Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Cleanness is improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent article comprising an agent able to convey a perception to the wearer, without the need to create the external condition perceived

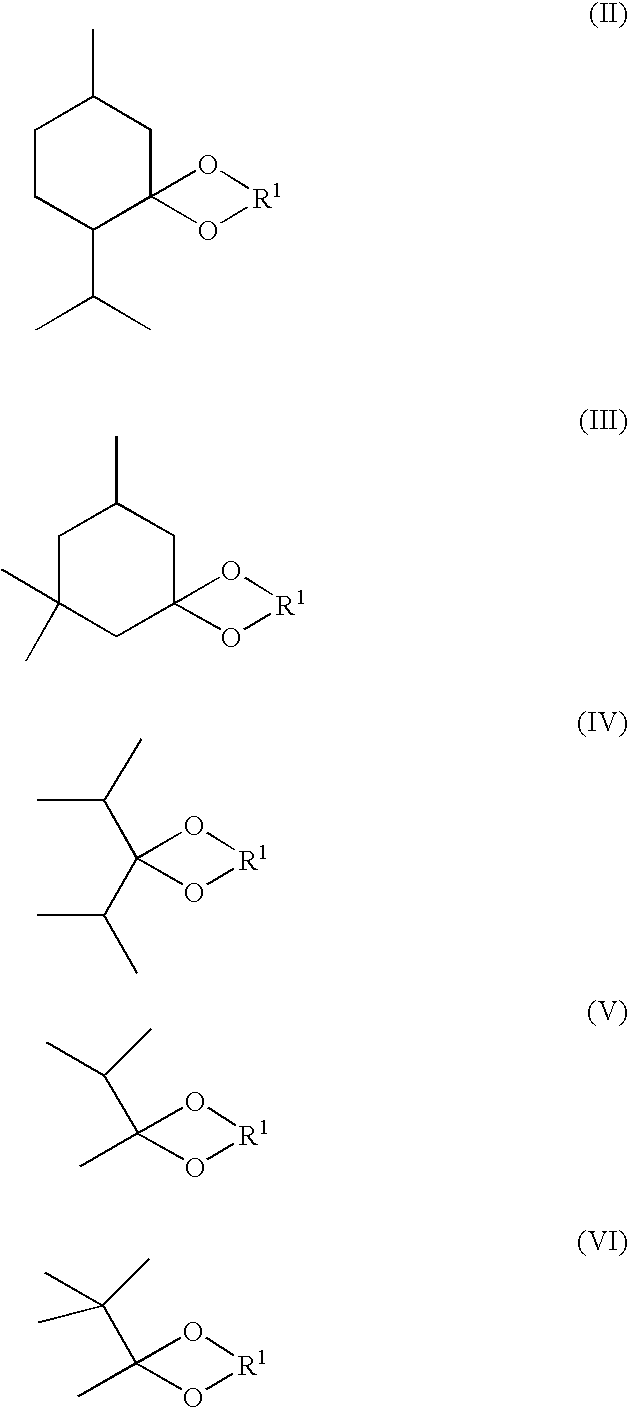

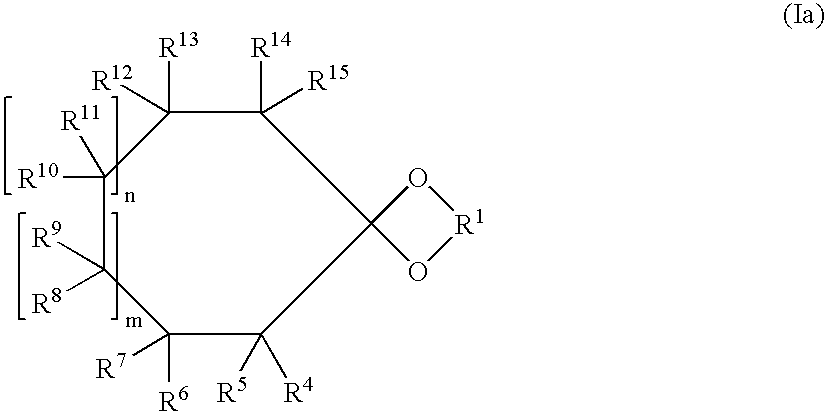

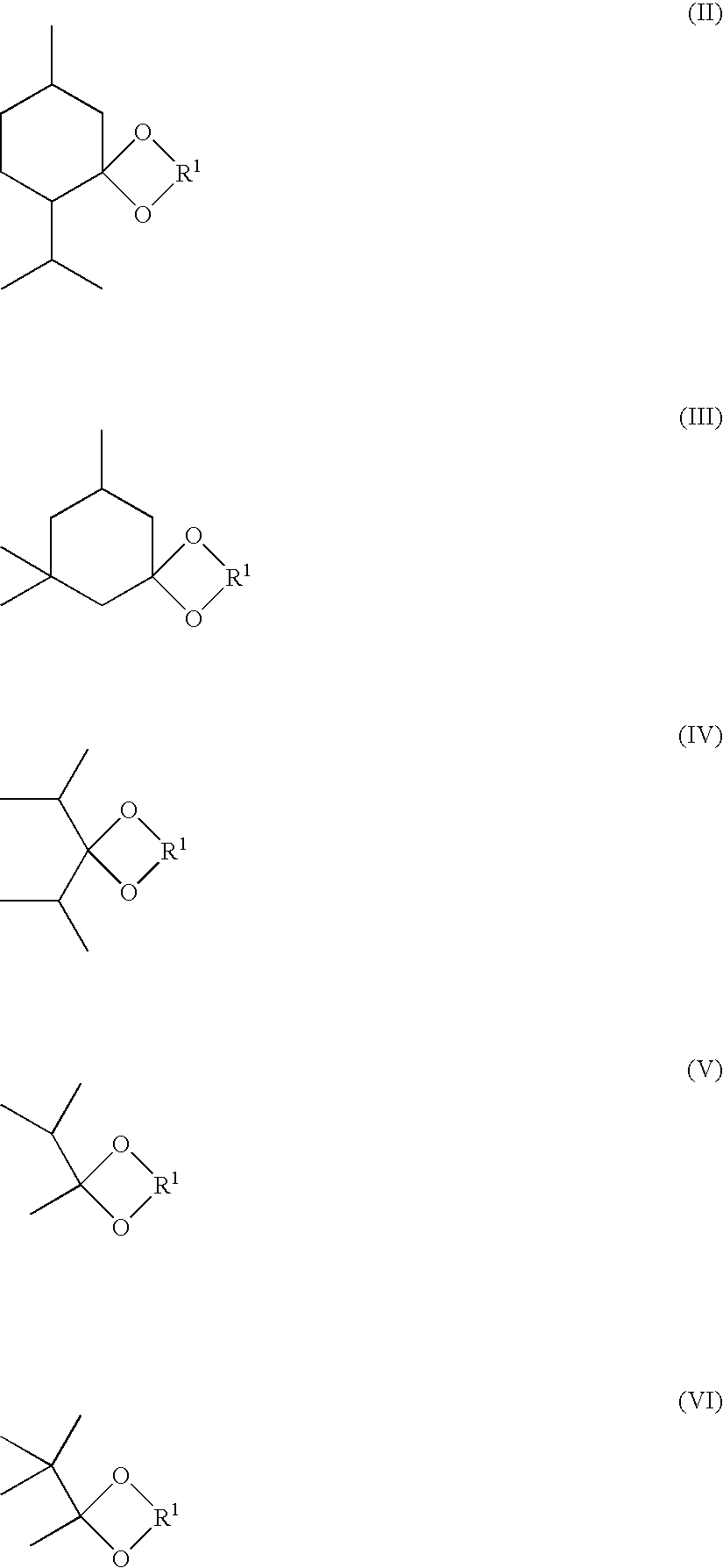

InactiveUS20040082928A1Maintaining or even improving skin healthFreshness and dryness sensationMedical applicatorsBaby linensPhysical medicine and rehabilitationInfant nappy

The present invention relates to absorbent articles, such as sanitary napkins, panty-liners, nursing pads, baby diapers and the like, comprising an agent able to convey a perception to the wearer, without the need to create the external condition perceived by the wearer. Such absorbent articles are able to improve comfort, by, for example, conveying to the wearer thereof a long lasting freshness sensation upon prolonged wearing time of such articles

Owner:THE PROCTER & GAMBLE COMPANY

Absorbent article comprising an agent able to convey a perception to the wearer, without the need to create the external condition perceived

InactiveUS20050203473A1Maintaining or even improving skin healthFreshness and dryness sensationBaby linensTamponsPhysical medicine and rehabilitationInfant nappy

Owner:PROCTER & GAMBLE CO

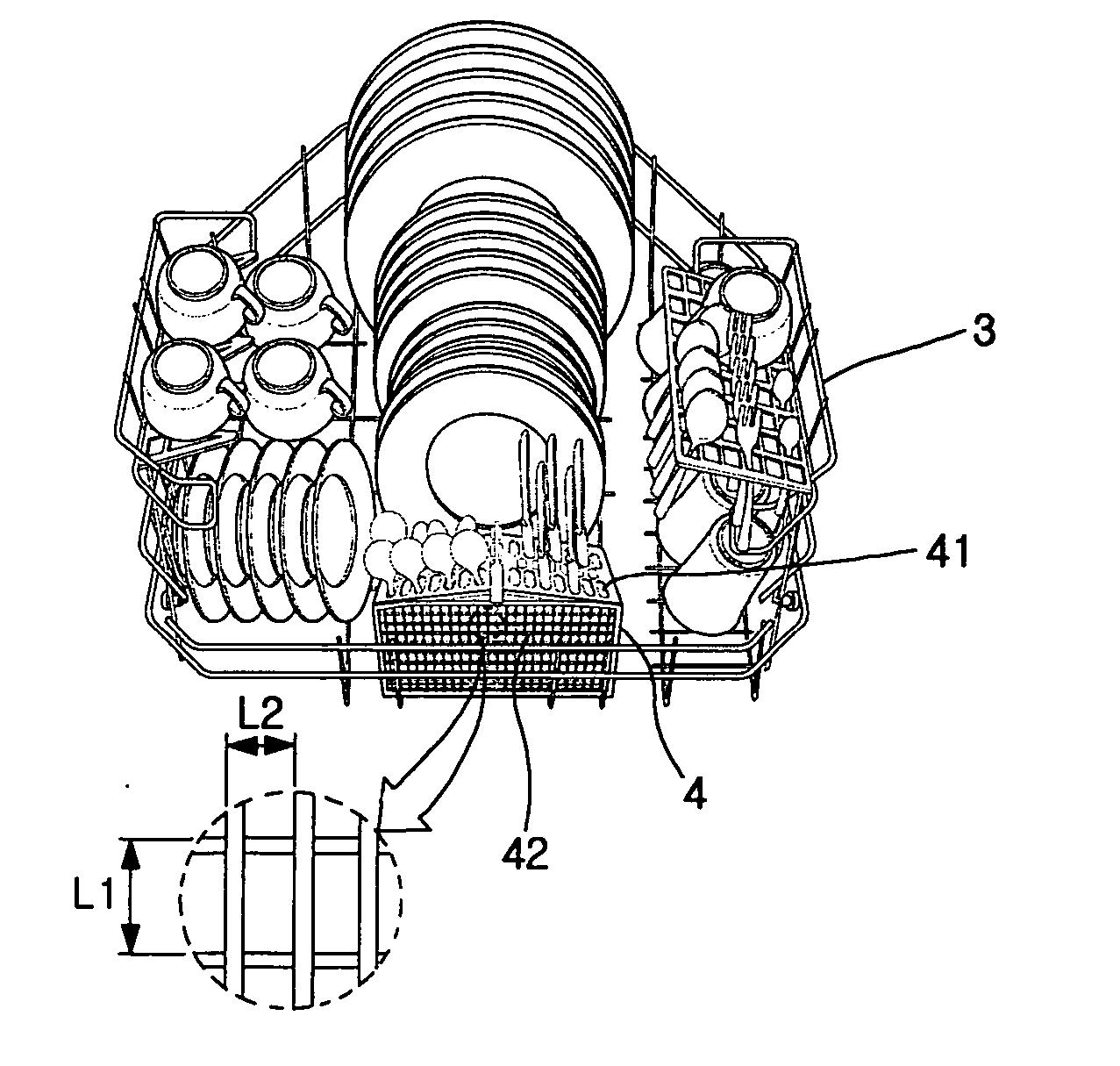

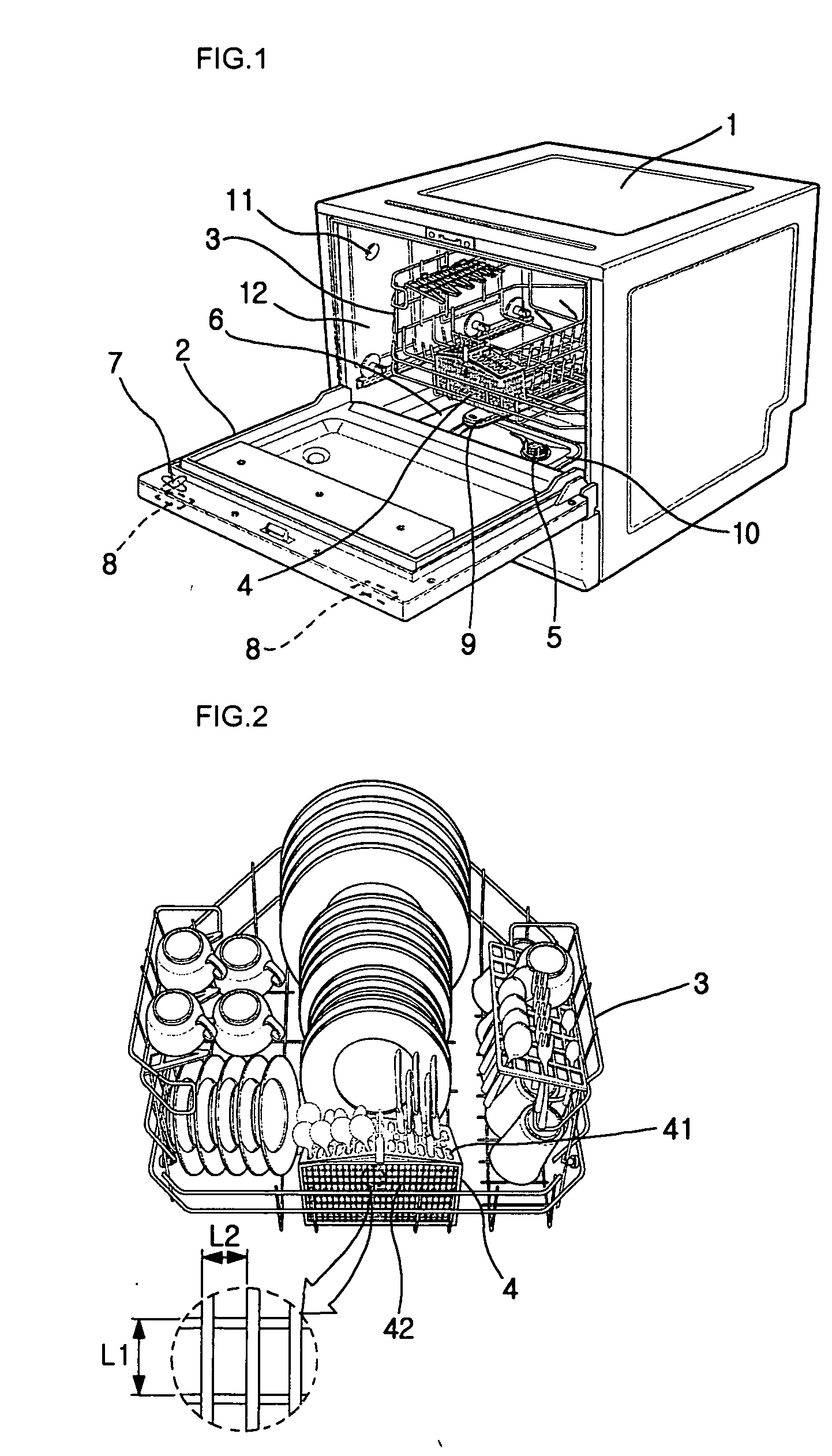

Dish washing machine

InactiveUS20050150528A1Improve hygieneEliminating bad smellTableware washing/rinsing machine detailsElectrostatic cleaningPlasma coatingProcess engineering

A dish washing includes a cabinet having a washing room formed in the cabinet to receive dishes, an injection arm for injecting a washing water toward the dishes, and many components contacted with the washing water. In order to improve the utilization efficiency of the dish washing machine, the machine also includes a plasma coating layer formed on an outer surface of each of the components, a heater for heating the washing water, an air ventilation hole for discharge humid air while the dishes are dried, and a discharge fan for forcibly flowing air through the air ventilation hole.

Owner:LG ELECTRONICS INC

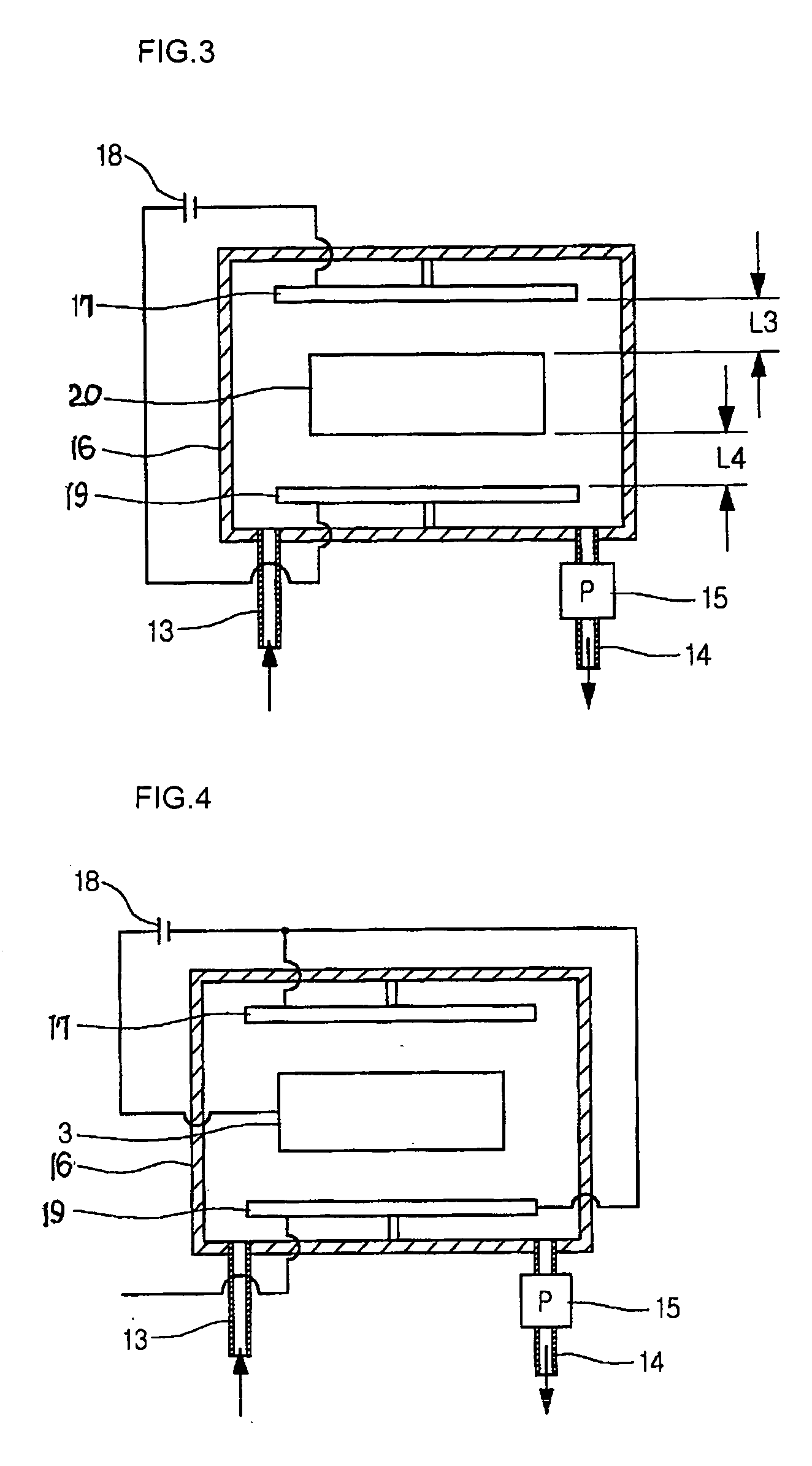

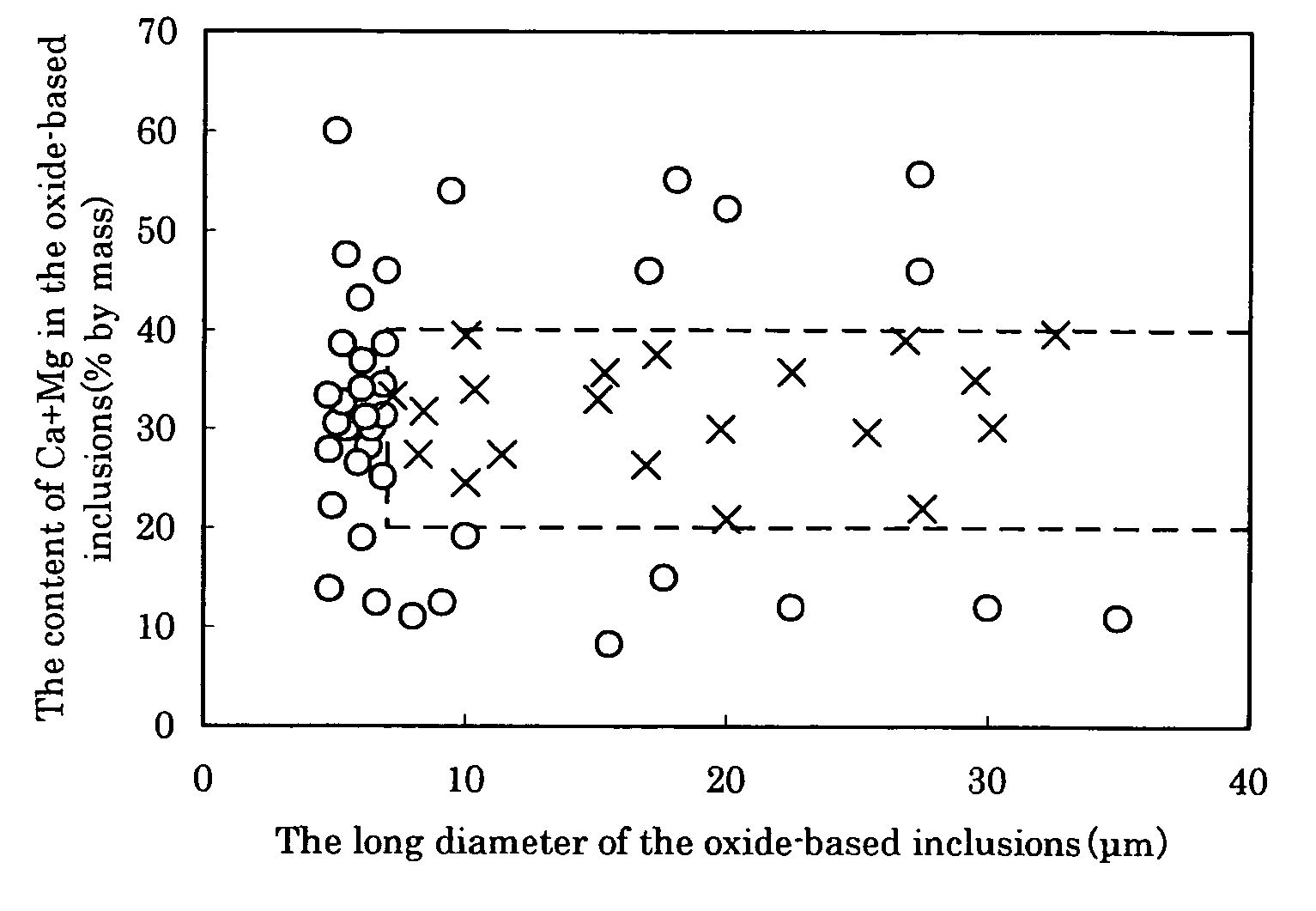

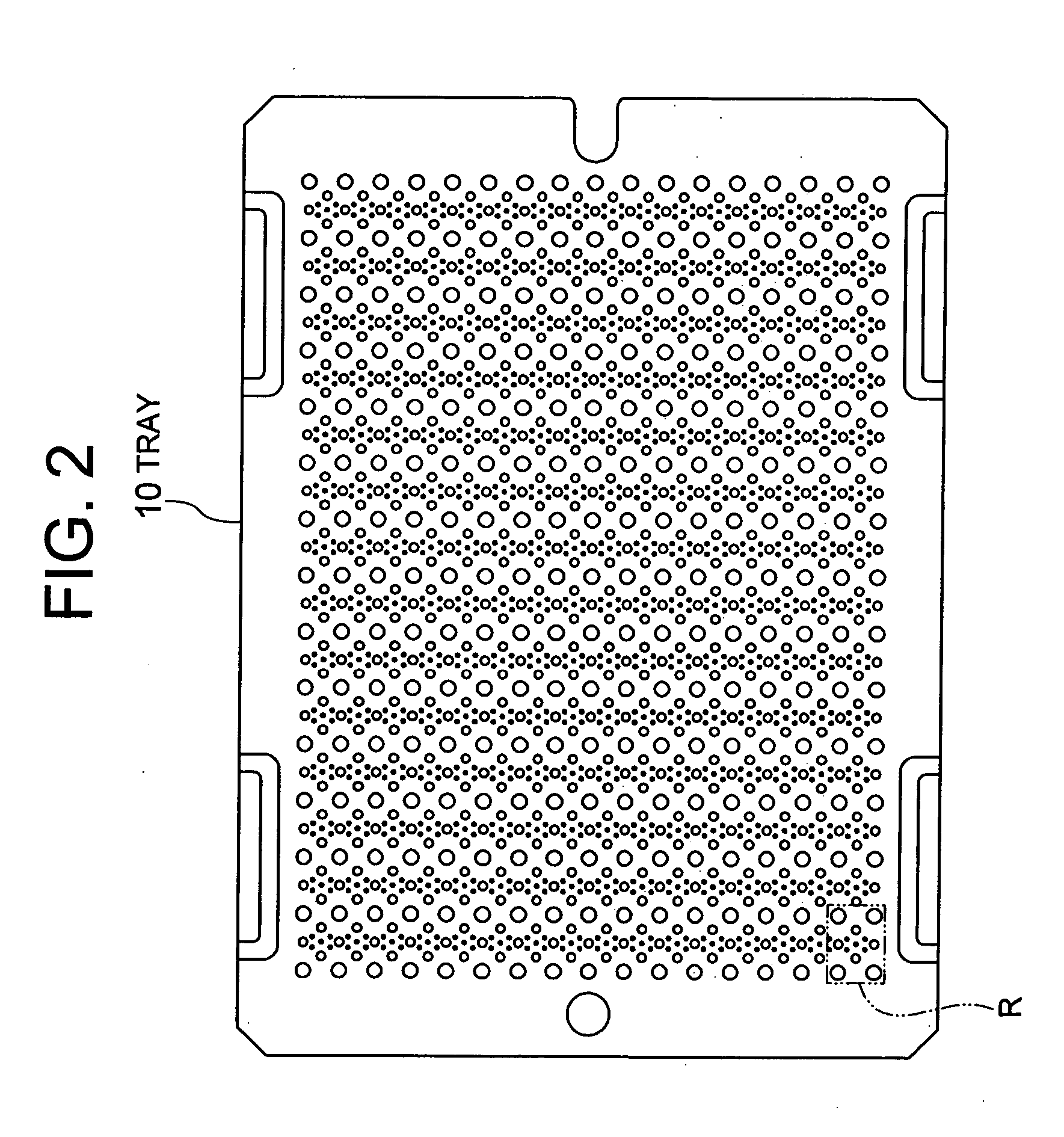

Duplex stainless steel and manufacturing method thereof

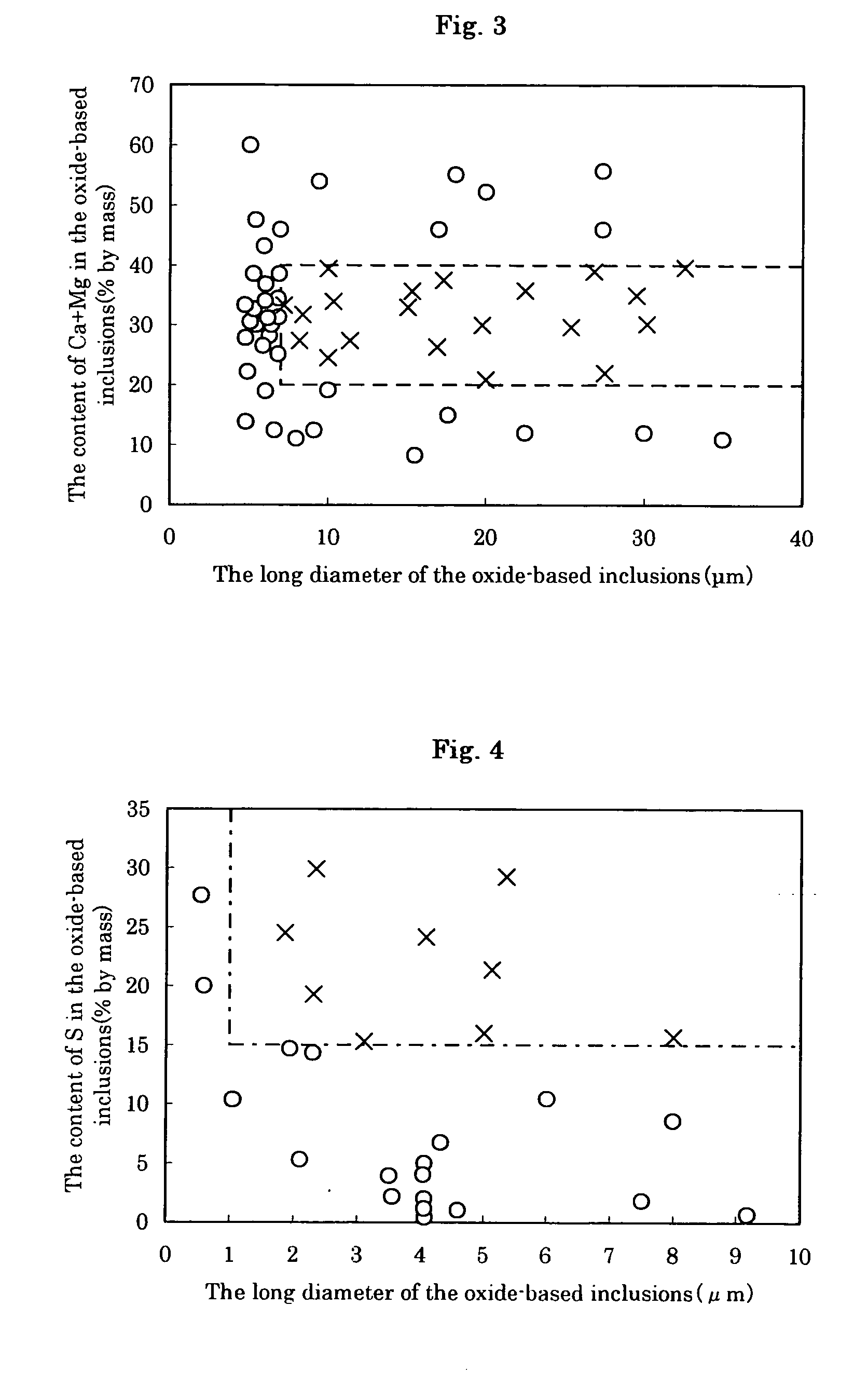

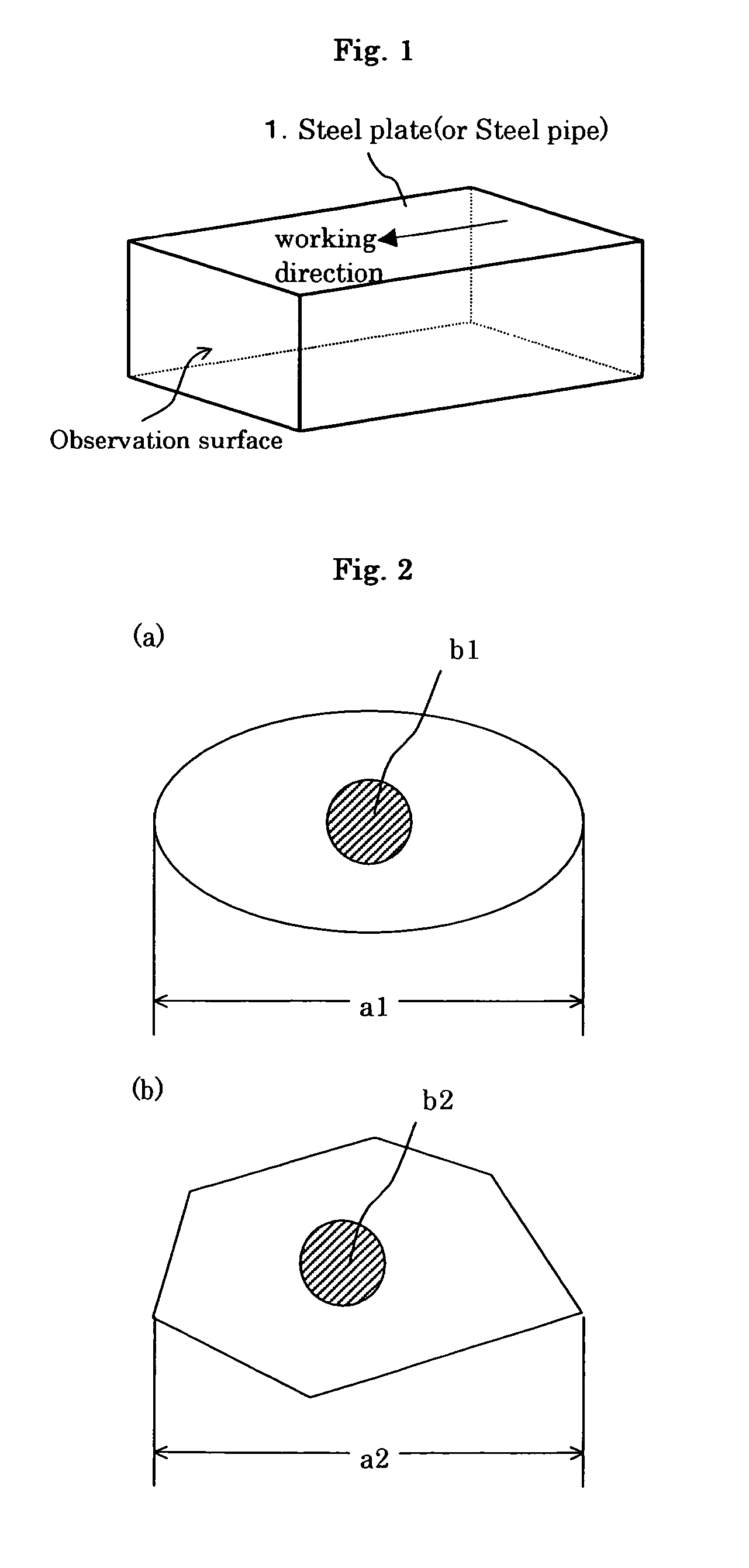

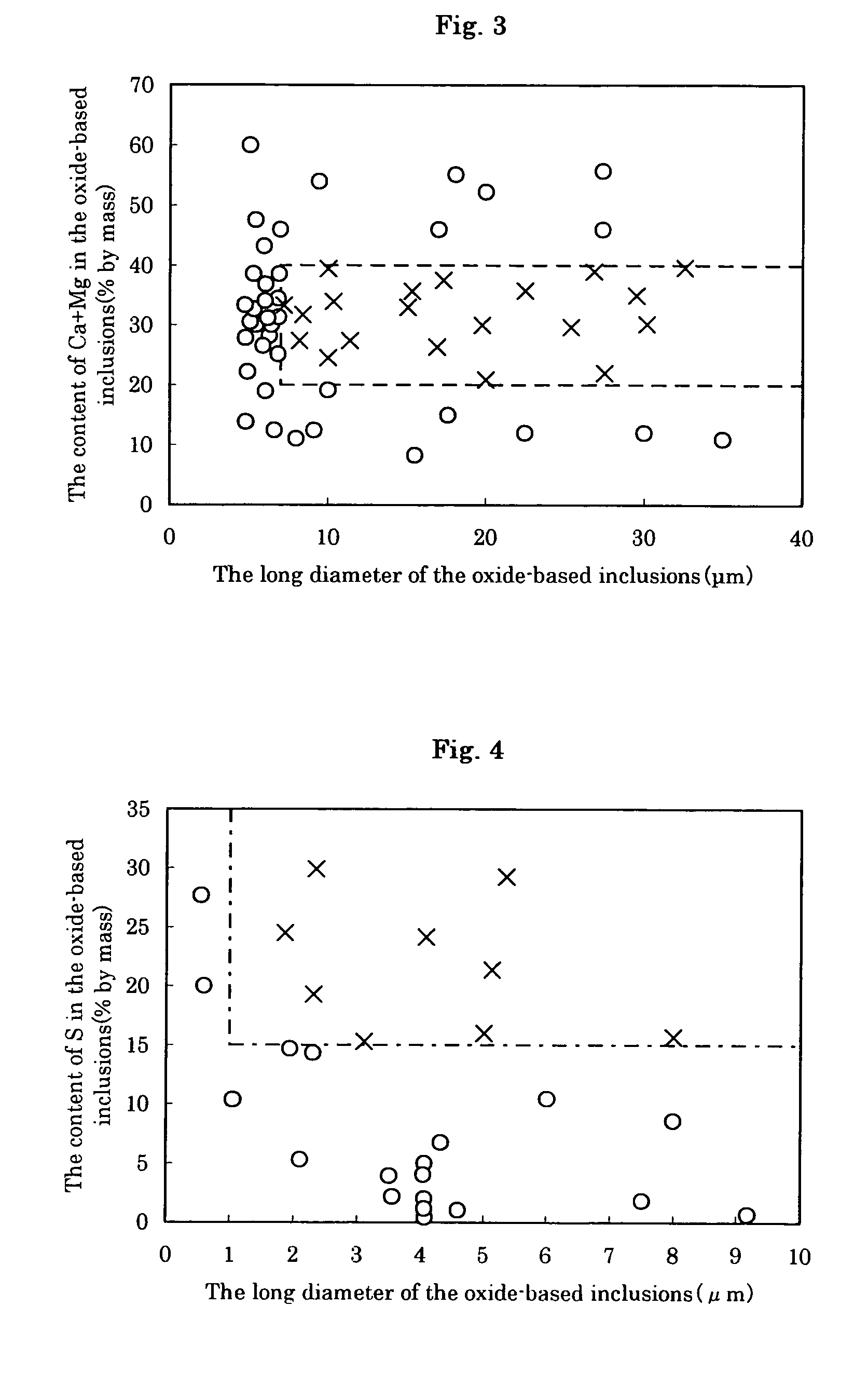

ActiveUS20050211344A1Good resistanceImprove the immunityFurnace typesQuenching agentsLongest DiameterOxide

A duplex stainless steel containing C, Si, Mn, P, S, Al, Ni, Cr, Mo, N (nitrogen, O (oxygen), Ca, Mg, Cu, B, and W, and the balance Fe and impurities, where a number of oxide-based inclusions, which have a total content of Ca and Mg of 20 to 40% by mass and also have a long diameter of not less than 7 μm, is not more than a 10 per 1 mm2 of the cross section perpendicular to the working direction, or further, the number of oxide-based inclusions, which have a content of S of not less than 15% by mass and also have a long diameter of not less than 1 μm, is not more than 10 per 0.1 mm2 of the cross section perpendicular to the working direction. Particularly, the contents of Cu, B and W are desirably 0.2 to 2%, 0.001 to 0.01%, and 0.1 to 4% by mass, respectively.

