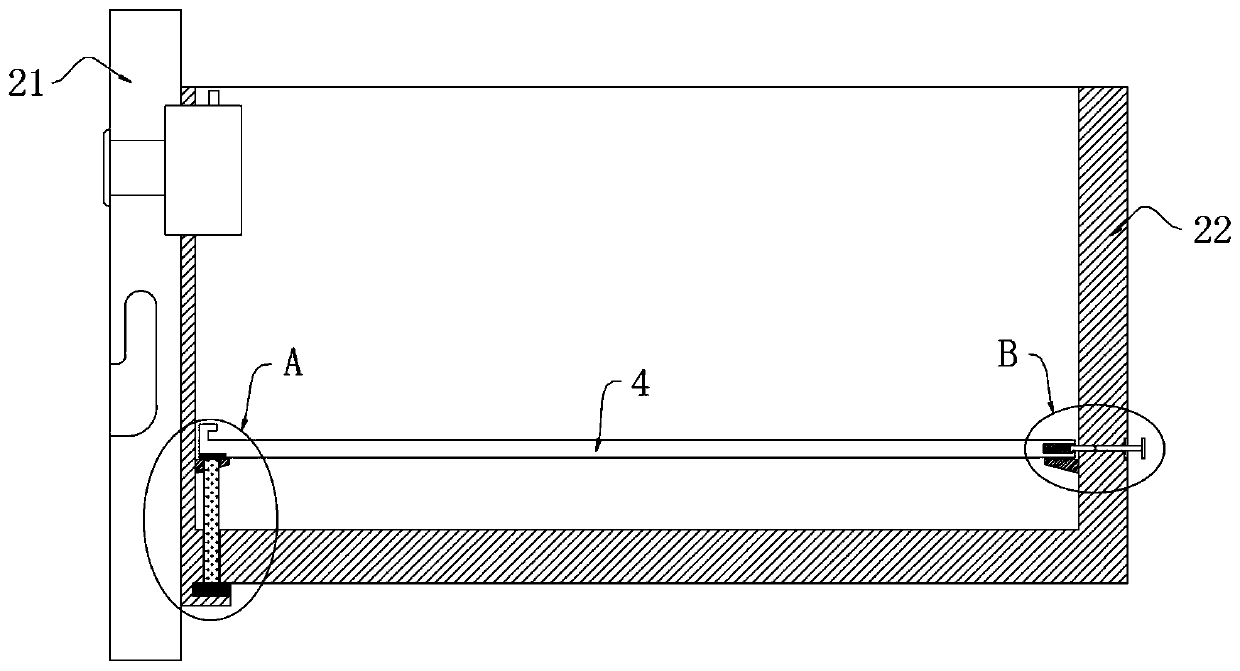

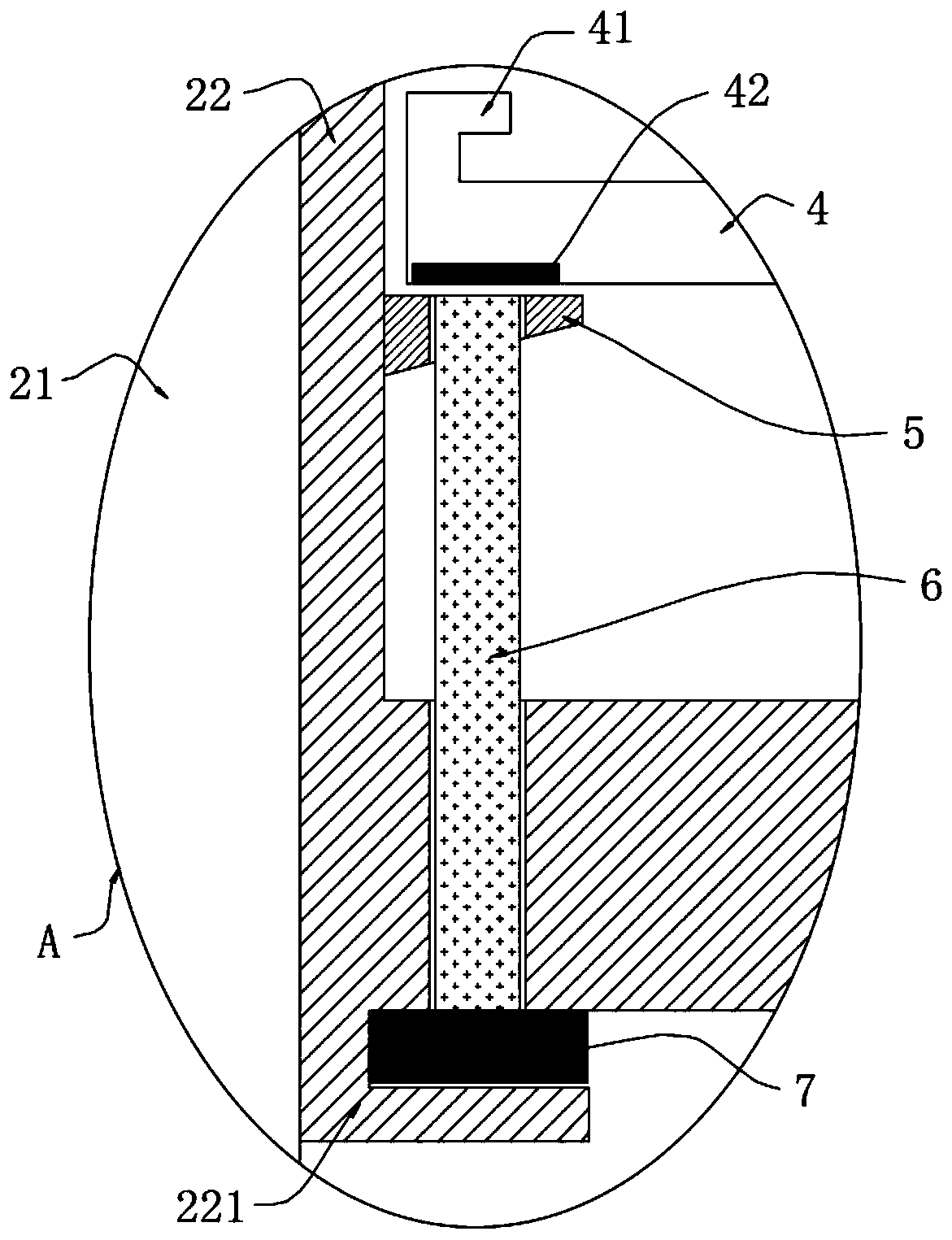

Multi-protection safety drawer cabinet

ActiveCN111329258AAvoid shakingAvoid opening directlyChestsDressing tablesStructural engineeringMechanical engineering

Owner:BBMG TIANTAN FURNITURE CO LTD

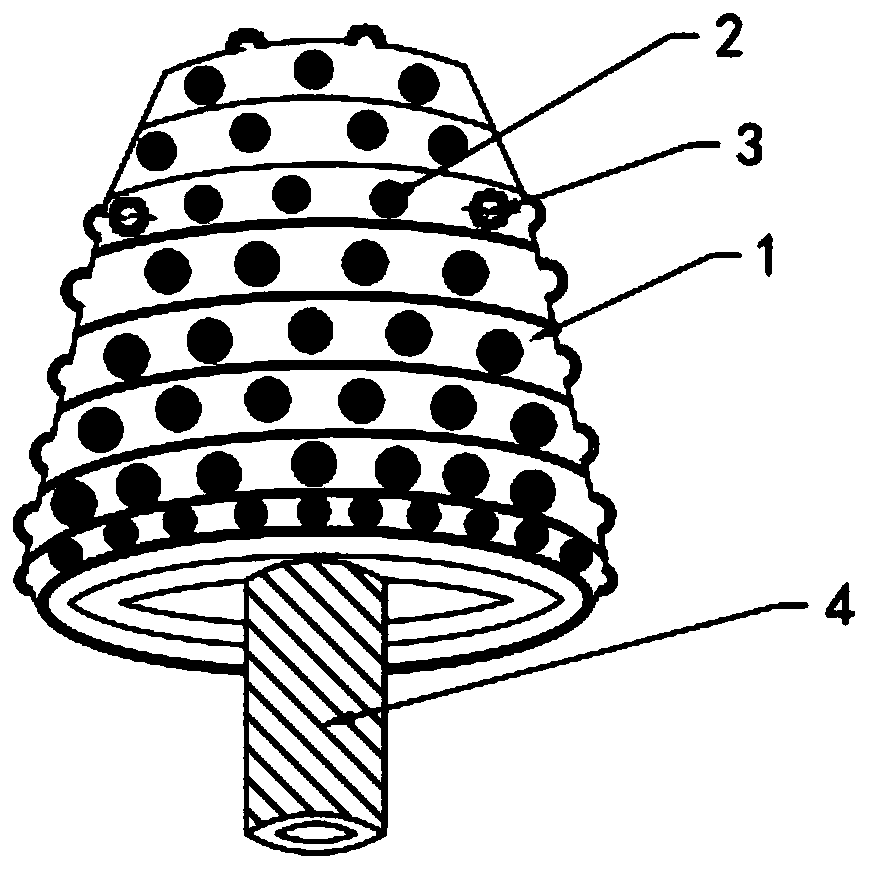

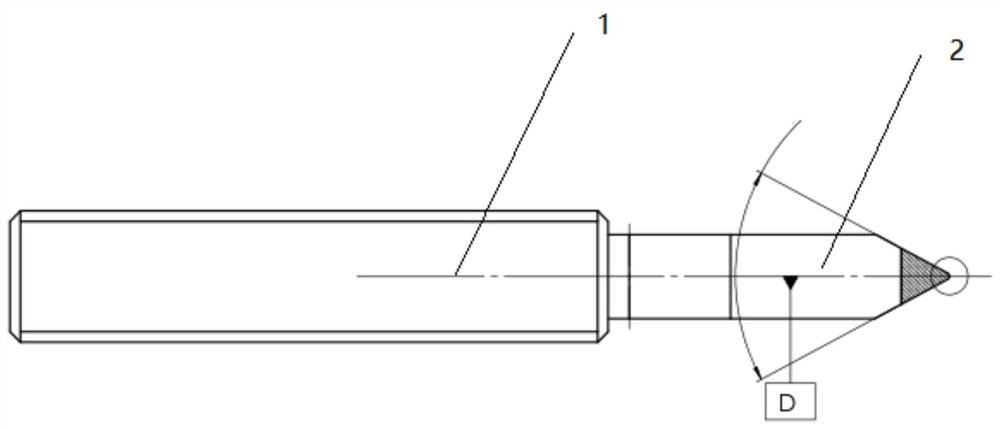

Novel coal mine drill bit

PendingCN111577145AExtended service lifeAvoid getting stuckConstructionsAnchoring boltsMining engineeringMechanical engineering

The invention discloses a novel coal mine drill bit and relates to the technical field of mining equipment. The novel coal mine drill bit comprises a drill bit body; the drill bit body is conical shaped, and the upper diameter of the conical shape is greater than the lower diameter of the conical shape; a plurality of drilling teeth are arranged on the outer side face of the drill bit body; and aplurality of water outlets are further formed in the drill bit body. The conical drill bit body enables the contact surface of the drill bit body and a top plate to be more stable; during the drillingprocess, the drill bit body closely fits the contact surface, so that the situation that graves fall off when a gap exists is avoided; and moreover, during the drilling process, as the drilling teethon the drill bit body rotate, the inner walls of the drilled holes are smooth to avoid blocking, and the gravels are prevented from blocking a drill pipe to prolong the service life of the drill bit.

