Full face type pulling plate and clamping piece structure

A full-plane, clamping technology, applied in the field of transformers, can solve problems such as inappropriate processing, unstable structure, unstable clamping, etc., and achieve the effects of reducing processing difficulty, high assembly efficiency, and stable contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

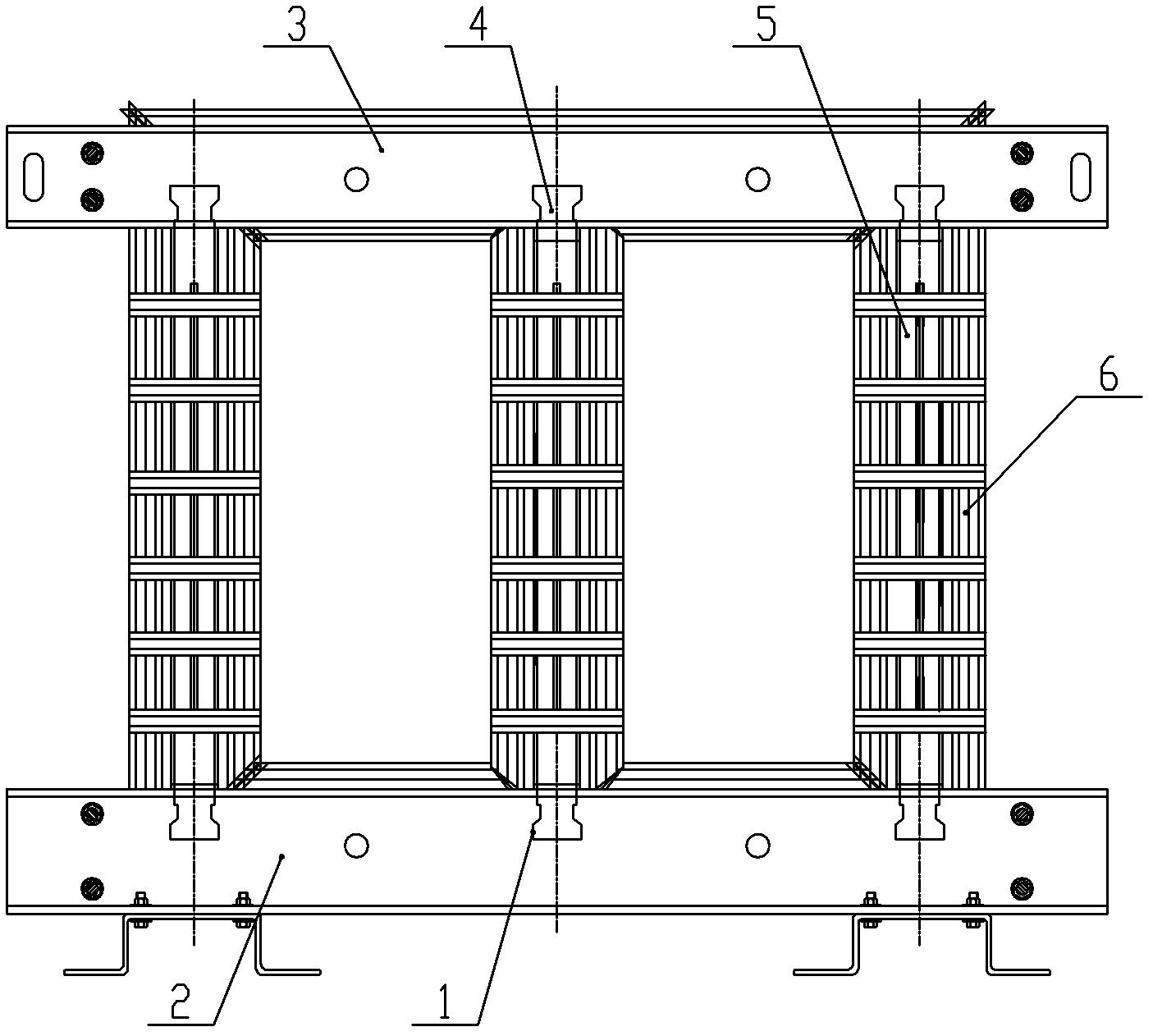

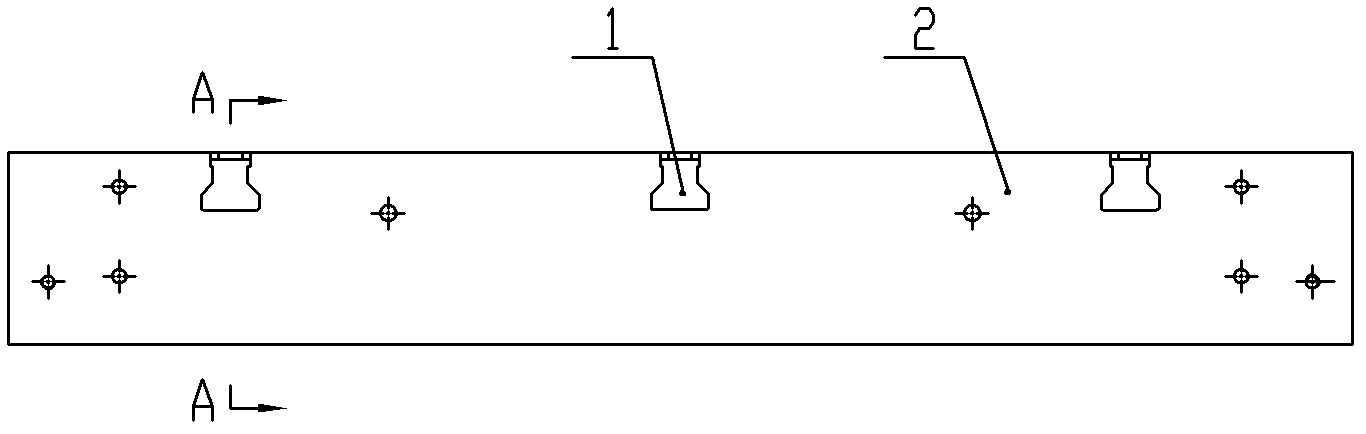

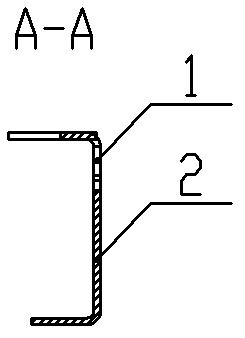

[0023] Figure 1~Figure 8 Among them, it includes card slot 1, lower clip 2, upper clip 3, chuck 4, pull plate 5, iron core 6, long slot 7, notch 8, etc.

[0024] Such as figure 1 As shown, the present invention is a full-plane pull plate clamp structure, which reinforces the core column in the axial direction, clamps and reinforces the laminated iron core into a whole magnetic circuit, and prevents the upper and lower yoke joints of the iron core from exerting force on the iron core. The seam brings damage, which affects the increase of core loss. It includes an upper clamp 3 , a lower clamp 2 and a pull plate 5 . Pull plate 5 has three.

[0025] Such as Figure 2 ~ Figure 4 As shown, the cross-section of the lower clip 2 is groove-shaped, and is formed by flanging steel plates, and the width of the upper flange plate is greater than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com