Owner:NIPPON STEEL CORP

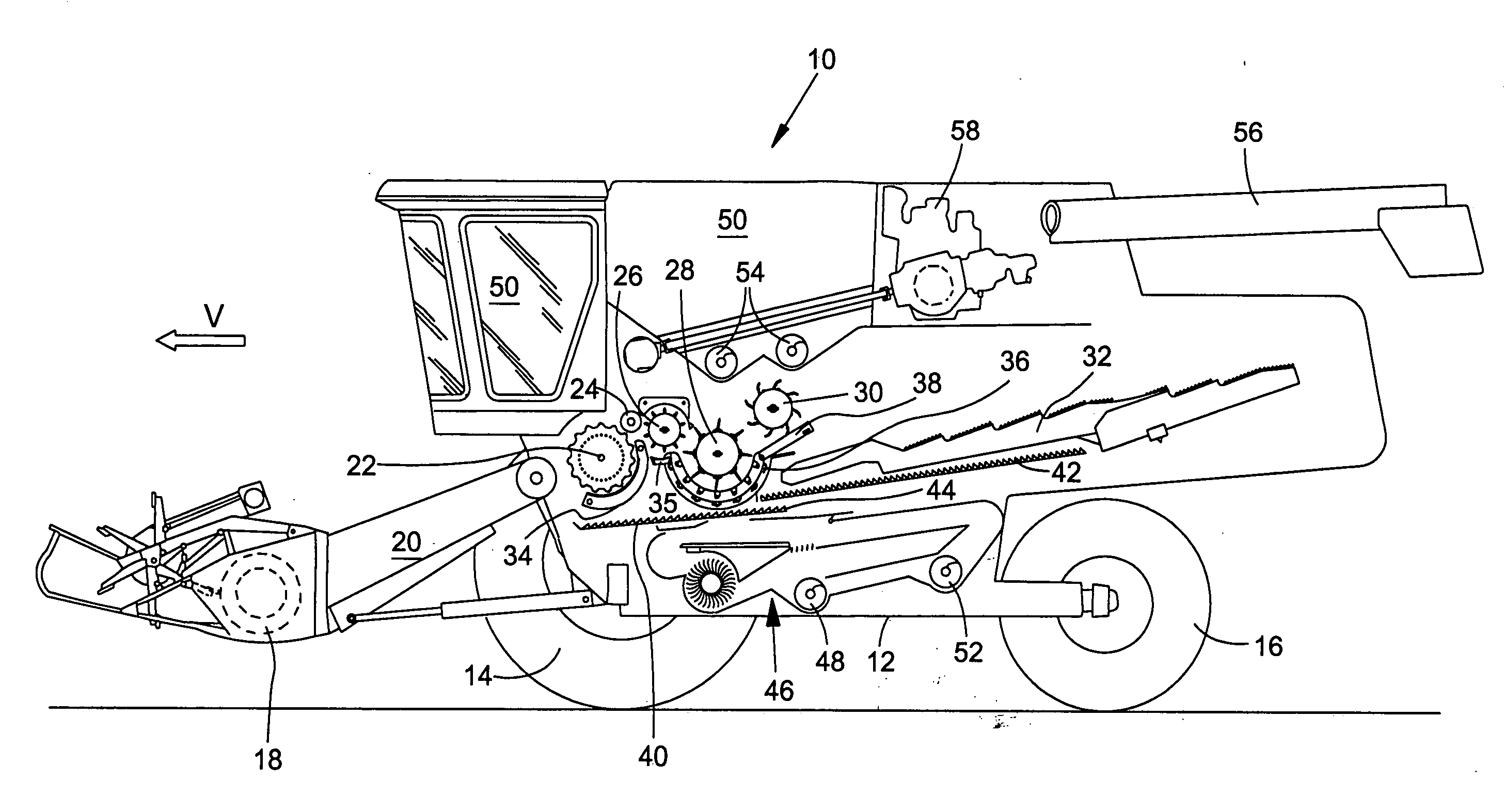

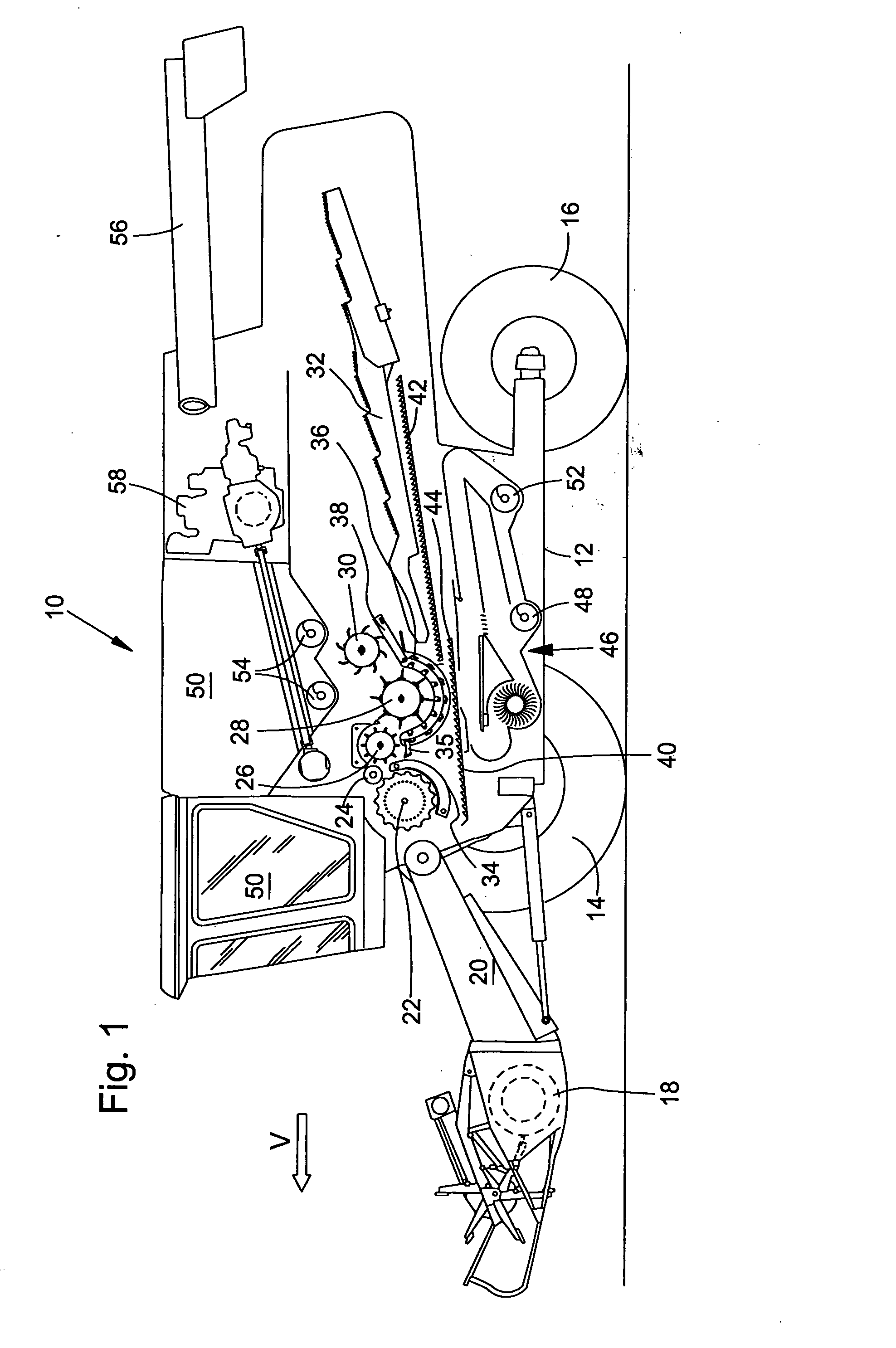

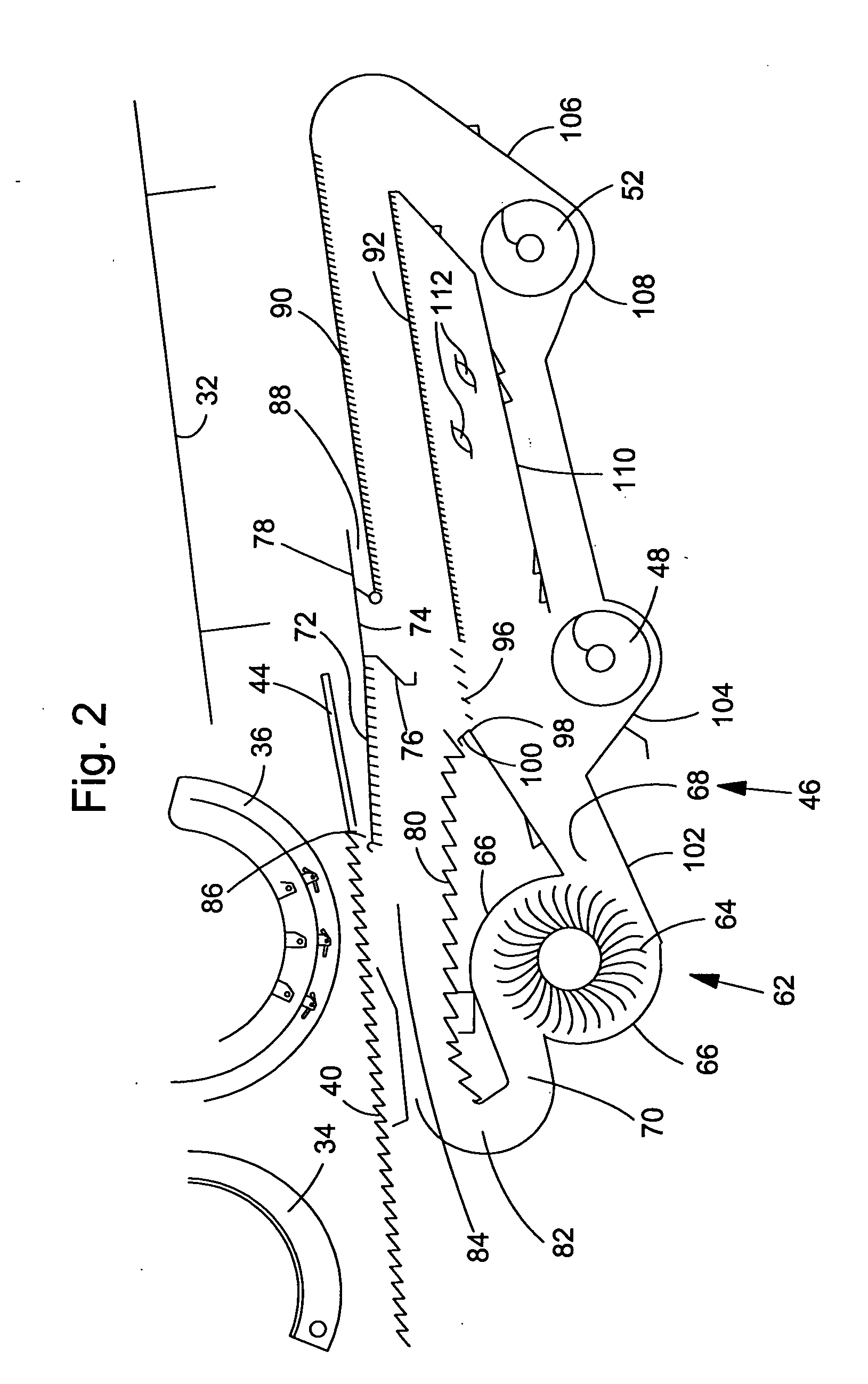

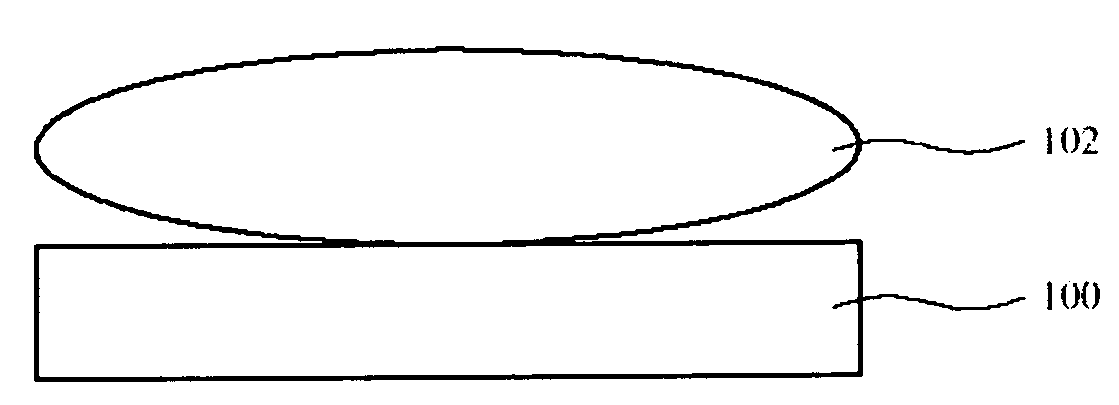

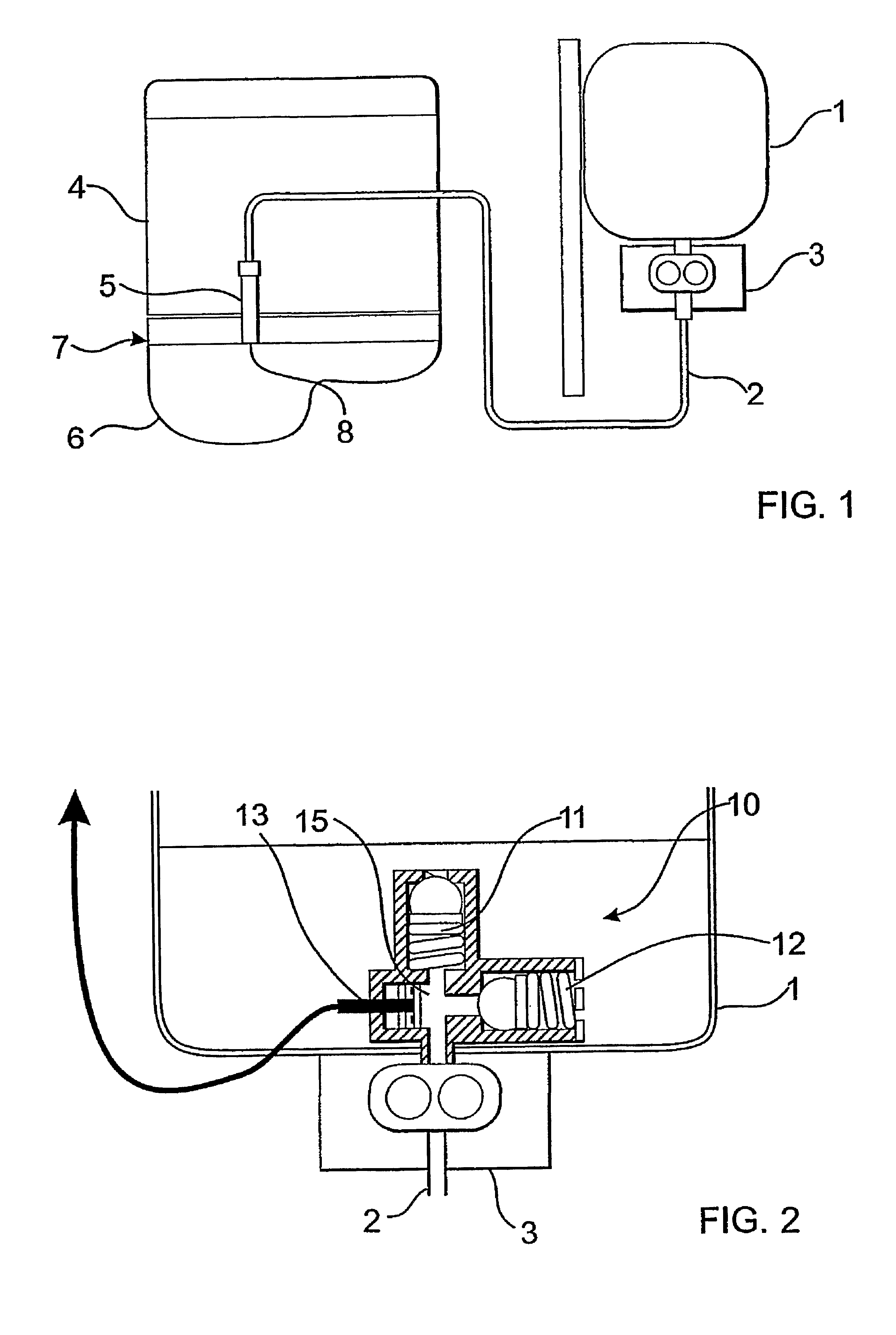

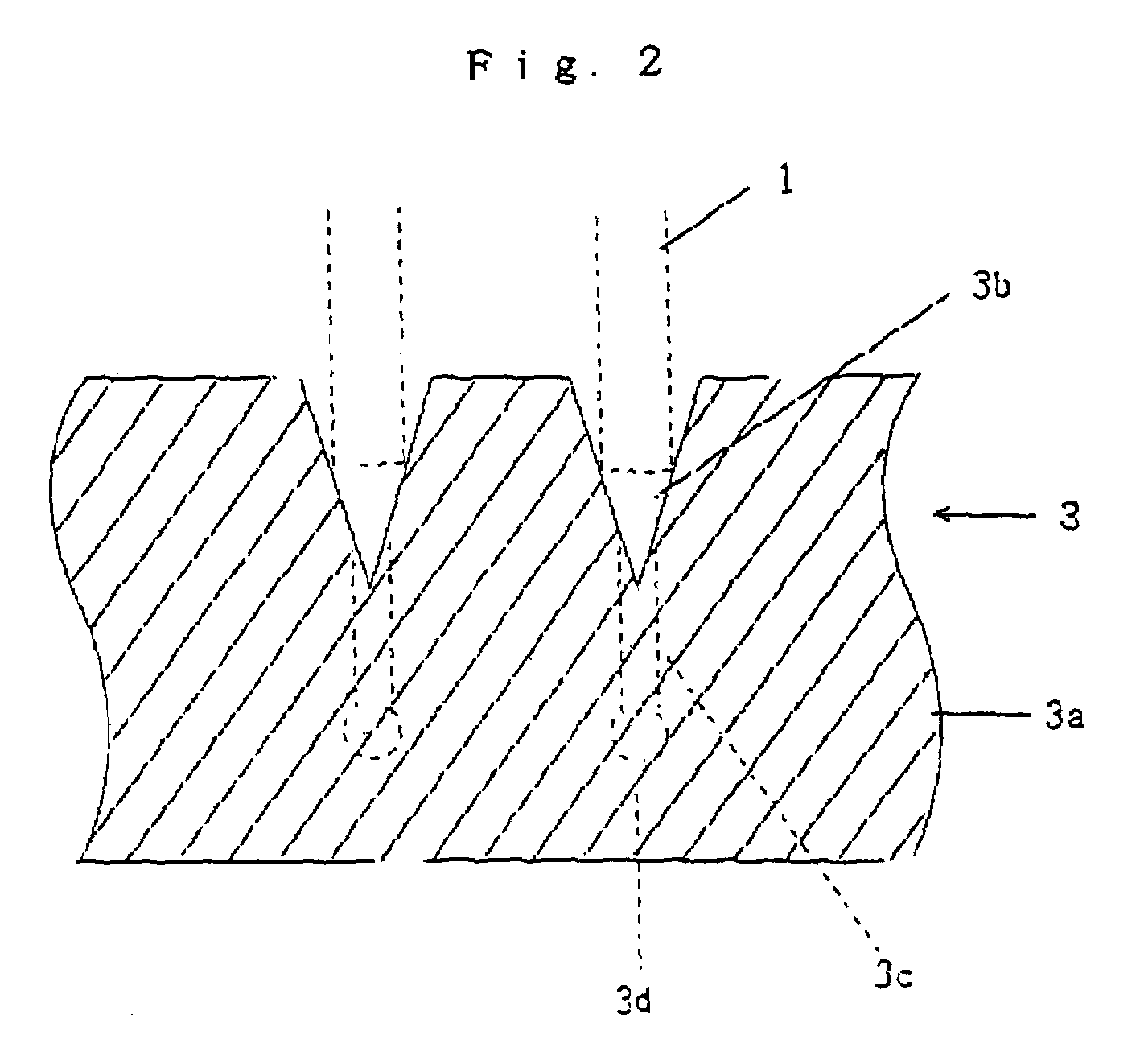

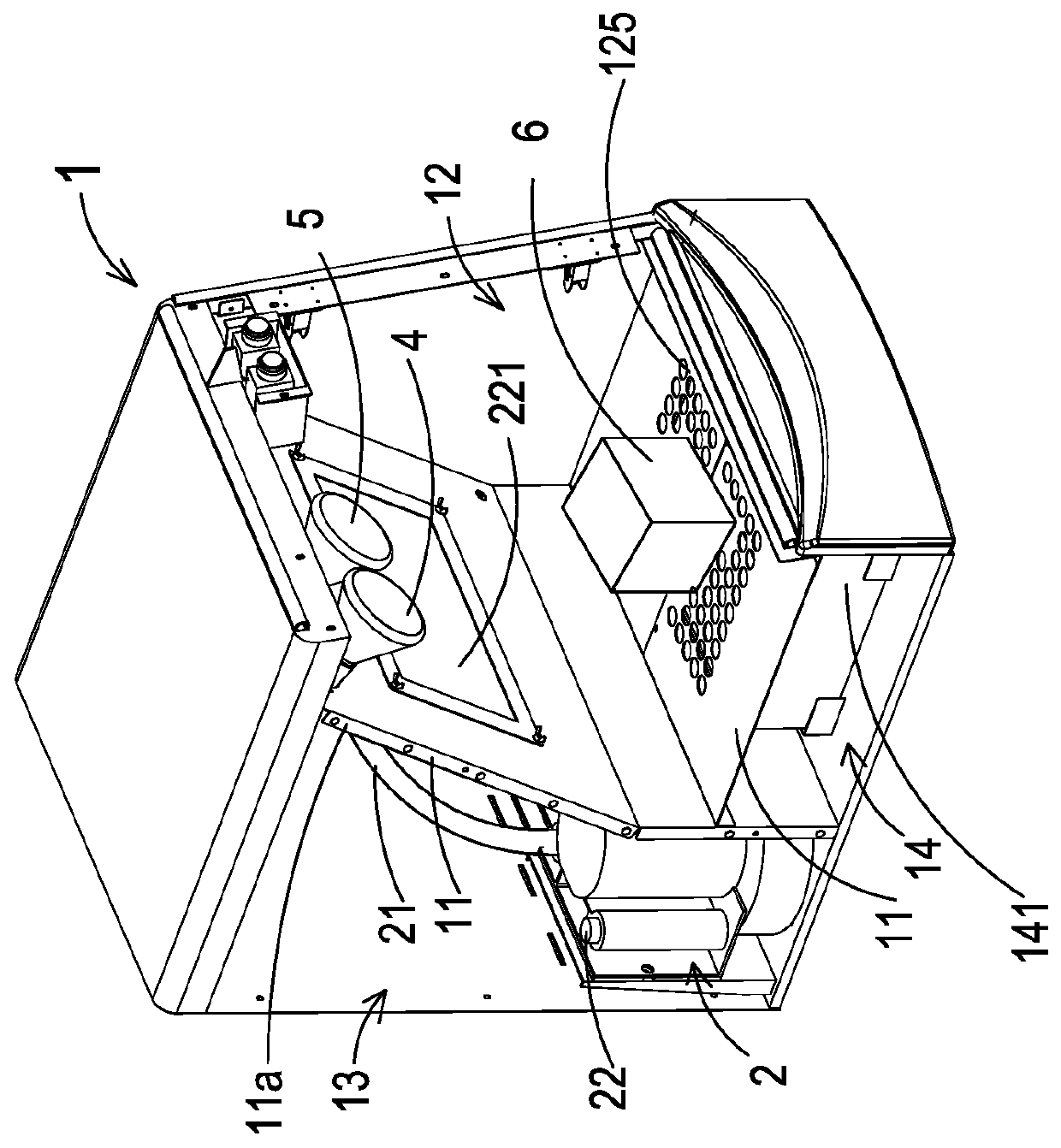

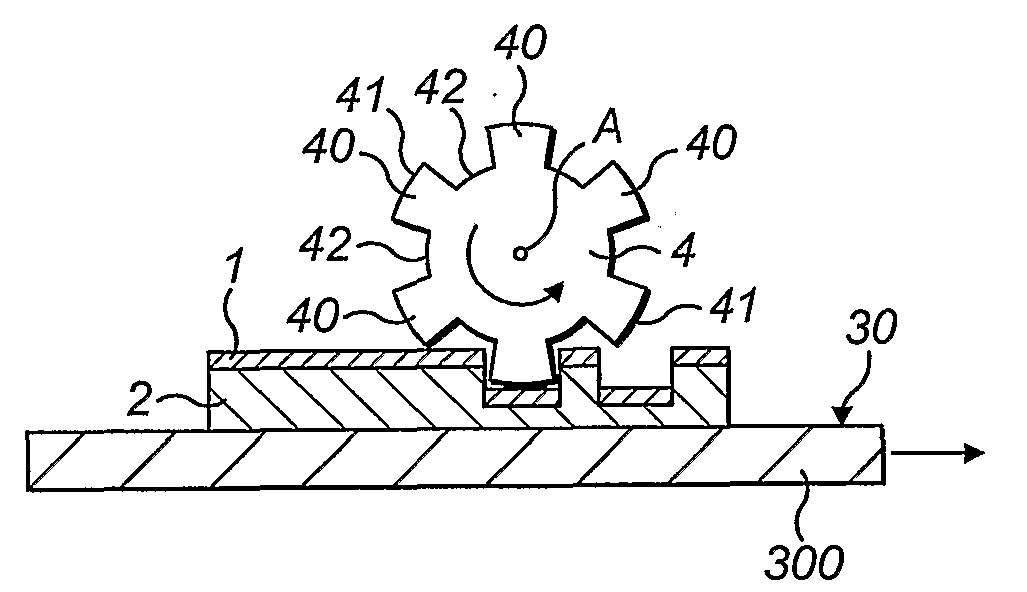

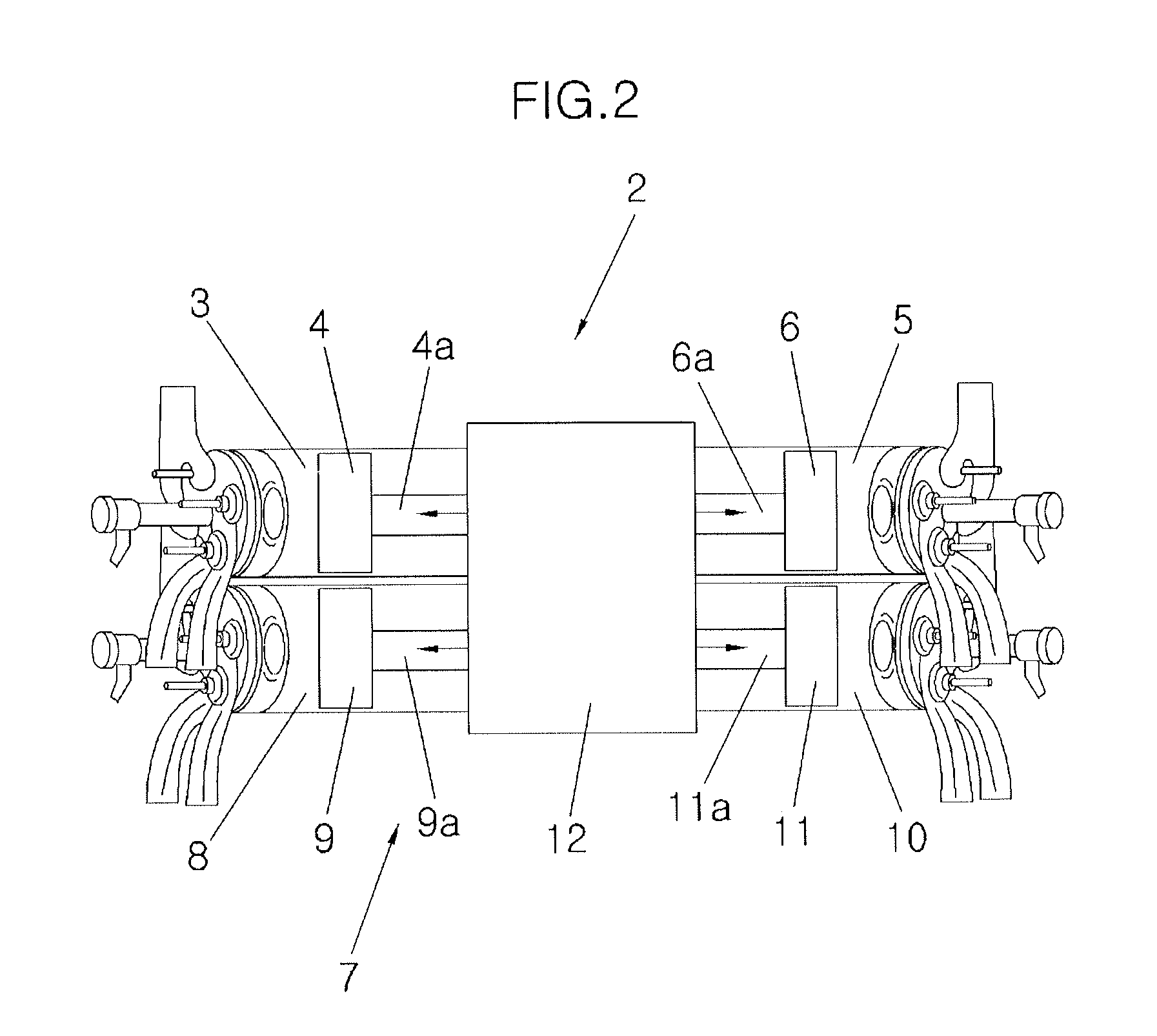

Grate between precleaner and sieve

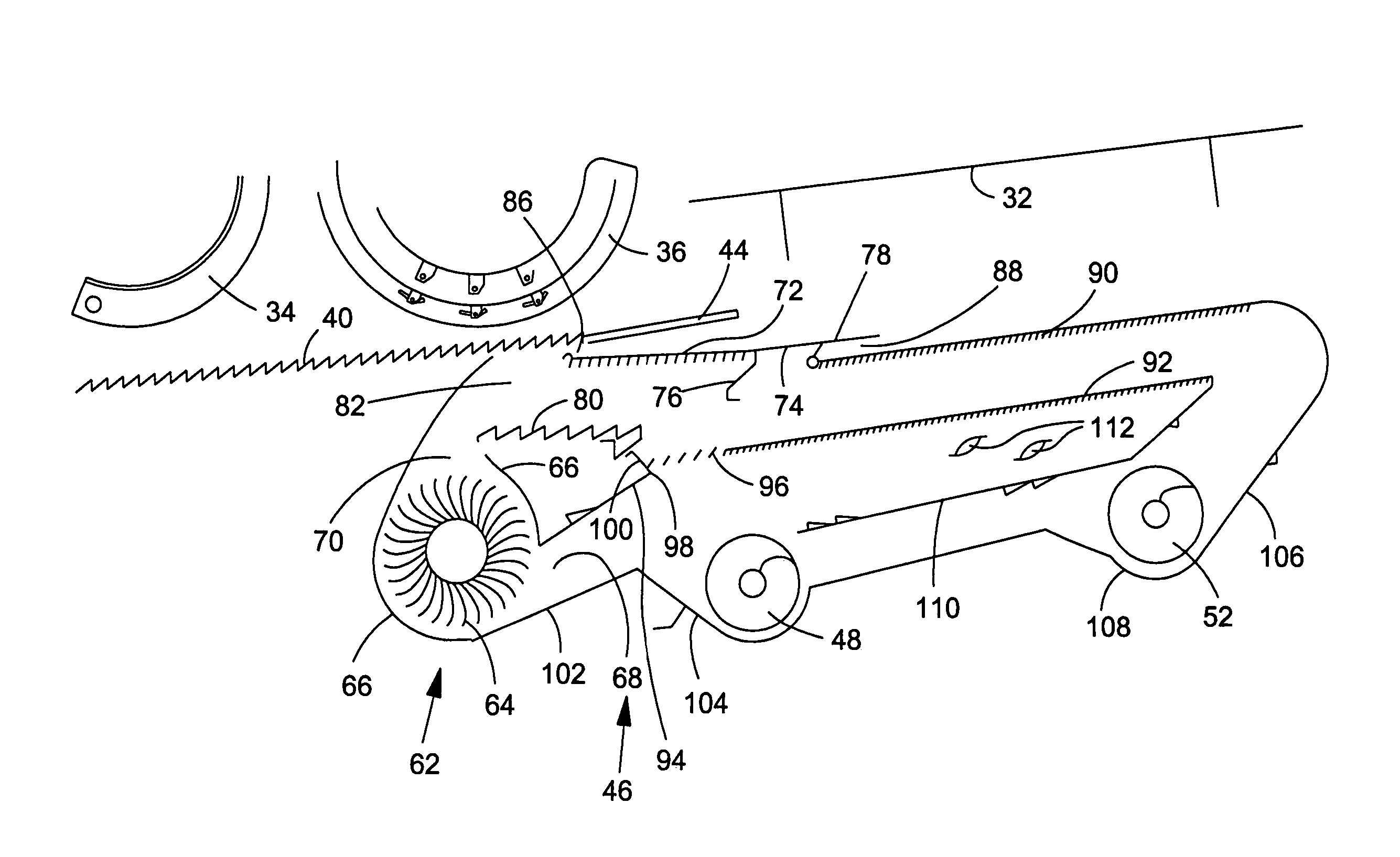

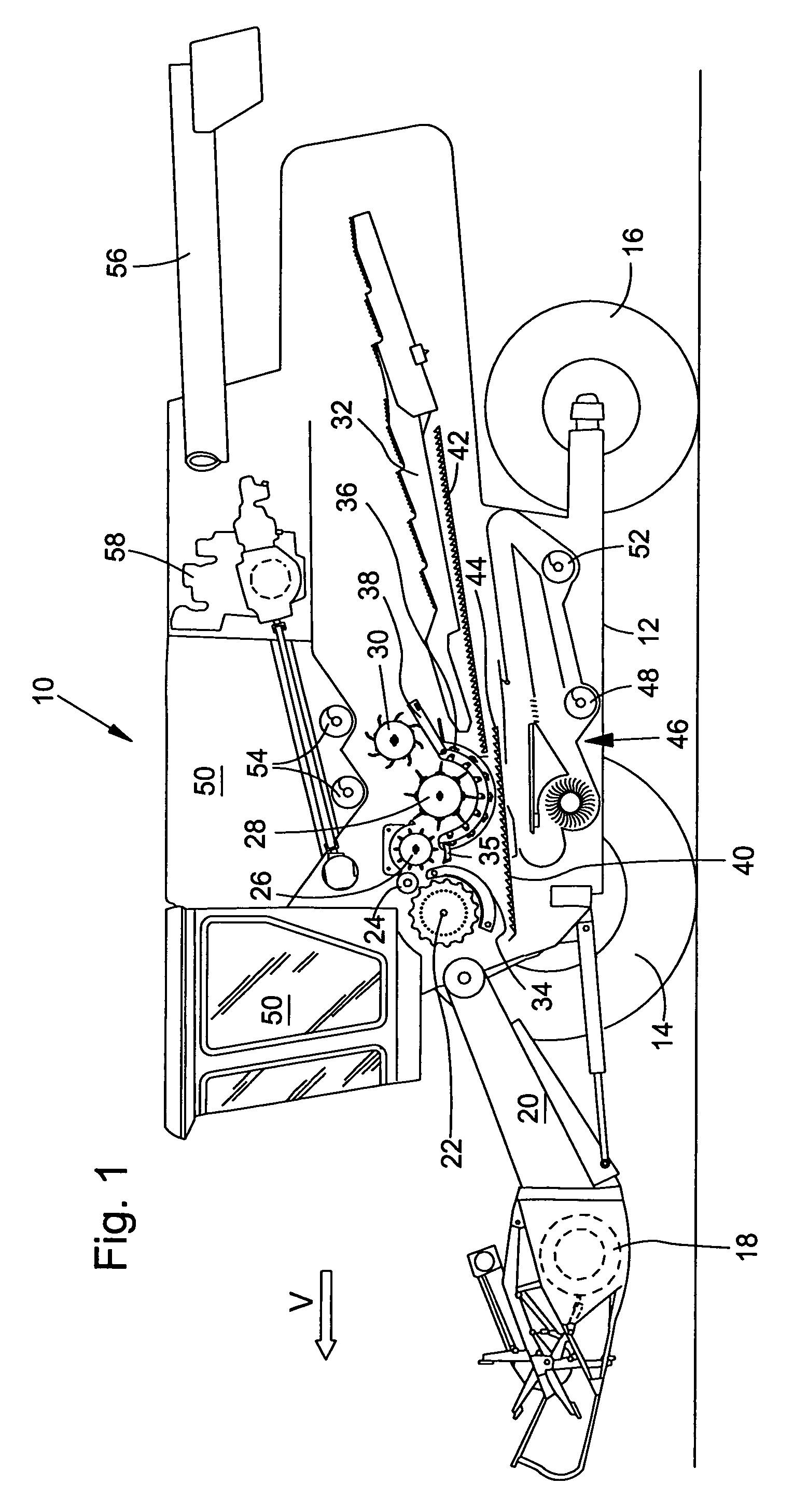

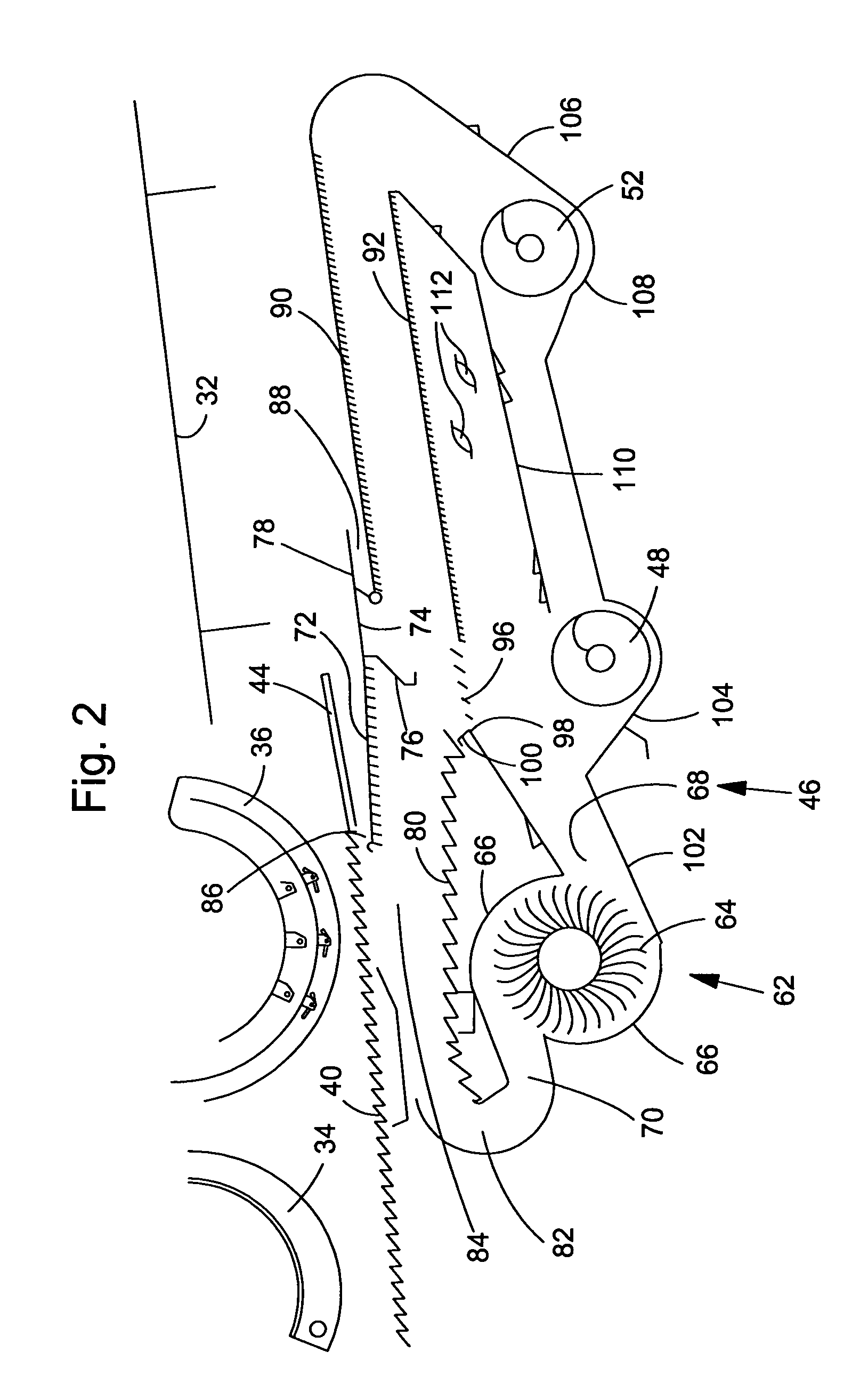

The subject matter of the present invention relates to a cleaning device for a combine harvester, with a precleaning sieve, to the upper surface of which a mixture of grain and chaff can be fed during the operation, an upper sieve, to which the mixture of grain and chaff rearwardly discharged from the back surface of the precleaning sieve can be fed, a lower sieve, to which the mixture of grain and chaff passing through the precleaning sieve can be fed, and with a fan for applying currents of air to the precleaning sieve, the upper sieve and the lower sieve. On its way between the precleaning sieve and the lower sieve, the mixture of grain and chaff that has passed through the precleaning sieve be passed via a grating which is permeable to air and disposed separately from the lower sieve, to which grating a current of air can be applied by the fan as well.