Owner:柴卫国

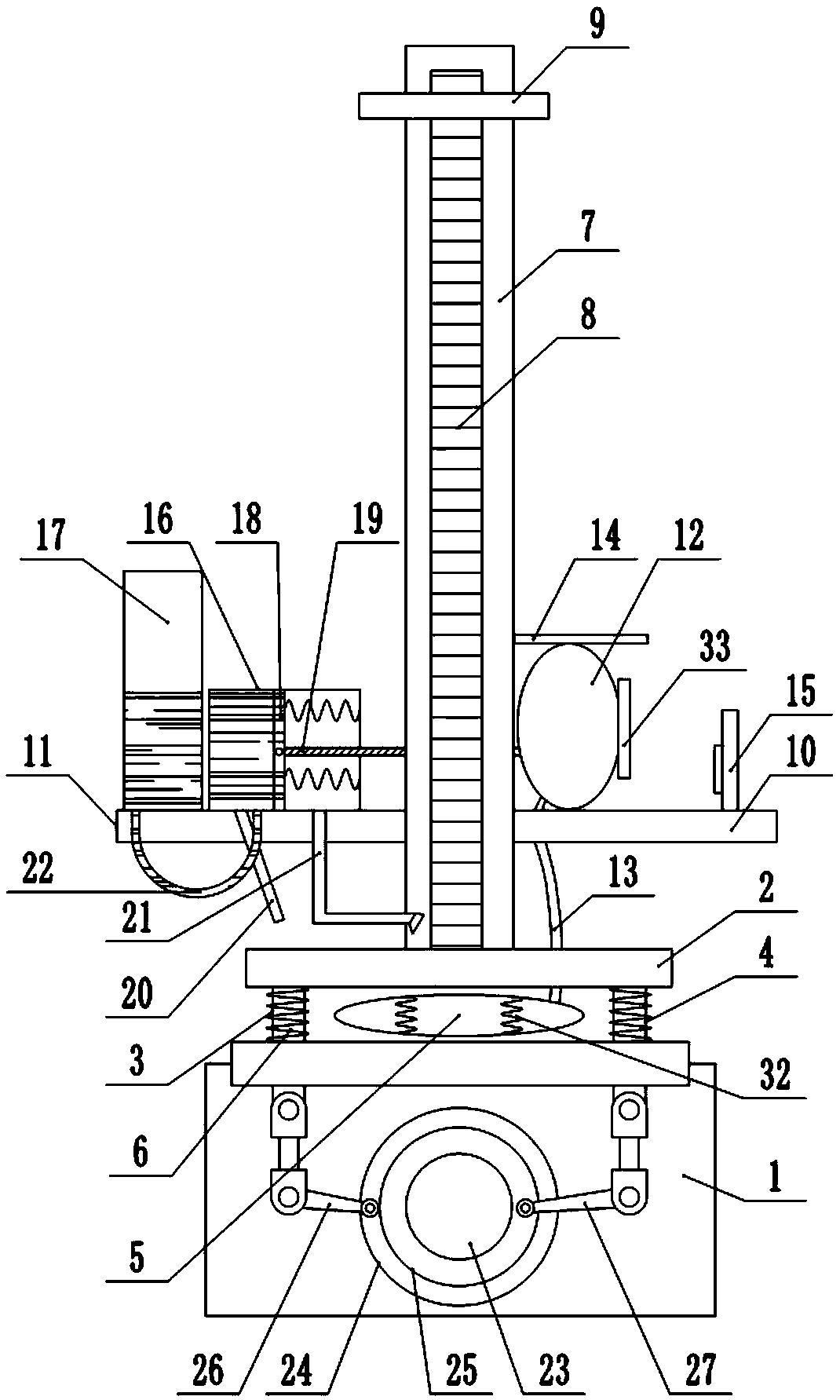

Force measuring device

ActiveCN106644211AHigh measurement accuracyReduce shockApparatus for force/torque/work measurementEngineeringMechanical engineering

Owner:CHINA PETROCHEMICAL CORP +4

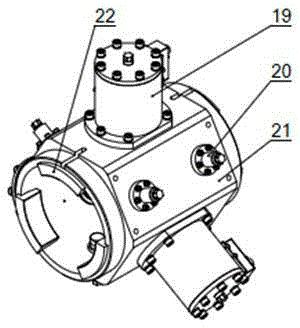

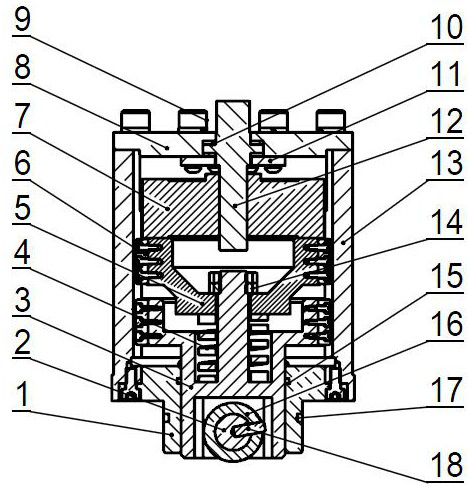

Pneumatic contactor of large-scale motor for mine

InactiveCN111725010AImprove compatibilityImprove adaptabilityContact driving mechanismsElectromagnetic relay detailsElectric machineStructural engineering

The invention provides a pneumatic contactor of a large-scale motor for a mine. The pneumatic contactor is provided with an arc extinguishing cover, the interior of the arc extinguishing cover is divided into an upper space and a lower space through a transverse partition plate in the middle of the interior of the arc extinguishing cover, and a driving air cylinder and an electromagnetic valve forcontrolling the driving air cylinder are installed in the lower space; an insulating supporting plate is arranged at the upper end of a piston rod of the driving cylinder; three groups of moving endwiring boards which are arranged side by side are fixedly arranged on the insulating supporting plate; two ends of each group of moving end wiring boards are respectively provided with a moving contact; the two sides of each moving end wiring board are respectively provided with a static end wiring board corresponding to each moving contact, each static end wiring board is erected through an insulating supporting plate arranged on the transverse partition plate, one end of each static end wiring board extends out of the side wall of the arc extinguishing cover, and the other end of each staticend wiring board is provided with a static contact. The contactor provided by the invention greatly reduces the use and later maintenance cost, is low in noise and high in safety, and has a very goodfield actual use value.

Owner:HUANGSHI HAOYUN MINING EQUIP ENERGY SAVING DEV CO LTD

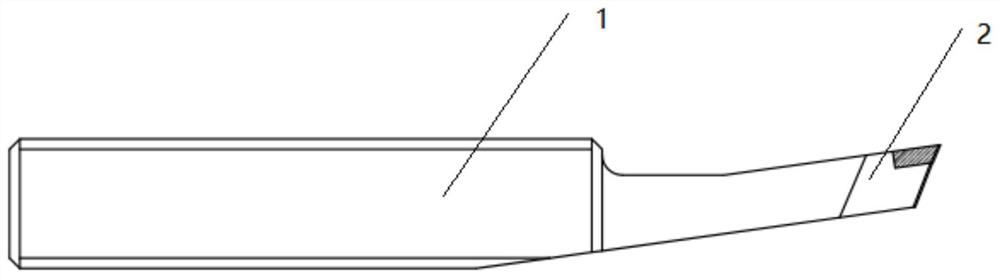

Motor commutator machining turning tool and machining method

InactiveCN111889702AContact surface stabilityReduce lossAuxillary equipmentMeasurement/indication equipmentsElectric machineryTool bit

The invention is applicable to the technical field of motor machining, and provides a motor commutator machining turning tool and a machining method. The commutator machining turning tool comprises aturning tool main body and a tool bit; the tool bit is arranged at the end part of the turning tool main body; and the tool bit is arranged to be a positive sharp tool with the angle ranging from 58 degrees to 63 degrees, and the tool included angle R ranges from 0.30 mm + / -0.05 mm to 0.50 mm + / -0.05 mm. The turning tool turns the inter-blade section difference, the commutator surface roughness isimproved, Ra is 0.5-0.7 micros, the number of tool grains is 14-17 bar / mm, and no teeth or burrs exist; and the turning surface roughness conforms to the N4-N6 standard, the contact surface of a carbon brush and a commutator is stable, the electrical loss is small, the roughness with the appropriate number of textures and tool grains is generated, and the running-in quality of the carbon brush and the commutator is directly improved. The labor cost is saved, and the product qualification rate is high.

Owner:袁四会

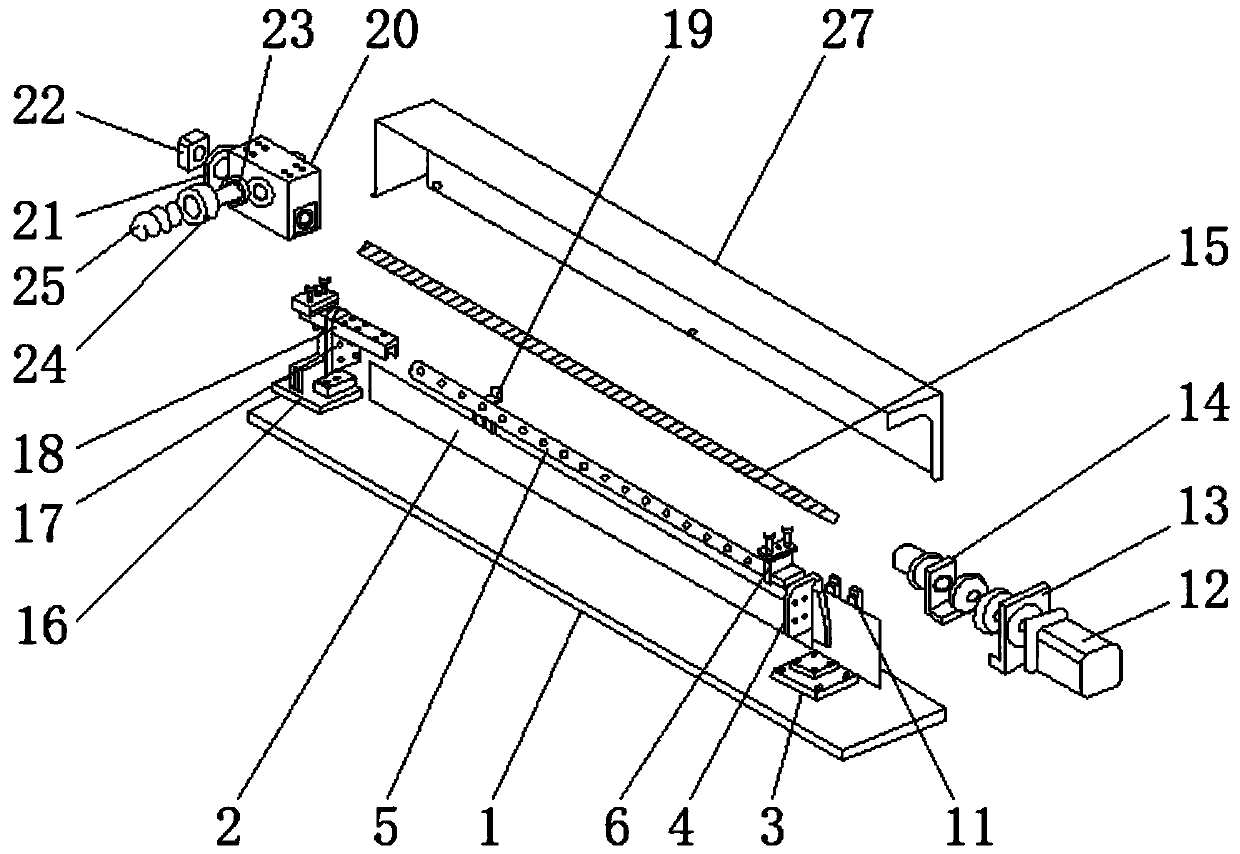

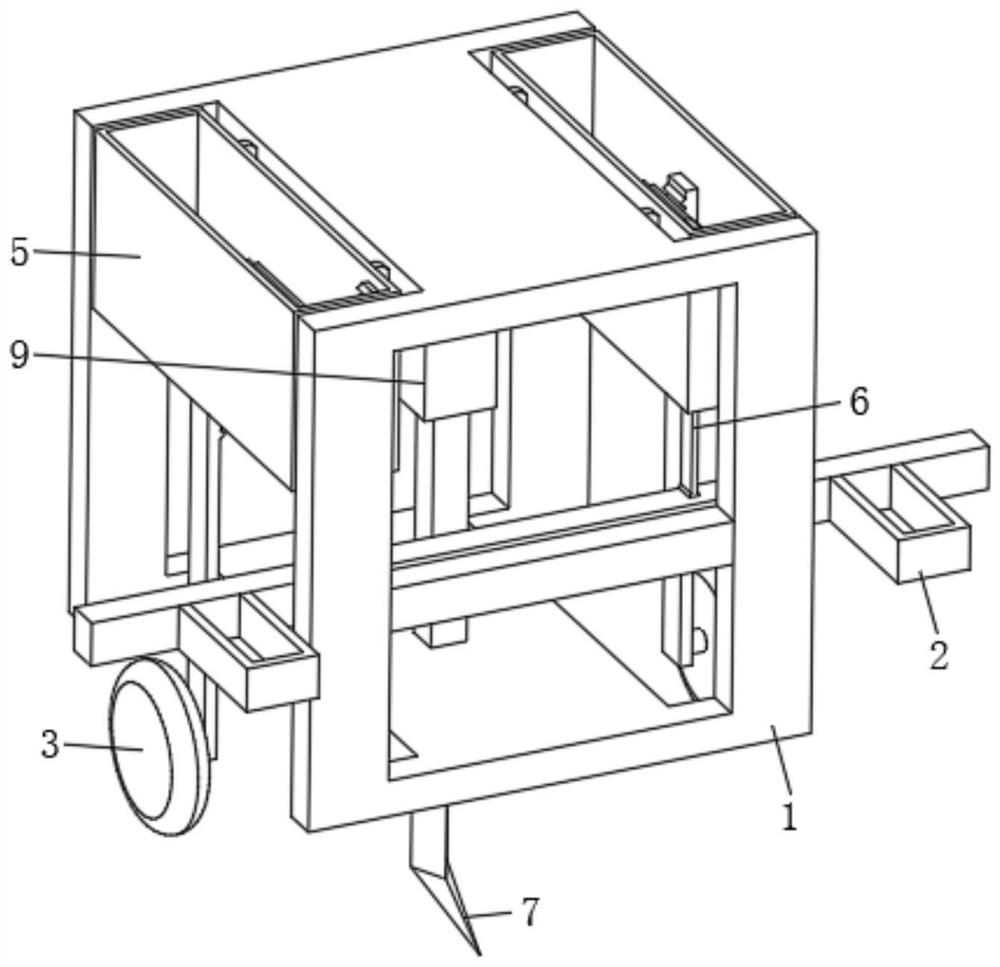

Light bar bending resistance testing machine

PendingCN110007252AUniform pulling forceImprove efficiencyElectrical measurement instrument detailsMaterial strength using tensile/compressive forcesGeneral assemblySurface mounting

The invention discloses a light bar bending resistance testing machine. The light bar bending resistance testing machine comprises a general assembly bottom plate, a motor base, an adjusting end bottom plate and an action block, wherein a linear guide rail is arranged on the surface of the general assembly bottom plate, a lead screw is arranged at the upper portion of the linear guide rail, a protective baffle is arranged at the side surface of the general assembly bottom plate, a fixed seat is arranged on the surface of a fixed seat support table, butterfly nuts are connected at the internalportions of fixed screw holes, a motor is arranged on one side of the motor base, and one end of the lead screw penetrates through a fixed end support piece and then is connected with the motor; the surface of an adjusting end vertical plate is provided with a guide rail sliding block, the outer side of a poke rod is connected with a roller, and the surface of the roller is provided with guide slots. The light bar bending resistance testing machine is provided with the motor, the lead screw and the action block, and the motor and the thread transmission mode allow the roller to move at a constant speed so as to solve the stability of dragging for a long time, avoid the instability of manual operation and the fatigability of long-time operation and improve the efficiency of test work.

Owner:HUIZHOU WISVA OPTOELECTRONICS CO LTD

Transportation device with convenient angle adjusting function for electronic products

InactiveCN108792504AEasy to movePrevent slidingConveyorsSupporting framesSlip resistanceCivil engineering