Owner:DEERE & CO

Grate between precleaner and sieve

InactiveUS20060281506A1Improve throughputCleanness is improvedSievingScreeningSubject matterEngineering

The subject matter of the present invention relates to a cleaning device for a combine harvester, with a precleaning sieve, to the upper surface of which a mixture of grain and chaff can be fed during the operation, an upper sieve, to which the mixture of grain and chaff rearwardly discharged from the back surface of the precleaning sieve can be fed, a lower sieve, to which the mixture of grain and chaff passing through the precleaning sieve can be fed, and with a fan for applying currents of air to the precleaning sieve, the upper sieve and the lower sieve. On its way between the precleaning sieve and the lower sieve, the mixture of grain and chaff that has passed through the precleaning sieve be passed via a grating which is permeable to air and disposed separately from the lower sieve, to which grating a current of air can be applied by the fan as well.

Owner:DEERE & CO

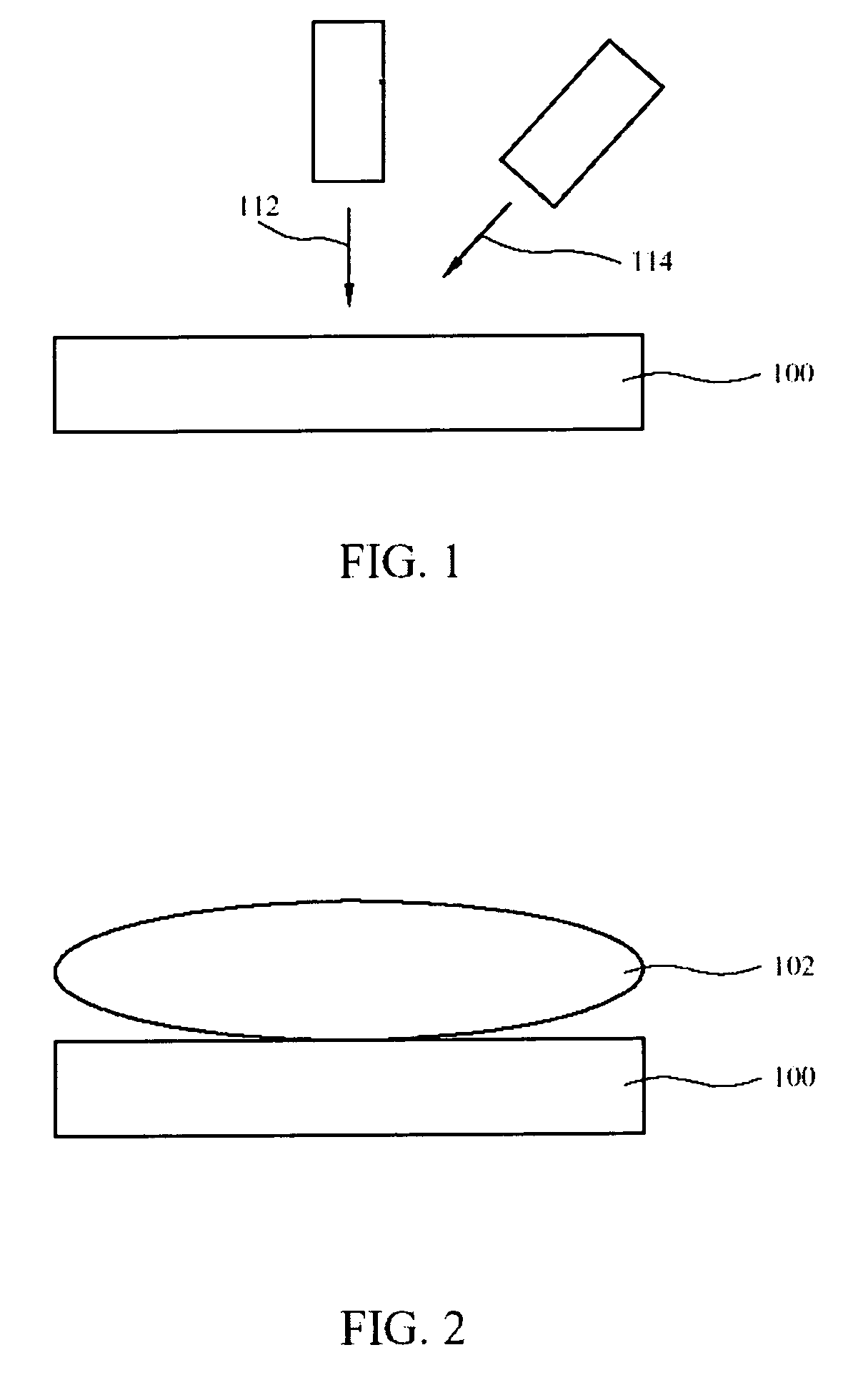

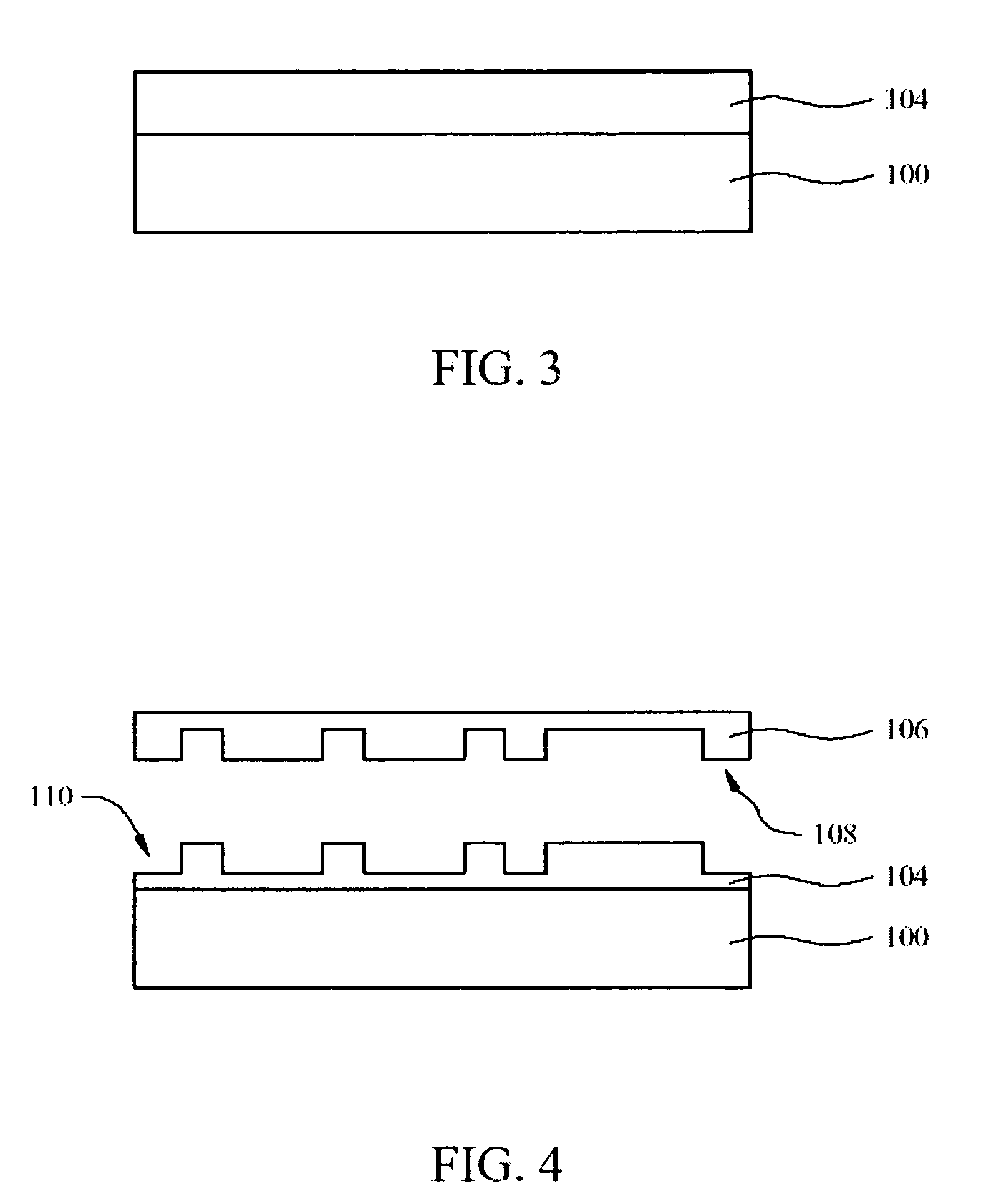

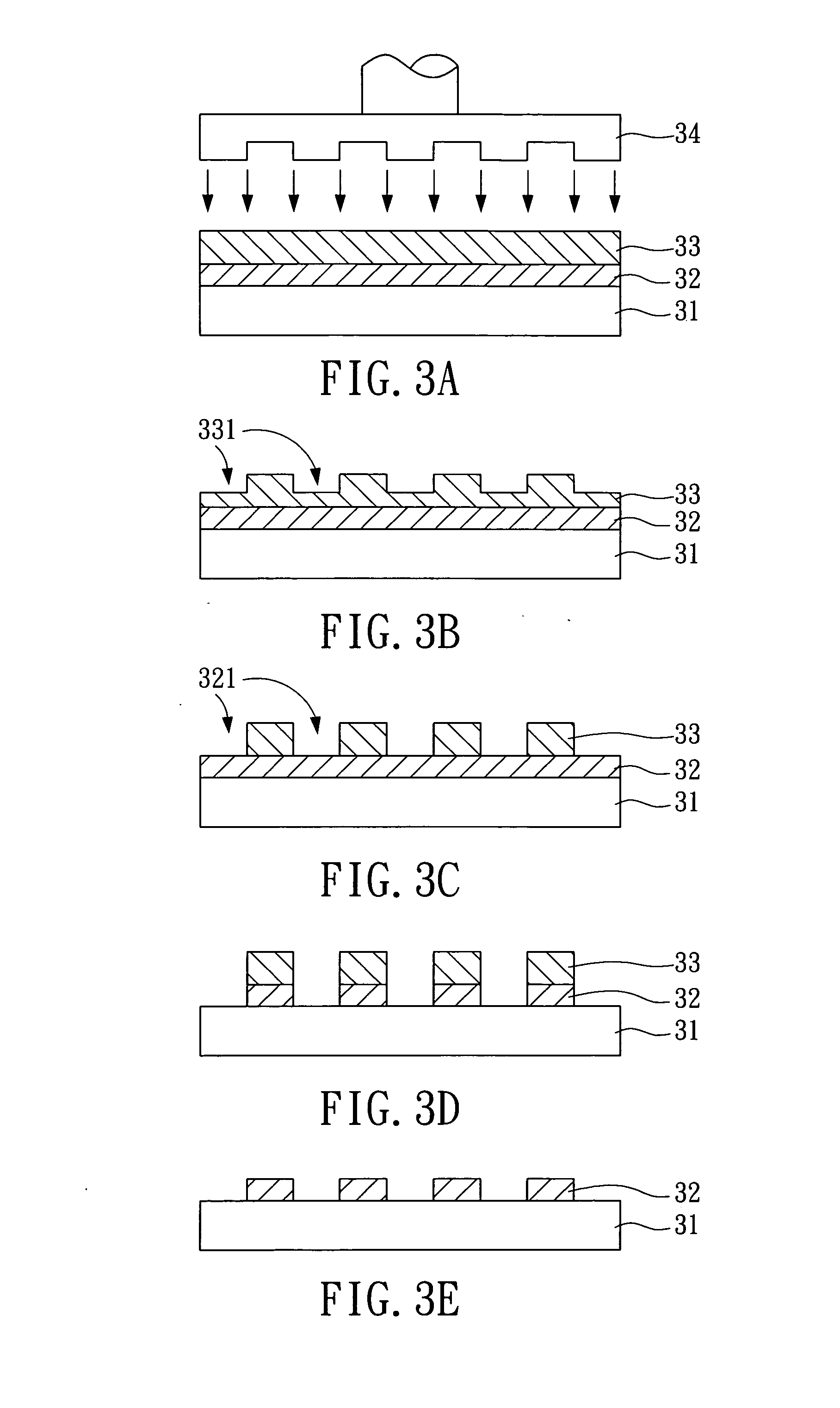

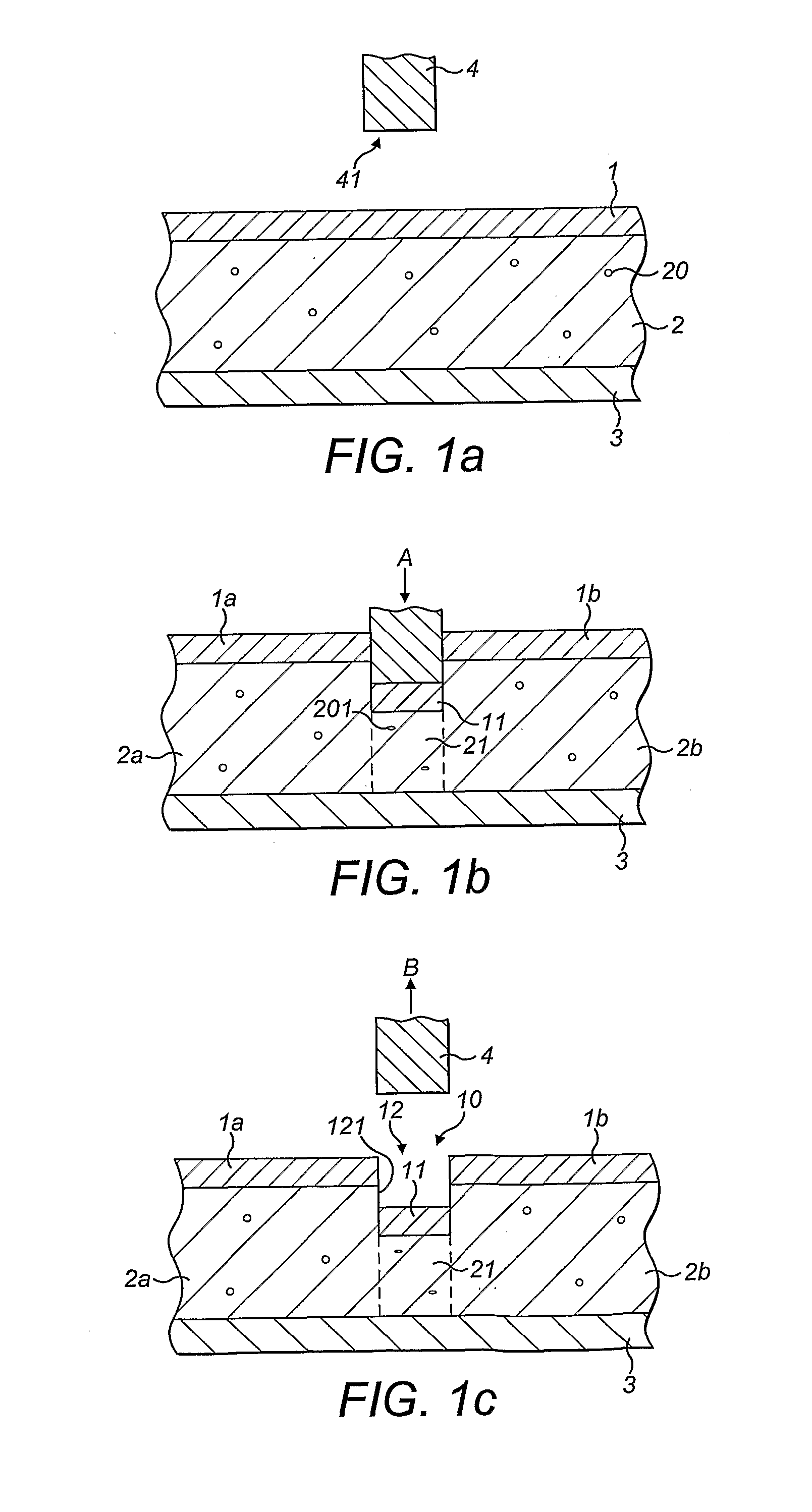

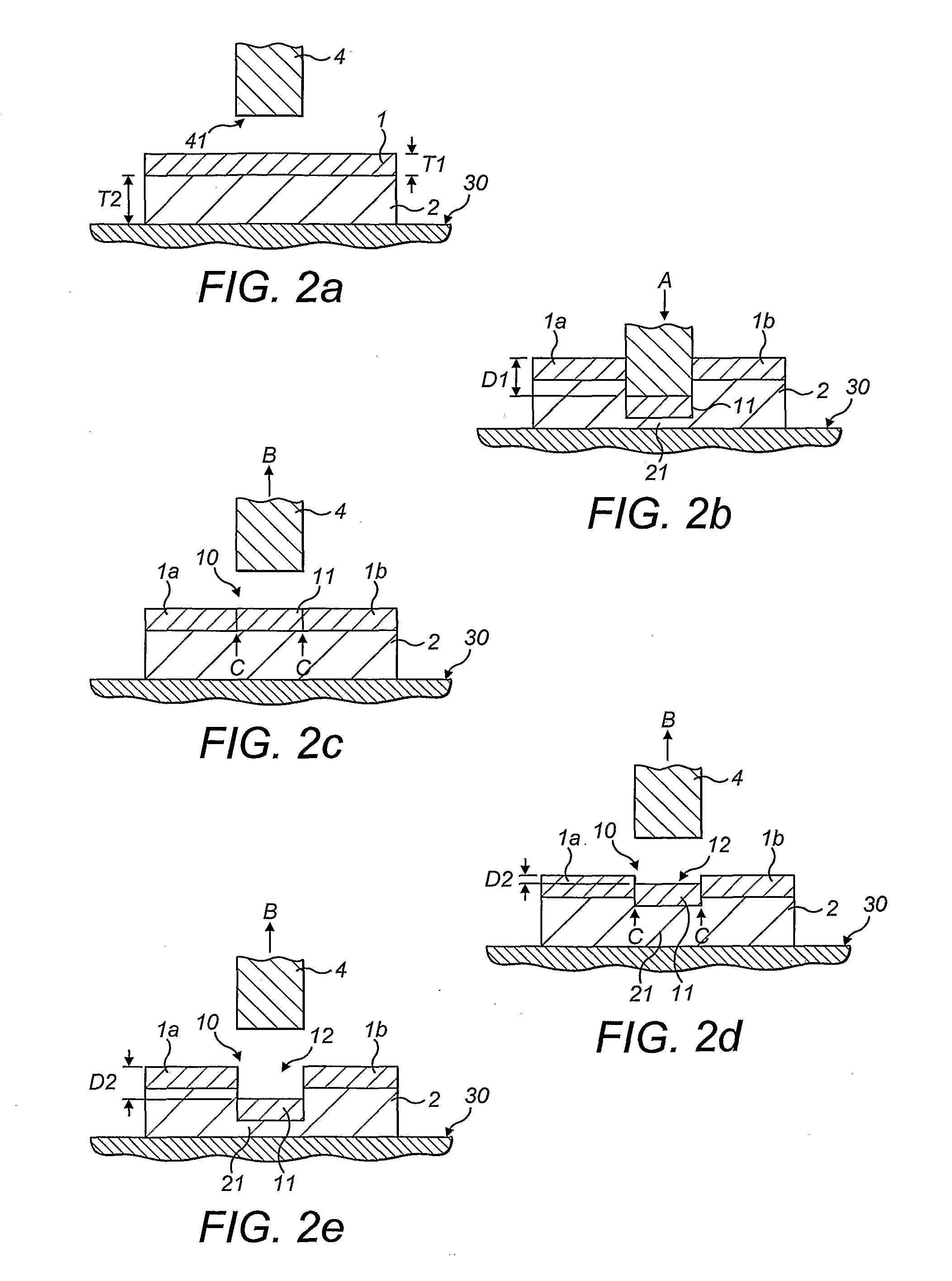

Pretreatment process of a substrate in micro/nano imprinting technology

InactiveUS20060045988A1Increase productionCleanness is improvedNanoinformaticsPhotomechanical apparatusChemical reactionReactive gas

A pretreatment process of a substrate in a micro / nano imprinting technology is disclosed, comprising deposing the substrate on a holder and performing a plasma treatment or an ion treatment on the substrate. In the plasma treatment of the substrate, a reactive gas is first injected into the chamber to form a plasma, such that the plasma causes a physical reaction and a chemical reaction on the substrate to activate the substrate surface and also remove particles and contaminants adhering to the substrate surface. When the ion treatment is performed on the substrate, an ion source is placed into the chamber and ions and neutral atoms generated by the ion source bombard the substrate, causing a physical reaction and a chemical reaction on the substrate to activate the substrate surface and also remove particles and contaminants adhering to the substrate surface.

Owner:NAT CHENG KUNG UNIV

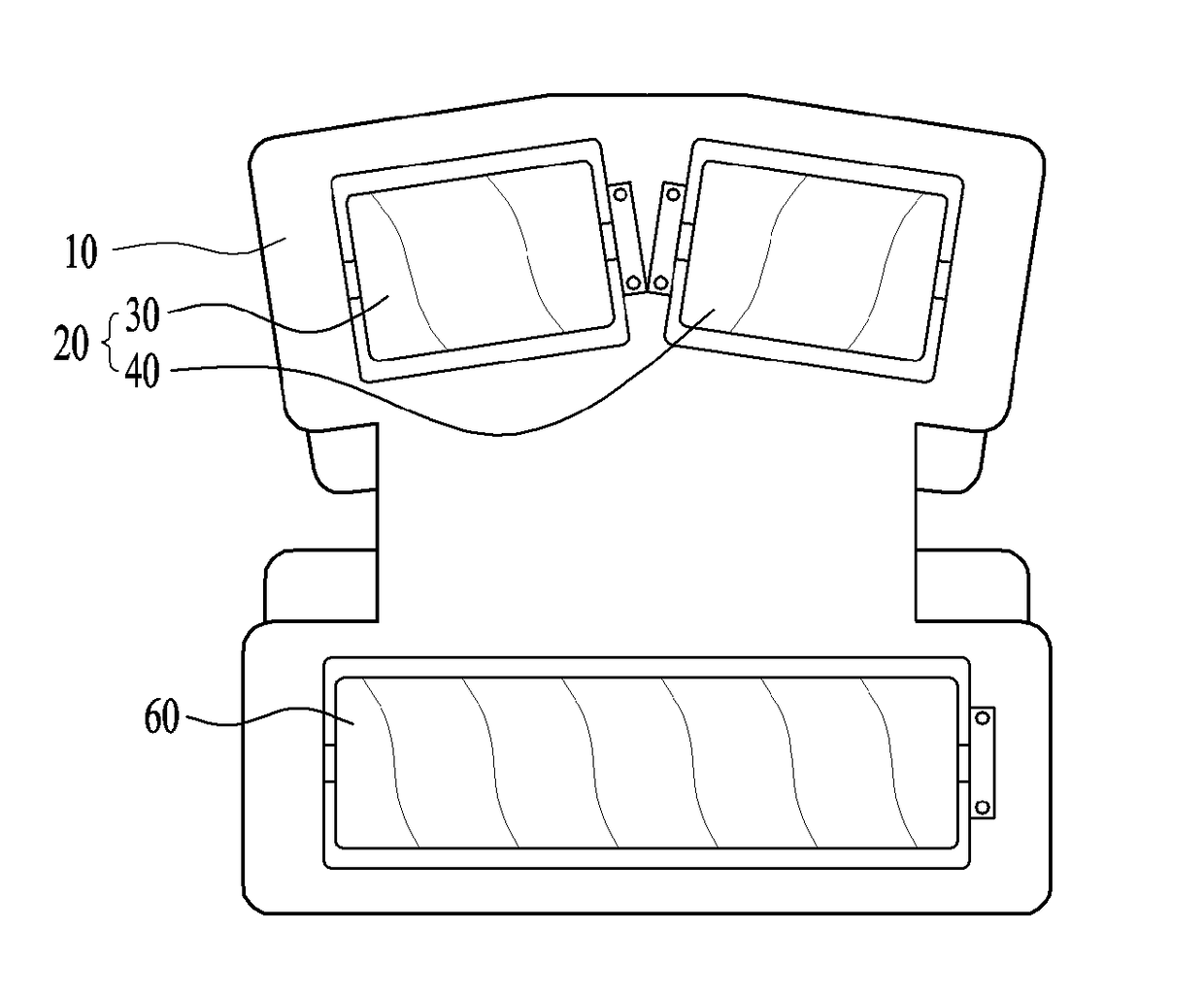

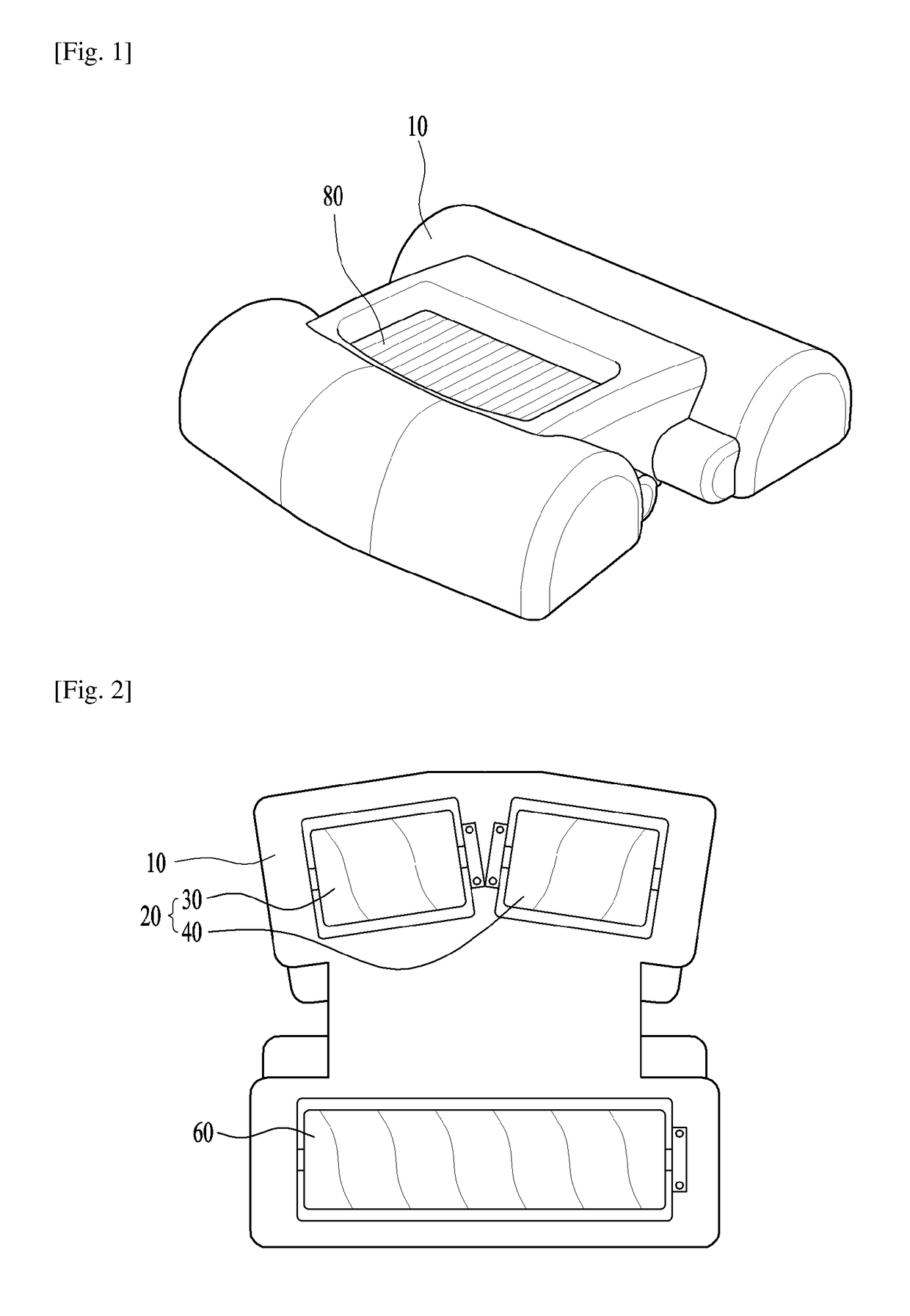

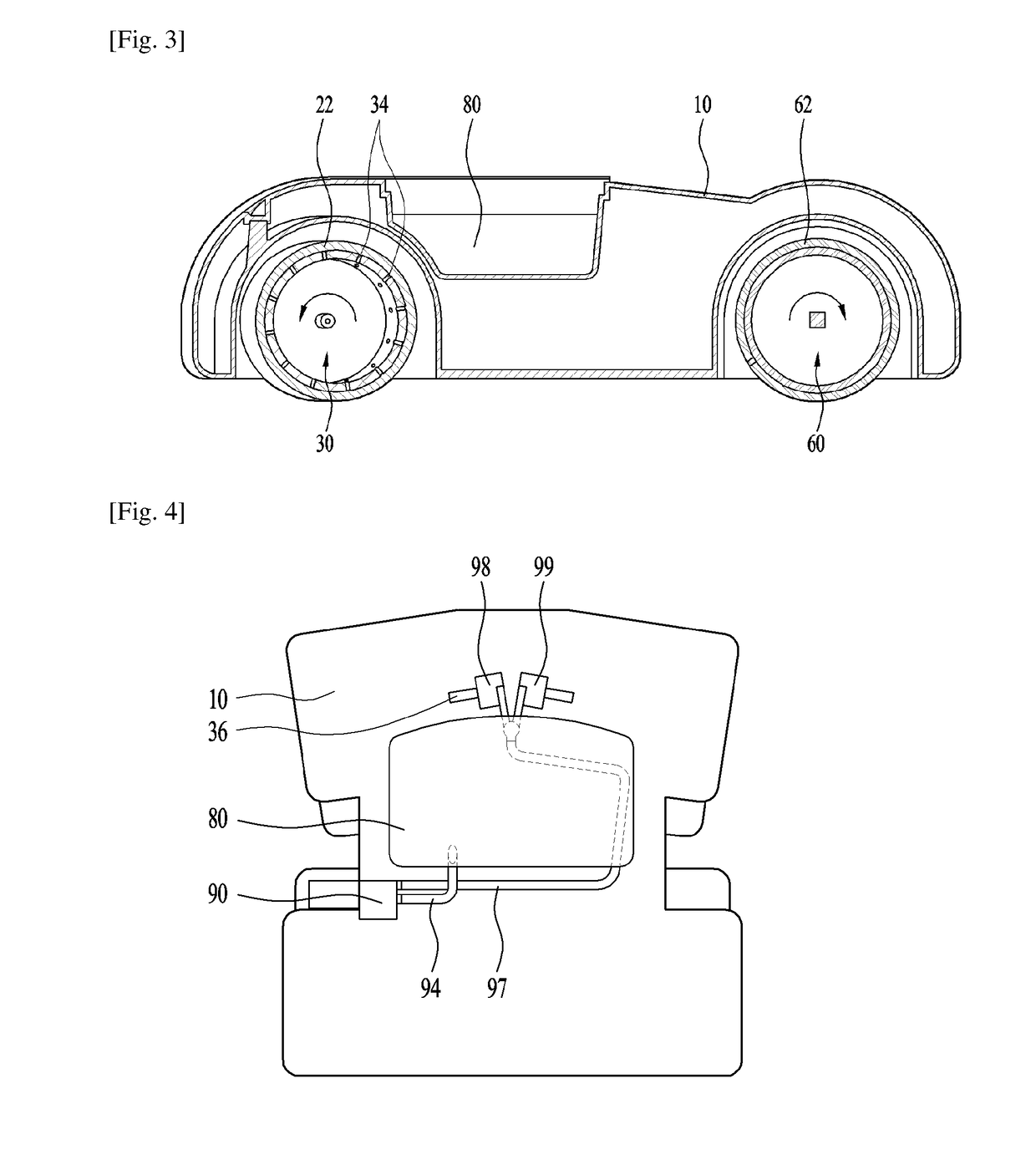

Robot cleaner

ActiveUS20180242810A1Increase forceCleanness is improvedAutomatic obstacle detectionTravelling automatic controlEngineeringElectric motor