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

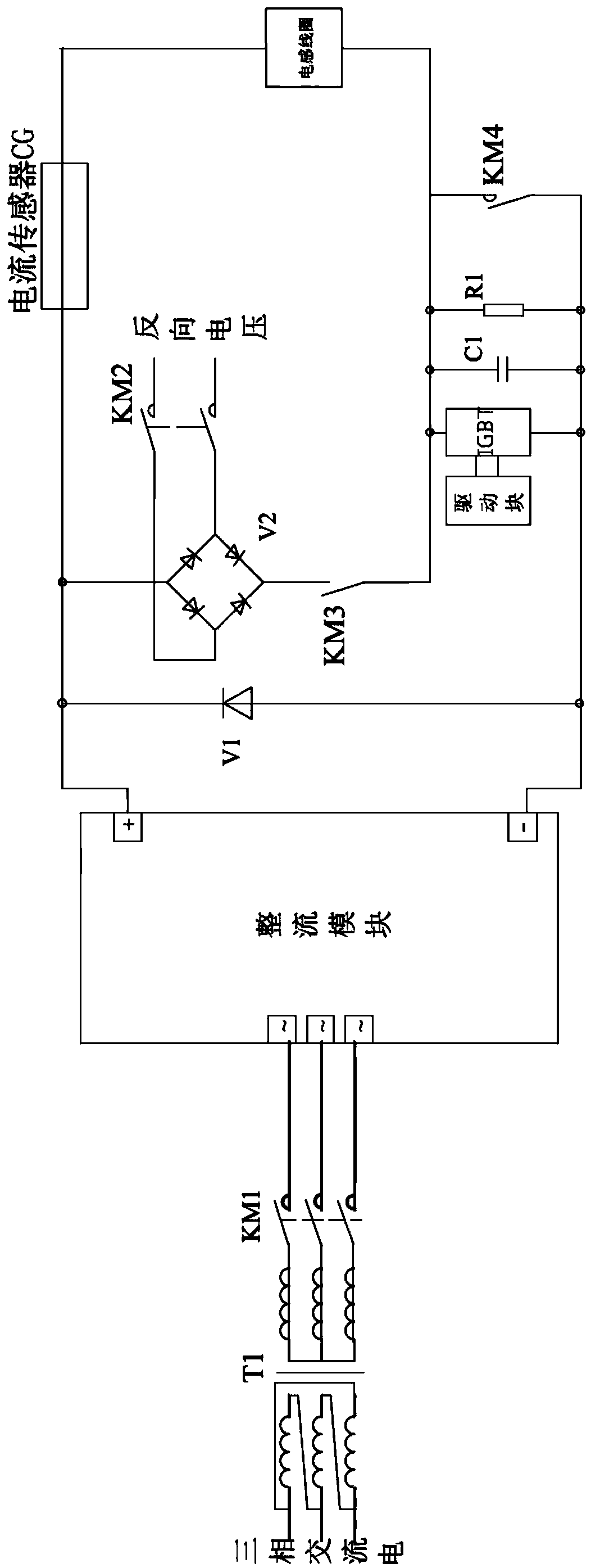

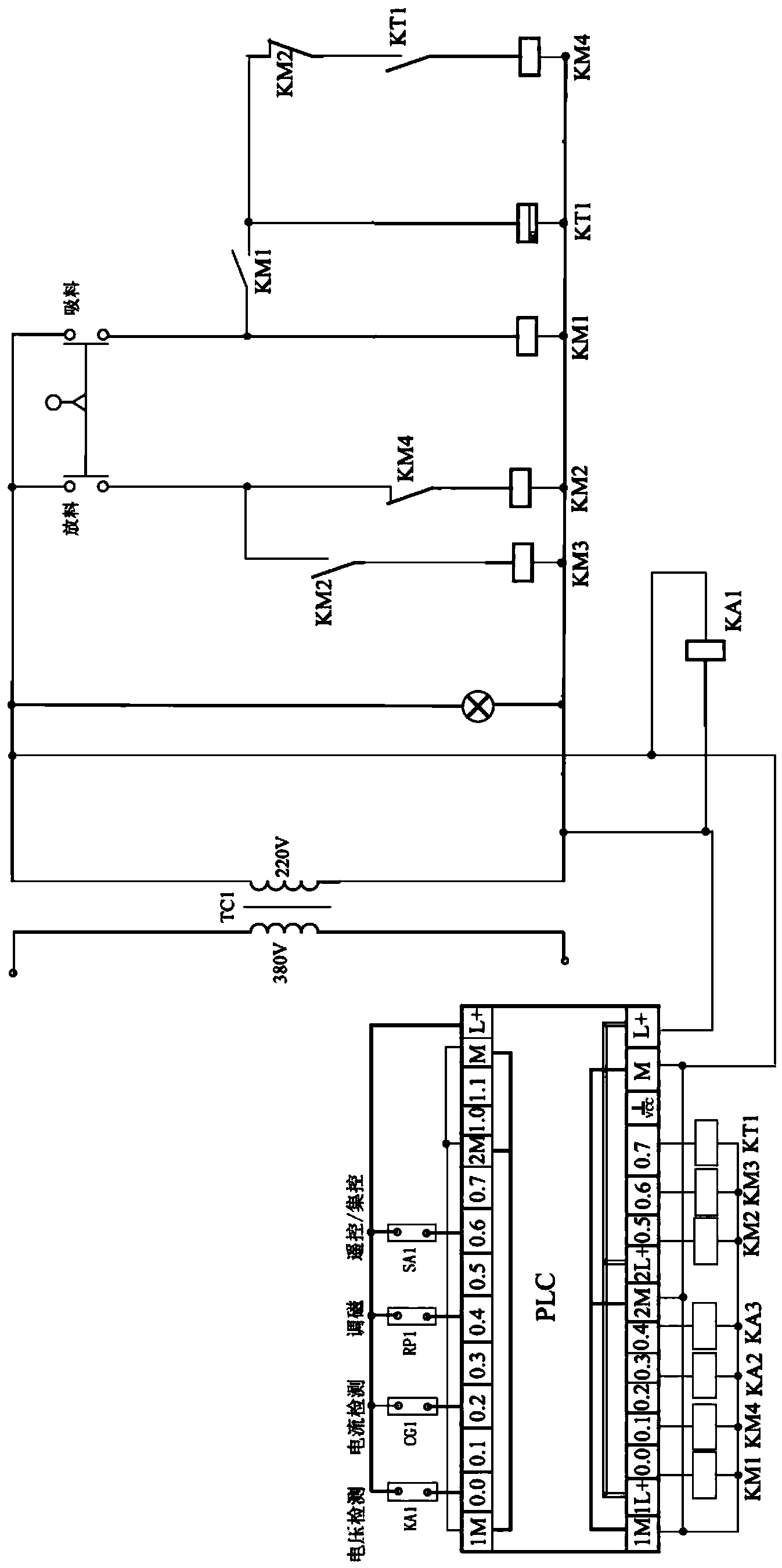

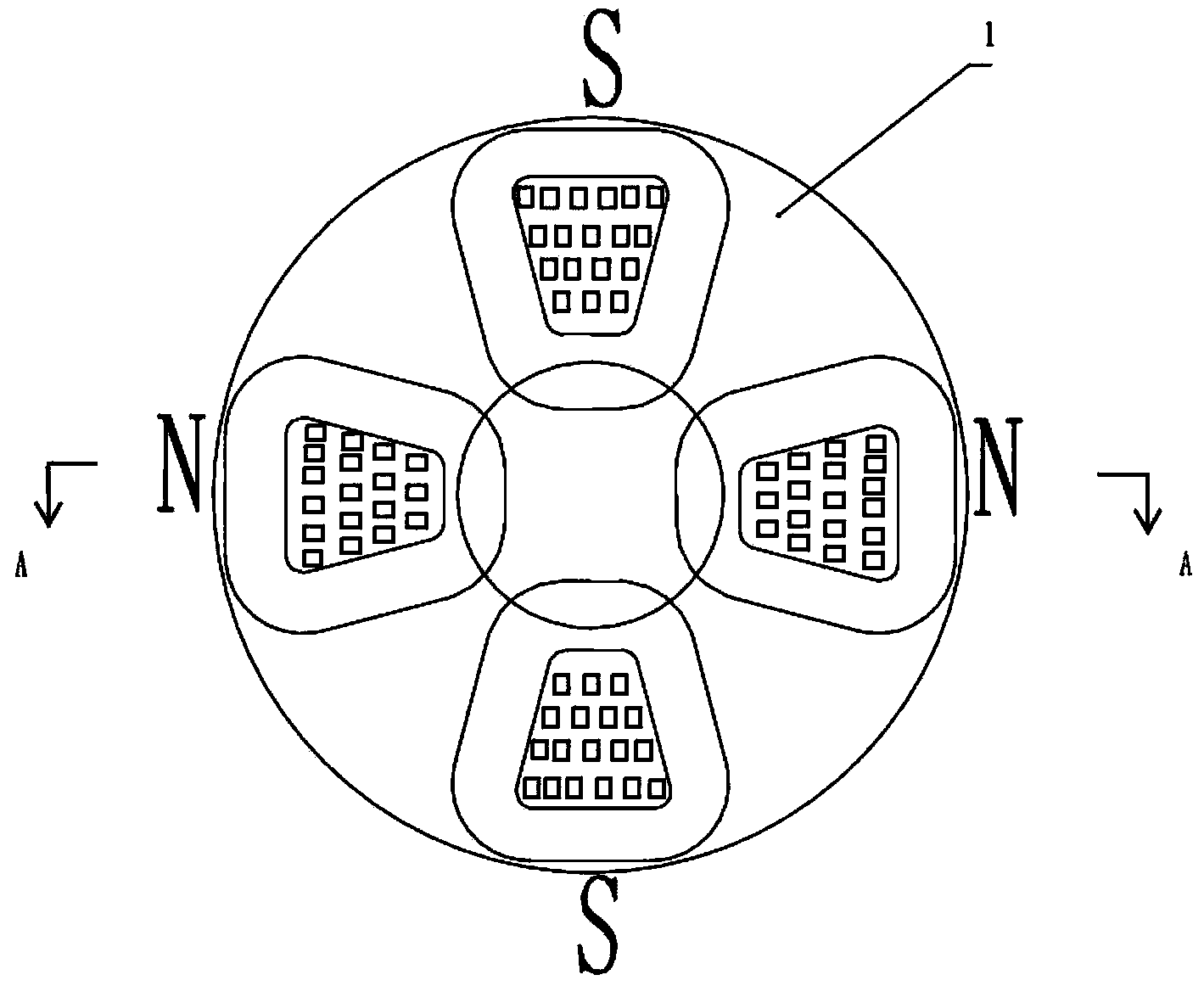

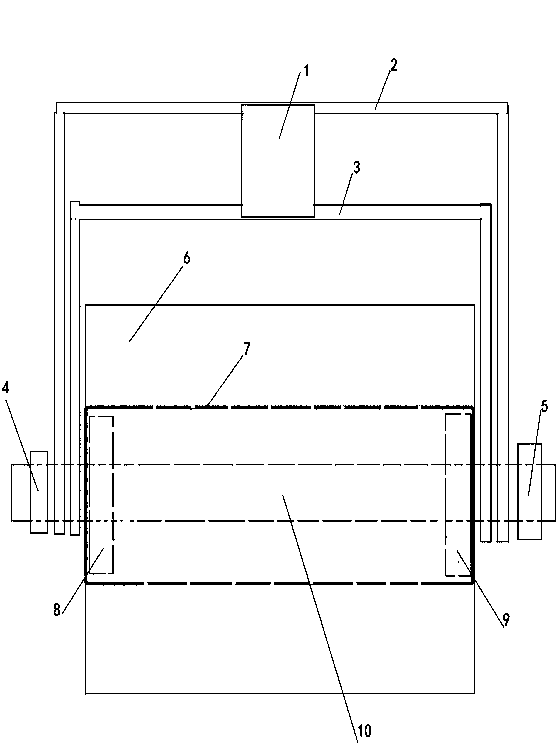

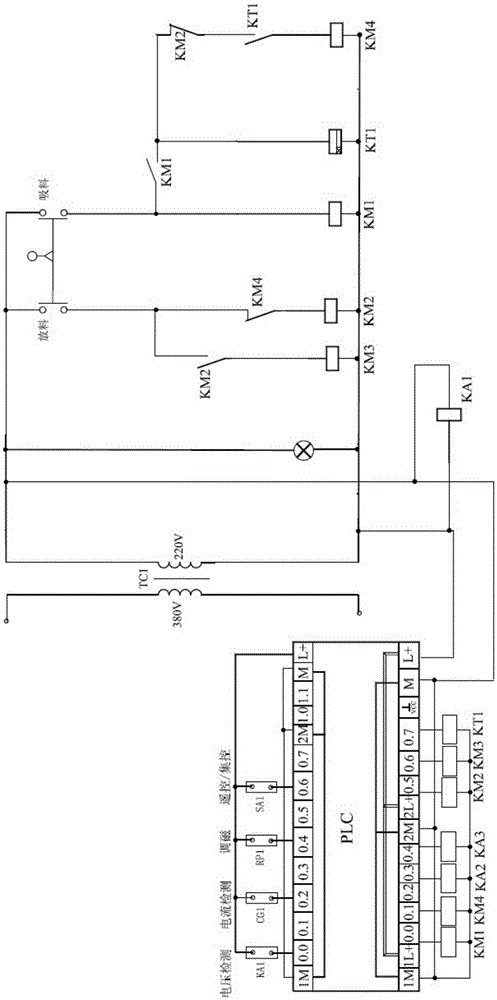

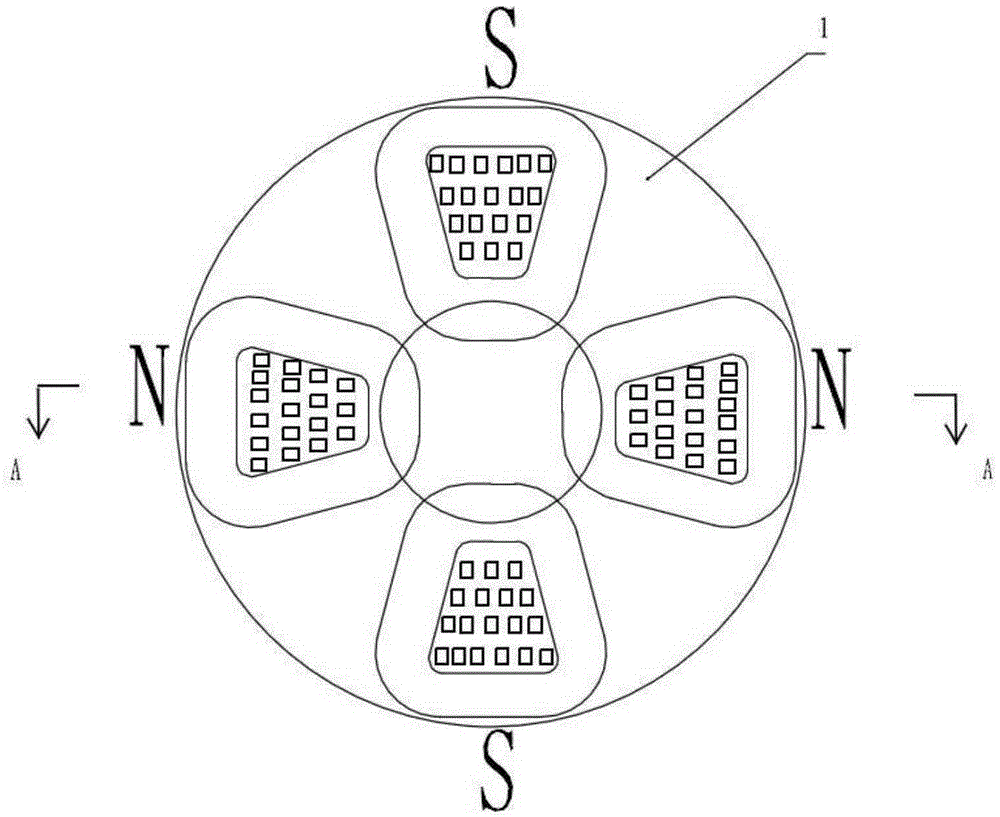

Lifting electromagnetic device for performing contactless electronic control lifting and transporting on vertical-type steel coils

ActiveCN103922217AGuaranteed automatic ochiaiGuaranteed durabilityLoad-engaging elementsGlass fiberSuction force

The invention provides a lifting electromagnetic device for performing contactless electronic control lifting and transporting on vertical-type steel coils. The lifting electromagnetic device comprises a main body part and an electronic control part; the main body part consists of a yoke plate, a shell, through shaft movable magnetic poles, coils, concentrating flux plates, a support plate and a junction box body; the upper part of the yoke plate is provided with a plurality of square holes according to the sizes of spacing blocks on the through shaft movable magnetic poles; a through shaft mode is adopted for connection and installation of the through shaft movable magnetic poles; the plurality of through shaft movable magnetic poles are distributed in a 'plum blossom petal' structure and act as coil iron cores, and a layer of concentration flux plates are surrounded at the periphery of the coil iron cores so as to form trapezoidal frames; each trapezoidal frame corresponds to a coil; the coils are made of two-glass-fiber enamel-cover flat aluminium wire materials; after the coils wind around the concentration flux plates, insulation materials are arranged on the outer periphery in a paving manner, so that multiple problems of insufficient electromagnetic suction force, over-low safety coefficient and the like which are caused by adverse factors such as relatively high steel coiled tower shape, severe environment temperature, and over-high coil temperature rise are solved.

Owner:LONGI MAGNET CO LTD

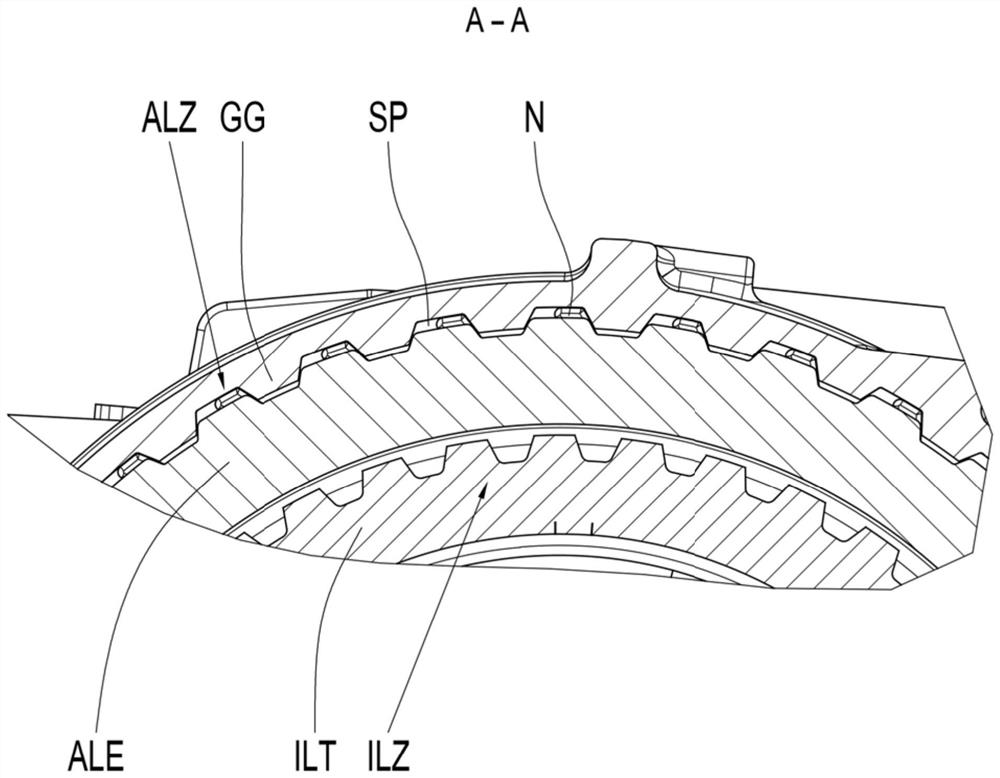

Wet running plate clutch and motor vehicle transmission

PendingCN114110036AContact surface stabilityReduce drag torqueFluid actuated clutchesGear lubrication/coolingControl theoryMotorized vehicle

The invention relates to a plate clutch (B) for wet operation of a motor vehicle transmission (G), in which a piston (K) is arranged on a first side of the plate clutch (B), by means of which a force acting in the axial direction can be exerted on friction plates and outer friction plates (IL, AL) in order to close the plate clutch (B), wherein the plate clutch (B) is supported on the contact surface (AF) on a second side opposite the first side by means of an end friction plate (ALE) of the outer friction plate (AL), and wherein grooves (N) are provided on the contact surface (AF) and / or on the end friction plate (ALE), the grooves being designed and arranged such that a cooling fluid (O) supplied to the plate clutch (B) can flow out of the plate clutch (B) through the grooves (N); the invention further relates to a transmission (G) for a motor vehicle having such a plate clutch (B).

Owner:ZF FIEDRICHSHAFEN AG

Construction method for foundation connecting joint of steel pipe column of fabricated bailey truss

InactiveCN112112187AContact surface stabilityEasy to installFoundation engineeringBuilding constructionsSteel platesRebar

The invention discloses a construction method for a foundation connecting joint of a steel pipe column of a fabricated bailey truss. The construction method comprises the steps that A, a first steel plate is arranged in a foundation pouring and pre-burying mode, and a center hole with the outer diameter of a steel pipe as the diameter is cut in the middle of a second steel plate; B, foundation steel bars are bound, the first steel plate is welded into the foundation steel bars through connecting bars, and a prefabricated foundation is placed on the horizontal ground; C, concrete is poured intothe first steel plate; D, the second steel plate with the center hole pre-formed in the step A is welded to the steel pipe column, and the steel pipe column is sleeved with the center hole of the second steel plate; E, the two axes of the first steel plate pre-buried in the foundation are found, and a vertical steel plate is additionally arranged on the outer side wall of the steel pipe column; and F, the steel pipe column is hoisted through a crane, mounted to a socket and stably combined with the socket, and thus mounting is completed. According to the construction method, the purposes thatmounting is convenient, recycling can be achieved, damage to the steel pipe is small, perpendicularity control is good, and construction is safer are achieved.

Owner:GUANGZHOU NO 2 MUNICIPAL ENG CO LTD

An automatic cleaning device for a measuring instrument

ActiveCN108814612BFast dryingAutomate the disinfection processDiagnostic recording/measuringSensorsMeasuring instrumentLiquid storage tank

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Right-angle pipe fitting mold with efficient molding and demolding function

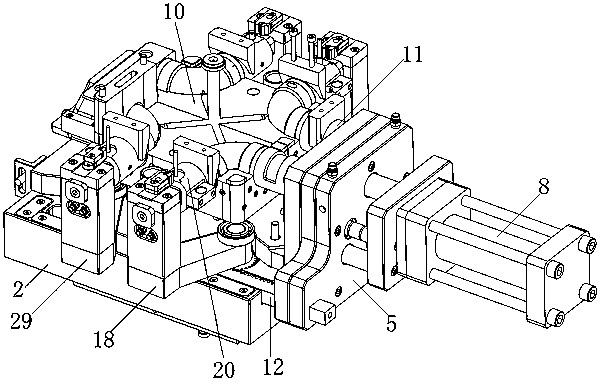

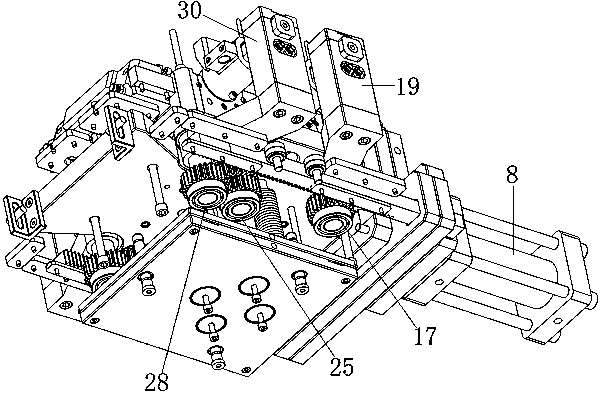

PendingCN111251544ARealize processing operationsQuick release operationTubular articlesPipe fittingGear wheel

The invention discloses a right-angle pipe fitting mold with an efficient molding and demolding function, and relates to the technical field of pipe fitting mold machining devices. In the right-anglepipe fitting mold, an output connecting rod mechanism of a transverse power cylinder is connected with a transverse connecting pipe / intra-pipe mold core in a matched manner; a transverse adjustment rack plate is movably installed on a first bottom-side clamping base; a first matching gear matched with the transverse adjustment rack plate is movably installed on the first bottom-side clamping base;a second upper-side driving gear matched with the transverse adjustment rack plate is movably installed on the first bottom-side clamping base; a movable mold clamping base is installed in an upper-side movable mold set periphery body; a pair of injection molding movable molds are installed in the movable mold clamping base; the middle parts of movable mold cavities of the injection molding movable molds are provided with middle injection holes communicating with an injection molding channel; and one injection molding movable mold is independently provided with an end opening replacement moldin a matched manner. The right-angle pipe fitting mold can efficiently complete the operation of machining multiple right-angle pipe fittings, quickly complete the operation of demolding the molded pipe fittings and make contact surfaces on two sides firmer.

Owner:台州市黄岩必凌特模塑有限公司

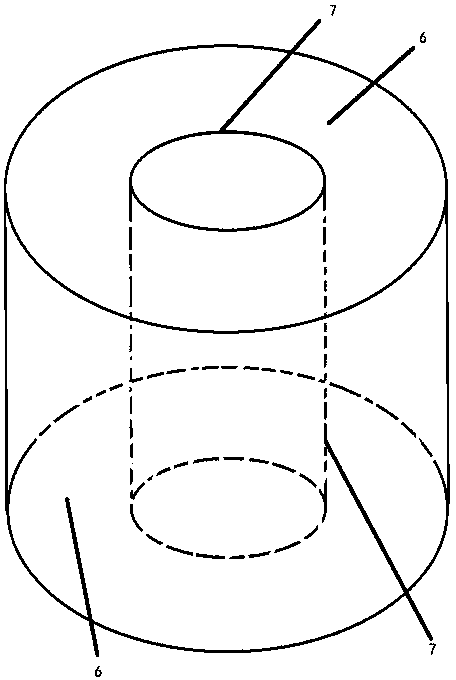

Cooling device with finned muffler

InactiveCN103982282BReduce weightContact surface stabilityExhaust apparatusSilencing apparatusAbsorbent materialEngineering

The invention discloses a silencer heat radiating device with fins. The silencer heat radiating device with fins comprises a silencer barrel body, wherein the silencer barrel body is a casing of a resistive silencer in the prior art, a sound-absorbent material of a silencer is arranged at the inner wall position close to the side wall of the silencer barrel body, the side wall of the silencer barrel body is provided with at least one cooling fin chute, and the cooling fin chute is composed of a first groove cavity and a second groove cavity. The silencer heat radiating device with fins further comprises cooling fins identical to the cooling fin chutes in number and a circular-ring-shaped cooling fin end cover matched with the side wall of the silencer barrel body. The cooling fins are installed in the side wall of the silencer through the chutes, enough stable contact between the cooling fins and the side wall of the silencer is ensured through the chutes, the fins of the cooling fins extend out of the chutes, the whole heat radiating area is increased, accordingly heat absorbed by the resistive sound-absorbent material arranged on the inner wall of the silencer during running is led out, and the temperature stabilizing and sound absorption effects of the resistive material are reduced.

Owner:CHENGDU LINGCHUAN SPECIAL IND

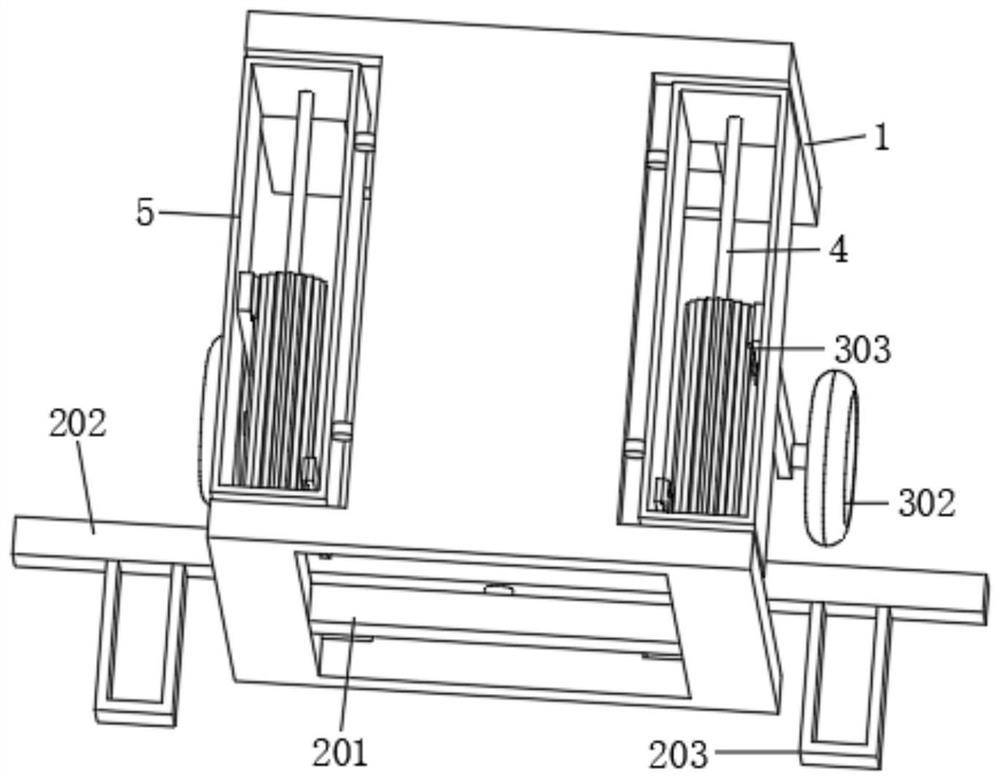

Tillage part performance test bench for improving degraded grassland

InactiveCN114689350AGuaranteed test accuracyContact surface stabilityStructural/machines measurementAgricultural engineeringEdaphic

The invention relates to the field of tests, and discloses a cultivation component performance test bench for degraded grassland improvement, which comprises a cultivation component, a data acquisition device arranged on the cultivation component, a clamping piece for fixing the cultivation component and a frame fixedly connected with the clamping piece, and hollow shells are rotatably mounted on two sides of the frame. A rotating assembly is rotatably mounted in the shell, a moving assembly in transmission connection with the rotating assembly is slidably mounted in the shell, a control assembly is fixedly mounted in the frame and comprises a long rod, and an adjusting assembly in transmission connection with the rotating assembly is rotatably mounted on the upper surface of the long rod. Through cooperation of the control assembly, the moving assembly, the rotating assembly, the adjusting assembly and the like, when plane soil and inclined plane soil are tested, the cultivation component can be adjusted to be in a vertical state to complete the test, so that the contact surface of the cultivation component and the soil is stable, and the testing accuracy of the cultivation component can be effectively guaranteed.