Owner:LG ELECTRONICS INC

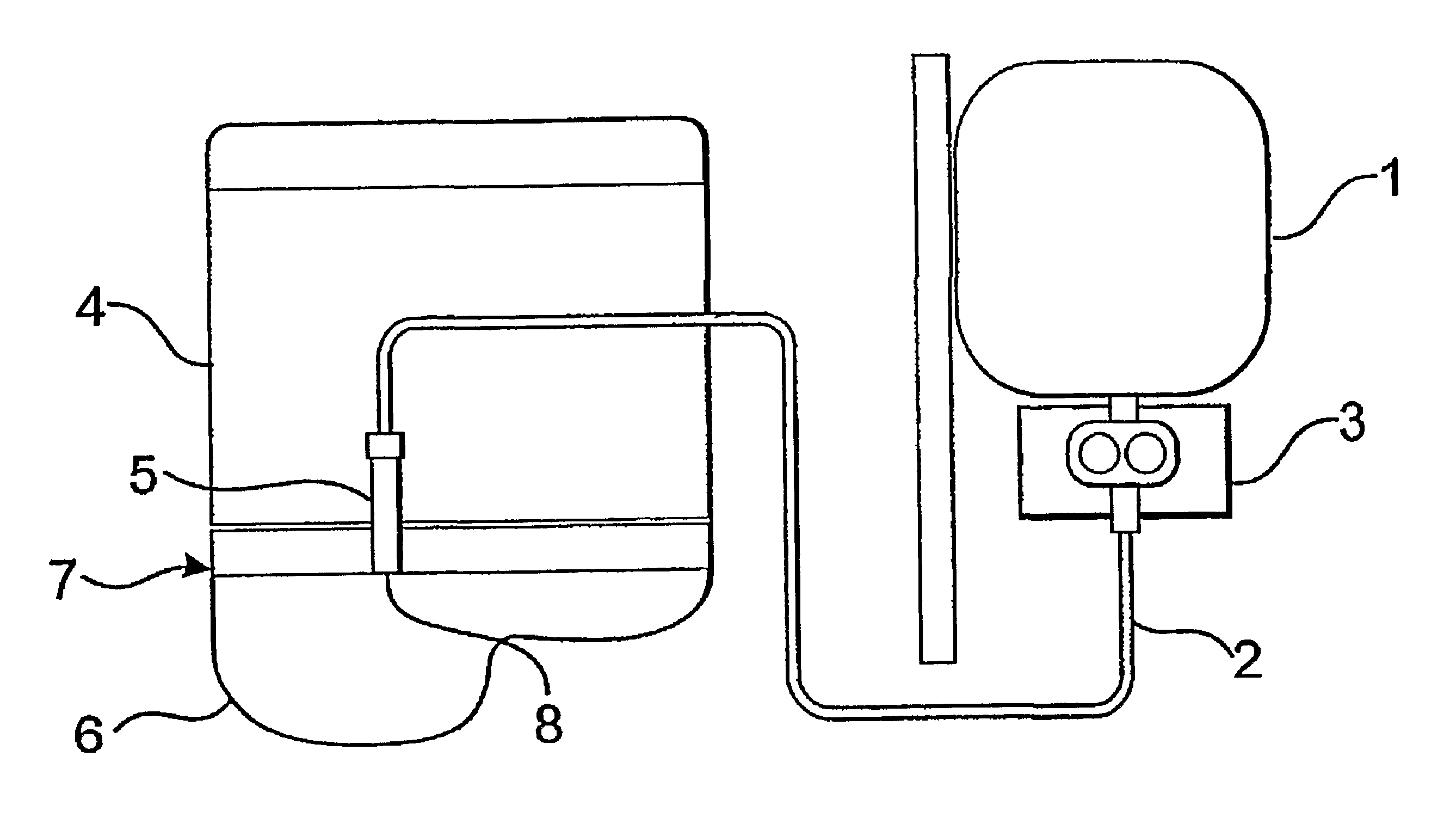

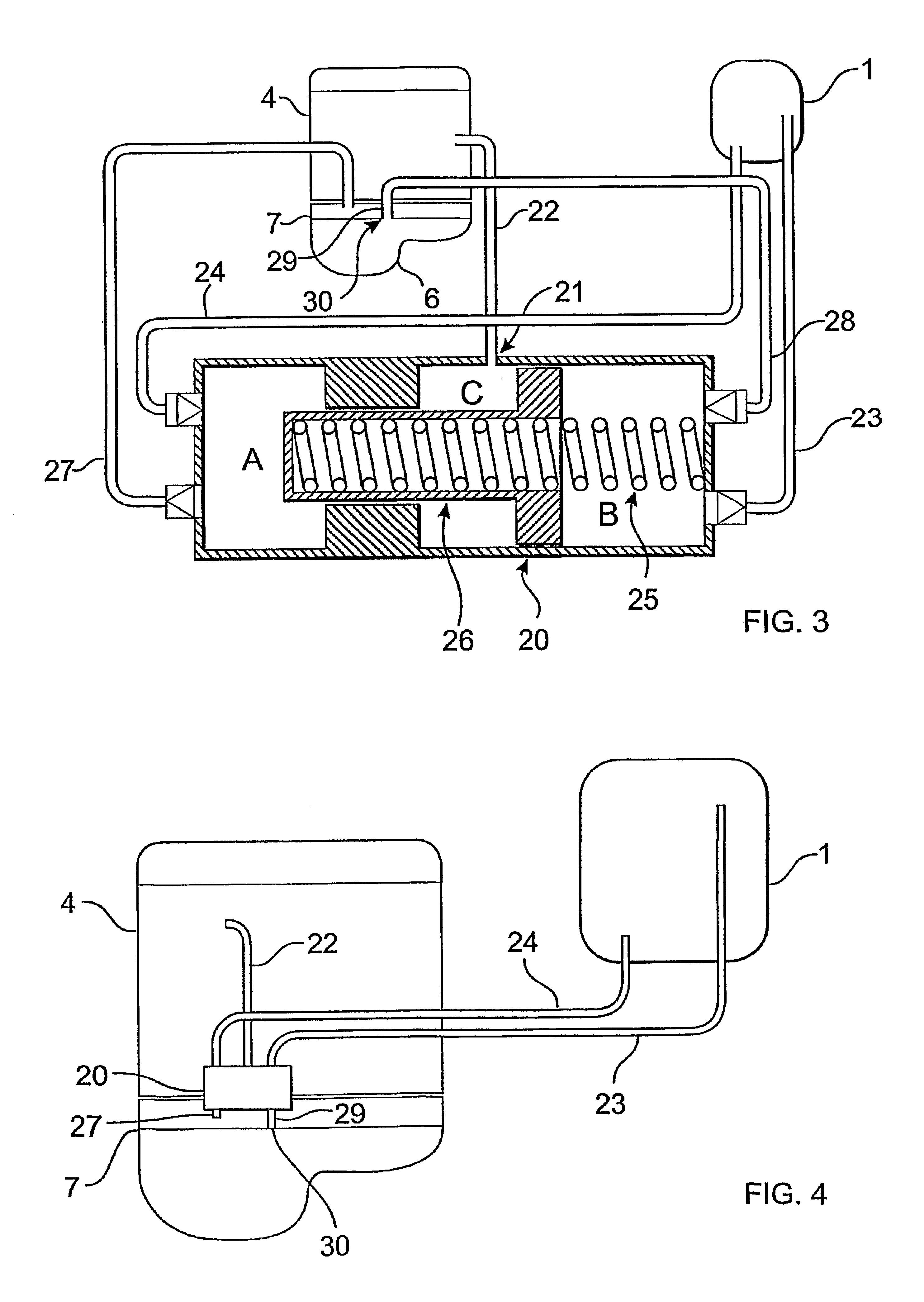

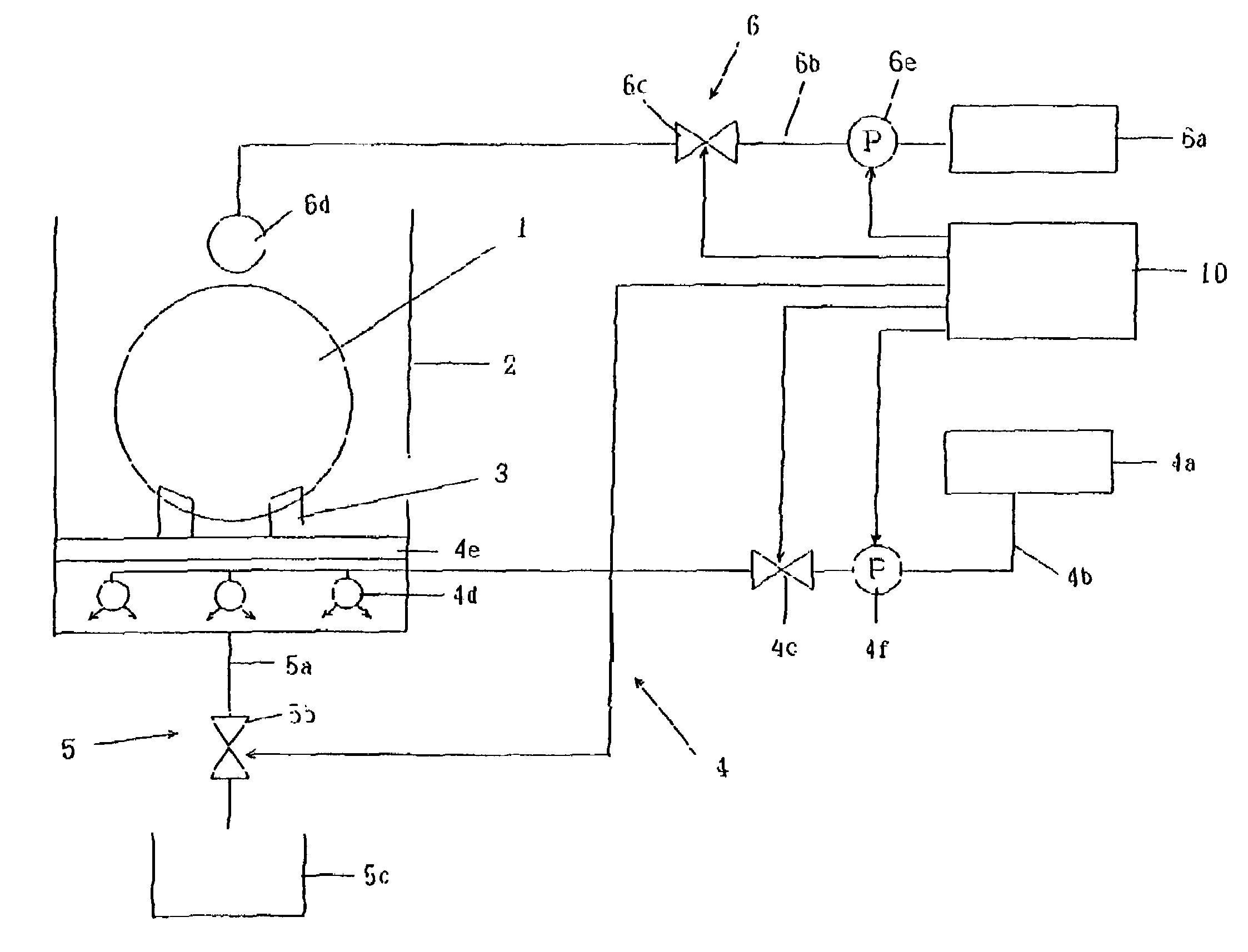

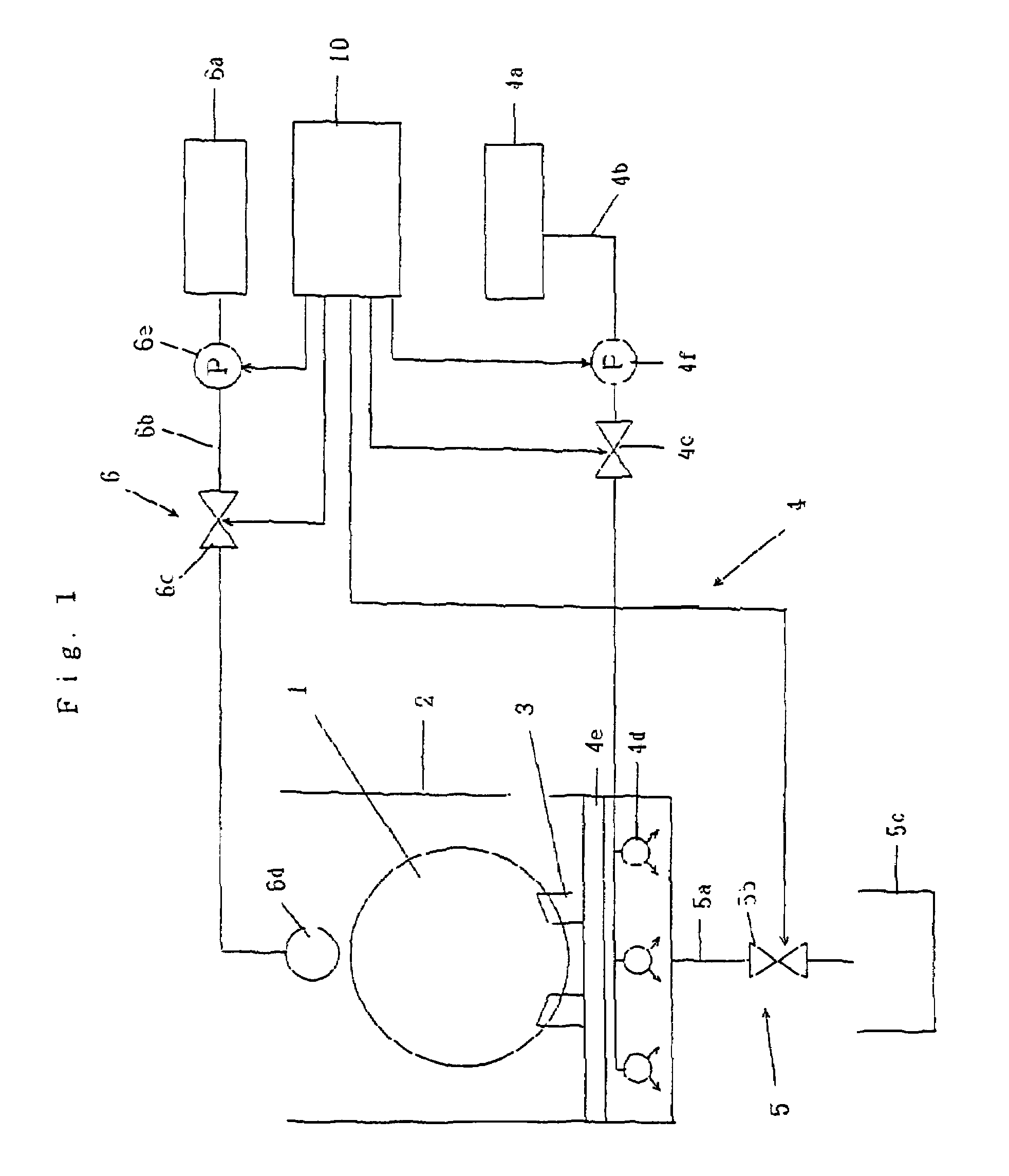

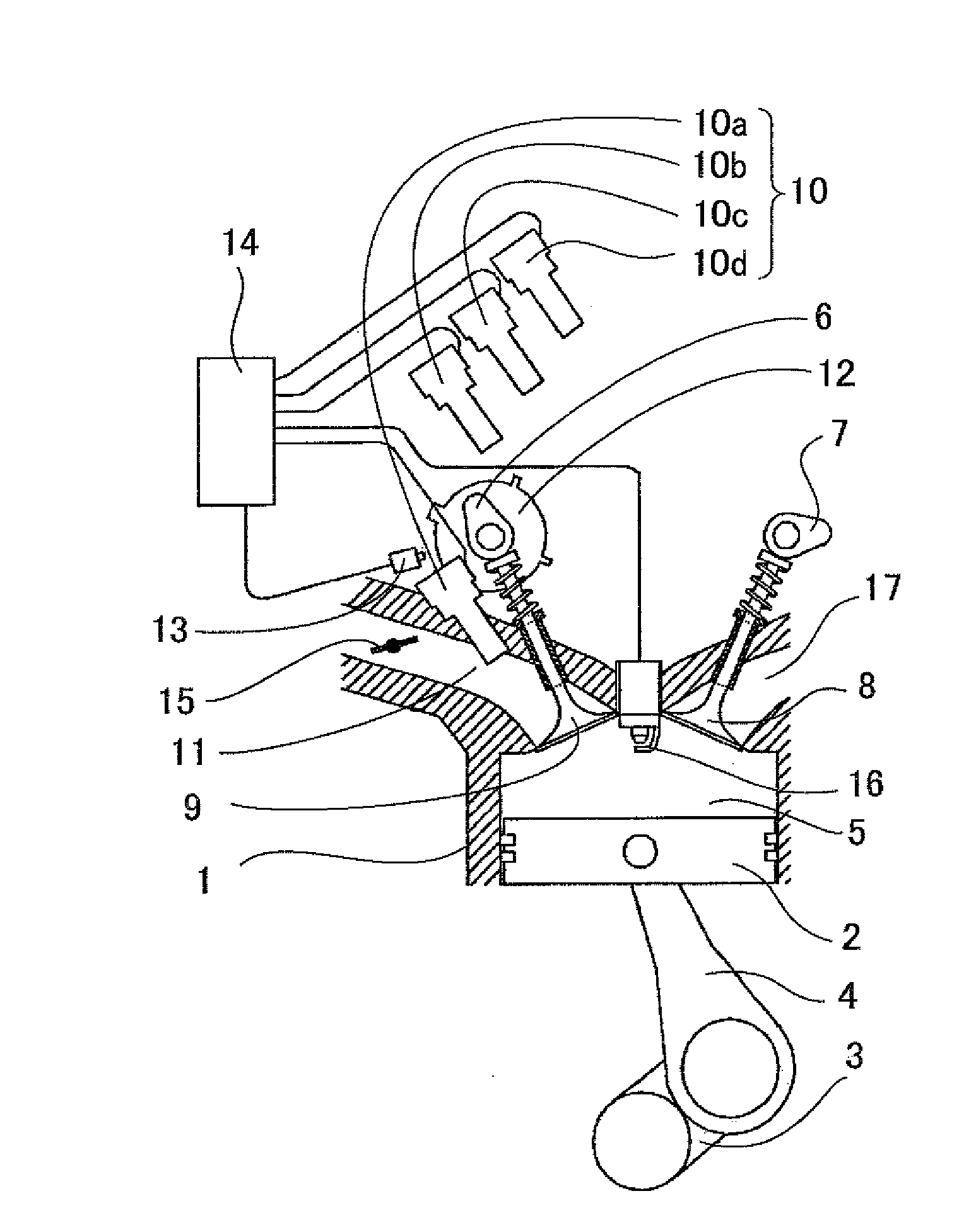

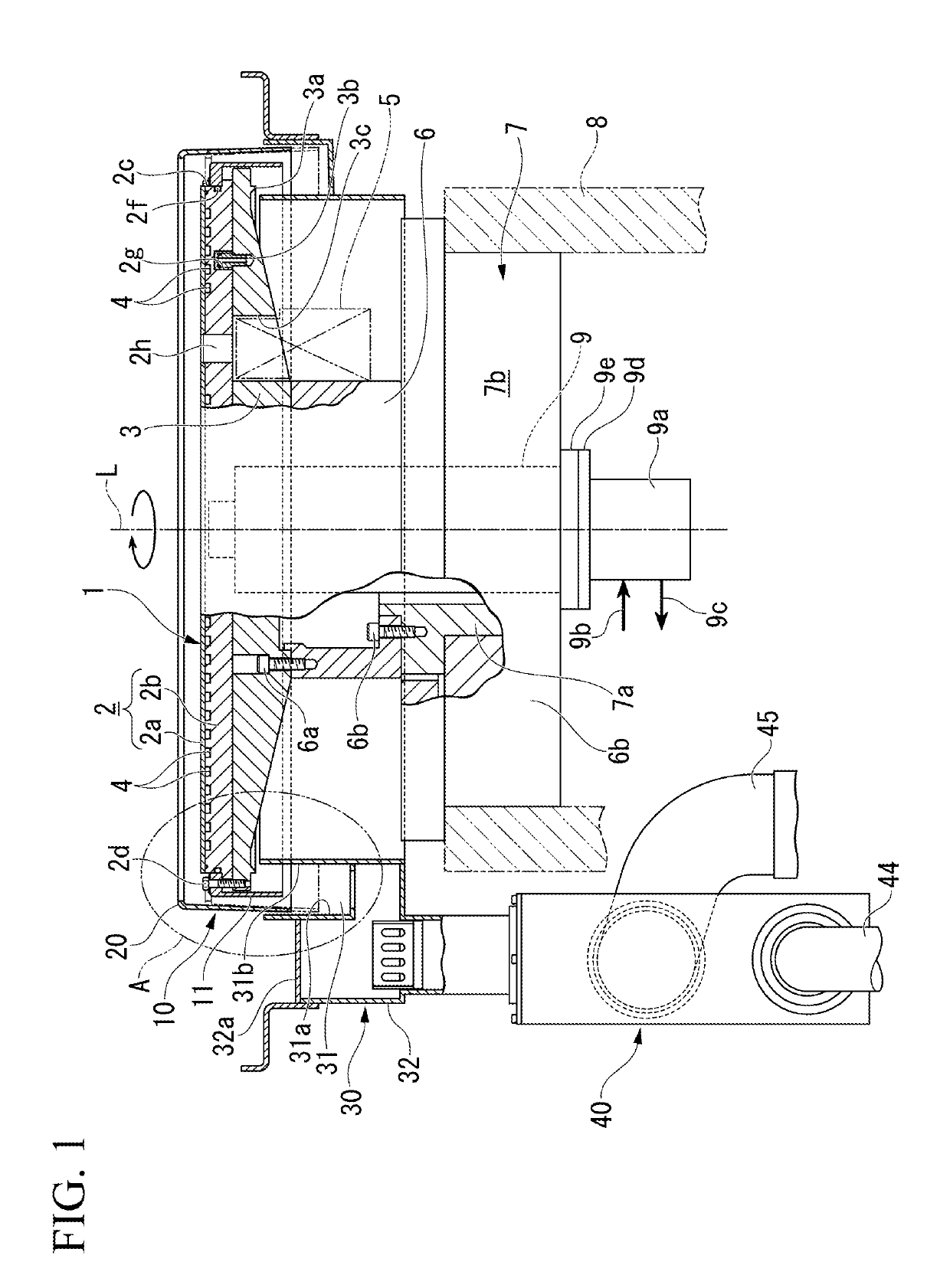

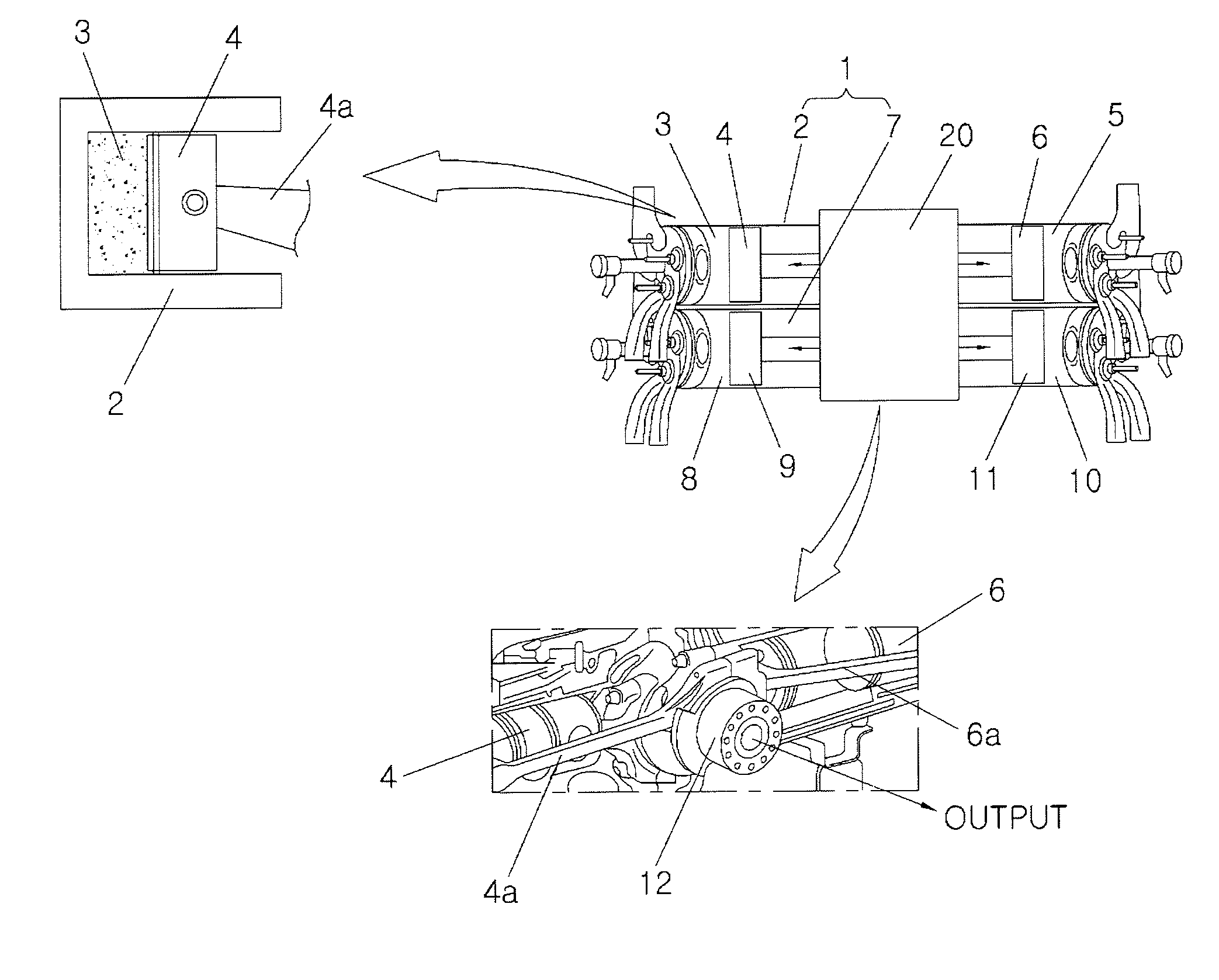

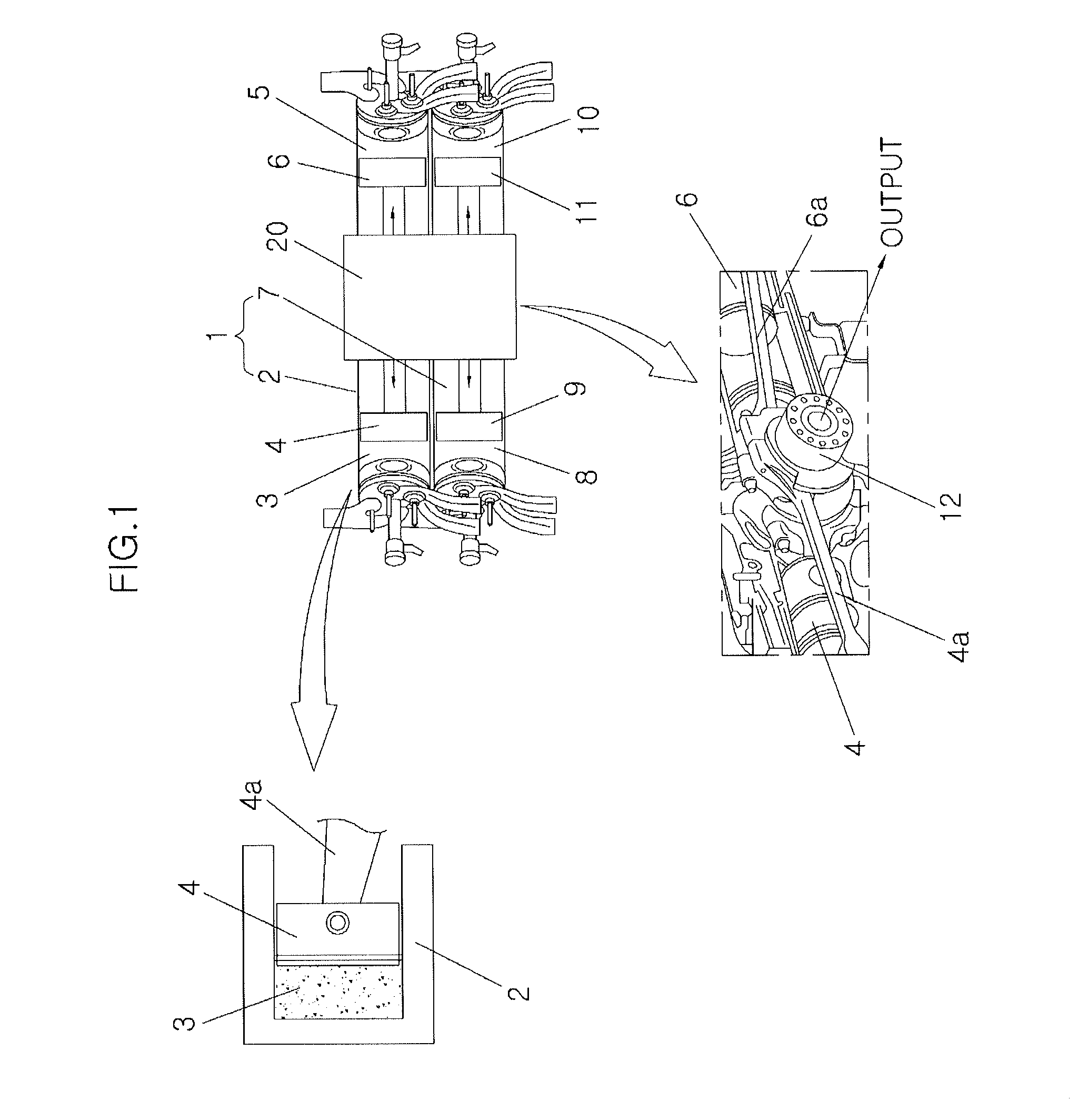

Apparatus for controlling a lubrication fluid level

InactiveUS6928976B2Quantity minimizationLong changeLubrication of auxillariesLubricant conduit arrangementsEngineeringInternal combustion engine

System and a method for automatically topping up an internal combustion engine (4) with lubricant. A lubricant container that includes a (1), a pipe (2) which connects the container to the internal combustion engine (4), a level pipe (5) which defines the oil level in a sump (6) and an apparatus (3) for transferring lubricant. The apparatus (3) for transferring lubricant makes it possible to transfer lubricant both from the container (1) to the internal combustion engine (4) and from the internal combustion engine (4) to the container (1).

Owner:VOLVO LASTVAGNAR AB

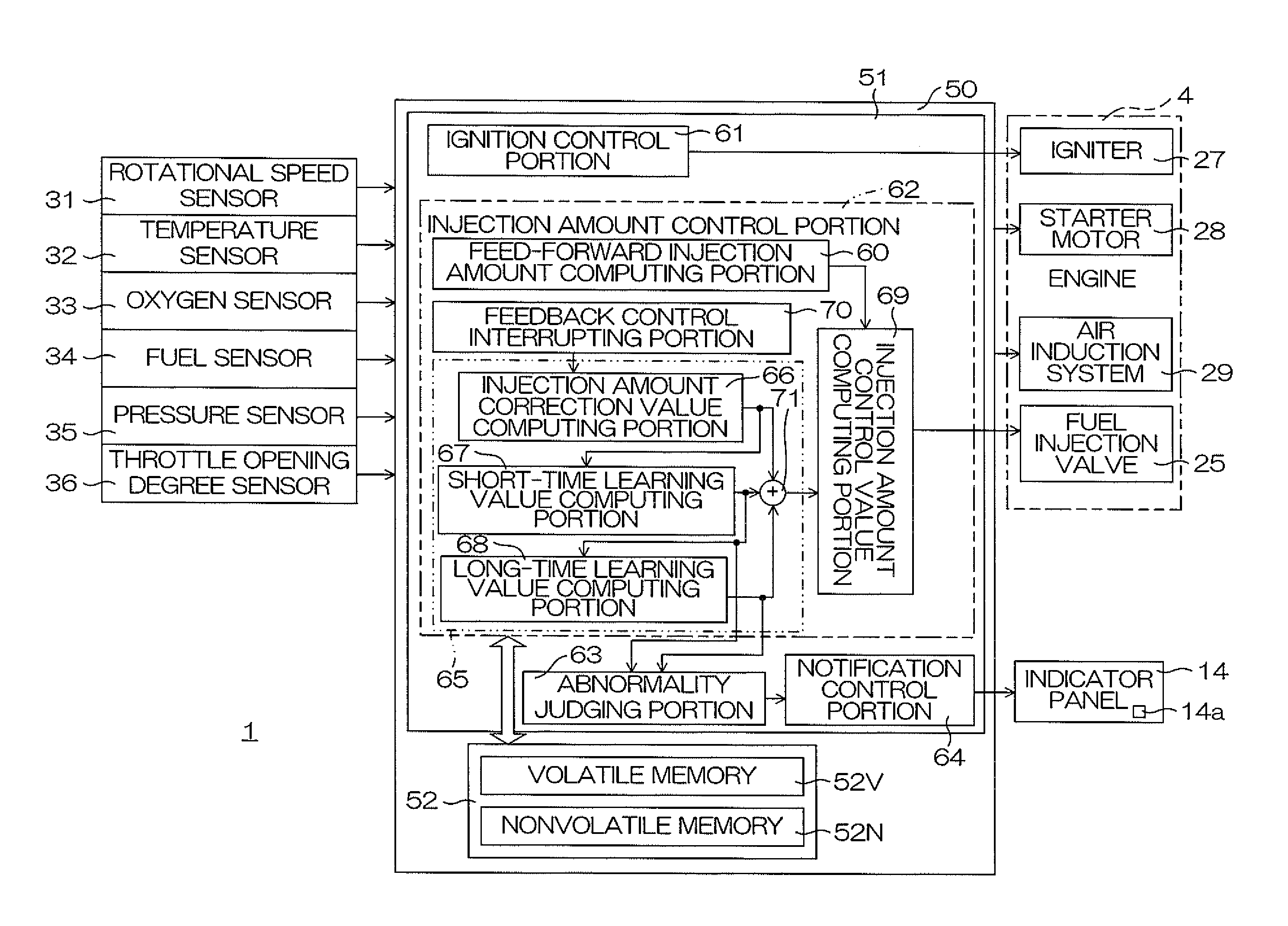

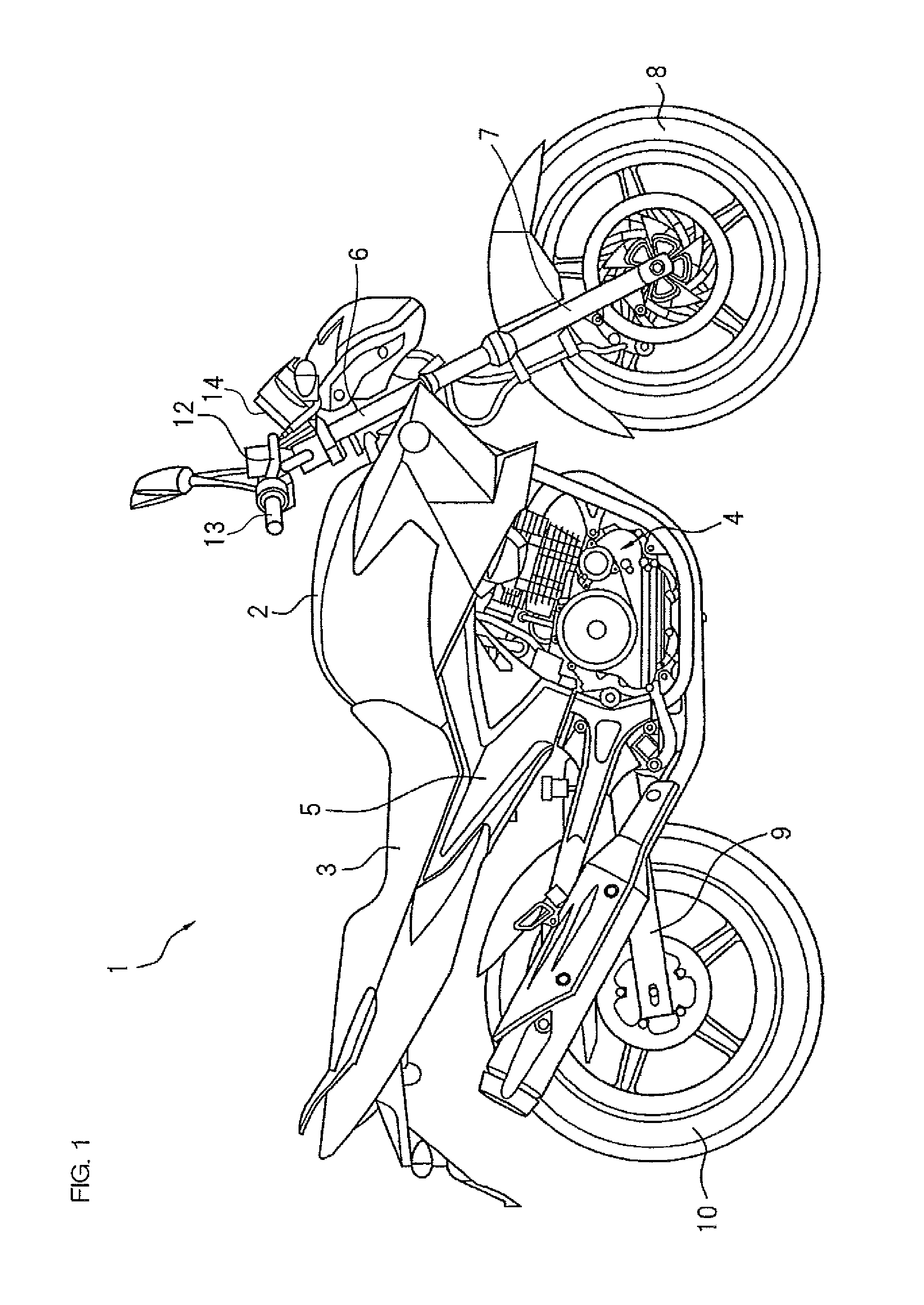

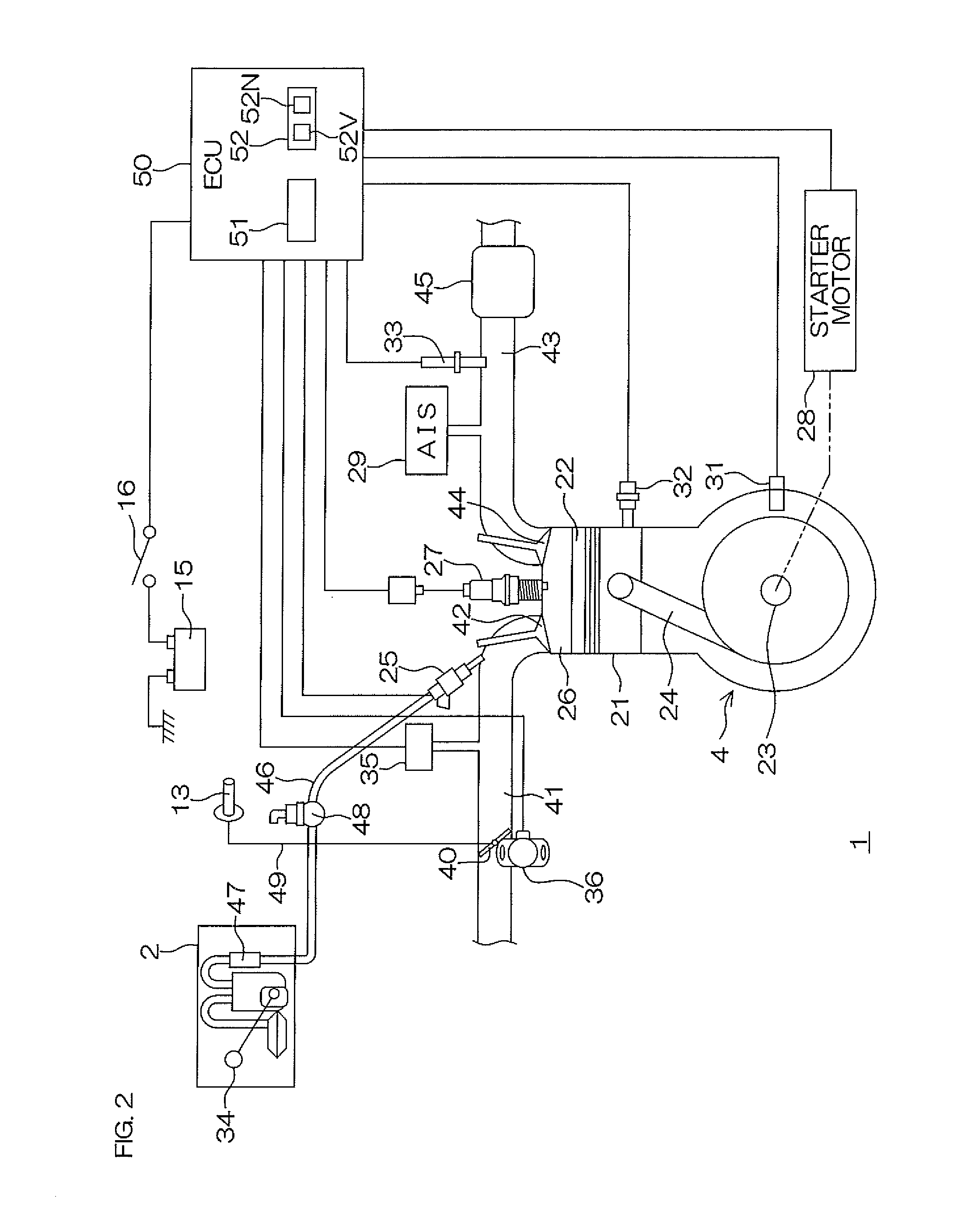

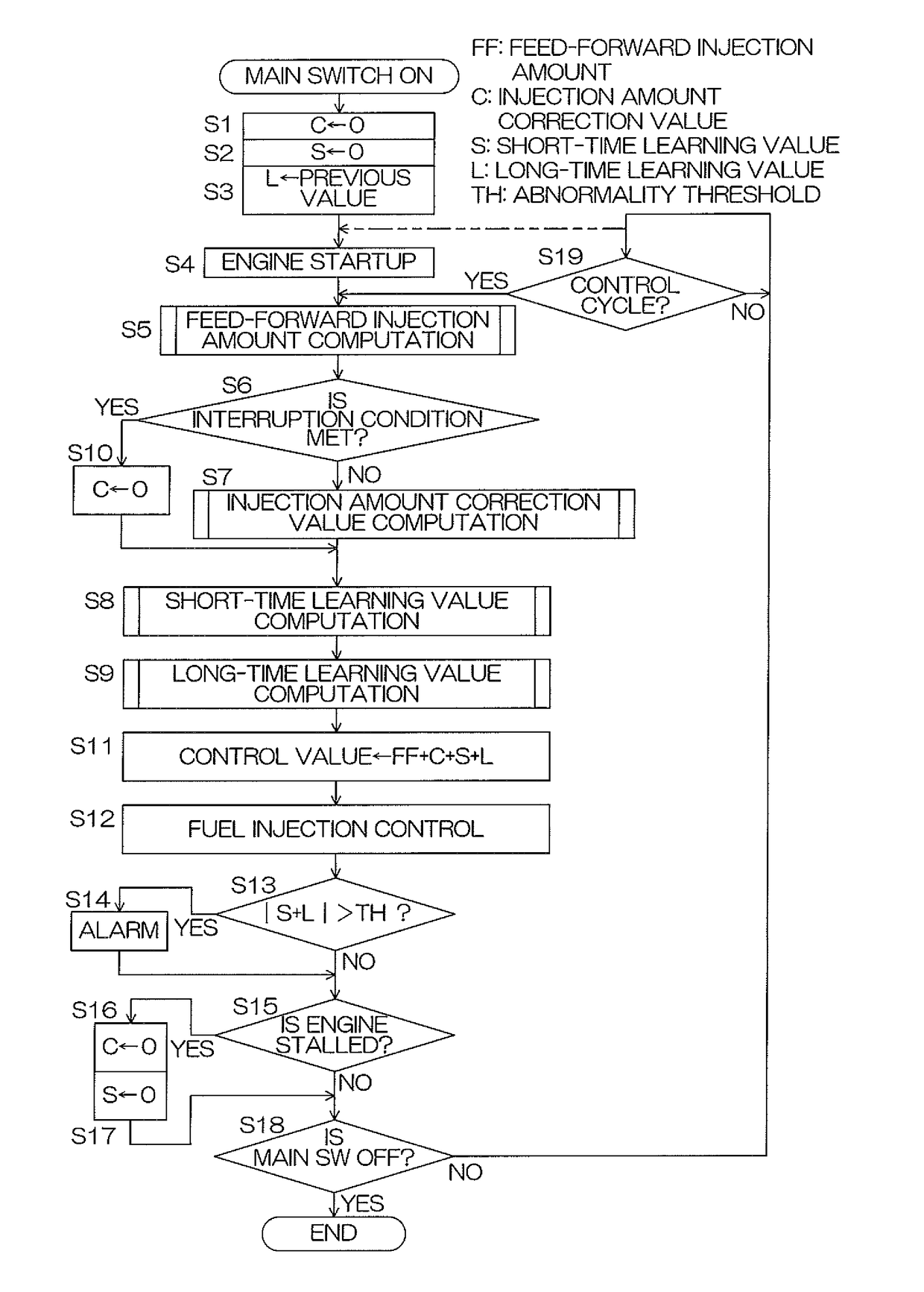

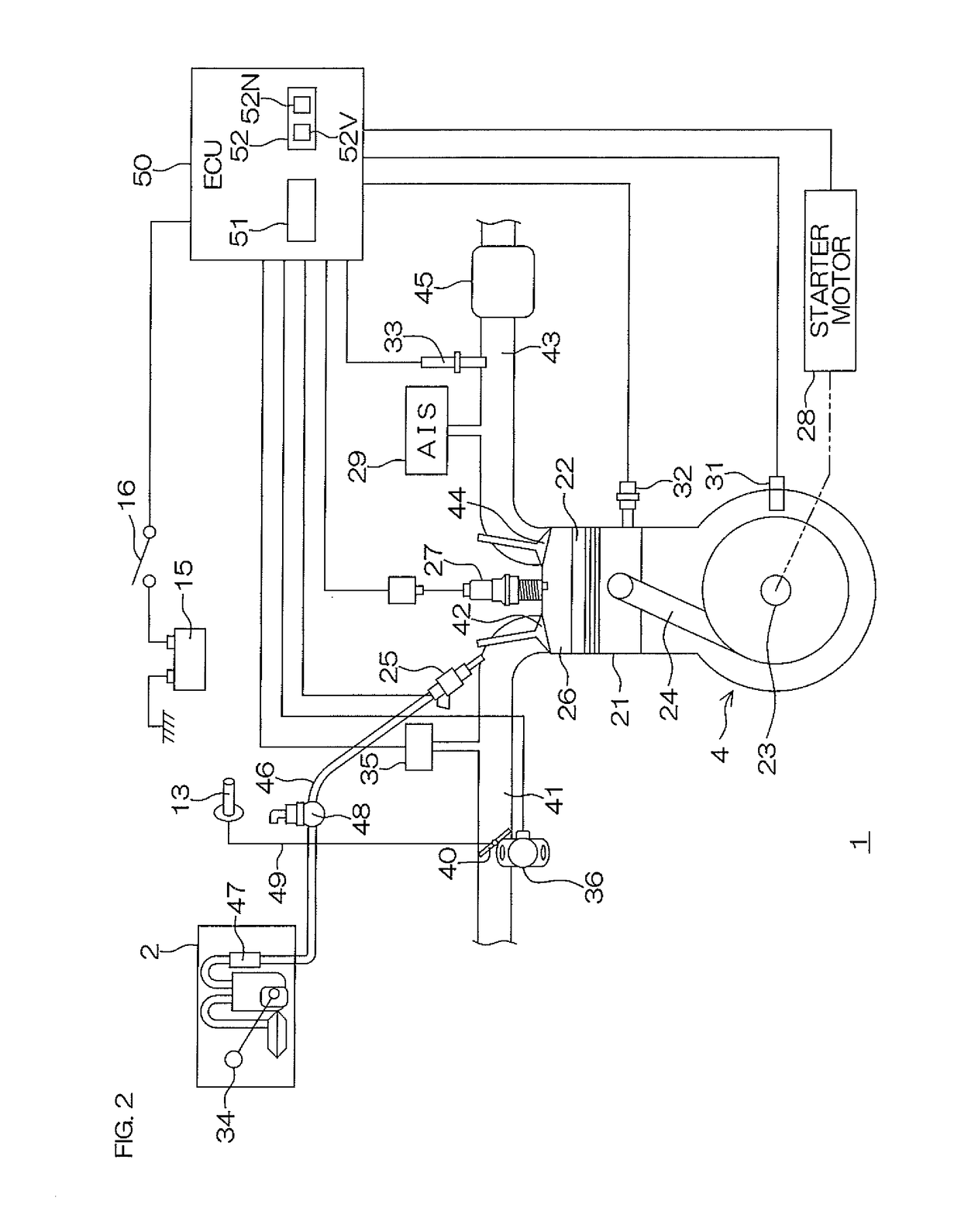

Fuel injection controller

ActiveUS20140288805A1Improve fuel efficiencyAppropriate performanceElectrical controlDigital data processing detailsOxygen sensorControl theory

A fuel injection controller includes an oxygen sensor that responds to an oxygen concentration inside an exhaust passage, and an injection amount control unit programmed to control a fuel injection amount based on the output of the oxygen sensor. The injection amount control unit includes an injection amount correction value computing unit that determines an injection amount correction value based on the output of the oxygen sensor, a short-time learning value computing unit that determines a short-time learning value based on the injection amount correction value, a long-time learning value computing unit that determines a long-time learning value based on the short-time learning value; a feedback correction amount computing unit that computes a feedback correction amount, an injection amount control value computing unit that computes a control value of the fuel injection amount, and a long-time learning value holding unit that holds the long-time learning value.