Owner:黑龙江省农业科学院畜牧兽医分院

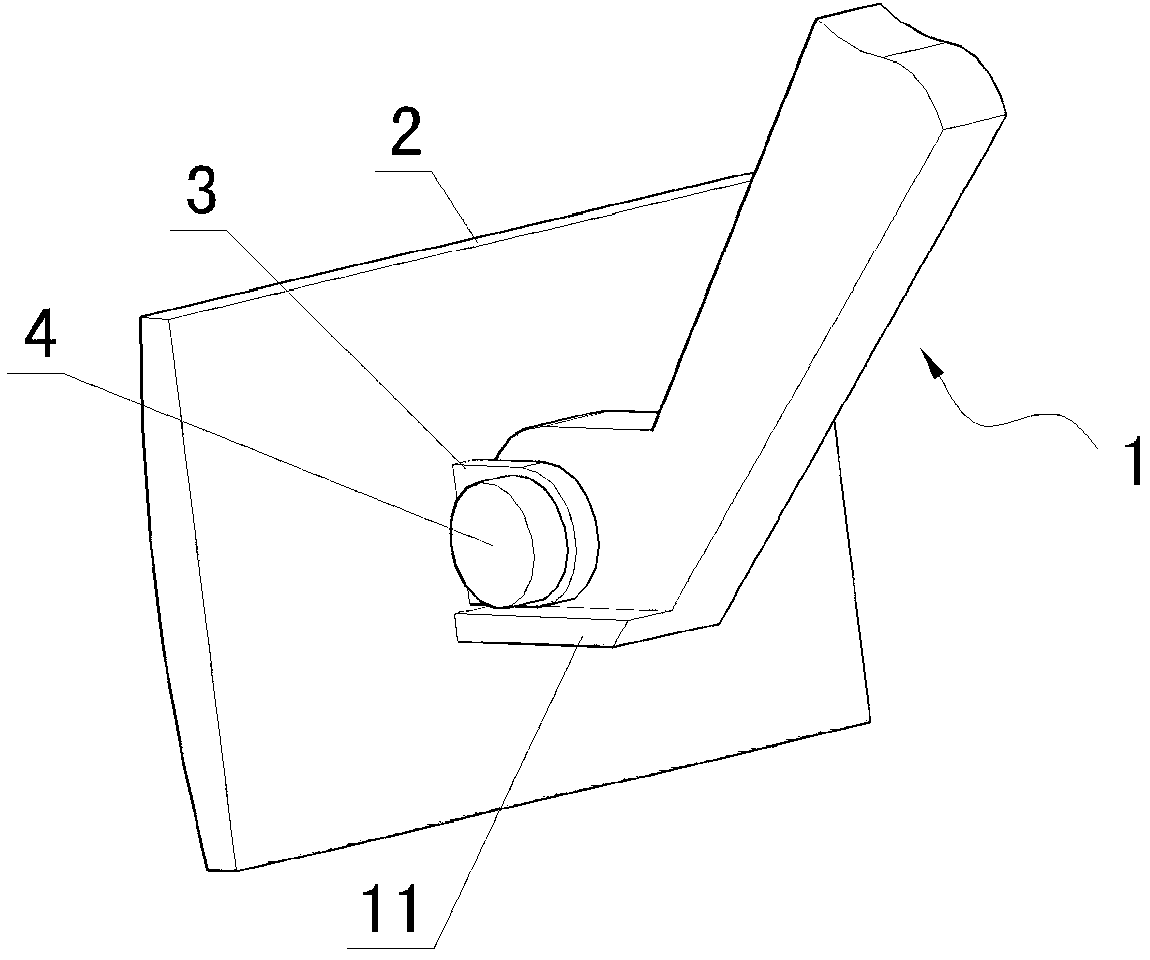

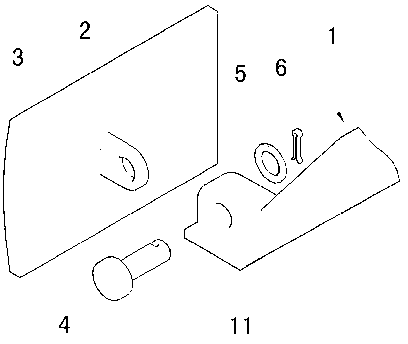

Novel pedal

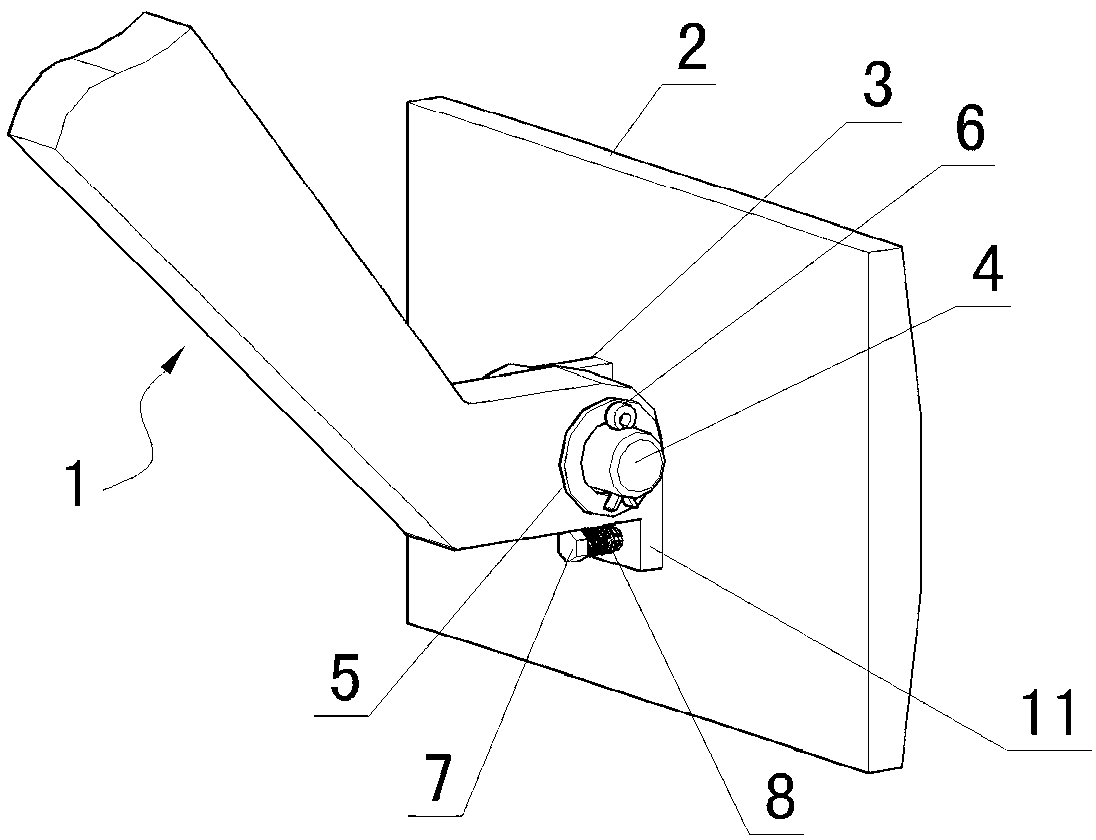

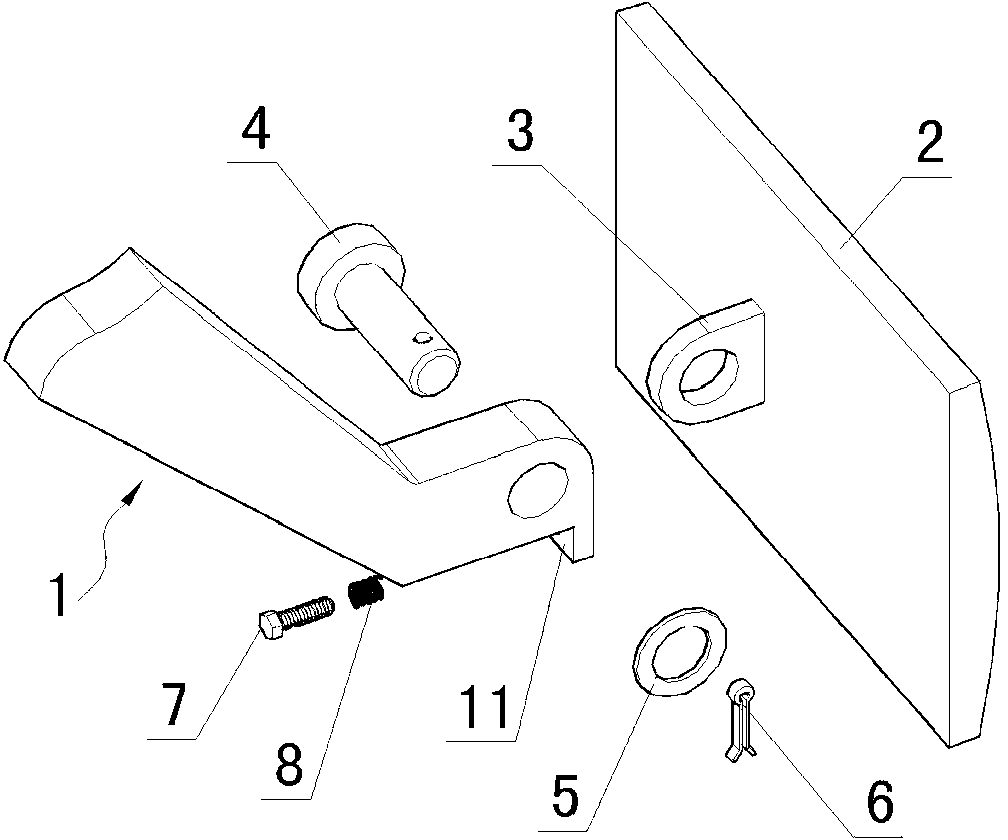

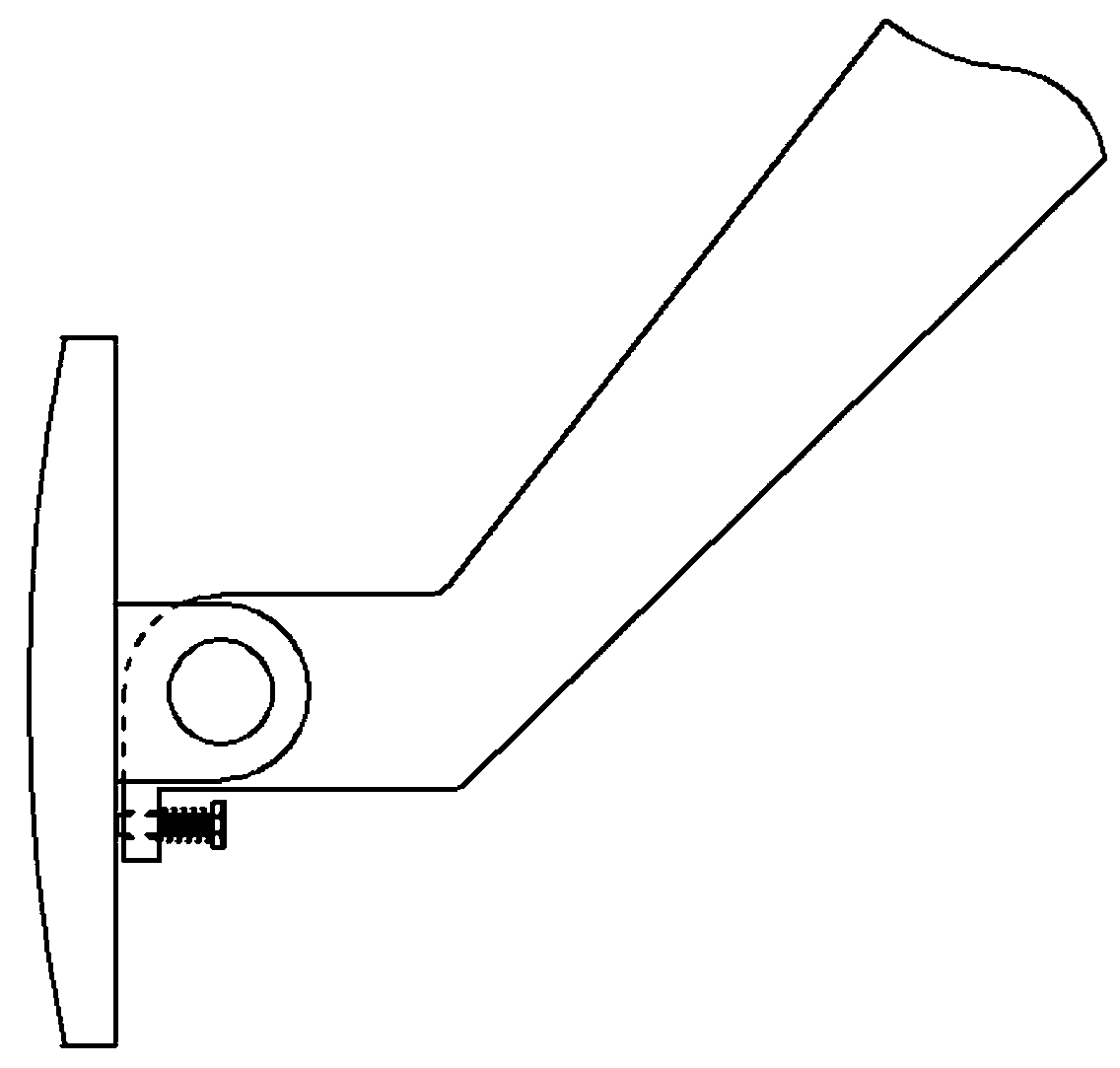

ActiveCN103287265AContact surface stabilityReduce experienceFoot actuated initiationsPropulsion unit arrangementsSplit pinMechanical engineering

A novel pedal comprises a working rod, a pedal body 2, a connecting lug 3, a fixing shaft 4, a washer 5, a split pin 6, an adjusting screw 7 and a spring 8. A stopper 11 is arranged below the lower end of the working rod 1, a screw through hole is formed in the stopper 11, and the adjusting screw 7 penetrates the spring 8 to be screwed in the screw through hole in the stopper 11. The novel pedal has the advantages that the stopper is arranged below the working rod, and the adjusting screw is arranged on the stopper, so that an operator can adjust angle of the pedal in the stationary state according to requirements, an angle between the pedal and the working rod can be adjusted automatically, stability of a contact surface between the sole and the pedal is maintained, and requirements on experience and ability of the operator are lowered.

Owner:广州广意广汽车用品有限公司

Bionic rolling-type massager

The invention relates to a hand-imitating structural massager for assisting massagists to massage by a rolling method. The massager is made by human body silica gel with a certain thickness wrapping a hard tube and connected with a support and a handle through the center of a bearing, and is used for assisting the massagists to reduce wrist movement so as to save energy and protect wrists since the rolling method is needed during massaging, and also can be used for assisting non-professional massagists to use the rolling method to reach the massaging level of professional massagists during massaging.

Owner:马春毅

A lifting electromagnet device for lifting vertical steel coils with non-contact electric control

ActiveCN103922217BGuaranteed automatic ochiaiGuaranteed durabilityLoad-engaging elementsGlass fiberSuction force

The invention provides a lifting electromagnetic device for performing contactless electronic control lifting and transporting on vertical-type steel coils. The lifting electromagnetic device comprises a main body part and an electronic control part; the main body part consists of a yoke plate, a shell, through shaft movable magnetic poles, coils, concentrating flux plates, a support plate and a junction box body; the upper part of the yoke plate is provided with a plurality of square holes according to the sizes of spacing blocks on the through shaft movable magnetic poles; a through shaft mode is adopted for connection and installation of the through shaft movable magnetic poles; the plurality of through shaft movable magnetic poles are distributed in a 'plum blossom petal' structure and act as coil iron cores, and a layer of concentration flux plates are surrounded at the periphery of the coil iron cores so as to form trapezoidal frames; each trapezoidal frame corresponds to a coil; the coils are made of two-glass-fiber enamel-cover flat aluminium wire materials; after the coils wind around the concentration flux plates, insulation materials are arranged on the outer periphery in a paving manner, so that multiple problems of insufficient electromagnetic suction force, over-low safety coefficient and the like which are caused by adverse factors such as relatively high steel coiled tower shape, severe environment temperature, and over-high coil temperature rise are solved.