Owner:YAMAHA MOTOR CO LTD

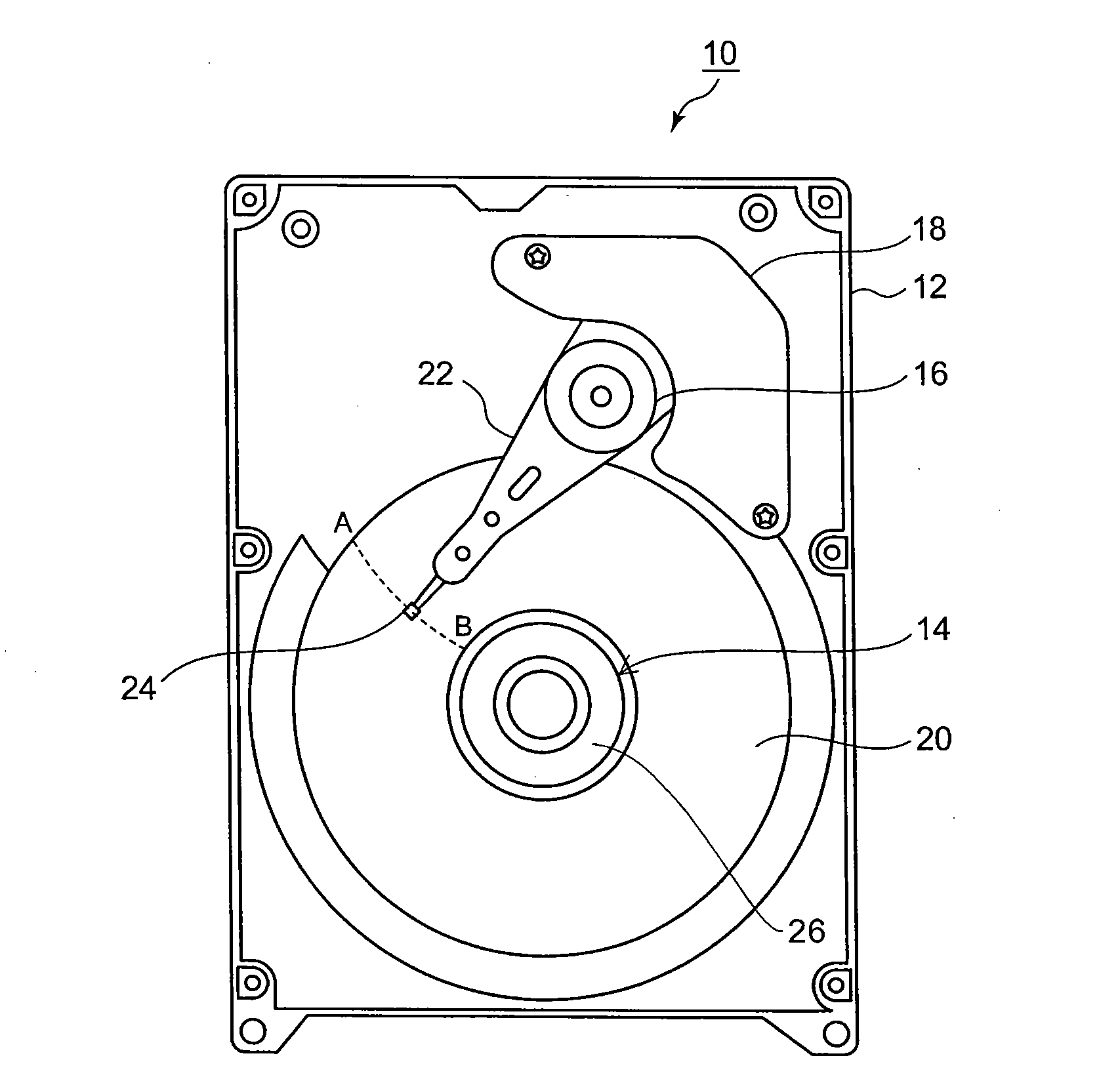

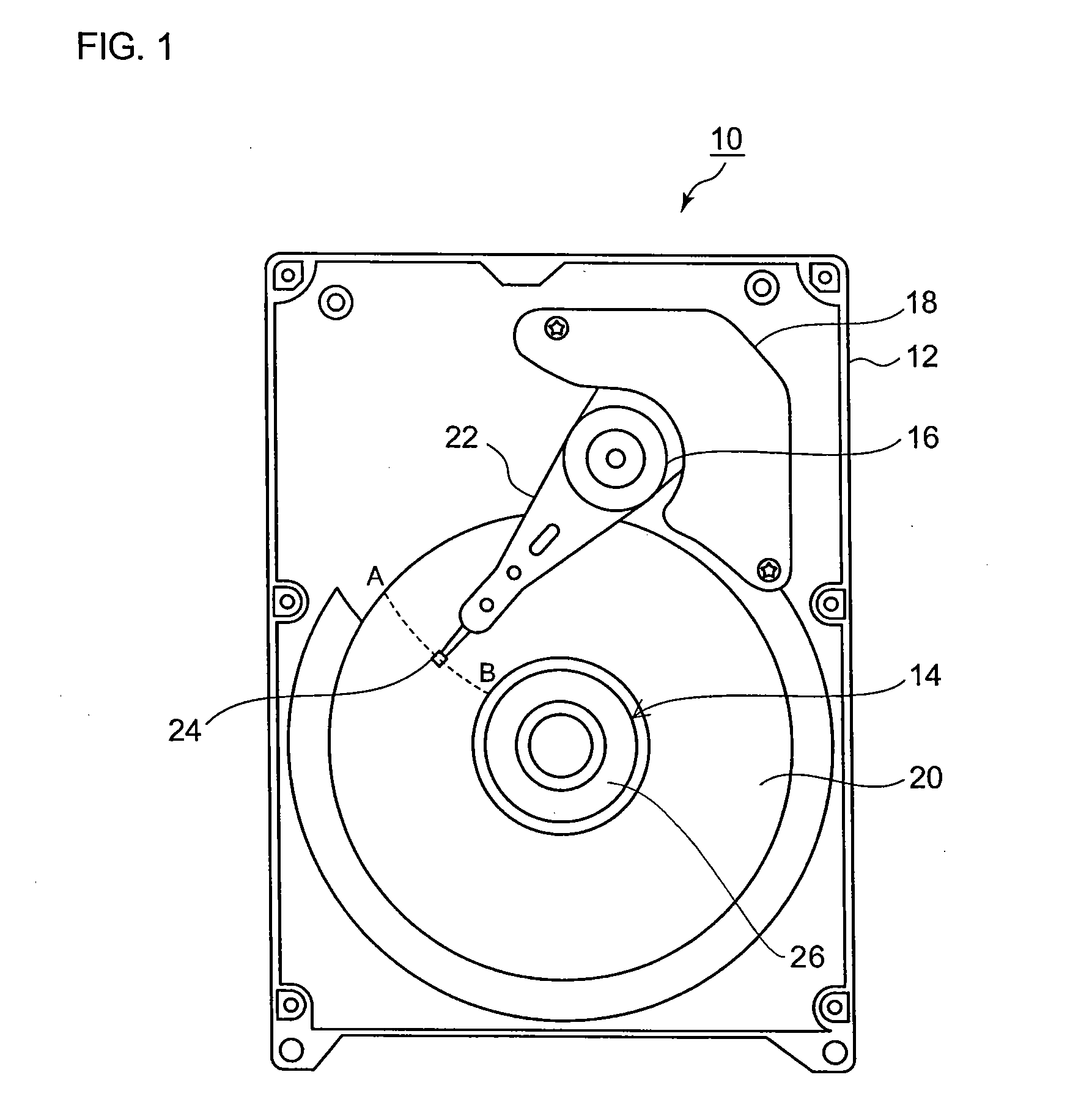

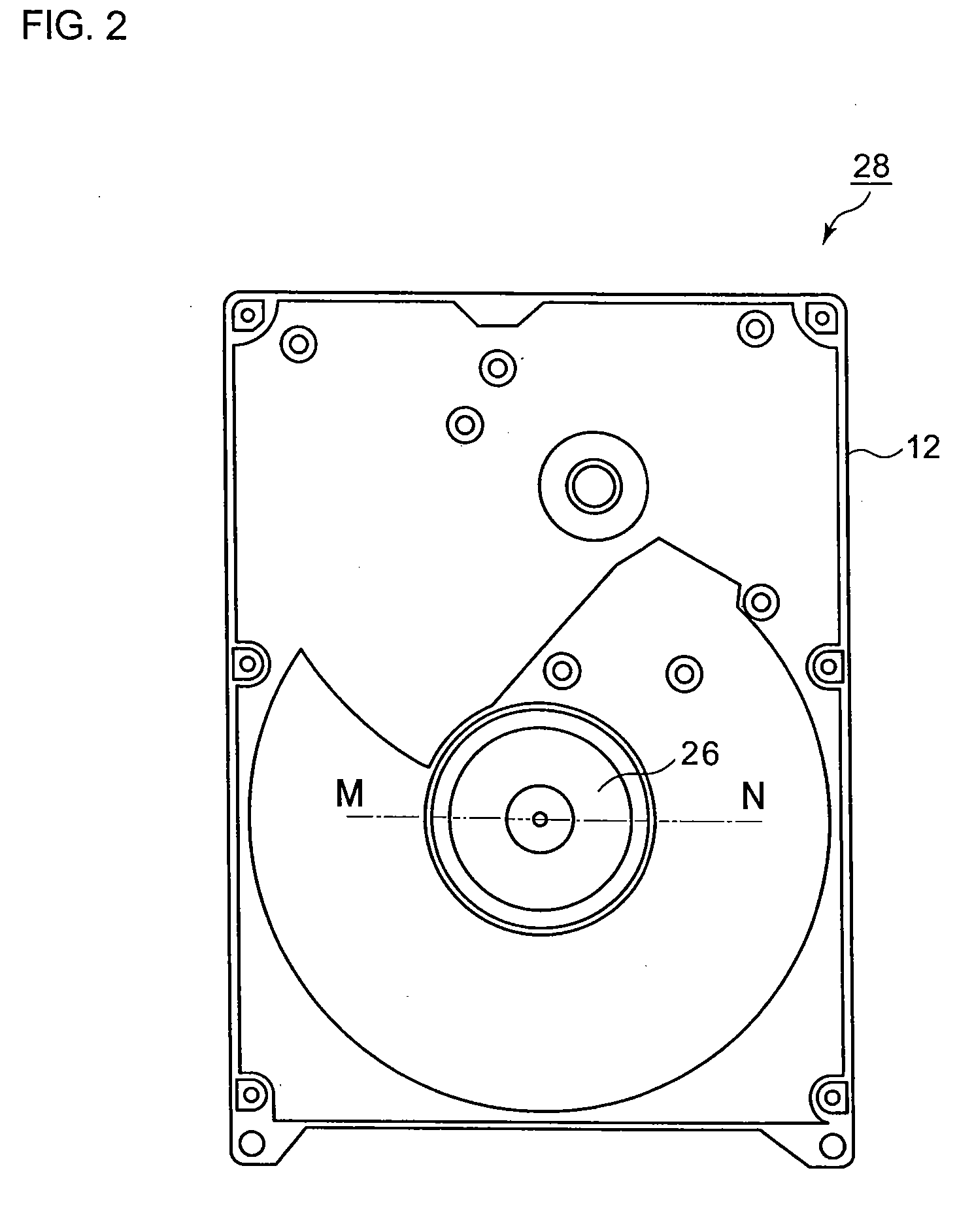

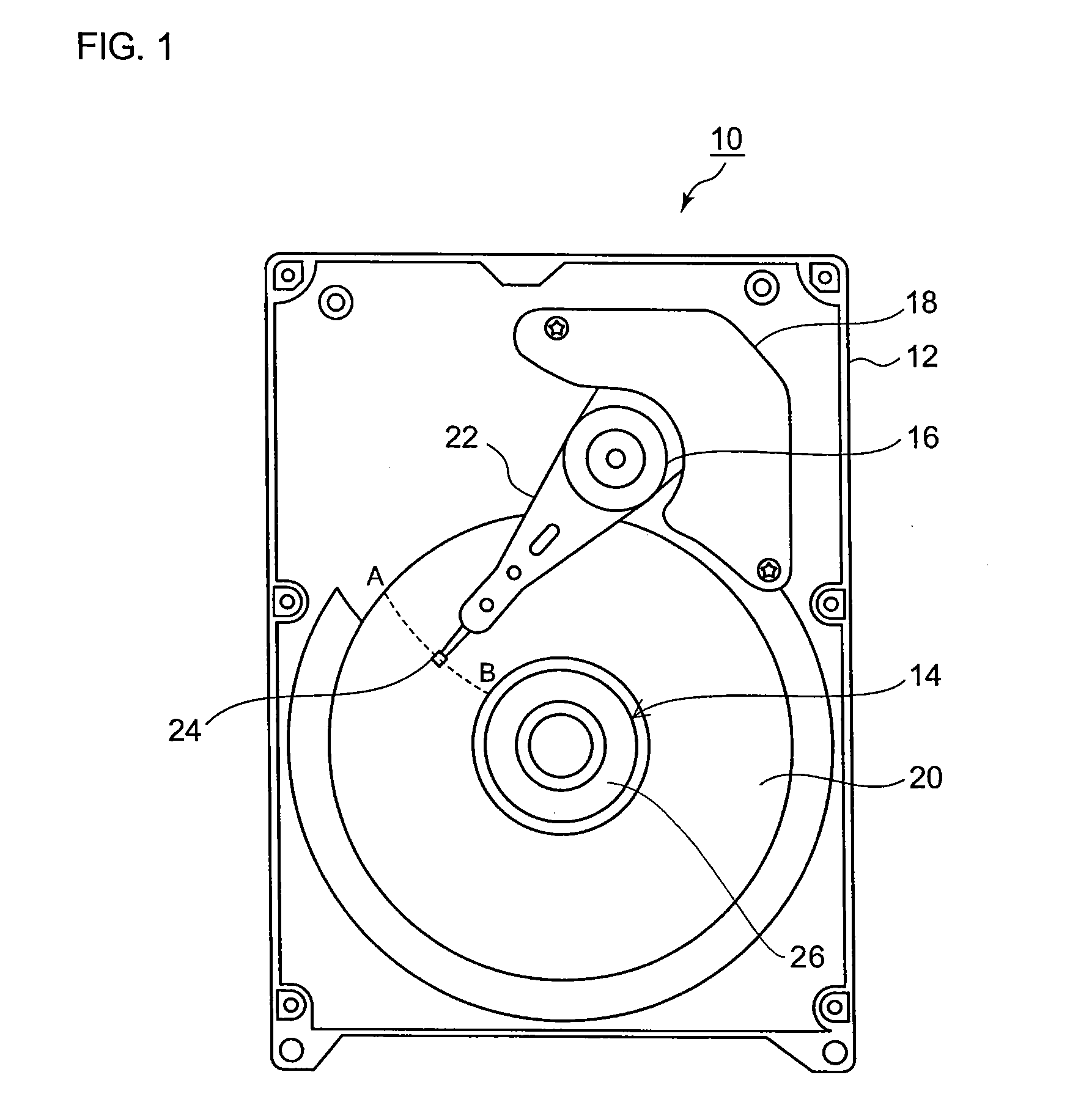

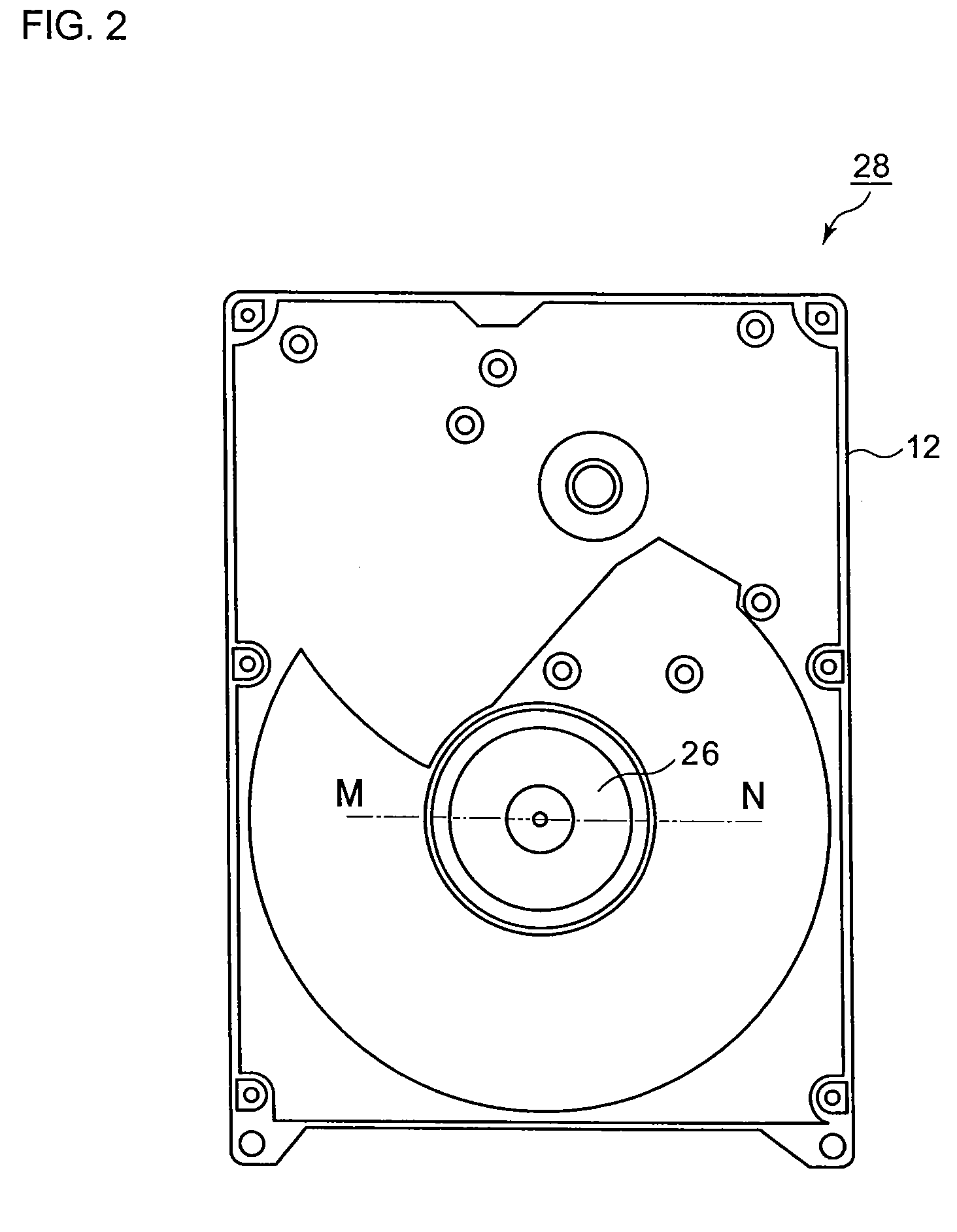

Method of manufacturing disk drive device for reducing adhesive amount of particles, and disk drive device manufactured by the method

InactiveUS20100254043A1Improve the level ofReduce incidenceWave amplification devicesElectrostatic cleaningEngineeringMechanical engineering

In a method of manufacturing a disk drive device, a cleaning process and an assembly process are performed in succession in a clean room having a predetermined cleanness level. The cleaning process includes an alkali cleaning process, a first purified water cleaning process, a second purified water cleaning process, a spray cleaning process, a draining process and a drying process. In the first purified water cleaning process, purified water ultrasonic wave cleaning is sequentially performed on the base member of the disk drive device to be cleaned by using ultrasonic waves of frequencies of 40 kHz, 68 kHz and 132 kHz in purified water filled in a first purified water cleaning tank. The cleaned base member and other components having a predetermined cleanness level are assembled in the assembly process continuous from the cleaning process.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

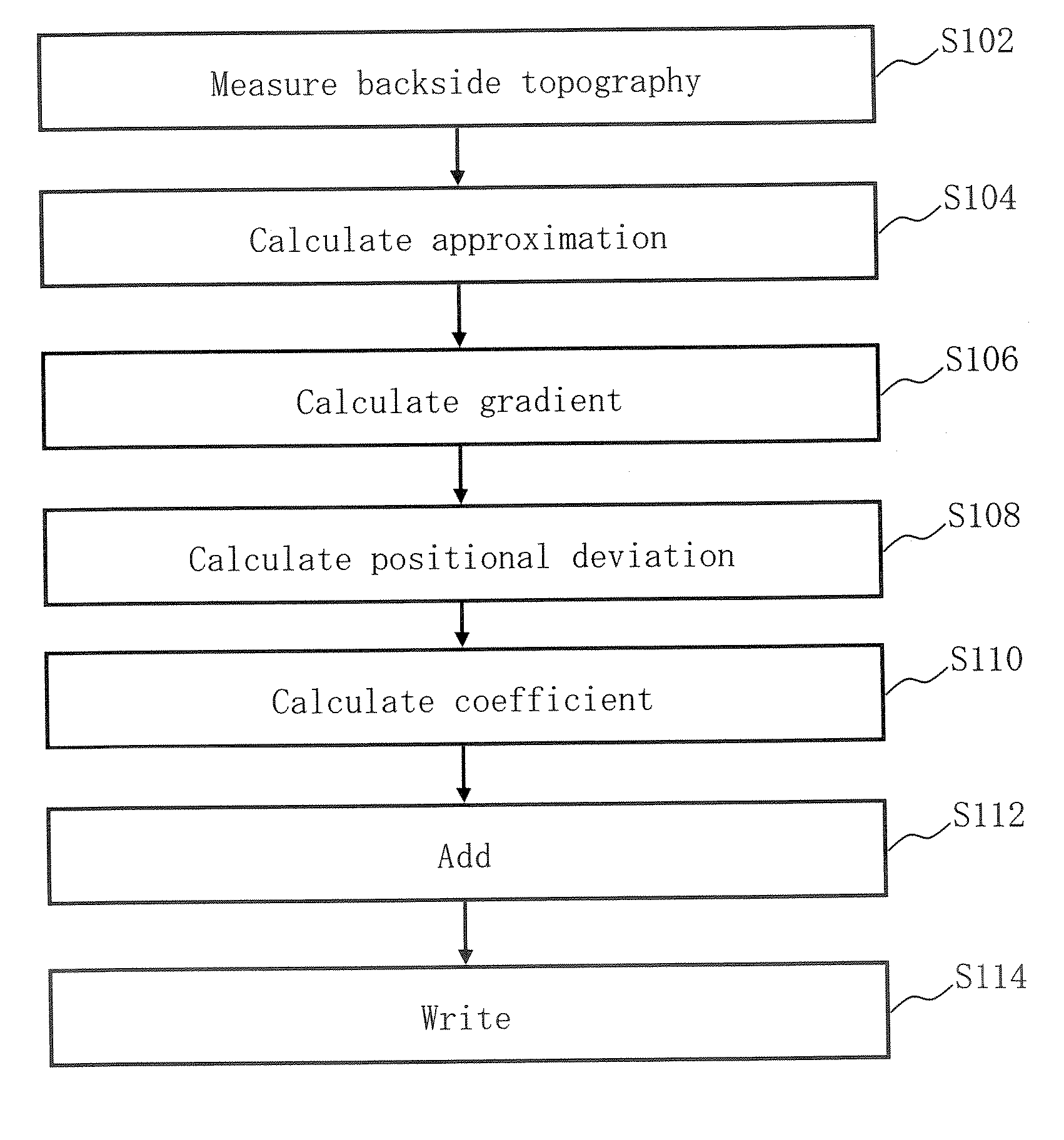

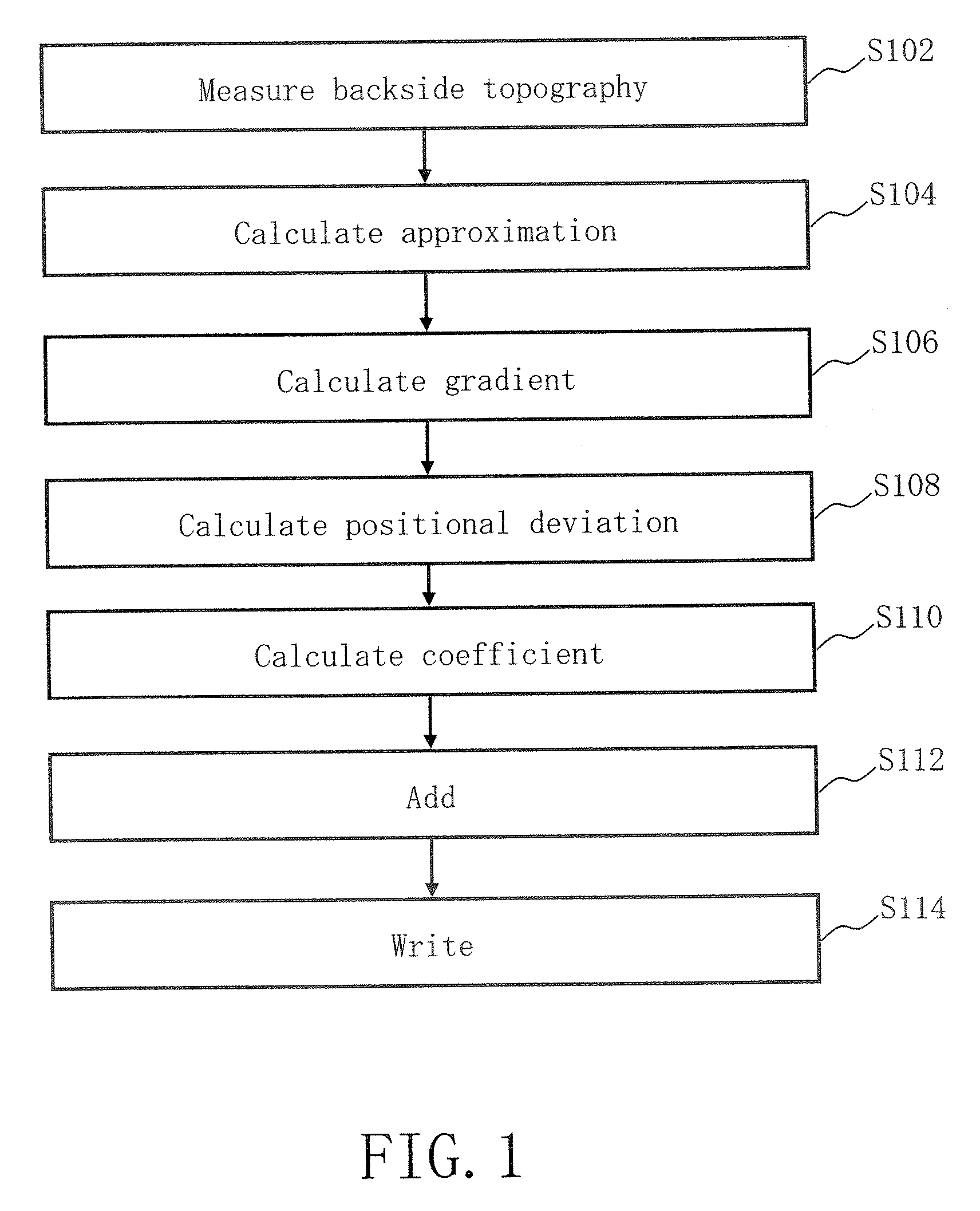

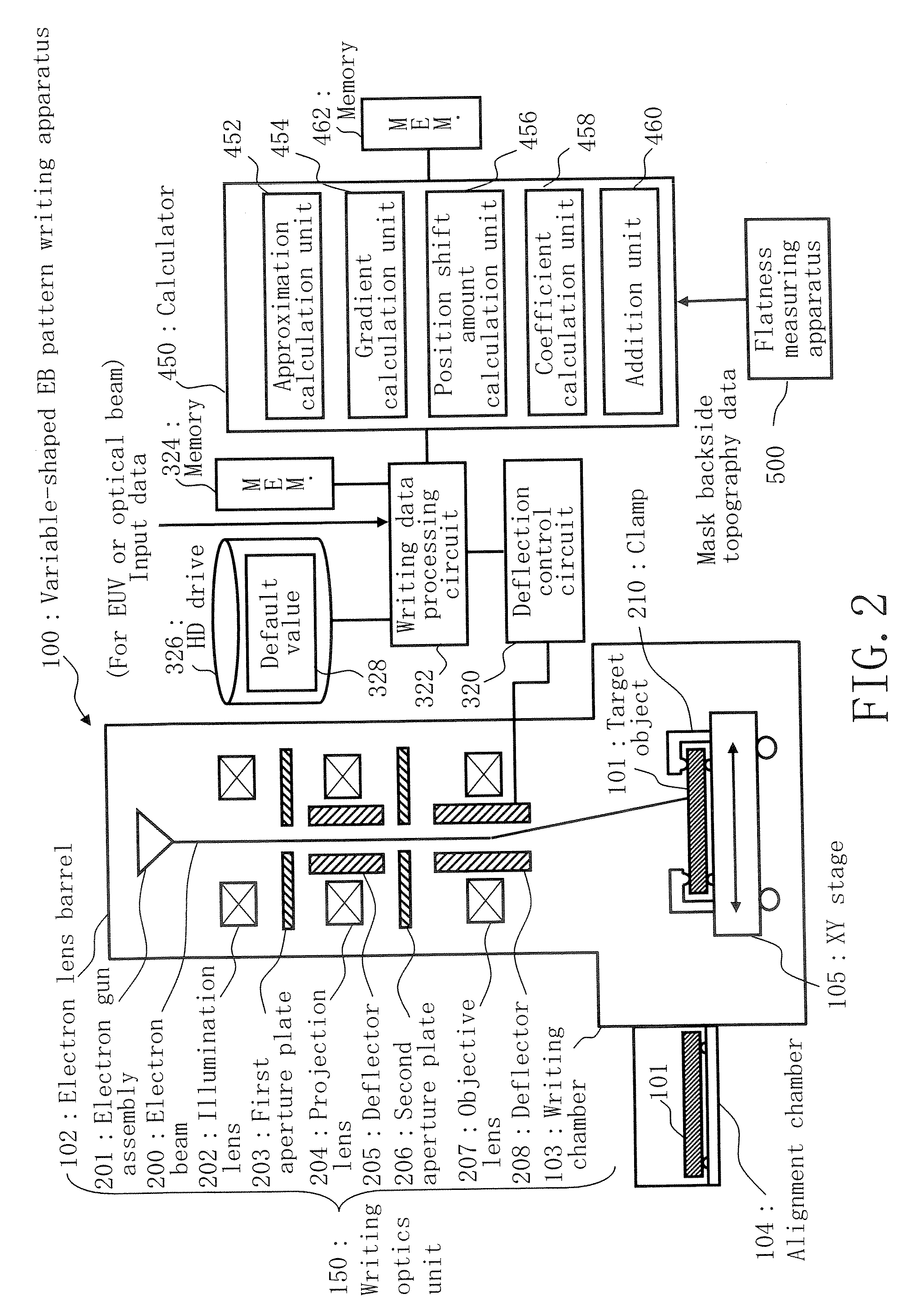

Writing method and writing apparatus of charged particle beam, positional deviation measuring method, and position measuring apparatus

ActiveUS7554107B2Cleanness is improvedHigh precision measurementElectric discharge tubesNanoinformaticsComputational physicsTopography

A charged particle beam writing method includes measuring a topography of a backside of a substrate without an influence of a gravity sag, calculating a first positional deviation amount of a pattern written on a frontside of the substrate in a case of the backside of the substrate having been corrected to be flat, based on the the backside topography of the substrate, calculating a first coefficient of a first approximate expression indicating a positional deviation correction amount for correcting the first positional deviation amount, based on the first positional deviation amount, adding the first coefficient to a second coefficient of a second approximate expression indicating a positional deviation correction amount for correcting a second positional deviation amount of the pattern written on the frontside of the substrate in a case of the backside of the substrate having not been corrected to be flat, and writing the pattern on the frontside of the substrate utilizing a charged particle beam, based on one of a positional deviation correction amount obtained by a third approximate expression indicating a positional deviation correction amount using a third coefficient obtained as a result of the adding, and the positional deviation correction obtained by the second approximate expression.

Owner:NUFLARE TECH INC

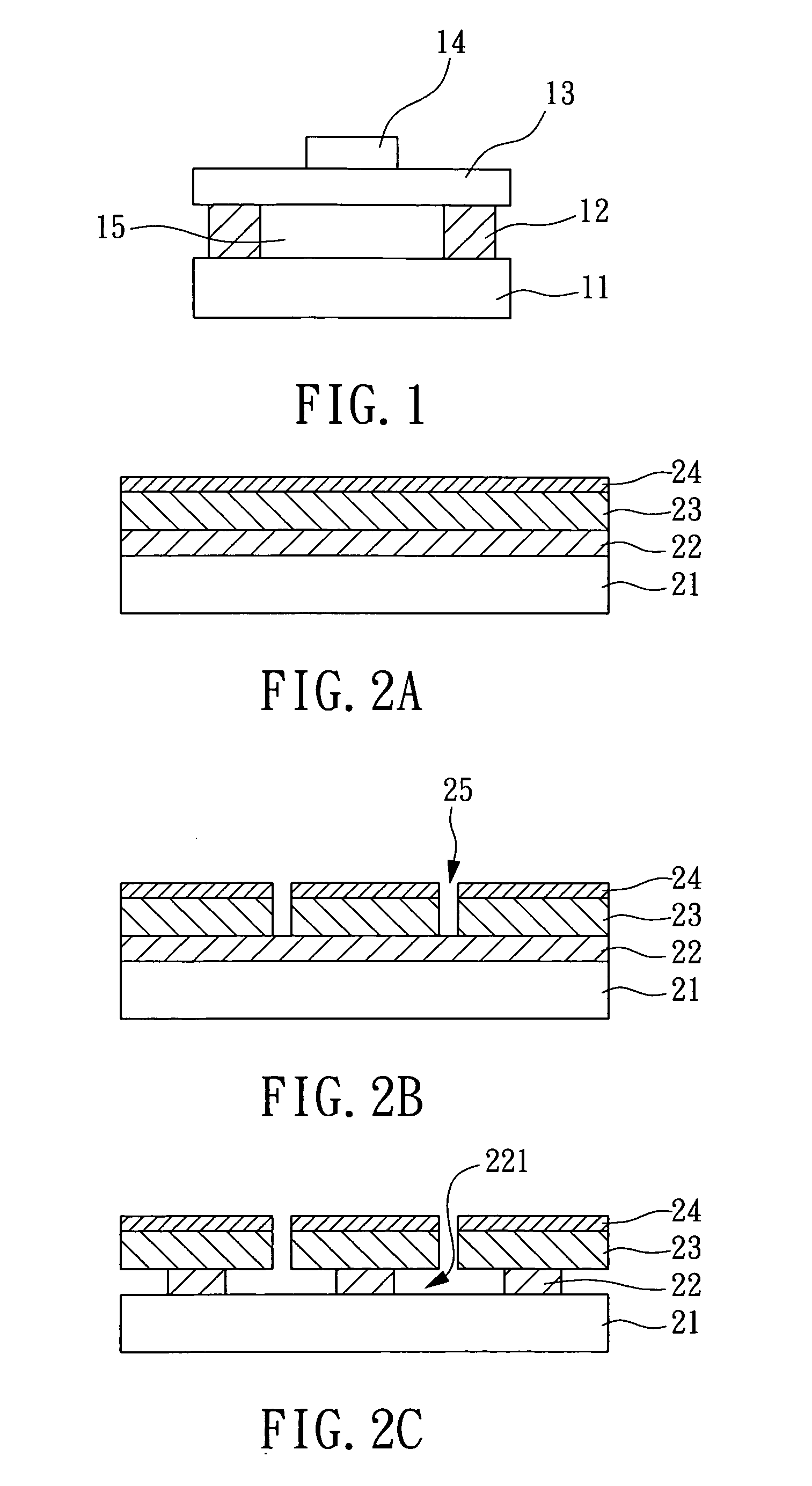

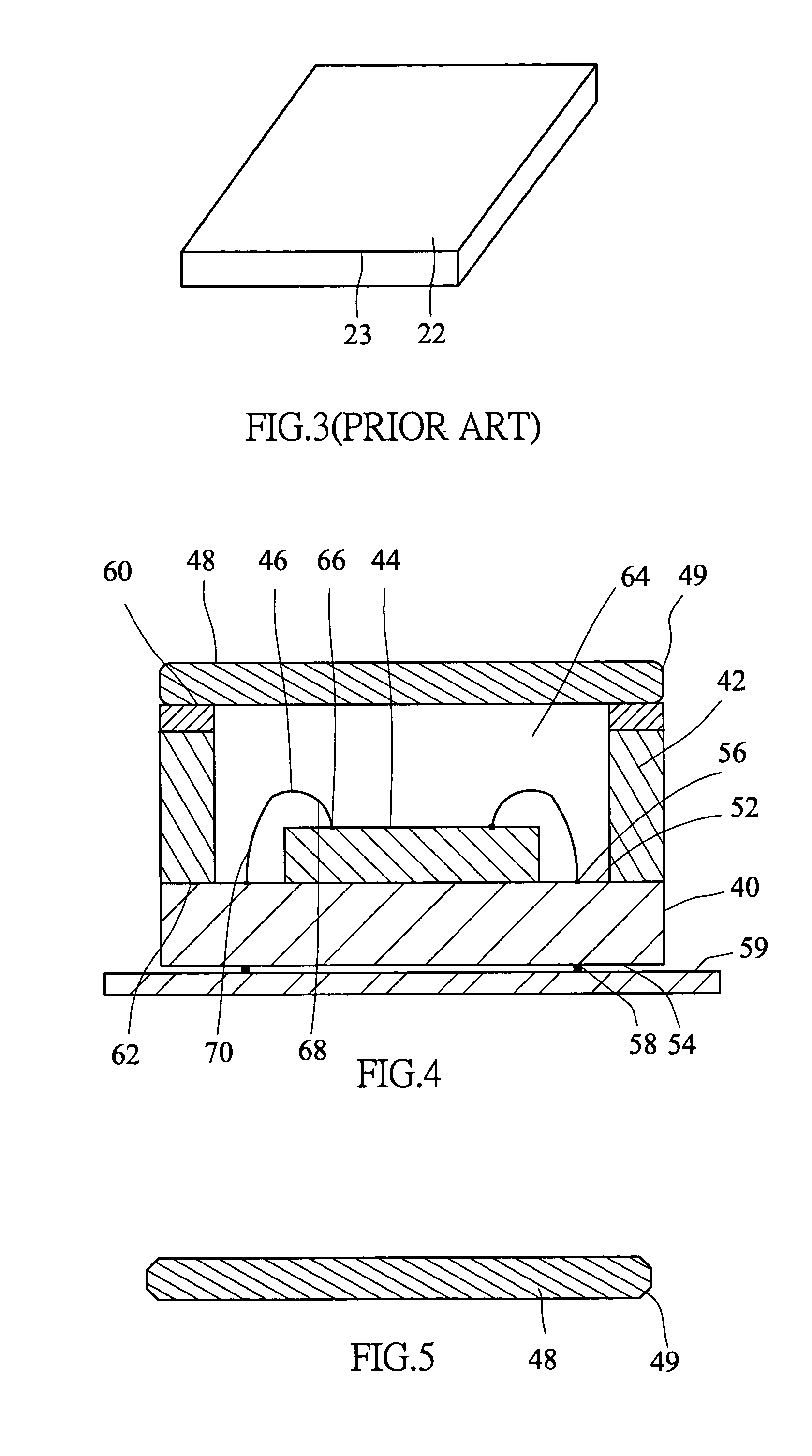

Imprint method for manufacturing micro capacitive ultrasonic transducer

ActiveUS20050127033A1Low costUnified controlElectrical transducersDecorative surface effectsBiomedical engineeringTransducer

Owner:IND TECH RES INST

Method and device for drying substrate

InactiveUS7377053B1Cleanness be improveCleanness is improvedDrying solid materials with heatDrying solid materials without heatProcess engineeringSemiconductor

A device for drying substrate comprising a processing vessel housing a specified number of substrates such as semiconductor wafers installed erectedly in parallel to one another, a first substrate supporting member supporting substrates within the processing vessel, the processing fluid supplying section supplying to the processing vessel, the processing fluid for performing processing such as cleaning processing on the substrates, a processing fluid exhausting section exhausting processing fluid from the processing vessel, and a drying fluid supplying section supplying, to the processing vessel, the liquid drops of drying fluid for performing drying processing on the substrates.

Owner:TOHO KASEI CO LTD +1

Dust cleaning apparatus

InactiveUS20140311106A1Cleanness is improvedDispersed particle filtrationTransportation and packagingEngineeringMoving parts

A dust cleaning apparatus comprising a sieve, a beater and a driver is provided. The beater includes a moving part and a beating part. The moving part rotates around a shaft for a circular motion or vibrates relative to a supporting rod for a vibration motion. The beating part is disposed on the moving part and beats the sieve by the movement of the moving part. The driver connects the shaft or the supporting rod to drive the moving part in motion.

Owner:BENQ CORP

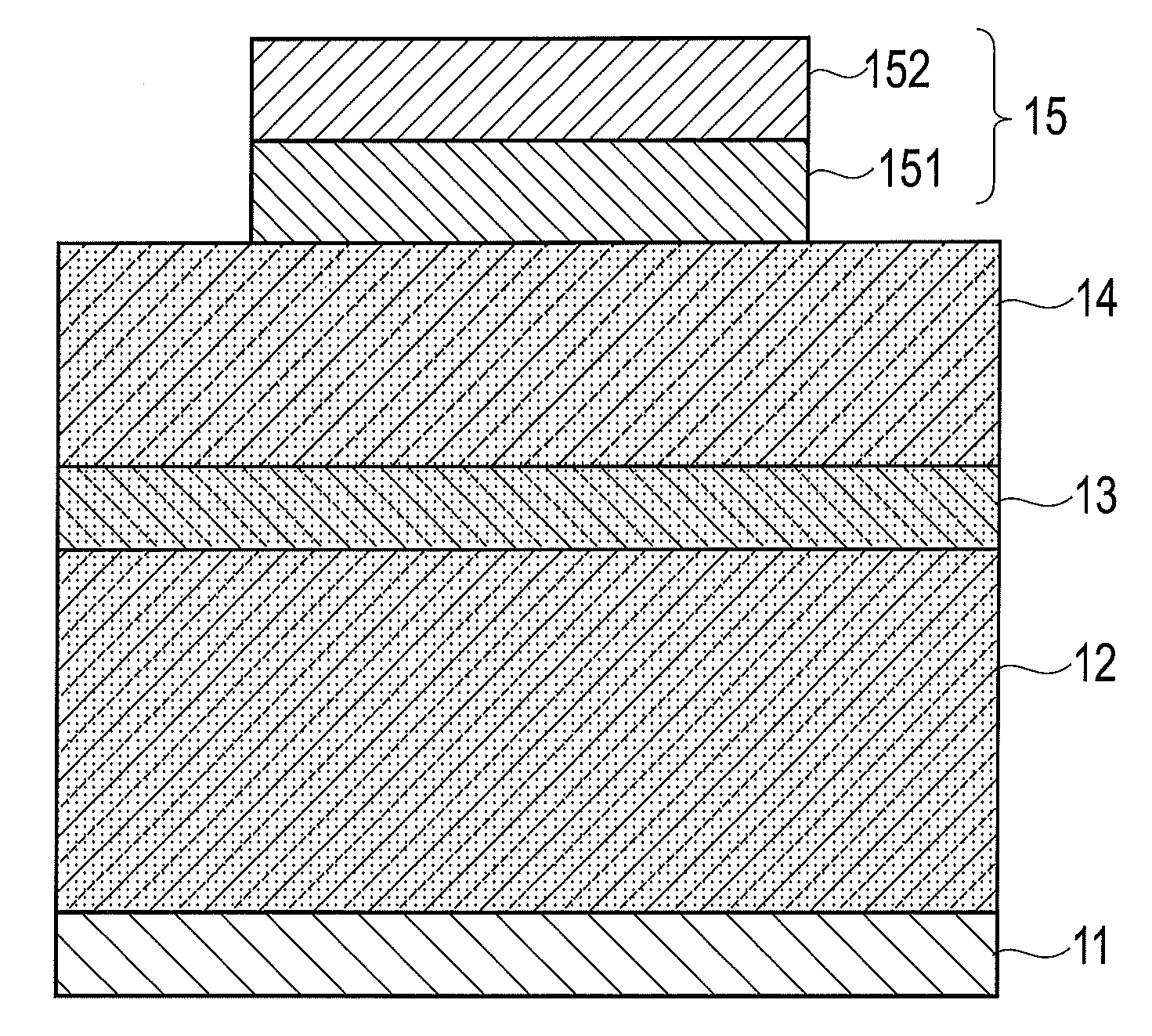

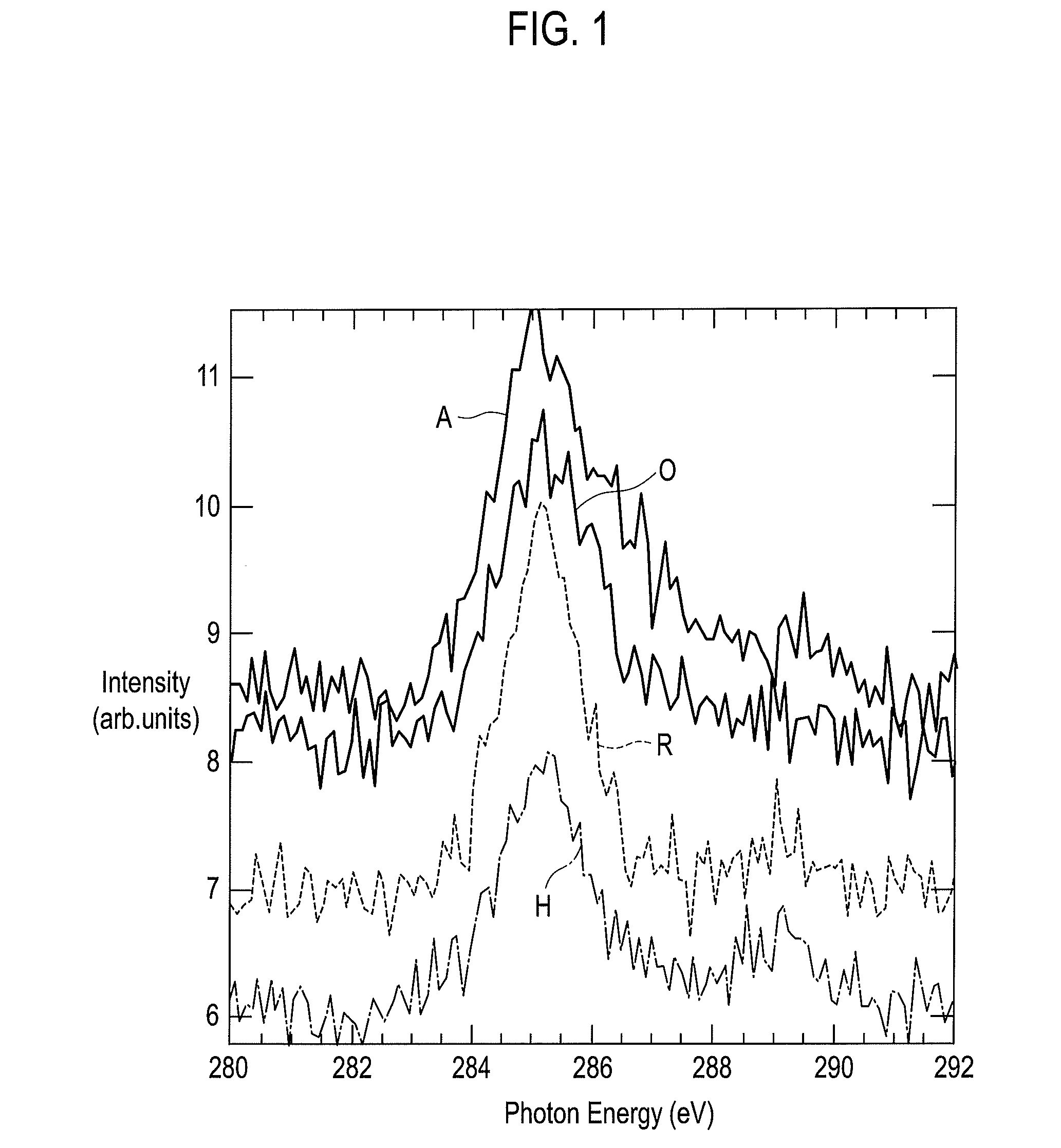

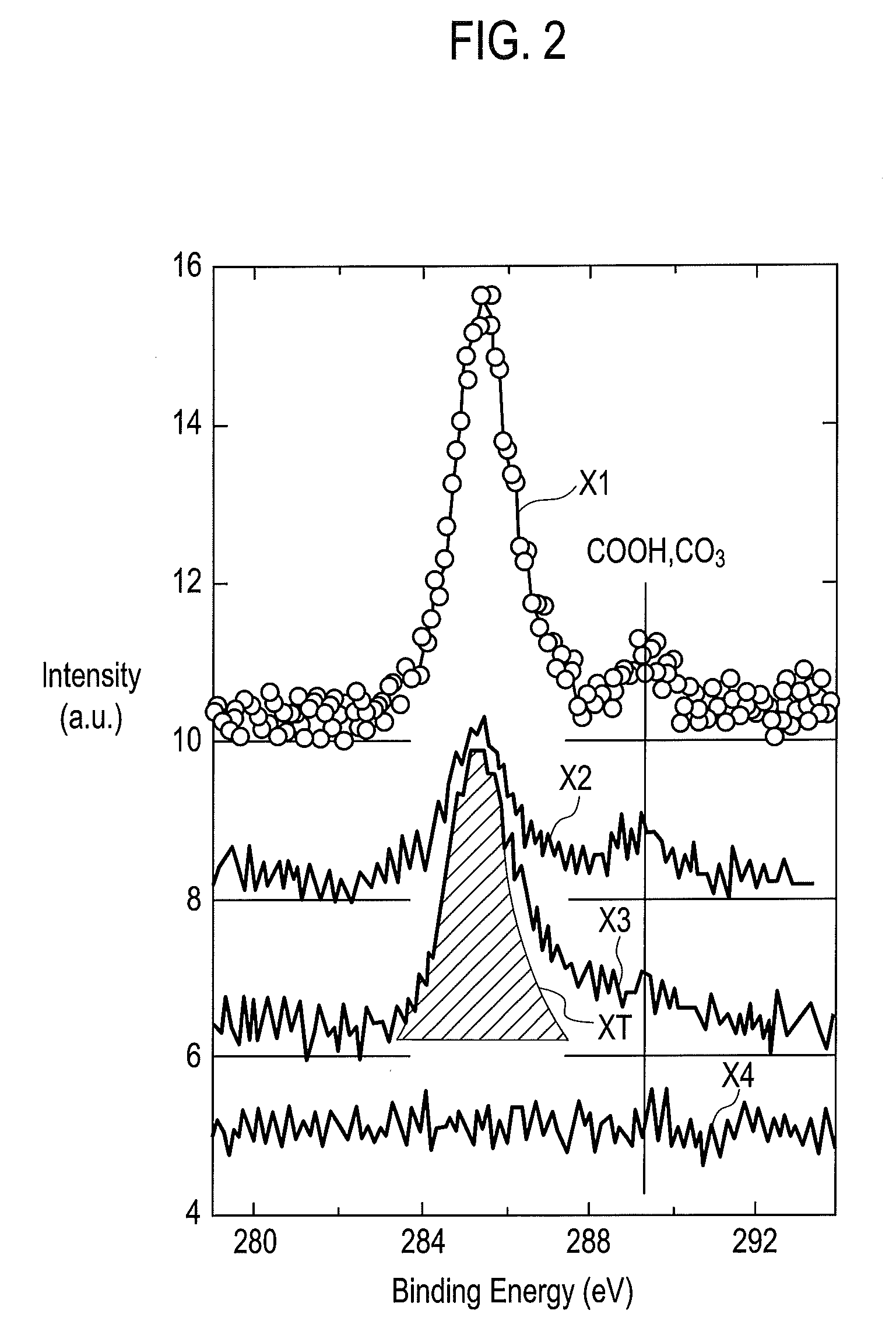

ZnO-BASED SUBSTRATE, METHOD FOR PROCESSING ZnO-BASED SUBSTRATE, AND ZnO-BASED SEMICONDUCTOR DEVICE

InactiveUS20100308327A1Cleanness is improvedQuality improvementPolycrystalline material growthAfter-treatment detailsOxygen plasmaDevice material

Provided are a ZnO-based substrate having a high-quality surface suitable for crystal growth, a method for processing the ZnO-based substrate, and a ZnO-based semiconductor device. The ZnO-based substrate is formed such that any one of a carboxyl group and a carbonate group is substantially absent in a principal surface on a crystal growth side. Also, in order for a carboxyl group or a carbonate group to be substantially absent, any one of oxygen radicals, oxygen plasma and ozone is brought into contact with the surface of the ZnO-based substrate before the crystal growth is started. Consequently, cleanness of the surface of the ZnO substrate is enhanced, thereby enabling fabrication of a high-quality ZnO-based thin film on the substrate.

Owner:ROHM CO LTD

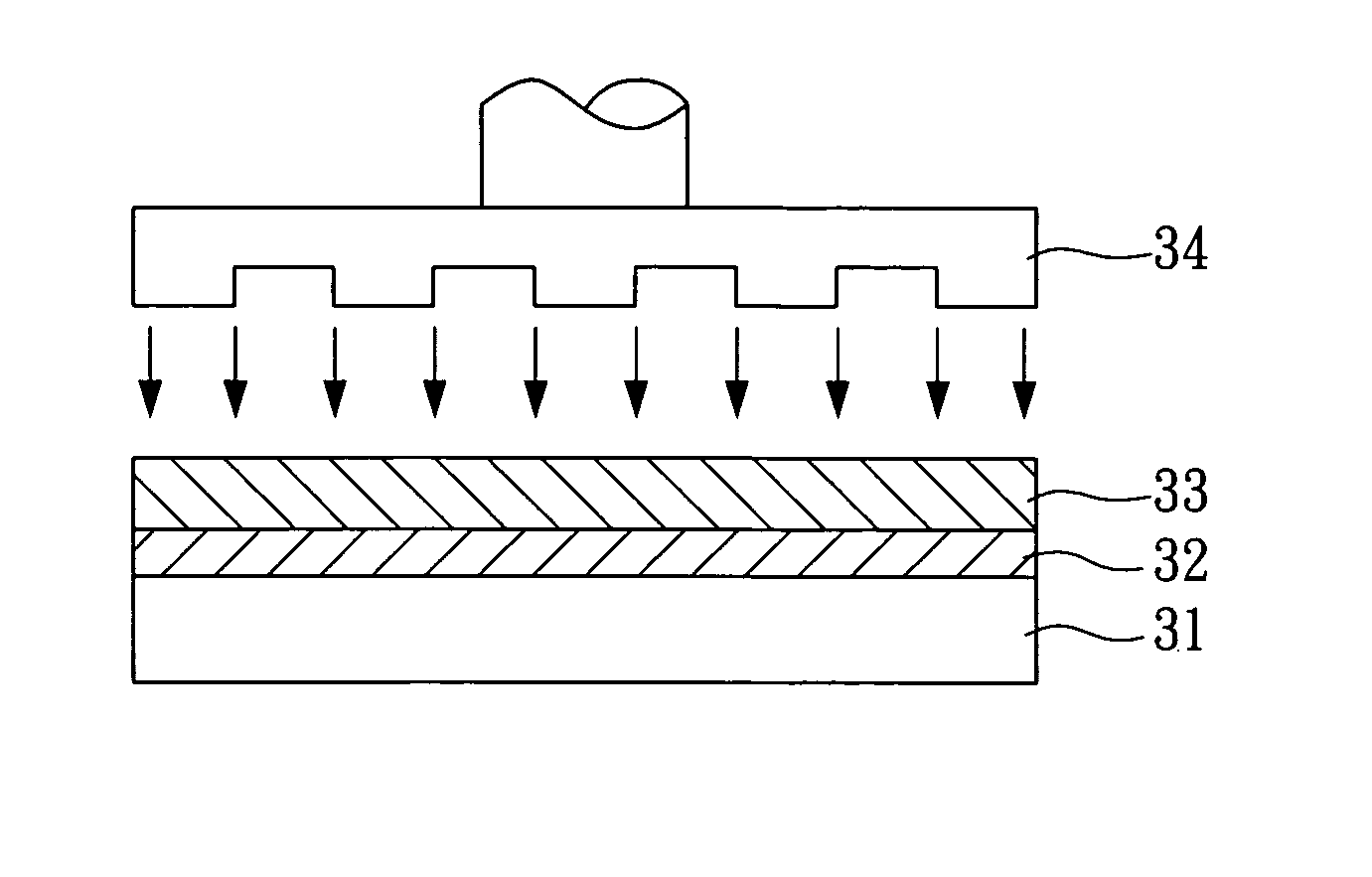

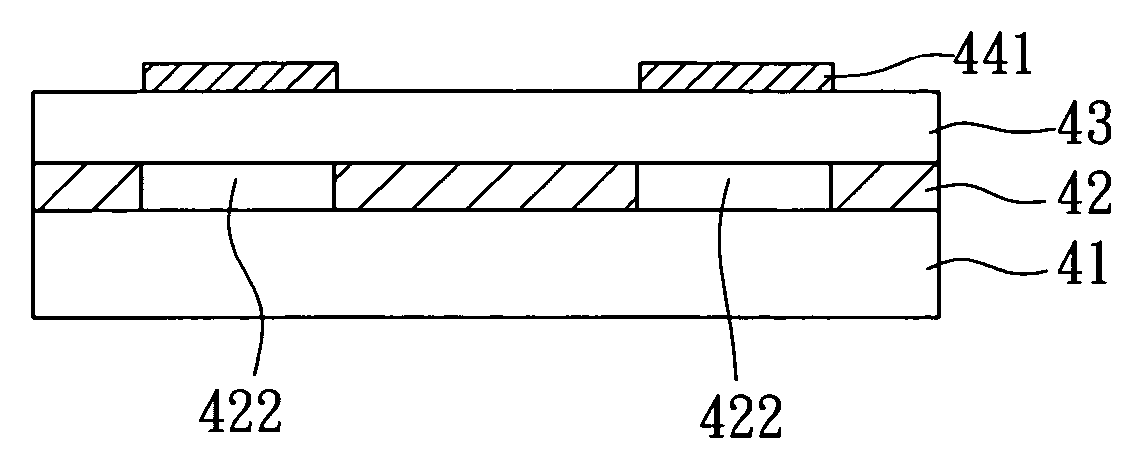

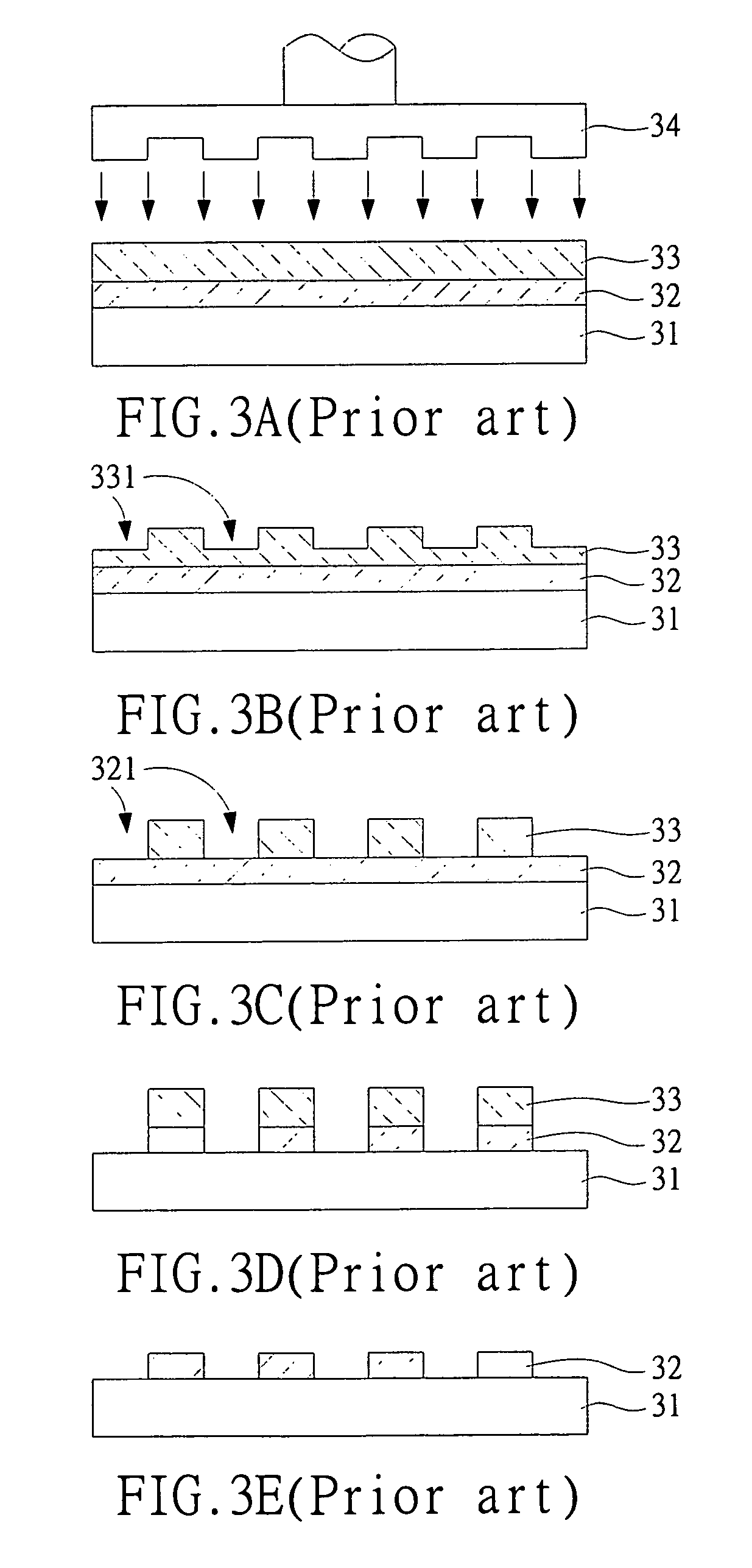

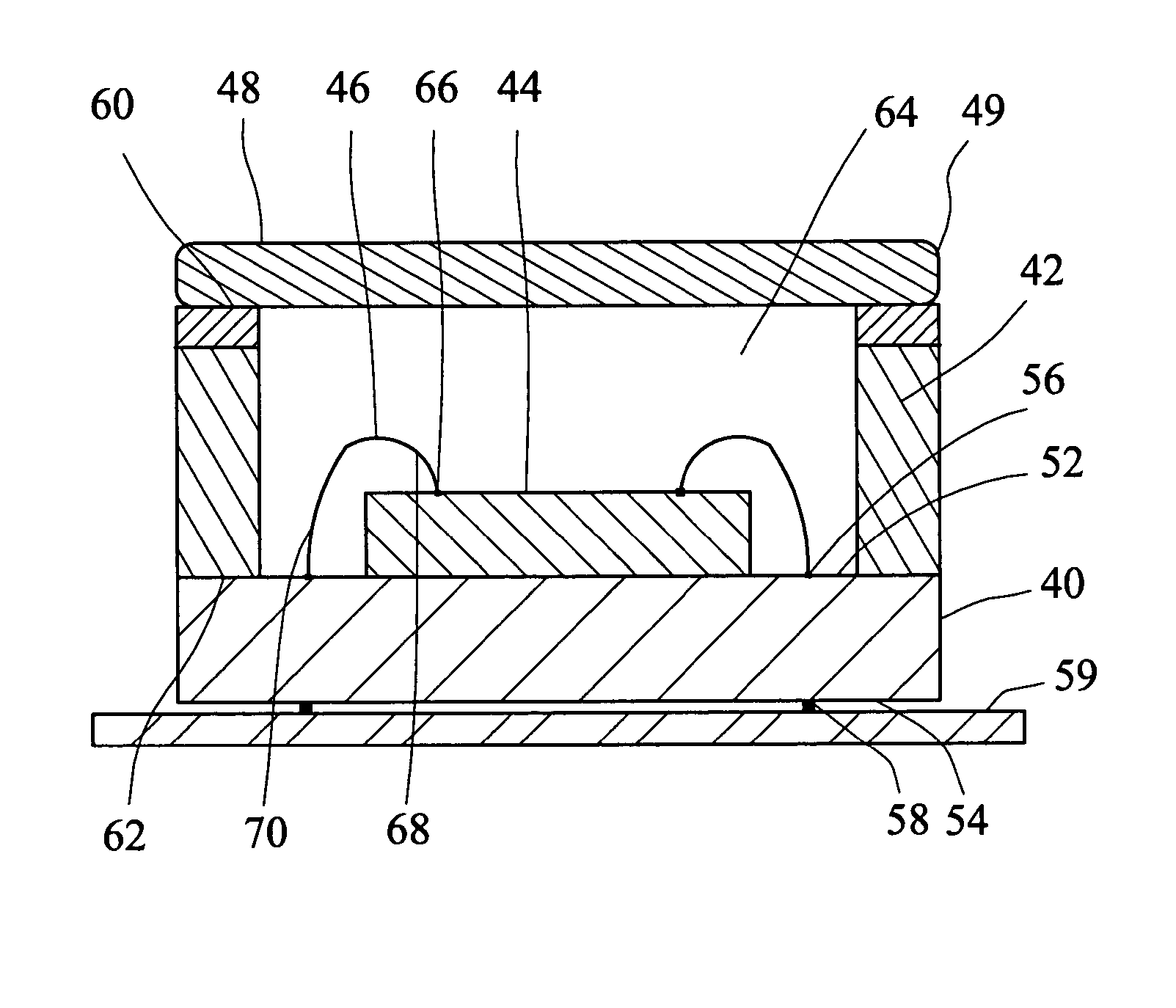

Imprint method for manufacturing micro capacitive ultrasonic transducer

ActiveUS7438823B2Low costHigh sensitivityElectrical transducersDecorative surface effectsUltrasonic sensorTransducer

The present invention relates to an imprint method for manufacturing micro capacitive ultrasonic transducer, which uses a mold with a particularly patterned surface to imprint into a flexible material thus forming the oscillation cavities of the ultrasonic transducer. Such imprint method not only realizes the volume manufacturing and reduces the cost, but also can precisely control the geometrical size of the oscillation cavities and thus shorten the distance between the upper and the lower electrodes to the micro / nano level, largely improving the sensitivity of the transducer. Moreover, the present invention further changes the procedure for manufacturing micro capacitive ultrasonic transducer of the prior art, which can both save the process steps and overcome the disadvantages in the prior art.

Owner:IND TECH RES INST

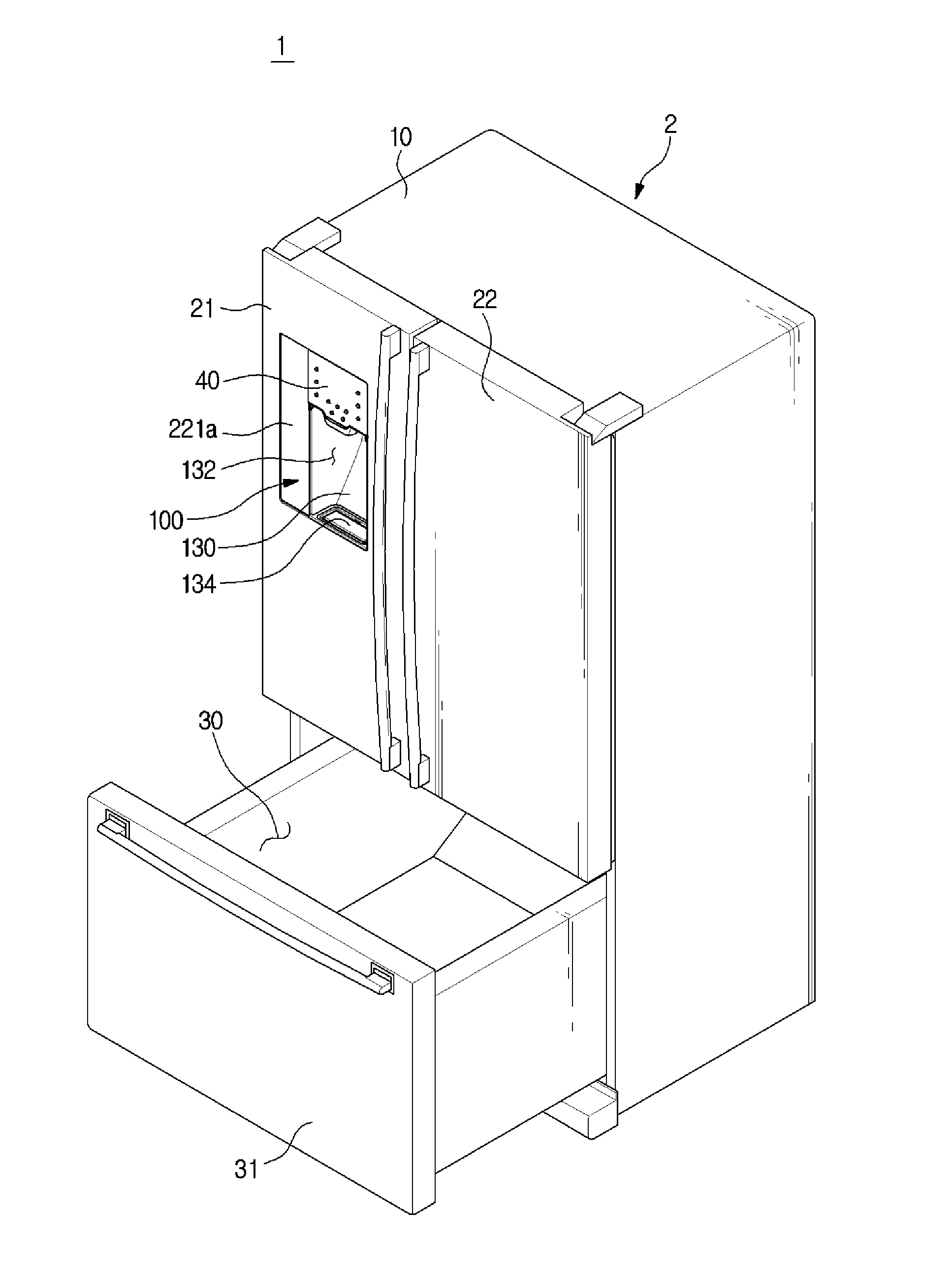

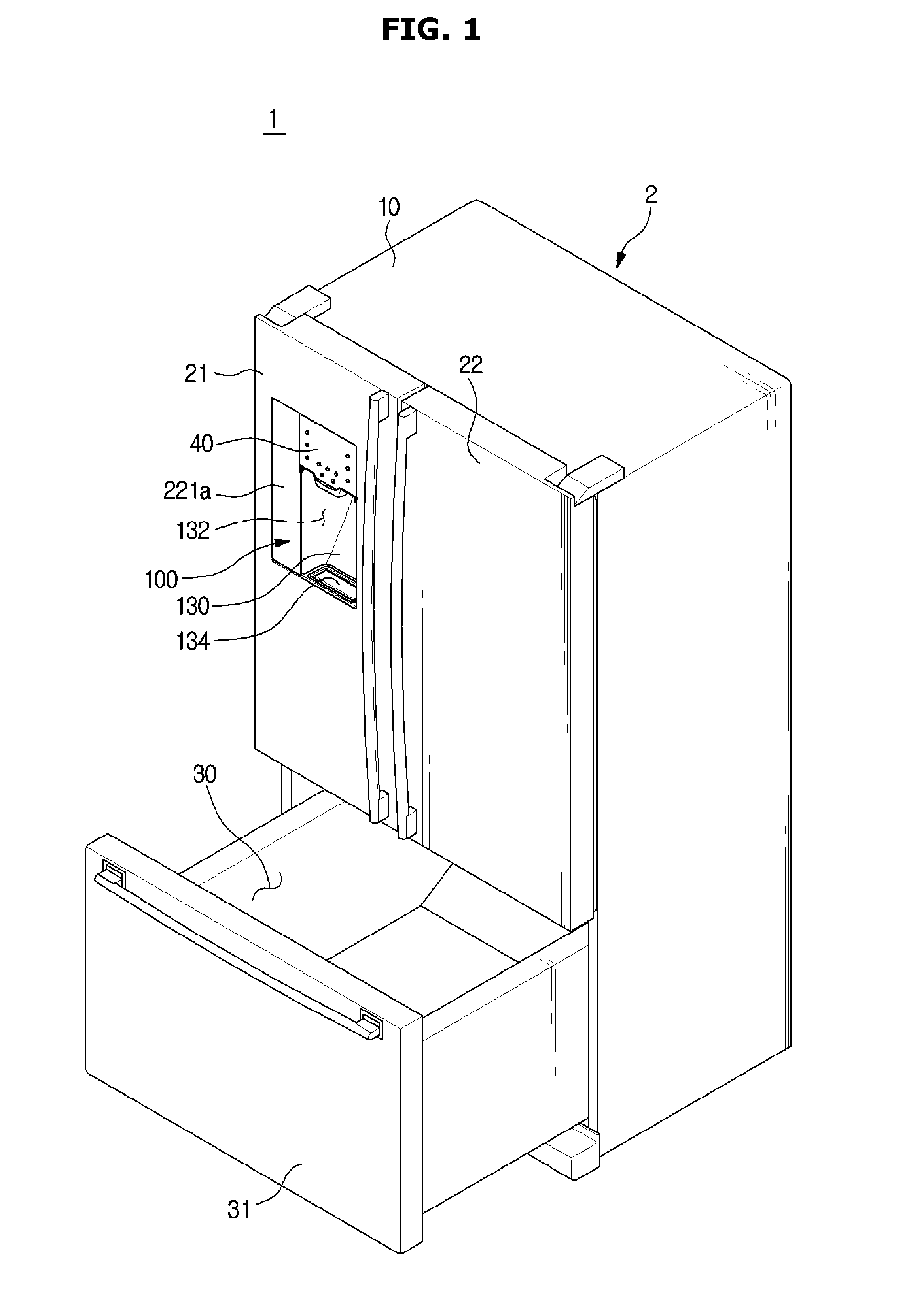

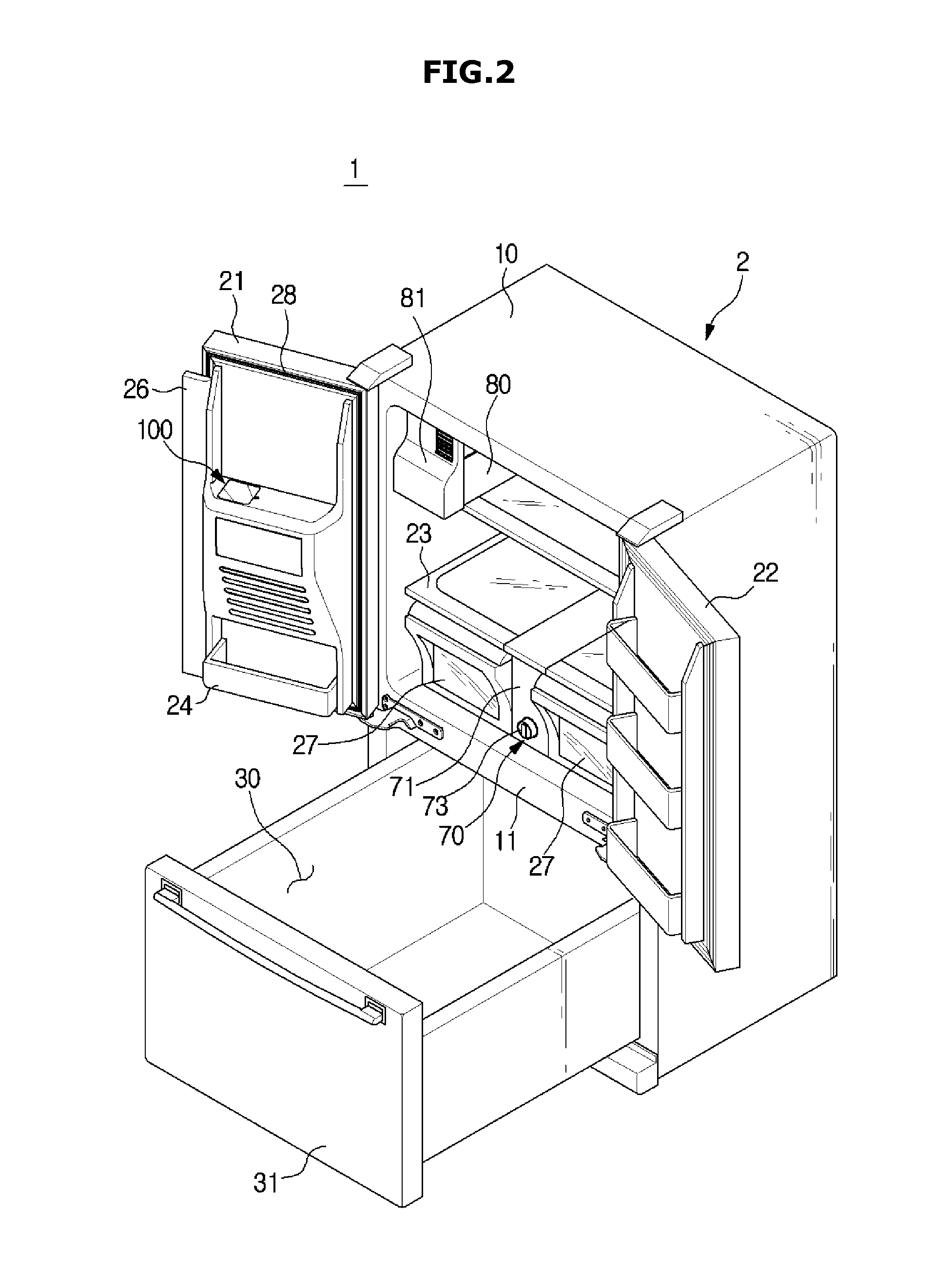

Refrigerator

ActiveUS20160238305A1Easily produces carbonated waterImprove securityLighting and heating apparatusMixing methodsRefrigerated temperaturePurified water

Disclosed herein is a refrigerator which includes a carbonated water production assembly, wherein the carbonated water production assembly includes a structure in which purified water or carbonated water which overflow from a carbonated water container in which the carbonated water is produced is discharged by detouring. Through this, cleanliness of the carbonated water container may be improved, and safety may be improved during the carbonated water production.