Owner:LONGI MAGNET CO LTD

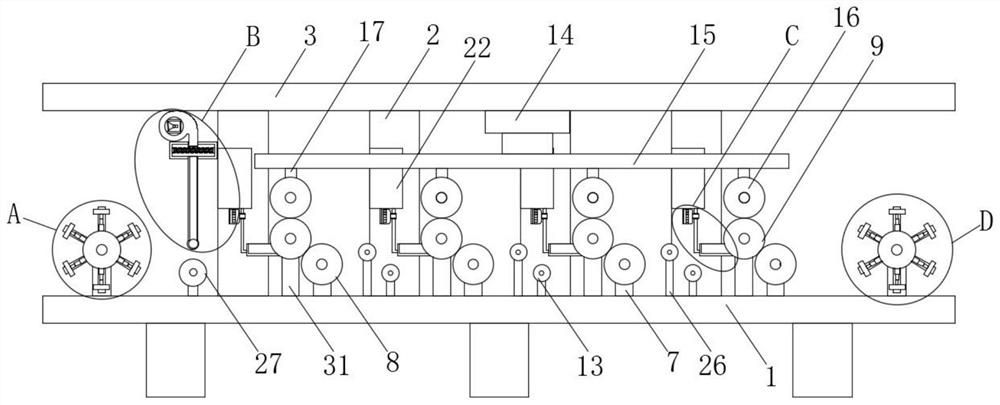

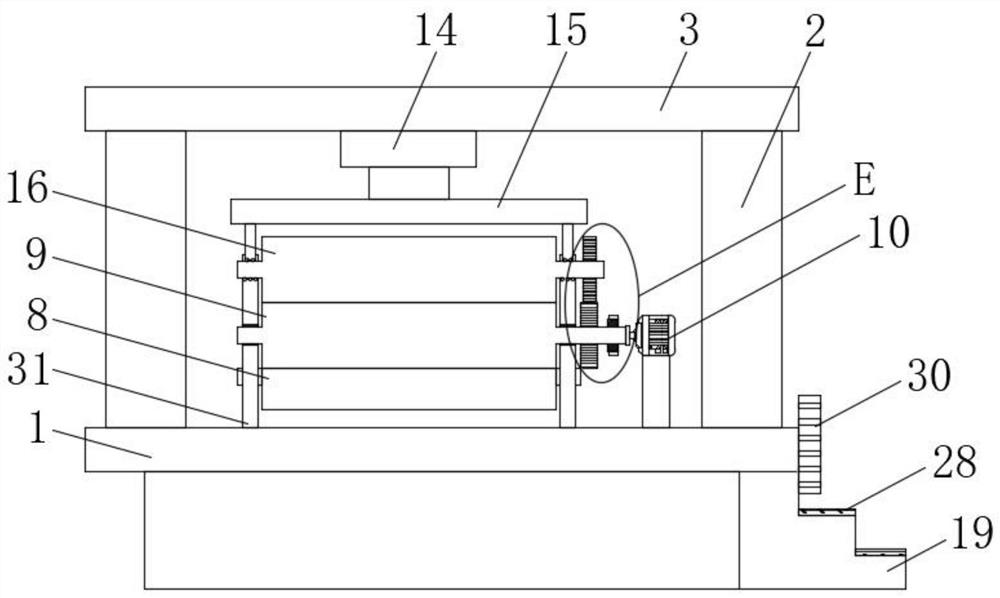

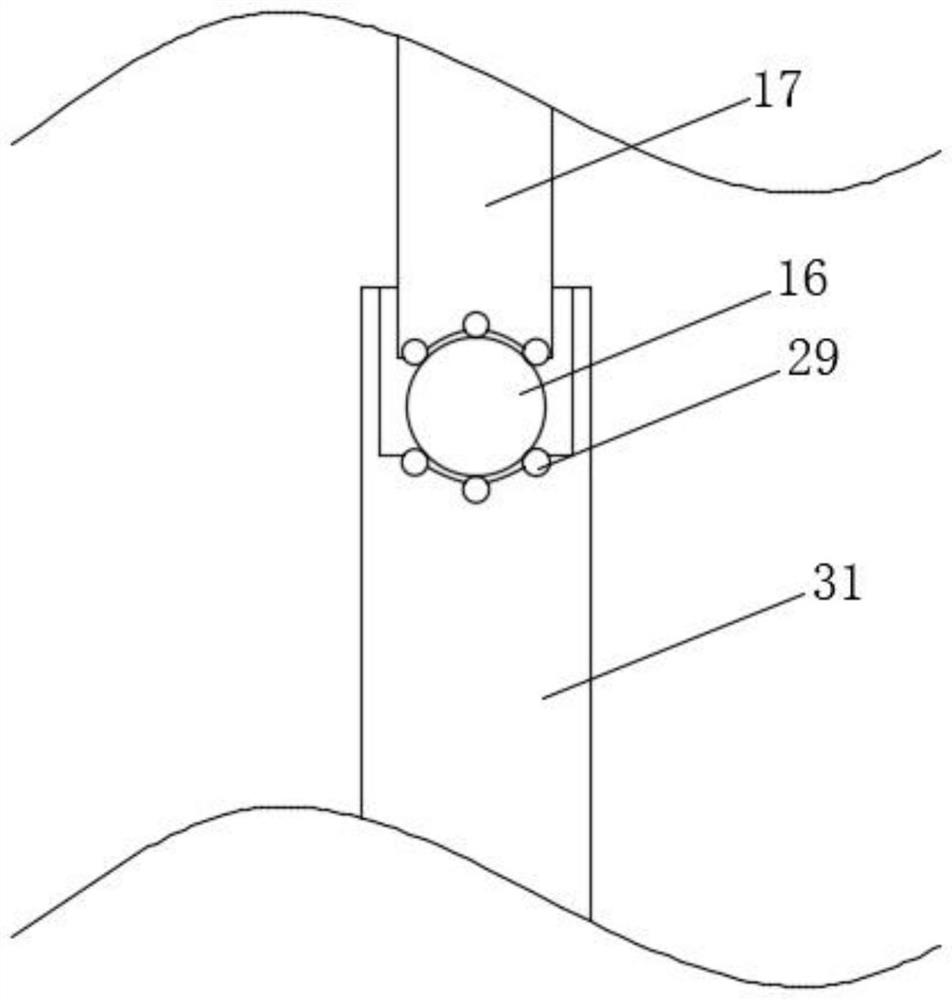

Full-automatic full-servo four-color printing machine

PendingCN111993774AGuaranteed clarityContact surface stabilityRotary pressesPrinting press partsColor printingEngineering

The invention discloses a full-automatic full-servo four-color printing machine, and belongs to the field of four-color printing machines. The full-automatic full-servo four-color printing machine comprises a frame, wherein the top of the frame is fixedly connected with eight pillars, the top of the eight pillars is fixedly connected with an integral top plate, the top of the frame is respectivelyprovided with an unwinding mechanism and a winding mechanism, the bottom of the top plate is provided with a drying device, the top of the frame is fixedly connected with eight first support plates,four printing rollers are rotatably connected inside the eight first support plates respectively, eight second support plates are fixedly connected to the top of the frame, and four rubber rollers forink transfer are respectively rotatably connected to the inside of the eight second support plates. The invention can print one to four patterns and colors, is convenient to change patterns, ensuresthe pattern definition of printed products, and at the same time, can adjust the winding diameter and unwinding diameter according to different situations, which has fast production speed and is convenient to meet the production needs.

Owner:江西德乐智能科技有限公司

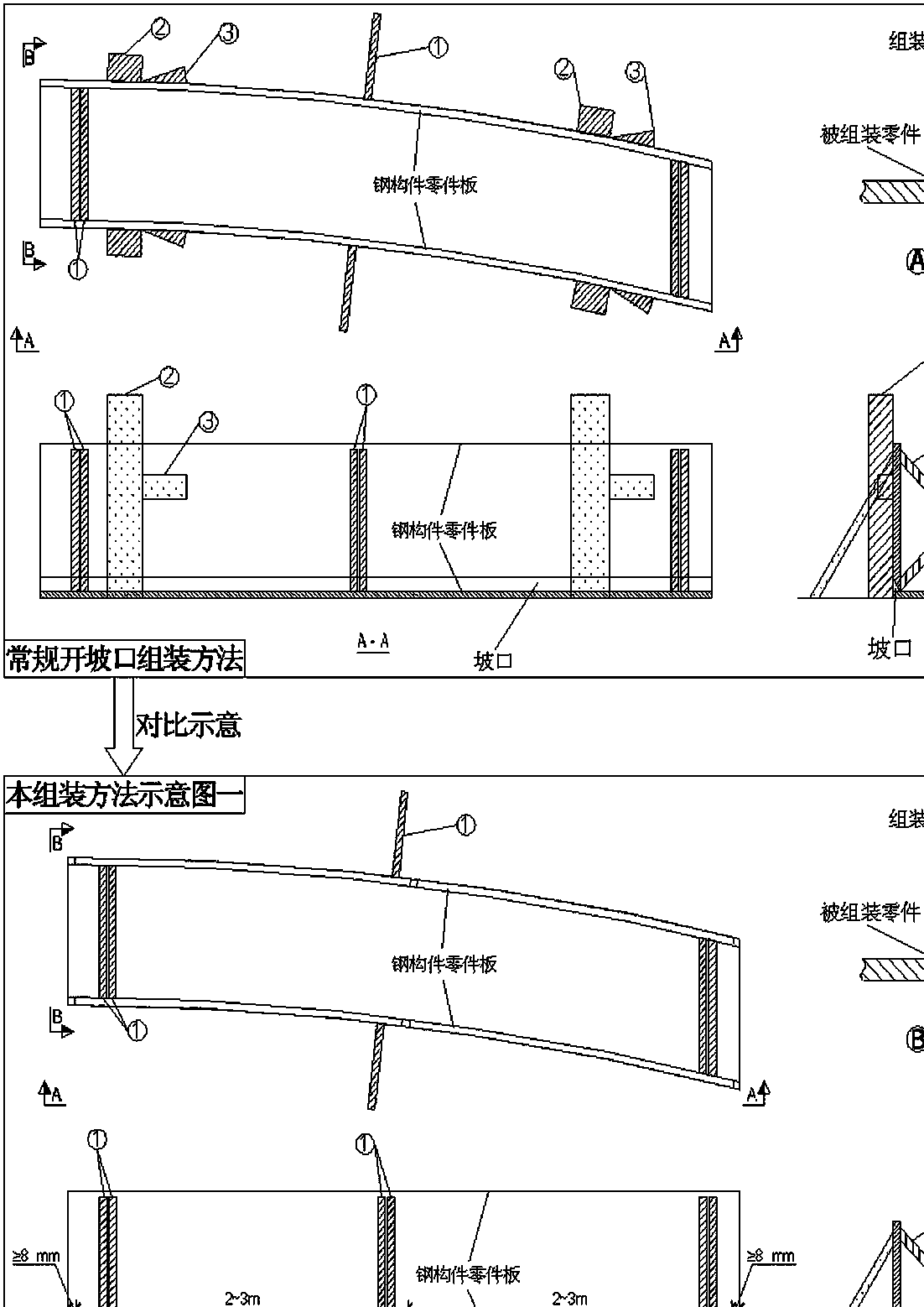

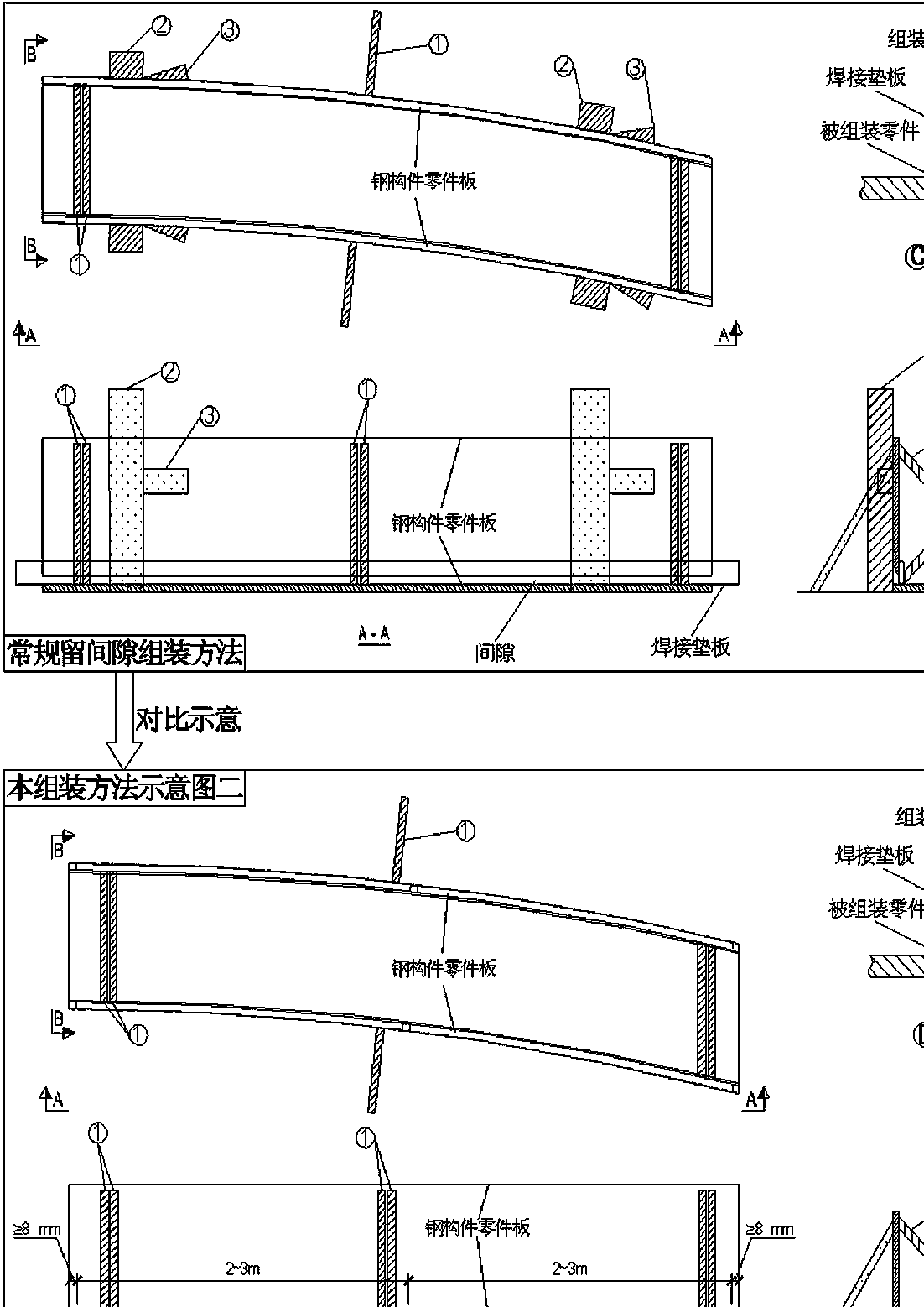

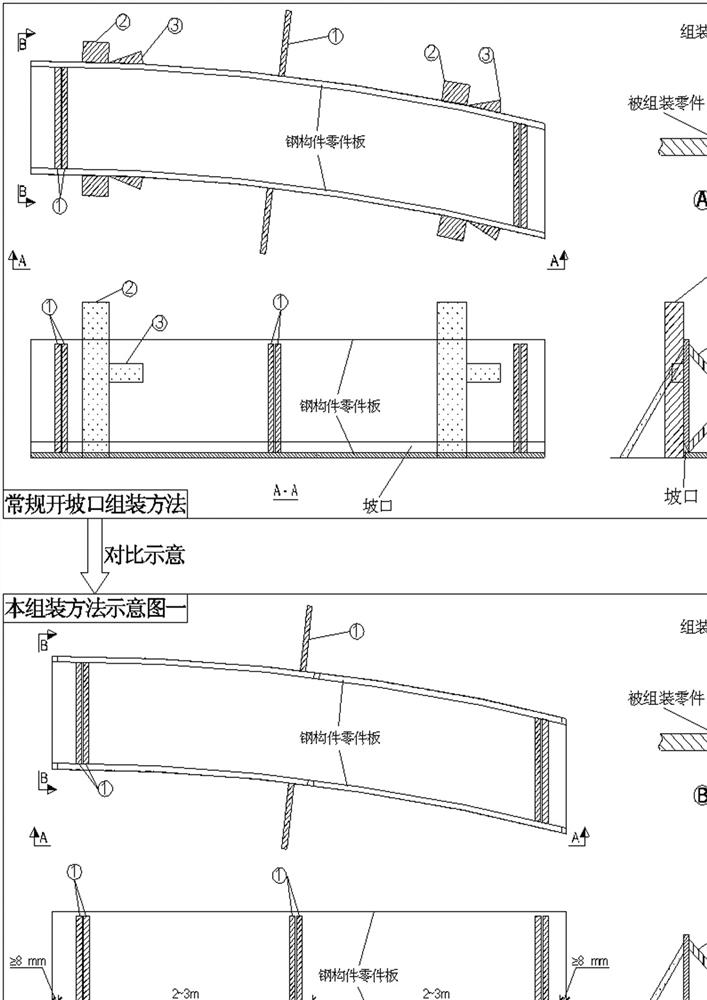

Steel component assembly method with supporting and positioning functions

ActiveCN111482748AAssembly reduction measuresImprove crane utilizationWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringFlange

The invention specifically discloses a steel component assembly method with supporting and positioning functions. The steel component assembly method is characterized by comprising the following steps: leaving un-cut flanges with length not smaller than 8 mm on the two end heads of a part of a to-be-assembled part and positions every 2-3 m during groove cutting or gap welding for the part of the to-be-assembled part; defining an effective stable contact surface by the uncut flanges during component assembling, further defining positioning lines beside the un-cut flanges on the two end heads ofthe part of the component for assisting part mounting, positioning and assembling, thereby further improving stability of a bent steel component during bent steel component assembling; accomplishingcomponent assembling, and not repeatedly regulating the position by a backer and a wedge in the process. The method can precisely control the part mounting position by assembling the reserved flangesof the part, reduces fixing measures, simplifies the processes, shortens the assembly time, and effectively controls welding gaps among the part plates.

Owner:中冶(上海)钢结构科技有限公司

A multi-protection safe drawer cabinet

ActiveCN111329258BAvoid shakingAvoid opening directlyChestsDressing tablesEngineeringStructural engineering

Owner:BBMG TIANTAN FURNITURE CO LTD

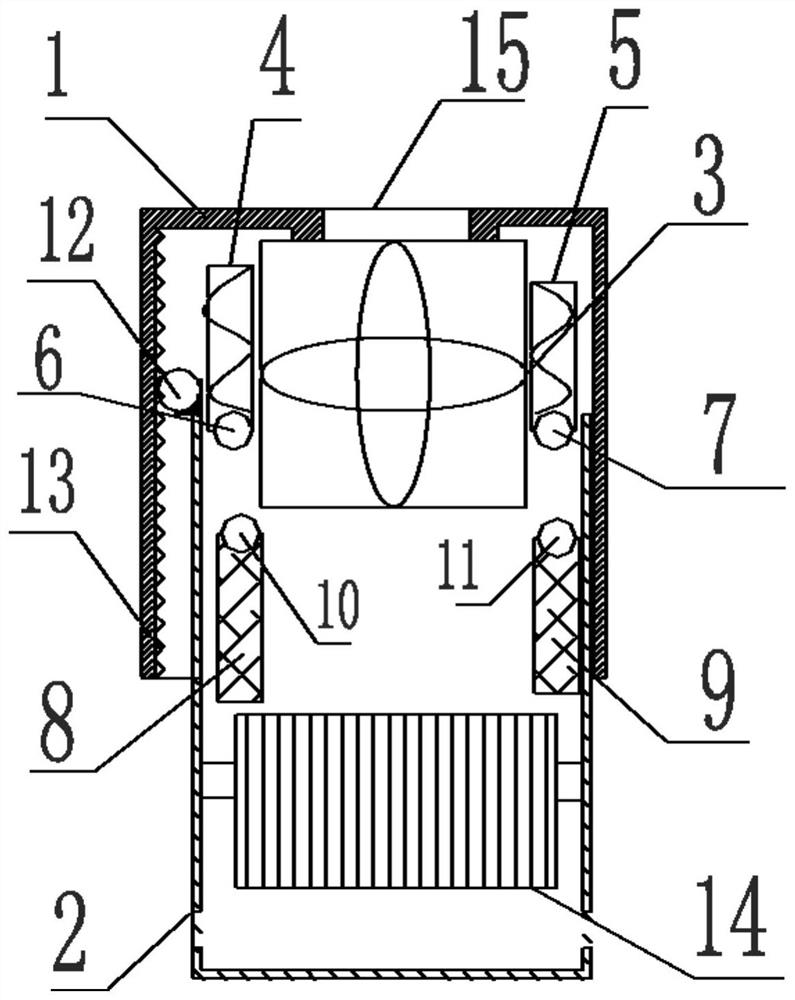

Air purifier

PendingCN111649414AReduce loadLower the altitudeMechanical apparatusLighting and heating apparatusAir purifiersEngineering

The invention provides an air purifier. A fan and a first shell move synchronously, and a filter screen component and a heating component can form a fan channel for the fan to pass through by arranging a first driving piece and a second driving piece; a pushing piece drives the first shell and the fan to move towards a second shell, and the filter screen component and the heating component entersa non-working state when the first shell and the fan move to a purification position, and then the whole device only performs electric purification operation; due to the fact that the filter screen component and the heating component have formed the fan channel for the external air to enter, the amount of the air acting on the heating component is greatly reduced, and the pollution on the heatingcomponent by the air can be effectively avoided; and due to the first shell can move in the vertical direction relative to the second shell, the first shell is controlled to move to the purification position when the air purifier needs to be stored, and then the overall height of the air purifier is reduced, and the storage is convenient.

Owner:GREE ELECTRIC APPLIANCES INC

a force measuring device

ActiveCN106644211BHigh measurement accuracyReduce shockApparatus for force/torque/work measurementContact testMechanical engineering

Owner:CHINA PETROCHEMICAL CORP +4

Mobile pedal

InactiveCN103287262AContact surface stabilityReduce experienceFoot actuated initiationsControl devicesEngineeringMechanical engineering

A novel pedal is composed of a working beam 1, a pedal 2, a lug 3, a fixing shaft 4, a gasket 5, a split pin 6, an adjusting screw 7 and a spring 8. A stop block 11 arranged on the lower portion of the tail end of the working beam 1 is provided with a screw through hole, and the adjusting screw 7 penetrates out of the spring 8 to be screwed in the screw through hole in the stop block 11. By arrangement the stop block on the lower portion of the working rod and the adjusting screw on the stop block, an operator can adjust angles of the pedal in an idle state as required, and the angles between the pedal and the working rod can be automatically adjusted to keep a stable contact surface between a sole and the pedal, so that requirements of the operators for experience and ability are lowered.

Owner:李耀强

Measuring device and method for unconfined bearing capacity of freshly mixed mortar

InactiveCN104034595BObservable exposureReduce distortionMaterial strength using tensile/compressive forcesMeasurement deviceTest sample

The invention relates to a measurement device for fresh mortar non-lateral-confinement bearing capacity. The measurement device comprises a frame body, a loading device and a vertical displacement measurement device which are arranged from bottom to top respectively, wherein the frame body comprises a base, as well as a screw rod and a plurality of nuts for mounting the loading device and the vertical displacement measurement device, the loading device comprises a loading barrel, a loading plate is arranged on the bottom surface of the loading barrel, a loading barrel upper cover is arranged at the top of the loading barrel, a test sample is arranged between the loading plate and the base, and the vertical displacement measurement device comprises a screw rod fixing cross beam, a dial gauge mounting beam and a dial gauge. The device can be used for utilizing the dead load of liquid to load, and can load continuously and eliminate load unevenness, and the measurement device is simple in structure and convenient in use, and can easily measure the bearing capacity and displacement change of fresh mortar in a corresponding loading direction.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

A steel member assembly method with self-supporting and positioning functions

ActiveCN111482748BIncrease profitPrecisely locate the assembly positionWelding/cutting auxillary devicesAuxillary welding devicesFlangeManufacturing engineering

Specifically, the present invention is a method for assembling steel components with its own support and positioning functions; its feature is: when cutting grooves or welding gaps for the parts of the steel components to be assembled, at the two ends of the parts to be assembled and at a distance of 2 A non-cut flange of not less than 8mm is left at the position of ~3m; when the components are assembled, the non-cut flange forms an effective smooth contact surface, and further, the non-cut flanges at both ends of the component parts The positioning line formed on the side also assists in the installation and positioning of assembly parts. In this way, the stability of the assembly of curved steel components is further increased; the assembly of components is completed, and the process does not need to repeatedly adjust the position with additional abutment and wedges. The method utilizes the reserved flanges of the parts for assembly, so that the installation position of the parts can be precisely controlled, the fixing measures can be reduced, the process can be simplified, and the assembly time can be shortened; at the same time, the welding gap between the part plates can be effectively controlled.

Owner:中冶(上海)钢结构科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com