Owner:SAMSUNG ELECTRONICS CO LTD

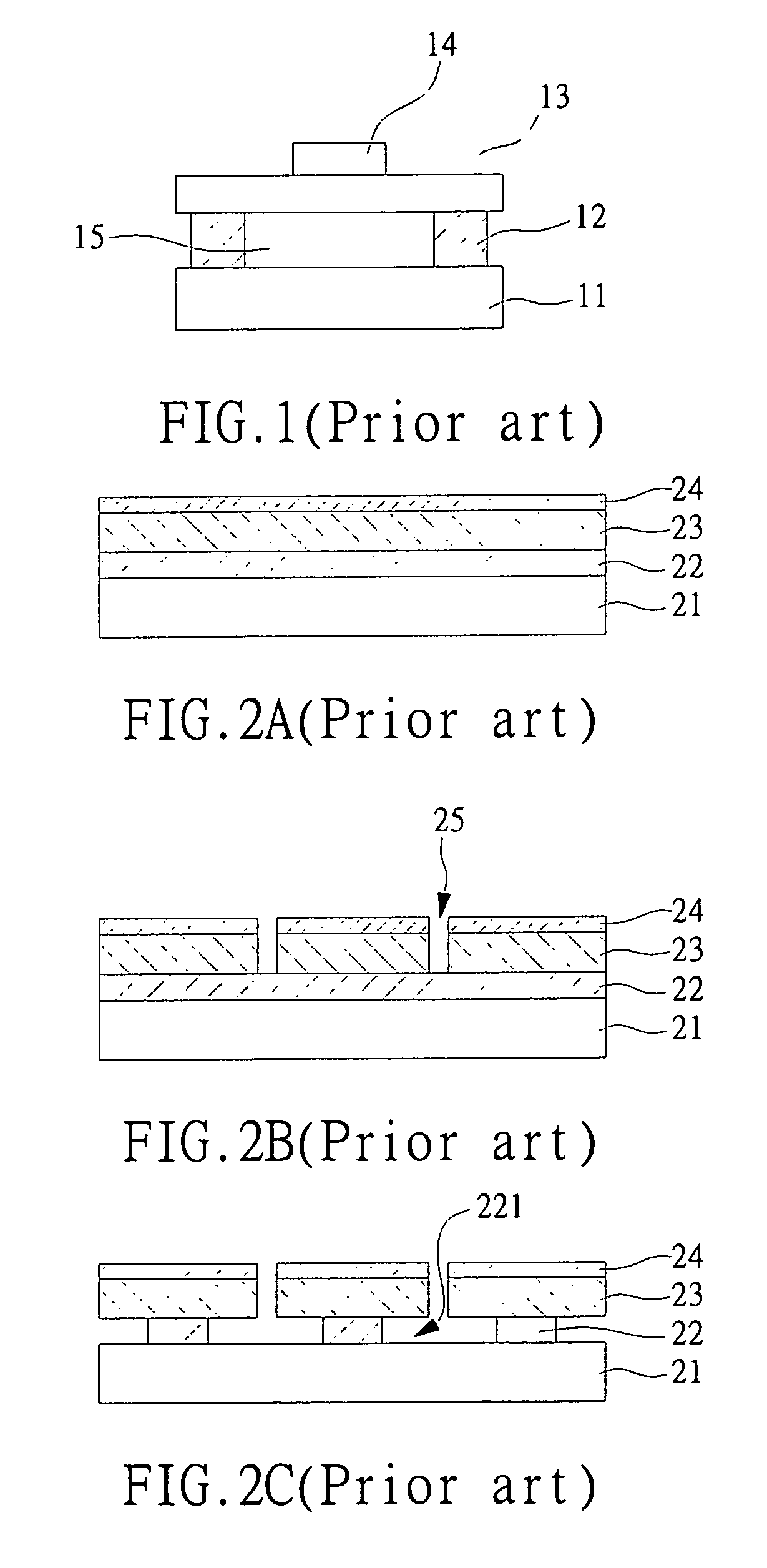

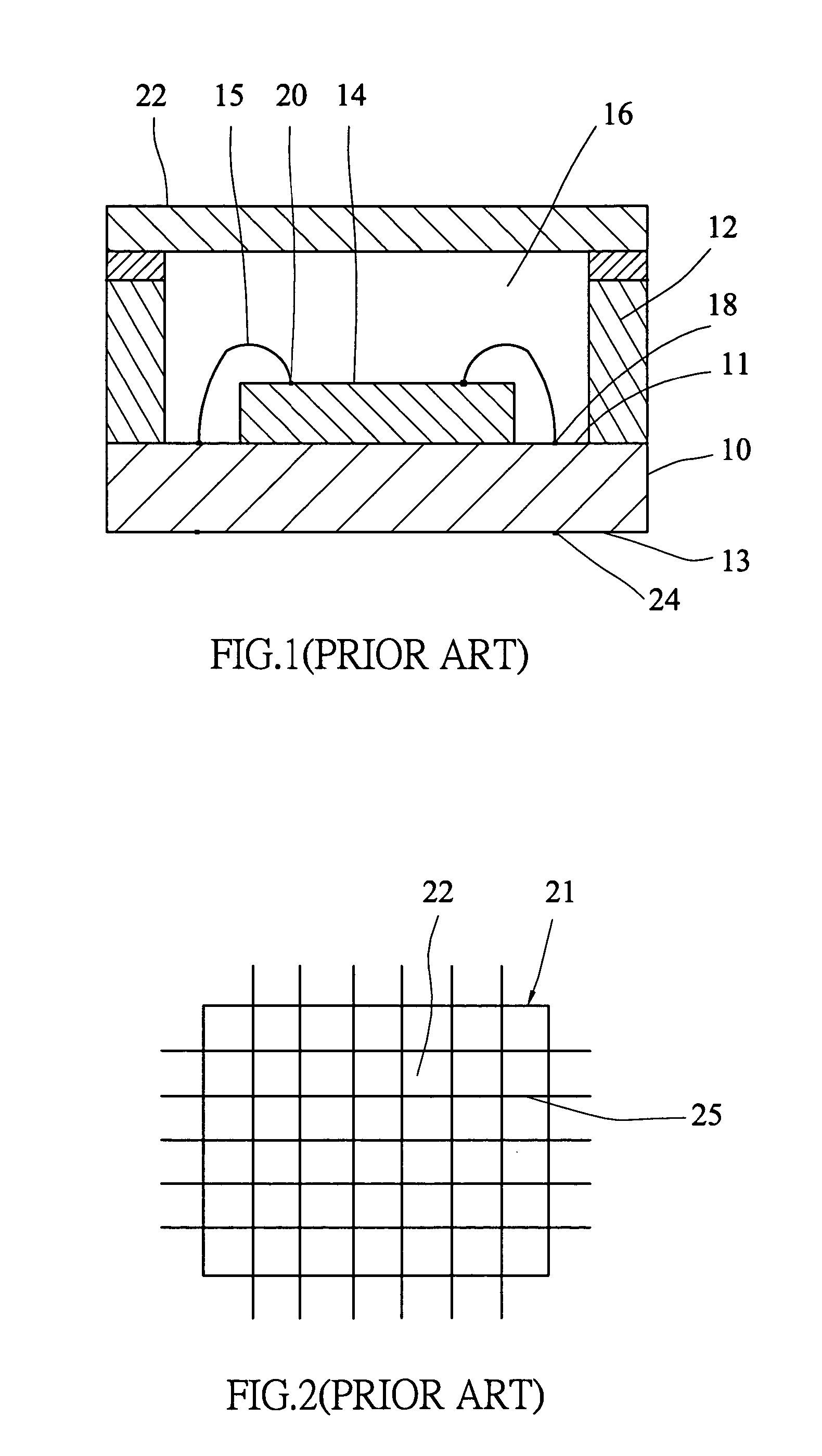

Image sensor having an improved transparent layer

ActiveUS20050012170A1Reduce collisionCleanness is improvedSolid-state devicesRadiation controlled devicesEngineeringImage sensor

An image sensor having an improved transparent layer includes a substrate, a frame layer, a photosensitive chip, a plurality of wires, and a transparent layer. The substrate has an upper surface formed with a plurality of first connected points. The frame layer is arranged on the upper surface of the substrate so as to form a cavity together with the substrate. The photosensitive chip is mounted on the upper surface of the substrate and within the cavity. The plurality of wires are electrically connected the photosensitive chip to the first connected point of the substrate. The transparent layer is covered on the frame layer for covering the photosensitive chip so that the photosensitive chip may receive optical signals passing through the transparent layer, respectively, at the peripheries of the transparent layer are formed with cut-corners. Therefore, the transparent layer may be decreased collision and may be increased the cleanness of the transparent layer, therefore, simplifying the manufacturing processes and decreasing the manufacturing cost.

Owner:TONG HSING ELECTRONICS IND LTD

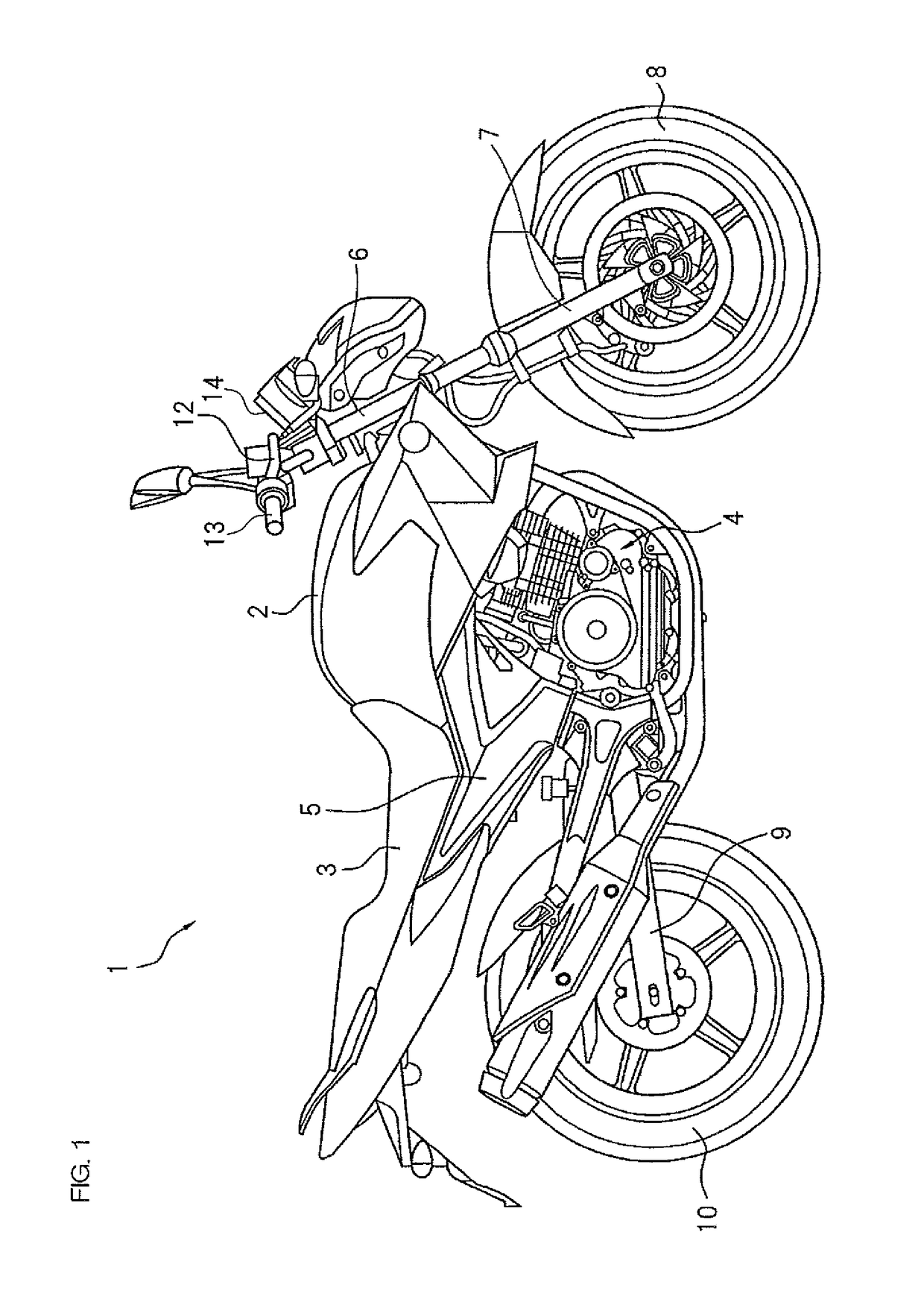

Fuel injection controller

ActiveUS9745913B2Improve fuel efficiencyImprove cleanlinessElectrical controlMachines/enginesOxygen sensorControl theory

A fuel injection controller includes an oxygen sensor that responds to an oxygen concentration inside an exhaust passage, and an injection amount control unit programmed to control a fuel injection amount based on the output of the oxygen sensor. The injection amount control unit includes an injection amount correction value computing unit that determines an injection amount correction value based on the output of the oxygen sensor, a short-time learning value computing unit that determines a short-time learning value based on the injection amount correction value, a long-time learning value computing unit that determines a long-time learning value based on the short-time learning value; a feedback correction amount computing unit that computes a feedback correction amount, an injection amount control value computing unit that computes a control value of the fuel injection amount, and a long-time learning value holding unit that holds the long-time learning value.

Owner:YAMAHA MOTOR CO LTD

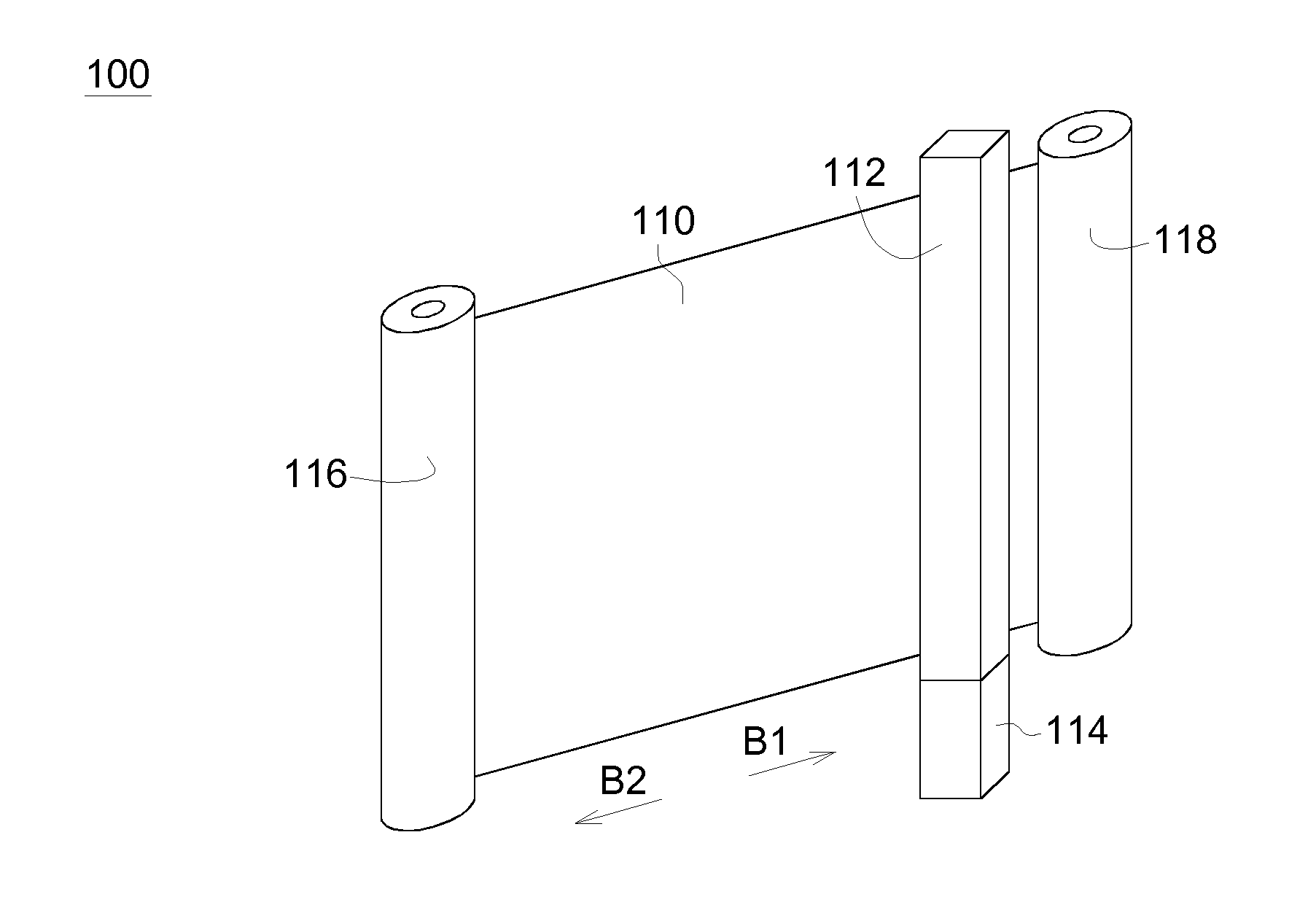

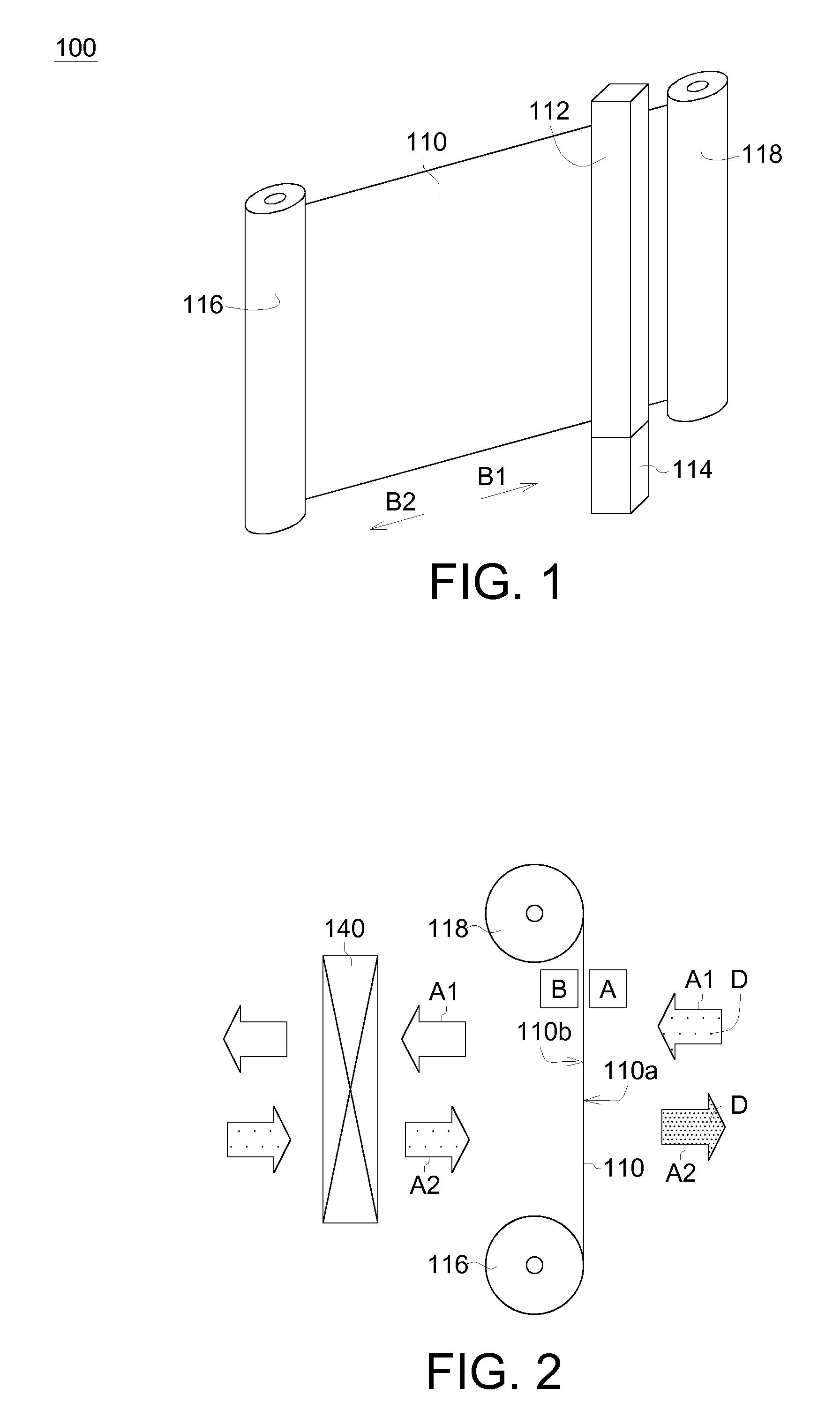

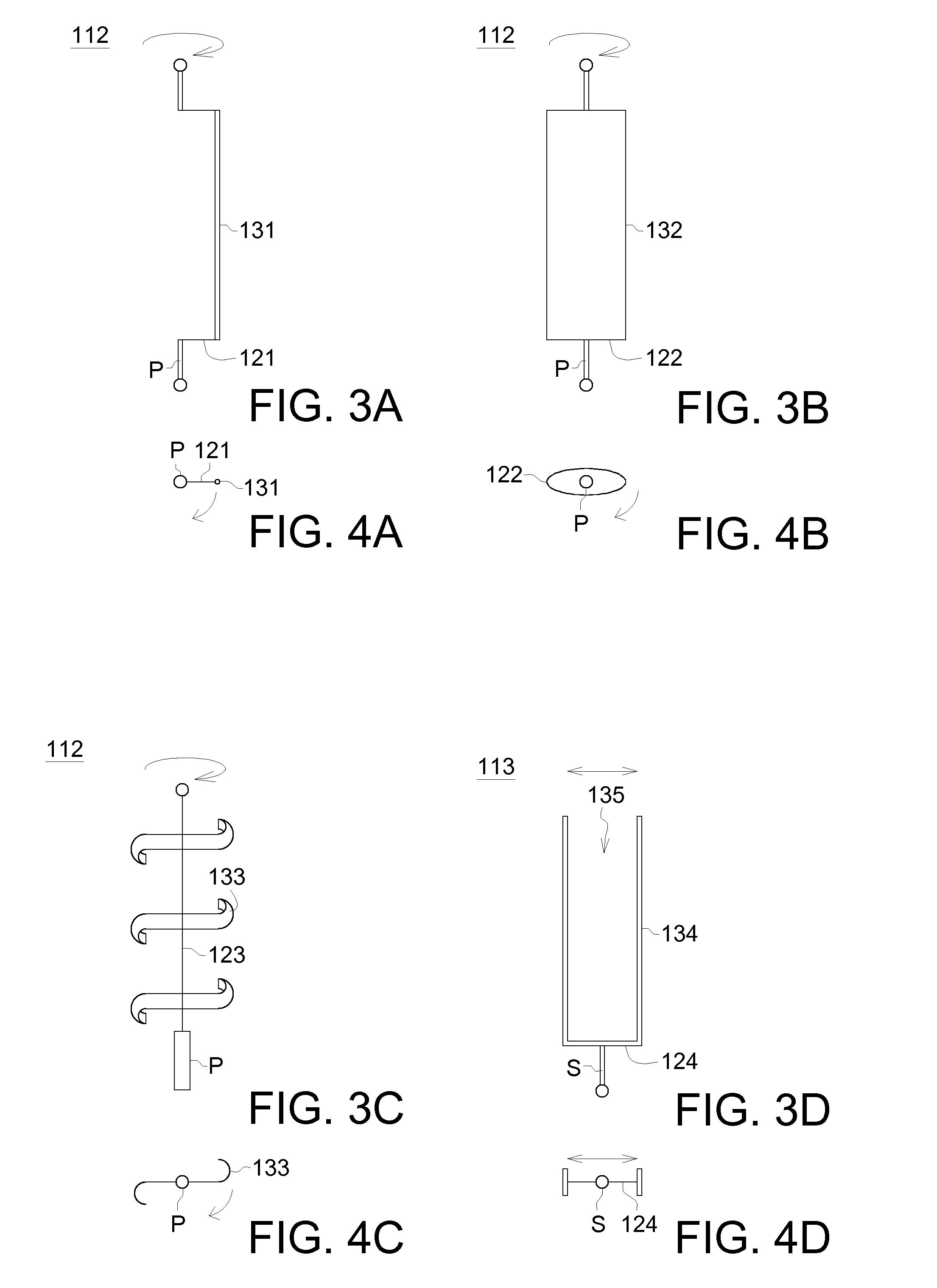

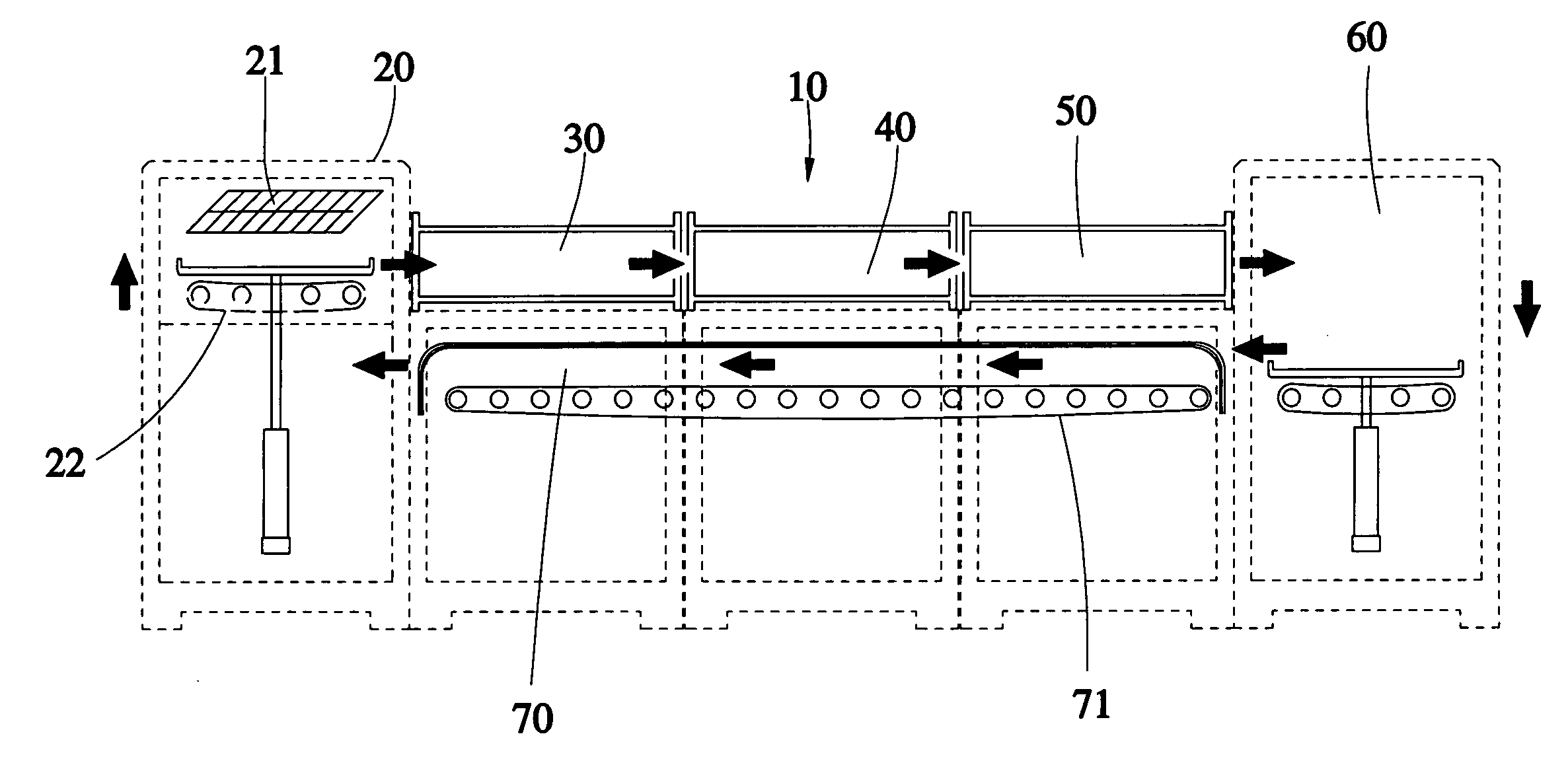

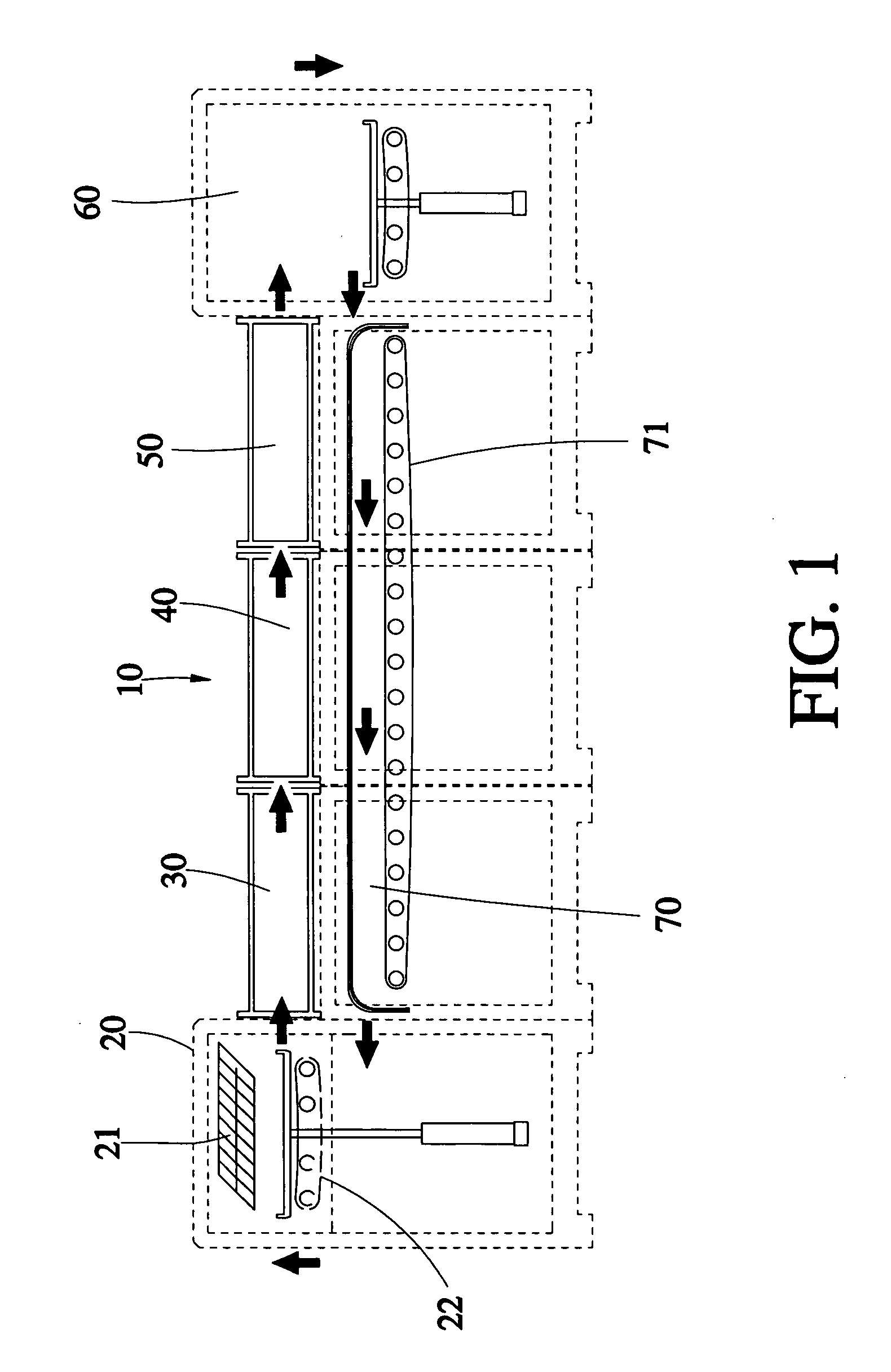

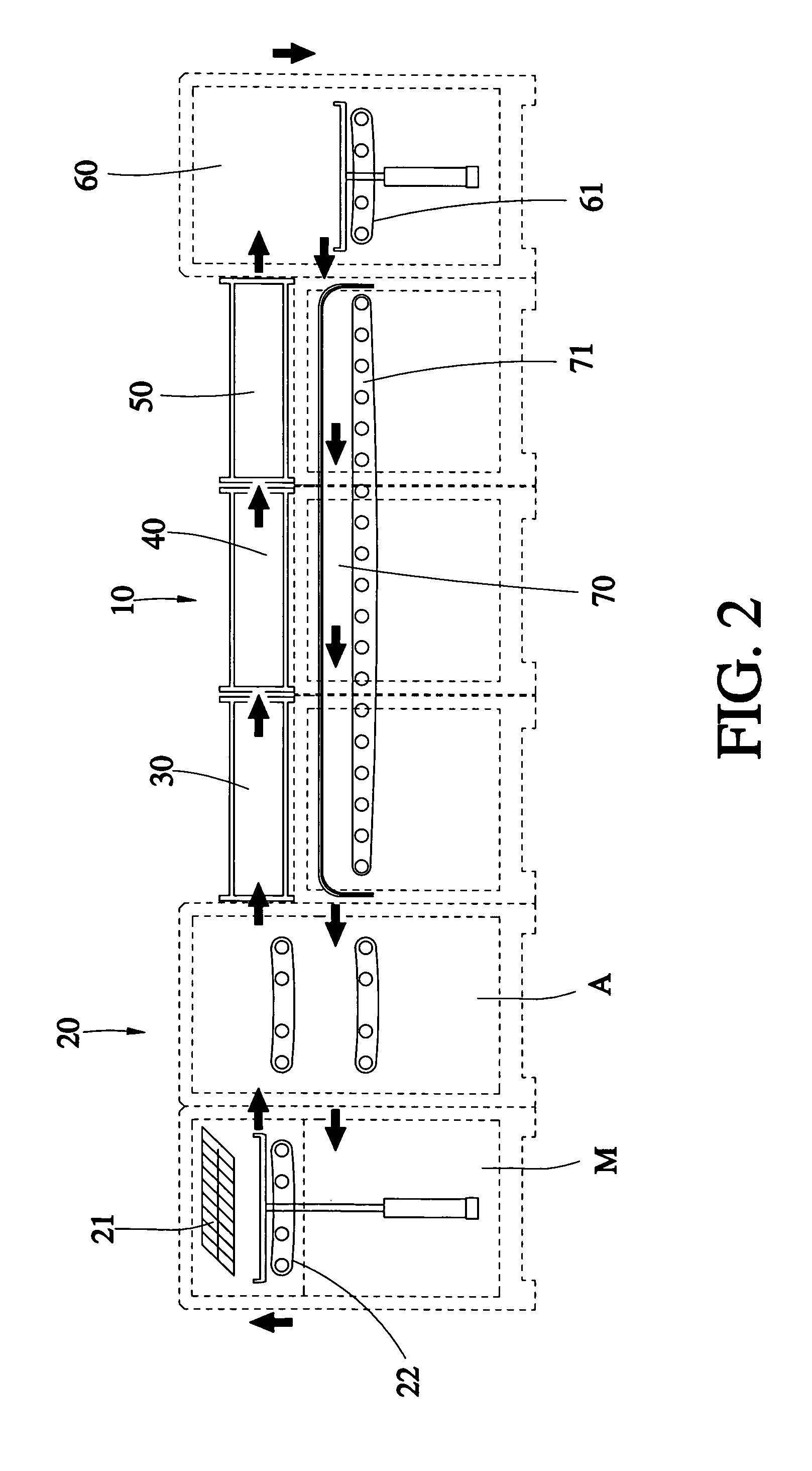

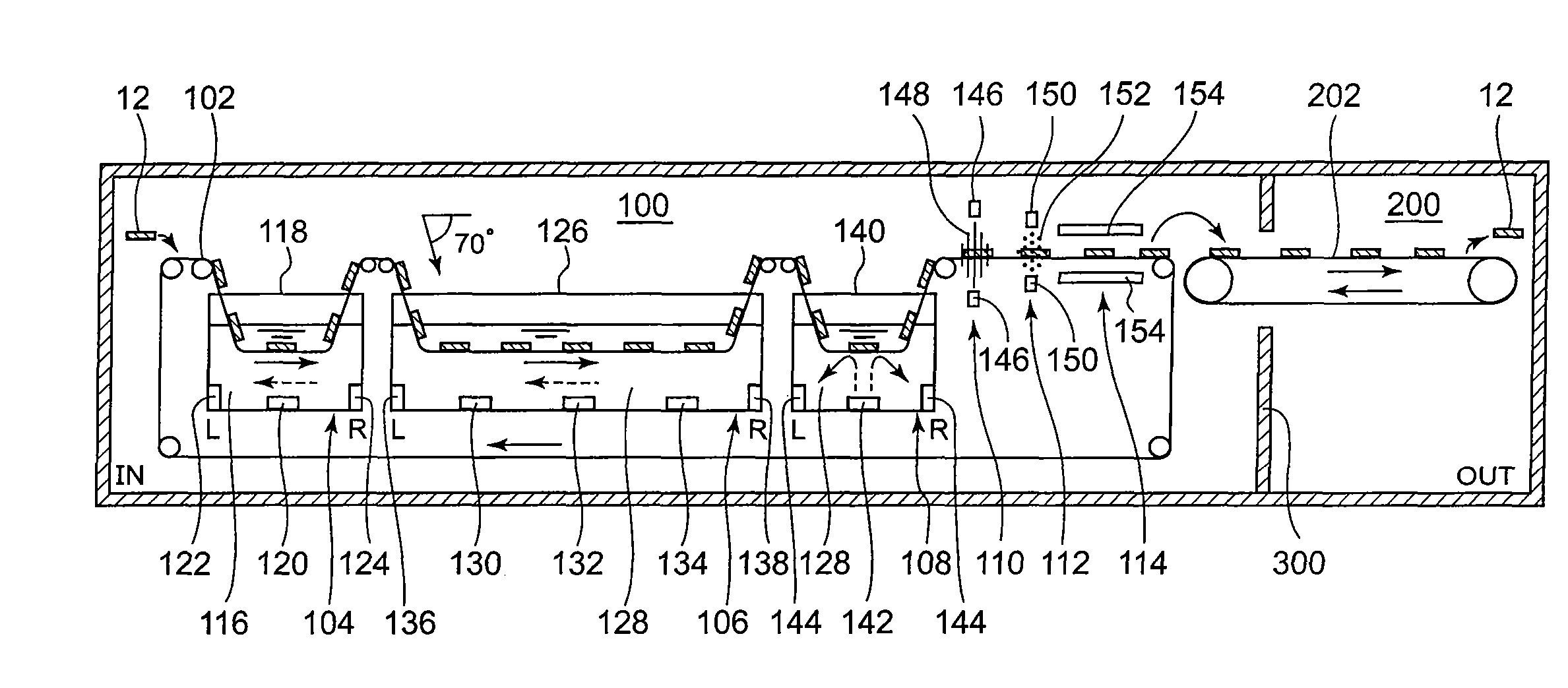

In-line coating/sputtering system with internal static electricity/dust removal and recycle apparatuses

InactiveUS20060157345A1Cleanness is improvedReduce extra spaceCellsVacuum evaporation coatingSputteringEngineering

An in-line coating / sputtering system includes a clean region with an internal static electricity / dust removal apparatus and an elevator device therein. A loading region has a pressure-down chamber with two gates on opposite ends thereof, one of which is communicated with the clean region. A coating / sputtering region has a vacuum chamber with two gates on opposite ends thereof, one of which is communicated with the pressure-down chamber of the loading region. An unloading region has a pressure-up chamber with two gates on opposite ends thereof, one of which is communicated with the vacuum chamber of the coating / sputtering region. A rear reversible region has an open chamber communicated with the pressure-up chamber of the unloading region, in which an elevator device is provided. A return region having a channel connecting the rear reversible region and the clean region, in which a backward transmission device is provided.

Owner:UVAT TECH

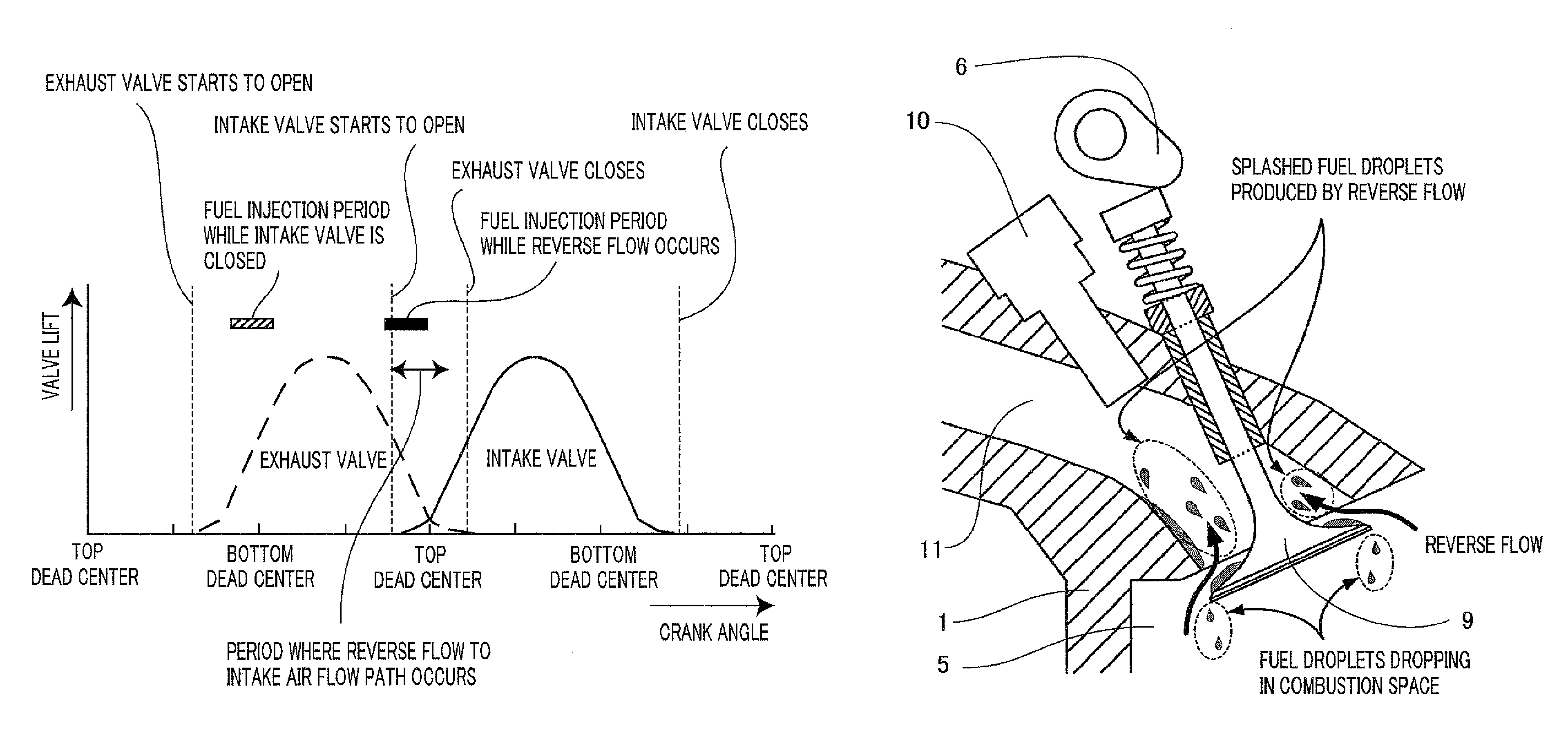

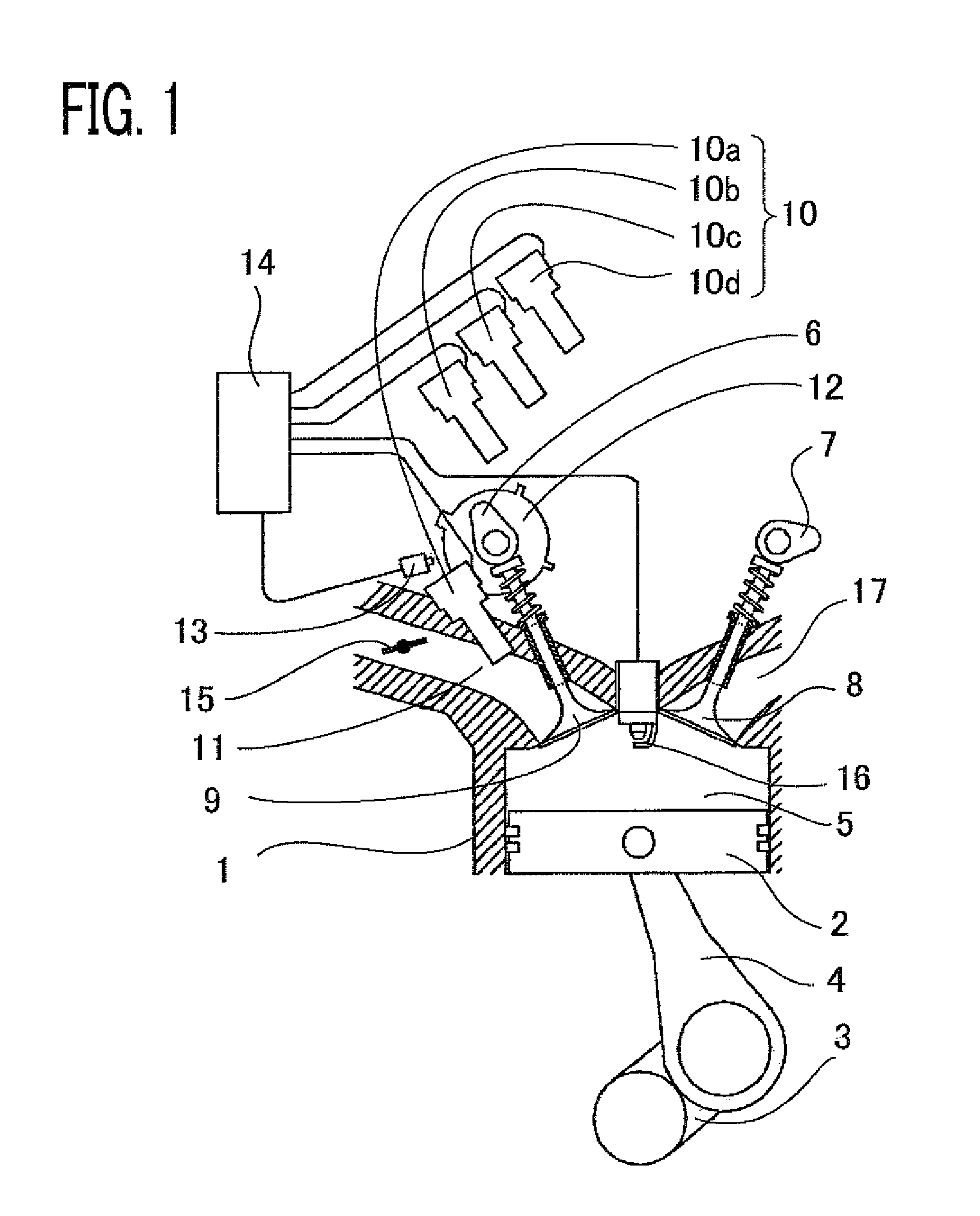

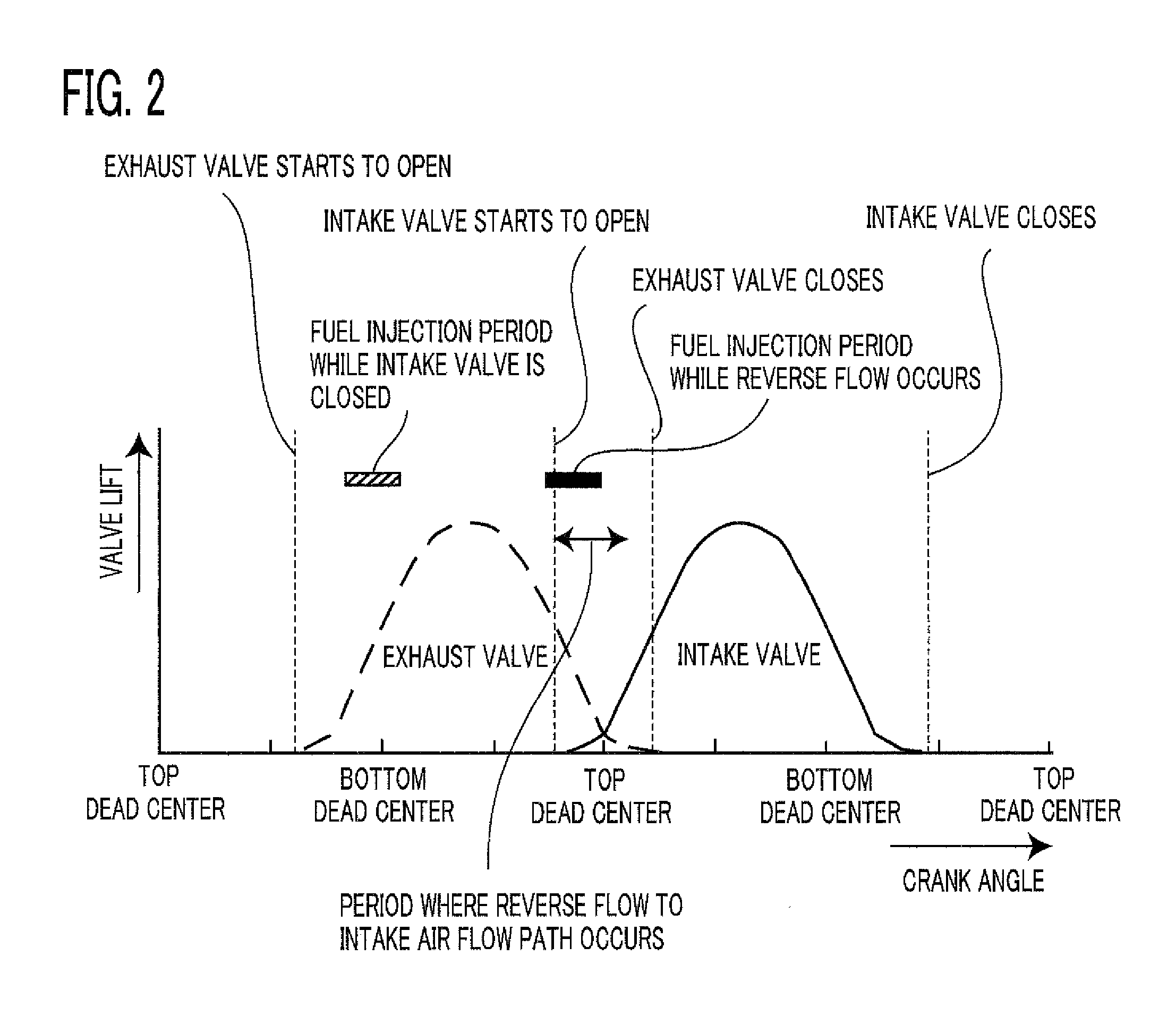

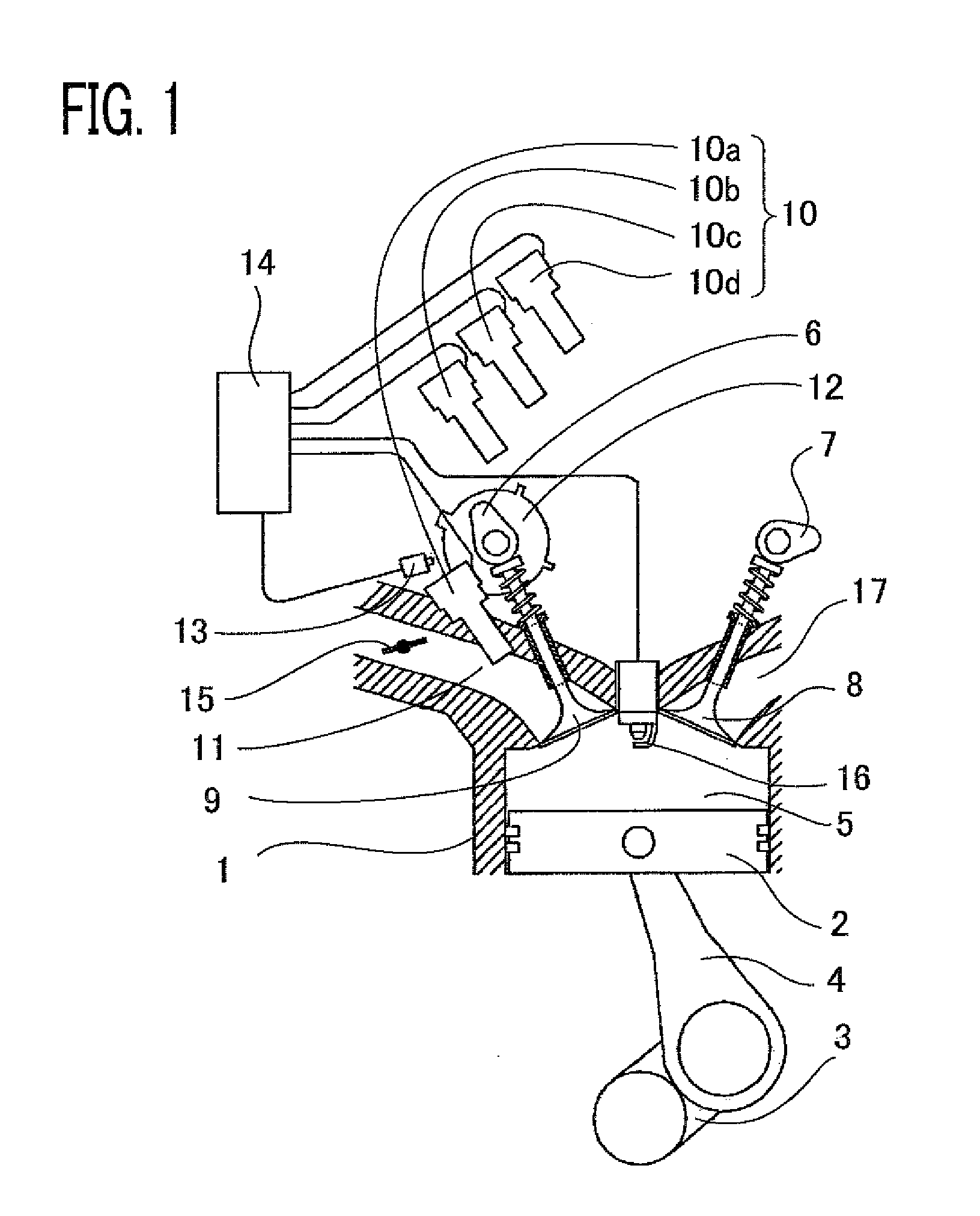

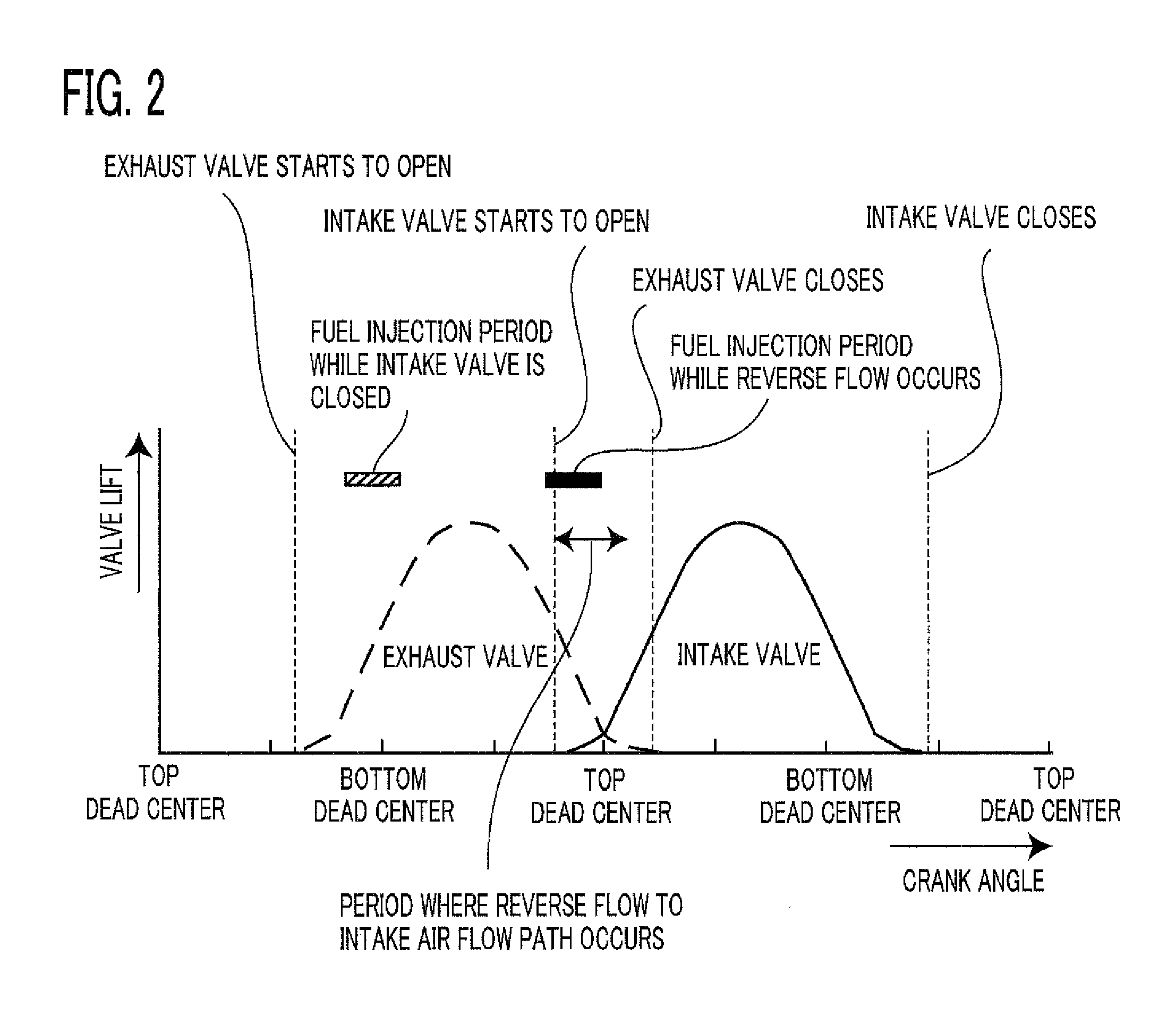

Internal combustion engine fuel injection control method

ActiveUS8433501B2Low-temperature cleannessAvoid stickingValve arrangementsElectrical controlInlet valveEngineering

In an internal combustion engine provided with a fuel injection valve for injecting fuel into an intake air flow path for each cylinder, there is performed a plurality of fuel injections during one cycle for each cylinder, one injection thereof being performed in synchronization with a period during which an intake valve is being opened and reverse flow of in-cylinder gas into the intake air flow path occurs. In accordance with a measurement quantity that changes as the temperatures of the surface, at the intake air flow path, of the intake valve and the inner wall face of the intake air flow path change, there is set the proportion of the amount of fuel injected in synchronization with the period during which reverse flow occurs to the total amount of fuel injected in one cycle for each cylinder.

Owner:MITSUBISHI ELECTRIC CORP

Powder recycling system

InactiveUS10005240B2Avoid work environmentFacilitate removing excess powderAdditive manufacturing apparatusDirt cleaningMetallurgyRapid prototyping

Owner:MICROJET TECH

Electronic devices, circuits and their manufacture

ActiveUS20120153428A1Cleanness is improvedMinimising smearingSolid-state devicesSemiconductor/solid-state device manufacturingCompressible materialSemiconductor materials

A method of manufacturing an electronic device, comprising a layer of semiconductive material and at least one insulative feature arranged to interrupt the layer of semiconductive material, comprises: providing a layer of semiconductive material, and a layer of compressible material supporting the layer of semiconductive material; and forming the or each insulative feature by a method comprising displacing a respective selected portion of the layer of semiconductive material towards the compressible material so as to compress compressible material under the or each displaced portion and separate at least partly the or each displaced portion from undisplaced semiconductive material.

Owner:PRAGMATIC PRINTING

Internal combustion engine fuel injection control method

ActiveUS20110118956A1Low-temperature cleannessAvoid stickingValve arrangementsElectrical controlInlet valveInternal combustion engine

In an internal combustion engine provided with a fuel injection valve for injecting fuel into an intake air flow path for each cylinder, there is performed a plurality of fuel injections during one cycle for each cylinder, one injection thereof being performed in synchronization with a period during which an intake valve is being opened and reverse flow of in-cylinder gas into the intake air flow path occurs.In accordance with a measurement quantity that changes as the temperatures of the surface, at the intake air flow path, of the intake valve and the inner wall face of the intake air flow path change, there is set the proportion of the amount of fuel injected in synchronization with the period during which reverse flow occurs to the total amount of fuel injected in one cycle for each cylinder.

Owner:MITSUBISHI ELECTRIC CORP

Method of manufacturing a disk drive device for reducing adhesive amount of particles

InactiveUS8516685B2Cleanness is improvedImprove the level ofElectrical transducersDisposition/mounting of recording headsPurified waterWaste management

In a method of manufacturing a disk drive device, a cleaning process and an assembly process are performed in succession in a clean room having a predetermined cleanness level. The cleaning process includes an alkali cleaning process, a first purified water cleaning process, a second purified water cleaning process, a spray cleaning process, a draining process and a drying process. In the first purified water cleaning process, purified water ultrasonic wave cleaning is sequentially performed on the base member of the disk drive device to be cleaned by using ultrasonic waves of frequencies of 40 kHz, 68 kHz and 132 kHz in purified water filled in a first purified water cleaning tank. The cleaned base member and other components having a predetermined cleanness level are assembled in the assembly process continuous from the cleaning process.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

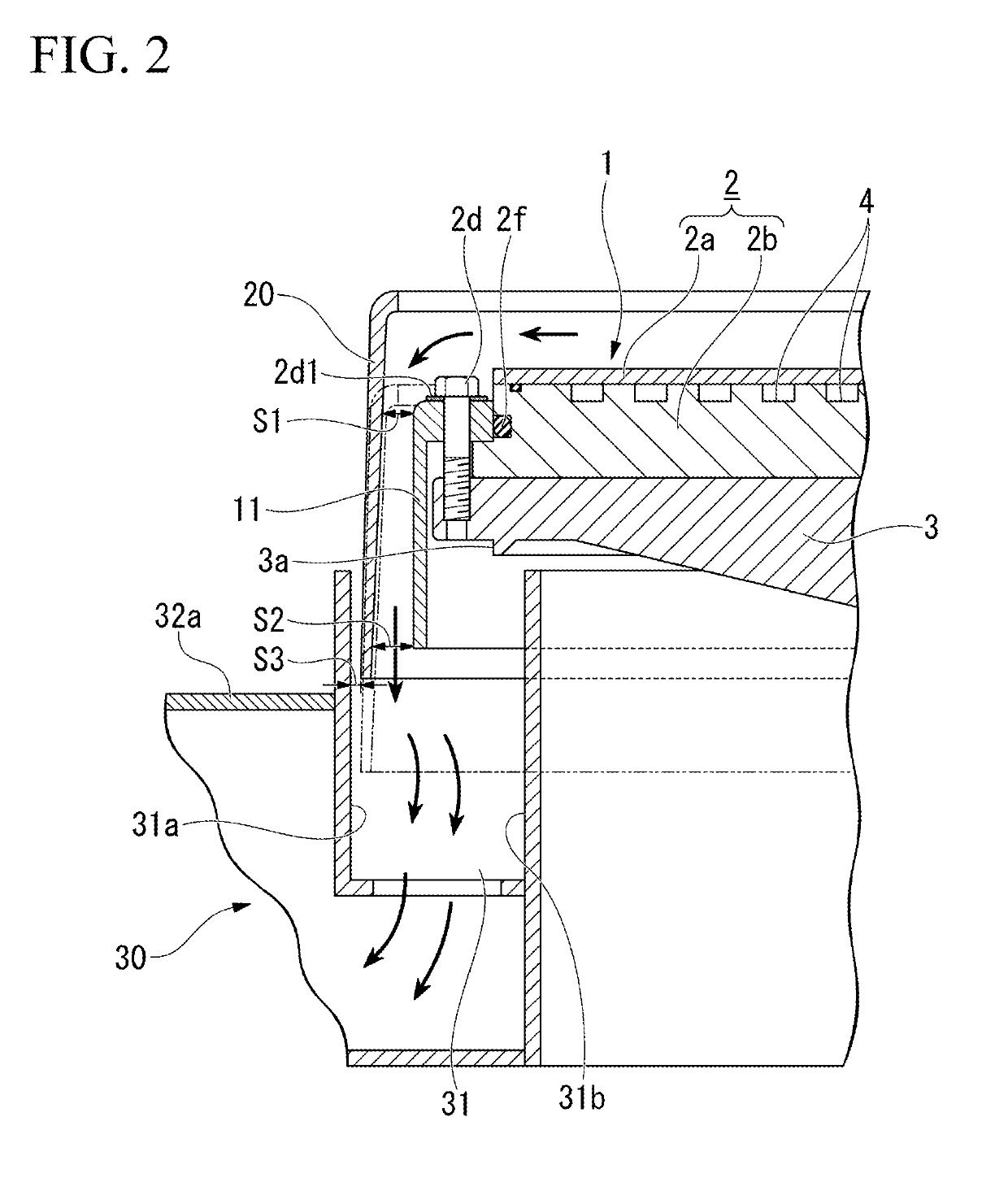

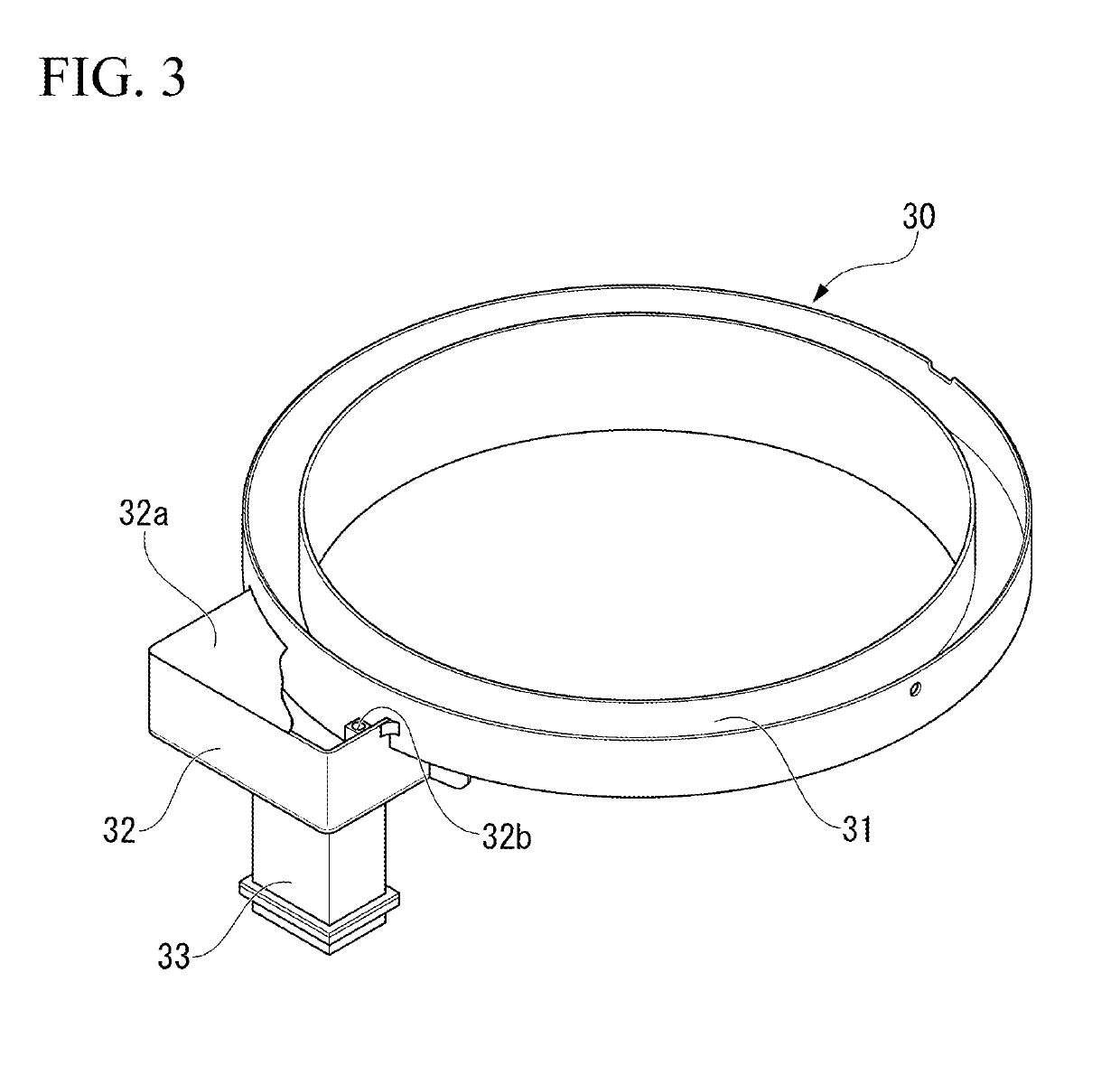

Polishing apparatus and substrate processing apparatus

PendingUS20190299360A1Cleanness is improvedLow costLapping machinesAbrasive surface conditioning devicesMechanical engineering

A polishing apparatus includes a polishing table supplied with liquid on a upper surface and rotating around a central axis, a liquid receiver having an annular shape and disposed below a peripheral portion of the polishing table, and a drain member having a tubular shape, attached to a peripheral portion of the polishing table, and including a lower end portion extending toward the liquid receiver.

Owner:EBARA CORP

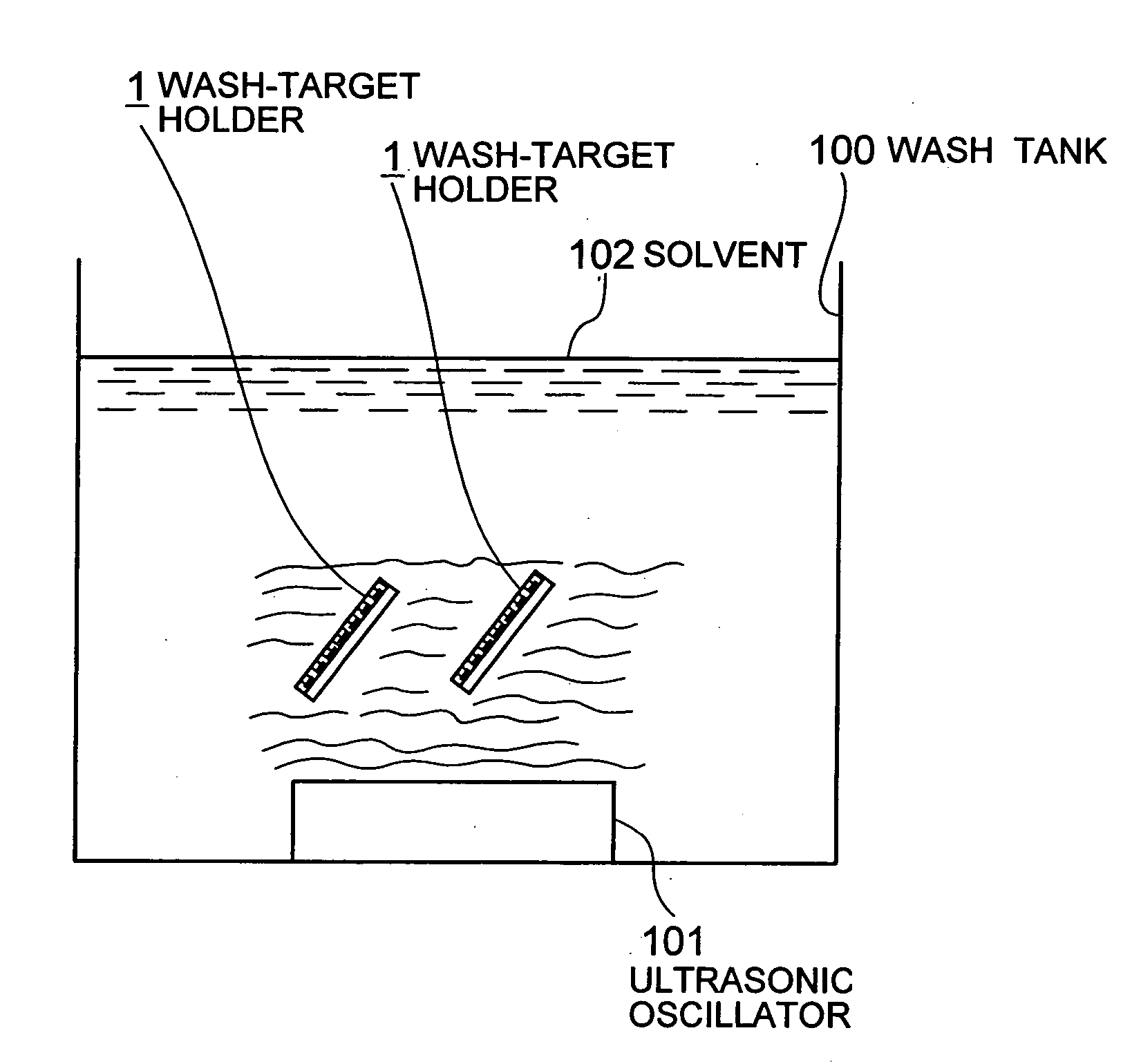

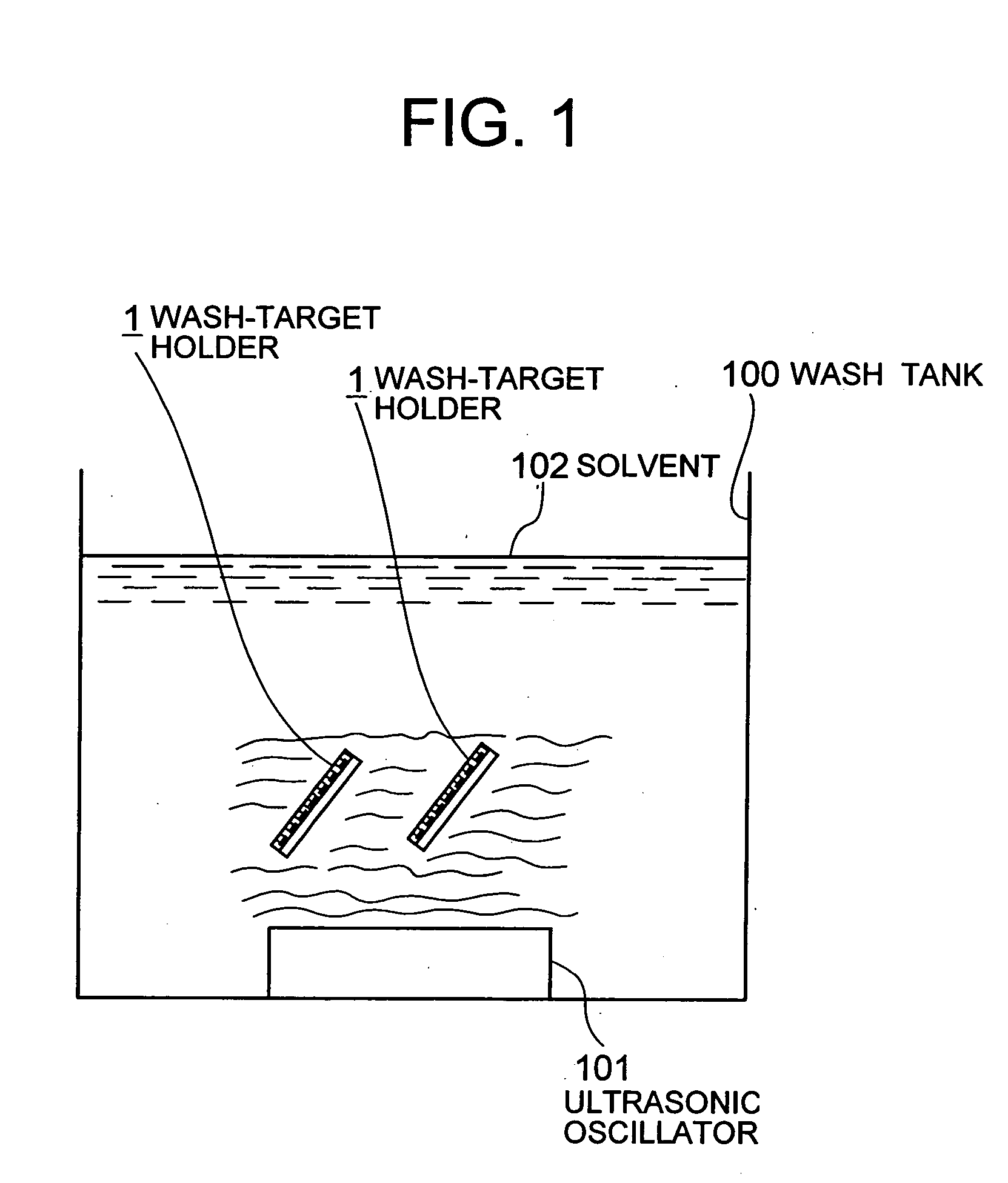

Wash-target holder and method for washing wash-target using the same

InactiveUS20060042652A1Cleanness is improvedImprove the inconvenienceElectrostatic cleaningSemiconductor/solid-state device manufacturingSolventBiomedical engineering

An object is to improve the cleanness achieved by washing through effectively suppressing the residual of solvent remained on a wash-target after washing. The present invention is a wash-target holder soaked in a wash tank by holding a wash-target, which comprises a tray for placing the wash-target, a surrounding member, which is provided standing up on a wash-target placing face of the tray, for surrounding the periphery, and a defluxion-restricting member for restricting the defluxion of the wash-target from the tray. In the periphery of the wash-target surrounded by the surrounding member, an opening for letting in and out the solvent used for washing the wash-target is formed.

Owner:SAE MAGNETICS (HK) LTD

Duplex stainless steel and manufacturing method thereof

ActiveUS7396421B2Improve the immunityCleanness is improvedFurnace typesQuenching agentsLongest DiameterNitrogen

Owner:NIPPON STEEL CORP

Hybrid vehicle and method of operating engine of the same

ActiveUS20130096750A1Improve vehicle performanceIncrease commercial qualityBatteries circuit arrangementsElectrical controlHcci combustionElectricity

A hybrid vehicle may include a linear engine controlled by HCCI (Homogeneous Charge Compression Ignition) combustion in an operation section where an engine power may be used for generating electricity after being started and reaching up to a predetermined RPM, and a motor-combined generator engaged to the liner engine and starting the linear engine and charging a battery by converting an entire engine power of the linear engine generated by the HCCI combustion into electricity generation power.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com